3D print bugatti

Bugatti refines 3D printing perfection

Molsheim

January 21, 2021

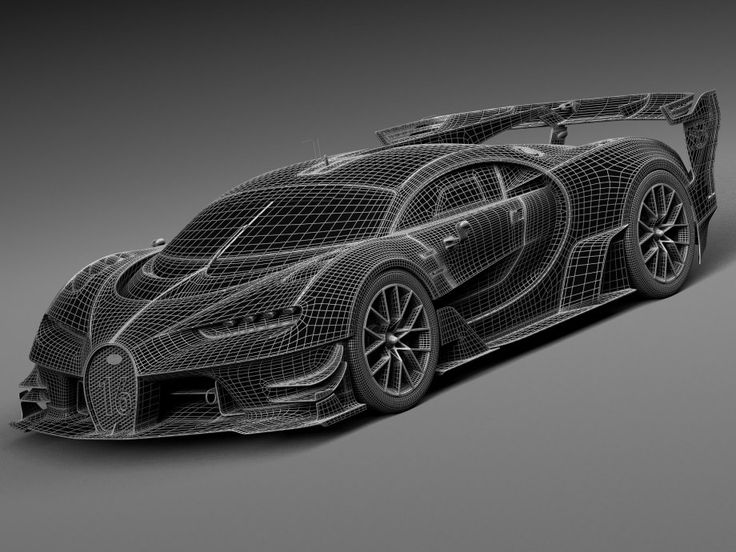

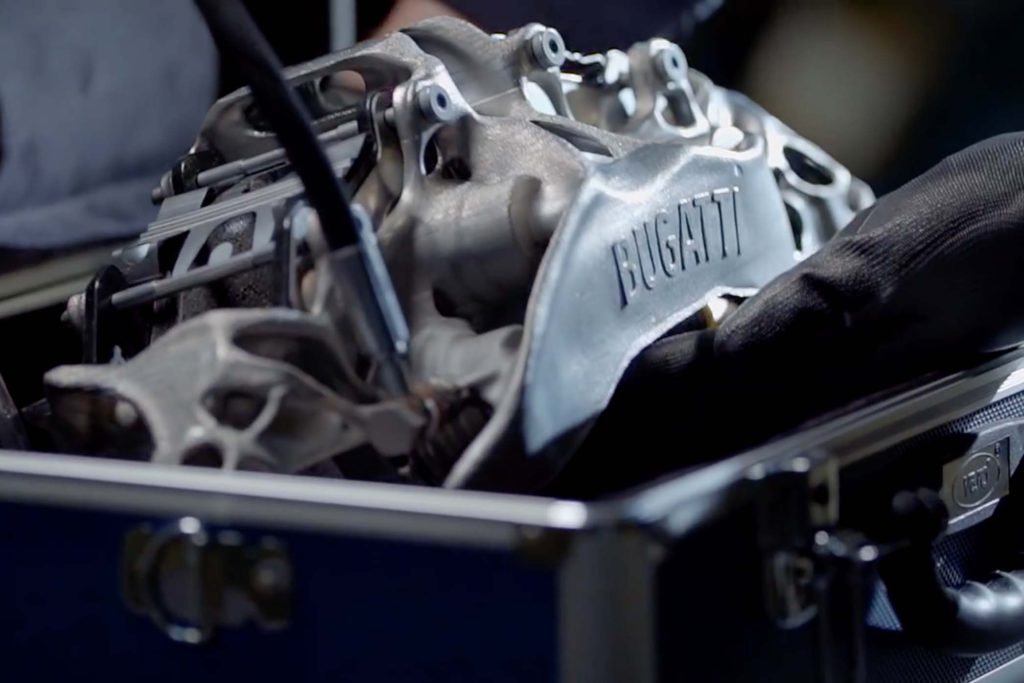

The French luxury brand is expanding its technological leadership with the development of highly accurate 3D-printed components used to make the Bugatti Bolide.

Imagine ultra-lightweight components that are as strong as a reinforced concrete column. Now this is possible, thanks to technology led by innovative Bugatti engineers. The newly developed 3D-printed pushrod – a pressure-loaded coupling rod in the chassis area – weighs just 100 grams and can transmit forces of up to 3.5 tonnes. The hollow titanium structure with internal supporting arch gives incredible strength and is another engineering breakthrough demonstrated by the expertise of Bugatti.

This new project is led by Henrik Hoppe, a doctoral student in the New Technologies department at Bugatti, who has been developing innovative metal materials and manufacturing processes since 2017. He wrote his master’s thesis on a calculation methodology for a 3D-printed titanium brake calliper, which is 43 percent lighter than the already highly weight-optimised Chiron1 production component, and just as rigid. “Through the process known as selective laser melting, commonly known as 3D printing, new, hollow, ultracomplex components that are stiffened from the inside can be produced which are very lightweight and yet extremely rigid and strong. We are utilising these benefits for an increasing number of components in our hyper sports cars,” explains Hoppe.

In his doctoral thesis, the industrial engineer goes one step further. Hoppe is pioneering a new system, owing to the cost- and time-intensivity involved with the complete cycle of the manufacturing process chain, from concept to delivery. Hoppe uses this system to identify the commercial and technological potential of functional 3D-printed metal components for automotive manufacture, and can enhance this potential with applied targeting at specific parts. Previously, these types of components were used predominantly in the aerospace sector.

3D printed components with a complex, bone-like structure

Bugatti routinely uses this innovative 3D printing technology to enhance components with complex three-dimensional structures. The French luxury manufacturer applies principles from the field of bionics to give the printed components a bone-like structure: featuring thin walls, a hollow interior, and fine branching. And this is precisely how the components obtain their remarkable rigidity despite their low weight – with wall thicknesses of up to just 0.4 millimetres. “We will continue to reduce the weight of our cars while increasing their innovative features in every conceivable area,” explains Henrik Hoppe. From conception through production to installation in the vehicle, the engineer designs and plans the individual steps and carries out all of the calculations. This also includes evaluation of the commercial feasibility for production of the components. “Although Bugatti demands the highest quality standards in terms of materials, manufacturing processes and components, they must be commercially viable,” he adds.

The French luxury manufacturer applies principles from the field of bionics to give the printed components a bone-like structure: featuring thin walls, a hollow interior, and fine branching. And this is precisely how the components obtain their remarkable rigidity despite their low weight – with wall thicknesses of up to just 0.4 millimetres. “We will continue to reduce the weight of our cars while increasing their innovative features in every conceivable area,” explains Henrik Hoppe. From conception through production to installation in the vehicle, the engineer designs and plans the individual steps and carries out all of the calculations. This also includes evaluation of the commercial feasibility for production of the components. “Although Bugatti demands the highest quality standards in terms of materials, manufacturing processes and components, they must be commercially viable,” he adds.

Bugatti takes the lead in 3D printing

Bugatti is the technological leader in the field of metal 3D printing. Since production began of the Chiron, the hyper sports car has been fitted with the industry’s first series-produced metal 3D-printed functional component: a small, water-carrying high-pressure pump console next to the transmission fluid reservoir. In 2018, the world’s largest 3D-printed titanium component, a titanium brake calliper, was presented by Bugatti. This was followed by the world’s largest hybrid functional assembly made of 3D-printed titanium and coiled carbon. “These components are extremely lightweight, robust and durable, and therefore absolutely suitable for use in production vehicles,” says Frank Götzke, Head of New Technologies at Bugatti.

Since production began of the Chiron, the hyper sports car has been fitted with the industry’s first series-produced metal 3D-printed functional component: a small, water-carrying high-pressure pump console next to the transmission fluid reservoir. In 2018, the world’s largest 3D-printed titanium component, a titanium brake calliper, was presented by Bugatti. This was followed by the world’s largest hybrid functional assembly made of 3D-printed titanium and coiled carbon. “These components are extremely lightweight, robust and durable, and therefore absolutely suitable for use in production vehicles,” says Frank Götzke, Head of New Technologies at Bugatti.

The new materials and manufacturing processes are now being used in the Bugatti Bolide2 technology carrier, which celebrated its world premiere in late October 2020. “As an experimental vehicle in the form of a racing car, the Bolide is no show car; it is an uncompromisingly road-ready extract of Bugatti’s complete technological expertise. Bugatti enthusiasts will also find these cutting-edge technologies in other vehicles in the future,” says Frank Götzke.

Bugatti enthusiasts will also find these cutting-edge technologies in other vehicles in the future,” says Frank Götzke.

Just like the turbofans typically used in motorsport, Bugatti has found a way of including radial compressors on ultra-lightweight magnesium forged wheels. Their appearance is similar to that of a wheel rim, but they perform multiple functions: they pump the air out of the wheel housings through the brakes and draw the warm air to the outside. In this way, the turbofans cool the brakes and minimise lift. In contrast to the well-known monomaterial solutions, the Bolide components have a hybrid structure. This consists of a central bowl made of 3D-printed titanium with a thickness of 0.48 millimetres, and a 0.7-millimetre thick carbon plate with small inner blades, also made of carbon. Cross-pieces with a width of 0.48 millimetres further increase the rigidity of the central titanium bowl, which weighs just 100 grams. All of this adds up to a total weight of under 400 grams for an individual 18 ¼-inch turbofan on the rear wheels (17 ¼-inch at the front). This would not be possible with a monomaterial solution due to the fact that it is not possible to achieve the specific buckling resistance and flexural rigidity.

This would not be possible with a monomaterial solution due to the fact that it is not possible to achieve the specific buckling resistance and flexural rigidity.

325 grams to hold 1.8 tonnes

Highly complex components from the 3D printer are also used in hidden places. A mounting bracket for the front wing, on which the front wing can be mounted at three different heights, is printed in titanium by Bugatti. With a hollow interior and a wall thickness of 0.7 millimetres, the mounting bracket can withstand an aerodynamic downforce of up to 800 kilograms – with a weight of just 600 grams. The downforce of the rear wing, which can reach up to 1.8 tonnes at 320 km/h, is introduced via the Bolide’s central carbon fin into the upper structural matrix, which forms the upper termination of the high-strength stainless steel rear frame. Inside this central fin there is a laminated and printed titanium component for connecting the fin to the wing, for which the angle can be adjusted by means of a coupling rod. Despite its rigidity, it weighs just 325 grams. The engineers also use titanium to print the bracket for mounting the steering column, which features an integrated dashboard support, the support collar for the steering column throughfeed, and the two air vents in the vehicle interior. All components are designed as lightweight hollow structures, with a uniform wall thickness of 0.5 millimetres.

Despite its rigidity, it weighs just 325 grams. The engineers also use titanium to print the bracket for mounting the steering column, which features an integrated dashboard support, the support collar for the steering column throughfeed, and the two air vents in the vehicle interior. All components are designed as lightweight hollow structures, with a uniform wall thickness of 0.5 millimetres.

The Bolide features wheel control based on double wishbone kinematics on both the front and rear axles. On the rear axle, the spring damper elements have a vertical configuration, while on the front axle they are arranged horizontally at right angles to the direction of travel. The springs are made of titanium, and the dampers feature an adjustment mechanism and a reservoir, which is integrated internally on the front axle dampers. In the case of the horizontal spring damper elements on the front axle, the vertical contact forces are transmitted by means of a linkage located directly beside the swivel bearings on the lower wishbones via pushrods and rockers. The brackets that control the rockers have a wall thickness of just 0.4 millimetres and weigh only 95 grams each. The rockers weigh just under 195 grams each. Since air flows completely through the Bolide’s front axle, its kinematic components – both the 3D-printed titanium components and the high-strength stainless steel wishbones – are extremely lightweight, rigid and aerodynamically optimised. The tensile strength of this and all other 3D-printed elements is 1,250 N/mm2. “Using a special heat treatment process developed in-house, we achieve this high tensile strength with a simultaneously high fracture strain of at least 19 percent,” explains Götzke.

The brackets that control the rockers have a wall thickness of just 0.4 millimetres and weigh only 95 grams each. The rockers weigh just under 195 grams each. Since air flows completely through the Bolide’s front axle, its kinematic components – both the 3D-printed titanium components and the high-strength stainless steel wishbones – are extremely lightweight, rigid and aerodynamically optimised. The tensile strength of this and all other 3D-printed elements is 1,250 N/mm2. “Using a special heat treatment process developed in-house, we achieve this high tensile strength with a simultaneously high fracture strain of at least 19 percent,” explains Götzke.

Pushrod weighs just 100 grams

The developers are particularly proud of the pushrods in the Bolide. “They transfer a force into the rockers which, depending on the driving manoeuvre, is equivalent to a weight of up to 3.5 tonnes. Nevertheless, thanks to the implementation of multiple ideas, they only weigh as much as a bar of chocolate, in other words 100 grams each,” explains Henrik Hoppe. For the first time, the Bugatti developers varied the wall thickness of the thin-walled, hollow rods. They become thicker towards the centre and then thinner again, meaning that they are optimally adapted to localised stress. Similar to a human bone, the component has an internal structure. This special structure was also recently registered as a patent.

For the first time, the Bugatti developers varied the wall thickness of the thin-walled, hollow rods. They become thicker towards the centre and then thinner again, meaning that they are optimally adapted to localised stress. Similar to a human bone, the component has an internal structure. This special structure was also recently registered as a patent.

In the tailpipe trim cover, a hybrid component made of 3D-printed titanium and ceramic, Bugatti reduced the weight by around half compared to the already weight-optimised titanium tailpipe trim covers well known from series production. The component, which measures more than 280 millimetres in length and has a consistent wall thickness of just 0.5 millimetres, therefore weighs less than 750 grams. Since ceramic material is a significantly less effective heat conductor than titanium, Bugatti introduced special ceramic elements that are built into the titanium housing and centre the cover with respect to the carbon outer skin, so that the outer skin is not damaged even at high exhaust gas temperatures. This thermal shield is also supported by a built-in Venturi nozzle: when hot exhaust gas enters the tailpipe trim cover, fresh air is drawn in, thereby creating a jacket of cool air around the hot exhaust gas flow. In its entirety, this is an invention for which Bugatti has submitted a patent application.

This thermal shield is also supported by a built-in Venturi nozzle: when hot exhaust gas enters the tailpipe trim cover, fresh air is drawn in, thereby creating a jacket of cool air around the hot exhaust gas flow. In its entirety, this is an invention for which Bugatti has submitted a patent application.

Lightweight components found in the Bolide

With the launch of the Bolide – the track-oriented hyper sports car – a few months ago, Bugatti presented an extraordinary technological concept. The iconic 8.0-litre W16 engine, with up to 1,850 PS˚, powers a car weighing just 1,240 kilograms˚˚. This equates to an incredible weight-to-power ratio of 0.67 kg/PS, a top speed of over 500 km/h˚˚˚, perfect handling and maximum agility. “It is the Bolide’s many technological highlights that make it so special. But these can also be transferred to production vehicles. This is what we are continuing to develop and work on, because Bugatti has set itself apart with its impressive innovations for over 110 years – and will continue to do so in the future,” says Frank Götzke.

˚ When using 110-octane racing petrol; engine power with 98-octane petrol is 1,600 PS

˚˚ The weight specification is based on the theoretically possible dry weight

˚˚˚ Simulated figures

1 CHIRON: WLTP: Fuel consumption, l/100km: low 43.33 / medium 22.15 / high 17.99 / particularly high 18.28 / combined 22.32; CO2 emissions, combined, g/km: 505.61; efficiency class: G

2 BOLIDE: Fuel consumption, l/100km: this is a concept study and therefore not subject to Directive 1999/94/EC.

Read More

Bugatti Bolide - Vehicle overview from the front

Bugatti Bolide - Vehicle overview from the front

Bugatti Bolide - Vehicle overview from behind

Laminated mounting bracket for the rear wing

Steering column bracket, steering column support with integrated dashboard support, steering column throughfeed collar, air vents

Contact

FOR MEDIA ENQUIRIES:

Nicole Auger

Head of Communications

E-Mail: [email protected]

Bugatti best STL files for 3D printer・Cults

Bugatti T59

€5 -40% €3

Bugatti Bolide

€3. 50

50

Bugatti Type 35

€5 -40% €3

Bugatti Chiron

€3.50

Keychain Bugatti

€0.65

radial rim8 r8cm9 concave19 inches 1/18 1/12 1/24 1/10

€1.50

Bugatti atalntic scale 1-10

€7.50

GP explorer

Free

Assembly Manual - BUGATTI 100P 'RACER SPIRIT'

Free

R/C BUGATTI 100P 'RACER SPIRIT'

€14.41

Bugatti Centodieci

€15

Bugatti Bolide

€3

BUGATTI TYPE 57 ATLANTIC 1936 PRINTABLE CAR BODY

€5. 87

87

BUGATTI TYPE 57 ATLANTIC 1936 PRINTABLE CAR IN SEPARATE PARTS

€11.74

Bugatti Divo

€2.20

1/8 scale bugatti atlantic

€10

Bugatti Galibier 2009 Printable Body Car

€8.33

Bugatti Chiron

€8

Bugatti Veyron

€8

Bugatti Divo

€8

Bugatti Bolide

€8

Bugatti Galiber Concept 2009

€8

Bugatti EB110

€8

bugatti

€1.50

Bugatti Galibier

€20

Bugatti EB110 style rims 1/64

€2

Bugatti EB110 Hommage 2019

€7. 96

96

Exclusive Bugatti La Voiture Noire 2019

€24.82

Bugatti Bolide 2024 with a saloon.

€7.96

Tomica Bugatti Veyron Display Base

Free

Bugatti divo 3d printable

€3

Bugatti bolide 3d printable

€3

Bugatti chiron 3d printable

€3

bugatti chiron

€25

Bugatti logo

€3

Bugatti veyron

Free

Bugatti Chiron Lego stand + logos

Free

Bugatti Chiron

€20

BUGATTI 3D LOGO

€0. 60

60

Dual 1/64 Gran Turismo 25th Anniversary Theme Display

Free

Coche Bugatti

€0.50

Lamborghini 2D

€0.99

Lamborghini 2D

€0.99

Porsche GT3

€0.99

Bugatti veyron logo/car

€0.50

CAR - Bugatti Chiron

€2.35

Bugatti Atlantic 'La voiture noire' 1/64

€5

Bugatti Chiron

€5

3D printed brake caliper for Bugatti supercar in 45 hours

3D printing of a brake caliper for a Bugatti supercar in 45 hours- Industry

- Automotive

- Task

-

Brake caliper optimization for Bugatti Veyron and Chiron supercars.

- What has been done

-

The development of the caliper was carried out by Laser Zentrum Nord in only about three months. Bugatti performed process modeling, supporting structure development and 3D printing. The new part was printed in 45 hours on an SLM Solutions 3D printer using a titanium alloy commonly used in the aerospace industry. Upon completion of the 3D printing process, the part was heat treated in an oven at temperatures up to 700°C to eliminate residual stress and ensure dimensional stability. Then the supports were removed, and the surface of the part was ground by mechanical, chemical and technological methods, which significantly improved its fatigue strength. The contours of the functional surfaces were then processed on a CNC machine for another 11 hours.

- Result

-

- Titanium eight-piston monobloc brake caliper is the first 3D printed and largest in automotive history. It is also the largest component of titanium that is produced in an additive way.

- With titanium 3D printing, the caliper is about 40% lighter and at the same time stronger than the original aluminum construction.

- Previously, titanium could not be used as a material for the manufacture of calipers, because due to its high strength it is extremely difficult to mill or stamp a titanium blank.

Company *

E-mail *

Telephone *

Message

Software product

Magics RP

Import Module

Sinter Module

Structures Module

SG Module

Tree Support Module

SG+ Module

Simulation Module

Slice Module

Select 3D printing material from the list *Photopolymer Metal

Software product

Geomagic Design X

Geomagic Control X

Geomagic for SolidWorks

Geomagic Wrap

Company *

E-mail *

Telephone *

Subscribe to blog

Subscribe to news

An error occurred

Please try again later!

Bugatti Automobiles successfully tested a 3D printed brake caliper They print small parts and massive houses, they print tools for craftsmen and automotive spare parts.

The other day, information appeared on the network that Bugatti Automobiles created a brake caliper (caliper) by 3D printing.

The other day, information appeared on the network that Bugatti Automobiles created a brake caliper (caliper) by 3D printing. Of course, this part is made of metal, not plastic, but still, the method of its creation belongs to the "printed". After the element was ready, it was tested, and the caliper passed all the checks, including heating during braking up to a thousand degrees.

The advantage of 3D printing is that it allows you to create complex parts that require little or no post-processing. In addition, it is possible to print composite parts in a single piece, which cannot be done by any other method. The structure of a part can be arbitrarily complex - advanced 3D printers can handle any task.It is worth noting that 3D printing allows you to create analogues of conventional parts, but with less weight. This is achieved, in particular, by changing the overall structure of the element. As for the caliper, it is standard, it was decided not to change its geometric characteristics.

The production time for this part leaves much to be desired, as the process took 45 hours (unfortunately, the company did not say how long it takes to create a standard part). The brake element was created from metal powder and sintered with a 400 watt laser beam. In total, the part consists of 2313 layers of titanium powder.

The tests were carried out not in the field, but on the stand. The brake disc was spun up to a speed corresponding to a speed of 400 km/h under normal conditions. Then the brake was started, the disk stopped. During the second test, the disk warmed up to 1.1 thousand degrees. The temperature was so high that the brake pads caught fire. The company recognized the tests as successful.

If further tests go well, then Bugatti Automobiles will use the new manufacturing process to build all Chiron hypercar calipers.

It is worth noting that not only car parts are printed. For example, in the UK they plan to print spare parts for train interiors.

In a normal situation, these parts are damaged quite often, and railroad workers are unlikely to carry a large supply with them. In addition, the problem is trains that have been in operation for a long time, and the mass production of spare parts for which has been stopped.

In a normal situation, these parts are damaged quite often, and railroad workers are unlikely to carry a large supply with them. In addition, the problem is trains that have been in operation for a long time, and the mass production of spare parts for which has been stopped. As a result, railway workers have to ask manufacturers to accept piece orders, which is quite expensive. And if we are not talking about a cosmetic, but a major overhaul, then its cost increases significantly compared to the price of a major overhaul of a conventional train, for which there are spare parts.

Source: railway-technologyInitially, railway workers will create the most breakable elements - plastic handles, various types of sheathing elements, plastic covers, armrests. They often break even in new cars, not to mention those that have served several terms.

3D printing is nothing new for vehicle designers. A few years ago, Boeing applied for a patent in the field of 3D printing.

Learn more

- Titanium eight-piston monobloc brake caliper is the first 3D printed and largest in automotive history. It is also the largest component of titanium that is produced in an additive way.