3D printed bacteria

Researchers Are 3D Printing With Bacteria to Create Bone-Like Composites

3D printing news News Researchers Are 3D Printing With Bacteria to Create Bone-Like Composites

Published on February 28, 2023 by Madeleine P.

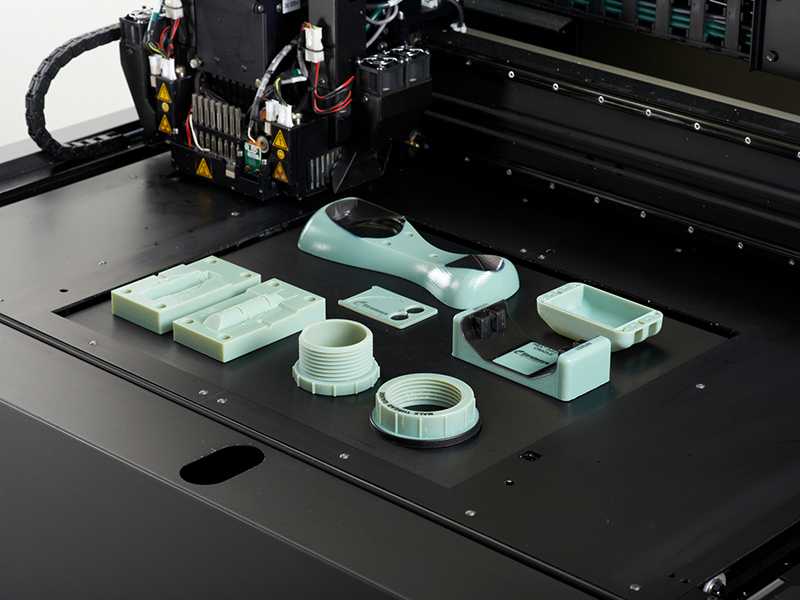

It is well known that 3D printing can be done with any numbers of unusual materials including cells, chocolate and more. But what about bacteria? Well, in a recent project, EPFL (École Polytechnique Fédérale de Lausanne AKA the Swiss Federal Institue of Technology Lausanne) researchers have done just that. More specifically, they have published a method for 3D printing with an ink that contains a calcium carbonate-producing bacteria. The resulting biocomposite has a number of interesting applications and is strong, light and environmentally friendly.

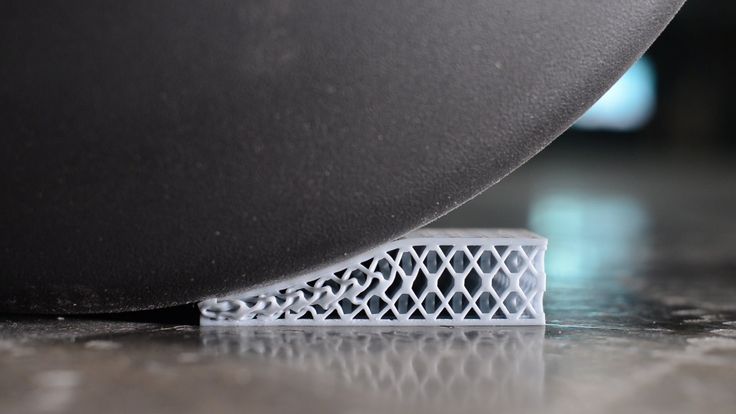

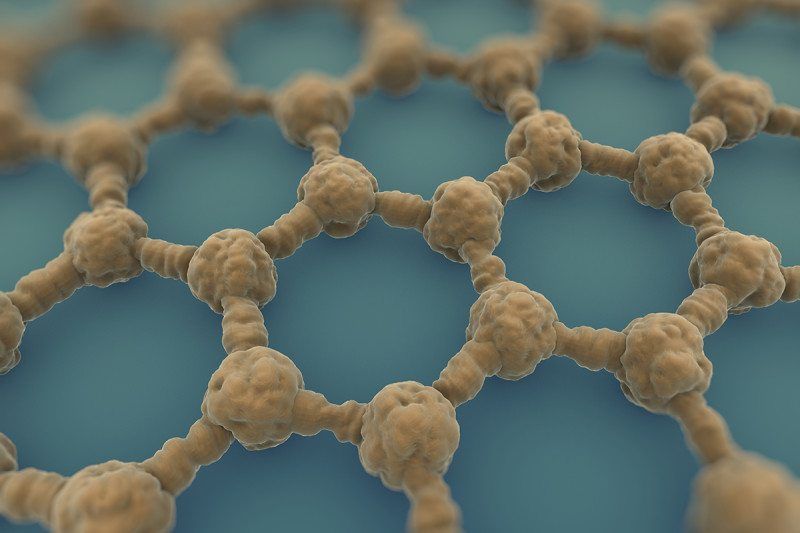

This is certainly not the first time that scientists have turned to the wider natural world to seek solutions for additive manufacturing. In fact, biomimicry, or the practice of imitating life, is popular in 3D printing as it allow for more optimization of parts, such as with lattice structures which imitate beehives. A similar reasoning is behind this project. The researchers looked towards nature which is able to produce composite materials that are simultaneously light and strong, porous and rigid (nearly impossible to do in a lab or factory) such as with mollusk shells or bone. Ultimately, they hope to produce materials that have these properties while also being environmentally friendly. Now with this this 3D printable ink, they have achieved just that.

By combining a bacteria-loaded ink (called BactoInk) and 3D printing, the scientists have successfully created a strong, light and environmentally friendly biocomposite

3D Printing Bacteria to Create Better Composites

In the paper published in Materials Today, 3D printing of living structural biocomposites, researchers at EFPL’s Soft Materials Laboratory, outlined how they were able to create the process. Namely, they created a 3D printable ink using the bacterium Sporosarcina pasteurii. This bacterium was chosen because it has an interesting ability, when exposed to a urea-containing solution, a mineralization process that produces calcium carbonate (CaCO3) is triggered. The new ink, dubbed BactoInk, is capable of printing virtually any shape and then will mineralize over the course of a few days.

The new ink, dubbed BactoInk, is capable of printing virtually any shape and then will mineralize over the course of a few days.

The choice to use an ink that would mineralize was due to a need to get around issues often centered on 3D printing with inks (namely that they can be difficult to manage as they require certain flow conditions and also tend to be soft or shrink after printing). The Soft Materials Lab head, Esther Amstad explained, “So, we came up with a simple trick: instead of printing minerals, we printed a polymeric scaffold using our BactoInk, which is then mineralized in a second, separate step. After about four days, the mineralization process triggered by the bacteria in the scaffold leads to a final product with a mineral content of over 90%.”

Co-authors and Soft Materials Lab researchers Matteo Hirsch and Lorenzo Lucherini

The result is a strong and resilient biocomposite that can even be produced using a standard 3D printer. Moreover, the final products no longer contain living bacteria. The material is also particularly interesting because it is not only strong and light, but porous which can be quite difficult to achieve with additive manufacturing.

The material is also particularly interesting because it is not only strong and light, but porous which can be quite difficult to achieve with additive manufacturing.

The researchers have already outlined a number of applications for the material in different fields. One application is of course the restoration of artworks, as the ink could be directly injected into the site and then just grow to fit the crack or chip. But thanks to its use of environmentally friendly materials, it could also be very exciting for building artificial corals in order to regenerate damaged marine reefs, a pressing environmental concern.

Amstad, concludes, “The versatility of the BactoInk processing, combined with the low environmental impact and excellent mechanical properties of the mineralized materials, opens up many new possibilities for fabricating lightweight, load-bearing composites that are more akin to natural materials than to today’s synthetic composites.” If you would like to learn more, you can find the full study HERE.

What do you think of the EPFL researchers’ work in using bacteria-loaded ink and 3D printing to create biocomposites? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Eva Baur/EPFL

Bacteria best 3D printer files・Cults

Bacteriophage Anatomy

€18.01

Dragon ball Bacterie

Free

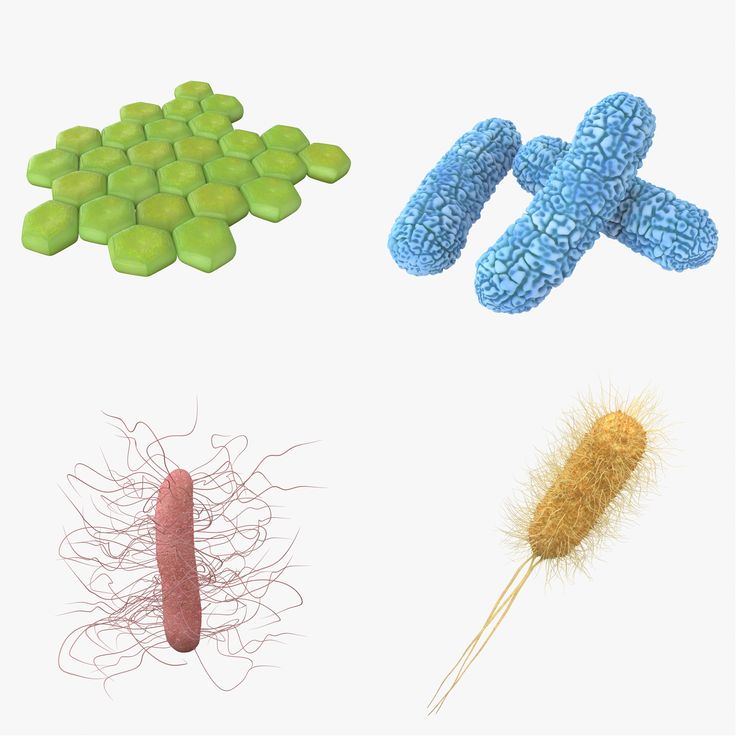

Prokaryotic Bacterial Cell Anatomy

€27.50

Toon Bacteria

€3.09

funny shapes

€2

Gradius III Bacterion

Free

Bacteria (Prokaryotic) Cell

Free

Aquarium BioBall

Free

Fago key ring

Free

File: Fog lamp attachment in digital format

Free

Bactérie Gram- aimantée - Magnetic Gram negative bacteria

Free

Mask Holder 3D print model

€1

Petri Dish Rack, 9 x 90mm Plates

Free

BIOHAZARD

Free

Bacteriophage

€9. 47

47

Antibody-bacterial model

Free

Mask attachment : Optimization : lecutterjaune

Free

Coronavírus COVID-19

Free

PocketBac Hand Sanitizer Clip

Free

Sanitizer Lighter - Push button

Free

Coronavirus protects against Trump

€0.90

Bacteriophage to assemble

€5

Tool - Non-contact - Optimization: gun

Free

Covid19 Hands free door handle opener.

Free

anti covid-19 shopping trolley handle

€0.56

Coronavirus cookie cutter Covid-19 bacteria

€0. 82

82

Coronavirus coffee or food stencil COVID-19

Free

pink virus crown

€1.90

Corona virus bacteria

€2.10

handless door opener

Free

Corona Virus Pod

€9.06

Coronavirus COVID-19

€15.03

E. Coli Led Lamp

Free

Immune system cookie cutter colection WIP

Free

Bacteria Cookie Cutter

Free

vertical soap holder

€2.50

chemistry and biology kit

Free

Prismatic soap holder

€2. 50

50

Bacterial "ink" for 3D printer | Nauka i Zhizn

With the help of three-dimensional printing of bacteria, it is possible to quickly create a variety of chemical sensors and even microcircuits for a "cellular computer".

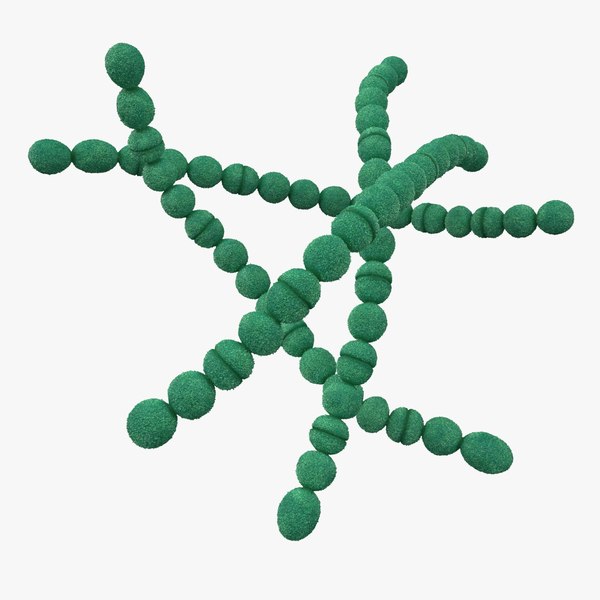

Hand with 3D printed bacterial tree; the three parts of the figure correspond to three different genetic modifications of the bacteria. (Photo: MIT.)

In the printed tree of bacteria, the three parts of the pattern reacted to each substance. (Photo: MIT.)

‹

›

View full size

3D printing technology allows the use of a variety of substances as "ink". Indeed, in recent years, everything has been loaded into 3D printers, ranging from ingenious thermo- and light-sensitive polymers, from which objects are made that change shape when temperature or light changes, and up to proteins, from which semi-synthetic organs are created. (We once wrote about one such organ - it was the ovary, the protein framework for which was created precisely with the help of a 3D printer. )

)

Moreover, from time to time, researchers try to print something directly from living cells. But so far, cell printing has not advanced far, for the simple reason that our cells, which are protected from the external environment by only a two-layer lipid membrane, do not withstand the conditions of the method and die.

But what if we take not human and animal cells, but bacteria? After all, in addition to the membrane, they also have a fairly powerful cell wall, and in general, bacteria are not as sensitive to extreme influences as eukaryotic cells, so it is quite possible that they will easily survive a 3D printer.

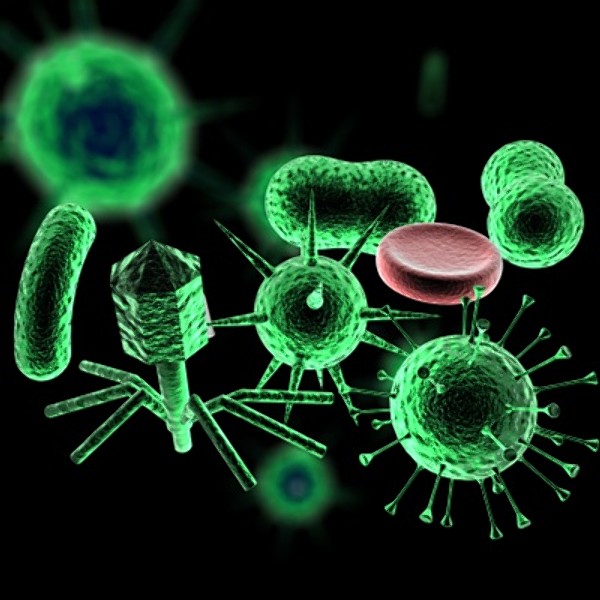

To print with bacteria, they need to find an environment in which they could live, being applied to the surface. In the bacterial "ink" created by Xuanhe Zhao ( Xuanhe Zhao ) and his colleagues at the Massachusetts Institute of Technology, a hydrogel based on pluronic acid was used as a carrier for bacteria: such a hydrogel retains water with nutrients, allowing cells to live and function, and is quite suitable for 3D printer.

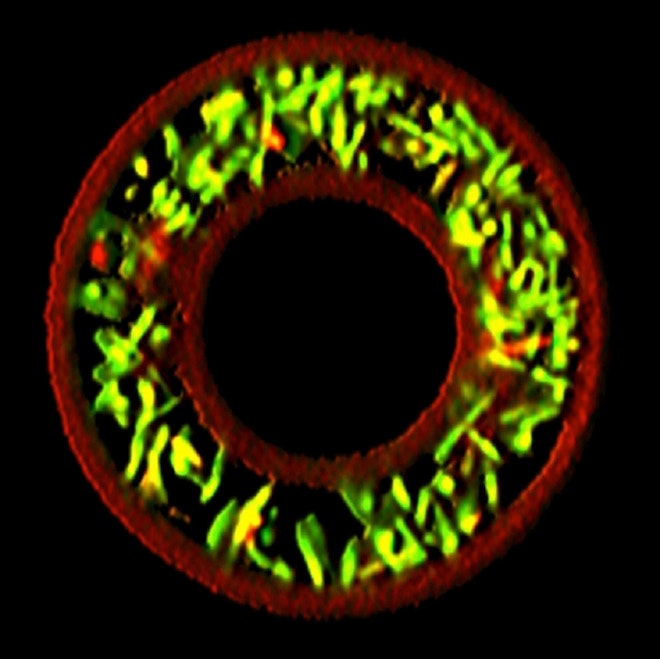

Before the experiment, the bacteria underwent genetic modification, which made them sensitive to a particular substance: if the desired substance appeared in the medium, the bacteria synthesized a fluorescent protein. Then, using a 3D printer, a tree-like pattern was printed on a special elastic material, consisting of three types of bacteria that react to three different substances (it is clear that the printer allows you to mix and alternate the “ink” as we please). The resulting pattern was glued to a human hand, which had previously been moistened with a solution with three types of signal molecules - and as a result, the pattern on the hand began to glow: different bacteria each felt their own substance and made a fluorescent protein in response.

An article in Advanced Materials states that bacterial "3D ink" allows printing at very high resolutions of up to 30 micrometers, which in turn is suggestive of bacterial microcircuits, in which groups of bacteria perform logical operations, similar to microcircuits. in computer.

in computer.

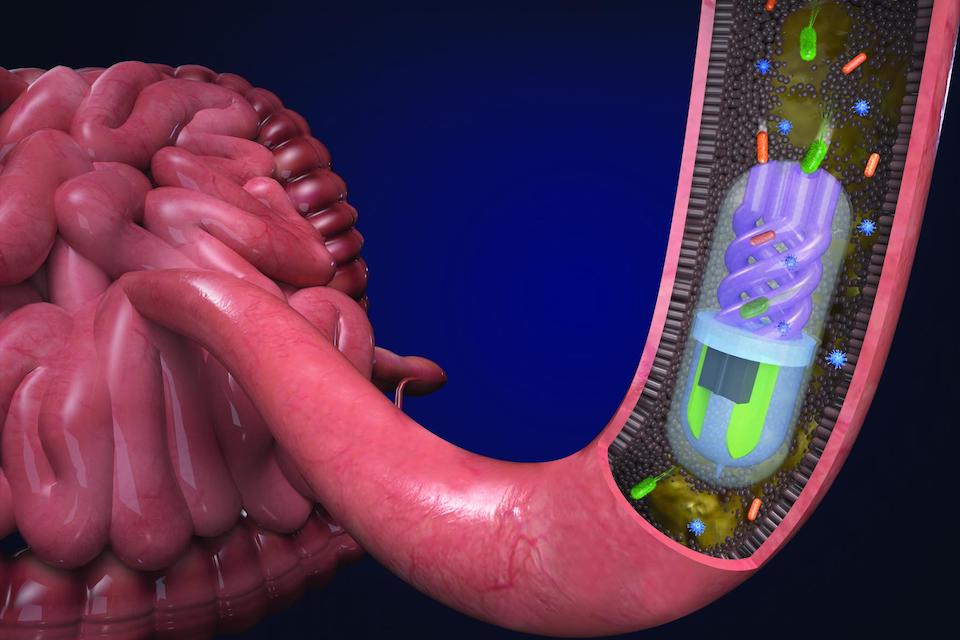

We have already written about the bacterial calculator. Its essence is that bacteria process certain chemical signals, which can be combined according to the rules of logical operators AND, OR, etc. In the case of a bacterial microcircuit, bacteria can transmit signals to other bacteria, which, depending on the combination of signals, will formulate a response. Such a microcircuit may well analyze the complex chemical conditions of the environment, taking into account combinations of different substances, temperature, etc. (Some of these microcircuits were printed by the authors of the work themselves.)

But even if we do not think about “cellular computers” yet, then in a simple form, bacterial “printouts” can play a big role in biotechnology and medicine. Since genetic engineering methods make it possible to "tune" bacteria to a variety of compounds, one can imagine how many different chemical sensors can be made quite quickly using 3D printing, in addition, they can be used to make smart drugs that would release drugs at a strictly defined time and under strictly defined conditions.

Will 3D printed bacteria be the electronics of the future?

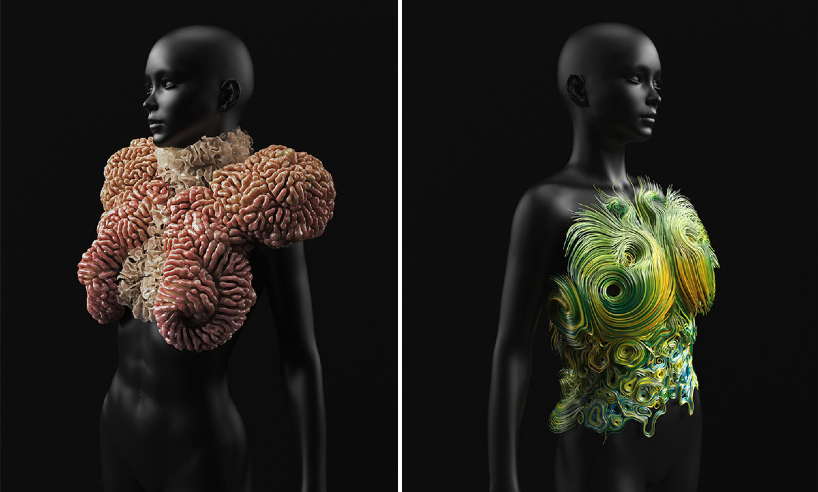

"Wearable technology" - the so-called "smart" electronic devices that can be worn on oneself or implanted in the body. Offering enticing prospects for innovative technology developers in sports, healthcare, fashion and entertainment, 3D printing opens up new possibilities for wearable technology such as second e-skin and smart fabrics.

In a recent study, a team of scientists from the Massachusetts Institute of Technology (MIT) has developed a "living" biological ink for 3D printers that is not only "smart", but also has the potential to completely change the way we think about this technology. Using the natural reactions of bacteria, devices made with such inks are the basic building blocks of wearable technology that does not use electricity.

This 3D printed bio-ink comes from the same MIT group that recently came up with soft robotic fishing gloves. The new ink expands the vast portfolio of smart materials being developed at MIT.

3D printing and programming of genetically engineered bacteria

This materials research at MIT was led by Prof. Xuanhe Zhao and Dr. Timothy Lu of the Soft Active Materials Laboratory. As a proof of concept, a team of scientists demonstrated how bacteria in 3D printer bioink can be genetically modified to glow when it receives a specific chemical signal.

First, the ink is prepared, the ingredients of which make it an ideal microenvironment for living matter. To the hydrogel base, the scientists added a photosensitizer that provides the setting of the material, as well as bacterial cell granules, nutrients and deionized water.

When preparing the ink, it was very important to choose the right bacteria because previous attempts using other cells had failed. “It turned out that these cells died during the printing process, because mammalian cells are basically two-layered lipid bubbles,” explains Hyunwoo Yuk, one of the co-authors of the study. “They are too weak and break easily. ”

”

Bacterial cells were chosen because the walls protecting them are able to withstand the pressure of the 3D printing process and live in the aquatic environment of hydrogels. The bacteria have been genetically modified to allow them to produce green fluorescent proteins (GFPs), either normally or when activated by a specific chemical signal.

3D printing of complex living structures with living ink

As a first example, scientists 3D printed complex structures visible to the naked eye (3 cm in size) with microscopic precision (30 microns).

This included a square, a solid pyramid, a pyramid with voids, and a dome. These complex designs were designed using SOLIDWORKS and CADfusion software, then cut into layers and printed at room temperature using Aerotech's 3-axis robotic application technology.

Hydrogel ink was dispensed from a 5 ml UV-impermeable syringe barrel through nozzles ranging in diameter from 30 to 250 µm.

Initially, the ink was applied by a 3d printer on a cross matrix. This design was necessary to ensure the viability and sensitivity of cells in a living network. Chemical crosslinking was then created by exposing the 3D printed hydrogel to UV light. Thereafter, the cross-linked hydrogel ink was placed in humid conditions.

To demonstrate how different signaling chemicals can activate GFP production in different areas of the mold, the scientists 3D printed a pyramid using two different strains of bacteria.

When exposed to a specific chemical signal, the top and base of the pyramid turned fluorescent green, while the sides remained red.

Complex objects 3d printed using living hydrogel ink. Photograph by VCH-Verlag.3d printing of living tattoos

The second example was the use of three different hydrogel inks, using different strains of bacteria. Here, 3D printing has been used to create a "living tattoo" that reflects the presence of certain chemical signals on the skin.

The tattoo was printed with cells of living bacteria, and was a tree-like pattern on a thin layer of elastomer. Then it was glued to human skin.

Three branches of a tree were 3D printed with different strains of live bacteria that respond to different chemical signaling compounds. Within hours, tree branches began to glow when the bacteria reacted to the appropriate chemical irritant on the skin.

Diagram showing a 3D printed tattoo with different skin stretch (b). Illumination with GFP as a result of a reaction in different areas of the skin (c). Photograph by VCH-Verlag.Possible computer applications for 3d printing of hydrogel inks

The third possibility of using hydrogel inks in 3d printing is computational operations. Instead of the interaction of electronic components in a computer chip, it is possible to program the interaction of cells and chemical compounds, creating logic gates to perform Boolean operations.

The ink lines are arranged in such a way that instead of an electronic input, a value of 0 or 1 corresponds to the absence or presence of active components. Similarly, the absence or presence of produced GFPs corresponds to a value of 0 or 1 on the output. In this way, you can program the material.

Similarly, the absence or presence of produced GFPs corresponds to a value of 0 or 1 on the output. In this way, you can program the material.

“Each cell in the structure performs a simple computational operation,” Lu explains. “However, when spatially combined into three-dimensional structures, the interaction between different cell types and chemical compounds in different regions can generate informative circuits and provide complex logical calculations.”

Diagram showing how certain combinations of chemicals and bioink can form logic gates. Photograph by VCH-Verlag.From Smart Mechanics to Smart Biology

In addition to being used in the creation of logic gates and chemical detectors, 3D printing using living bioink also has medical applications.

“We can use bacterial cells as workers in a 3d factory,” Lu says. “They can be genetically engineered to produce drugs inside 3d platforms, and their uses are not limited to devices placed on the skin. As long as the method of making the ink and the approach used keep the bacteria viable, applications such as implants and food are possible.