2 nozzle 3d printer

The Best Dual Extruder 3D Printers in 2022 (for Dual 3D Printing and Multicolor 3D Printing)

Welcome to the Thomas guide to the best dual extruder 3D printers 2022. Thomas has been connecting North American industrial buyers and suppliers for more than 120 years. When you purchase products through our independent recommendations, we may earn an affiliate commission.

3D printing in itself is a progressive technology that is extremely useful in many businesses, but it's also a fun activity for DIY hobbyists too. With rapid advancements taking place in the sector regularly, we have seen a lot of impressive things from this industry and can expect to see a lot more in the near future.

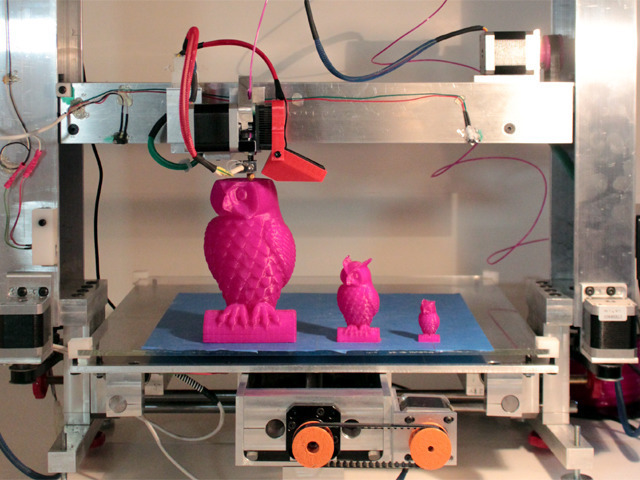

Dual extruder 3D printers can produce colorful and creative projects with two different filamentsImage credit: Shutterstock/Alex_Traksel

Although it's been around for a long time in the professional 3D printing world, one of the newer technologies introduced to at-home 3D printers is dual extrusion which allows users to print with two filaments at the same time, meaning you can mix colors and multiple materials—from PETG, ABS, PLA, and carbon, to metal, wood fill, and multicolor printing filaments—to produce extremely creative projects that can even be created simultaneously.

What is a Dual Extruder 3D Printer?

Dual extrusion in 3D printing refers to the art of printing using different materials, whether you choose different colors or different types of filaments with various effects, such as plastic filaments with metallic, or wooden effects.

This gives you the ability to make superior and more impressive products, and many professionals, as well as 3D printing enthusiasts, and those who own small businesses, i.e. Etsy shops selling 3D printed creations, swear by it.

Dual Extruder Printer—Buying Guide

3D printers with dual extruding capacity are, understandably, slightly pricier than single extruders, but it is a major upgrade from the single types, and there are many dual extruder 3D printers on the market at reasonable prices of around US$300-US$400. Since you’ll be spending quite a bit on this impressive piece of equipment, you want to make sure you’re buying the best one for your needs.

Types of Dual Extruder 3D Printers

Though most dual printing machines allow for multi-color printing with different materials, there are two main types of dual extruder 3D printers available:

Independent dual extruder system

IDEX printers have two print heads and two nozzles with each print head able to either mirror the other in mirror mode, duplicate items with duplication mode, or print two completely separate objects.

Dependant dual extruders

These dual extruders have two extruders that are connected and move together to create one object using two different filaments. Two spools are loaded on the 3D printer and the printer alternates using them. These printers have the key advantage of reducing printing time since more print material can be produced than with just a single print head.

Dual Extrusion Printers—Considerations

Here are some other factors to consider why trying to find the best dual extruder 3D printers for your needs.

Print bed

As with regular 3D printers, print beds in dual extruder printers come in heated or non-heated options. A 3D printer with a heated print bed is, understandably, usually more expensive than a non-heated option but a heating plate can offer better print quality by keeping the bottom layers warm and reduce the chances of your prints warping during the printing process.

Print heads

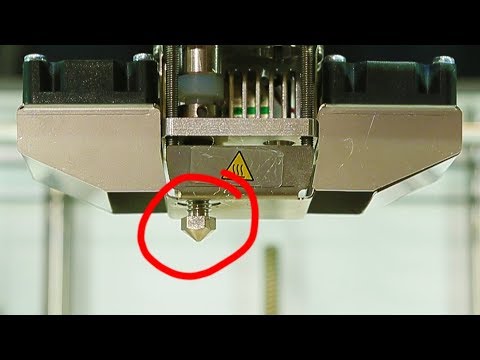

Whereas a regular 3D printer just has one print head, a dual extruder printer will have more than one print head, with either two extruders, and sometimes even three. Some dual extruder 3D printers might have just one print head but a dual nozzle that can use two separate filaments on one print. A dual nozzle is great for printing an object in several materials or colors.

Print volume

Print volume, also referred to as the printing volume or the build volume, is how big an object you can build on any given printer. For an at-home printer, projects that would need a huge build volume would likely involve a printing process that would see the object printed off in separate parts and then stuck together afterward. The average size of a 3D printer with a larger build plate would be around 300 x 300 x 400mm.

For an at-home printer, projects that would need a huge build volume would likely involve a printing process that would see the object printed off in separate parts and then stuck together afterward. The average size of a 3D printer with a larger build plate would be around 300 x 300 x 400mm.

Calibration

If you’re a beginner to the world of 3D printing, a printer with automatic calibration is highly recommended. As with most aspects in 3D printing, calibrating a 3D printer has a learning curve and an automatic calibration feature can save you time and hassle and do the hard work for you.

Other factors

Another consideration you may want to keep in mind is cost. A dual extruding printer will be priced higher than a regular single head printer, plus maintenance costs will be higher, too, because there are more parts to this machine. In addition, if you’ll be working with various filaments at the same time (or even the same filament but with two extruders), factoring in higher costs for different materials is also a must.

Some machines even come with an added laser engraver feature or you could buy a compatible laser engraver to use with it. Whatever you’re after in a dual extruding 3D printer, our below list has some of the best models on the market to suit an array of styles, needs, and budgets.

Thomas’ Top Picks for the Best Dual Extruder 3D Printers 2022

We've scoured around and found some of the best 3D dual extruders worth taking a look at.

Best-Rated Dual Extruder 3D Printer: BIBO 3D Dual Extruder Printer | Buy Now

Best Dual Independent Extruder 3D Printer: TENLOG TL-D3 Pro Dual Extruder 3D Printer | Buy Now

Best Enclosed Dual Extruder 3D Printer: FlashForge Dreamer Dual Extruder 3D Printer | Buy Now

Best Cheap Dual Extruder 3D Printer: Sovol SV02 3D Printer | Buy Now

Best Professional Dual Extruder 3D Printer: Raise3D E2 Desktop 3D Printer | Buy Now

Best Quiet Dual Extrusion Machine: JG AURORA Artist-D Pro IDEX 3D Printer | Buy Now

Scroll down to read more about our top picks for the best dual extruder 3D printers according to thousands of happy buyers.

*Prices listed in this article were as shown in US$ on Amazon.com (USA) as of April 2022

1. Best-Rated Dual Extruder 3D Printer—BIBO 3D Printer Dual Extrusion

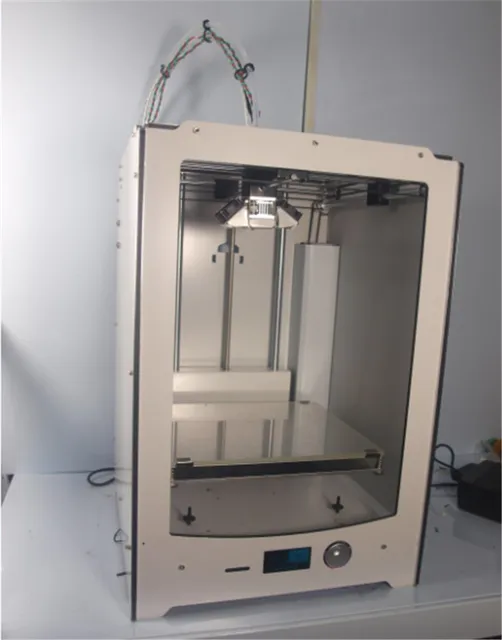

A great printer well under the US$1000 mark, is this BIBO dual extruding 3D printer; a fully enclosed model with a very sturdy frame, full-color touch screen, WiFi capabilities, a demountable glass bed, and a low filament detector to let you know when you need to replace it before it's too late.

You can operate it via your phone or tablet if you so wish, and, in addition to printing two colors, it also has the ability to print two objects at the same time. This printer can print in two colors or filament materials, and can also print the dissolvable filament for support material.

One five-star review reads, "The dual extruder function is great, I'm able to use PLA filament and a soluble filament to print out some gears that impressed my friends and coworkers. .. Customer support is AMAZING. Every problem I had is solved very promptly and professionally, even though my printer is well out of their warranty."

.. Customer support is AMAZING. Every problem I had is solved very promptly and professionally, even though my printer is well out of their warranty."

Specifications

Build volume: 8.4 x 7.3 x 6.3 inches

Layer resolution: 0.05-0.3mm

Filament compatibility: multiple filaments including ABS, PLA, HIPS, TPU, PETG, nylon, PC, carbon fiber

BUY NOW:

US$579, Amazon2. Best Independent Dual Extruder 3D Printer—TENLOG Independent Dual Extrusion 3D Printer with Dual Nozzle

Whereas other dual extruding printers have one nozzle that can print from two pre-loaded filament spools, a 3D printer with independent dual extruding capabilities, like this model from TENLOG, has two separate nozzles, each with its own spool, that print at the same time but independently from each other.

This dual nozzle printer can print a duplicate in one go with its duplication or mirroring print modes, in the same or multiple colors, and many customers were left impressed with the high print quality this printer offers.

One happy buyer who described himself as a "3D printing veteran", wrote that the printer is "amazing" and that its print quality is "gorgeous", while another reviewer added "the touch screen and print quality are excellent."

Specifications

Build volume: 11.8 x 11.8 x 13.8 inches

Print speed: 10-150mm/s

Layer thickness: 0.1-0.4mm

Filament compatibility: PVA, TPU, ABS, PLA, nylon

BUY NOW:

US$499.99, Amazon3. Best Enclosed Dual Extruder 3D Printer—FlashForge Dreamer Dual Extruder 3D Printer

The Dreamer by FlashForge is a fan favorite for many reasons; its fully enclosed design and sleek look, WiFi connectivity, user-friendly and high-res color touch screen, built-in 4G memory, full manufacturer's warranty, FlashForge's superior customer service, and, of course, it's dual extruder capabilities.-360x360.jpg)

In addition, some consider this dual extrusion printer to be a professional piece of kit at the price of more beginner-level 3D printers and its large printing volume helps users get creative.

"This printer is the best bang for your buck to create large, very high-quality prints," one happy buyer reviewed. "[It] has a very high quality, well planned/built enclosure, which you won't find in many printers at this price. It even has two filament spool holders inside the enclosure."

Specifications

Build volume: 230 x 150 x 150 mm

Print speed: “100 micron and can really go to 75 micron at slower printing speed” (as per one customer)

Resolution: 0.1-0.2mm

Filament compatibility: ABS, PVA, PLA,

BUY NOW:

US$699, Amazon4. Best Cheap Dual Extruder 3D Printer—Sovol SV02 3D Printer

Great for beginners, this dual extrusion 3D printer from Sovol with large print volume capacity comes 95% pre-assembled so you can get to printing pretty much straight out of the box. Its full-metal body is stable and made to last, and the touch-screen is user-friendly.

Its full-metal body is stable and made to last, and the touch-screen is user-friendly.

With an impressive build volume, and the ability to print in two colors (or two types of filament), you'd be hard-pressed to find another 3D printer with the same capabilities at this price. In addition, you could buy an extra kit that will turn this thing into a laser engraving machine too if you’d like to add that something special that laser engraving can bring to your projects.

"I purchased it for the dual extrusion capability, and the large build area," wrote one buyer. "I was very impressed with the smoothness of this printer. The only sound during operation is the sound from the fans." Another happy purchaser helpfully added that the "dual extrusion is awesome, but for most prints, you will waste a lot of filament with the purge tower due to the shared hot end. It is a necessary evil."

Specifications

Build volume: 240 x 280 x 300 mm

Print precision: ±0. 1mm

1mm

Layer thickness: 0.1-0.4mm

Filament compatibility: can support material including PLA, ABS, PETG, WOOD, TPU

BUY NOW:

US$359, Amazon5. Best Professional Dual Extruder 3D Printer—Raise3D E2 3D Printer

For a professional 3D printing matching (with a price tag to match), the Raise3D is actually rather simple to use and even easier to set up. It has an auto bed leveling system and will guide you through the offset calibration system via a video.

It has an intuitive user interface with a large 7-inch touchscreen, and also many other features such as independent dual direct-drive extruders, a filament run-out sensor, resume-printing function, WiFi connectivity, and a live, built-in camera so you can monitor your prints remotely.

There's even a HEPA filter to clear any harmful and annoying fumes. It's compatible with almost any filament available. "This is my second dual-extruder printer," wrote one thrilled customer, "and compared to all of the less expensive units, the difference is night and day... Where the less expensive printers leave you feeling like the printer itself is more of a prototype, this one screams quality polished product."

"This is my second dual-extruder printer," wrote one thrilled customer, "and compared to all of the less expensive units, the difference is night and day... Where the less expensive printers leave you feeling like the printer itself is more of a prototype, this one screams quality polished product."

Specifications

Build volume: 11.6 x 9.4 x 9.4 inches

Minimum layer height: 20 microns (0.02 – 0.25 mm)

Precision: 0.78125, 0.78125, 0.078125 micron

Filament compatibility: practically all of them (PLA, ABS, HIPS, PC, TPU, TPE, Nylon, PETG, ASA, PP, PVA, glass fiber infused, carbon fiber infused, metal fill, wood fill)

BUY NOW:

US$3,499, Amazon6. Best Quiet Dual Extrusion Machine—JG AURORA Artist-D Pro IDEX 3D Printer

With super quiet functioning so that you can leave it printing all night if needed without waking up the whole household, the Artist-D Pro 3D printer by JG AURORA has an IDEX system, an ejectable nozzle for easy replacement, changes, and maintenance, and an industrial-grade linear rail for smooth and practically friction-free precision.

It provides the option to change to an optical limit switch, and, as a step up from the Artist-D, has a color touch screen. There are power-resume and filament runout detector functions and duplicate as well as mirror printing options.

One customer with a lot of experience in 3D printing with industrial printers felt that this printer is “the best desktop printer I have ever purchased,” and added, “it has features that my more expensive desktop printers do not have… It has been printing since it showed up at my door, well-needed production parts.”

Specifications

Build volume: 300 x 300 x 340mm build plate

Precision: up to 0.001 mm

Filament compatibility: PLA, TPU, PETG, PVA

BUY NOW:

US$599, AmazonThe BIBO 3D Printer (US$579, Amazon) is a great foray into the world of dual extruding, but for something a bit more economical, the price-performance ratio of the Sovol SV02 3D printer (US$359, Amazon) is impressive too.

We hope our review of the best dual Extruder 3D printers has been helpful and you found the best dual extrusion printer for your needs to get creative and print objects in multiple colors, shapes, and sizes, and perhaps even add laser engraving to the mix too. For more 3D printers and other 3D printing suppliers, including 3D printer filaments suppliers, additive manufacturing suppliers, 3D photographic printing services, and 3D sand printing additive manufacturing, consult our additional guides, or visit the Thomas Supplier Discovery Platform.

Other 3D Printing Articles- The Best 3D Printers under $300

- The Best 3D Printers under $200

- The Best 3D Printer Under $1000

- The Best 3D Printer Under $500

- Top 3D Printing Services Companies in the USA

- Origins of 3D Printing and Additive Manufacturing

- Overview of 3D Printing Technologies

- Top 3D Printing Manufacturers and Suppliers (Publicly Traded and Privately-Owned)

- Top Suppliers of Additive Manufacturing Consulting Services

Other Best Product Articles

- The Best Cordless Impact Wrenches

- The Best Portable Generators

- The Best Portable Band Saws

- The Best Electric Space Heaters

- The Best Mini Milling Machine

- The Best Attic Ladders

- The Best Air Purifiers for Smoke

- The Best Circuit Breaker Locator

- The Best Engine Hoists and Accessories

- The Best Drywall Lifts

- The Best Whole-House Generators

- The Best Home Automation Systems

- The Best Quietest Portable Generators

- The Best Uninterruptible Power Supply Systems

- The Best Commercial Patio Heaters

- The Best Electric Bikes

- The Best Electric Pressure Washers

- The Best Keyless Door Locks

- The Best Electric Lawnmowers

- The Best Electric Hand Warmers

More from Custom Manufacturing & Fabricating

Best Dual Extruder 3D Printers and Their Benefits

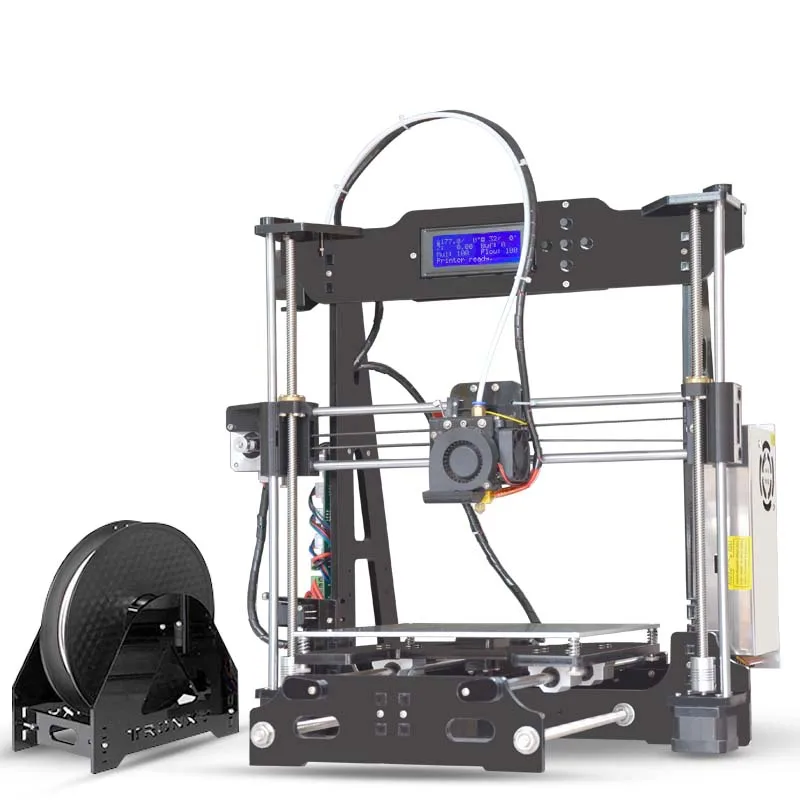

When they first appeared in the market, FDM 3D printers were only able to print with one filament at a time. More sophisticated multi-color or multi-material projects used to be a real challenge, requiring serious user skills. But demand creates its own supply, and a new technology to solve the problem couldn’t but come up. Thus dual extrusion printers entered the market, breaking new grounds for customers.

More sophisticated multi-color or multi-material projects used to be a real challenge, requiring serious user skills. But demand creates its own supply, and a new technology to solve the problem couldn’t but come up. Thus dual extrusion printers entered the market, breaking new grounds for customers.

This is Top 3D Shop, and in this article, we are going to dwell upon the types and peculiarities of dual extrusion, and find out how to choose a 3D printer offering this function.

Is dual extrusion worth it?

The answer to this question, like always, depends on your particular printing tasks. Generally, if you are going to print mostly single-color and single-material models with relatively simple geometries, you can get by with a single extruder device; although even in this case dual extrusion can be of some help. For more complex projects, dual extrusion 3D printers prove definitely useful, if not indispensable in some cases.

What are the benefits of a dual extruder 3D printer?

There are two main types of dual extruder 3D printers, based on the use of dependent or independent extruders. We will discuss each type in detail a bit later, and now let’s see how customers can benefit from using a dual extrusion machine.

We will discuss each type in detail a bit later, and now let’s see how customers can benefit from using a dual extrusion machine.

Pros

Support structures. Virtually, the most important advantage of a dual extruder is its ability to print supports with soluble filaments. Some complex models with overhanging elements require support structures to prevent deformation while printing. With a single extruder, supports are printed with the same filament as the model, and then removed with the risk of damaging the part. Besides, some models need internal supports, which are impossible to remove after the part has been printed. Using the second extruder for printing supports with a soluble filament solves this problem.

Credit: filament2print.com

The most common materials for support structures are PVA and HIPS. Once the part is ready, all you need to do is just submerge it in water or limonene (if HIPS is used) to completely dissolve the supports. This reduces post-processing time and eliminates the risk of damaging the part.

Multi-color printing. Dual extruder printers allow printing with two filaments simultaneously, creating dual-color parts without the need to change filaments.

Credit: dummies.com

Multi-material printing. The second extruder can be used not only for creating support structures, but also for printing dual-material models, combining different properties of both materials used. For example, you can print certain elements of the model with a carbon fiber-filled filament, thus strengthening the whole structure, while the rest of the part can be printed with less expensive PLA. Some 3D printers, like Creatbot D600 Pro, use two extruders for different filament types: the left extruder for printing low-temp materials, such as PLA or ABS, and the right one — equipped with a 420 °C hotend — for printing high-temp nylons, carbon fiber-filled thermoplastics, and PC.

Credit: news.softpedia.com

Increased speed. The use of two extruders allows speeding up the process, compared to single extrusion printing. With an independent dual extruder you can double the production volume of your 3D printer by making two similar parts in one go, using mirror or duplication modes.

With an independent dual extruder you can double the production volume of your 3D printer by making two similar parts in one go, using mirror or duplication modes.

Minimized downtime. If one extruder is clogged, you do not have to stop printing immediately, but can continue with the second extruder, thus minimizing downtime and increasing the efficiency of the printing process.

Besides a great number of obvious advantages, dual extrusion has its shortcomings, though not numerous.

Cons

High price. As dual extrusion printers are more complicated mechanisms, consequently, they are more expensive than their single extruder counterparts.

Heavier weight. The dual extruder adds some weight, which can interfere with the smooth print head movement and lead to printing failures, like stringing issues. To avoid this, you have to slow down the printing speed.

Maintenance. Dual extruder printers need more frequent maintenance and more complicated calibration than devices with a single extruder. They also require a bit more preparation of the digital model, as you have to specify the printing tasks for both extruders.

They also require a bit more preparation of the digital model, as you have to specify the printing tasks for both extruders.

How to pick a dual extruder 3D printer

There is a large variety of dual extrusion 3D printers in the market, which differ greatly in functionality and, certainly, price range. To make the best of the technology and not to pay extra, it is worth knowing which types of dual extrusion 3D printers are available in the market, and what each type is capable of.

Types of dual extruder 3D printers

Dependent dual extruder system

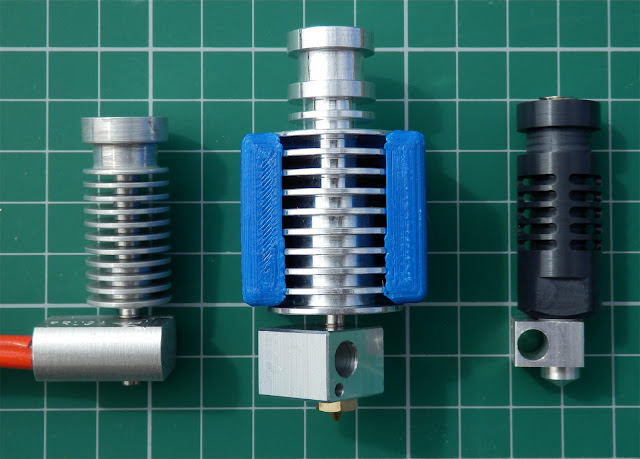

The dependent dual extrusion system has two variations, implying the use of one or two nozzles.

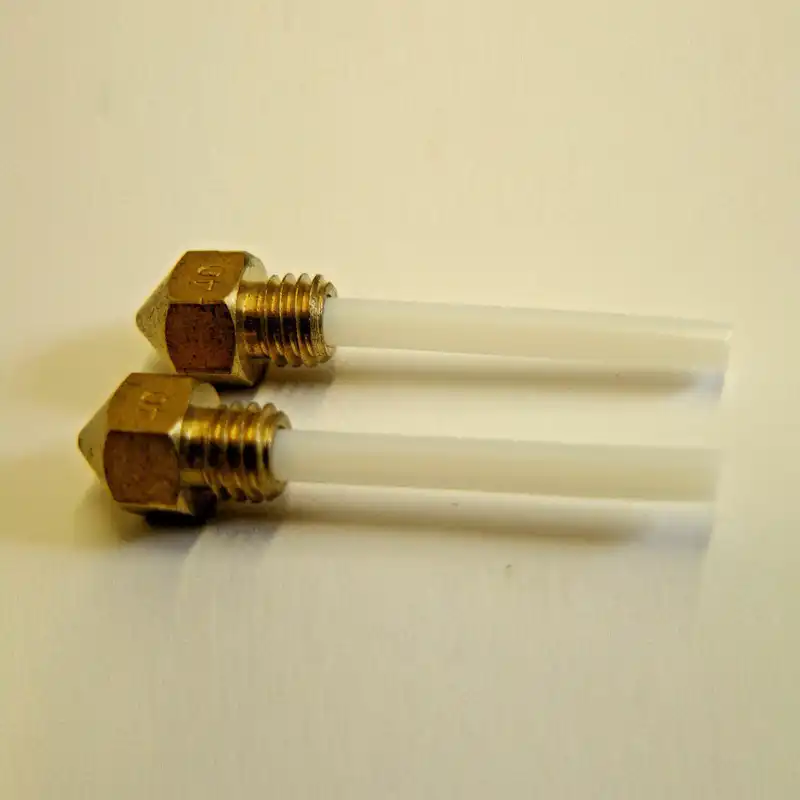

Single nozzle. Such systems are equipped with two extruders using one print head with a single nozzle. The filaments print in turn, and after each change, the remains of the previous material should be completely removed from the nozzle to avoid color blending. In order to do this, a purge block, or prime tower, is printed to extrude the remaining filament — not the best way to save on material, though.

Credit: easy3dhome.com

An interesting example of such a system, although it is not a printer itself, is the Mosaic Palette 3 Pro filament splicer, allowing for continuous printing with up to 8 filaments. The device is compatible with most single-extrusion FDM printers, and allows converting them to multi-color machines. The Palette 3 Pro also helps to save on purge blocks, as they can be included in the printed model as the infill parts.

Another example of a single nozzle dual-extrusion system is the Creality CR-X Dual Color 3D printer with a large build volume and vast creative opportunities.

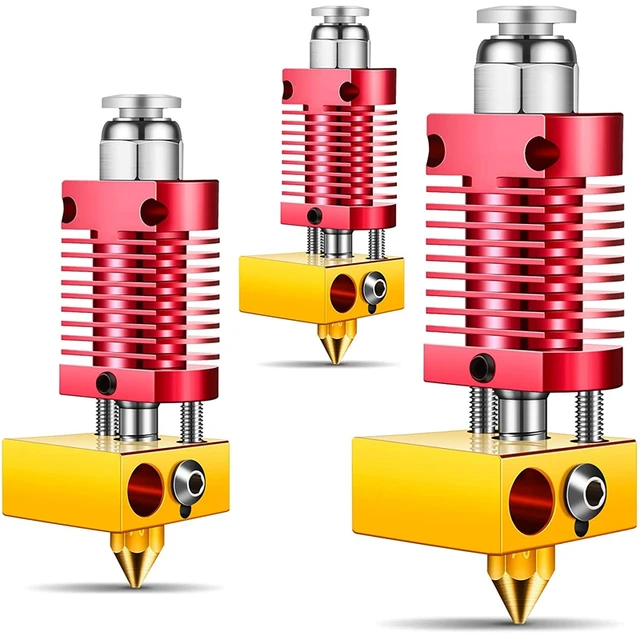

Dual nozzle. This type of dependent dual extrusion uses a single print head with two dependent nozzles. This type of dual extrusion is faster than that using a single nozzle setup, as you do not spend time on switching filaments. It also gives you more freedom, as you can print with different filament types, using various nozzle diameters. Printing water-soluble support structures is a great advantage of this system.

On the downside, there is a risk of oozing, which can be minimized by creating an ooze shield — a one-layer wide wall created around the printed part to catch the remaining filament on the nozzle. Another way to avoid oozing, already mentioned above, is to build a prime tower, that is a block next to the part being printed.

Independent dual extruder system

The Independent Dual Extruder system, called IDEX, is the most advanced dual extrusion technology, as it uses two print heads moving independently from each other on the X-axis (still being dependent on the Y / Z-axes). Featuring all the benefits of a dependent dual extrusion system, like multi-material or multi-color printing, IDEX provides a huge advantage, which is simultaneous printing of two copies of the same model, either in duplication or in mirror mode. The latter can be used, for example, for making two insoles for a pair of shoes in one go. This ability means that you can double the production speed, which sounds great for batch manufacturing.

As nothing is perfect, IDEX also has its drawbacks. Firstly, the second print head adds considerable weight, thus introducing the risk of Z-wobbling. Another thing with using IDEX printers is the reduced build volume when printing in single or dual extrusion modes; while duplication mode uses the entire effective build plate area. The example of this is the CraftBot Flow IDEX XL dual extrusion 3D printer. It features the total build area of 425 x 250 x 500 mm, which is reduced to 386 x 250 x 500 mm in single print head mode, and to 351 x 250 x 500 mm in dual print head mode; while duplication mode uses the whole 425 x 250 x 500 mm build area.

Best dual extruder 3D printers 2022

Best dual extruder 3D printers under $500

QIDI Tech X-Pro

The QIDI Tech X-Pro is one of the most affordable dual extrusion FDM 3D printers in the market. The device has an enclosed build chamber and the print volume of 230 x 150 x 150 mm. The X-Pro is equipped with a direct drive dual extrusion module with 4-side air-blow turbofans and two 0. 4 mm nozzles with the maximum temperature of 250 °C. The removable magnetic print bed heats up to 110 °C. The 4.3" touchscreen allows for an easy settings adjustment. The maximum layer height of 50 microns and fully enclosed build chamber with a heated print bed ensure consistent printing with all popular consumer plastics, including PLA, PETG, ABS, and TPU. The QIDI Tech X-Pro comes with the QIDI print software.

4 mm nozzles with the maximum temperature of 250 °C. The removable magnetic print bed heats up to 110 °C. The 4.3" touchscreen allows for an easy settings adjustment. The maximum layer height of 50 microns and fully enclosed build chamber with a heated print bed ensure consistent printing with all popular consumer plastics, including PLA, PETG, ABS, and TPU. The QIDI Tech X-Pro comes with the QIDI print software.

Credit: reddit.com

Pros:

- Removable heated print bed

- Print resume function

- Enclosed build chamber

- Open material system

Cons:

- The extrusion unit requires installation

- No auto bed leveling

Flashforge Creator Pro

The Flashforge Creator Pro FDM 3D printer is an upgraded version of the Flashforge Creator model. The device features a rigid metal frame and a fully enclosed build chamber of 227 x 148 x 150 mm, and can print up to 60% faster than the original Creator. Probably, the most distinctive feature of the Creator Pro is its dual extrusion system with two dependent print heads, which allow dual-color and dual-material printing, including printing water-soluble support structures. The maximum hotend temperature of 240 °C and the heated removable print bed allow working comfortably with most consumer plastic filaments, such as ABS, PLA, PVA, flexible materials and composites. The Creator Pro is compatible with the proprietary FlashPrint software.

Probably, the most distinctive feature of the Creator Pro is its dual extrusion system with two dependent print heads, which allow dual-color and dual-material printing, including printing water-soluble support structures. The maximum hotend temperature of 240 °C and the heated removable print bed allow working comfortably with most consumer plastic filaments, such as ABS, PLA, PVA, flexible materials and composites. The Creator Pro is compatible with the proprietary FlashPrint software.

Credit: @kreativeoutlet77 / Instagram

Pros

- High print quality

- Heated removable print bed

- Low noise level

- Wide range of compatible filaments

- Affordable price

Cons

- No auto bed leveling

- No print resume function

Flashforge Dreamer

The Flashforge Dreamer is an affordable reliable FDM 3D printer featuring a dual extrusion system. Two dependent print heads allow the user to create dual-material models and build water-soluble PVA support structures. The printer is equipped with two blower cooling fans to avoid warping while printing with PLA-like filaments. The enclosed chamber and the heated print bed ensure compatibility with all the most popular consumer plastics. 100-micron minimum layer height provides decent print quality, but the software allows the user to set up half the layer height for even more detailed prints with smoother surface finish. The build volume of 230 x 150 x 140 mm is enough for most home-use applications. The LED bar inside the printer is convenient when printing in dark environments.

The printer is equipped with two blower cooling fans to avoid warping while printing with PLA-like filaments. The enclosed chamber and the heated print bed ensure compatibility with all the most popular consumer plastics. 100-micron minimum layer height provides decent print quality, but the software allows the user to set up half the layer height for even more detailed prints with smoother surface finish. The build volume of 230 x 150 x 140 mm is enough for most home-use applications. The LED bar inside the printer is convenient when printing in dark environments.

Credit: @tjwill95 / Instagram

Pros:

- Fully enclosed build chamber

- Wide range of printable materials

- Heated print bed

- Wi-Fi connectivity

Cons:

- Rather noisy

- Little room for filament spools inside the printer

Budget dual extruder 3D printers under $1,000

BIBO 2 Touch

The BIBO 2 Touch is a dual extrusion FDM 3D printer with a build volume of 214 x 186 x 160 mm. The device is equipped with a direct drive dual extruder with two hotends, sitting side-by-side on a single print head. Alongside the ability to build dual-color and dual-material models, the BIBO 2 Touch can print in copy printing mode, which allows making two copies of the same part in one go. To reduce the risk of oozing, the inactive hotend is cooled down to 175° C, although such a solution decreases print speed. The fully enclosed build chamber and detachable glass heated print bed make for printing with a lot of filament types, including ABS, PLA, PVA, HIPS, TPU, PC, PETG, nylon, wood, and others. The BIBO 2 Touch is compatible with most popular slicing software, like Cura, Repetier-Host, or Simplify3D. An optional laser-engraving module can be bought separately to expand the functionality of the device.

The device is equipped with a direct drive dual extruder with two hotends, sitting side-by-side on a single print head. Alongside the ability to build dual-color and dual-material models, the BIBO 2 Touch can print in copy printing mode, which allows making two copies of the same part in one go. To reduce the risk of oozing, the inactive hotend is cooled down to 175° C, although such a solution decreases print speed. The fully enclosed build chamber and detachable glass heated print bed make for printing with a lot of filament types, including ABS, PLA, PVA, HIPS, TPU, PC, PETG, nylon, wood, and others. The BIBO 2 Touch is compatible with most popular slicing software, like Cura, Repetier-Host, or Simplify3D. An optional laser-engraving module can be bought separately to expand the functionality of the device.

Credit: @melbamorph / Instagram

Pros

- Copy printing mode

- 50 microns minimum layer height

- Removable heated print bed

- Print resume function

- Filament runout detection

Cons

- Somewhat inconvenient user interface

- The build volume is comparatively small

Flashforge Creator Pro 2

The Flashforge Creator Pro 2 is a Cartesian-style FDM 3D printer featuring an independent dual extruder system, which is rarely found in sub $1,000 models. The IDEX system allows printing not only in multi-material and soluble support modes, but also in mirror and duplication modes, providing a double speed boost. The nozzles can heat up to 240 °C and feature an improved design to prevent clogging. The heated print bed and a fully enclosed build chamber prevent temperature fluctuations and ensure consistent printing results with all consumer filaments, like PLA, ABS, HIPS, TPU and others. The Creator Pro 2 is operated via a 3.5" touchscreen with a clear and simple UI.

The IDEX system allows printing not only in multi-material and soluble support modes, but also in mirror and duplication modes, providing a double speed boost. The nozzles can heat up to 240 °C and feature an improved design to prevent clogging. The heated print bed and a fully enclosed build chamber prevent temperature fluctuations and ensure consistent printing results with all consumer filaments, like PLA, ABS, HIPS, TPU and others. The Creator Pro 2 is operated via a 3.5" touchscreen with a clear and simple UI.

Credit: reddit.com

Pros

- Independent dual extrusion system (IDEX)

- Enclosed build chamber

- Heated print bed

- Affordable price

- User-friendly interface

Cons

- No Wi-Fi / Ethernet connectivity

- No auto bed leveling

Professional dual extruder 3D printers $1,000+

QIDI Tech i-Fast

The QIDI Tech i-Fast is an industrial-grade FDM 3D printer featuring a direct drive dual extruder, equipped with wear-resistant ruby nozzles with a maximum temperature of 300 °C, and two nozzle cooling fans. The printer’s build volume is 360 x 250 x 320 mm when printing in a single extruder mode, which is reduced to 330 x 250 x 320 mm for a dual extruder mode. The device is capable of printing two identical models at a time. The i-Fast boasts an enclosed chamber heated up to 60 °C, which is unusual for a (relatively) affordable printer. This feature is extremely useful when printing with temperature-sensitive filaments, like nylon or ABS. The printer is operated via a 5" LCD touchscreen, and supports Wi-Fi and Ethernet connection. It comes with the proprietary QIDI Tech slicer, but is also compatible with Simplify3D and Cura.

The printer’s build volume is 360 x 250 x 320 mm when printing in a single extruder mode, which is reduced to 330 x 250 x 320 mm for a dual extruder mode. The device is capable of printing two identical models at a time. The i-Fast boasts an enclosed chamber heated up to 60 °C, which is unusual for a (relatively) affordable printer. This feature is extremely useful when printing with temperature-sensitive filaments, like nylon or ABS. The printer is operated via a 5" LCD touchscreen, and supports Wi-Fi and Ethernet connection. It comes with the proprietary QIDI Tech slicer, but is also compatible with Simplify3D and Cura.

Credit: @torquay_audio / Instagram

Pros

- Heated build chamber

- A wide range of compatible materials, including carbon fiber

- Heated magnetic build plate

- Print resume function

- Filament runout sensor

Cons

- Large footprint

Creatbot DX / DX Plus

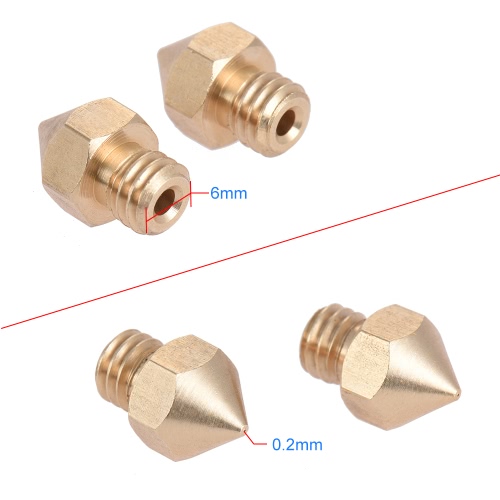

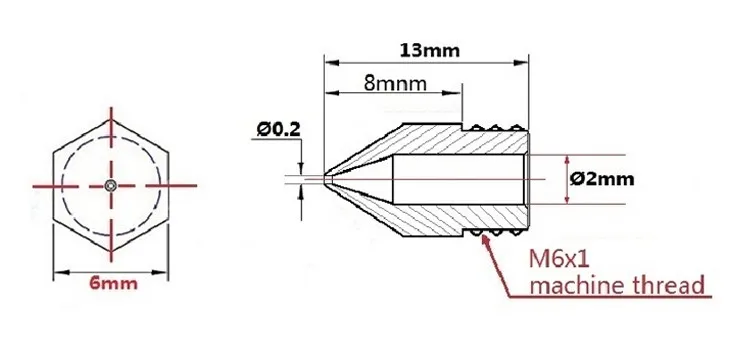

The Creatbot DX and DX Plus are large-scale industrial-grade FDM 3D printers. The two models differ in the build volume, which is 300 x 250 x 300 mm for the DX model, while the taller DX Plus offers the print volume of 300 x 250 x 520 mm. The Creatbot DX / DX Plus is a unique device, as it features a triple extrusion module that can be equipped with up to three adjustable-height nozzles. The standard nozzle diameter is 0.4 mm, but they can be replaced with 0.3, 0.5, 0.6, 0.8, and 1.0 nozzles, depending on your printing tasks. The maximum hotend temperature of 260 °C allows for printing with a variety of filaments, including PLA, ABS, carbon fiber, PTEG, and others. Both models offer a number of useful functions, such as print resume, filament runout detection, and automatic shutdown, which turns the machine off when printing is over.

The two models differ in the build volume, which is 300 x 250 x 300 mm for the DX model, while the taller DX Plus offers the print volume of 300 x 250 x 520 mm. The Creatbot DX / DX Plus is a unique device, as it features a triple extrusion module that can be equipped with up to three adjustable-height nozzles. The standard nozzle diameter is 0.4 mm, but they can be replaced with 0.3, 0.5, 0.6, 0.8, and 1.0 nozzles, depending on your printing tasks. The maximum hotend temperature of 260 °C allows for printing with a variety of filaments, including PLA, ABS, carbon fiber, PTEG, and others. Both models offer a number of useful functions, such as print resume, filament runout detection, and automatic shutdown, which turns the machine off when printing is over.

Pros

- Triple extruder

- Interchangeable nozzles

- Large build volume

- High print quality

- A number of safety functions

- Heated ceramic-glass print bed

- Open material system

Cons

- No automatic bed leveling

Creatbot F430

The Creatbot F430 is an industrial-grade FDM 3D printer featuring a dual extrusion system with two different hotends: the left one heats up to 260 °C and is used for printing PLA, ABS, PC, nylon, carbon fiber and flexible filaments, while the right hotend, with the maximum temperature of 420 °C, is made of martensite steel and can print with high performance materials, such as PEEK, ULTEM, etc. The device features a large build volume of 400 x 300 x 300 mm and a ceramic-glass removable print bed. The build chamber can heat up to 70 °C, which allows for reliable high-quality printing with such materials as ABS or PC. The BLTouch auto leveling function allows for proper first layer adhesion and prevents warping.

The device features a large build volume of 400 x 300 x 300 mm and a ceramic-glass removable print bed. The build chamber can heat up to 70 °C, which allows for reliable high-quality printing with such materials as ABS or PC. The BLTouch auto leveling function allows for proper first layer adhesion and prevents warping.

Credit: @innovative_engines_engineering / Instagram

Pros

- High-performance materials compatibility

- Large build volume

- Minimum layer height of 40 microns

- Heated print bed and build chamber

- Air filtration system

- BLTouch auto bed leveling

Cons

- No built-in camera

- No Wi-Fi or LAN connectivity

Professional IDEX systems $1,000+

Raise3D E2

The industrial Raise3D E2 FDM 3D printer is equipped with the Independent Dual Extrusion system which allows doubling the machine’s production volume. The E2 is equipped with two V3P hotends with the maximum nozzle temperature of 300 °C. The standard nozzle diameter is 0.4 mm, which can be replaced with 0.2–1.0 mm optional nozzles. The detachable steel build plate heats up to 110 °C, and can be easily bent for hassle-free print removal. The auto leveling adjusts the nozzle height to keep it at the right distance from the build plate, thus ensuring high-quality prints with proper first layer adhesion. 20-micron minimum layer height provides highly-detailed accurate parts, so that the E2, unlike many FDM machines, can even print dental appliances.

The E2 is equipped with two V3P hotends with the maximum nozzle temperature of 300 °C. The standard nozzle diameter is 0.4 mm, which can be replaced with 0.2–1.0 mm optional nozzles. The detachable steel build plate heats up to 110 °C, and can be easily bent for hassle-free print removal. The auto leveling adjusts the nozzle height to keep it at the right distance from the build plate, thus ensuring high-quality prints with proper first layer adhesion. 20-micron minimum layer height provides highly-detailed accurate parts, so that the E2, unlike many FDM machines, can even print dental appliances.

Credit: @3deltaworkshop / Instagram

Pros

- IDEX system

- Printing with high-performance materials

- High resolution prints

- Enclosed chamber with a HEPA filter

- Door opening detection

- Auto bed leveling

Cons

- Auto bed leveling can take pretty much time

Flashforge Creator 3

The Flashforge Creator 3 is a professional dual extrusion FDM 3D printer featuring all the benefits of the IDEX system, namely duplication and mirror modes. The nozzle temperature of 300 °C ensures compatibility with high-performance materials, such as PA, CF, PC, ASA, GF, and others. The heated steel print bed is flexible and can be removed from the printer to conveniently detach the printed part. The build volume of 300 x 250 x 250 mm is large enough for printing sizable parts or batches of smaller models in one go. A 4.5" touchscreen with a user-friendly interface is used for operating the device. Besides, the Creator 3 can be controlled via Wi-Fi, Ethernet, or a cloud-based application.

The nozzle temperature of 300 °C ensures compatibility with high-performance materials, such as PA, CF, PC, ASA, GF, and others. The heated steel print bed is flexible and can be removed from the printer to conveniently detach the printed part. The build volume of 300 x 250 x 250 mm is large enough for printing sizable parts or batches of smaller models in one go. A 4.5" touchscreen with a user-friendly interface is used for operating the device. Besides, the Creator 3 can be controlled via Wi-Fi, Ethernet, or a cloud-based application.

Credit: @alma.filament / Instagram

Pros

- IDEX setup

- Removable heated print bed

- Auto bed leveling

- Built-in camera

- Highly precise printing

- Wide range of compatible materials, including high-temp

- HEPA h23 air filters

Cons

- Large footprint

- No heated build chamber

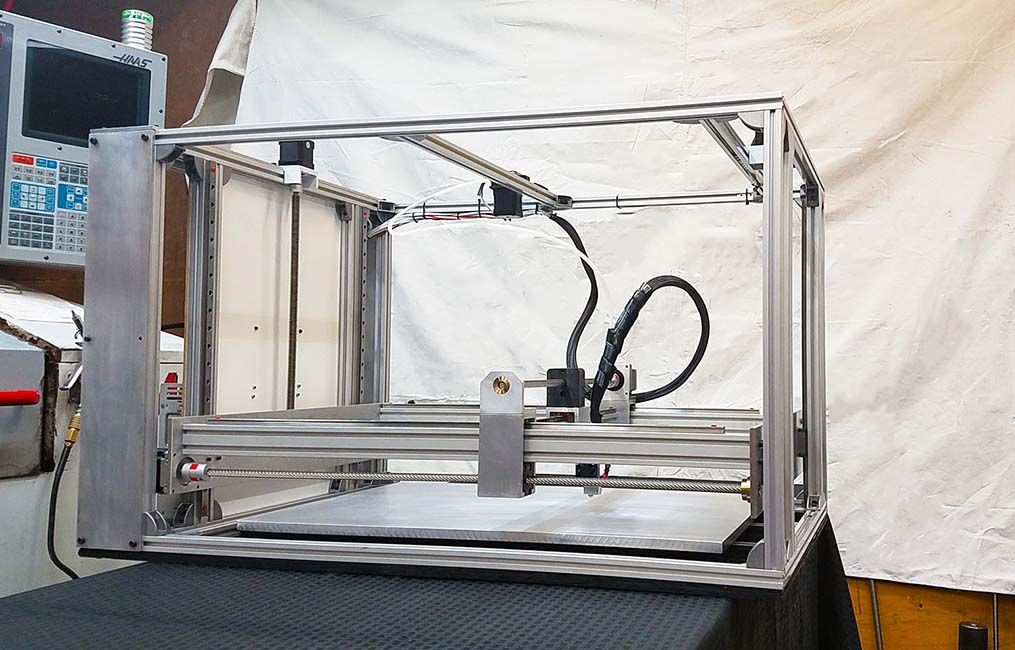

Craftbot Flow IDEX XL

The Craftbot Flow IDEX XL features a large build volume of 425 x 250 x 500 mm and an open design with a sturdy reinforced steel construction. The printer is equipped with the IDEX system of independent dual extrusion. The all-metal hotends with a filament dosage monitoring system support the maximum temperature of 300 °C, which allows printing with high-performance materials. The list of compatible filaments is pretty long, and includes PLA, ABS, PET, nylon, carbon-fiber reinforced composites, wood, and brass. The multilayered heated print bed is made of metal, tempered glass, and Kapton sheets, and can be removed when printing is over.

The printer is equipped with the IDEX system of independent dual extrusion. The all-metal hotends with a filament dosage monitoring system support the maximum temperature of 300 °C, which allows printing with high-performance materials. The list of compatible filaments is pretty long, and includes PLA, ABS, PET, nylon, carbon-fiber reinforced composites, wood, and brass. The multilayered heated print bed is made of metal, tempered glass, and Kapton sheets, and can be removed when printing is over.

Credit: @craftbot3d / Instagram

Pros

- Independent Dual Extrusion

- Large build volume

- High-temp printing

- Heated removable print bed

- Onboard camera

Cons

- Lack of enclosure (can be bought separately)

Large-format dual extruder 3D printers

Raise3D Pro3 Plus

The Raise3D Pro 3 Plus is an upgraded version of the Raise3D Pro 3 FDM 3D printer, featuring the enlarged build volume of 300 x 300 x 605 mm. The dual extrusion system with two independent extruders is equipped with interchangeable nozzles with 0.2–1.0 mm diameters. The maximum operating temperature of 300 °C allows printing with a wide range of materials, including PLA, ABS, HIPS, TPU, PC, nylon, TPE, FLEX, PETG, metallic PLA, wood PLA, carbon fiber, and others. The cooling fan is helpful while working with PLA-type filaments. Featuring the auto bed leveling function and a removable flexible steel build plate, the Pro 3 Plus provides high-quality prints with a perfect first layer adhesion. A bundle of convenient functions, like EVE smart virtual assistant, adds to consistent reliable printing.

The dual extrusion system with two independent extruders is equipped with interchangeable nozzles with 0.2–1.0 mm diameters. The maximum operating temperature of 300 °C allows printing with a wide range of materials, including PLA, ABS, HIPS, TPU, PC, nylon, TPE, FLEX, PETG, metallic PLA, wood PLA, carbon fiber, and others. The cooling fan is helpful while working with PLA-type filaments. Featuring the auto bed leveling function and a removable flexible steel build plate, the Pro 3 Plus provides high-quality prints with a perfect first layer adhesion. A bundle of convenient functions, like EVE smart virtual assistant, adds to consistent reliable printing.

Credit: @3d_prima / Instagram

Pros

- IDEX setup

- Consistent print quality

- 10 mm minimum layer height

- High-temp printing

- Built-in HD camera

- HEPA air filter

Cons

- Requires nozzle upgrades for printing with carbon fiber

Modix Big 60 V3

The Modix Big 60 V3 is a large-format industrial FDM 3D printer with the same modular design as all the other Modix machines. The device comes as a DIY kit and allows for a great number of various upgrades, including the enclosure for the build chamber. The huge build volume of 600 x 600 x 660 mm gives the opportunity to print almost any model as one piece. By default, the Big 60 V3 is equipped with an E3D Aero direct extruder and a V6 Volcano hotend. The new Duet 2 controller unit supports dual extrusion, as well as a lot of other useful features, so the printer can be upgraded with an improved dual print head for multi-material or multi-color printing. BLTouch auto bed leveling ensures the proper distance between the nozzle and the build plate. The maximum hotend temperature of 285 °C and the heated build plate make for the printer’s compatibility with a great number of filaments, like PLA, PETG, PVA, ABS, ASA, PC, nylon, TPU, carbon composites and others.

The device comes as a DIY kit and allows for a great number of various upgrades, including the enclosure for the build chamber. The huge build volume of 600 x 600 x 660 mm gives the opportunity to print almost any model as one piece. By default, the Big 60 V3 is equipped with an E3D Aero direct extruder and a V6 Volcano hotend. The new Duet 2 controller unit supports dual extrusion, as well as a lot of other useful features, so the printer can be upgraded with an improved dual print head for multi-material or multi-color printing. BLTouch auto bed leveling ensures the proper distance between the nozzle and the build plate. The maximum hotend temperature of 285 °C and the heated build plate make for the printer’s compatibility with a great number of filaments, like PLA, PETG, PVA, ABS, ASA, PC, nylon, TPU, carbon composites and others.

Credit: @fablablepointu / Instagram

Pros

- Modular design, easily upgradable

- Huge build volume

- High print quality

- Wide range of compatible materials

- Auto bed leveling

- All popular slicer software support

- Affordable price

Cons

- Dual extruder and enclosure come as an option only

- Takes time to assemble

Creatbot D600 Pro

The large-scale professional FDM 3D printer Creatbot D600 Pro features the common for Creatbot devices dual-extrusion system, with the left 260°C hotend for printing with standard plastics, like PLA, ABS or flexible materials, and the right hotend that can reach the temperature of 420°C — for high-performance thermoplastics such as PC and high-temperature nylons. The spacious build volume of 600 x 600 x 600 mm makes the D600 Pro perfectly suitable for a variety of industrial applications. The heated air chamber makes for more predictable printing results with such filaments as nylon or ABS. BLTouch auto leveling function ensures perfect first layer adhesion and reduces the risk of print failures. The D600 Pro comes with the free CreatWare software based on the popular Cura slicer.

The spacious build volume of 600 x 600 x 600 mm makes the D600 Pro perfectly suitable for a variety of industrial applications. The heated air chamber makes for more predictable printing results with such filaments as nylon or ABS. BLTouch auto leveling function ensures perfect first layer adhesion and reduces the risk of print failures. The D600 Pro comes with the free CreatWare software based on the popular Cura slicer.

Credit: @ilmakerspaces / instagram

Pros

- High-quality build

- Sizable build volume

- Industrial-grade materials support

- Heated build chamber and print bed

- Auto bed leveling

- Filament drying room

Cons

- Small build chamber door

Dual extruder printers — buyer’s guide. Answers to FAQ

What is a dual extruder 3D printer?

A dual extruder 3D printer, as the name suggests, is equipped with two extruders, which allows the user to combine two (or sometimes more) filaments in one project. There are different types of a dual extrusion system, with the IDEX being the most powerful. Besides multi-color and multi-material printing, as well as printing soluble support structures, it features duplication and mirror modes, which can double the production volume.

There are different types of a dual extrusion system, with the IDEX being the most powerful. Besides multi-color and multi-material printing, as well as printing soluble support structures, it features duplication and mirror modes, which can double the production volume.

Credit: bigrep.com

Can the Ender-3 do dual extrusion?

The Creality Ender-3 is a very popular model of an affordable consumer FDM 3D printer. It is equipped with a single extruder, but there are some options allowing the user to upgrade it to the dual extrusion system. The most obvious and safe way to do it is to buy a filament splicer, or changer, that can work with most FDM 3D printers (more of that below).

Another option is to upgrade your printer with one of the DIY open-source solutions, but they usually require serious modifications that are often irreversible. So, be sure that you really need it. The most popular modifications are DIY Chimera Project, Cyclops Hot End, and some others.

Can dual extruder printers print with soluble filaments?

Yes, they can. Dual extruder printers can use one nozzle for printing the part with the main material (PLA, for example) and the other for PVA water-soluble supports. For ABS parts, HIPS (which dissolves in limonene) is often used for building support structures.

Credit: simplify3d.com

Does dual extruder print faster?

When two nozzles are used instead of one, the overall printing time shortens significantly. Moreover, with the IDEX printers, you can double the productivity of your device using duplication and mirror modes.

How many extruders can a 3D printer have?

Normally, FDM 3D printers are equipped with a single or dual extrusion system. There are a few printer models in the market featuring triple extrusion, but they are not so popular, as the dual extrusion system is complicated enough and requires more maintenance, not to mention the triple one. There are also various third-party mods allowing for three or even four-nozzle setup.

There are also various third-party mods allowing for three or even four-nozzle setup.

Do dual extruder printers have an enclosed build area?

The situation is pretty much the same as with single extrusion models. Most entry-level consumer devices feature an open design, which sometimes can be complemented with an optional enclosure. More expensive professional-grade printers are usually fully-enclosed. The enclosure is absolutely necessary if you plan on printing with high-performance materials.

Can you 3D print multiple objects at once?

With IDEX printers you can print two copies of the same model either in duplication or in mirror mode.

What is the average price of a dual extruder 3D printer?

With the development of 3D printing, a lot of technologies that were only used in professional printers have now become affordable for consumers. Today you can buy an entry-level dual extrusion 3D printer for less than $500.

How do you print multiple filaments?

In dual extrusion printers, you don't have to manually change filaments to print with different materials, as they are equipped with two extruders, and the switch between them happens automatically. Dependent dual-extrusion systems only allow printing with two filaments in turn, while IDEX printers can use both nozzles simultaneously, increasing the print speed.

Credit: kickstarter.com

How to make a dual extruder 3D printer?

If you already have a single extruder FDM 3D printer, you do not necessarily have to buy a dual extrusion device to give a try to multi-material printing. You can upgrade your printer with a filament splicer, like the Mosaic Palette 3 Pro, mentioned above.

Another affordable option is the 3D Chameleon automatic color changer, allowing for the use of up to four filaments in one model.

One more way to make your printer work with different filaments (up to 12!) is the SMuFF V6 — an open-source DIY smart multi-filament feeder. It may not be the choice for beginners, as it requires certain skills in configuring your printer’s firmware, but if you feel confident with that, it is definitely an option.

It may not be the choice for beginners, as it requires certain skills in configuring your printer’s firmware, but if you feel confident with that, it is definitely an option.

How to choose a 3D printer for printing with 2 materials?

Good afternoon everyone!

In this article, we would like to talk about the issue that torments many customers when choosing a 3D printer with 2 extruders. Namely, which is better? What is more stable? Which 3D printer to choose? Why do dual extruder 3D printers alone cost significantly less, and what is the difference between them?

First of all, let's start with the fact that by printing with 2 extruders (or 2-component printing), we mean the ability to print with 2 materials, for example, PLA (base material) and PVA (temporary support material removed chemically, using water in this case ). nine0003

It is possible to print in two different colors. But in practice this has not received any great distribution. Printing of complex models with dissolvable supports is in demand.

Therefore, you need to decide for yourself why you need a 3D printer with two extruders? For most tasks, it is enough to use a 3D printer with 1 extruder.

The use of a dual extruder 3D printer is a must when printing complex 3D models with dissolvable supports. Usually such 3D printers are chosen by manufacturing companies for printing geometrically complex prototypes or owners of 3D printers with 1 extruder who understand that they cannot realize with a 3D printer with 1 extruder. nine0003

But do all 3D printers with 2 extruders have the same capabilities? Or is it that the differences in design, and, accordingly, in price, are of decisive importance?

Let's consider various solutions for 3D printing with 2 materials on the 3D equipment market.

To implement this function, manufacturers use the following solutions:

Decision No. 1

Use of 2 static extruders. As a rule, these are 2 hot-ends with two independent material feed motors. There are many options. But all of them, to one degree or another, repeat the solutions on the Makerbot Replicator 2, released in 2012. nine0003

There are many options. But all of them, to one degree or another, repeat the solutions on the Makerbot Replicator 2, released in 2012. nine0003

There are several technical solutions, but they all have a common list of disadvantages and features.

Weaknesses :

1) Be sure to align both nozzles horizontally with respect to the desktop of the 3D printer. In other words, the nozzles of each hotend should be at the same height, ideally with an error of no more than 0.1 mm.

2) Using a utility tower (or analogues) to clean the inactive nozzle from plastic drips (drop formation) before switching to the active mode for printing. Let's consider an example: if nozzle No. 1 prints a model with blue plastic, then in order for nozzle No. 2 to start printing white, the printer must first print the 1st layer of the tower with nozzle No. 2 to remove plastic residue, and only then move it to print the base model ( see picture). And so every switch. This greatly (at times) slows down the print speed, relative to the same model but when printing in 1 color. Moreover, there is a possibility of the collapse of the utilitarian tower (the layer did not fit well, or peeled off from the desktop) and, as a result, the marriage of the entire project. nine0003

And so every switch. This greatly (at times) slows down the print speed, relative to the same model but when printing in 1 color. Moreover, there is a possibility of the collapse of the utilitarian tower (the layer did not fit well, or peeled off from the desktop) and, as a result, the marriage of the entire project. nine0003

3) There is no guaranteed result. Due to the complexity and imperfection of the extruder architecture. Large marriage rate. A nozzle that is currently inactive can leak plastic and ruin the part.

Advantages:

1) Low cost solution

2) Simplicity of design, as a result - high maintainability.

This option has the lowest price and the lowest overall performance. The complexity of the settings, to obtain a high-quality result, makes this implementation option a testing ground for experiments at home. In a more or less intensive implementation of projects, this option is quite problematic. nine0003

nine0003

Solution #2

Using a Diamond type extruder. These types of extruders use a single feed motor and a radiator(s) (or cooling module) with multiple internal plastic passages.

Basically, such an extruder is used to print different colors. But this, as we already know, has not received much distribution in reality. Printing with solvent material will be somewhat difficult. Firstly, the base material and support material have different operating temperatures. This will cause some difficulties for quality printing. nine0003

And in any case, this design has almost the entire list of disadvantages, like the first option.

Only there is no point about the alignment of the nozzles - here it is one.

Weaknesses :

1) There remains the need to use a utility tower (or analogues) to clean the nozzle from plastic streaks (drop formation) before switching to another material. This "tower" is visible in the photo. This greatly (at times) slows down the print speed, relative to the same model, but when printing in 1 color. Here it will still probably take time to change the temperature of the nozzle, when changing the base material to supports. Or the possibility of poor-quality printing will greatly increase. nine0003

This "tower" is visible in the photo. This greatly (at times) slows down the print speed, relative to the same model, but when printing in 1 color. Here it will still probably take time to change the temperature of the nozzle, when changing the base material to supports. Or the possibility of poor-quality printing will greatly increase. nine0003

2) There is no guaranteed result. Due to the complexity and imperfection of the extruder architecture. Large marriage rate.

3) This type of extruder is equipped with Bowden-scheme plastic feeding. This entails difficulties (more often, even the impossibility of printing with flexible plastics)

The benefits are gone too.

Such a solution is quite expensive. And it has a complex structure.

Advantages:

1) Better print quality than option #1. nine0003

As a result, in the option of printing with two materials with dissolvable supports, there are no special advantages over the first solution. But this option has a higher price.

But this option has a higher price.

Resolution #3

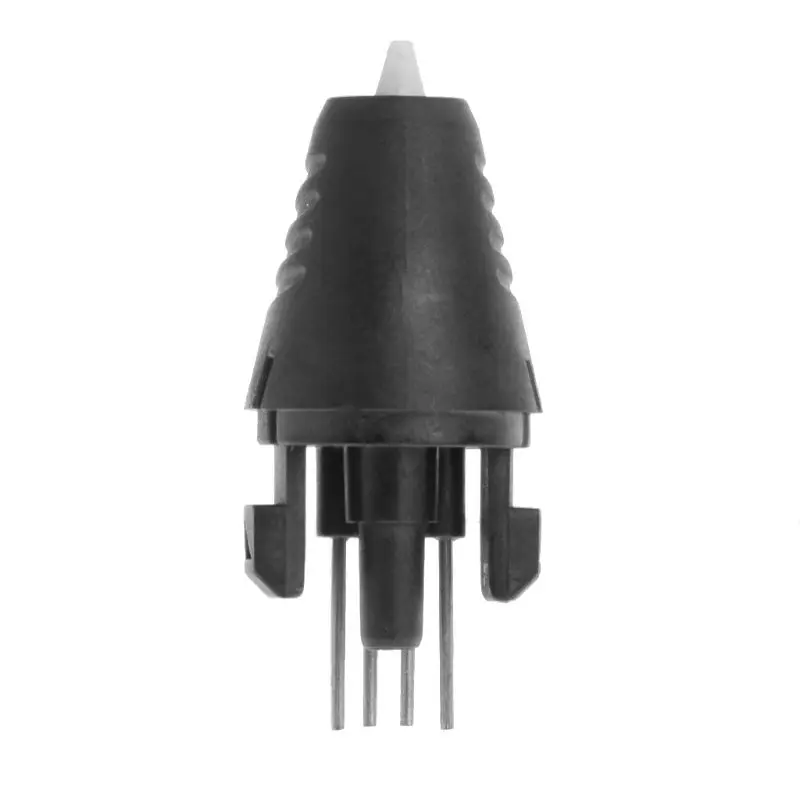

Extruder designs where the currently inactive nozzle rises to avoid problems. Today's most famous commercial printer is the JetSwitch™ circuit.

Rotary nozzle system from PICASO 3D. nine0003

There is one plastic feed motor, which facilitates the design.

The main feature is that with the help of a rotary mechanism, one of the nozzles, which is active at the moment, is lowered to the working level. The second is closed at this time, and no molten plastic flows out of it.

Advantages:

1) High quality printing

2) There is no need to build a utilitarian "tower". Therefore, the switching time between extruders is short. Printing speed with two materials is MUCH faster than options 1.2. Below is a comparison table from PICASO 3D. nine0003

Weaknesses :

1) Relatively complex design, and as a result - a high price.

There are several more options for extruders with lifting nozzles. All of them are united by one thing - a much higher print quality with two materials than the "classic" option No. 1. Yes, they all have a higher price, but the print quality is drastically different.

The conclusions are as follows - by purchasing an inexpensive design, you save money, but spend many times more time on setup and printing itself. With the remaining risk of marriage, which reduces all efforts to zero. At the same time, the print result will still be worse than that of designs with lifting nozzles. nine0003

If you need a high-quality result and the printing time of complex models is critical, then it makes sense to choose a model with lifting nozzles:

1) PICASO 3D Designer X PRO - https://3dtool.ru/product/3d-printer-picaso-3d-designer-x-pro-2/

2) Raise3D Pro2 - https://3dtool.ru/product/3d_printer_raise3d_pro2/

3) Ultimaker 3 - https://3dtool.ru/product/3d-printer-ultimaker-3/

Why 2 extruders in a 3D printer? / Habr

Good afternoon everyone! In this article, we would like to talk about the issue that torments many customers when choosing a 3D printer with 2 extruders. Namely, which is better? What is more stable? Which 3D printer to choose? Why do dual extruder 3D printers alone cost significantly less, and what is the difference between them? nine0003

Namely, which is better? What is more stable? Which 3D printer to choose? Why do dual extruder 3D printers alone cost significantly less, and what is the difference between them? nine0003

A bit of theory

First of all, let's start with the fact that by printing with 2 extruders (or 2-component printing), we mean the ability to print with 2 materials, for example, PLA (base material) and PVA (temporary support material removed chemically, using water in this case ).

It is possible to print in two different colors. But in practice this has not received any great distribution. The printing of complex models with dissolvable supports is in demand. nine0051

Therefore, you need to decide for yourself why you need a 3D printer with two extruders? For most tasks, it is enough to use a 3D printer with 1 extruder.

The use of a dual extruder 3D printer is a must when printing complex 3D models with dissolvable supports. Usually such 3D printers are chosen by manufacturing companies for printing geometrically complex prototypes or owners of 3D printers with 1 extruder who understand that they cannot realize with a 3D printer with 1 extruder. nine0003

nine0003

But do all 3D printers with 2 extruders have the same capabilities? Or is it that the differences in design, and, accordingly, in price, are of decisive importance?

Consider different solutions for 3D printing with 2 materials on the 3D equipment market.

To implement this function, manufacturers use the following solutions:

Solution No. 1

Use of 2 static extruders. As a rule, these are 2 hot-ends with two independent material feed motors. There are many options. But all of them, to one degree or another, repeat the solutions on the Makerbot Replicator 2, released in 2012. nine0003

There are several technical solutions, but they all have a common list of disadvantages and features.

Disadvantages :

1) Be sure to align both nozzles horizontally with respect to the 3D printer desktop. In other words, the nozzles of each hotend should be at the same height, ideally with an error of no more than 0. 1 mm.

1 mm.

2) Using a utility tower (or similar) to clean the inactive nozzle from plastic drips (drop formation) before switching to the active mode for printing. Consider an example: if nozzle #1 prints a model with blue plastic, then in order for nozzle #2 to start printing white, the printer first needs to print the 1st layer of the tower with nozzle #2 to remove the remaining plastic, and only then move it to print the base model ( see picture). And so every switch. This greatly (at times) slows down the print speed, relative to the same model but when printing in 1 color. Moreover, there is a possibility of the collapse of the utilitarian tower (the layer did not fit well, or peeled off from the desktop) and, as a result, the marriage of the entire project. nine0003

3) No guaranteed result. Due to the complexity and imperfection of the extruder architecture. Large marriage rate. A nozzle that is currently inactive can leak plastic and ruin the part.

Advantages:

1) Low cost solution

2) Simplicity of design, as a result - high maintainability.

This variant has the lowest price and the lowest overall performance. The complexity of the settings, to obtain a high-quality result, makes this implementation option a testing ground for experiments at home. In a more or less intensive implementation of projects, this option is quite problematic. nine0003

Solution #2

Using a Diamond type extruder. This type of extruder uses a single nozzle, and a radiator(s) (or cooling module) with multiple internal plastic passages.

Basically, this extruder is used to print different colors. But this, as we already know, has not received much distribution in reality. Printing with solvent material will be somewhat difficult. Firstly, the base material and support material have different operating temperatures. This will cause some difficulties for quality printing. nine0003

And in any case, this design has almost the entire list of disadvantages, like the first option.

Only there is no point about the alignment of the nozzles - here it is one.

Disadvantages :

1) There remains the need to use a utility tower (or equivalents) to clean the nozzle from plastic drips (drop formation) before switching to another material. This "tower" is visible in the photo. This greatly (at times) slows down the print speed, relative to the same model, but when printing in 1 color. Here it will still probably take time to change the temperature of the nozzle, when changing the base material to supports. Or the possibility of poor-quality printing will greatly increase. nine0051 2) There is no guaranteed result. Due to the complexity and imperfection of the extruder architecture. Large marriage rate.

3) This type of extruder is equipped with Bowden-scheme plastic feeding. This entails difficulties (more often even the impossibility of printing with flexible plastics)

The advantages have also disappeared.

Such a solution is quite expensive. And it has a complex structure.

And it has a complex structure.

Advantages:

1) Better print quality than #1. nine0003

As a result, in the variant of printing with two materials with dissolvable supports, there are no special advantages over the first solution. But this option has a higher price.

Solution #3

Extruder designs where the currently inactive nozzle rises to avoid problems. The most famous today, among serial printers, is the JetSwitch circuit.

Rotary nozzle system from PICASO 3D. There is one plastic feed motor, which facilitates the design. nine0003

The main feature is that one of the nozzles, which is active at the moment, is lowered to the working level with the help of a rotary mechanism. The second is closed at this time, and no molten plastic flows out of it.

Advantages:

1) High print quality

2) There is no need to build a utilitarian "tower". Therefore, the switching time between extruders is short.