3D print naughties

▷ naughty files 3d models 【 STLFinder 】

Naughty

cults3d

To celebrate this halloween .... ...Alone or as a couple, just have fun

Naughty Banana

sketchfab

No description provided.

Naughty Santa

cults3d

My first sculpt in blender! ...I made this as an award for a naughty-ugly-sweater contest.

Naughty dice

cults3d

Naughty games to spice up your relationship life. Composed of 4 dice with each one a function: the place, the part of the body, the action to be performed and the time to play the game... And for the greedy men who always want more, a naughty...

naughty fort

sketchfab

naughty fort children’s playground Joy ball pool

NAUGHTY NOBY

thingiverse

NAUGHTY NOBY http://www.3dupndown.com/content/?page=&pcode=cont_view_new&mtype=au&idx=18268&chargeType=

Naughty Keychain

sketchfab

This is a model of an old kexchain I found several years ago. ...Made it and handpainted it in Blender.

...Made it and handpainted it in Blender.

Naughty Plug

cults3d

Naughty plug with a twist. ... Satisfying inside out.

Naughty Companion

cults3d

Sometimes it is necessary to leave a well-thought-out object to reach its point G.

Naughty Bill

sketchfab

Model based on a concept by the friend Matheus Oliveira.

Naughty Santa

thingiverse

My first sculpt in blender! . ..I made this as an award for a naughty-ugly-sweater contest.

..I made this as an award for a naughty-ugly-sweater contest.

Naughty Turret

cults3d

Sometimes it is necessary to leave a well-thought-out object to reach its point G.

Naughty child

sketchfab

No description provided.

Naughty Nice Earrings

thingiverse

Just add some earring hooks and voila! Note- My first design to upload! Print Settings Printer: Dremel 3D Idea Builder Rafts: . ..

..

Naughty-Velma-01

cults3d

3D Printable Model

Naughty Pen Holder

cults3d

Well balanced anal pen holder. I have included a version without the mask. You can rescale her if you want to fit a larger or smaller pen. ...Cheers

Naughty Aleph stencil

thingiverse

Customized version of http://www.thingiverse.com/thing:55821 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=55821 Instructions Using the following options:. ..

..

Naughty Zen Gnome

thingiverse

Enjoy this little fellow ;) It needs supports for the hands. ... Support Overhang Angle : 52º Support Density : 40% Support Z distance: 0.2mm Support x/y distance:1mm

Naughty Cookie cutters

thingiverse

Feed your friends a bag of dicks! ... and other naughties. ... Printed in PLA Layer height: 0.2mm - 0.3mm Nozzel: 210 Bed: 60

Naughty male hook / hanger

cults3d

Naughty male hook for bathroom, Sauna etc.

Nude Elf naughty version

cults3d

Who needs clothes? Not elves! More appropriate version included too. ...See: https://cults3d.com/en/3d-model/art/nude-elf

Naughty_Cat_Support

thingiverse

A cat shaped support for holding a pen. ... Credit: https://www.3dzyk.cn/thread-18201-1-1.html

Naughty Disney Litho Lamp

cults3d

Litho the naughty diameter 150 Sphere, base and cap Submersible LED light,. .. ...https://www.amazon.fr/dp/B073TZF4KL?ref=ppx_pop_mob_ap_share base and cap made by Ludo3D https://cults3d.com/fr/utilisateurs/Ludo3D/cr%C3%A9ations SALE FORBIDDEN

.. ...https://www.amazon.fr/dp/B073TZF4KL?ref=ppx_pop_mob_ap_share base and cap made by Ludo3D https://cults3d.com/fr/utilisateurs/Ludo3D/cr%C3%A9ations SALE FORBIDDEN

Naughty Dog Logo

thingiverse

Hello everyone! ...This is my first upload, I started to design this with an image on Inkscape, than I imported the svg file on Fusion 360 and created all the part.

Naughty / Couple games

cults3d

These naughty dice will allow you and your partner to liven up your evenings. They will dictate specific actions to be accomplished with each roll of the dice. In this file you can find 2 dice: The one containing the actions to realize: To bite, To. ..

..

Naughty Cat Food Saver

thingiverse

My cat kicks out food while she eating it. so I made this to prevent wasting food. ...it's been three days so far so good hope it can help some one has same problem the bow size might different just share the idea ...

Naughty Arale Norimaki

cults3d

Arale Norimaki (Japanese: 則巻アラレ, Hepburn: Norimaki Arare) is a fictional character and the protagonist of the Dr. Slump manga series, created by Akira Toriyama. If this girl is naughty number 2, then I don't think anyone will be number 1. ...:)))

Naughty :( or Nice :)

thingiverse

The perfect ironic gift box - or not - judge them like Santa does! Instructions Naughty :( Scale and print coal. stl - preferably in black. It's 1/3 the size of coal_top.stl and coal_bottom.stl to...

stl - preferably in black. It's 1/3 the size of coal_top.stl and coal_bottom.stl to...

Naughty Surprising Egg (NSFW)

thingiverse

A slightly more adult surprising egg. Looking at it printed, I guess it could have been a little bigger ... although I guess we always say that ;-) EDIT: Now with extra girth! See comparison pictures for difference in size between original and...

Cartoon version - Naughty statue

3docean

Game scene model low-modulus model, all models have materials, textures format format : 3DMax 2009 : OBJ : 3DS : FBX

JINKAIJIA Women's Fashion Flirty Sexy Funny Naughty Animal 3D Printed Cute Low- rise Underpants Single Party Gifts Briefs

4. 4 out of 5 stars 1,370 ratings

4 out of 5 stars 1,370 ratings

Fit:

True to size. Order usual size.

Size:

Select Medium Large X-Large Select Update Page

Color: Bride

Size Chart

US 3D Printed Underwears

| Brand Size | Waist |

|---|---|

| M | 25. 2 - 35.4 2 - 35.4 |

| L | 27.6 - 39.4 |

| XL | 29.9 - 43.3 |

Free 3D file Free suture pattern Laser gun of destruction for naughty knights・3D printing plan for download・Cults

Suturus Pattern Carapace Missile Launchers For Questing Knights (Free!)

Free

Suturus Pattern-Ultimate Saws and Claws Compilation For Mechs and Knights

6.17 €

Project "Maggie" and Styx Mega Bundle

15.45 €

[FREE] Suturus Pattern LasWeapon For Questing Mechs and Knights

Free

Maggie's Project Knight Quest Conversion Kit - All files

9.27 €

Project Abby Conversion Kit for Naughty Knights

8.83 €

Complete Dominator: Super Heavy Laser Cannon, Plasma Cannon, Flamer Cannon and Harpoon Of Doom.

And much more!

And much more! €15.45

Maggi electric shooter for quest knights

4.11 €

Project Styx for Questing Knights-Discount Group File Package

9.26 €

Project IronHorse Bulk Discount Lancing Knights Conversion Kit

€10.29

Charity Skulls For Knights

3.08 €

Project Styx Heat Gun for Quest Knights

5.14 €

Best 3D printer files in Game category

Zweihander 2

Free

Biplane with Heart

Free

BOW WITH A HORN FROM EL'DAN RING

4 €

Nerf Bigshock removable barrel with Flash hider

1,99 €

Playmobil 3D printer

1 €

Retrocruiser Sport - 3D printed motorbike in scale 1:7

8 €

Transformers Soundwave Tardis

Free

G1 Optimus Prime

Free

Bestsellers in the Game category

Armored arms and hands

4 €

Snake and rattlesnake

4. 11 €

11 €

Exolotreftes Truescal

5 €

Flying unicorn

1.05 €

Ground lock Megaton

4.11 €

Vodfolk Explorer

10.31 €

Healer conversion kit SM

6 €

Voidwalker Exosuits Truescale

€14.83

First Line Attack Troops - Truescale

5 €

Lev Fu

5.50 €

Lazy Cat

4.11 €

Champion Alteira

5.15 €

Chirping bird whistle

1.79 €

Heavily Armored Cataphrac Warriors - Season 9 Weapon Pack

3.10 €

Dancing Skeleton

3.61 €

Heavily armored warriors Catafrac - set of limbs

1,85 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people , so support us in maintaining activities and making future designs of is very easy. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

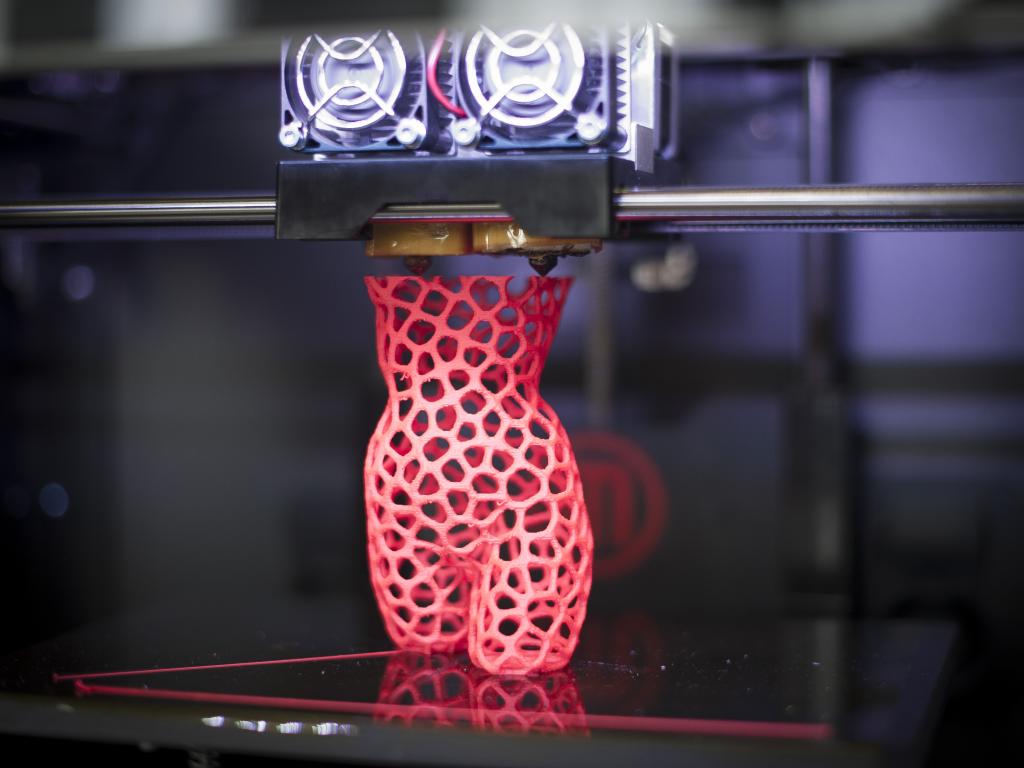

We found out the dangers of 3D printing. The main myths about technology

Vladislav Kochkurov General Director of the Center for Additive Technologies

The first product on a 3D printer was printed at 1983 - it was a small container in the form of a bowl. Now researchers are creating aircraft engines and rockets, jewelry, food, and even houses. Despite the fact that there is a lot of information about this area, many people still do not understand exactly how 3D printing works. Vladislav Kochkurov, General Director of the Center for Additive Technologies, talks about the misconceptions we face when talking about layer-by-layer creation of three-dimensional objects.

Despite the fact that there is a lot of information about this area, many people still do not understand exactly how 3D printing works. Vladislav Kochkurov, General Director of the Center for Additive Technologies, talks about the misconceptions we face when talking about layer-by-layer creation of three-dimensional objects.

Read Hi-Tech in

Myth #1. 3D printing takes place almost without human intervention

When many people hear about 3D printing, they think of a 3D printer as the central part, which distributes consumables in layers - this is how a new product is born. One gets the false impression that the entire cycle of additive manufacturing consists only of the operation of equipment, and a person hardly participates in this - he only turns on a 3D printer and loads a polymer, metal powder or other material into it.

But the key role in building an object is played by its 3D model. It is a map on which the finished product will be built. The quality and characteristics of the future subject depend on its detailed study. Here, the participation of specialists with high competencies in the fields of design, technology and materials is needed.

The quality and characteristics of the future subject depend on its detailed study. Here, the participation of specialists with high competencies in the fields of design, technology and materials is needed.

In industrial production, the construction of a 3D model is carried out in AutoCAD computer-aided design systems. The design engineer, in accordance with the terms of reference and using various calculation methods, creates the geometry of the future product. Even if the 3D model already exists and does not need to be built from scratch, AutoCAD programs carry out its topological optimization - redesign for additive manufacturing.

This process aims to eliminate stress raisers and thin-walled features that can cause cracks or other damage during the printing process. Together with the 3D model, the location of technological supports is also designed - support structures needed for optimal positioning of the part on the platform, heat removal and reduction of the risk of deformation during the printing of the product. Printing is also preceded by the process of developing technological modes of construction, which is being worked on by a process engineer.

Together with the 3D model, the location of technological supports is also designed - support structures needed for optimal positioning of the part on the platform, heat removal and reduction of the risk of deformation during the printing of the product. Printing is also preceded by the process of developing technological modes of construction, which is being worked on by a process engineer.

Further, based on the prepared 3D model, the printer prints on its own, sometimes working for several days in a row. But before that, the equipment needs to be prepared - make sure that the build platform is level and all the mechanisms move as they should. Even the powder in the 3D printer is not just poured, but goes through the stages of incoming control and preparation.

Another mandatory stage in the production cycle of a product that requires human participation is post-processing.

Myth #2: A finished product comes out of a 3D printer

Many people think of 3D printing as it is shown in films. Robotic installations in a matter of minutes create superhero costumes and print elements of spaceships. Technology, of course, is striving for this, but today all products removed from the printer need post-processing.

Robotic installations in a matter of minutes create superhero costumes and print elements of spaceships. Technology, of course, is striving for this, but today all products removed from the printer need post-processing.

To relieve the internal stress that occurs during the printing process, the product undergoes alternating heating and cooling procedures. This way it achieves full mechanical properties. Then technological supports are cut off - they have already fulfilled their function. Removal of excess powder and surface treatment of the product are carried out using a sandblasting chamber. If it is necessary to achieve absolute smoothness of surfaces, then milling, turning, electrochemical and grinding machines are used. For plastic products, chemical post-treatment with acetone or other solvents is sometimes used.

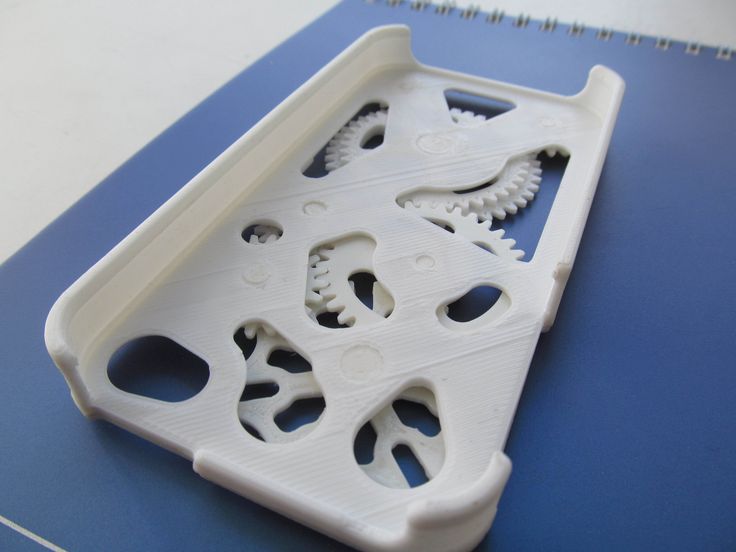

Myth #3: You can 3D print anything

Innovations in the field of additive technologies appear every year and already surpass our imagination. Synthetic meat steaks, a human heart, and a whole house are already being printed. It seems that the possibilities of additive manufacturing are endless and a 3D printer can do anything. But now there are several limitations related to the size and material of the product - it is impossible to create very large and very small objects.

Synthetic meat steaks, a human heart, and a whole house are already being printed. It seems that the possibilities of additive manufacturing are endless and a 3D printer can do anything. But now there are several limitations related to the size and material of the product - it is impossible to create very large and very small objects.

For example, the Center for Additive Technologies has an installation with a build chamber up to half a meter, the largest printer in Russia based on selective laser melting technology. Elements of Russian aircraft engines are already being “grown” there.

“Innovations in the field of additive technologies appear every year” The capabilities of polymer printers are much wider - one of them, listed in the Guinness Book of Records, can create objects up to 30 m long. In 2017, a monolithic boat was printed on it, weighing 2 tons and 7 m long. The smallest object printed on a 3D printer is a ship. Its length is 2-3 times less than the thickness of a human hair - only 30 micrometers (0. 03 mm).

03 mm).

3D printers are already used to create even at home. A construction printer works by analogy with an FDMD printer that prints plastic products, but instead of polymeric materials, cement mixtures are used as “inks”. In size, such a mechanism is much larger. The world's largest 3D printed building has an area of 641 square meters. m. and is located in the UAE.

Other limitations in additive manufacturing are not related to the size of the 3D printer's build chamber, but to the material used. During the printing process, it is in a liquid or molten state, therefore, it should melt normally. Wood, fabric, or paper objects cannot yet be printed, as they will burn before the material can be melted. Although here you can find a loophole: if you mix crushed cellulose fibers with a water-based gel, and then freeze the object, gradually removing water from it, you will get products made of a material similar to wood.

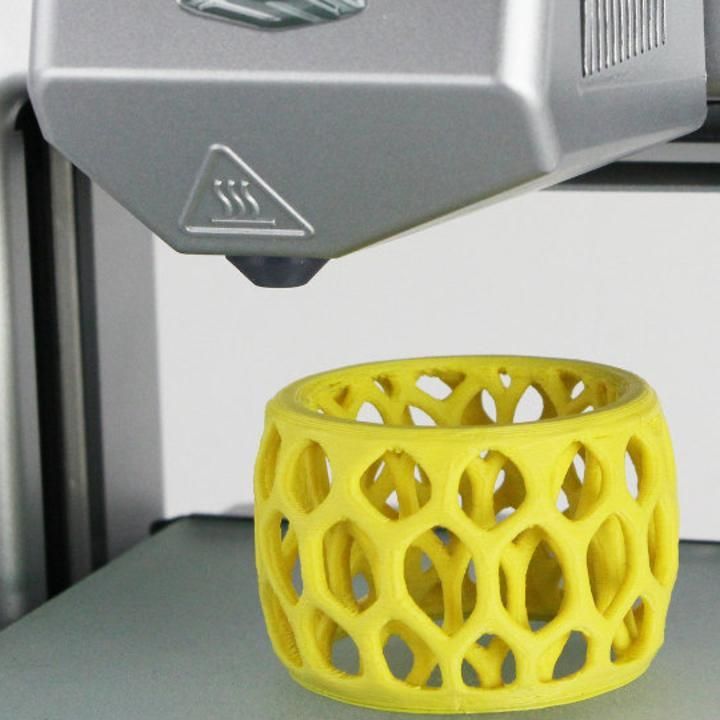

Myth No. 4. 3D printed products are of poorer quality

Visually, the 3D printing process looks like a layer-by-layer application of material. This may raise the question: how firmly are the layers interconnected?

This may raise the question: how firmly are the layers interconnected?

3D printing can introduce several defects, so it is important to follow the workflow. A lot depends on the quality of the materials. In industrial production, all metal powders undergo input control, this process is regulated by standards. Even if the material is certified, it is very important to observe the conditions for proper storage: avoid moisture and dampness, place in a special package. If you do not check the condition of the nozzle, set the temperature or print speed incorrectly, misalignment of layers, overheating, or other defects may occur.

If all conditions are met, then the product will not be inferior in properties, and often even surpass the analog made by traditional methods. If you compare two aluminum objects under a microscope, the printed product will have a denser structure.

“If all conditions are met, then the product will not be inferior in properties, and often even surpass analogs made by traditional methods” Myth #5.

Learn more