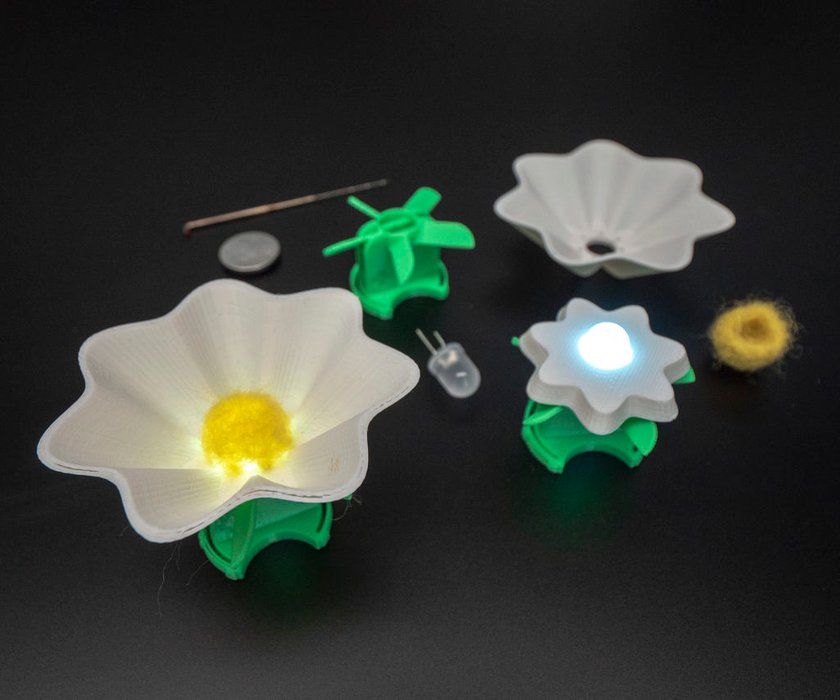

3D printed light diffuser

Any good guides on making LED diffusers that I've missed? : 3Dprinting

I've googled around and made a couple experiments and here's what I've found.

Point-ish powerful sources (e.g. a flashlight)

Apparently the easiest option is to just use plain white filament in a thin-ish layer and accept that tons of light will be lost. Best authority I've found is /u/ChickenPicture who designed a ton of flashlight diffusers with white filament https://www.thingiverse.com/ChickenPicture/designs and posted about their design (check their post history)

Slight diffusion which leaves single LEDs visible

An example: https://www.reddit.com/r/3Dprinting/comments/5e69v8/transparent_filament_makes_for_a_perfect_led/

Printing transparent PETG on "normal" settings (so no hot-and-thin overextrusion to make it more transparent as in https://www.youtube.com/watch?v=QkfQri2B0PY) in multiple layers works for that because of all the bubbles of air trapped in, so the light gets diffused. Judging by the video, single LEDs are still pretty evident.

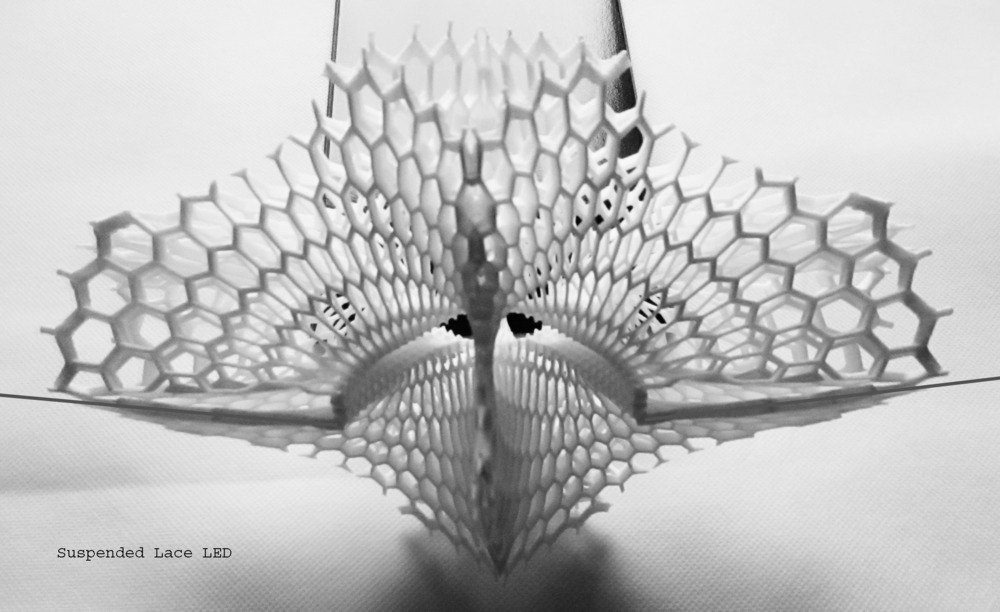

Diffusers that create evenly illuminated surfaces from point sources (e.g. LED stripes)

This is apparently the trickiest one. Nice examples that I found:

https://newscrewdriver.com/tag/glow-flow/ I'm not 100% sure, but it looks like it's white filament in single layers so it looses some light and might a bit fragile

https://hackaday.io/project/34274-atltvhead/log/159126-led-diffusion-log and https://www.youtube.com/watch?v=7Fr_Idwm-YI this looks like transparent PETG printed "normally" (so it's hazy) with tons of layers and structures inside to even the light out (here are some sections of the STEP files he kindly shared https://imgur.com/a/RMBtmyr)

Someone somewhere also mentioned using self-adhesive diffusing film, which might actually be a nice option to combine with clear PETG, using PETG just to provide structural strength.

I've also tried a few single or double perimeter towers in transparent PETG, here is what I've learned:

transparent PETG layers act as tiny lenses, so while it's possible to diffuse a wide-spaced LED strip with clear PETG with a wide standoff (like that: LED strip - a few mm - first layer of PETG - a cm or two - second layer of PETG) it diffuses it into an "image" of an even strip of light instead of a glowing surface (see an example here).

The effect disappears if layers are parallel to the strip (obviously in hindsight). It's pretty efficient though, those two layers don't cast much shadow

The effect disappears if layers are parallel to the strip (obviously in hindsight). It's pretty efficient though, those two layers don't cast much shadowsanding doesn't help much or I do it wrong, rough surface does soften the image of the line a bit but it's still there

So in the end it looks like there are two ends to this tradeoff: it's either white filament with nice diffusion, but low light efficiency and/or fragile parts (because they have to be thin to be adequately transparent), or transparent filament that seemingly can't diffuse properly without tons and tons of layers and internal structure (those transparent PETG light tubes are 12mm thick!). How can we try and push the boundary further? Any good guides on this?

Edit: according to this guy https://www.reddit.com/r/led/comments/awfqek/what_efficient_diffuser_do_you_recommend/ehqkibs/ purpose-made light diffusers are practically 100% efficient, so it is possible, the question is if it's possible with 3d printing.

Printed Diffusers – Luximprint

Skip to contentLoading...

Printed Diffusersadmin2018-02-09T15:50:12+00:00

Printed diffusers are a unique process capability directly arising from the Luximprint additive optics fabrication process. A novel feature whereby surface structures with a predefined ‘roughness’ are printed, eventually along with clear surface finishes, in one single process. This novel process feature – named ‘Frosted Finishes’ – greatly enhances the variety of products we 3D print for our users, as we can now add a next dimension to it: diffusivity.

A quick and dirty photo demonstration including the performance of various frosted finishes applied onto a SMD LED panel.

Printed Diffusers by Luximprint

Combining printed micro-structure expertise with sheet- and thinfilm capabilities, we have defined a range of Frosted Finishes we can apply onto the various product types we print: Optical Plastics, Optographix, Textured Surfaces, 3D printed reflectors, mold tooling and finally: Printed Diffusers.

When preparing our users’ CAD files for 3D printing, we can either define a ‘smooth’ surface finish for optimal smoothness, clarity and performance or, on the contrary, apply a ‘frosted finish’ onto the surface. This actually results in an undefined or defined scattering of light aiming for better light control, reflectivity, source hiding, efficiency and finally also aesthetics. And thus, our new product group ‘Printed Diffusers’ was born.

Roughly, we can break down Printed Diffusers into two application categories:

1) Functional Diffusers

Depending on what definition of roughness is choosen, light rays get ‘broken’ and start to move into all possible directions, rather than being directed to a certain target specifically. As such, the structure may create elliptical, (a)symmetric beams or serve RGB-W color mixing purposes.

Some practical examples of applied functional frosted finishes are 3D printed reflectors, diffusers and light guiding plates for applications in general lighting, automotive lighting or retail lighting.

Allthough they might be close in properties, functional lens sheets differ from printed lens diffusers in feature size and function.

2) Aesthetical Diffusers

From an aesthetic point of view, on the contrary, diffusers may include sheets or thin-films that are intended for use in decorative applications. As such, the finish does not have a direct function, the structure absorbs the light and emits it into undefined directions, or illuminates a certain predefined area.

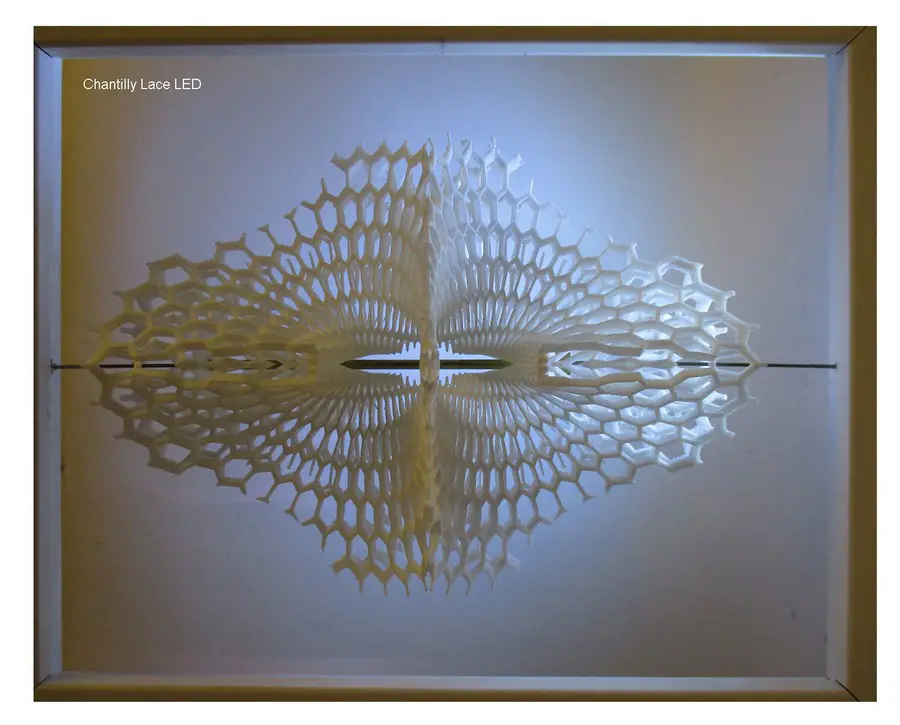

Example of aesthetic frosted finish applications are window decorations (window shields, divider walls), privacy films (office spaces, shower walls, front doors) or decorative luminous patterns. When properly illuminated, either by sun or artificial light, the structures come to life and creates stunning effects.

Optical micrographics, company logos and patterned structures can easily be integrated when printing diffuser sheets.

Printed Custom and/or Customized Diffuser Sheets

Where ‘custom’ in most cases may refer to the fact we can tailor our optical plastics to our users’ needs from a functional perspective, another interesting feature arises here: customized diffusers. From our process, customizing diffusor sheets with e.g. a company logo’s, text, pattern, symbols and other features is very well possible. Some interesting features are shown below, in fact, the possibilities are endless!

From our process, customizing diffusor sheets with e.g. a company logo’s, text, pattern, symbols and other features is very well possible. Some interesting features are shown below, in fact, the possibilities are endless!

Marketing Printed Diffusers

At Luximprint, we do not run large volumes of printed diffuser sheets, but stack to enabling the upfront design and engineering by providing functional test samples to our users in a fast, flexible and cost-effective ways, in lane with our overall service offering. Those masterpieces are generally used for validation of new concepts and design simulations. For those firms that want to create their custom diffuser optics or need small project volumes, we aim to be the preferred prototyping partner. In case of further questions, remarks or project queries, please contact us!

In addition, the ‘frosted finish’ feature can be traced on other types of printed optical plastics, serving functional, decorative or protective needs, as shown below:

Frosted finishes can be applied in one single process onto functional optics and lens arrays to generate straylight or avoid blinding.

CORRELATION VALUES AND MOLD ROUGHNESS

The correlation between the units of measure used to define frosted surface finishes and how they compare to for example mold roughness, is a commonly raised question in our user group. Here in Europe, we are accustomed to the standard of measurement for defining mold surfaces, such as Roughness Average (RA) and Root Mean Square (RMS), but elsewhere (such as in the US) they might be used to the definitions as set forth by the Society of the Plastics Industry (SPI).

Fortunately, the science behind frosted finishes can be left to a qualified engineer who can help achieve the surface finish that best matches his customer requirements or the mold tool to be ordered.

Soon, we will officially launch our ‘Frosted Finishes’ capabilities including the specific measurement values. Stay tuned!

Crestron SolarSync™ Daylight and Color Temperature Sensoradmin2022-02-04T15:30:53+00:00

Oligo Birly Pendant Lightadmin2017-12-14T10:59:02+00:00

Connected Color Domesadmin2017-12-12T10:45:53+00:00

Toggle Sliding Bar Area

Recent Works

Samples

Order your Sample Kit now and get 50% refunded on your next order! >>>

Visit our Sample Shop!

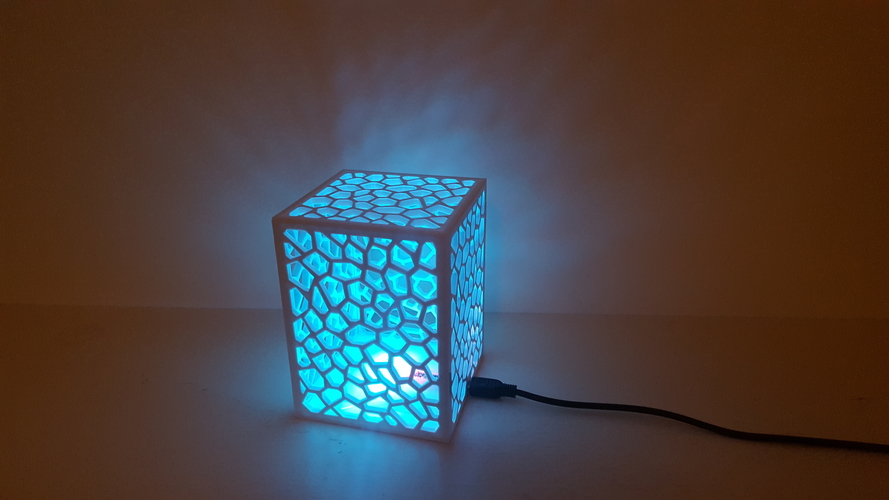

Page load link Go to TopFree STL file Crystal tower lantern

Dragonscale pot and planter - vase mode

€1. -33% 0.76 €  14

14

Cactus pot and planter

€0.94 -34% 0.62€

Geometric origami flower pot and planter for indoor plants

€0.90 -22% 0.70 €

Geo Crystal Pot and planter for plants - vase mode

€1.14 -25% 0.86€

Shard vase

€0.81 -23% 0. 62 €

62 €

Spiral plant pot

€0.81 -23% 0.62 €

€0.99 -20% 0.79 €

GeoStone pot and planter for your plants - vase mode

0,90 €

Chinese origami pot and potted planter

€0.80 nine0007 -25% 0.60 €

Geometric origami flower pot and planter for indoor plants

€0.90 -22% 0. 70 €

70 €

Geo Crystal Pot and planter for plants - vase mode

€1.14 nine0007 -25% 0.86 €

Gum pot and planter - vase mode

€0.81 -23% 0.62 €

Best 3D Printer Files in Home Category

nine0003 Coffee capsule dispenserFree

Superman Book Holder, Bookend

3.99 €

Vase mode Christmas tree baubles

Free

Valeria Lamp

Free

Spherical box for tablets in three sizes

0. 50 €

50 €

0.82 €

CAT TOILET TRAINING KIT v2.2 - CAT TOILET TRAINING KIT v2.2

4,74 €

1€ and 2€ shopping cart unlock key

Free

Bestsellers in the Home category

Crystal corner decor - printing on site

1.54 €

nine0003 Venus and Aphrodite3.60 €

HAIRY FLEXIBLE GNOME FOR ON-SITE PRINTING

2.38 €

Quick Print Gift/Storage Boxes - Ultimate Collection (Vase Mode)

€5.66 -25% 4.25 €

1 €

Another quick-change toilet roll holder

1 €

Key ring for weapons

1 €

Ornamented tea holder

€2. -25% 2.14€ 85

85

Clothes hanger "Wolf"

2,13 €

Wallet card holder (universal package)

1.29 €

Secret tray for bowls of ramen noodles

2.66 €

Waste bin with hinged lid

3.20 €

nine0003 Box / Travel bag2.60 €

Treasure chest Printed in place

1.25 €

Wall shelf "Ostrea Fungus"

2,40 €

Kawaii dim sums in a cute basket

1.54 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon. nine0008

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

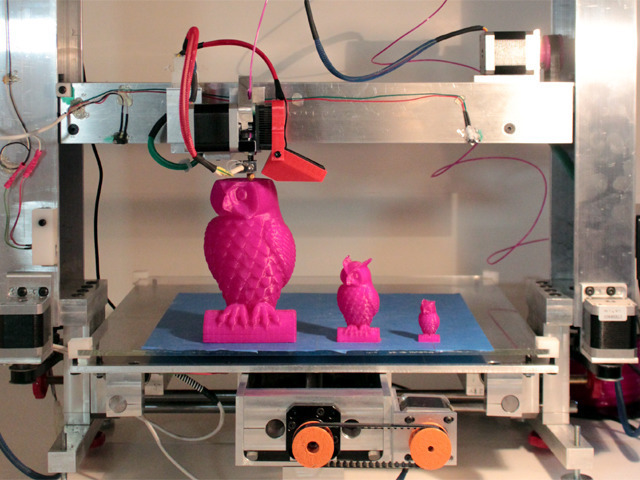

3D printer light. Variants and implementation

3DPrintStory Reviews 3D printer backlight. Variants and implementation

Have you ever got up in the middle of the night to check how 3D printing is going and frantically illuminated with a flashlight from your mobile? Or do you want your 3D printer to look cooler in the dark? The backlight can illuminate the entire 3D printer, workspace, or even the printhead, so there's room for your creative choices.

In addition to aesthetics and better visibility, another benefit of proper lighting is webcam accuracy, which is essential for programs like The Spaghetti Detective to track 3D print failures. nine0008

In this article, we'll look at a few different lighting options for your 3D printer, printhead, or entire desktop. However, before we present these options, let's discuss some of the specifics of your lighting setup.

What to Look for When Choosing a 3D Printer Light

There are several factors to consider when deciding which 3D printer light is best for you. nine0008

- Placement and Orientation: If you direct the light towards the center of the 3D printer, it will illuminate the area of the printed model. If you place the backlight outward, then this illumination will be enough not only for your part, but for the entire 3D printer.

- Power: 3D printer backlighting can be implemented through the printer's power supply or take a separate power supply.

If your printer uses a motherboard that supports backlighting, such as the SKR Mini E3 V2 or MKS Robin E3D, you can connect a compatible light source (same voltage) directly to the printer. However, if your motherboard does not have this feature, you can power the lighting from an external source, such as a computer or wall socket. nine0201

If your printer uses a motherboard that supports backlighting, such as the SKR Mini E3 V2 or MKS Robin E3D, you can connect a compatible light source (same voltage) directly to the printer. However, if your motherboard does not have this feature, you can power the lighting from an external source, such as a computer or wall socket. nine0201 - Color: If you need different colors, look for RGB (red, green and blue) lights that can produce any color. If you want a plain white light, we recommend that you choose a richer white color (brighter and whiter) for better illumination.

Now let's look at the options! Please note that although some of the suggested options are for the Ender 3, it is not difficult to change them for your specific 3D printer.

Illumination of the extruder zone on a 3D printer from profiles

The first option involves attaching an LED strip to your 3D printer's horizontal portal profile. Many 3D printers use aluminum V-groove profiles as part of the frame and gantry design, making them a great option for mounting LEDs. There are a huge number of options, it all depends on the number of tapes and your desires.

There are a huge number of options, it all depends on the number of tapes and your desires.

In essence, this lighting option for a 3D printer comes down to mounting an LED strip on a V-groove profile. Implementation may vary, there are many mounting options. For example, you can use mounting strips printed on a 3D printer and attach the LED strip to them already. Or mount the tape directly on the profile without using additional parts. nine0008

There is an interesting way to illuminate the extrusion zone with a flashlight. The Thingiverse link below will have a fastener that you can print and mount to your frame if you are using an Ender 3 3D printer. to the body, you can do it in other ways. There are many standard fixtures for lighting fixtures, so there are many options. As a general rule, these mounts are fine if you have a closed-case 3D printer. nine0008

You can 3D print fasteners yourself. For example, here is a variant of fixtures for LED strips. You can use screws or glue for fastening. The fasteners are pretty versatile.

The fasteners are pretty versatile.

There are options for more specialized LED strip fixtures for a specific 3D printer. For example, here is a mount for mounting on the body of a Prusa 3D printer. For example, these 3D printable models are designed to fit on the frame of a Prusa 3D printer.

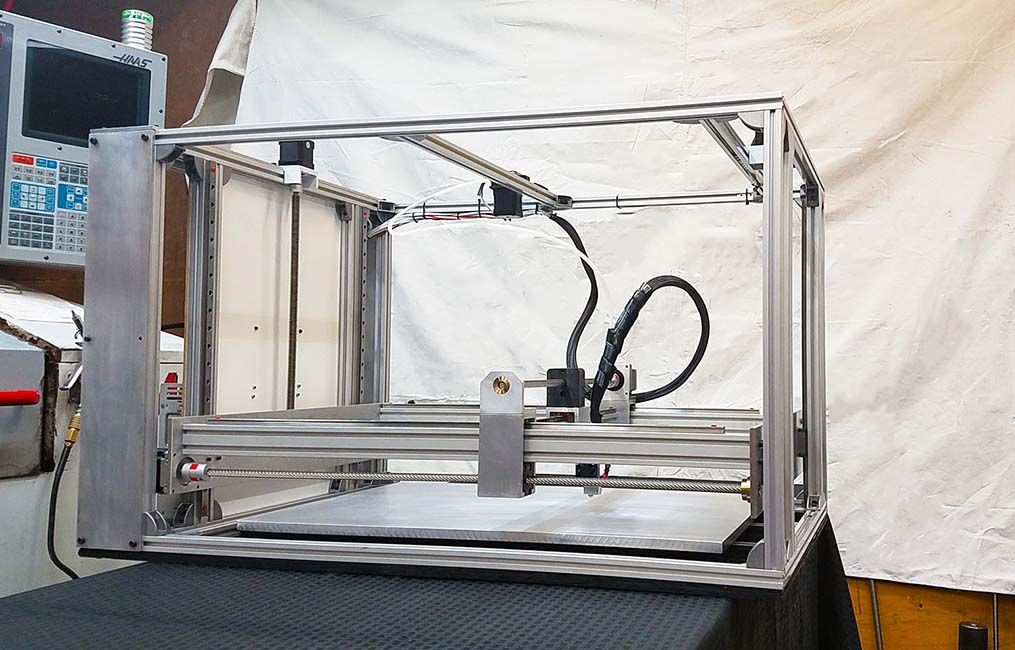

3D Printer Arch Light

Another cool option that requires a bit more effort but works great for lighting your 3D printer is the arch. After installing this arch with LEDs on your 3D printer table, you will be able to monitor both the 3D printing process and, in principle, use the large illuminated area for soldering and repairing small parts and assemblies. To make an arch, you will need a lot of 3D printed models and a rather large piece of LED strip, but the result is worth it. nine0008

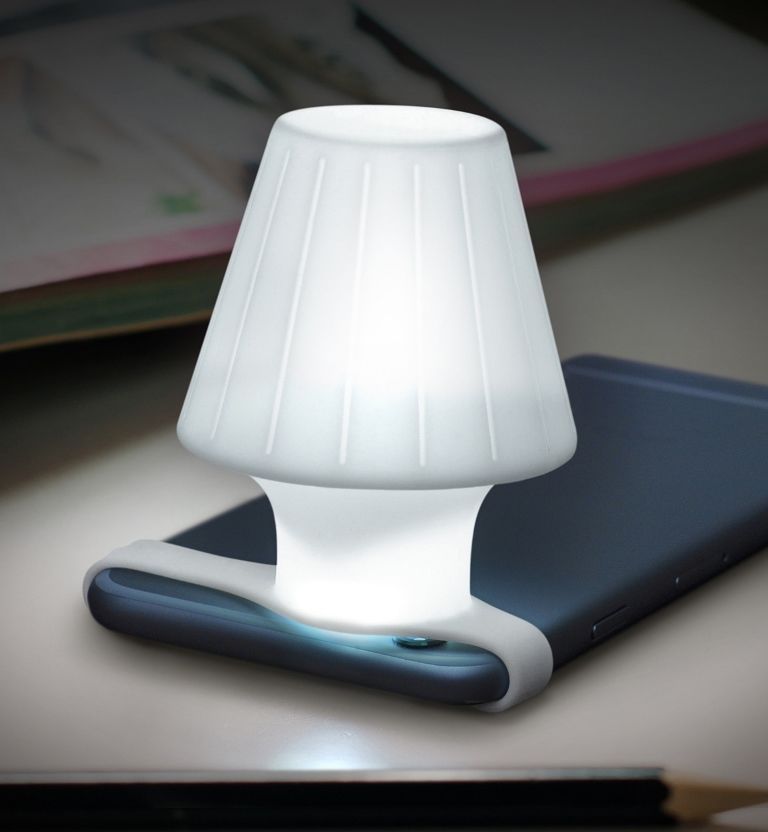

3D printer light on print head

If you want to light the 3D print area directly, you can add light on the print head. This performance will help you directly illuminate the area of the current 3D print, as the source itself will move with the print head.