3D printed house in austin

About 3D-printed Homes – ICON

It's Time for an Upgrade

ICON 3D-printed Homes

Homes Built forthe 21st Century

ICON’s high-performance 3D-printed homes use modern materials, engineering, and robotics to create incredibly strong homes that are safer and more resilient.

The Benefits of an ICON Home

Designed to WithstandExtreme Weather

ICON homes are designed to withstand extreme weather and can withstand damaging winds and flying debris better than conventional homes.

ICON’s specially formulated cement forms walls that are resistant to water, mold, termites, and fire damage, greatly reducing the impact of natural disasters.

The Benefits of an ICON Home

Strength + DurabilityThe printed ICON wall system exceeds building code design requirements by over 350%.

As a testament of its strength and durability, ICON Homes printed in Nacajuca, Mexico withstood a 7. 4 magnitude earthquake during summer 2020.

Energy Efficient

Advanced MaterialsCreate Comfort

ICON’s thick printed walls provide better insulation compared to conventional construction. These printed cement walls decrease the home’s temperature fluctuations in the summer and winter or during extreme weather events. This means lower energy consumption and lower energy bills.

The physical mass of the ICON wall system not only creates an energy-efficient home but also deadens sound creating a cozy home environment.

BeautifullyDesigned

ICON homes are created by some of the most renowned architects and designers in the world. 3D printing allows these architectural minds to innovate in ways that are simply not possible with traditional construction.

Walls can be printed in a variety of shapes, patterns, and textures to create unique homes that are both stunningly beautiful and completely livable. This extreme level of design expertise and craft is a standard feature of all ICON homes.

This extreme level of design expertise and craft is a standard feature of all ICON homes.

Advanced Architecture

Digitally NativeAn ICON Home uses digitally native architecture, meaning advanced home designs can be created, tested, and validated before construction ever begins. This digital approach means architecture can edited right up to the point where the home is printed by ICON’s robotic construction system.

Need to move a door or add another window?

Not a problem with a digital construction system powered by ICON’s BuildOS software suite.

Advanced Construction

Precise Robotic ConstructionWith automated construction, you’re able to deliver a home’s full wall system with extreme accuracy and reduced waste compared to traditional construction. Construction waste from building the average American home is equivalent to 4 tons. Our system puts down only the material you need.

Home ReservationsBegin 2023

Get on the List

Off-World Construction – ICON

Project Olympus

HelloMoon

Olympus is a space-based construction system under development to support future exploration of the Moon.

Project Olympus

Olympus is a space-based construction system under development to support future exploration of the Moon.

Lunar Construction

Off-WorldAdditive Construction

Building humanity’s first home on another world will be the most ambitious construction project in human history and will push science, engineering, technology, and architecture to literal new heights. NASA’s investment in space-age technologies like Project Olympus can not only help to advance humanity’s future in space, but also to solve very real, vexing problems we face on Earth.

It's time to return... This time to stay.

How Lunar Construction Works

In order to thrive on the lunar surface, we must learn to “live off the land” using local materials found on the Moon rather bringing buildings materials all the way from Earth. Olympus’ printing technology processes local lunar regolith (moon dust) into a super strong building material using only energy and then 3D-prints structures with it.

Lunar Architecture

Building a sustainable presence on the Moon requires more than rockets. For a permanent lunar presence to exist, robust structures will need to be built on the Moon that provide better thermal, radiation, and micrometeorite protection than metal or inflatable habitats can provide.

Entirely new types of architecture will be required that is purposed designed for additive construction processes like Olympus. From landing pads to habitats, these collective efforts are driven by the need to make humanity a spacefaring civilization.

All civilizations become either spacefaring or extinct.

Carl Sagan

All civilizations become either spacefaring or extinct.

Carl Sagan

The technology being developed for the harsh lunar environment also

works on other planets – like Mars + Earth

The Lunar environment is open of the most demanding environments for technology development with its lack of atmosphere, high radiation, and extreme temperatures. By developing the Olympus technologies for such an extreme environment, translation to friendlier environments on planets and moons with atmospheres like Mars and Earth will be faster and more efficient.

By developing the Olympus technologies for such an extreme environment, translation to friendlier environments on planets and moons with atmospheres like Mars and Earth will be faster and more efficient.

From the Moon to Mars:

MEET MARS DUNE ALPHA

Mars Dune Alpha is a real 3D-printed structure for NASA located at the Johnson Space Center in Houston, Texas. ICON’s Vulcan construction system completed a 1,700 square-foot structure, designed by world-renowned architecture firm BIG-Bjarke Ingels Group, that will simulate a realistic Mars habitat to support long-duration, exploration-class space missions. Mars Dune Alpha takes Project Olympus technology for additive construction and begins to apply to another planetary body.

LEARN MORE

From the Moon to Mars:

MEET MARS DUNE ALPHA

Mars Dune Alpha is a real 3D-printed structure for NASA located at the Johnson Space Center in Houston, Texas. ICON’s Vulcan construction system completed a 1,700 square-foot structure, designed by world-renowned architecture firm BIG-Bjarke Ingels Group, that will simulate a realistic Mars habitat to support long-duration, exploration-class space missions.![]() Mars Dune Alpha takes Project Olympus technology for additive construction and begins to apply to another planetary body.

Mars Dune Alpha takes Project Olympus technology for additive construction and begins to apply to another planetary body.

FOLLOW OUR MISSIONS

Sign Up for Updates

Construction 3D printing is waiting for a breakthrough The first construction projects using this technology appeared only in 2014. We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed. nine0003

Construction is the world's number one market. And, if many technological innovations are being introduced in the field of high-rise construction, then little has changed in the field of low-rise construction over the past decades. The last 30 years have seen the availability of the Internet, mobile phones, mobile internet, robotics taken to a new level, etc., but when you get to a house construction site, you are unlikely to find many technological innovations. Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more. nine0003

The last 30 years have seen the availability of the Internet, mobile phones, mobile internet, robotics taken to a new level, etc., but when you get to a house construction site, you are unlikely to find many technological innovations. Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more. nine0003

This Internet meme shows what happened to the cost of building materials in just a year. And the process is still going on. At the same time, there is a serious rise in the cost of labor, and there is an acute shortage of it. All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development. nine0003

So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development. nine0003

Preparing to write an article, I turned to the founder of Arkon - Boris Kozlov y. Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

- Construction 3D printing appeared in 2014, but no mass introduction of this technology followed in 7-8 years. Why do you think this happened, and why is there a surge of new projects right now? nine0010

- It seems to me that the reason is the snowball effect. The technology had to mature, grow from a hypothesis to a pilot implementation, and finally to commercialization and scaling (what is happening now). In addition, it should be borne in mind that construction is one of the most conservative industries, where, unlike even aviation and the automotive industry, there is still an extremely low introduction of digital solutions and automation in the field of the production process itself - the construction itself.

The issue of regulation and certification also plays an important role - this process is long and creates an additional lag. nine0021

In 2014-2016 the first samples of building 3D printers and prototypes of printed buildings appeared. The concepts of various form factors of construction 3D printers and types of printing materials were tested.

In 2017-2018 in the world, the first notable investments were made in a number of construction 3D printing start-ups. Further, by 2020, these investments "rolled" in the form of reaching a certain level of technology maturity - the first commercial products (3D printers and houses) appeared. nine0021

Finally, in 2020-2022 it became clear that the hypotheses of the effectiveness of construction 3D printing were justified (cheaper, faster, more environmentally friendly), and large investments began in the industry. A striking example is the investment of GE (the French division of General Electric) in the Danish COBOD or the achievement of a capitalization of $ 2 billion by the American company ICON.

/i.s3.glbimg.com/v1/AUTH_08fbf48bc0524877943fe86e43087e7a/internal_photos/bs/2018/Z/q/TFPL2MT5q0i8Yvlft0dw/projeto-usa-impressora-3d-para-construir-casas-em-paises-de-baixa-renda.jpg)

In 2022-2023 over 1,000 buildings will be printed worldwide already, scaling from single buildings/pilot projects to entire villages and major infrastructure/reinforced concrete implementations. In addition, in a number of countries, by now, a regulatory framework has been created or is being actively created for the introduction of additive technologies in the construction industry. nine0021

Thus, I believe that the specified time period is a fairly natural cycle of technology development, which is likely to experience exponential growth in the next decade.

According to ResearchAndMarket report, the global construction 3D printing market is valued at USD 354.3 million in 2022 and is projected to reach USD 11068.1 million by 2027, growing by 99.04%.

Various market processes affect the prices and behavior of participants in the global 3D construction printing market. They create price signals that are the result of changes in the demand and supply curves for a product or service. They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals. nine0003

They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals. nine0003

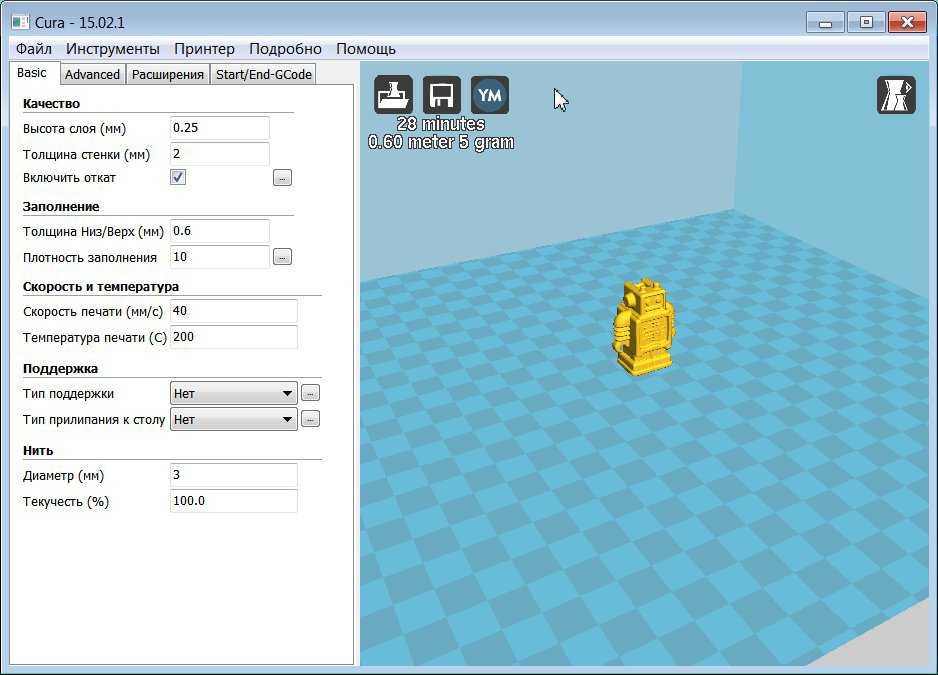

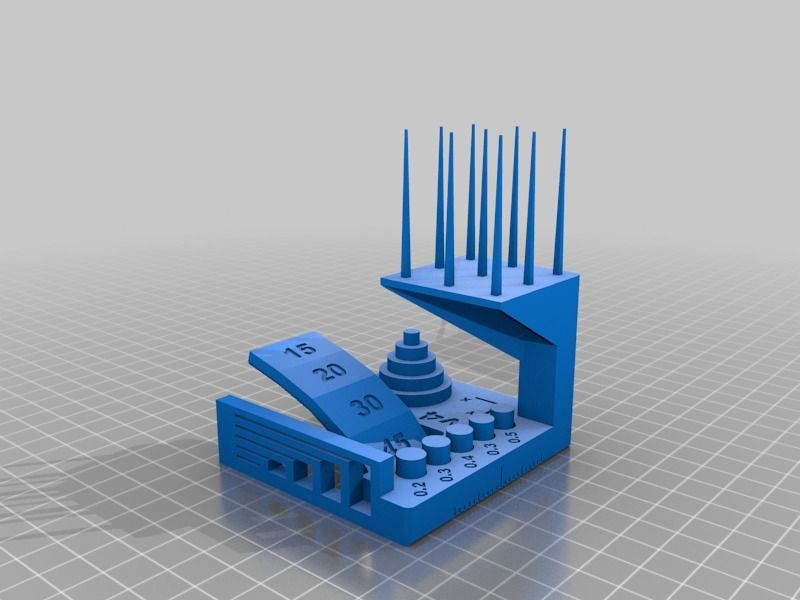

Now let's take a quick look at what the construction 3D printer is. Without delving too deeply into the technology, we can say that construction 3D printers are very similar to classic FDM/FFF printers that print with plastic, but instead of plastic, the material here is a cement mixture, which is fed directly into the nozzle and forms an object by layer-by-layer overlay. Printers are also portal, on the basis of a flying boom, with a robotic arm.

Pictured left is a construction printer based on a boom. The figure on the right is a gantry construction 3D printer

In the figure above, a construction 3D printer in the form of a robot arm installed on a mobile platform.

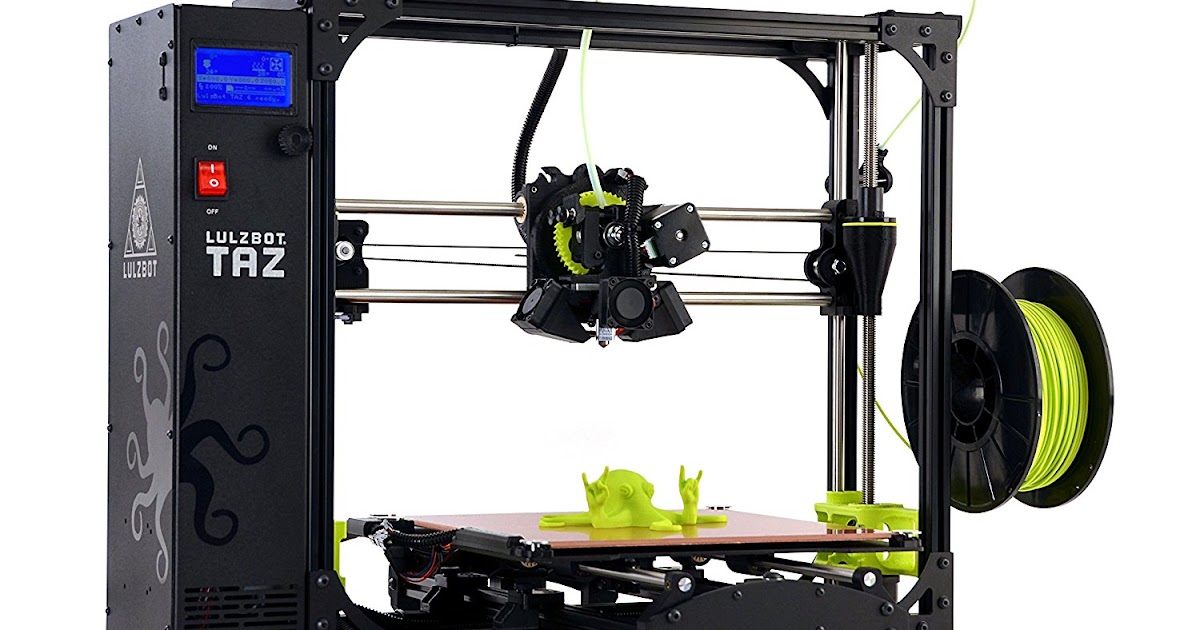

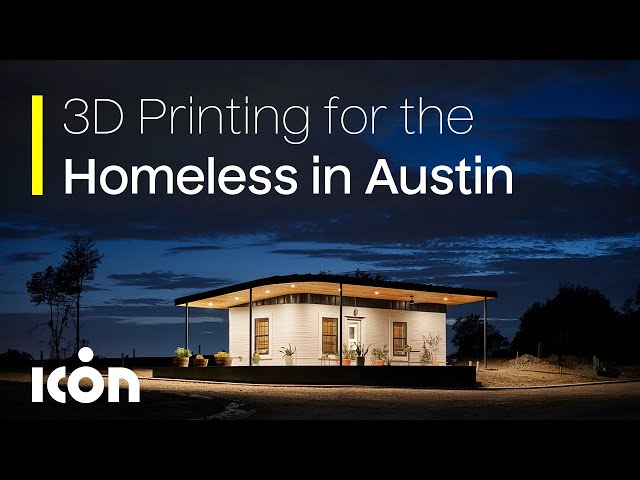

Everything changed completely when, in the summer of 2021, the American company ICON, which was trying to introduce 3D printing into the construction of various auxiliary facilities, signed a contract with one of the largest American developers, Lennar, to build a village of 100 houses in Texas and immediately became a unicorn , having received 200 million dollars of investments from several investment funds. nine0003 Pictured is a 3D printed house in Austin, Texas. A 3D printed house in Austin, Texas.

nine0003 Pictured is a 3D printed house in Austin, Texas. A 3D printed house in Austin, Texas.

At the same time, the Danish company COBOD, created by the world's largest construction formwork company PERRI, began selling its gantry 3D construction printers and participating in construction projects around the world. In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

Few things unite developed, developing and poor countries, everywhere their problems and tasks, but Affordable housing shortage is a global agenda . If in poor countries there is an acute problem with the increase in the number of homeless people due to a lack of housing, as such, then in developing countries it is necessary to dramatically accelerate the number of new housing being built to meet the needs of a growing population. In developed countries, the problem is primarily in the cost of housing, which has risen in price to such an extent that it has become practically inaccessible to young people. And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse. nine0003

And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse. nine0003

At the same time, the trend towards "green agenda " is developing, reducing CO2 emissions, building with more environmentally friendly materials, etc. But, unfortunately, so far the construction industry is the absolute leader in CO2 emissions, as well as in the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples. nine0003 3D printed walls.

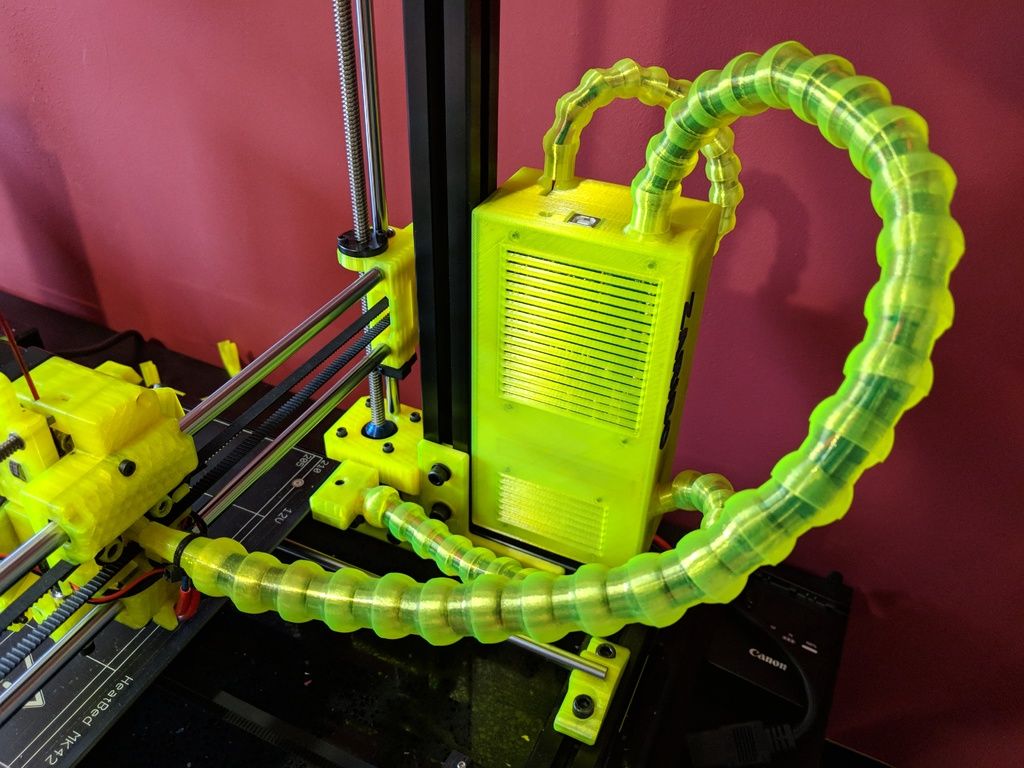

Today, when we talk about 3D printing houses, we are talking about printing walls. Everything else (foundation, windows, doors, ceilings and roof) is done in the traditional way. 3D printed walls are built as fixed formwork, which significantly saves the amount of cement used , and this, in turn, reduces the cost of construction and reduces the environmental impact of cement production. In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly. nine0003

In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly. nine0003

Eco-concrete with the addition of polymers is being actively developed, the production of which reduces CO2 emissions from 30% to 100%. The Apis Cor company mentioned at the beginning of the article, which built a house in the suburbs in 2015, is now based in hot Florida, plans to start using this material in its projects.![]()

Another startup from Russia, Mighty Buildings, headquartered in California, initially relied on a polymer with the addition of mineral chips. And while the company doesn't build entire homes, it only makes wall panels, it has won numerous design awards, as well as a $400 million valuation in several investment rounds. nine0003

As a result, with a rough calculation, we can say that the total savings on the construction of walls can reach 30%, and the total cost of the house can be reduced by 10%. This is true for houses designed for conventional construction. And if you initially design with 3D printing, you can improve this ratio by optimizing the laying of communications, the ability to immediately print interior walls, bookmark niches for bathrooms, fireplaces, built-in wardrobes and kitchens, as was done in the house built by COBOD in Germany. nine0003

"There are spots on the sun." Despite all the advantages of construction 3D printing, has several significant disadvantages of . The main one is layering, which cannot be avoided at the current level of technology development.

The main one is layering, which cannot be avoided at the current level of technology development.

The photo above shows the layering of the 3D printed walls.

This task can be worked in several directions:

-

Ribbed walls can be plastered, painted and played with as a design element. That's how ICON does it in the US, for example their latest project House Zero is done that way and has won a number of design awards. nine0003

-

Use special "shutters" on the print head that allow smooth layers, as COBOD and other manufacturers do. The photo below shows that this does not ensure the complete absence of layering.

-

Fully sand the surface to get the usual smooth wall for plastering, painting, wallpapering or other finishing. It is possible, but it will require huge labor costs, which can reduce the overall efficiency of using 3D printing.

nine0003

nine0003

Pictured above is a 3D printed wall sanded smooth.

The second problem is the required temperature. Ideally, printing should take place at temperatures between +5C° and +30C°. Humidity is also important. Using additives, you can push these boundaries, but not indefinitely. At strong sub-zero temperatures, printing will be possible in the field only if the construction site is covered with a dome and the required temperature is reached inside with the help of heat guns. In conditions of intense heat, it is preferable to print at night. Another solution could be to print the wall panels in the shop and assemble them on site. Of course, each of these decisions will have a negative impact on the economic efficiency of the project. nine0003

Building 3D printing can be useful not only for the construction of houses . With its help, you can solve many other problems, and there its disadvantages will not matter. For example, the American concern GE uses COBOD printers to build towers for wind turbines in the shop. Ribbed surface and temperature restrictions in this case do not play any role. Construction takes place in the shop, after which the object is transported to the installation site.

Ribbed surface and temperature restrictions in this case do not play any role. Construction takes place in the shop, after which the object is transported to the installation site.

Alexander Cornweitz

Expert in the field of additive technologies and 3D printing, Head of Tsvetnoy Mir

Read news - 10 most innovative companies in the field of additive production in 2022

15. 07.2022

07.2022

Advances in additive manufacturing are visible everywhere. This article highlights the top 10 most innovative companies driving this and moving technology forward faster than anyone else in 2022. nine0003

Innovation is an integral part of additive manufacturing. This industry is not only one of the fastest growing manufacturing technology sectors with a large number of start-ups, but covers all markets from aerospace and healthcare to construction and consumer products.

The companies discussed below have developed innovative approaches to creating products. They are disrupting traditional manufacturing markets, enabling other companies to build better and produce more, and innovate on their own. Whether it's a one-of-a-kind rocket engine or the house next door, these companies' designs help bring forward-thinking design and industrial reality together. nine0003

They are full of ideas and knowledge about how additive manufacturing can improve your company, your industry and society as a whole.

Icon

Innovation: The innovation is not in the 3D printer, but rather in what it prints. The 2022 House Zero project is a 3D printed house in Austin, Texas. According to the construction company ICON, which built it, House Zero will be a completely new type of sustainable development of houses. It is energy efficient, such construction takes less time, labor and costs than the traditional one. The house has a wall structure that provides thermal insulation and resistance to extreme weather conditions such as hurricanes. In addition, it is beautiful and comfortable, which proves that 3D printed houses are not a compromise between design and functionality. nine0003

Company: ICON was founded in 2017 and is located in Texas. ICON is on a bold mission to revolutionize home building. Using a 3D construction printer called Vulcan and a self-developed concrete-like material called Lavacrete, the company built homes for low-income communities around the world, military barracks, designed potential habitats on Mars, and entered the mainstream housing market to show how our homes can be built faster, safer and more sustainable.![]() nine0003

nine0003

Relativity Space

Innovation: Relativity Space has created the Stargate Factory of the Future, which it plans to open by 2022. The company is vertically integrating robotics, software and proprietary 3D printing technologies to digitize the production of reusable rockets and engines. In addition to the Stargate 3D printers, which are the largest in the world, the plant will also house a metallurgical laboratory, a machine shop and a mission control center designed to launch 3D printed rockets into space. By developing the Factory of the Future and manufacturing missiles, Relativity expands its capabilities to improve design, manufacturing, quality and speed. nine0003

Company: Relativity Space is a California-based aerospace manufacturing company founded in 2015 to develop additive manufacturing technologies, launch vehicles, and rocket engines for commercial orbital launches. Using a giant patented Stargate 3D printer, the company produces fully reusable rockets in just 60 days, while traditional aerospace companies have been doing it for years. The first test launch of the Terran 1 rocket is scheduled for 2022. nine0003

Axial3D

Innovation: Axial3D has created a cloud service that allows surgeons and other medical professionals to upload 2D images of patients to a portal with a patented technology for automatic image segmentation and 3D printing files creation. Physicians can then 3D print these models (or send them to a 3D printing service) to create visual aids that improve surgery planning and patient education. Axial 3D continues to raise significant funds to expand its business beyond surgery in nearly 30 countries. nine0003

Company: Axial3D was founded in 2014 and is based in Belfast. The company aims to contribute to the field of surgery through the development of 3D scanning technology and 3D printing of models tailored to individual patients. This makes diagnosis and treatment more accurate and individual. Axial 3D offers its portal and 3D printing as a service to healthcare professionals around the world.![]()

Fluicell

Innovation: In early 2022, Fluicell launched the Biopixlar AER 3D bioprinter, which prints cell-by-cell detailed biological tissues with high precision. It is the world's first microfluidic high-precision bioprinter, compact enough to fit inside a standard biosafety cabinet. Its advent expands the technology's reach to new consumer segments in the rapidly growing life sciences, pharmacology and medical research sectors. The combination of compactness, ease of use, remote control, proprietary software and portability makes it flexible enough for a wide range of applications from aerospace to deep sea exploration. nine0003

Company: Founded in Sweden in 2012 as a subsidiary of Chalmers University of Technology, Fluicell is a state-owned biotech company specializing in high resolution 3D bioprinting and single cell biology. The company is a pioneer in open volume 3D microfluidics for processing and studying drug effects in single cells at a unique level of detail. Fluicell is also developing advanced therapeutics based on transplant biocomposites printed on Biopixlar. The company operates in three therapeutic areas, where the main cause of the disease is tissue damage. nine0003

Fluicell is also developing advanced therapeutics based on transplant biocomposites printed on Biopixlar. The company operates in three therapeutic areas, where the main cause of the disease is tissue damage. nine0003

Velo3D

Innovation: California-based Velo3D is a metal 3D printing company with the patented Sapphire system. Sapphire is a new way to design and manufacture products for the aerospace, energy and other critical industries. In 2022, the company added support for copper 3D printing and expanded its presence in Europe. Sapphire is not just a metal 3D printer, it is a complete manufacturing solution that includes software and quality control features. The emergence of such products is pushing companies such as SpaceX, Launcher, Honeywell and Honda to rethink how they manufacture their metal components and overcome the limitations of traditional manufacturing. nine0003

Company: Velo3D founded in 2014. The company offers a metal 3D printing solution that opens up a wide range of design possibilities and allows customers to create previously impossible metal products. The integrated solution enables additive manufacturing to realize humanity's space ambitions, make cost-effective supersonic flight a reality, and take the energy and manufacturing sector to new levels of efficiency and scalability. nine0003

The integrated solution enables additive manufacturing to realize humanity's space ambitions, make cost-effective supersonic flight a reality, and take the energy and manufacturing sector to new levels of efficiency and scalability. nine0003

Nexa3D

Innovation: Nexa3D will expand its hardware portfolio by launching two 3D printers in 2022 and a third (powder QLS 820) shortly after. These machines greatly expand the manufacturing sector's access to high-speed 3D printing. The company's patented Light-Layer Photo-Cure (LSPc) technology is a key feature of the NXE 200 3D printer and desktop XiP, with print speeds up to 18 cm per hour. With these fast machines, designers, engineers and manufacturers have access to accurate and affordable prototyping and manufacturing solutions to create innovative products. nine0003

Company: Nexa3D is a California-based manufacturer of ultra-fast 3D printers for industrial applications. Nexa3D aims to sustainable digitize the global supply chain with the fastest industrial resin 3D printers available to professionals and businesses of all sizes. The company's groundbreaking technology breaks down traditional barriers to productivity and opens up new opportunities, going beyond the established injection molding market.

The company's groundbreaking technology breaks down traditional barriers to productivity and opens up new opportunities, going beyond the established injection molding market.

nine0003

Formlabs

Innovation: 3D printer, materials and software maker Formlabs is upgrading its already market-leading Form 3 and 3B resin printers in 2022. The new Form 3+ and Form 3B+ are up to 40% faster than previous models thanks to software developments, higher intensity lasers and new proprietary material settings. The company has made innovations backwards applicable so owners of previous models can achieve the same efficiency without buying a new machine. In 2022, the company also launched ESD Resin, one of the industry's only materials for dissipating static electricity, which greatly expands the application possibilities of resin 3D printing in electronics. nine0003

Company: Formlabs was founded in 2011 and is based in Massachusetts. The company aims to expand access to digital manufacturing, "so that anyone can do anything. " Formlabs are the professional 3D printers of choice for engineers, designers, manufacturers and decision makers around the world, bringing flexibility and versatility to the businesses of tomorrow. Formlabs also develops its own high-performance materials that push the boundaries of 3D printing, as well as software. nine0003

" Formlabs are the professional 3D printers of choice for engineers, designers, manufacturers and decision makers around the world, bringing flexibility and versatility to the businesses of tomorrow. Formlabs also develops its own high-performance materials that push the boundaries of 3D printing, as well as software. nine0003

WAAM3D

Innovation: The launch of the WAAM3D large-scale industrial metal 3D printer RoboWAAM in 2022 marks a breakthrough in arc welding additive manufacturing. The system is controlled by proprietary software with material specific algorithms, providing process monitoring, control and ease of use. With RoboWAAM, the technology can be applied to heavy industry, shipbuilding, construction and mining at a time when these industries have been hit hard by supply chain disruption. nine0003

Company: The British company WAAM3D was founded in 2018 and grew out of research conducted at Cranfield University. The company aims to offer a cost-effective way to 3D print massive, complex metal structures at completely new speeds with less waste, thus challenging traditional processes such as subtractive manufacturing and metal casting.

BCN3D

Innovation: BCN3D's VLM (Viscous Lithography Manufacturing) technology is not yet commercially available, but is already considered a significant step forward in resin 3D printing. The patented lithography-based 3D printing process allows thin layers of high-viscosity resins to be applied to transparent film, producing high-quality parts in a very fast, affordable and scalable manner. The hallmark of VLM is the ability to create completely new categories of polymer materials and create parts from multiple materials. VLM gives material engineers the freedom to develop resins and modifiers to achieve new thermal and mechanical properties. nine0003

Company: The Spanish company BCN3D Technologies was founded in 2019 and started as a division of the Polytechnic University of Catalonia. BCN3D aims to provide reliable, versatile and productive 3D printers and advanced manufacturing materials.

Raise3D

Innovation: In the past 12 months, Raise3D has introduced four new 3D printers (RMF500, MetalFuse, Pro3 series, E2CF). The company makes 3D printing more democratic by developing affordable and easy-to-use solutions that meet modern quality requirements. Based on its experience in FDM 3D printing technology and customer requests, Raise3D has expanded its portfolio with 3D printers that print from high-performance engineering grade materials, carbon fiber and metal filaments. Raise3D has also introduced an intelligent assistant for its latest Pro3 line called EVE, which offers solutions to printing problems that arise. The Digital Assistant helps users diagnose and fix issues that may affect print quality, analyzes the system, and sends reminders to users to service the printer. nine0003

The company makes 3D printing more democratic by developing affordable and easy-to-use solutions that meet modern quality requirements. Based on its experience in FDM 3D printing technology and customer requests, Raise3D has expanded its portfolio with 3D printers that print from high-performance engineering grade materials, carbon fiber and metal filaments. Raise3D has also introduced an intelligent assistant for its latest Pro3 line called EVE, which offers solutions to printing problems that arise. The Digital Assistant helps users diagnose and fix issues that may affect print quality, analyzes the system, and sends reminders to users to service the printer. nine0003

Company: California-based Raise3D was founded in 2014 and designs and manufactures 3D printers and additive manufacturing solutions for businesses of all sizes. The line of desktop and industrial 3D printers covers a wide range of materials (polymers, composites and metal) and many applications.

Selection method

The editors of the All3DP portal conducted a study and submitted a pool of companies to their selection committee.