3D printed homes michigan

Michigan’s first 3D printed house coming to Detroit in 2023

We were founded in 2020 with the mission of reporting on issues that matter to Detroiters. We do this every day through our community-driven stories and engagement. Will you help us keep writing in 2023? Your tax-deductible donation of any amount will be matched dollar for dollar by the NewsMatch DEI Partner Fund!

Donate

Skip to content

Posted inHousingby Bryce Huffman

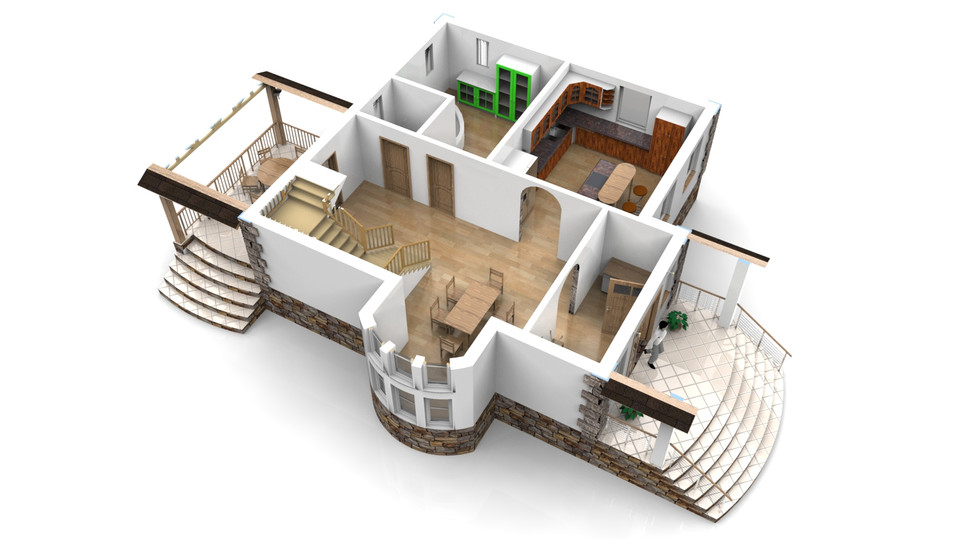

A 3D printer is laying the concrete for the first wall in the city’s first 3D-printed house. The 850-square-foot, two-bedroom, one-bath house will be geared toward senior living. (BridgeDetroit photo by Bryce Huffman.)A 3D-printing robot has begun creating the concrete walls for Detroit’s first factory-printed home.

The nonprofit Citizen Robotics began the work Tuesday in its warehouse in southwest Detroit. The house, also expected to be the first in the state of Michigan, will be built in sections and later assembled in the Islandview neighborhood on the city’s southeast side.

The single-story, two-bedroom house will be 850 square feet and marketed to low-income individuals earning 80% of the area median income – which is about $50,240 for a two-person household in Detroit.

Tom Woodman, executive director of Citizen Robotics, said if cities, states, and construction companies don’t begin to invest in the technology that makes building this home possible, “our housing stock will continue to decline.”

“Then the cost of housing will continue to go up and we’ll no longer be able to afford to live in vibrant walkable communities,” Woodman said.

Tom Woodman is the executive director of Citizen Robotics, which is building a 3D-printed home that will be located in the city’s Islandview neighborhood on the southeast side. Woodman expects building homes with this technology will make homes more energy efficient. (BridgeDetroit photo by Bryce Huffman)

Woodman expects building homes with this technology will make homes more energy efficient. (BridgeDetroit photo by Bryce Huffman)A shift toward 3D-printed homes can help fill two of Detroit’s needs: more affordable housing units and making use of this city’s wide swaths of vacant land – about 19 square miles, according to Detroit Future City. Woodman told BridgeDetroit in April that he chose Detroit for the project because the city is “striving for solutions.”

Citizen Robotics also has other 3D-printed home projects planned for Flint and Grosse Pointe Woods. One of the benefits, Woodman said, is that 3D-printed homes are expected to need much less energy to heat and cool than a house made with conventional construction.

“That’s not only better for the future homeowners’ budget, it’s also more sustainable for the planet,” he said.

The structure of the home is expected to be done by the end of the year. The entire project, designed by Bryan Cook of Develop Architecture, who also is president of the Detroit chapter of the National Organization of Minority Architects, is expected to be fully complete in spring 2023.

Cook watched the printing robot Tuesday as it put down the first layers of concrete for one of the walls of the home and said “there’s still a lot of work to go.”

“But it feels really good to be standing here and actually like to see that it’s going up,” Cook said. “It’s happening so I’m just very proud and excited.”

Detroit City Councilman Coleman A. Young II recently requested an analysis from the council’s legal and policy staff on the prospect of a pilot program to build 3D houses in the city’s most impoverished neighborhoods. He was seeking input from Detroit’s Housing and Revitalization Department and evaluating if the city could acquire a 3D printer and what it would cost.

The entire project in Detroit will cost about $230,000, according to Evelyn Woodman, the co-founder of Citizen Robotics, which is paying for some of the construction costs.

The Michigan State Housing Development Authority (MSHDA) is covering the remaining $150,000. MSHDA officials have said the 3D house in Detroit will serve as a “proof of concept project” to help the state determine whether 3D home building is sustainable, cost-effective and energy efficient.

Last summer, Gov. Gretchen Whitmer joined with Detroit Mayor Mike Duggan and Citizen Robotics at the nonprofit’s warehouse to announce the state’s plan to invest $100 million in federal COVID-19 relief funding toward the construction of thousands of affordable homes statewide.

The first full 3D printed home in the country was unveiled at Austin’s South by Southwest conference in 2018, according to a city policy brief.

Thanks to all the funding partners who make BridgeDetroit possible!

A list of BridgeDetroit's funders can be found here.

Bryce Huffman is a reporter for BridgeDetroit. He was formerly a reporter for Michigan Radio, and host of the podcast, Same Same Different. More by Bryce Huffman

Get quality, relevant, multimedia journalism and information that is directly responsive to Detroiters’ information needs and desires.

Submitting...

Thank you, your sign-up request was successful! Please check your email inbox to confirm.

{{message}}

Leave this field empty if you're human:BridgeDetroit is powered by generous grant support from the Knight, Ford, Erb, Skillman, Kresge, Wilson, McGregor, and Hudson-Webber foundations, the Community Foundation for Southeastern Michigan, and Facebook.

Gov. Whitmer, MSHDA Celebrate Start of Construction on Detroit’s First 3D-printed Home

Media Contacts:

- Katie Bach, [email protected]

- Anna Vicari, [email protected]

Citizen Robotics founder, MSHDA and project architect to speak on the project’s impact on homebuilding innovation

LANSING, Mich. – The Michigan State Housing Development Authority (MSHDA) celebrated the construction kickoff of Detroit’s first 3D-printed home during a Wall Printing Ceremony in Detroit today. The event, hosted by Citizen Robotics, is the first step in utilizing and investing in advanced homebuilding techniques in Michigan.

The construction of the two-bedroom, 1,000-sq. ft. home, meant for senior living, will utilize robots and 3D-printing technology to lower construction cost, minimize environmental impact and attract and train young people in advanced construction techniques.

“3D-printed homes are an innovative, cutting-edge endeavor with the potential to change the affordable, attainable housing landscape in Michigan,” said Governor Gretchen Whitmer. “Today’s Citizen Robotics project is an exciting first step as we continue exploring innovative homebuilding programs. If this pilot proves that we can effectively scale up the 3D-printed home production, we can lower construction costs, reduce environmental impact, and create good-paying jobs. Together, let’s build more places for people to call home.”

The ceremony began with words from Citizen Robotics Founder Tom Woodman, the architect of the project Bryan Cook and Director of Neighborhood Housing Initiatives at MSHDA, Tonya Joy, who discussed the purpose of the project and its impact on the future of homebuilding. Following the remarks, attendees were able to witness the first walls of Detroit’s inaugural 3D-printed home be printed.

Following the remarks, attendees were able to witness the first walls of Detroit’s inaugural 3D-printed home be printed.

“This initiative is an exciting part of MSHDA and the governor’s goal to increase Michigan’s stock of safe, attainable housing for folks across the state,” said Joy. “We believe alleviating Michigan’s housing issues will take a collective effort between housing developers and government organizations to implement thoughtful and impactful programs – and 3D-printed homes could be a part of that solution.”

This project productively supports desired goals for the City of Detroit, including walkable neighborhoods, increased affordable housing, support for minority real estate developers, among others, and was made possible via a grant from MSHDA, according to Citizen Robotics.

Michigan residents can learn more about MSHDA’s efforts to address housing issues at https://www.michigan.gov/mshda.

About MSHDA

The Michigan State Housing Development Authority (MSHDA), established in 1966, provides financial and technical assistance through public and private partnerships to create and preserve safe and decent affordable housing, engage in community economic development activities, develop vibrant cities, towns and villages, and address homeless issues.

###

An American printed a house in 24 hours on a 3D printer of his own design

News

Today, the 3D printed construction industry tends to be dominated by large corporations with big budgets. Nevertheless, startups and individual makers do not intend to stand aside and periodically make the world freeze with delight, demonstrating their wonderful ideas and the results of their implementation. Among them is Alex Le Roux, a student from Houston, Texas, who just completed a 3D printed house project, the first 3D printed residential building in the United States. In his work, he used a V2 Vesta 3D printer of his own design. nine0003

Of course, this is not the first 3D printed house in the world. The first place was taken by the Chinese company WinSun back in 2014. Well, how not to remember the fantastic castle of Andrey Rudenko?

And yet, Alex was the first in the US to build a 3D printed building that you could live in. .. theoretically. This building is the continuation of a project that has been going on for a couple of years. It all started with the fact that a year ago, a student of the Faculty of Mechanical Engineering at Baylor University independently assembled a construction 3D printer with a working volume of 2.4 m x 2.4 m x 2.4 m, printing with concrete. nine0003

.. theoretically. This building is the continuation of a project that has been going on for a couple of years. It all started with the fact that a year ago, a student of the Faculty of Mechanical Engineering at Baylor University independently assembled a construction 3D printer with a working volume of 2.4 m x 2.4 m x 2.4 m, printing with concrete. nine0003

The 3D printer is based on RepRap blueprints and diagrams, made available to the public. At the end of 2015, a student assembled an updated version of the V2 Vesta with a working volume of 3 m x 3 m x 3 m, with which it was possible to build a quite decent concrete house. This RepRap 3D printer, like its predecessor, is designed for use right on the construction site and in harsh weather conditions. While most concrete 3D printers need to be used indoors (and then incur the additional cost of transporting the blanks to the construction site), the V2 Vesta can work right on the construction site. What's more, it only takes 30 minutes to set up for the first time, making it extremely user-friendly and easy to manage. nine0003

nine0003

The technical specifications of the V2 Vesta are impressive: print speed is about 9 cm per second (horizontal) and flow rate of liquid concrete is 4 liters per second. Alex had only to demonstrate it in action to prove all of the above. This is how the Tiny House project was born. And as you can see in the photos, it ended in success. Although it looks more like a barn than a house, this 2.4 m x 1.5 m x 2.1 m structure is still a clear demonstration of the capabilities of a 3D printer and is admired. nine0003

According to Alex, the printing process did not cause any problems. The project was partly funded by Modeco Development LLC and took only 24 hours to complete. During such construction, the presence of only one person is enough, who monitors the operation of the computer and fills the concrete into the printer.

Among other things, Alex used a relatively inexpensive Portland cement mix, ie. his costs were reduced to a minimum. Other makers may, of course, experiment with more environmentally friendly cement mixes, which will only make this zero-waste technology even more attractive. nine0003

Other makers may, of course, experiment with more environmentally friendly cement mixes, which will only make this zero-waste technology even more attractive. nine0003

While you and I definitely don't want to live in such a house (even a mattress won't fit in it!), it's obvious that Alex is moving in the right direction. In August, he plans to introduce the third version of his V3 Vesta 3D printer, which will print three times faster than the V2. He also received a commission to print a house in Michigan. Now Alex is trying to find financial support from institutional investors. Considering the pace at which he moves, he will definitely succeed.

Source

Subscribe author

Subscribe

Don't want

2

STL file Lansing, MI 1943・Model for download and 3D printing・Cults

sonic 3d lego spinner - with mesh

0,61 €

Pokémon fish aquarium house - or home decor 3d model

0. 61 €

61 €

Funny Cartoon Joke Sport Indoor/Outdoor Sign

0.85 €

Unicorn - 3d model

2.82 €

Daffy Duck - 3d foil card + night light cover

1.17 €

Family Guy - Herbert the pervert 3d model with mesh

1.55 €

3d model Dante's Inferno

0.61 €

nine0004 jesus - do it yourself cross tile night light0,65 €

The best files for 3D printers in the Tools category

P[L]AN-B

3 €

Dagoma Discoeasy 200 Coil Holder

Free

Pentax K-01 SMC DA-40mm lens cover

Free

nine0004 BIC Mini Waterproof Case (Floats)Free

Cover for Raspberry Pi 3

Free

Pattern roll

Free

Low Cost Seed Drill for Hard Soil

Free

Bestsellers in the Tools category nine0075

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang.

CR-10, Micro Swiss direct drive and bowden compatible. No support required for printing

CR-10, Micro Swiss direct drive and bowden compatible. No support required for printing 1.56 €

telephone ring holder

0,90 €

ENDER 3 S1, S1 PRO, SPRITE, HOT END DUCT 4020 OR 5015 FAN, PROBE NO Y OFFSET

€2.28 -twenty% 1.82 €

Tool holder for 3D printer V3.0

1.03 €

PRECISION CALIPER 3D PRINT DIY

3,12 €

Fire hydrant storage container

1.88 €

Quick print stackable parts containers / storage boxes

2.83 €

Business card embossing system

3 €

ENDER 3 S1/S1 PRO REEL HOLDER AND DEPORTED COIL

€2. -twenty% 1.70€ 12

12

ENDER 3 S1, S1 PRO, SPRITE, V3 AIR DUCT FAN 5015, ACCELEROMETER, LED strip

€2.68 -twenty% 2.14 €

PRECISE DIAL INDICATOR 3D PRINT DIY

1.91 €

Ender 3 S1 BEST cable guide - vertical

€2.50

Armadillo - flexible wire conduit

€1.67 -10% 1.50 €

INDICATOR FOR BETTER BED LEVELING FOR ENDER 3 V2

2.81 €

PET-Machine, make your own plastic bottle filament at home! nine0005

15 €

Cooling system Minimus Hotend

€2.![]()

Learn more