3D print platform

Welcome to 3D Platform

3D Printing Case Studies

Alstom and Amtrak

Alstom and Amtrak

Prototyping the train cockpit

Read More...

Highland Community College

Highland Community College

Aiding higher education, inspiring elementary students, and connecting with local organizations.

more...

Idaho Virtualization Lab: Giant Spider

Idaho Virtualization Lab: Giant Spider

IVL uses large 3D printed parts to create stunning exhibits.

more...

Idaho Virtualization Lab: Prehistoric Fish

Idaho Virtualization Lab: Prehistoric Fish

Idaho Virtualization Lab (IVL) 3D prints a giant Prehistoric Fish

more...

PBC Linear Factory Model

PBC Linear Factory Model

Using 3D printed models to diagram the new manufacturing facility

Read more...

Ridoret Group

Ridoret Group

Window prototypes and manufacturing

Read More. ..

Sunnyslope High School

Sunnyslope High School

Components for robotics competition

Read More...

C7 Cabon

C7 Cabon

Prototypes and consumer-ready car parts

Read More...

PBC Linear

PBC Linear

Ramp fixtures for shop floor

Read More...

Rapid 3D: Not So Miniature

Rapid 3D: Not So Miniature

Radio-controlled truck body

Read More...

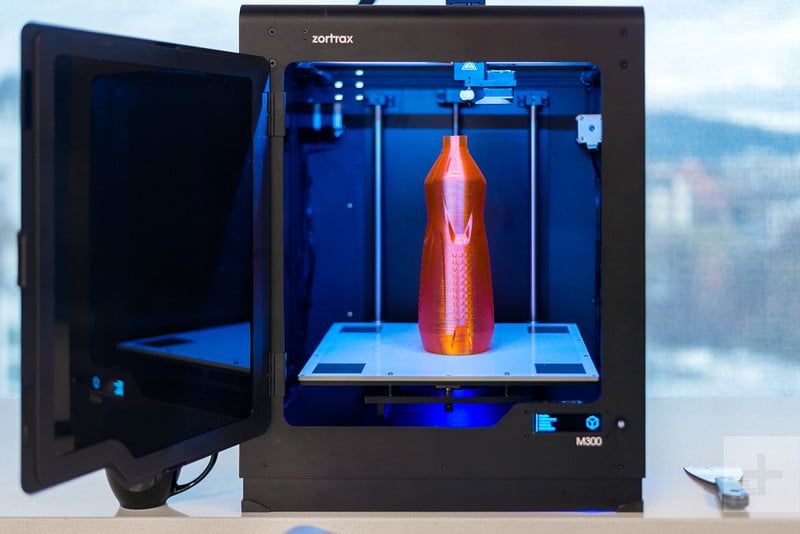

3D Printing Tech

3D Printing Tech

Giant Coke bottle promotion

Read More...

Fox Sports Robot

Fox Sports Robot

Larger-than-life FOX Sports Robot

Read More...

Thermoform

Thermoform

Large thermoforming dies

Read More...

Progress Rail

Progress Rail

Casting and machining tool mock-ups

Read More...

Thingergy

Thingergy

Specialty item techniques

Read More. ..

..

Warwick Drone

Warwick Drone

Seven-foot drone

Read More...

Titanic Design

Titanic Design

Full sized models

Read More...

Innovative 3D

Innovative 3D

Metal parts with complex shapes

Read More...

Gonzaga University

Gonzaga University

Ankle Foot Orthosis

Read More...

XFAB Printing Lab

XFAB Printing Lab

Marine Corps capitalizes on 3D Printing technology.

more...

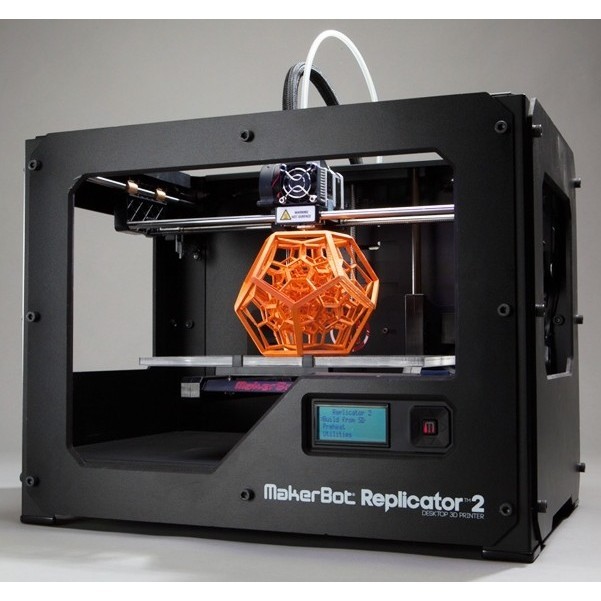

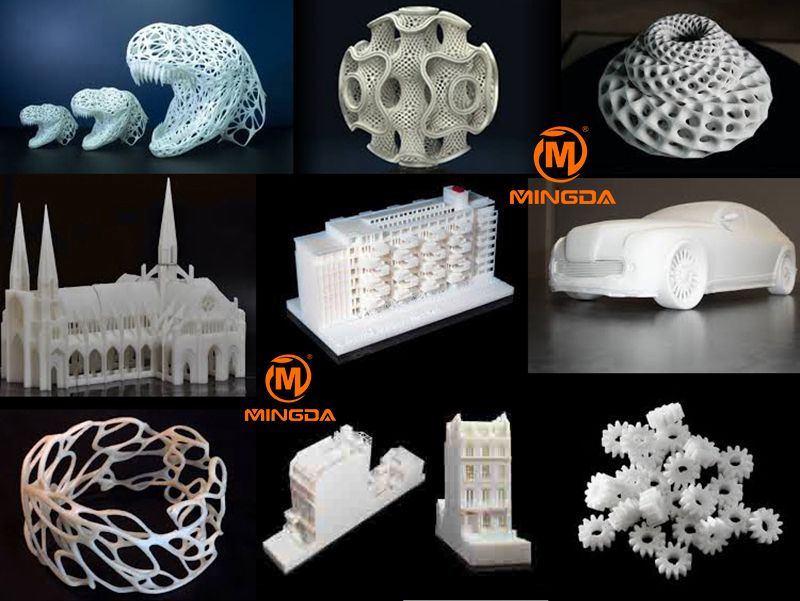

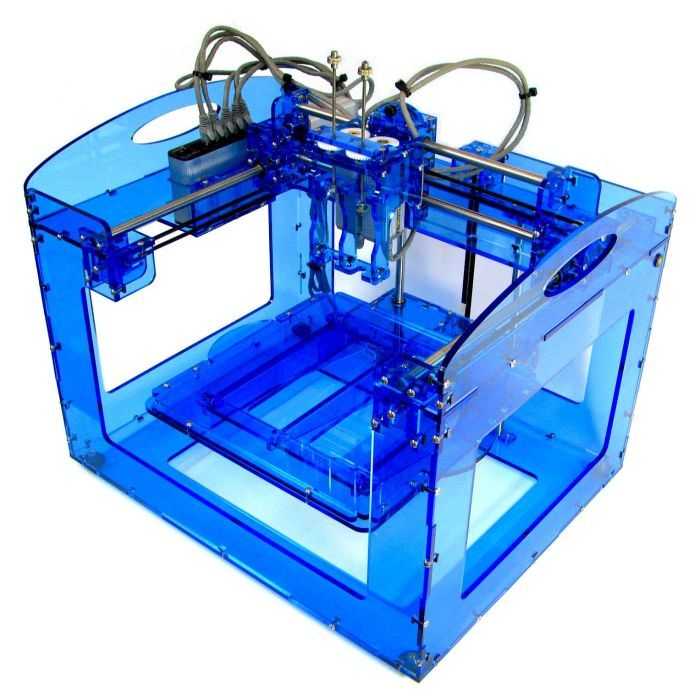

Large build volume

3D Platform is committed to making your biggest ideas a reality. We design products that push the limits of innovation, and that’s why we are a leader in the manufacturing of large format, industrial-strength 3D printers. A widening variety of industries in manufacturing, entertainment, and academia have continued to take full advantage of these large format printers to create prototypes, mass-produce products, and build the future.

What is large? Our large build area is up to 1 meter x 1.5 meter x 0.7 meter. This offers over 200-percent more creative space than a typical desktop 3D printer, and means our customers don’t have to scale down or print multiple parts that require assembly. In addition, a large build area can incorporate rapid design iterations to vastly reduce market entry time.

Traditional desktop 3D printers are fine for prototyping parts, but can be costly in terms of volume production and time-to-market. In contrast, industrial manufacturers can customize our large format 3D printers, providing the ability to produce near-net shape parts. The result is decreased costs and reduced time-to-market.

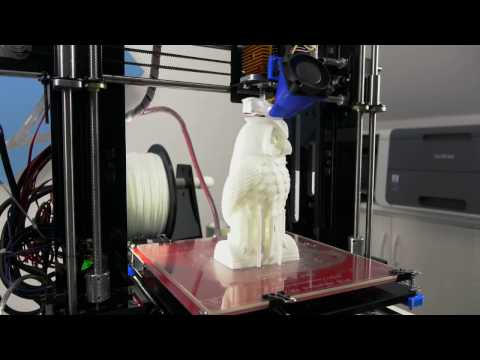

Large format 3D printing made easy

Don’t let the words industrial strength or large format scare you! Printing with 3DP can be as easy as easy as 1 - 2 - 3D! Learn the different steps on how to successfully create a 3D print by watching our video 1-2-3D Printing.

Create your 3D model. Start with a 3D model that was either created in 3D modeling software or download from the internet. Next, save the model as an OBJ or an STL file. The 3D printer processing software best understands these file types.

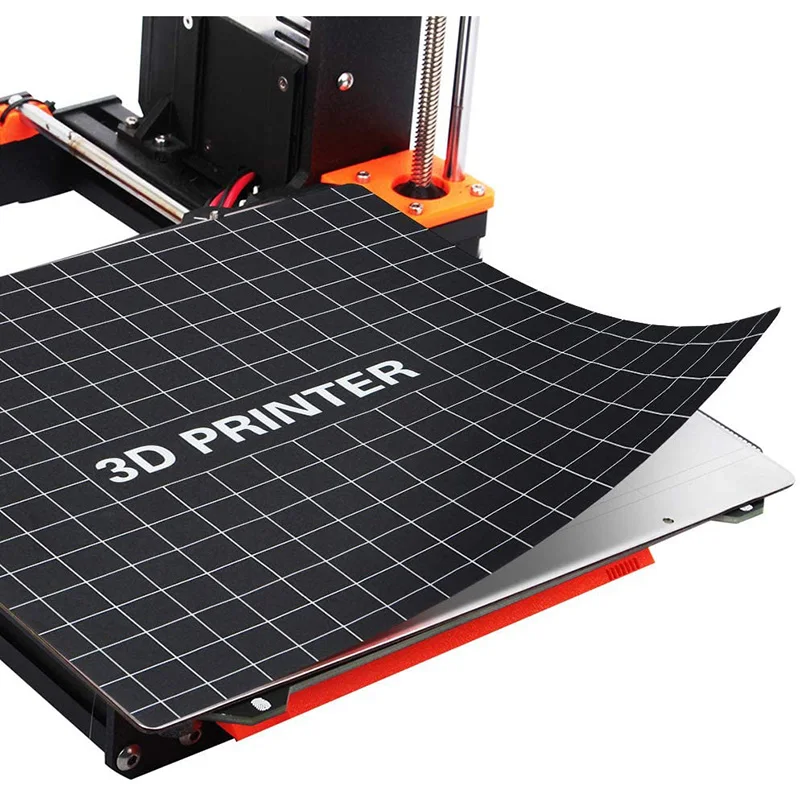

Process the model in 3D printing software. Import the file and set a few standard model modifiers such as the number of top and bottom layers, perimeters, and infill. Next, increase the strength in the infill box by setting the interior fill percentage to 20 percent. If supports are needed, they can be added by clicking the “generate support material” button. Click “Ok” to accept the process settings and observe the model with its new layer slices. Finally, save the file in g-code format, which gives the printer step-by-step instructions.

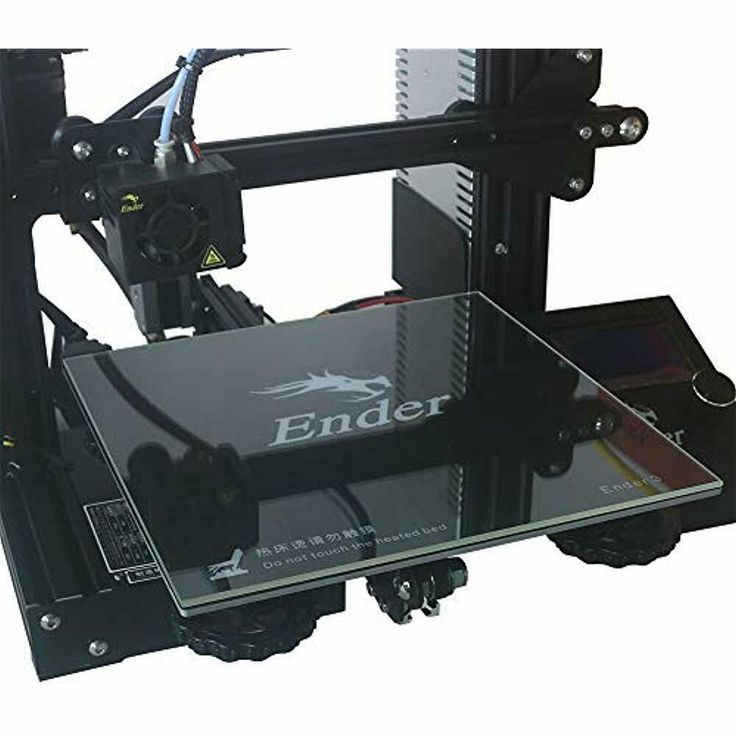

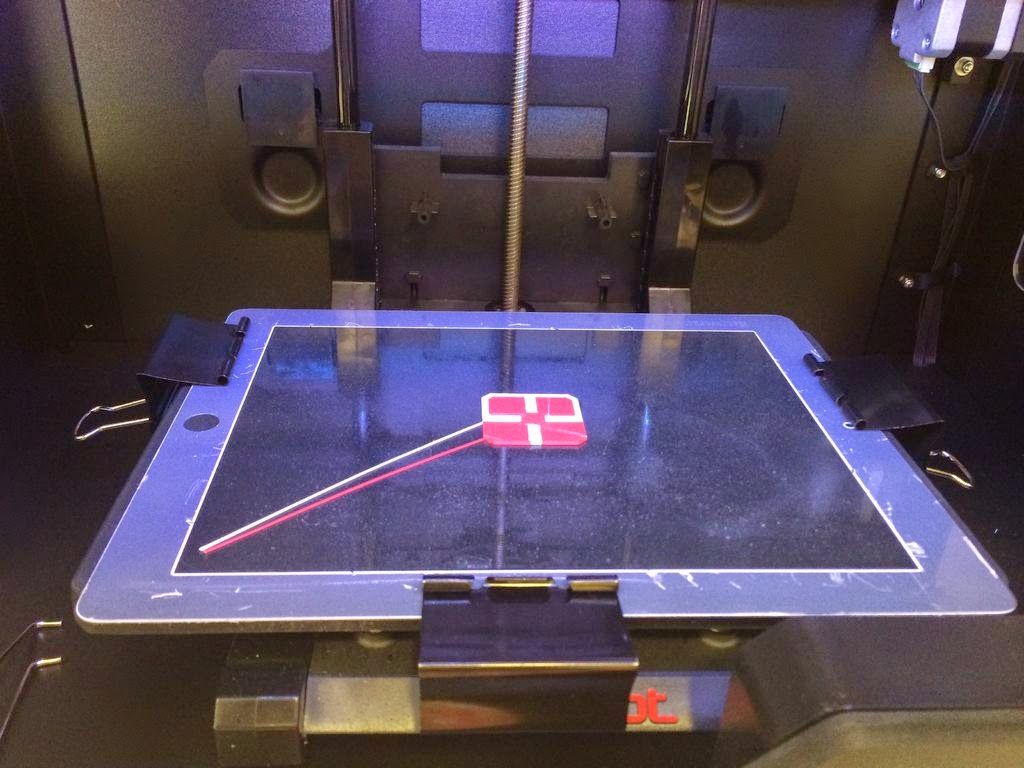

Send file to printer. Heat the bed and remember to home the axes prior to each print. Next, select the g-code file. Once the target temperature for the extruder is reached, then the print will begin. Watch the first few layers to make sure the print adheres to the build area and that the filament is flowing smoothly.

Watch the first few layers to make sure the print adheres to the build area and that the filament is flowing smoothly.

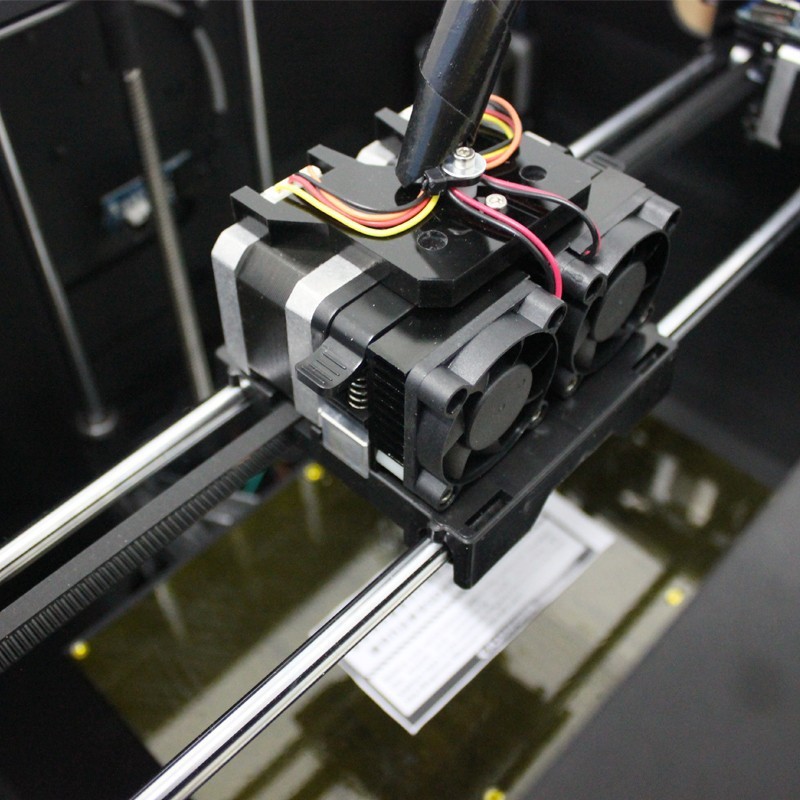

Unmatched speed with 3DP extruders

Push your additive manufacturing to new heights with 16-times the speed of competitors’ extruders. Current market extruders are limited in terms of their thermal capacity, therefore making them insufficient in their abilities to melt and dispense filament rapidly. They typically have an average throughput of 36 grams per hour. In contrast, our HFE 900 high flow extruders can provide a throughput of 1,350 grams per hour, resulting in a substantial decrease in 3D print time.

Our flexible line of extruders allows you to change nozzles depending upon your application and purpose. Use a small diameter nozzle for fine layer resolutions or go bigger with large diameter nozzles for fast printing and strong parts. Modular designs can accommodate filament sizes from 1.75 mm to 6 mm and nozzles sizes from 0.2 mm to 5 mm. In addition, quick-swap dual extruder heads deliver high quality 3D prints while being independently controlled for speed and extruded material amounts.

Modular designs can accommodate filament sizes from 1.75 mm to 6 mm and nozzles sizes from 0.2 mm to 5 mm. In addition, quick-swap dual extruder heads deliver high quality 3D prints while being independently controlled for speed and extruded material amounts.

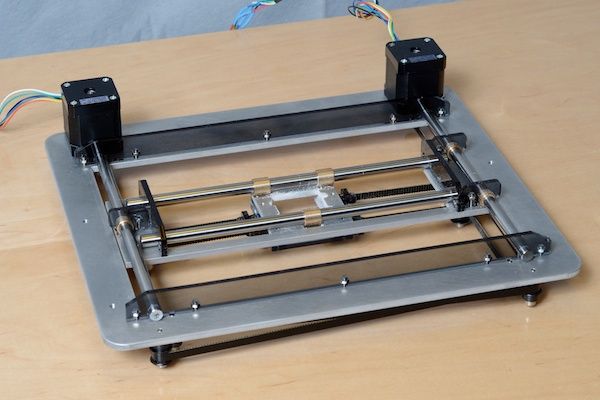

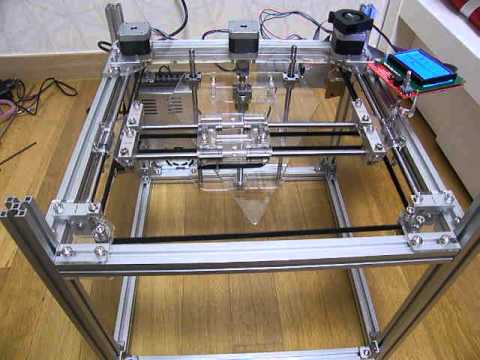

Reliability with the open market advantage

Technology used for commercial-grade products won’t work for production applications. Therefore, companies need to answer the demands of reliability and performance by utilizing industry-proven mechanical and electrical components. For this reason, 3DP offers motion system technology that improves cycle time and final part quality.

3DP is harnessing the energy of a global network of material scientists by using open market solutions. Within these open markets, skilled experts blend various polymers to achieve specific end goals for certain projects. Additionally, open software markets can spark innovation by providing real-time 3D printed models that can be easily accessed and shared. Open source and reliability are why top industry leaders look to 3D Platform to stay competitive in demanding markets.

Open source and reliability are why top industry leaders look to 3D Platform to stay competitive in demanding markets.

Go big with the power of innovation

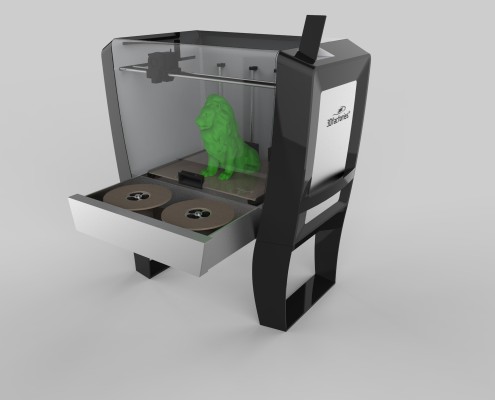

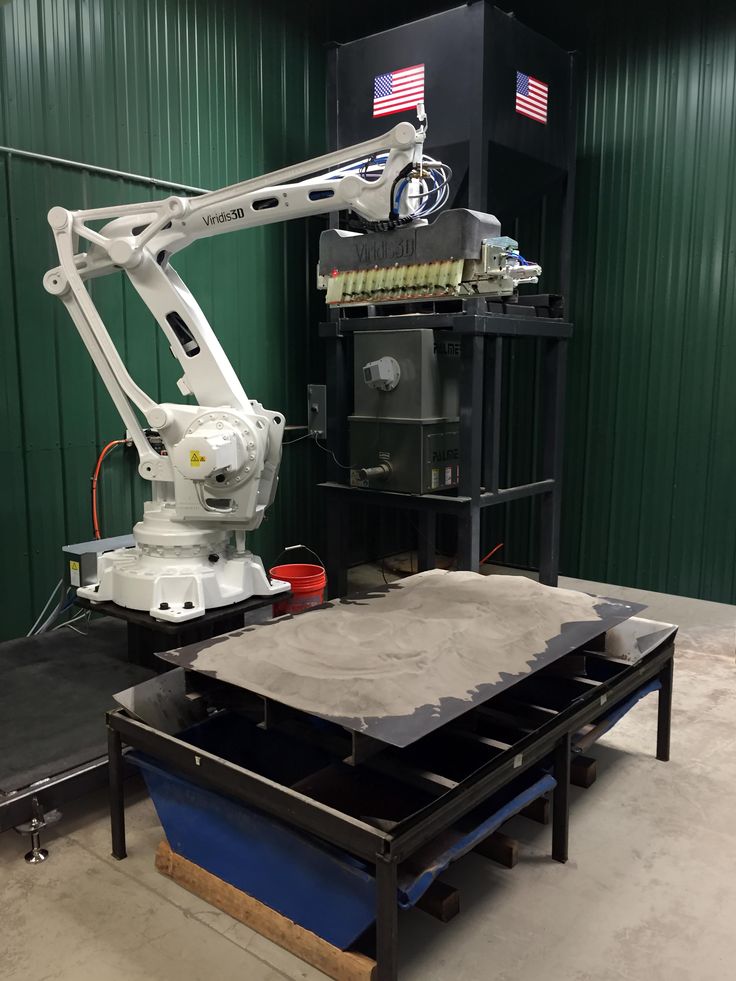

Think BIG, Print BIG, Save BIG! 3D Platform is using innovation to create large format 3D printers that are sized to meet any need. Take a look at the future of 3D printing!

WorkCenter 500 Series – This extra-large format 3D printer not only boasts a bigger build area, but it’s also affordable. The extra-large build volume of 1,400 mm x 2,800 mm x 700 mm provides affordability, but without sacrificing quality or throughput. The WorkCenter 500 is currently the only machine in the large format category to provide the option of pellet or filament extruder(s) – or both!

WorkCell – Our large format 3D printer with heated enclosure is currently in the design process! With a print volume of more than 1 cubic meter, the WorkCell’s heated enclosure will enable users to go beyond polymers that are typically printed in an open ambient environment, including commodity plastics, engineered plastics, and high-performance plastics.

Blog Posts from 3D Platform

3D Printer Configurator

Request a Sample

Large Scale 3D Printer, Commercial and Industrial Solutions

400 Series Workbench Xtreme

$49,999.00

Configure

For customized, full-scale printing capabilities that accelerate time from ideation to application at an affordable price, the WorkSeries 400 (Workbench Xtreme) is the only large scale 3D printer that has been engineered from the ground-up. Most importantly, the unique, parametric design can be easily adjusted to match the needs of our customers.

- Print Volume: 1000 mm x 1500 mm x 700 mm (1.05 m³, +2×)

- Extruder Standard Type: HFA

- Standard Max Throughput: 2×

- Extruder Option Type: HFE

- Option Max Throughput: Up to 16×

- Controller: 32-bit, 120MHz ARM Cortex M4 Processor

- Display: 7” TFT, with Wifi

- Remote Monitor & Operation: Standard

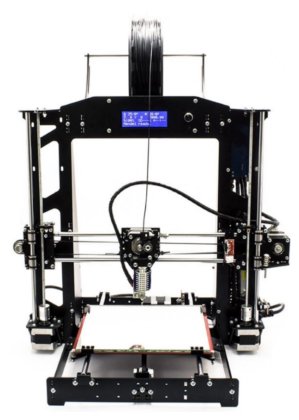

300 Series Workbench Pro

$37,999. 00

00

Configure

Our 300 Series WorkbenchPro is a Fused Filament Fabrication (FFF) additive manufacturing system with a large 1 m x 1 m x 0.7 m build area. Therefore, its industrial strength mechatronics deliver superior performance and reliability. Further, with SIMO Series actuators and Constant Force™ anti-backlash lead screws and nuts, the WorkbenchPro provides a rugged, industrial framework that won’t let you down. Additionally, the 3DP WorkbenchPro large scale 3D printer delivers 40% more build volume and up to 16x faster print rates with its unique features.

- Print Volume: 1000 mm x 1000 mm x 700 mm (0.7 m³, 1.4×)

- Extruder Standard Type: HFA

- Standard Max Throughput: 2×

- Extruder Option Type: HFE

- Option Max Throughput: Up to 16×

- Controller: 32-bit, 120MHz ARM Cortex M4 Processor

- Display: 7” TFT, with Wifi

- Remote Monitor & Operation: Standard

200 Series Workbench Classic

$28,999. 00

00

Configure

Print larger parts at faster rates with the 200 Series Workbench Classic large scale 3D printer. Overall, this classic printer features auto-mesh bed leveling, SurePrint Step-Servo hybrid motors, and duel electronics with remote operating and monitoring capabilities.

- Print Volume: 1000 mm x 1000 mm x 500 mm (0.5 m³, 1×)

- Extruder Standard Type: Volcano

- Standard Max Throughput: 1×

- Extruder Option Type: HFE

- Option Max Throughput: Up to 16×

- Controller: 32-bit, 120MHz ARM Cortex M4 Processor

- Display: 7” TFT, with Wifi

- Remote Monitor & Operation: Standard

100 Series Work Table

$17,999.00

Configure

The 100 Series WorkTable large scale 3D printer features the same build area size and mechanical features as the Workbench Classic. It is designed for smaller businesses, schools, and entry-level designers looking to implement large-format, industrial strength 3D printing into their projects.

It is designed for smaller businesses, schools, and entry-level designers looking to implement large-format, industrial strength 3D printing into their projects.

- Print Volume: 1000 mm x 1000 mm x 500 mm (0.5 m³, 1×)

- Extruder Standard Type: Volcano

- Standard Max Throughput: 1×

- Extruder Option Type: HFA

- Option Max Throughput: 2×

- Controller: 16 MHz Processor

- Display: LED

- Remote Monitor & Operation: NA

Sigma D25 3D Printer

$3,995.00

Buy Now

The Sigma D25 from BCN3D is a new generation of our best-known 3D printer, engineered to grant maximum productivity through a hassle-free experience thanks to features like its massive print volume and full connectivity. Powered by our Independent Dual Extruder (IDEX) system, the Sigma D25 delivers quickly functional prototypes with quality and precision.

- Print Volume: 420 x 300 x 200 mm

- Printer Size: 690 mm (W) x 530 mm (D) x 550 mm* (H) (27.2” x 20.9” x 21.7”) *720mm with bowden (28.3”)

- Precision Z axis: 1.0 microns

- Precision XY axis: 1.25 microns

- Max. extruder temperature: 300ºC

- Operating temperature: 15 ºC - 30 ºC

- Max. bed temperature: 80 ºC

- Nozzle diameters: 0.4 mm / 0.8 mm

- 5 printing modes: Single, Duplication, Mirror, Multimaterial, Soluble Supports

Epsilon W27 3D Printer

$5,995.00

Buy Now

The Epsilon W27 from BCN3D is a powerful professional 3D printing solution, designed to deliver large-scale parts with industrial-grade materials. It features a passive heated chamber, full enclosure, and humidity-controlled environment. Powered by our Independent Dual Extruder (IDEX) system, the Epsilon Series delivers exceptionally strong functional parts with quality and precision.

For an all-in-one 3D printing solution, customers can opt for a Smart Cabinet Bundle. The Epsilon W27, together with the Smart Cabinet (SC) filament storage system, work seamlessly together to help boost your printer's performance and keep your materials in optimal condition for a superior 3D printing experience.

- Print Volume: 420 x 300 x 200 mm

- Printer Size: 690 mm (W) x 530 mm (D) x 750 mm* (H) (27.2” x 20.9” x 29.5”)

- Precision Z axis: 1.0 microns

- Precision XY axis: 1.25 microns

- Max. extruder temperature: 300ºC

- Operating temperature: 15 ºC - 30 ºC

- Max. bed temperature: 120 ºC

- Nozzle diameters: 0.4 mm (default) / 0.6 mm / 0.8 mm / 1.0 mm / Hotend X: 0.6 mm

- 5 printing modes: Single, Duplication, Mirror, Multimaterial, Soluble Supports

Epsilon W27 3D Printer with Smart Cabinet (SC)

$9,495.00

Buy Now

Save $500 when you bundle an Epsilon W27 3D printer with a Smart Cabinet Filament Management System from BCN3D. The Smart Cabinet (SC) completes the Epsilon ecosystem, offering seamless integration with Epsilon W27 while maximizing its uptime. Its filament humidity control boosts your printers’ performance, keeping your materials in optimal condition. In addition, its uninterruptible power supply protects your work at all times, avoiding the risk of losing your print job due to power outages.

The Smart Cabinet (SC) completes the Epsilon ecosystem, offering seamless integration with Epsilon W27 while maximizing its uptime. Its filament humidity control boosts your printers’ performance, keeping your materials in optimal condition. In addition, its uninterruptible power supply protects your work at all times, avoiding the risk of losing your print job due to power outages.

The BCN3D Smart Cabinet is equipped with sturdy caster wheels that allow the 3D printing workstation to be moved smoothly within any environment including manufacturing, universities, or even a garage. The Smart Cabinet is also stocked with a sliding drawer to keep all the necessary 3D printing tools in one convenient location. This is the complete solution for professional 3D printing production.

Epsilon W50 3D Printer

$7,995.00

Buy Now

The W50 3D printer from BCN3D is the larger of the two Epsilon Series. It offers a powerful professional 3D printing solution, delivering large-scale parts with industrial-grade materials. It includes features such as a passive heated chamber, full enclosure, and humidity-controlled environment. The Epsilon Series is powered by an Independent Dual Extruder (IDEX) system, delivering exceptionally strong functional parts with quality and precision.

It offers a powerful professional 3D printing solution, delivering large-scale parts with industrial-grade materials. It includes features such as a passive heated chamber, full enclosure, and humidity-controlled environment. The Epsilon Series is powered by an Independent Dual Extruder (IDEX) system, delivering exceptionally strong functional parts with quality and precision.

For an all-in-one 3D printing solution, customers can opt for a Smart Cabinet Bundle. The Epsilon W50, together with the Smart Cabinet (SC) filament storage system, work seamlessly together to help boost your printer's performance and keep your materials in optimal condition for a superior 3D printing experience.

- Print Volume: 420 x 300 x 400 mm

- Printer Size: 690 mm (W) x 530 mm (D) x 900 mm* (H) (27.2” x 20.9” x 35.4”)

- Precision Z axis: 1.0 microns

- Precision XY axis: 1.25 microns

- Max. extruder temperature: 300ºC

- Operating temperature: 15 ºC - 30 ºC

- Max.

bed temperature: 120 ºC

bed temperature: 120 ºC - Nozzle diameters: 0.4 mm (default) / 0.6 mm / 0.8 mm / 1.0 mm / Hotend X: 0.6 mm

- 5 printing modes: Single, Duplication, Mirror, Multimaterial, Soluble Supports

BCN3D Smart Cabinet (SC)

$3,995.00

Buy Now

The Smart Cabinet (SC) completes the Epsilon ecosystem, offering seamless integration with your BCN3D Epsilon printers and maximizing their uptime. Its filament humidity control boosts your printers’ performance, keeping your materials in optimal condition, and its uninterruptible power supply protects your work at all times, avoiding the risk of losing your print job due to power outages.

FEATURES

- Optimal for all materials

- Low Energy consumption: 12 W Avg / 100 W Max

- 10 storage slots for small filament spools (4 for big spools)

- Prints while in dry storage

- Humidity-controlled environment, dries without heat

- No consumable parts

SPECIFICATIONS

- Cabinet Size: 690 x 530 x 950 mm

- Weight: 85 kg

- Output: 230V / 120V / 100V

- Data connection: USB connection (Type-A to Type-B cable)

- Sensors: Internal and external humidity sensor

- Filament diameter: 2.

85 mm

85 mm

Epsilon W50 3D Printer with Smart Cabinet (SC)

$11,495.00

Buy Now

Save $500 when you bundle an Epsilon W50 3D printer with a Smart Cabinet Filament Management System from BCN3D. The Smart Cabinet (SC) completes the Epsilon ecosystem, offering seamless integration with Epsilon W50 while maximizing its uptime. Its filament humidity control boosts your printers’ performance, keeping your materials in optimal condition. In addition, its uninterruptible power supply protects your work at all times, avoiding the risk of losing your print job due to power outages.

The BCN3D Smart Cabinet is equipped with sturdy caster wheels that allow the 3D printing workstation to be moved smoothly within any environment including manufacturing, universities, or even a garage. The Smart Cabinet is also stocked with a sliding drawer to keep all the necessary 3D printing tools in one convenient location. This is the complete solution for professional 3D printing production.

This is the complete solution for professional 3D printing production.

WorkCenter 500

$250,000.00

Now Available! – Starting at $250k USD, we have designed this extra large-scale 3D printer to provide affordability – without sacrificing quality or throughput. It uses a Fused Filament Fabrication (FFF) system and is currently the only machine in the large format category to provide the option of pellet or filament extruder(s) – or both!

- Print Volume: 1,400 mm x 2,800 mm x 700mm (2.7 m3 of print volume)

- Extruder Standard Type: Spool and Pellet

- Throughput Range: 1 kg/hr up to 6.8 kg/hr (15 lb/hr)

Please see our brochure for more information on the WorkCenter 500!

Introducing the WorkCell — Our large format 3D printer with heated enclosure!

Coming Soon – With a print volume of more than 1 cubic meter, the WorkCell’s heated enclosure will enable users to go beyond polymers that are typically printed in an open ambient environment, including commodity plastics, engineered plastics, and high performance plastics.

FOLLOW US

6402 E. Rockton Road

Roscoe, Illinois 61073 USA

+1.779.771.0000

© 2021 Copyright 3D Platform

About 3D Platform

Contact

Resellers

Terms & Conditions

Purchase Order Terms & Conditions

Privacy Policy

End of Life

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

SLA 3D printing technology

Laser stereolithography (SLA) is a 3D printing technology based on the layer-by-layer curing of a liquid material under the action of a laser beam.

- The principle of operation

- Technology features

- where they use

- Examples of print

- Select 3D printer

- The principle of operation

- Technology features

- where they use

- Sections

- Seams

- .0024

- Production of models of any complexity (thin-walled parts, small parts)

- Light processing of the completed prototype

- High build accuracy and high surface quality

- The properties of the polymers used make it possible to use the grown prototype as a finished product

- Larger chamber than other 3D printers

- Low support consumable percentage

- Low Noise

- Production of models of any complexity (thin-walled parts, small parts)

- Light processing of the completed prototype

- High build accuracy and high surface quality

- The properties of the polymers used make it possible to use the grown prototype as a finished product

- Larger chamber than other 3D printers

- Low Support Consumable

- Low Noise

What is better to print: functional prototypes, high-precision products, burnt-out master models.

Advantages: high construction speed, complex geometry, excellent detail and surface quality.

Alternative: SLS (higher product strength), PolyJet and MJP (lower finished product cost).

What is better to print: functional prototypes, high-precision products, burnt-out master models.

Advantages: high construction speed, complex geometry, excellent detail and surface quality.

Alternative: SLS (higher product strength), PolyJet and MJP (lower finished product cost).

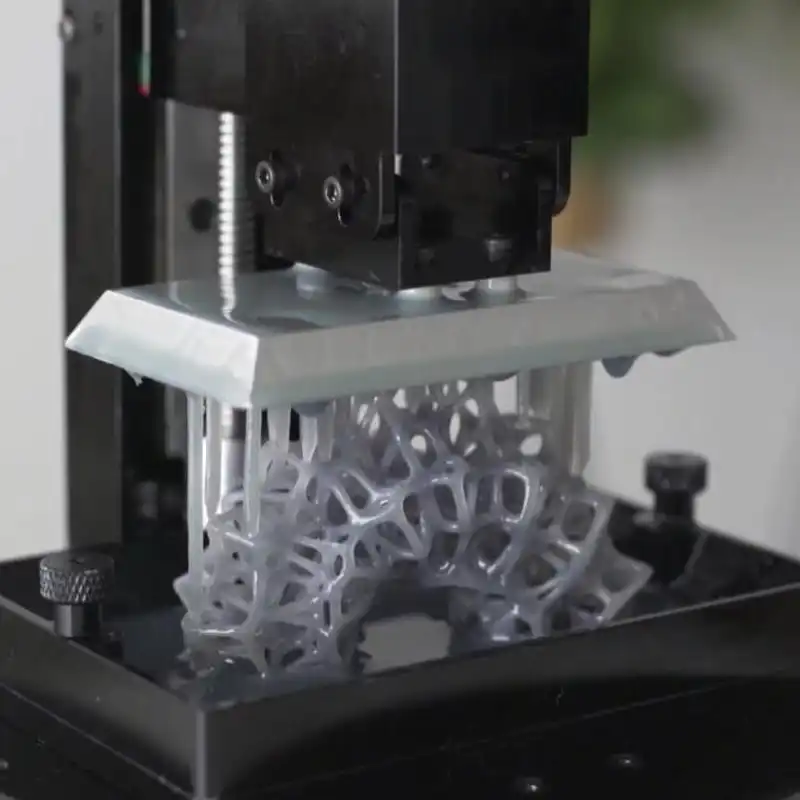

Professional SLA printers feature large build chambers

Professional SLA printers feature large build chambers

How it works

A mesh platform is placed in the tank with liquid photopolymer, on which the prototype will be grown. Initially, the platform is installed at such a depth that it is covered by the thinnest layer of matter, only 0.05-0.13 mm thick - in fact, this is the layer thickness in laser stereolithography. Next, a laser is turned on, affecting those parts of the polymer that correspond to the walls of a given object, causing them to harden. After that, the entire platform is immersed exactly one layer, that is, to a depth of 0.05-0.13 mm.

How it works

A mesh platform is placed in a container with liquid photopolymer, on which the prototype will be grown. Initially, the platform is installed at such a depth that it is covered by the thinnest layer of matter, only 0.05-0.13 mm thick - in fact, this is the layer thickness in laser stereolithography. Next, a laser is turned on, affecting those parts of the polymer that correspond to the walls of a given object, causing them to harden. After that, the entire platform is immersed exactly one layer, that is, to a depth of 0.05-0.13 mm.

Next, a laser is turned on, affecting those parts of the polymer that correspond to the walls of a given object, causing them to harden. After that, the entire platform is immersed exactly one layer, that is, to a depth of 0.05-0.13 mm.

After printing is completed, the object is immersed in a bath with a special composition to remove excess elements and completely clean. Then - the final irradiation with light for the final hardening. Like other 3D prototyping techniques, SLA requires the printing of supporting structures, which are then removed.

After printing is completed, the object is immersed in a bath with a special composition to remove excess elements and completely clean. Then - the final irradiation with light for the final hardening. Like other 3D prototyping techniques, SLA requires the printing of supporting structures, which are then removed.

Technology features

Most SLA 3D printers produce objects around 50x50x60 cm, but there are exceptions. The American company 3D Systems has created a device capable of creating objects much larger than classical ones - 1500x750x550 mm, which opens up new horizons for the application of this technology.

The American company 3D Systems has created a device capable of creating objects much larger than classical ones - 1500x750x550 mm, which opens up new horizons for the application of this technology.

Technology features

Most SLA 3D printers produce objects around 50x50x60 cm, but there are exceptions. The American company 3D Systems has created a device capable of creating objects much larger than classical ones - 1500x750x550 mm, which opens up new horizons for the application of this technology.

Applications

Scientific research

Since it is possible to obtain a plastic model of almost any complexity for any purpose in a matter of hours, SLA technology becomes an indispensable assistant in various kinds of scientific research. Models have sufficient strength and transparency, so it is possible to visualize gas and hydrodynamic flows inside the models.

Medicine

In maxillofacial surgery and orthodontics, a new direction has been formed with the advent of SLA. The patient is given magnetic resonance imaging of the problem area, a 3D computer model is formed from it, and a real 3D model of bone tissue is grown from it. Thus, the doctor already the next day has at his disposal a model of the bones or teeth of a real patient.

Burnt-out casting

If there is a need to obtain a metal part, the following technology is used: the SLA model is poured with molding sand, then calcined at high temperatures (up to 1000 °C). In this case, the plastic completely burns out, and metal is poured into the formed mold under vacuum in its place. After it solidifies, the form is destroyed and the part is removed.

In this case, the plastic completely burns out, and metal is poured into the formed mold under vacuum in its place. After it solidifies, the form is destroyed and the part is removed.

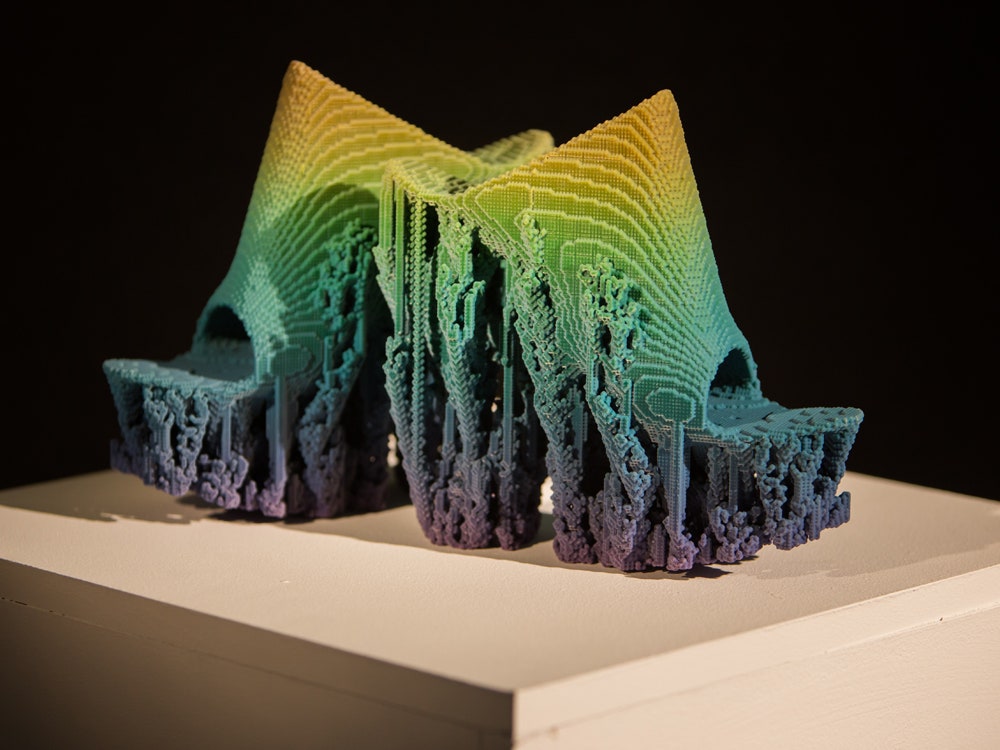

Art

Sculptors, fashion designers and jewelers are taking production to the next level with laser stereolithography technology. The process of 3D printing of prototypes significantly reduces the time for testing experimental samples, which has a positive effect on the speed and quality of creating a future piece of jewelry or sculpture. SLA technology is very well suited for this: the models are durable and easy to paint.

Applications

Scientific research

Since it is possible to obtain a plastic model of almost any complexity for any purpose in a matter of hours, SLA technology becomes an indispensable assistant in various kinds of scientific research. Models have sufficient strength and transparency, so it is possible to visualize gas and hydrodynamic flows inside the models.

Medicine

In maxillofacial surgery and orthodontics, a new direction has been formed with the advent of SLA. The patient is given magnetic resonance imaging of the problem area, a 3D computer model is formed from it, and a real 3D model of bone tissue is grown from it. Thus, the doctor already the next day has at his disposal a model of the bones or teeth of a real patient.

Burnt-out casting

If there is a need to obtain a metal part, the following technology is used: the SLA model is poured with molding sand, then calcined at high temperatures (up to 1000 °C). In this case, the plastic completely burns out, and metal is poured into the formed mold under vacuum in its place. After it solidifies, the form is destroyed and the part is removed.

Art

Sculptors, fashion designers and jewelers are taking production to the next level with laser stereolithography technology. The process of 3D printing of prototypes significantly reduces the time for testing experimental samples, which has a positive effect on the speed and quality of creating a future piece of jewelry or sculpture.