Sti 3d printing

Sti best 3D printing models・Cults

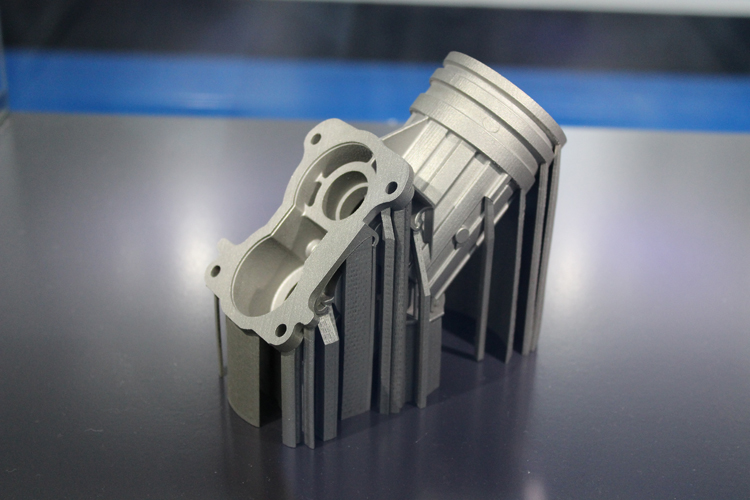

Scaled Model of Flat 6 Engine

€10.39

2003-2005 Subaru Impreza WRX STi Keytag

Free

Lithophane picture Impreza STI hawkeye.

€1.65

Lithophane picture Impreza wrx STI

€1.65

Lithophane picture Impreza wrx sti

€1.65

Subaru İmpreza Sti Spoiler

€4

WRX STI 2008-2013 full throttle switch for Waterinjection or Waterspray

€2.01

WRX STI 2008-2013 DAB Receiver ventilation

€3.02

O.Z Racing Ultrallegera 2d (keychail/picture

€0.83

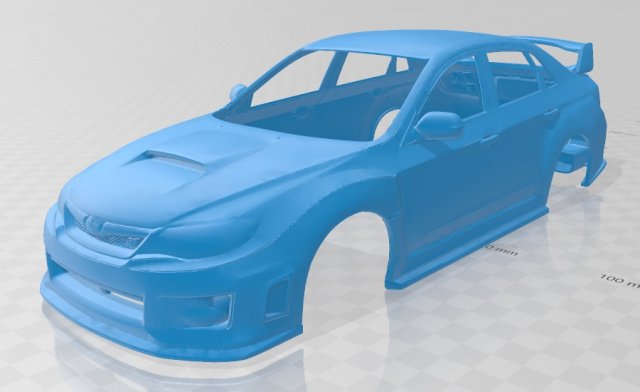

Subaru Impreza WRX STI 2006 PRINTABLE CAR BODY

€5. 12

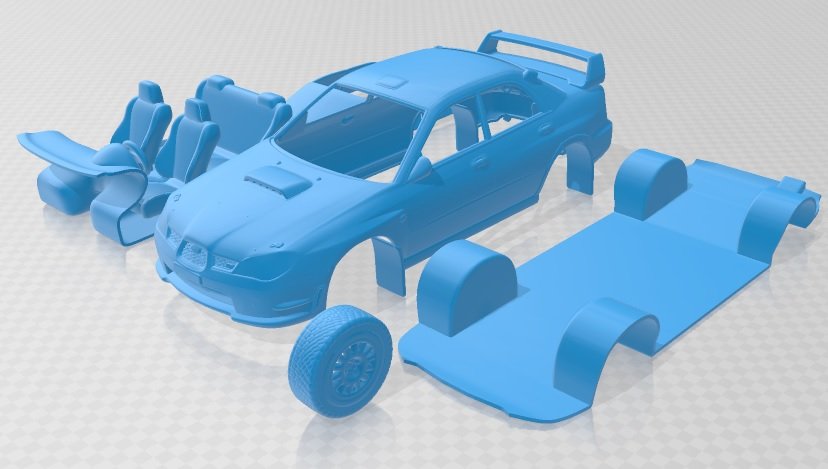

Subaru Impreza WRX STI 2006 PRINTABLE CAR IN SEPARATE PARTS

€10.25

SUBARU IMPREZA STI 2001 PRINTABLE CAR BODY

€5.12

SUBARU IMPREZA STI 2001 PRINTABLE CAR IN SEPARATE PARTS

€9.68

Subaru GC Lamco Gauge Pod

€15

Metamorphosis keychain - Subaru Impreza Hawkeye WRX STI

€3

COBB ACCESSPORT MOUNT FOR 2007 - 14 SUBARU IMPREZA WRX / STI

€6.59

Blobeye WRX STi Flip Art

€3.77

Subaru Impreza WRX STI Hawkeye key silhouette

€1

Subaru WRX STI 2002-2007 - 52mm Gauge Pod

€3

Subaru Impreza STi WRC 2006 Printable Body Car

€8. 33

33

Rc Subaru Impreza 22B 1998 spotlight

Free

Subaru Impreza STi WRC 2006 Printable Car

€12.50

Subaru wrx sti GC8 GF8 v1 v2 v3 v4 Fog light covers

€20.73

2008-2014 Subaru WRX/STI Wireless Charging Mod

Free

Triple 52mm Gauge Holder for Subaru Impreza WRX/STI (2015-Present)

€4.85

registration mark holder for Honeycomb

€5.36

Subaru Legacy Air Ramp

€7.19

EJ22 Short Block With Heads

€10.39 -25% €7.79

WRX themed keychain

€0. 80

80

Impreza Fuel Cap Holder

€0.93

Paul Walker Memorial Decoration

€0.94

Suba-roo! Keychain

€0.94

Subaru Keychain "Driven by Whats Inside".

€0.94

Decorative With Car Theme

€0.94

Car Theme Keychain

€0.94

Subaru Impreza "Made in Japan Perfected in my Garage".

€1.41

Subaru Mafia Keychain

€0.93

Subaru Impreza Wrx Keychain

Free

2018-2021 Subaru Wrx/STI Keychain

€4.66

spoiler subaru sti 11 1/24 1/18.

..

..€1.50

Subaru Impreza WRX STI Tuned

€5

Subaru Outback Roof Rack Plug

Free

COBB ACCESSPORT MOUNT FOR 2002 - 08 SUBARU FORESTER

€4.71

Subaru WRX STI TCR printable

€5.99 -65% €2.10

Universal rollbar mount for Cobb Accessport

€3.77

Subaru Impreza WRX STi 2004-2005 - Turbo Racing 1:76

Free

Bugeye wrx

€1.58

Windshield wiper arm caps

€0.94

How Do You Make & Create STL Files for 3D Printing – Simple Guide – 3D Printerly

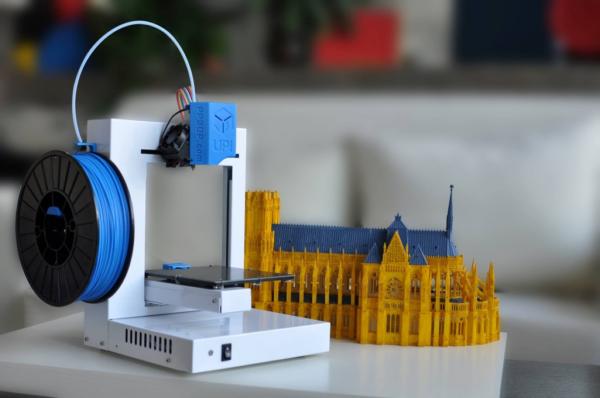

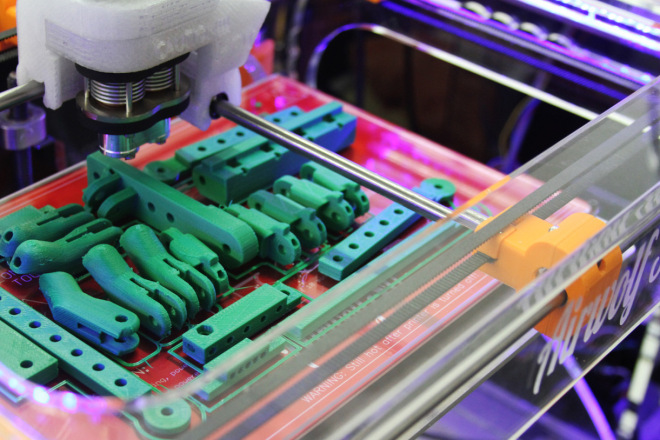

When you are in the field of 3D printing, there are steps you have to follow to be able to actually 3D print your objects. Many steps are done for you but making 3D printer files is one of the most important ones.

Many steps are done for you but making 3D printer files is one of the most important ones.

This article will show you exactly how 3D printer files are made so read on if you’d like to know.

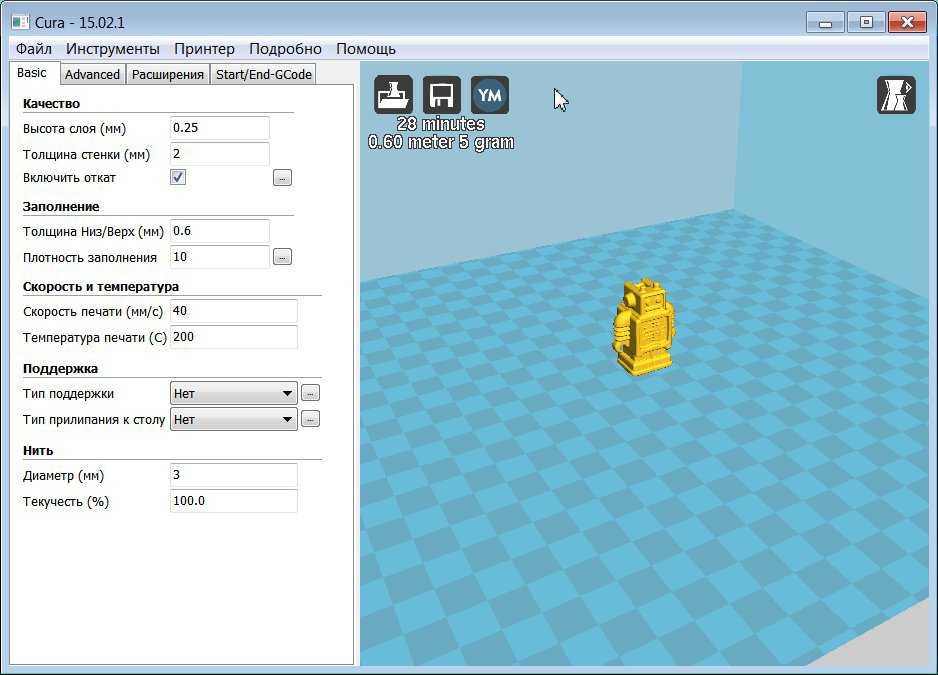

3D printer files are made by using Computer Aided Model (CAD) software which allows you to create what your model will look like. After your model is complete, you need to ‘slice’ your CAD file in a slicer program, the most popular being Cura. After your model is sliced, it will be ready for 3D printing.

Once you understand the steps of this process and do it for yourself, it all becomes very easy and clear. I will do my best to detail the step-by-step process on how beginners create 3D printer files.

Creating models for 3D printing and learning how to make your own 3D model is a great skill to learn, so let’s get right into it.

- Choose & open a CAD program

- Create a design or model using the tools in your chosen program

- Save & export your completed design to your computer (STL file)

- Choose a slicer program – Cura for beginners

- Open & ‘Slice’ your file with your desired settings into a G-Code File

If you want ready-made files that you can get 3D printed, check out my article 7 Best Places for Free STL Files (3D Printable Models).

Choose & Open a CAD Program

There are many CAD programs out there that can be used to create your model, but some are definitely more tiered towards beginners which is what I’ll focus on in this article.

Also, many higher level programs actually need to be purchased, so you’ll be happy to know everything I recommend will be completely free.

The best CAD programs for beginners are:

- TinkerCAD – click and create your own account

- Blender

- Fusion 360

- Sketch Up

- FreeCAD

- Onshape

Check out my article Best Free 3D Printing Software – CAD, Slicers & More.

The one that I will focus on and do recommend is TinkerCAD for beginners because it was definitely designed for you guys in mind. Beginners don’t want a complicated CAD program that takes a while getting used to, they want to be able to put something together in the first 5 minutes and see its capabilities.

One of the great features of TinkerCAD is the fact that it’s browser-based so you don’t have to install some huge program file to get started. Just go to TinkerCAD, create an account, go through the short tutorial on the platform and get to modeling.

Just go to TinkerCAD, create an account, go through the short tutorial on the platform and get to modeling.

Once you get the hang of one CAD program and the way designing a model works, you can move onto other programs, but at first just stick to one simple program.

TinkerCAD has enough capabilities to keep you modeling there for at least a few months, before you think about moving to a software with more features. For now, it will work wonders!

Create A Design Using the Tools in Your Chosen Program

TinkerCAD specializes in ease of use, as you put together blocks and shapes to gradually build a more complex structure that you can be proud of. The video below will show you a quick tutorial on exactly how it looks and how it’s done.

It’s always best to follow a video tutorial when learning how to create designs, while doing the same thing in the program yourself.

Reading a guide of some sort is great when you understand the program and are looking for ways to do cool, new things but when just starting out, get the experience behind you.

Once you’ve created some of your own models by following a tutorial, a good point to go to next is to play around in the program and get creative. One thing I chose to do is find a few household objects and try to model it as best as I could.

This ranged from cups, bottles, small boxes, vitamin containers, anything really. If you want to get really accurate, you can get a sweet pair of Calipers from Amazon.

If you want a quick, cheap but reliable set I’d recommend the Sangabery Digital Caliper.

It has four measuring modes, two unit conversion & zero setting function. You can get very accurate readings with this device, so I do recommend you getting one if you don’t already. Also comes with two spare batteries!

If you want a higher quality Caliper, go for the Rexbeti Stainless Steel Digital Caliper. It is more premium with a polished finish and a case to hold the device. It comes with IP54 water & dust protection, has 0.02mm accuracy and is great for the long-run.

It is more premium with a polished finish and a case to hold the device. It comes with IP54 water & dust protection, has 0.02mm accuracy and is great for the long-run.

Once you get some good practice creating different items, you’ll be a lot more prepared to start making useful and complex 3D printer files.

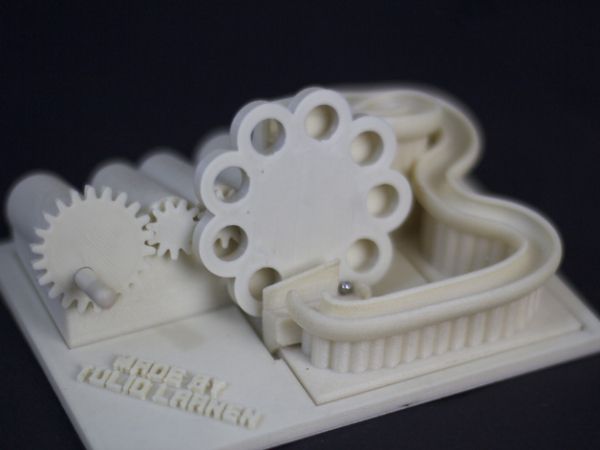

At first, it seems like all these simple shapes and holes won’t be able to make much. This is what I thought at first before seeing what people could really create in this software.

The following was made on TinkerCAD by Delta666 found on MyMiniFactory. It would be hard to describe this as a simple design, which just goes to show you the potential you could have with designing your own 3D printer files.

Save & Export Your Completed Design to Your Computer (STL File)

The great thing about TinkerCAD is how it’s made for things to be easy to use. This also includes saving and exporting your STL files straight to your computer.

Unlike some downloaded CAD software, this one auto-saves your work each change you make so you don’t have to worry about losing your work.

As long as you have named your work in the top left, it should continue to save. You’ll see a small message saying ‘All Changes Saved’ so you know if it’s working.

As you can see in the picture, exporting your CAD files into a downloadable STL file is a piece of cake. Simply click the ‘Export’ button in the top right of your TinkerCAD page and a box will pop up with a few options.

When it comes to 3D printing files, the most common ones we see are the .STL files. There are a few things that people say it’s abbreviated from such as Stereolithography, Standard Triangle Language and Standard Tessellation Language. Either way, we just know it works pretty good!

The complex part behind STL files is that they are made up of several tiny triangles, with more detailed parts having more triangles. The reason behind this is 3D printers can better understand this information with this simple geometric shape.

Below is a clear illustration of these triangles making up a model.

Choose a Slicer Program – Cura for Beginners

If you’re in the 3D printing field, you either would have come across Cura by Ultimaker or are already well-versed in the program. Cura is the most popular, cross-platform slicing software that 3D printer hobbyists use to prepare their files for 3D printing.

There isn’t much point trying to go with another slicer because this one works so well and does exactly what you need it to do. It’s very beginner-friendly and doesn’t take long at all to get the hang of it.

There are other slicer programs out there like PrusaSlicer or SuperSlicer. They all essentially do the same thing but Cura is the choice I recommend.

Check out my article Best Slicer for the Ender 3 (Pro/V2/S1), which also goes for other 3D printers as well.

Open & ‘Slice’ Your File With Your Desired Settings Into a G-Code File

The term ‘slice’ your file is one that is widely used in the 3D printing field which means to prepare your CAD model and turn it into a G-code file which 3D printers can make use of.

G-code is basically a series of commands that tell your 3D printer what to do, from movement, to temperatures, to fan speed.

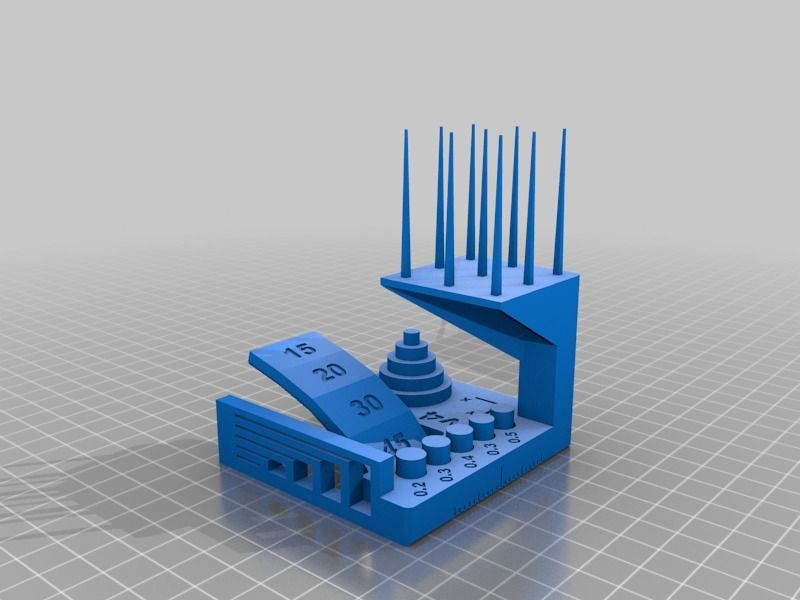

When you slice your file, there is a certain function where you can preview your model in its 3D printing form. This is where you view each layer of your 3D print from the ground, up and you can even see the direction your print head will go while in the printing process.

It really isn’t as complicated as it looks. All it really takes is looking over the settings and hitting the blue ‘Slice’ button on the bottom right of the program. The box to the top right shows a simplified way to change settings without getting into all the specific settings.

It’s a spice rack in case you’re wondering!There are many settings in your slicer you can take control of such as:

- Print speed

- Nozzle temperature

- Bed temperature

- Retraction settings

- Print order prioritization

- Cooling fan settings

- Infill percentage

- Infill pattern

Now just because it isn’t complicated to get started doesn’t it mean it can’t get as complicated as you’d like it. I’m sure there are settings that Cura experts have never thought about touching.

I’m sure there are settings that Cura experts have never thought about touching.

This really is a short list when you have seen just how many settings there are, but luckily, you don’t have to worry about most of the settings. Cura has default ‘profiles’ which give you a list of already done for you settings that you can input.

This profile usually works great by itself, but it can take a little tweaking on the nozzle & bed temperature before you get some great prints.

There is a cool menu which allows users to choose custom setting views for beginners to masters, down to custom so the functionality and ease of use is great.

After you follow all these steps, you’ll have created your 3D printer file which your printer can understand. Once I’ve sliced a model, I simply get my USB drive and micro SD card which came with my Ender 3, plug it into my laptop and select the ‘Save to Removable Device’ button and Voilà!

I hope these steps were easy to follow and help you get started making your own 3D printer files.

It’s an amazing skill being able to design your own objects from start to finish, so try your best to stick with it and become an expert in the future.

If you found this helpful, I have other similar posts like the 25 Best 3D Printer Upgrades/Improvements You Can Get Done & 8 Ways How to Speed Up Your 3D Printer Without Losing Quality so feel free to check them out and happy printing!

3D printing from scratch | BHV publishing house

- Description

- Details

- Reviews (0)

Description

The principles of operation of modern 3D printers are considered, advice is given on choosing, self-assembling and setting up such a device, an overview of the most popular models is given. The materials used in 3D printing are described, their comparative characteristics are given. All stages of 3D printing are described in detail: preparing the printer for operation, starting it, eliminating possible printing defects, post-printing processing of products. Attention is paid to working with the free programs Cura, Repetier-Host and the Tinkercad 3D editor, as well as modern 3D scanners that allow obtaining three-dimensional images of real objects…. nine0013

All stages of 3D printing are described in detail: preparing the printer for operation, starting it, eliminating possible printing defects, post-printing processing of products. Attention is paid to working with the free programs Cura, Repetier-Host and the Tinkercad 3D editor, as well as modern 3D scanners that allow obtaining three-dimensional images of real objects…. nine0013

About the Authors

Dmitry Gorkov is an entrepreneur and 3D printing enthusiast with over 20 years of experience in IT. I decided to create a business in the field of 3D printing in August 2013, having accidentally stumbled upon an article on this topic. After purchasing the first 3D printer, he began to implement his ideas by promoting 3D printing, and after a few months he began to fulfill regular orders. His business began to generate a stable income, which allowed him to develop other projects in parallel. Dmitry teaches master classes, speaks at specialized conferences, and also publishes articles on 3D printing on specialized Internet resources and on his own website http://3d-print-nt. ru. nine0013

ru. nine0013

Valentin Kholmogorov — writer, author of more than 40 books on computer technology, including "Encyclopedia of a personal computer", "Secrets of working in Windows", etc. Valentin's first publication was published in 1993, and since then Since then, in his luggage, there are several hundred articles in online and paper magazines. For many years he has been fond of 3D printing, he independently assembled his first 3D printer in 2014. Valentin's publications can be found in the popular Hacker magazine, as well as on the author's own website: http://holmogorov.ru. nine0013

Parts

| Art. No. | 2692 | |

|---|---|---|

| ISBN | 978-5-9775-6599-8 | |

| Number of pages | 256 | |

| Series | From scratch | |

| Binding | Paperback | |

| Printing | Black & White | |

| Year | 2020031 Dimensions, mm | 215 x 165 x 10 |

| Weight, kg | 0. 338 338 |

- ✓ New 2 weeks ahead of stores

- ✓ Prices from the publisher up to 30% lower

- ✓ Promotions and discounts for subscribers only

- ✓ BHV Important News

USEFUL BOOK NEWSLETTER

By subscribing to the newsletter, you agree to the privacy policy and the processing of your personal data. nine0013

We also recommend

-

AutoCAD Tutorial - Paper Book

1 250 RUB937 RUB - Gorelik Alexander Girshevich

Tutorial 3ds Max 2020

1169 ₽

877 ₽ Can 3D printing technology leave restorers without work? nine0013

Vera Chereneva (St. Petersburg)

In the next two or three years, St. Petersburg scientists intend to develop building mixtures that will allow 3D printing of stucco. This can make a real revolution in the field of facade repair, because the restoration of stucco molding in the historic houses of St. Petersburg is a complex and very costly undertaking. True, experts doubt that the new technology will allow restoring the decor of monument buildings.

Petersburg is a complex and very costly undertaking. True, experts doubt that the new technology will allow restoring the decor of monument buildings.

KGIOP press service

Yury Pukharenko, Head of the Department of Building Materials Technology and Metrology at St. Petersburg State University of Engineering and Engineering, says that the use of building 3D printers has already encountered problems related to building mixtures. nine0013

- Now the main question is not even structures for concreting units, they exist. The problem is in the effective application and creation of technologies for formless production, so that the freshly molded product does not float, says the researcher.

Simply put, the trouble is that gypsum or cement-based mixtures do not hold their shape. Therefore, 3D printing in its usual form will not work here. It is important that the product freezes instantly. The development of mixtures with such properties will be completed in two to three years. nine0013

nine0013

One of the most obvious areas of application of technology scientists see stucco. Gypsum stucco for interior decoration is obtained by pouring gypsum into molds. This is a very ancient technique, now 3D printing has come to this industry. In St. Petersburg, dozens of companies offer stucco molding with a 3D prefix. True, the peculiarity is that not the stucco elements themselves are printed on 3D printers, but metal molds into which gypsum is poured. This idea also has the right to life. But it is economically justified when it comes to creating standard forms, for example, sockets for the ceiling. These rosettes are put up for public sale in large quantities, and over time, the printing of the form pays off. When creating elements of stucco decoration of facades, the technology is different. nine0013

- The most important (and so far insoluble) problem is the material. In most cases, we are dealing with lime and gypsum compositions, the "recipe" for which is determined in each case individually, and the restoration methodology is developed by specialized design organizations, depending on the state of the restored elements. 3D printers are not yet able to print from materials used in restoration, and the restoration technique itself involves working with gradually solidifying compositions, and not solid elements that 3D printers can create, says Deputy General Director for Design of the Mironov and partners" Ivan Syuganov. nine0013

3D printers are not yet able to print from materials used in restoration, and the restoration technique itself involves working with gradually solidifying compositions, and not solid elements that 3D printers can create, says Deputy General Director for Design of the Mironov and partners" Ivan Syuganov. nine0013

Expanded polystyrene facade elements are short-lived and fire hazard. They are chosen because of their cheapness

Veniamin Norin, Associate Professor at St. Petersburg State University of Architecture and Engineering, believes that with the advent of innovative mixtures, specialists will be able to print one-off decorative elements, including very complex ones. This can improve the quality of facade repair. Indeed, now, if the facade is being restored not of a monument building, but of an ordinary house without a protected status, not restorers come to the object, but workers. nine0013

As a result, if there is some complex element on the facade of the house, for example, a bas-relief with a human face, then after repair this image can become caricatured. Photos of mutilated angels and nymphs regularly appear on social networks. The workers might be happy to do well, but they don't know how.

Photos of mutilated angels and nymphs regularly appear on social networks. The workers might be happy to do well, but they don't know how.

On such objects, 3D decor printing can be useful in perspective. In addition, the new technology may replace the phenomenon of printing decor elements from foam.

In fact, this industry began with foam ceiling moldings and sockets. Now manufacturers offer, among other things, elements for the exterior decoration of buildings. They differ from products for interior decoration with a coating, which, according to the manufacturers, protects the elements from rain, snow and mechanical damage. True, the coating does not save polystyrene foam, dents remain even from light touches. Nevertheless, foam stucco molding is actively used in the city. How long it will last is an open question. nine0013

Opinion

Nina Shangina, Chairman of the Council of the Union of Restorers of St. Petersburg:

- Styrofoam is short-lived and highly flammable. And they choose this material when decorating facades solely because of the price. If the problem of creating complex-shaped products using 3D printing, but using a mineral binder, is solved, then these products can be replaced with at least more durable ones. It would be incorrect to call materials printed from innovative building mixtures stucco molding. And in such an area as the restoration of monumental buildings, 3D printing is unlikely to be used. For us, the concept of "quality" is unambiguous: high-quality restoration does not improve the object, does not mix with historical material, and, most importantly, retains the individuality that is inherent in historical objects, not only because they were made by different masters, but also because they carry information about historical technologies. So the 3D printer in this case cannot positively influence the quality of the restoration. Therefore, the profession "restorer of stucco products" will not leave the list of those in demand in St.

And they choose this material when decorating facades solely because of the price. If the problem of creating complex-shaped products using 3D printing, but using a mineral binder, is solved, then these products can be replaced with at least more durable ones. It would be incorrect to call materials printed from innovative building mixtures stucco molding. And in such an area as the restoration of monumental buildings, 3D printing is unlikely to be used. For us, the concept of "quality" is unambiguous: high-quality restoration does not improve the object, does not mix with historical material, and, most importantly, retains the individuality that is inherent in historical objects, not only because they were made by different masters, but also because they carry information about historical technologies. So the 3D printer in this case cannot positively influence the quality of the restoration. Therefore, the profession "restorer of stucco products" will not leave the list of those in demand in St.