3D print eye

Eyeball best STL files for 3D printer・Cults

Halloween Chess Eyeball Case

Free

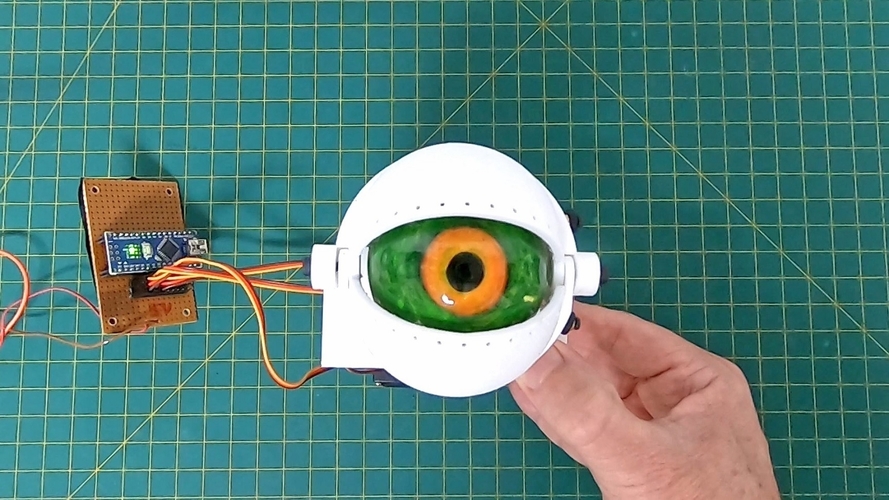

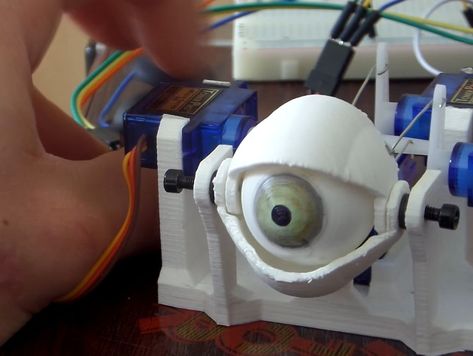

blinking cyclops eye

Free

Moving eye, Skull Planter, Halloween decoration, Skull bowl, Print in place, no support

€2.35

Two designs, Skull bowl with eye, Skull bowl, no supports, Candy dish, Halloween decoration

€1.18

Skull Ashtray, Skull with eyeball, Halloween themed, Creepy Skull, Smoking accessories, No supports

€1.18

The Watching Hand

€0.61

All Seeing Eye Creature

Free

TMNT Muckman and Joe eyeball

€4.71

TMNT Joe Eyeball

€0. 94

Eyeball Techno Head (Motu compatible)

€2.50

METALHEAD ROBOT VINTAGE TMNT ( TEENAGE MUTANT NINJA TURTLES) COMPLETE

€5.57

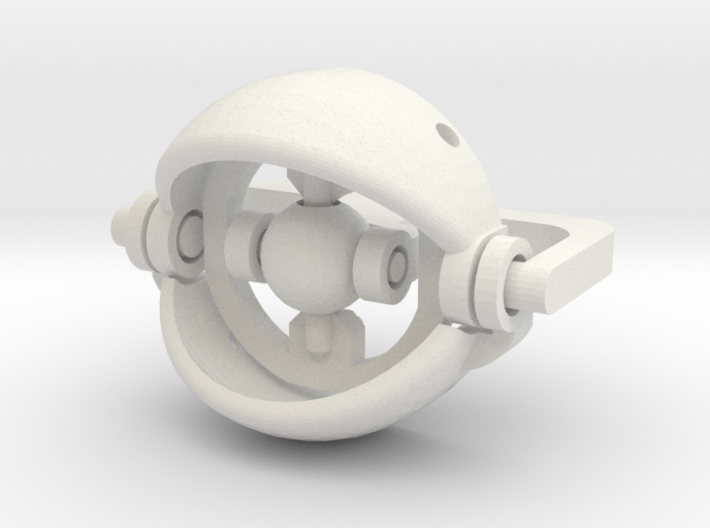

Rod End Ball Joint Eyeball

Free

DR EL VINTAGE TMNT ( TEENAGE MUTANT NINJA TURTLES) COMPLETE

€9.29

KRANG AND ANDROID BODY 11" TMNT ( TEENAGE MUTANT NINJA TURTLES) COMPLETE

€11.86

MOVIE STAR MIKI TMNT ( TEENAGE MUTANT NINJA TURTLES) COMPLETE

€5.62

TOKKA VINTAGE TMNT ( TEENAGE MUTANT NINJA TURTLES) COMPLETE

€5.23

HOT SPOT VINTAGE TMNT ( TEENAGE MUTANT NINJA TURTLES ) COMPLETE

€22.87

SHREDDER VINTAGE TMNT ( TEENAGE MUTANT NINJA TURTLES) COMPLETE

€5. 72

72

ROCKSTEADY VINTAGE TMNT ( TEENAGE MUTANT NINJA TURTLES) COMPLETE

€6.62

Eyeball Father in a teacup

Free

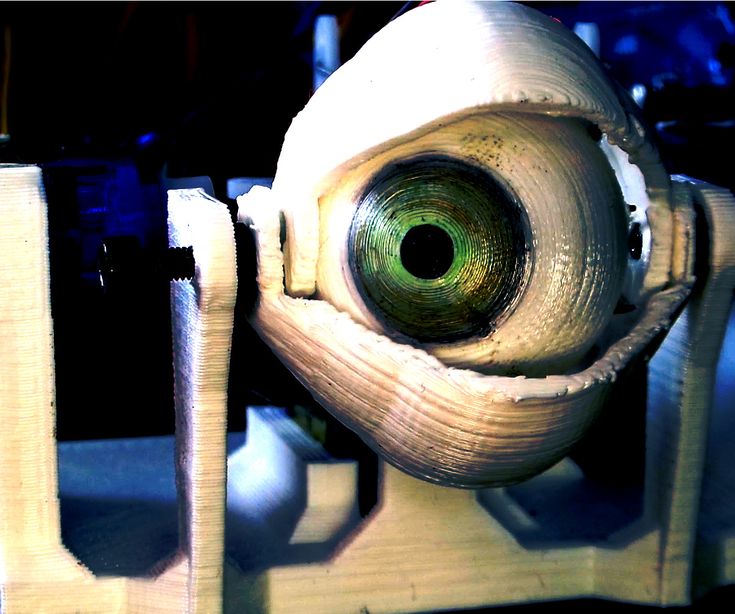

PUPPET EYE

€1.87

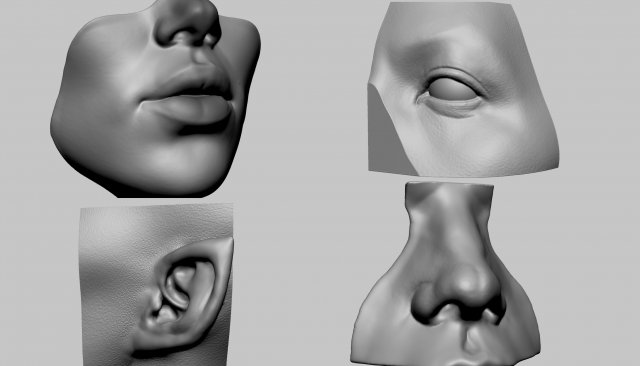

Human eyeball anatomy

€2.50

Free 3d eyes of the lost dawn

Free

MUCKMAN AND JOE EYEBALL VINTAGE TMNT ( TEENAGE MUTANT NINJA TURTLES) COMPLETE

€5.14

Free 3d eyes of glaring intent

Free

Free 3d eyes of abndoned hope

Free

Free 3d eyes of divine blindness

Free

All Seeing Eye Topper ($7 Cane/Walking Hiking Sticks)

Free

owl wall keychain

€1

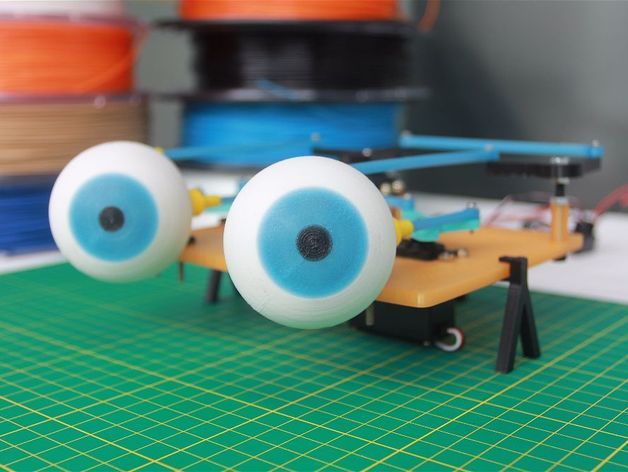

Eyeballs [no support, modular]

Free

Free eyes of split insight

Free

Free eyes of the lost seer

Free

Free eyes of lost wrath

Free

Free eyes of eternal foresight

Free

Free 3d rigged eyes of devastation

Free

Free eyes of redeeming insight

Free

Nemoriko`s : Tabletop Marker Secred Eye 02

€3. 32

32

Free eyes of furious perception

Free

free eyes of unruly insight

Free

NMC Eyeball

€1.88

Free eyes of silent laugher

Free

Spooky Eye Halloween keychain

€0.50

Free rigged eye of lost insight

Free

Free rigged flaming eyes

Free

Free rigged eyes of a shy goddess

Free

Free rigged eyes of deep insight

Free

Free 3d rigged eye of the lost era

Free

Free rigged eyes of redemption

Free

Fraunhofer Institute creates 3D-printed prosthetic eye

Using its proprietary software, the company has been able to create models in a fraction of the time typically needed for fitting one.

Steve Verze is the first ever patient in the world to be supplied with a fully digital 3D printed prosthetic eye November 25 at Moorfields Eye Hospital in London. (Image courtesy of Moorfields Eye Hospital NHS Foundation Trust)

The Fraunhofer Institute for Computer Graphics Research IGD has used its propriety Cuttlefish:Eye software to 3D-print a prosthetic eye.

According to the company, scientists have managed to create models in a fraction of the time typically needed for fitting one. Fraunhofer's new technology will undergo clinical trials in the Moorfields Eye Hospital in London, where 40 patients will get 3D-printed prosthetic eyes.

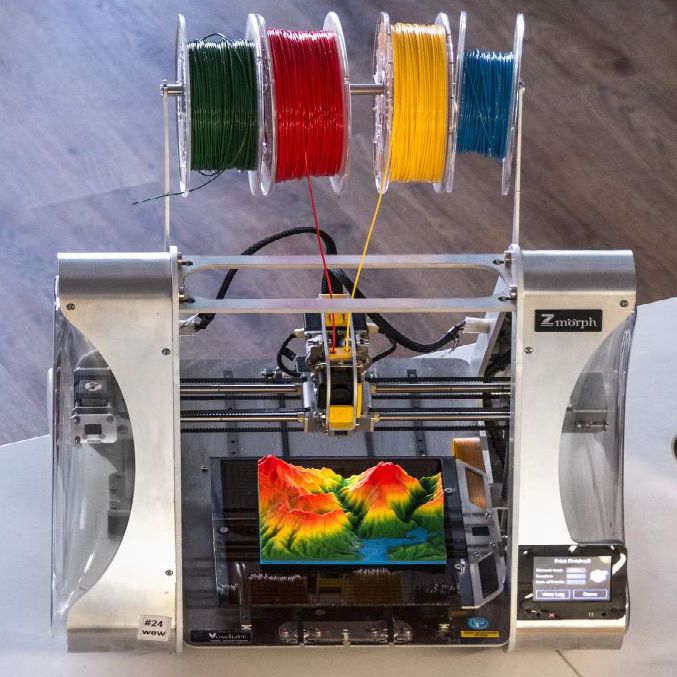

The company noted that its process creates a 3D scan of the eye socket and a color-calibrated photo of the healthy eye to create the prosthetic eye's 3D model. Fraunhofer's Cuttlefish 3D printing driver is used to print the model on a multicolor, multimaterial 3D printer.

The process

Fraunhofer noted that the process is made possible by the algorithms of Cuttlefish:Eye, a software solution from the Fraunhofer Institute for Computer Graphics Research IGD.

Working in close collaboration with the British company Ocupeye Ltd, the research team in Darmstadt has developed a unique process to create a virtual model from a scan of the eye socket together with a photo of the healthy eye. This serves as a reliable digital platform for 3D printing. The breakthrough technology to produce prostheses will now be fitted in patients for the first time in a clinical trial to be held at Moorfields Eye Hospital London.

Related: 3D printing in ophthalmology

Mandeep Sagoo, MD, PhD, a consultant ophthalmologist at Moorfields, pointed out that the company is excited about the potential for the fully digital eye.

“This has been a culmination of 4 years of development of sophisticated technology between Moorfields Eye Hospital, UCL Institute of Ophthalmology, Ocupeye Ltd and Fraunhofer,” he said. “We hope the forthcoming clinical trial will provide us with robust evidence about the value of this new technology, showing what a difference it makes for patients. It clearly has the potential to reduce waiting lists."

It clearly has the potential to reduce waiting lists."

A necessity

Ocular prostheses become necessary whenever an eye has had to be surgically removed for health reasons, such as a result of a serious injury or a life-threatening disease such as eye cancer, conditions that afflict more than 8 million people worldwide.

The method of individually measuring the eye socket and manufacturing the prostheses has remained largely unchanged for many decades. The invasive molding can be uncomfortable and in children a distressing experience that often requires a general anesthetic.

The process of handcrafting a prosthetic eye is time consuming and can result in a wait of several months, exacerbating what is already a stressful time for the patient. Utilizing leading-edge 3D printing technologies, the new process significantly speeds up production and provides patients with a quicker, better and an overall more comfortable experience.

The patient's 3D prothesis initial appointment begins with a 2. 4 second, noninvasive, non-ionizing scan from a specially modified Optical Coherence Tomography ophthalmic scanner, which is manufactured by TOMEY Japan. The medical scanner is routinely used in a hospital environment.

4 second, noninvasive, non-ionizing scan from a specially modified Optical Coherence Tomography ophthalmic scanner, which is manufactured by TOMEY Japan. The medical scanner is routinely used in a hospital environment.

Color-calibrated

The resultant scan of the eye socket and color-calibrated image of the healthy eye is seamlessly and digitally transferred to Fraunhofer IGD. Tomey has optimized its capability such that the socket of the removed eye is precisely measured and additionally a color-calibrated photo of the healthy eye is produced. Cuttlefish:Eye creates a 3D print model from this data in an equally short time.

The company noted the printers are controlled by the Cuttlefish universal 3D printer driver, which is characterized by its color consistency as well as realistic representation of even transparent materials. Fraunhofer IGD technology is used worldwide with many different types of printers. The 3D prostheses are printed by Lupburg based Fit AG which has many years of experience in additive manufacturing, especially in the field of medical technology. Once printed, the prostheses are inspected and given final polishing by a team of experienced ocularists. With a single 3D printer, Ocupeye can potentially fulfil the annual requirement of around 10,000 prostheses required for the UK market.

Once printed, the prostheses are inspected and given final polishing by a team of experienced ocularists. With a single 3D printer, Ocupeye can potentially fulfil the annual requirement of around 10,000 prostheses required for the UK market.

“Together with Fraunhofer, we have achieved the very first in human 3D printed prosthetic eye,” Gordon Bott, CEO of Ocupeye Ltd., said in a statement. “There now exists a complete technology that truly has the potential to reimagine prosthetic eye patients' expectations.”

Every step of the new manufacturing procedure has been subjected to strict quality controls. For example, the Cuttlefish:Eye software is certified as a Class 1 medical device. Extensive and exhaustive biocompatibility tests were performed on the 3D printing materials before the UK Medicines and Healthcare products Regulatory Agency -MHRA- provided a letter of approval for a clinical trial. The clinical trial will recruit around 40 patients to receive a 3D-printed ocular prosthesis; they will be examined several times by qualified clinical staff over the course of a year and be asked to report back on their experiences.

That is an important step that is bringing the project partners closer to fulfilling their vision. Namely to have the ability to routinely provide a realistic medical product to patients who require a prosthetic eye. This is made possible by a highly "disruptive" innovative process that begins with an optical coherence tomography medical device, manufactured by Tomey Japan and with their European HQ in Nürnberg. From the learnings already gained during the research and development phase, Tomey has adopted the enhanced functionality as standard and applied the enhancements to their next-generation devices.

Potentially with just one device per clinic and the deployment of a small number of geographically deployed 3D printers, the estimated global market demand for eight million people, approximately 0.1 percent of the world's population, could be met.

American scientists 3D printed a prototype of a bionic eye

News

Scientists from the University of Minnesota have demonstrated a prototype of a bionic eye with electronics printed on a 3D printer.

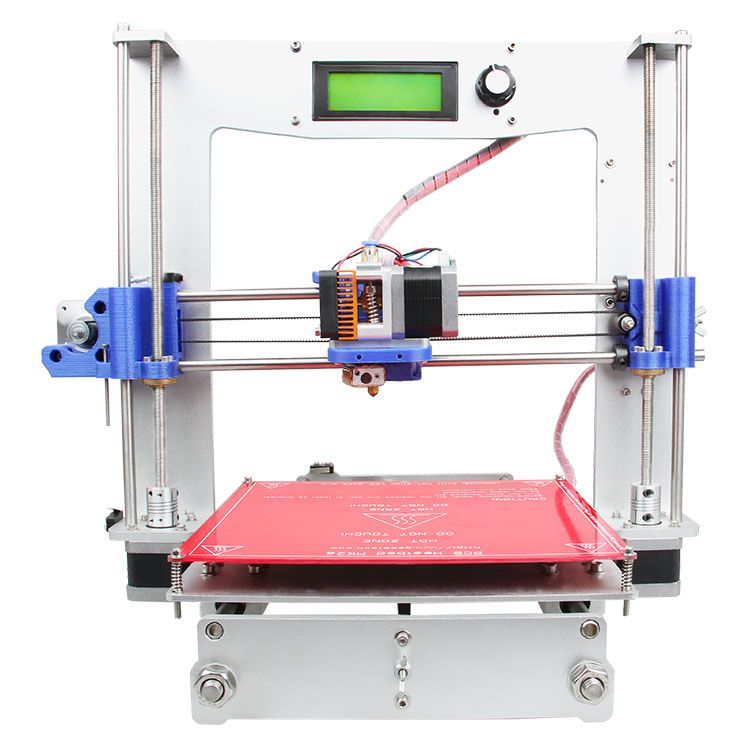

The new work is a continuation of research on 3D printing of electronics with an eye on biological integration by a research team led by University of Minnesota Associate Professor of Mechanical Engineering Michael McAlpine. The previous experiment involved 3D printing electronics over skin ( in illustration below ) using a modified Anycubic Kossel 3D printer, with the experimental system proving to be able to compensate for involuntary movements of the test subject during printing through a combination of 3D scanning and machine vision. The inspiration for the new experiment was the supervisor's mother, who lost sight in one of her eyes. The team decided to find out if a functional prosthesis could be printed.

“Bionic eyes are usually seen as something out of science fiction, but now, thanks to multi-material 3D printing, we are closer than ever to turning the idea into reality. We have a long way to go before additive manufacturing of active electronics becomes commonplace, but our 3D printed semiconductors show great potential and the ability to achieve efficiency on par with conventional semiconductor electronics. In addition, we can easily print semiconductor devices on curved surfaces, which mass electronics manufacturers can't do,” says McAlpine. nine0003

In addition, we can easily print semiconductor devices on curved surfaces, which mass electronics manufacturers can't do,” says McAlpine. nine0003

The device shown consists of a transparent hemisphere, internally lined with polyethylene terephthalate (PET) film. On top of the film, the researchers printed an array of photodetectors, each consisting of five layers—a silver-based conductive ink, then a transparent and flexible conductive PEDOT:PSS anode, a P3HT:PCBM photoactive polymer blend, an insulating silicone layer, and a liquid gallium cathode. indium alloy. The effectiveness of the prototype surprised the developers themselves: the ratio of the photocurrent at the external leads to the number of incident photons reaches 25.3%. Of course, the prototype is very primitive, but the team intends to continue experimenting with flexible and biocompatible substrates towards increasing the number of elements in the array and, if successful, creating the first true functional prosthetic eye. The report of the scientific team is published at this link. nine0003

The report of the scientific team is published at this link. nine0003

Do you have any interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

Follow author

Follow

Don't want

7

Article comments

More interesting articles

12

Follow author

Subscribe

Don't want

Serial production of Dobrynya quadrocopters has been launched at the Obukhov plant in St. Petersburg. Cost...

Read more

12

Subscribe to the author

Subscribe

Don't want

3MF is a file format created to replace STL and is characterized by increased usability and extended function. ..

..

Read more

sarkazm

Loading nine0003

04/01/2016

39956

68

Subscribe to the author

Subscribe

Don't want

News from the world of printing in a short line

FDplast announced the release of a free...

Read more

Read blogs

3D printed eyes on 3D printer: 3D printed corneas from IdiPAZ

Aug212017

3D printed eyes on 3D printer

In recent years, 3D technologies have given a huge impetus to the development of medicine, in particular, stem cell research and the creation of full-fledged living tissues. In a short time, scientists were able to artificially create various elements of the human body. We wrote about the fact that 3D printing of eyes on a 3D printer is becoming a reality last year. But then it was about realistic eye prostheses.

But then it was about realistic eye prostheses.

Today we want to talk about a more functional development - 3D printed cornea replacement. Specialists from the Spanish Institute for Biomedical Research at the Hospital of La Paz (IdiPAZ), not wanting to lag behind the general trend in the application of bioprinting, included it in their field of activity. True, their goal was not artificial skin or internal organs, but a more delicate structure: the cornea of \u200b\u200bthe eye. nine0003

3D printed artificial cornea

This is the first development in this direction that deserves attention. Previously, 3D printing of eyes on a 3D printer was not carried out by any organization, despite the fact that this is an extremely popular area of medicine. Every year, more than 10 million people in the world go blind as a result of various pathologies of the cornea. Partly, the reason for this is the extreme complexity and high cost of transplant operations. The ability to produce the cornea artificially in the laboratory will solve a lot of problems and give hope to patients who need such an operation. nine0003

nine0003

The focus of IdiPAZ's research is the 3D creation of the corneal stroma, the transparent layer that makes up the bulk of the cornea. The successful outcome of the project will completely eliminate the need for donors. You will have to wait for the manufacture of a replacement within only 5 days. And most importantly, the artificial cornea will be completely individual and adapted to a particular patient. Just imagine how much faster and easier treatment can be! nine0003

A team of researchers is currently exploring different options for 3D printing eyes on a 3D printer. The process that will form the basis of the development is the synthesis of a polymeric extracellular matrix of collagen, which completely imitates the structure of the human cornea. Stem cells from the patient's adipose tissue will be imprinted into this matrix using a 3D printer.

Present and future development

The 3D printing system is now complete. Its implementation requires obtaining the correct technology for creating a collagen matrix on a nanoscale.