Lulzbot ao 101 3d printer

3D Printer Review: LulzBot AO-101

Review Perspective

Although 3DPI offers great breadth and depth for following the developments in 3D printing technology and its applications, there is one angle I have found to be missing — a more practical approach — and it has been somewhat bothering me. Over the course of the coming months I, with a couple of other members of the team, hope to rectify this with a series of 3D printer reviews. For this first one, I would like to clarify that I am not a professional, not even a ‘prosumer’ so this review will not come from the same perspective as the majority of 3D printer (and related accessories) reviews, which tend to be conducted by either enthusiasts or advanced makers with years of experience.

Hopefully this perspective is something that you will find useful – with minimal tech jargon and more focus on practical issues. However, as 3DPI is a site for everyone interested in the world of 3D printing, we will also be sensitive to the more advanced user’s approach. I believe that combining the perspectives of different groups with different interests will offer a valuable learning experience for all parties. We’ll be also adding videos in our upcoming tests – and of course invite feedback from you.

Overview

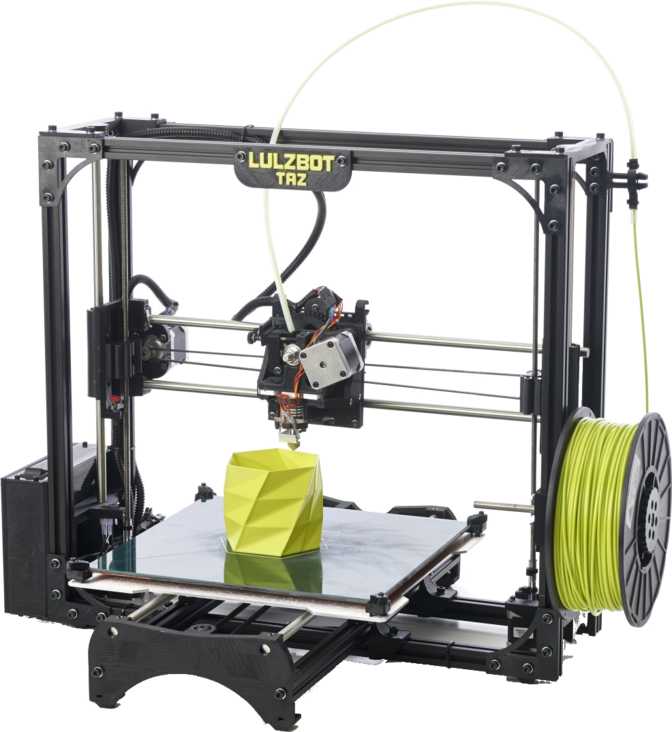

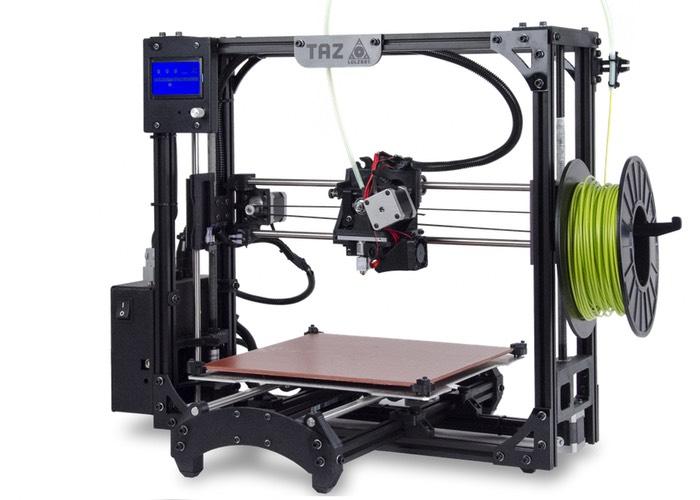

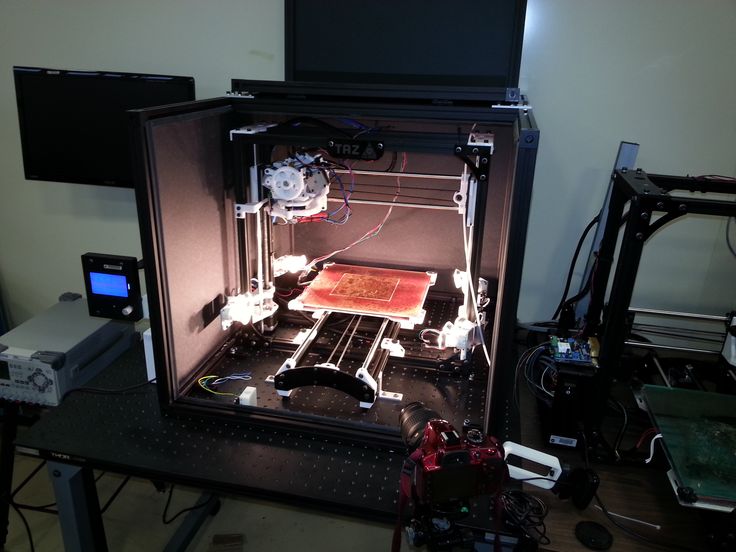

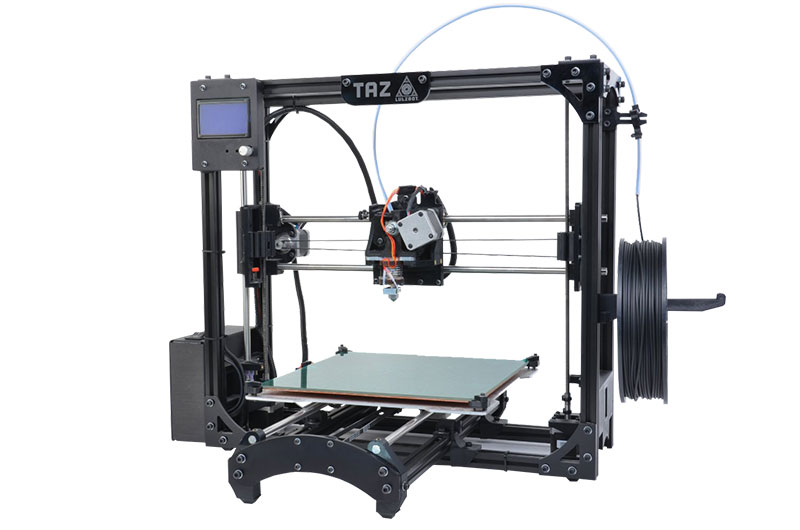

What we’re looking at here is the LulzBot AO-101 3D printer from Colorado-native Aleph Objects. The AO-101 model is a successor to the original AO-100. It pushes all the prosumer buttons — it’s modifiable, open, industrially (read minimalistically) styled and retails at $1,700.

The company’s overall approach to 3D printing is an open one and supports their target market of makers and prosumers worldwide – everything, starting from source codes, is open-source and thus available for modding. The spectrum of useable printable materials is also open, but assumes more than basic technical skills and the urge to tinker. This is an admirable approach and an homage to the global maker community, but not particularly relevant to the new user.

So where does the LulzBot AO-101 fit in the ever-more crowded 3D printer landscape? It is getting harder to differentiate between printers as more and more hit the market. There are many common denominators — they use fused filament fabrication (a nozzle that produces layers of molten plastic on the printing surface), process ABS and PLA plastics as basic materials and cost in the region of $1,500 to $2,000. Other 3D printers on this playing field include Ultimaker, Afinia, Leapfrog, the Cube or a Replicator [1].

Hardware

The LulzBot AO-101 3D printer comes almost fully assembled, and has an industrial rough appeal to it – with everything visible, from the mechanics to the RAMBo box. The build quality is also on level par to say the least — according to the manufacturer the AO-101 has been tested to print successfully even while a full grown adult stands on the machine. This is not necessarily the most obvious scenario, and with the machine on loan for the purposes of this review, I did not test it myself. The size of the printer is 20″ x 25” x 20” (HxWxD) from the most outermost points with the filament spool attached to the frame, so it should fit most desks with ease and weighs 18lbs.

The size of the printer is 20″ x 25” x 20” (HxWxD) from the most outermost points with the filament spool attached to the frame, so it should fit most desks with ease and weighs 18lbs.

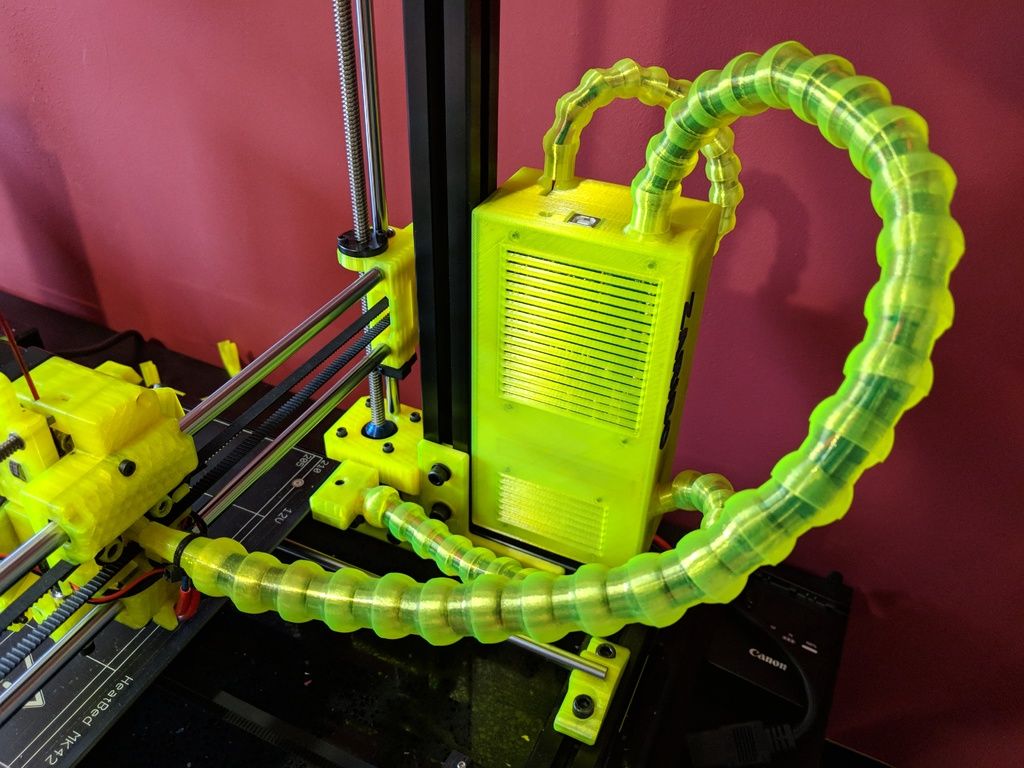

The most visually striking element of the AO-101 are the main frames, which are composed of a sturdy metal and a completely open solution – no styled covers, no plywood or any other conventional shape, just plain naked mechanical goodness in all its glory. The LulzBot AO-101 has its roots in RepRap and pays homage to this by virtue of the fact that 3D printed plastic parts also included in the set-up.

The printing bed is heatable and intended to be used with a glass plate, covered with a thin layer of adhesive plastic to help with the removal of parts — this is included in the equipment supplied. For anyone working to the ‘bigger is better’ mantra, the AO-101 might let some users down – the usable print area is 7.9” 7.5” x 3.9”. In my opinion, this is sufficient for many applications and definitely comparable with competitors’ equivalents. Of course there is always the option to print parts that can be assembled and then enjoy clicking them together.

Of course there is always the option to print parts that can be assembled and then enjoy clicking them together.

Overall the AO-101 is a very solid device hardware-wise. LulzBot’s choice of a sturdy metal frame with sufficiently sized bolts and nuts suggests there is no need for specific or delicate care to ensure perfect functioning from day to day. If the aesthetic design seems too spartan, however, building a simple custom casing from plywood or plastic shouldn’t prove to be too much of an issue for eager modders.

Bundle

The LulzBot AO-101 comes as an inclusive bundle and contains everything needed to start printing after a quick assembly. I was able to assemble everything and get to pluggin the power chord in after a less than hour (more on that later). There was an issue with attaching the filament guide to the frame – the slightly too short bolt – which is explained in the setting-up section in more detail. Besides the actual printer parts – the frame, filament guide and the filament spool – the basic kit includes a 5 lb roll of filament – natural white in colour, a quick-start guide and a comprehensive manual together with an extensive set of tool accessories from an Xacto knife to allen keys in a variety of sizes.

The problem of too many options is not something to worry about, as this bundle is currently the only available option for the AO-101.

In detail the kit contains the following:

Complete documentation, including a detailed manual with information for unpacking the printer, setup, downloading and the using software and starting your first print.

- Mountable Spool Holder

- Filament Feedtube

- Filament Feedtube Holder

- Startup supply of ABS filament, Natural, 3mm dia., 5lbs (2.3kg)

- Toolkit bag

- Allen Wrenches: 1.27mm, 2.5mm, 3mm, 4mm

- Combination Wrenches: 5.5mm, 13mm, 18mm

- Pliers, Needle Nose

- Tweezers

- Xacto Knife

- Dental Pick

- Flathed Bristle Brush

- Part Removal Knife (clam knife)

- Metric Ruler

- PET Sheet

- Acetone-safe Bottle (acetone not included)

- Nozzles: 0.5mm installed, includes 0.25mm and 0.35mm nozzles

- PTFE Tube for 1.

75mm Filament

75mm Filament - Micro SD card

- 90 Day Warranty

- 1 Year Support

[nggallery id=65]

Software

Following the open-source ethos most of the software needed to start up is available for download straight from LulzBot’s website. I stress ‘most’ here because not every folder contained actual downloadable files, such as the required drivers to have the 3D printer and the computer’s UI speak a common language. I think this was almost certainly an honest mistake, an oversight maybe.

[nggallery id=66]

Thankfully — for me — because the RAMBo units are also used in other 3D printers as well, the missing files were not hard to track down. Even step-by-step video guides for this stage are available online — you can always count on Youtube. What I, as an average Joe, would like for LulzBot to do is to follow the rest of the tech and electronic consumer market’s lead by including all the needed drivers, maybe on a USB stick or a Micro SD – which was already included in the bundle. This would create added value for the user by not having to rely on passing a click wall – even if a thin one – to get started even more quickly.

This would create added value for the user by not having to rely on passing a click wall – even if a thin one – to get started even more quickly.

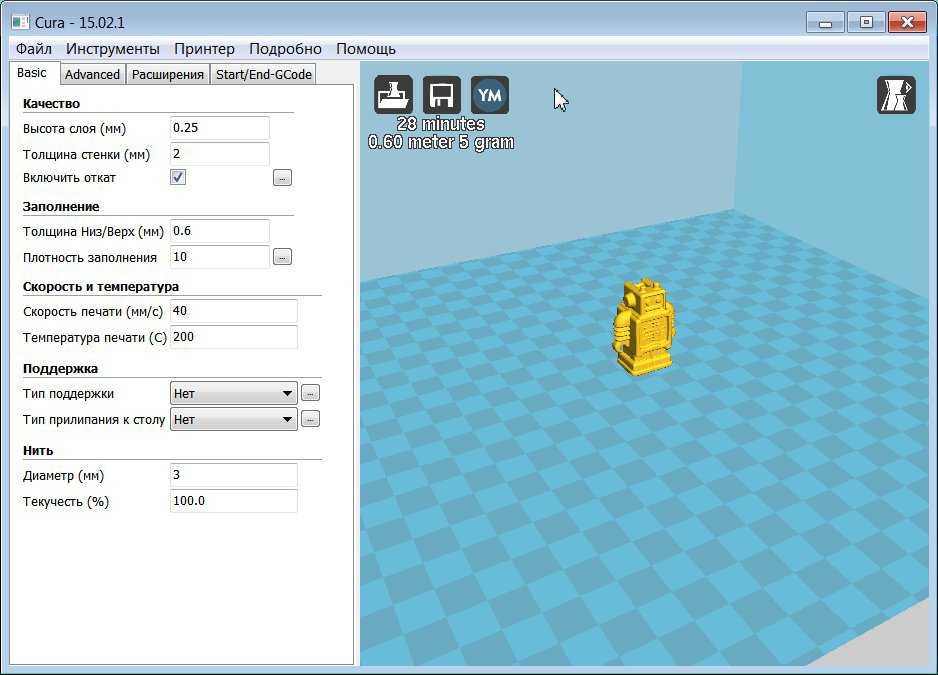

The software used for creating the GCODE files, including printing specs, is Slic3r, which is very intuitive and easy to use even for a beginner. Printrun is used for actually operating the printer. Even though the LulzBot’s manual provides guidance, for example on the recommended temperatures for both ABS and PLA, the guidelines could be less ambiguous I thought. For example, it would have been great if the fact that the desired temperature has to be set before exporting the GCODE file from Slic3er was displayed more clearly. Also, the default temperature settings in Printrun varied slightly from the manual and because of the underlying parameters created by Slic3er the recommended temperatures could not be reached in Printrun – before changing them in Slic3r. Obvious for many, but not for everyone.

Even understanding that this machine is targeting the prosumer market, i. e. users with at least some basic understanding of the 3D printing process set-up, I would also like to have seen a segment explaining the impact of changing different parameters. For example the effect of changing the layer height, fill density, travel speed of different parts of the print etc. As an illustration, the default speed for the non-print movement was too fast for most prints, resulting in the layers not attaching to each other properly. Also trying to use a 0.1mm layer height didn’t prove too successful with uneven and distorted outcomes with practically any tested models. Does this all seem too obvious? At least I would have benefitted from something like this – even though I have to admit that the learning process proved to be very enjoyable, when trying different settings and their effect on the printing outcome.

e. users with at least some basic understanding of the 3D printing process set-up, I would also like to have seen a segment explaining the impact of changing different parameters. For example the effect of changing the layer height, fill density, travel speed of different parts of the print etc. As an illustration, the default speed for the non-print movement was too fast for most prints, resulting in the layers not attaching to each other properly. Also trying to use a 0.1mm layer height didn’t prove too successful with uneven and distorted outcomes with practically any tested models. Does this all seem too obvious? At least I would have benefitted from something like this – even though I have to admit that the learning process proved to be very enjoyable, when trying different settings and their effect on the printing outcome.

Other issues that I experienced with the software were related to Printrun, which consistently had trouble displaying the printing image during the process, but also generally crashing several times (tested using WIN 7 Enterprise). However, overall while this program was not perfect it did prove sufficient.

However, overall while this program was not perfect it did prove sufficient.

In conclusion, LulzBot AO-101 and the (recommended) software are all fully functional and can be used with all modern operating systems, whether it be OSX, Windows or some Linux distro. There are other options in the open-source community, if needed, but these already established softwares handled the job just fine.

Materials

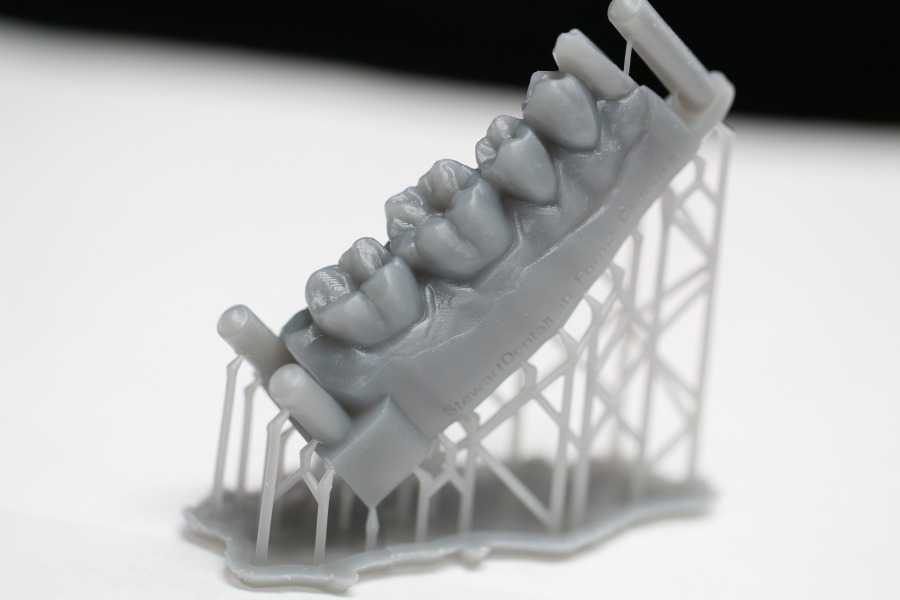

Out of the box the AO-101 deposits the typical duo of materials – ABS and PLA plastic. It should also be able to make use of the much-vaunted Laywoo-D3.

Unfortunately, due to time constraints, I was unable to test the AO-101 with other materials, but the general tweakability of the printer suggests to me that other plastics could be used. LulzBot has also announced that other printable materials will eventually follow – but these basic materials provide a good starting point for creating a wide variety of objects.

Setting up

“Assembled and Ready to Print, Out of the Box” is the slogan LulzBot applies to the AO-101. But what about in real life – in the hands of a first timer? I have already mentioned a couple of issues related to the software, but what about getting the printer to print?

But what about in real life – in the hands of a first timer? I have already mentioned a couple of issues related to the software, but what about getting the printer to print?

Generally I found that setting the LulzBot up hardware-wise was relatively simple. The machine would have been ready to be plugged in within an hour – if it wasn’t for the US power cord that was supplied and me using old world outlets (I am based in Finland). With a product for the global market, it would be convenient for the user to either include a set of different plugs, considered standard for many tech devices, or provide the user with a universal adapter. Nothing that can’t be done by the user himself, obviously, but for a machine that costs $1,725 an all inclusive approach suitable for any global region could be expected. Whether this is the standard with the prosumer grade 3D printers is irrelevant – I would see it more as something that should become the de facto standard – even with printers taking their power from the network instead of the computer’s USB port.

The actual set-up phase consisted of attaching the filament spool to the mount and the filament guide to the frame, applying the filament to the spool and feeding it through the tube to the extruder.

Even though the amount of assembly was quite minimal, I did experience some minor issues – regarding attaching the filament guide to the frame and tightening the extruder idler bolts after feeding the filament. I struggled a bit with the guide because the screws attaching them to the guide t-slot nuts – which are in the frame – were slightly too short and therefore I required a Philips screwdriver to lift the nuts to make the attachment possible. The idler, on the other hand, proved to be a bit challenging to raise back up and to push the springs back in their place after feeding the filament to the hot end.

Undoubtedly these, like the other issues I have mentioned are just small details – but nevertheless, should be refined, as the day of entering the major consumer market lies close ahead.

All of the calibration, end stop alignment and other adjustments had already been completed before leaving the factory. All that was left to do was to make sure that everything was indeed in order – which it was.

The printed user manual included is something that deserves a mention of its own – it is very illustrative, descriptive and easy to read – something for every tech company to compare their cryptic jargon-filled pages to.

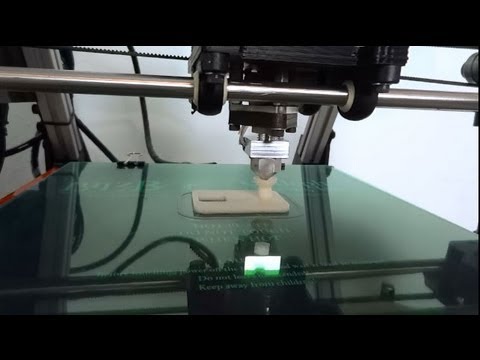

Printing

Turning the power on creates a noticeable level of hum – something comparable to many other 3D printers, not more, not less. The actual printing sound level is naturally louder, but bearable – just. An exterior case may go some way to reducing this however, simultaneously communicating solid quality — matching the hardware quality.

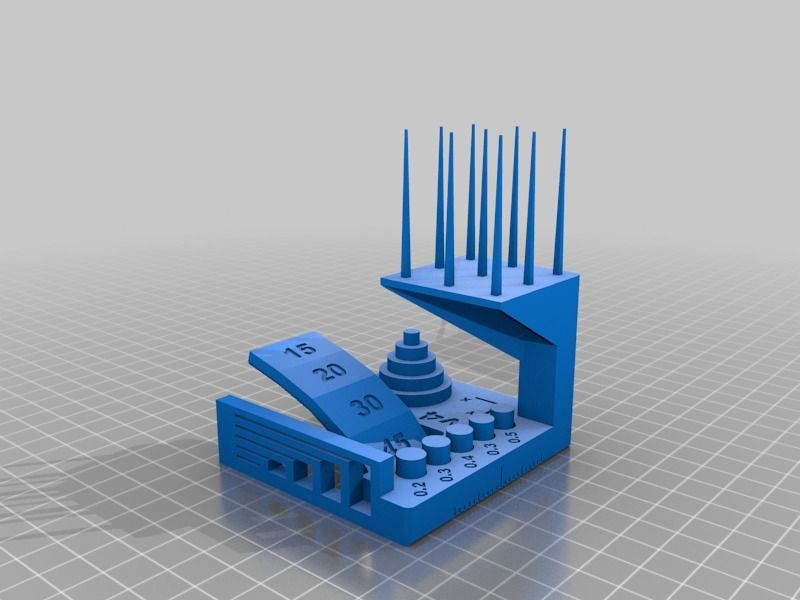

For testing the actual printing performance I chose to use several models from Thingiverse, as I come from a non-existent background with 3D modelling. The first object was tbuser’s Raktajino Mug – a quite simple design. Using the included roll of 3mm filament, I printed the mug first with a 0.2mm layer height and a 0.4 fill density with perfect results. The outcome was very smooth on all parts of the mug. But when trying a more complex structure to further test the performance of the LulzBot, I printed out a cover for my SGS3 (The3DLibrary – Honeycomb case), the result was disappointing. I used the same settings, but ran into some problems with the honeycomb structure, which got distorted as the layer height seemed to be too low for creating an even result. I then changed the layer height to 0.3mm and tried again – now with a new apparent problem: the Slic3r’s default travel speed for non-print moves – 130mm/s – was way too fast, which resulted in the ends of the filament lifting up with the nozzle. After modifying the settings of the non-print speed to 70mm/s I was finally able to get a perfect result. Regarding the speed in general, using the 30mm/s speed for perimeter printing and 60mm/s for all infills and bridges (with 20mm’s for gap fill) seemed to be the most fail proof set-up.

Using the included roll of 3mm filament, I printed the mug first with a 0.2mm layer height and a 0.4 fill density with perfect results. The outcome was very smooth on all parts of the mug. But when trying a more complex structure to further test the performance of the LulzBot, I printed out a cover for my SGS3 (The3DLibrary – Honeycomb case), the result was disappointing. I used the same settings, but ran into some problems with the honeycomb structure, which got distorted as the layer height seemed to be too low for creating an even result. I then changed the layer height to 0.3mm and tried again – now with a new apparent problem: the Slic3r’s default travel speed for non-print moves – 130mm/s – was way too fast, which resulted in the ends of the filament lifting up with the nozzle. After modifying the settings of the non-print speed to 70mm/s I was finally able to get a perfect result. Regarding the speed in general, using the 30mm/s speed for perimeter printing and 60mm/s for all infills and bridges (with 20mm’s for gap fill) seemed to be the most fail proof set-up.

To gain a better understanding of the capabilities of the LulzBot I tested several intricate designs – such as a couple of different rings with carved text – with a 0.1mm layer height. The AO-101 seemed to struggle with this, with the filament of the first layer not attaching to the printing bed properly. This happened with all of the tested models (different jewellery and artefacts with fine detail) – despite dropping all of the print move speeds to 15mm for trying to ensure better adhesive properties and co-operation with the filament and the bed. However, I was able to get good results with 50mm/s perimeter speed and 70mm/s for the infill – the most favourable fill pattern for higher speeds was rectilinear; honeycomb concentric didn’t bring good results. Above these speeds, however, the quality of the prints lowered significantly.

Overall a positive experience, then. The LulzBot AO-101 performs well overall. It might not be the fastest 3D printer on the market or capable of going under 0. 1mm heights with acceptable results, but it does perform solidly. I consider myself a complete novice as a 3D printer user, so ‘solidly’ is the key word here – the fact that the machine did not require any recalibration, but with the ideal settings did its job print after print is in fact its strongest point and the added value I was initially looking for. This also communicates excellence in terms of the build and design quality of the printer for me.

1mm heights with acceptable results, but it does perform solidly. I consider myself a complete novice as a 3D printer user, so ‘solidly’ is the key word here – the fact that the machine did not require any recalibration, but with the ideal settings did its job print after print is in fact its strongest point and the added value I was initially looking for. This also communicates excellence in terms of the build and design quality of the printer for me.

On the downside, the parts of the machine related to the filament, tend to have a slightly negative effect on the overall experience. As I mentioned earlier, a minor design flaw is revealed when attaching the filament guide to the printer’s top frame bar as the screws provided are slightly too short for doing this in a convenient manner. Another challenging aspect is apparent when loading the filament to the extruder unit – it requires some sleight to operate. However, the main weak point of the design is the filament spool and its arms designed to keep the filament roll in place. Even after repeatedly tightening the wing nuts as tight as humanly possible, eventually the inevitable happened – the arms sprung open and the roll of filament came partly off the spool – resulting in a tangled mess practically impossible to untangle in order to get going again.

Even after repeatedly tightening the wing nuts as tight as humanly possible, eventually the inevitable happened – the arms sprung open and the roll of filament came partly off the spool – resulting in a tangled mess practically impossible to untangle in order to get going again.

Despite the problems with the spool creating varying levels of annoyance, the pretty much perfect results from the printing are, of course, the most important thing. Therefore the overall experience is on good level.

[nggallery id=67]

Wrap-up

LulzBot AO-101 is a very solid performing 3D printer for the prosumer market. It is relatively fast and easy to start printing, provides consistent print quality and is open for modifying and tweaking according to the end user’s needs. The AO-101 also has a very sturdy design, which could even by stomped on during printing – literally.

Appearance-wise the beauty is in the eye of the beholder – it might be considered too industrial for some, but functionally beautiful to others. I myself belong to the latter group and find it very aesthetically pleasing.

I myself belong to the latter group and find it very aesthetically pleasing.

The negative aspects are related to some the functional parts of the design. The filament spool should be redesigned to better withstand the pressure from a full roll as well as the filament guide’s attachment to the frame.

But the bottom line – should you consider buying a LulzBot over the other options currently available in this class of 3D printer?

Unfortunately, I can’t give a yes or no answer here; the main reason being that there is no clear differentiating factor. In my opinion it’s priced realistically, it has specs to match its rivals and looks that even others besides a mother could love. But for me, the distinctive something – the intangible and emotional want-factor – did not come through. But it did offer a solid performance, which translates to reliability, trust and quality. I think if LulzBot takes this strong foundation and continues building on it, the company will do well. In a market where heritage is practically non-existent, this could be a factor that will be a cornerstone in creating a future success story.

In a market where heritage is practically non-existent, this could be a factor that will be a cornerstone in creating a future success story.

Big thanks to LulzBot and Kristin and Alicia from Wildrock PR & Marketing for providing the LulzBot for the purpose of this review.

Lulzbot AO-101 3D Printer Ready to Use out of the Box

Cabe Atwell | Feb 18, 2013

Watch This Webinar

As the increase in 3D printing popularity grows, so does the list of manufacturers that build them.

Since their inception in the early 80s, they have become smaller and more affordable, which has appealed to hobbyists around the globe. There was one drawback that impeded their growth in popularity -- initially there was "some assembly required" in order to use them.

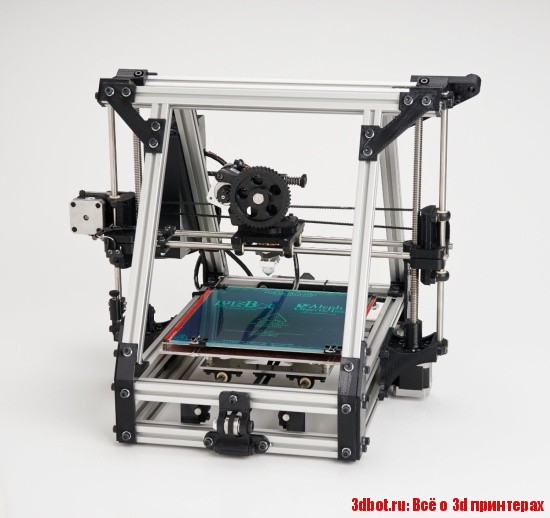

Not all users of 3D printers are adept at soldering or have limited building/assembling skills that were required for early models, such as Makerbot's Cupcake CNC machine or the RepRap (notably the Darwin and Mendel models). It is with this premise in mind, along with feedback from users of the previous model, that Lulzbot has developed and released its new 3D printer dubbed AO-101.

It is with this premise in mind, along with feedback from users of the previous model, that Lulzbot has developed and released its new 3D printer dubbed AO-101.

"Invent it, Create it, Produce it" is the motto Aleph Objects associated with the new printer, which makes the process of manufacturing prototypes and other creations easier for the average inventor. In essence, the AO-101 is an upgraded AO-100 based off of user feedback, and features the same overall design and sturdy frame (you can actually stand on it) of the 100 but incorporates improved electronics, sound reduction, and software.

The AO-101 upgrades over its predecessor aren't that extensive and feature pre-assembled installed RAMBo (RepRap Arduino-compatible Mother Board) electronics, a 12V DC 16A internal power supply (accepts PC power supply type plug), Budaschnozzle 1.2a hot end with available nozzle sizes from 0.25mm to 0.75mm, GT2 16 tooth pulleys, revised feed-tube, and filament spool-mount. The machines build volume has stayed the same as the 100s at 200mm x 190mm x 100mm, as well as its overall print speed at 200mm/sec. They have changed the Y belt tensioner so that it is adjustable, revised the Z-axis so there is less wobble while printing, and incorporated an aluminum heat tray.

They have changed the Y belt tensioner so that it is adjustable, revised the Z-axis so there is less wobble while printing, and incorporated an aluminum heat tray.

The printer also comes with an SD card that has the needed drivers and software pre-loaded (you may want to check Lulzbot's website for the latest revisions). They also were able to fit the whole set-up, including tools, 5 lb of free filament and replacement parts into one single box for shipping over the multiple boxes required by the AO-100.

The price for the Lulzbot AO-101 comes in at $1,725 US, which is decent for a pre-assembled printer of this quality. Others on the net have pointed out that the AO-101 is actually just a MendelMax variant that can be had at a reduced cost, but there is some assembly required. On the other hand, the 101 includes a set of tools, extra bed, a one-year warranty, and on-demand support, which is certainly an advantage for those not experienced enough to build their own machines.

Related posts:

- Implantable Cartilage Created With Hybrid 3D Printer

- Staples & Mcor Team Up to Bring High-Quality 3D Printing to the Masses

- Objet's Largest 3D Printer Doesn't Lose Precision

- Solidoodle 3 Provides High-Quality 3D Printing on the Cheap

- Patent Pushes Back Against 3D Printing Piracy

- Formlabs Launches 'Prosumer' 3D Printer

- Next-Gen 3D Printer Targets Professionals

- Engineer Pulls Trigger on 3D-Printed Gun

TAGS: Materials

Unsealed weapon / Habr

Grokru

Working with 3D graphics *

The Grizzly, the first 3D printed gun

new weapon models printed on a 3D printer. On Habré there was a detailed description of the sensational pistol "The Liberator" - How the "Liberator" works (Yes, we printed the gun). Its production required an $8,000 Stratasys Dimension SST printer. Very soon, Lulzbot improved the gun, which could already be printed on the Lulzbot AO-101 printer, costing only $1,700. nine0005

Its production required an $8,000 Stratasys Dimension SST printer. Very soon, Lulzbot improved the gun, which could already be printed on the Lulzbot AO-101 printer, costing only $1,700. nine0005

And the other day on Youtube there was a video of a test at the shooting range of a new rifle " The Grizzly ", named after the Canadian M4 tanks that were used during the Second World War. The author of the project is a Canadian under the nickname ThreeD Ukulele:

After a shot, longitudinal cracks about five centimeters long appeared on the barrel from both sides, as well as on the receiver. The author promises to improve the design. The gun is similar to The Liberator, many parts are identical, everything is printed on the same printer - Stratasys Dimension SST, the same caliber - .22L (5.6x15 millimeters). nine0005

In existing models of plastic weapons, there is only one metal part - the striker. And this means that it is much easier to carry such a pistol or even a rifle through the security service. Recently, while working on a report, Israeli journalists twice successfully carried a 3D-printed pistol into the Knesset (Israeli parliament) building, bypassing all security posts and metal detector frames. For the second time, a journalist with a weapon was in close proximity to Israeli Prime Minister Benjamin Netanyahu. nine0005

Recently, while working on a report, Israeli journalists twice successfully carried a 3D-printed pistol into the Knesset (Israeli parliament) building, bypassing all security posts and metal detector frames. For the second time, a journalist with a weapon was in close proximity to Israeli Prime Minister Benjamin Netanyahu. nine0005

And the Daily Mail journalists were able to ride the Eurostar train from London to Paris with the printed pistol "The Liberator"

I also advise you to watch a documentary about weapons printed on a 3D printer - Click. print. Gun from the Motherboard website:

It is very curious how this topic will develop in the future, not only the technical, but also the legal side of the issue is interesting: how will the state restrict the production of such weapons when the technology becomes simpler and 3D printers become much cheaper ? nine0005 Views

43K

Comments 58

Kirill @grokru

co-founder at Beau

Telegram

Comments Comments 58

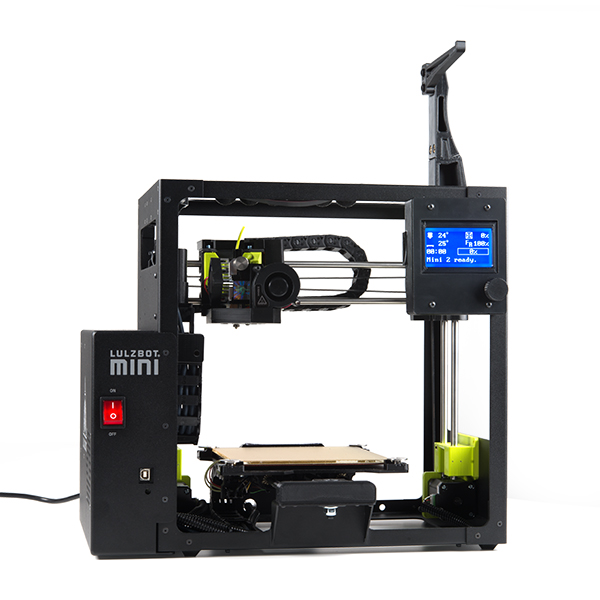

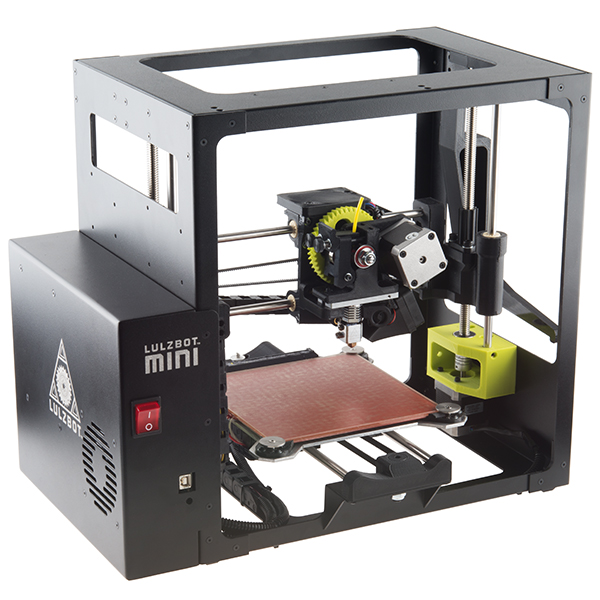

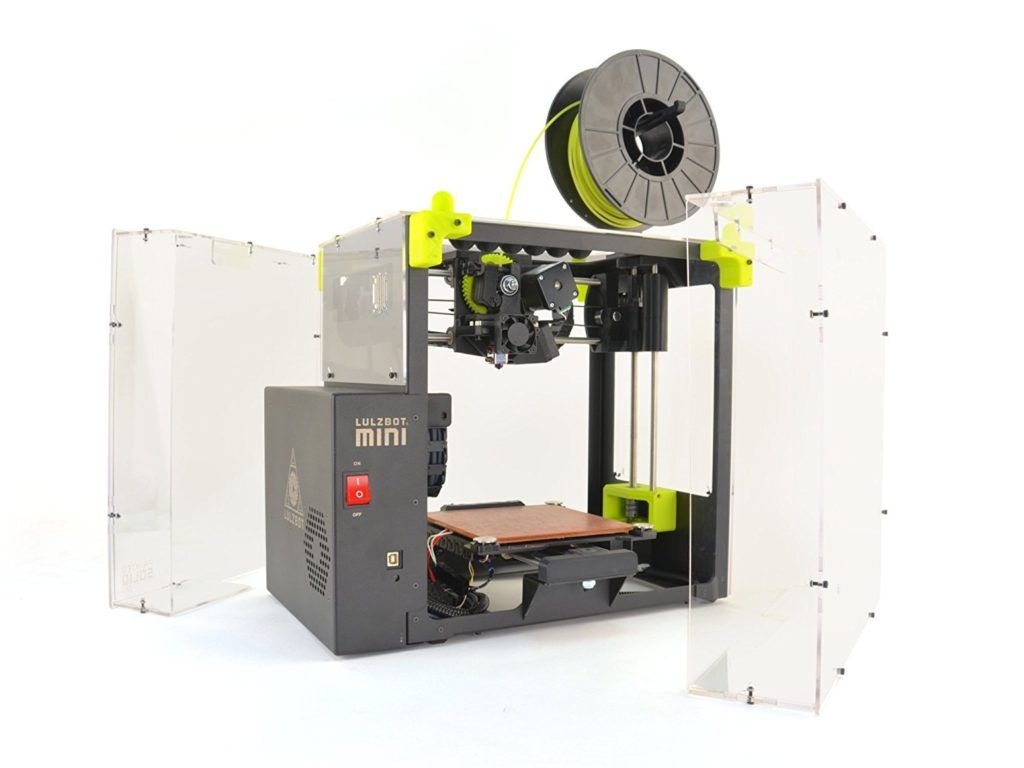

Overview of LulzBot Mini

open-source 3D printer The secret of a successful desktop 3D printer model may sound like this - set it up once and don't suffer anymore. All manufacturers strive to ensure that 3D printing is simple and painless. Your 3D printer should produce good results with minimal effort. nine0005

All manufacturers strive to ensure that 3D printing is simple and painless. Your 3D printer should produce good results with minimal effort. nine0005

Unfortunately, the reality is that most 3D printers designed for home, office or educational labs are far from ideal. If we put aside the promises of manufacturers and really high-quality marketing, the bottom line is this: a 3D printer is a very complex mechanism that requires patience and constant care.

And more often than not, printing doesn't work the way you want it to.

That's all to the fact that LulzBot Mini, which before this review was regularly used for several months, performed very well. Compared to other similar models, this 3D printer excels in excellent print quality and ease of use. nine0005

The best part is that it's open-source. So everyone who claims that open-source cannot match the quality of products with a closed ecosystem is wrong. In LulzBot Mini, important points for 3D printing are perfectly worked out and petty, not fundamental nuances are omitted. The result is a very high quality model.

The result is a very high quality model.

Pros

- Great for beginners

- Good design

- Great documentation

- Custom version of Cura 9 provided0048

- High -quality, stable results 3D Press

- amenable to modernization and expansion

- Automatic calibration and cleaning of nozzles

- PEI PRINT SURHFACE

Disadvantages

- . Optimized damage to the quality of small parts of the model

- Noisy

- Quite expensive compared to similar models in the class 9LulzBot Mini It might even be worth changing the name to “LulzBot Mighty” (English - mighty - powerful).

It is worth mentioning that working only from a laptop or a personal computer did not seem like the best idea at first. But with daily use, it turned out that if there is 1 less step in the 3D printing process (copying the G-code to a flash drive), then there are fewer errors. nine0005

Since the diameter of the extruder nozzle is 0.

5 mm instead of the usual 0.4, the printing speed is increased. This is good for large models, but reflects badly on the quality of small products with fine details. But the nozzle can be replaced by yourself. Oh, by the way, if you still prefer to work without a direct connection to a PC, you can implement it.

5 mm instead of the usual 0.4, the printing speed is increased. This is good for large models, but reflects badly on the quality of small products with fine details. But the nozzle can be replaced by yourself. Oh, by the way, if you still prefer to work without a direct connection to a PC, you can implement it. All in all, the LulzBot Mini has clearly been designed with love and attention to detail. As a result, its use will bring pleasure and high-quality printed products. nine0005

A little about the manufacturer Aleph Objects

Are you still reading? Fine. Then let's talk about the manufacturer itself. Aleph Objects is a small company based in Colorado, USA. Their business is based on the development of open-source components for 3D printing.

The company has earned a good reputation and popularity for its line of LulzBot 3D printers, which follow the RepRap philosophy and incorporate printed components into the design. Since it meets the open-source requirements, the LulzBot has received the "Respects Your Freedom" certification from the Free Software Foundation.

nine0005

nine0005 Based on all of the above, you can assume that the LulzBot Mini (or its older brother, the LulzBot Taz 6 model) will come as a DIY 3D printer kit. After all, it's open-source, so it should be built by geeks and engineers, right? But no. All 3D printers from the LulzBot line are already fully assembled.

Construction

The LulzBot Mini is a desktop 3D printer that uses Fused Deposition Modeling (FDM) technology. The material is pushed through the heated nozzle and the model is gradually formed, layer by layer. nine0005

The printer is working in a Cartesian coordinate system. The body is made of black, hardened metal. Some components (body parts, gear wheel of the feed mechanism) are made on a 3D printer. The extruder moves along the guides along the Z and X axes. The print table moves along the Y axis.

The material feed mechanism is a direct drive. Lulzbot Mini has one extruder.

Specifications

One of the features of LulzBot Mini is that there is no control panel.

There is also no SD card slot. There is only an on / off button and a USB output. As mentioned above, you definitely need a connected computer to work. This should be taken into account when buying. nine0005

There is also no SD card slot. There is only an on / off button and a USB output. As mentioned above, you definitely need a connected computer to work. This should be taken into account when buying. nine0005 General specifications are as follows:

- Heated print bed made of sealed borosilicate glass

- 3D printable area 152 x 152 x 158 (6 x 6 x 6.2 inches)

- Printable capacity is 3,650 cm3 ( 223 in3)

- Maximum print speed 275 mm/s (10.8 in/s) with layer height 0.18 mm

- Layer thickness 0.05 to 0.5 mm (0.002 to 0.020 in)

- Suitable media diameter 3 mm (0.1 in)

It is worth noting that automatic print table calibration, automatic nozzle cleaning, and a special PEI print surface are provided. More details about all this below.

Unpacking and setup

LulzBot Mini is neatly packaged. The kit comes with a small set of tools and documentation. Moving parts are fixed.

Includes model octopus (Rocktopus).

It was printed on this 3D printer of yours as a final test before shipping. nine0005

It was printed on this 3D printer of yours as a final test before shipping. nine0005 The documentation is very high quality. It consists of three parts. In the first list of components and parts, notes on precautions. The second part is an image of a 3D printer, where the main components and parts are marked, the terminology is clarified and there are links to additional useful sources of information.

And the last part is a beginner's tutorial that walks you step by step through the setup process, software installation, calibration, material loading and finally your first 3D print. Again, the instructions are very well written. nine0005

Materials

In terms of the ability to use different materials, almost the whole world of 3D printing is at your feet! LulzBot Mini can print ABS, PLA, HIPS, PVA, wood based materials, polyester (Tritan), PETT, copper and bronze materials, polycarbonate, nylon, PETG, conductive PLA and ABS plastics, luminescent materials, PCTPE, PC- ABS, Alloy 910, and many more.

But please note that 3D printing with materials with carbon additives is not recommended by the manufacturer. These materials have very good physical properties, but at the same time, due to the abrasive, the nozzle and the extruder itself wear out a lot. nine0005

During testing, we mainly printed Verbatim PLA, Biofila Silk and ColorFabb GlowFill. I also tried ColorFabb XT, Innofil3D PET and NinjaTek Armadillo (mostly for printing spinners, but that's another story).

Software

In the spirit of open-source, you can choose any 3D printing software. Cura LulzBot Edition is included. Other suitable softwares include OctoPrint, BotQueue, Slic3r, Printrun, MatterControl, etc. nine0005

Cura LulzBot Edition is a reworked version of Cura which unfortunately slices the model slower than the current version. The user interface has been redesigned, but in principle it resembles older versions of Cura, but in light green color tones.

The program is not only configured to work with your LulzBot Mini, but also provides a library for customization for different 3D printing materials.

There are a set of quick settings that depend on the media and print quality. The library of materials is quite large, it contains most of the popular grades of materials from different brands. You can also select the print quality - “standard” (standard), “high speed” (high speed) and “high detail” (high detail). nine0005

If you are a demanding, experienced user, you can switch to expert mode and set your own settings.

When the model is loaded, you can start 3D printing from the control panel. The same panel displays the status of printing and the 3D printer itself in real time. The format is quite convenient. From personal experience, we can say that it is even more convenient than tracking on built-in LCD screens. But this is already individual.

3D printing process

The working space of the LulzBot Mini is 152 x 152 x 158 mm. This is quite enough for a desktop 3D printer.

Before printing, two small but very important operations are carried out that directly affect the quality of 3D printing.

First, the extruder nozzle is cleaned. To do this, the kit comes with several pieces of special material. Later you can buy it. It is advisable to clean the nozzle before each new print. Thanks to this, the print will be of high quality from the very beginning. nine0005

Secondly, the print head is calibrated against the table. Since the table only moves along the Y axis, the calibration process is simpler than with Ultimaker or BCN3D Sigma, in which the table moves along the Z axis. Calibration of the LulzBot Mini is done by simply clamping the metal contacts in the corners of the table.

After calibration is completed, the working head moves into position and the nozzle starts to warm up.

A little more about the 3D printing process

The LulzBot Mini is not as quiet as it should be during operation. And this is despite the presence of IGUS polymer bushings on the guides.

The first layer lays down very well. Additionally, it is not necessary to increase the adhesion of the table.

This is due to the fact that a PEI table with a polyesterimide coating is used.

This is due to the fact that a PEI table with a polyesterimide coating is used. As for the products themselves, they are of very good quality. Moreover, the print quality is stable, from part to part. Since the nozzle diameter is 0.5 mm rather than the more usual 0.4, Lulzbot Mini gains in print speed, which is very good for large objects, but can be negative for printing small models with many small details. nine0005

Upgrade

Above, we focused on the ease and affordability of using the LulzBot Mini. This is because we are assuming that this is your first 3D printer. And trust me, you won't be disappointed with standard operations.

But that shouldn't limit the open source community where most people want to be able to experiment and understand the "innards" of a 3D printer. In how the design is implemented and what is needed in order to assemble your own analogue. Well, LulzBot Mini takes this into account. nine0005

You can find comprehensive information about optional upgrades and simply learn how it all works on the Open Hardware Assembly Instructions page.

Learn more