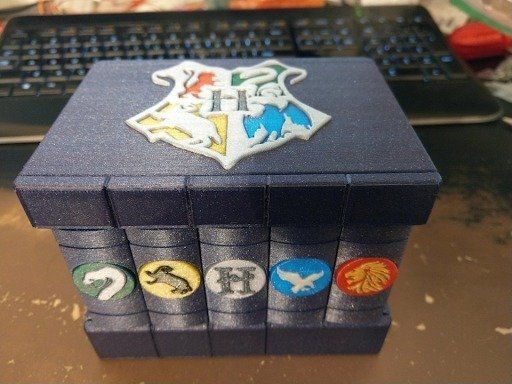

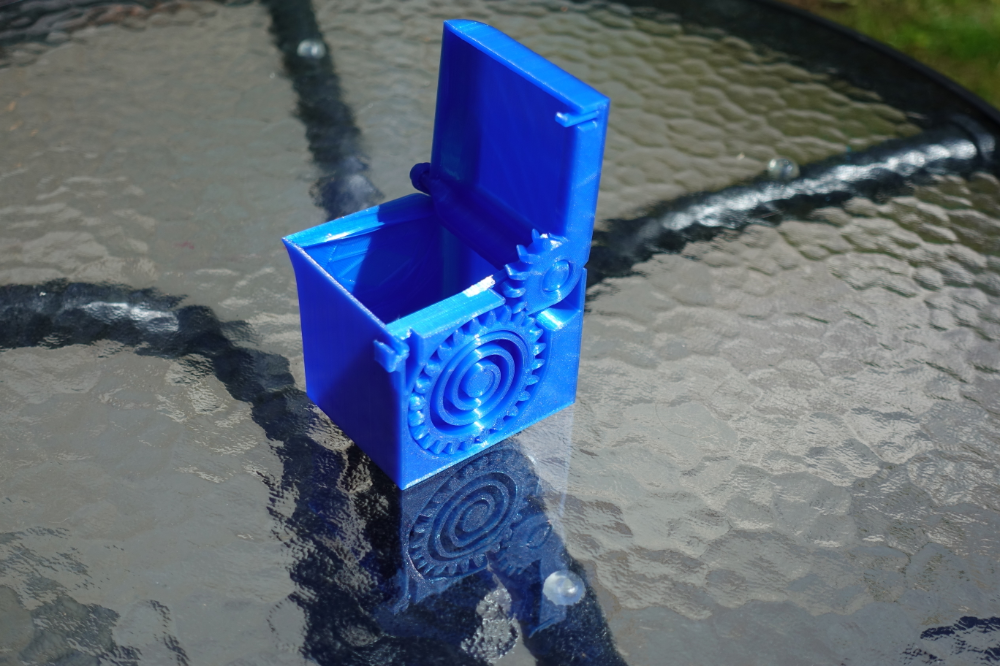

3D printed deck box

3d Printed Deck Box - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(192 relevant results)

▷ magic the gathering deck box 3d models 【 STLFinder 】

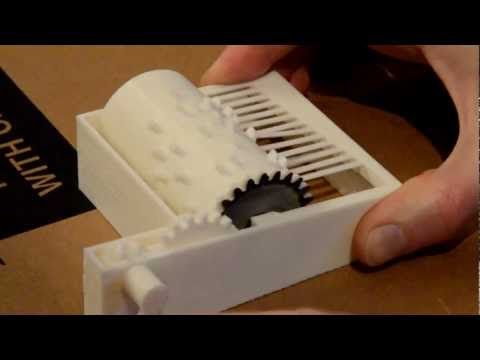

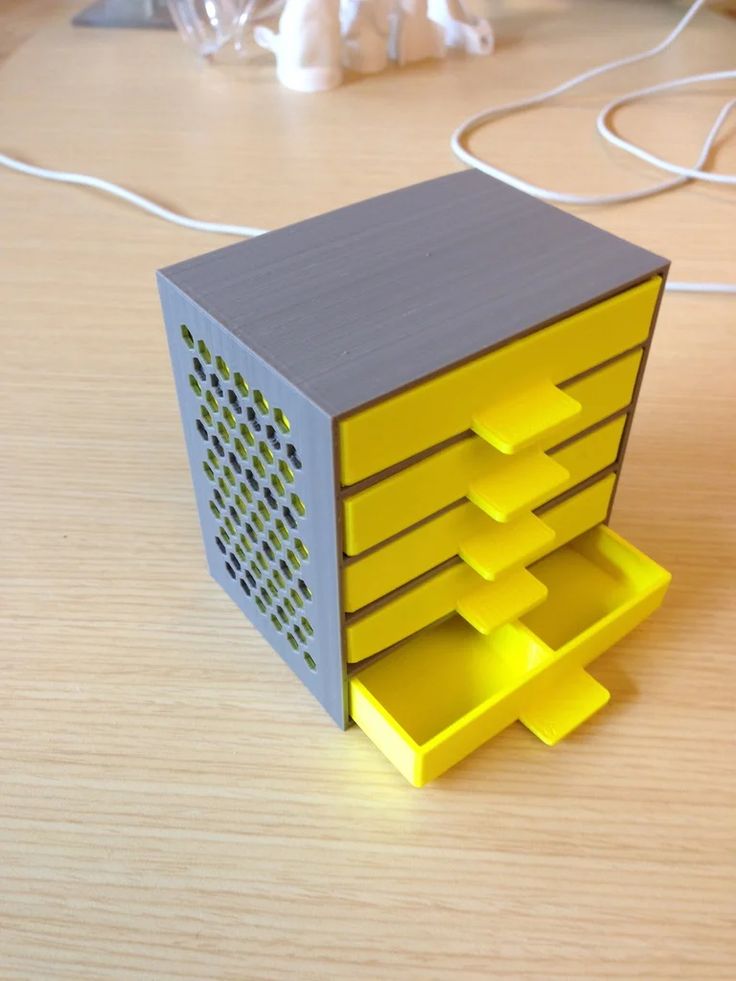

Magic the Gathering Deck Box

thingiverse

Simple Magic the Gathering Deck Box with the "M" logo from Magic.

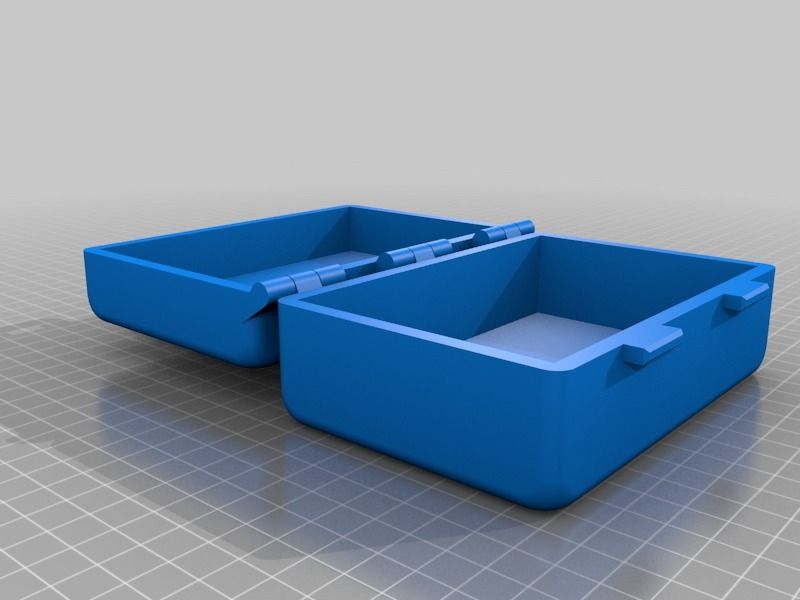

MAGIC the gathering Deck Box

thingiverse

MAGIC the gathering Deck box for sleeved cards. All printers are different so there are two types of hinges. test with the hinge samples which hinge is better for your printer. hinge_sample = Mtg_Deck_Box.stl hinge_sample_2 = Mtg_Deck_Box_2.stl...

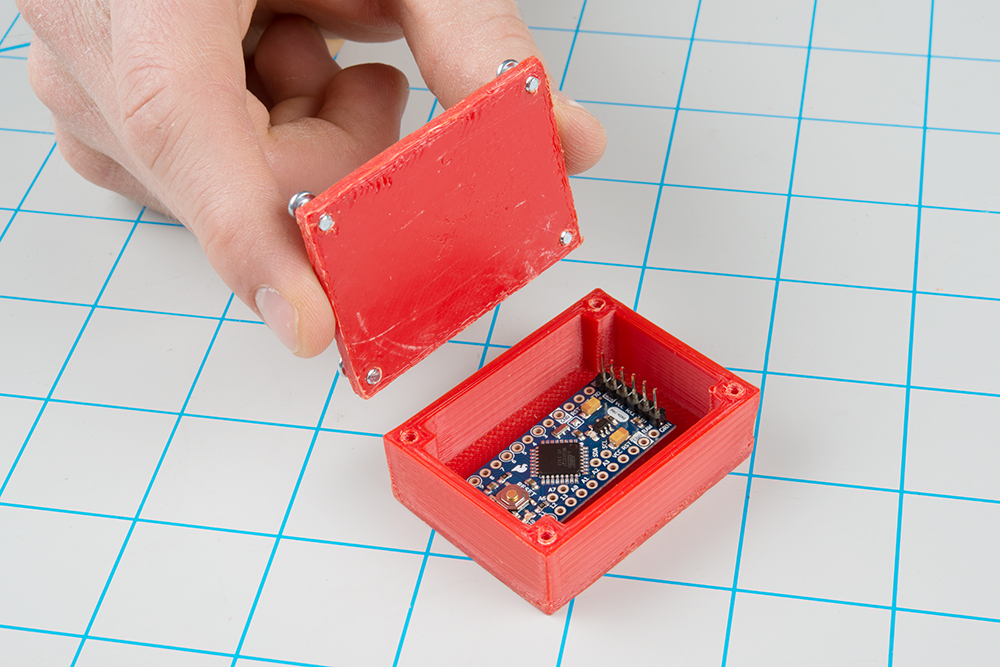

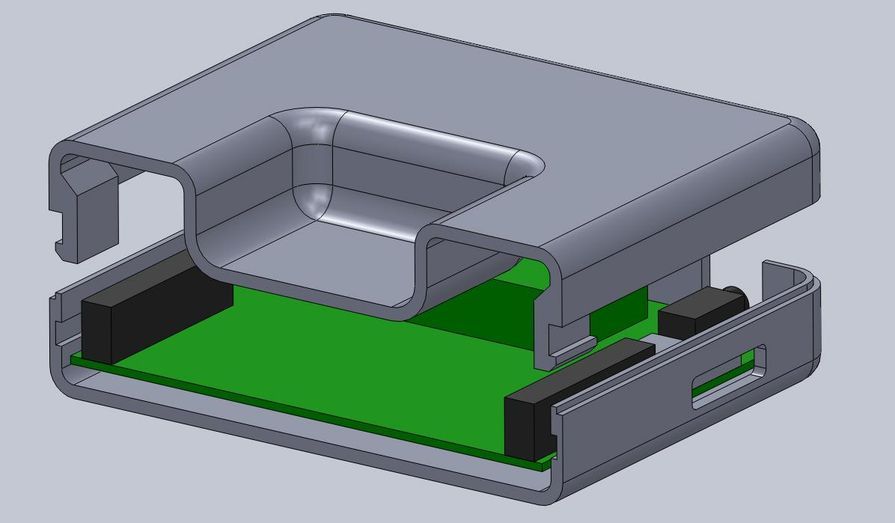

Magic the Gathering Deck Box

grabcad

Custom Magic the Gathering Deck Box. ...I created this to hold my Ravnica themed 360 card cube, and it holds the entirety of the cube, 200 basic lands, as well as tokens and dice.

Magic the Gathering Deck Box

thingiverse

Deck Box for a MTG Deck. Plenty of room even for those who's decks need trimming!

I reccomend printing the first few layers in a finer detail for the lid to unsure that the logos come out correctly. Do not use supports.

Hope you enjoy! Let me...

Plenty of room even for those who's decks need trimming!

I reccomend printing the first few layers in a finer detail for the lid to unsure that the logos come out correctly. Do not use supports.

Hope you enjoy! Let me...

Magic the Gathering Deck Box

thingiverse

A deck box designed to hold 100 cards sleeved with a little extra space for tokens.

Magic the Gathering Deck Box

prusaprinters

Deck Box for a MTG Deck. Plenty of room even for those who's decks need trimming!I reccomend printing the first few layers in a finer detail for the lid to unsure that the logos come out correctly. Do not use supports.</p><p>Hope you enjoy! ...Let me...

Do not use supports.</p><p>Hope you enjoy! ...Let me...

magic the gathering deck box

thingiverse

I made this cause there were no good deck boxes on thingiverse and I think it is pretty good for a first try I will come out with other versions but for this you need to sand the nubs a little so that it can get all the way in to the slot. ... it...

Magic The Gathering Deck Box

prusaprinters

The main box is the same just swap out the lid holds 100 cards

Magic the Gathering deck box

thingiverse

the lid and box can be printed in low res the axel need to be printed in high res supports is needed on the lid and box you need to pot the axel on a raft support hope you like it :)

Magic the Gathering Deck Box

grabcad

This is a box I came up with that is sturdy, can hold max number of cards but at the same time isnt to large or cumbersome to carry around. It has a spot for a playing mat as well as a set of dice. Can hold up to 540 cards between to bottom main box...

It has a spot for a playing mat as well as a set of dice. Can hold up to 540 cards between to bottom main box...

Magic the Gathering Deck-Box

thingiverse

... ...http://www.thingiverse.com/apps/customizer/run?thing_id=269203 Instructions Using the following options: Move_Image_Left_Right = 38 card_type = 69 Move_Image_Up_Down = 45 image_size = 50 image_rotation = 0 input = default_TNH card_count = 40

Magic: The Gathering Deck Box

thingiverse

... ...http://www.thingiverse.com/apps/customizer/run?thing_id=269203 Instructions Using the following options: input = default_TNH Move_Image_Up_Down = 45 image_size = 50 Move_Image_Left_Right = 33 card_type = 69 card_count = 40 image_rotation = 0

EDH Magic the Gathering Deck box

thingiverse

This is a simple EDH or commander deck box for Magic the Gathering. It holds comfortably 100 double-sleeved cards with some extra room for tokens. ...Based on the Ultimate Guard Boulders.

It holds comfortably 100 double-sleeved cards with some extra room for tokens. ...Based on the Ultimate Guard Boulders.

Magic the Gathering: Deck box with sideboard

thingiverse

This is an easy to print deck box with additional space for sideboard cards or tokens. The box fits sleeved cards. ...Based on the deck boxes by [Kvermette](https://www.thingiverse.com/Kvermette).

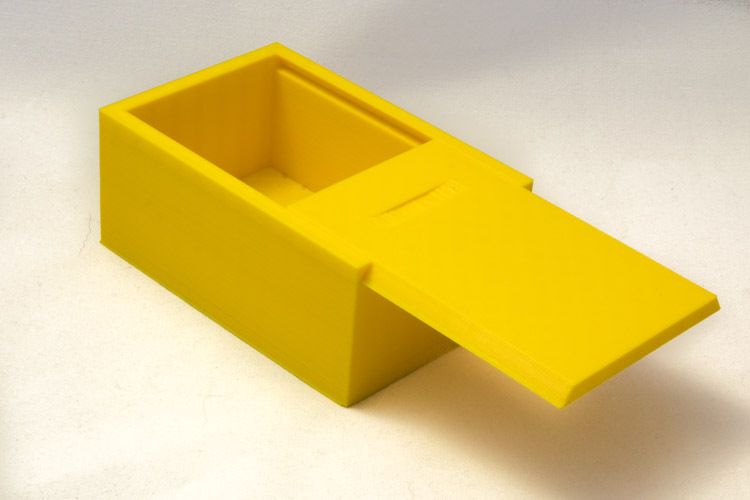

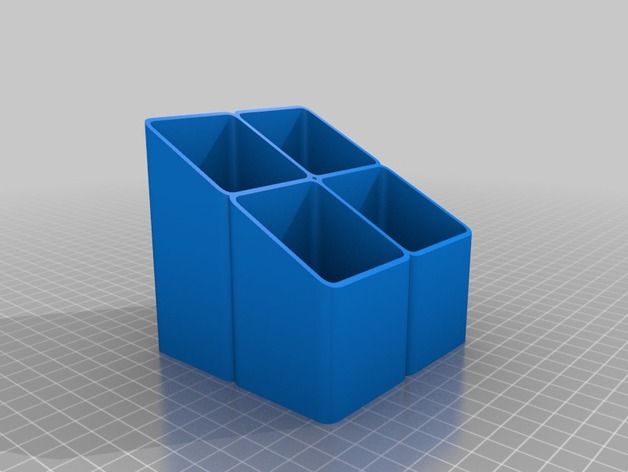

Basic Magic The Gathering Deck Box!

thingiverse

Here is a deck box for Magic: the Gathering, or Pokemon or Yu-gi-yo! This box holds a single sleeved Commander deck (100 cards), with a second compartment for tokens, counters or your sideboard! The second compartment does not hold a spin-down dice,. ..

..

Magic: the Gathering deck-box separators

thingiverse

I really like the idea of what's been done in https://www.thingiverse.com/thing:129254, but the tabs although helpful if you're keeping your cards in boxes, won't fit right in a deck box. ... I always like to have a separator between my deck and the...

Magic the Gathering Deck Box and Dice

thingiverse

customized the blank box

Mikaii Magic The Gathering Deck Box

thingiverse

Both will fit sleeved cards with approximately 46mm of room inside for a deck. (Based on 63 cards in sleeves) This thing was made with Tinkercad. Edit it online https://www.tinkercad.com/things/gqnx6dEX8rZ ...

(Based on 63 cards in sleeves) This thing was made with Tinkercad. Edit it online https://www.tinkercad.com/things/gqnx6dEX8rZ ...

Magic the Gathering Deck Box Front/Back

thingiverse

This is a remix of http://www.thingiverse.com/thing:126610 done by rbschultz. ...This is only the front/back grab the rest you need from the above link.

Magic: The Gathering Deck Box 100 Cards

thingiverse

... ...http://www.thingiverse.com/apps/customizer/run?thing_id=269203 Instructions Using the following options: input = default_TNH Move_Image_Up_Down = 45 image_size = 50 Move_Image_Left_Right = 33 card_type = 69 card_count = 60 image_rotation = 0

Magic the Gathering Deck Box

thingiverse

Please print at 105% Magnets used are 4x2mm fits roughly 100 cards

Magic the Gathering Deck box

thingiverse

Customized version of http://www. thingiverse.com/thing:269203 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=269203

thingiverse.com/thing:269203 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=269203

Magic the Gathering Deck Box with Life counter

thingiverse

This Magic the Gathering deck box includes a life counter. It can be attached on the side to another deck box or to my commander deck box design. Want some additional lids? Check out my collections! ... https://www.thingiverse.com/thing:4574971 ...

D20 mount for Magnetic Magic The Gathering Deck Box

thingiverse

This is a modified version intended to magnetically hold onto the magnetic deck box

Magic the Gathering Deck Box w/ My Face

thingiverse

I needed a Magic the Gathering card box and decided to make it pretty personal.

EDH Sized Magic: The Gathering deck box. Customized.

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=269738 Instructions Using the following options: circle_resolution = 120 card_z = 100 card_y = 70 card_x = 70 printing_tolerance = 0.2 build_plate_manual_y = 180 build_plate_manual_x = 180...

Magic: The Gathering | MTG | Deck Box

myminifactory

Inspired by https://www.myminifactory.com/object/3d-print-deck-box-mtg-pokemon-yu-gi-oh-24547. ...Fits 100 sleeved cards for Magic: the gathering.Lid and base have small extrusions to hold in place.

Magic the Gathering Commander Deck Box

thingiverse

This deck box is suitable for Magic the Gathering commander decks with a commander window. It is modular and they can be attached to each other. The print was testen on a Creality Ender 3 and Prusa MK3S. Support structures are not needed. Want...

Magic the Gathering Red deck box

prusaprinters

Red deck boxDeck box for 60+15 sleeved Magic the Gathering cards. The lid has the red mana symbol.This is a simple box that does not use a lot of filament. It's purpose is to hold a 60 card deck with a 15 card sideboard. It is meant to be printed in...

It is meant to be printed in...

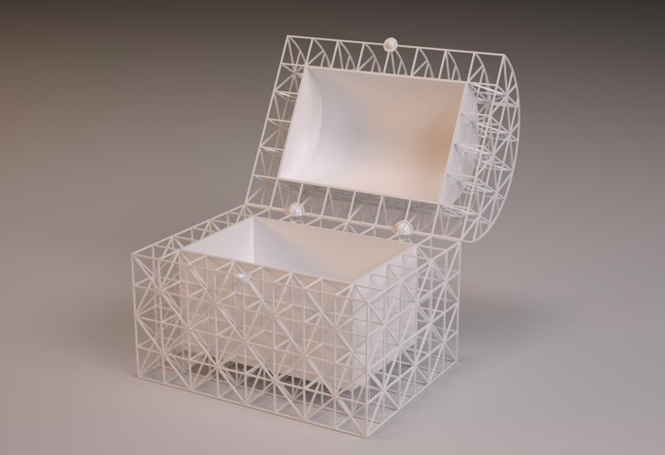

Magic The Gathering Commander Deck Box

thingiverse

This is a hexagonal shaped magic the gathering commander deck box, based on the mechanical movement nr. 221. ...If you turn the top in the right direction it unlocks and enables you to slide the side door up, so you can reach your cards.

20 Use Cases for 3D Printing

3D printing has progressed so rapidly in recent years that we will soon stop talking about what can be created using additive manufacturing. It will be easier to mention what cannot be done. Yes, this list will continue to grow rapidly. But for now, let's take a look at some examples showing the wide range of 3D printing possibilities. We warn you in advance: the list is far from complete.

Fruit

A gift for impatient parents

Young parents often experience an irresistible desire to acquire all sorts of items, one way or another related to their child, even if not yet born. The Japanese company Fasotec offers future parents models of unborn babies made from images of real fetuses obtained using magnetic resonance imaging. The finished model consists of two materials - a fetal figurine made of white photopolymer, and a transparent material that imitates the shape of the mother's womb. At around $1,275, the fun isn't cheap, but Fasotec already has some competition. So, 3D Babies offers a similar service for only $200, although the size of the finished model is much smaller, and the quality is not quite on the same level. nine0003

The Japanese company Fasotec offers future parents models of unborn babies made from images of real fetuses obtained using magnetic resonance imaging. The finished model consists of two materials - a fetal figurine made of white photopolymer, and a transparent material that imitates the shape of the mother's womb. At around $1,275, the fun isn't cheap, but Fasotec already has some competition. So, 3D Babies offers a similar service for only $200, although the size of the finished model is much smaller, and the quality is not quite on the same level. nine0003

Although the desire to get such a model may seem a bit strange, there is a perfectly logical explanation. As it turns out, the idea was originally aimed at giving blind parents the opportunity to "look" at the ultrasound of the unborn child.

Weapons

Functional 3D printed receiver from AR-15 without any numbers

The possibility of 3D printing of weapons has seriously alarmed law enforcement agencies around the world. After all, even simple FDM printers allow you to create all-plastic guns. Although such a weapon is primitive, even a disposable pistol with a single cartridge in the hands of a criminal can cost someone a life, and it is impossible to trace such a weapon. However, there are also people who believe that 3D printing of weapons should be allowed. Thus, the US Constitution gives citizens the right to freely carry weapons, although certain restrictions still apply. The non-profit organization Defense Distributed, which released the Liberator plastic pistol into the public domain, went further by unveiling the design of the lower receiver of the AR-15 carbine. AR-15 is actually a civilian counterpart, even a prototype of the M-16 automatic rifle, which is in service with several countries of the world. The lower part of the receiver bears the registration number - this is the only part of the rifle that cannot be purchased as a spare. Thus, the printing of this part can bypass the need to register weapons.

After all, even simple FDM printers allow you to create all-plastic guns. Although such a weapon is primitive, even a disposable pistol with a single cartridge in the hands of a criminal can cost someone a life, and it is impossible to trace such a weapon. However, there are also people who believe that 3D printing of weapons should be allowed. Thus, the US Constitution gives citizens the right to freely carry weapons, although certain restrictions still apply. The non-profit organization Defense Distributed, which released the Liberator plastic pistol into the public domain, went further by unveiling the design of the lower receiver of the AR-15 carbine. AR-15 is actually a civilian counterpart, even a prototype of the M-16 automatic rifle, which is in service with several countries of the world. The lower part of the receiver bears the registration number - this is the only part of the rifle that cannot be purchased as a spare. Thus, the printing of this part can bypass the need to register weapons. Some countries have already banned the 3D printing of weapons, although it is not entirely clear how to apply this ban in practice. nine0003

Some countries have already banned the 3D printing of weapons, although it is not entirely clear how to apply this ban in practice. nine0003

Clothes

One of Snezhana Gross' designs

Some consumables for 3D printing, especially soft photopolymers, are quite suitable for making clothes and even underwear. The bra in the illustration was laser sintered from nylon. This design from Continuum Fashion aims to showcase the possibilities that 3D printing opens up for couturiers. However, don't think this is an experimental model: the company offers finished products for sale on the Shapeways website. nine0003

Russian designers did not bypass the new technology either: Snezhana Gross demonstrated casual wear designs integrating functional 3D printed components.

Art

Easy to print. Take a picture - as lucky

Would you like a replica of the Venus de Milo? No problem, just choose the material and printing method. True, marble is not yet on the menu, but sandstone imitators are already available. Gypsum was one of the first materials for 3D printing. A three-dimensional image of the original can be obtained using a regular photo and then converted to 3D. In addition, more and more 3D scanners have recently appeared on the market, including portable hand-held options that can capture images of large objects. It remains a mere trifle - to agree on a stereo photo session with the security of the Louvre. nine0003

Gypsum was one of the first materials for 3D printing. A three-dimensional image of the original can be obtained using a regular photo and then converted to 3D. In addition, more and more 3D scanners have recently appeared on the market, including portable hand-held options that can capture images of large objects. It remains a mere trifle - to agree on a stereo photo session with the security of the Louvre. nine0003

Although, if you are too lazy to make digital models yourself, you can always download them.

Products

What's for breakfast?

Although giant hot dogs are still far away, 3D printers have already learned how to print minced meat. An example of this is the Foodini culinary printer, a simple and practical device using syringe extrusion. Moreover, printing is possible not only with minced meat, but also with any pasty product - dough, cheese, tomato puree. The only thing that Foodini is not yet capable of is heat treatment. It is to be expected that soon there will be devices that combine 3D printing with refrigeration units and, say, microwave ovens. Then sci-fi tales of "replicators" can come true. One press of a button, and the device will lay out the desired pizza and bake it to the delight of the user. Just one question: do you like thin dough or fluffy? nine0003

Then sci-fi tales of "replicators" can come true. One press of a button, and the device will lay out the desired pizza and bake it to the delight of the user. Just one question: do you like thin dough or fluffy? nine0003

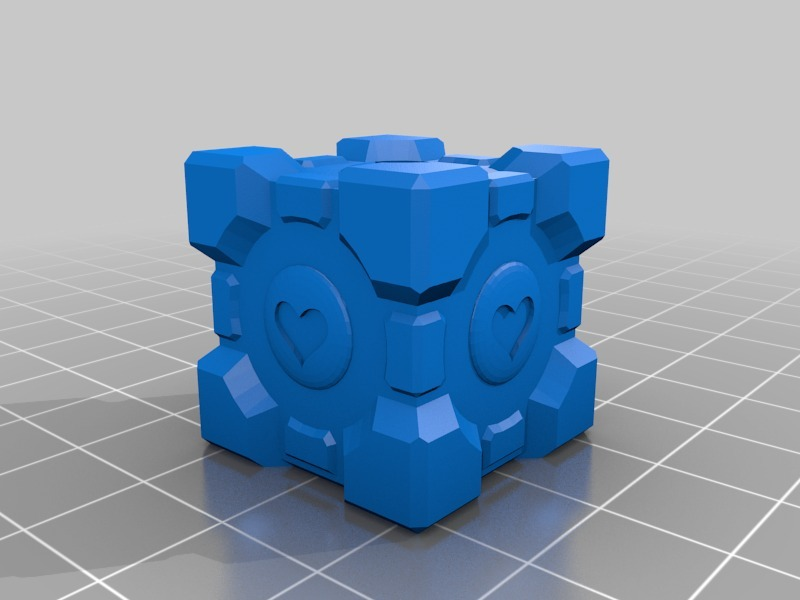

Characters

Parts of models used to animate ParaNorman's protagonist

Whether it's a miniature version of a giant robot from a favorite manga, a creepy alien creature from Alien, or a Keanu Reeves action figure (as in a black cape and sunglasses, and with a beard and a sandwich sitting on a bench), 3D printing allows you to create replicas of game and movie characters for the delight of fans. And the fact that such souvenirs can be printed even on household 3D printers opens up great opportunities for those who like to collect such models - after all, not all of them are available for sale. Do you want a model of a rare aircraft? Print it. nine0003

And what is most interesting, this application has already had the opposite effect. ParaNorman cartoon characters were still printed. Like the new RoboCop suit. True, inside it was still stuffing from a person. But why stop at simple visualization?

Like the new RoboCop suit. True, inside it was still stuffing from a person. But why stop at simple visualization?

Home Robots

Early Terminator Prototype

The advent of inexpensive Arduino boards made it possible to design a wide variety of electronic devices at home. Here are your own 3D printed robots. You printed the case, inserted the servos and the board, and you have a new au pair. But what about people who do not understand programming or elementary soldering? Scientists from the Massachusetts Institute of Technology are developing a project aimed at automating the design and construction of domestic robots. Ideally, the user will only have to set the necessary functions for the future device, after which the system will compile the required design and send it to print. A few hours later, it will be possible to pick up a ready-made device - a robot-spider for wiping chandeliers or a machine for turning pancakes. nine0003

Aviation

3D printed part used in Chinese fifth generation fighter aircraft prototypes

The toy airplanes we have already mentioned. What about real ones? There is also a place for additive manufacturing in the aircraft industry, although here one cannot do without expensive industrial plants capable of creating high-quality parts, including all-metal ones. Leading aircraft manufacturers, including Boeing and Lockheed Martin, are already testing laser sintering and melting technologies for the production of ventilation systems, structural components and even jet engine parts. Chinese engineers, on the other hand, set to work on a real scale, creating installations for the additive production of parts weighing up to 300 tons. nine0003

What about real ones? There is also a place for additive manufacturing in the aircraft industry, although here one cannot do without expensive industrial plants capable of creating high-quality parts, including all-metal ones. Leading aircraft manufacturers, including Boeing and Lockheed Martin, are already testing laser sintering and melting technologies for the production of ventilation systems, structural components and even jet engine parts. Chinese engineers, on the other hand, set to work on a real scale, creating installations for the additive production of parts weighing up to 300 tons. nine0003

Space

Dragon v2 is Space's latest creation

The space industry is not far behind the aviation industry in its interest in 3D printing. NASA has successfully tested titanium rocket engine nozzles, and a few weeks ago, Elon Musk, the head of the private space company SpaceX, held a presentation of the new Dragon v2 orbiter, which also uses engines with 3D printed parts.

Bioprinting

Biopens can help treat fractures

Vessels, tissues, whole organs - several companies are simultaneously developing the production of organic imitators that are completely similar to natural tissues. Although transplantation of 3D printed organs is still far away, work in this direction is underway. In parallel with the production of organic tissues from scratch, methods are also being developed to restore damaged tissues, such as cartilage or bone. Devices called "biopens" are able to apply living cells to damaged areas, promoting their healing. nine0003

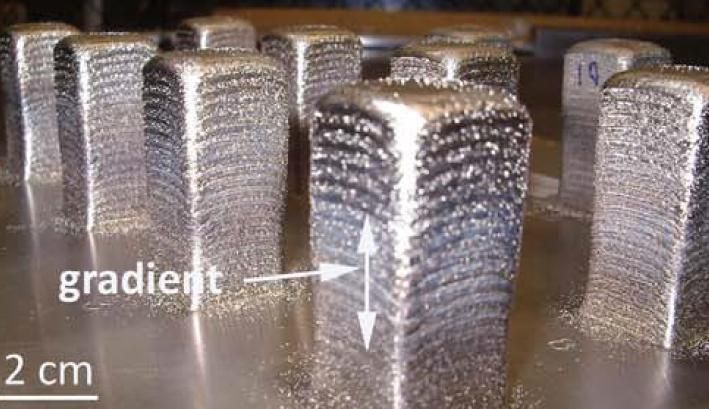

Prostheses

Titanium orthopedic prostheses with a porous structure for improved osseointegration

What if the tissues cannot be restored? 3D printing can help with prosthetics. Thus, the Swedish company Arcam creates installations for electron-beam melting, which make it possible to create virtually monolithic metal products, including titanium. Titanium orthopedic prostheses have become one of the most sought-after products created on the devices of this company - according to company statistics, their number exceeds thirty thousand copies. nine0003

nine0003

Not only that, 3D printed limbs can compete with high-tech designs with one difference - their cost cannot be compared. How many people can afford a tens of thousands of dollars of prosthetic hands? How about a $50 fully functional prosthesis? And it's possible.

An even more common application of additive manufacturing is in dental prosthetics. If you have recently had a crown or bridge placed, it is possible that they were cast from models created with a stereolithography printer that prints with photopolymer resins. nine0003

Musical instruments

3D printed musical instruments

Guitars? Flutes? Drums? Easy. Broke your oboe - print a new one. Of course, professional musicians can argue: plastic guitar? Not seriously. But who said that all tools have to be made of plastic? The same neck can be printed from wood resin, similar in density to natural wood. You can even print a composite carbon fiber core. And as far as simply decorating your favorite harpsichord, 3D printing can work wonders here. It would be fantasy! nine0003

It would be fantasy! nine0003

Shoes

Luc Fusaro's stylish trainers

Eight-time world sprint champion Usain Bolt is famous for his love of gold. This includes not only medals, but also cars and even shoes. During his contract with renowned manufacturer Puma, Bolt wore signature gold-plated sneakers. And more recently, engineer and designer Luke Fusaro has taken on the development of sports shoes that Usain would like. Its distinctive feature is its golden color. Oh yes - and it's also designed for 3D printing. The use of additive manufacturing has one important bonus, namely the ability to produce shoes that are precisely tailored to the size and contours of the athlete's foot. Such shoes are produced by laser sintering, although this technology has already had a competitor. nine0003

Drugs

3D printing can facilitate the production of mixed drugs and help with drug testing on living tissues often in combination with tissue engineering. Thus, the Organovo company directs its efforts to create artificial human liver tissues to test new drugs for toxicity without risk to human health. But the drugs themselves can also be printed by binding the drugs with a gel material. As a result, we get ordinary-looking pills, but with a complex content of drugs, tailored to a particular patient. nine0003

But the drugs themselves can also be printed by binding the drugs with a gel material. As a result, we get ordinary-looking pills, but with a complex content of drugs, tailored to a particular patient. nine0003 Cars

Doc Brown is introduced to 3D printing. That's about the reaction you'd expect.

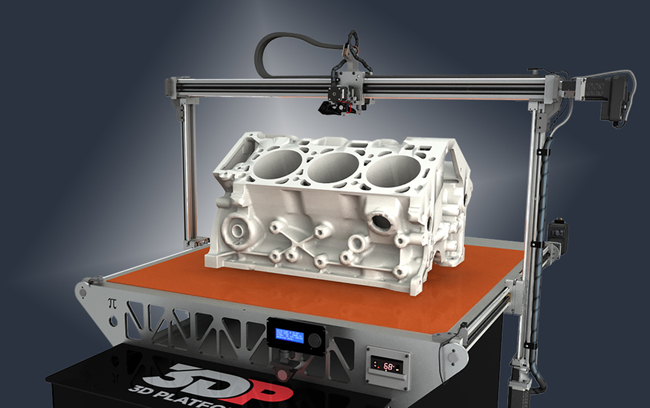

Most automotive components can be printed, but it's not economically viable when it comes to mass production. But for prototyping new cars, 3D printing is great. As, however, for the production of unique machines or components. For example, you can print replacement parts for low-volume, discontinued models. Where else can you find parts for, say, the DeLorean that inspired the Back to the Future time machine? The only small company still making parts for this car is in Texas. Shipping parts can cost more than the machine itself, quite inexpensive. nine0003

Customization

Maximum glamor at minimum cost

Why not take a finished product and add decorative elements? Turn your bike into a work of art for everyone to envy. Gold-plated openwork fasteners on a black chassis will make passers-by look back. But it is not necessary to stop at the decorative aspect! Maybe you are not satisfied with the seat? Why not print a new one? Or add more comfortable handles? Klaxon style 1910s?

Gold-plated openwork fasteners on a black chassis will make passers-by look back. But it is not necessary to stop at the decorative aspect! Maybe you are not satisfied with the seat? Why not print a new one? Or add more comfortable handles? Klaxon style 1910s?

Furniture

One of Joris Laarman's clever designs

Toy furniture? No, not only. The advent of composite materials for FDM printing makes it possible to print "wooden" furniture, almost indistinguishable from the real thing. Actually, the material Laywoo-D3 could not do without real wood in the form of micro-sawdust. This stuff even smells like wood! Finished products are easily machined and varnished.

Or do you prefer metal furniture? Dutch designer Joris Laarman has created his own machine for metal 3D printing, without the use of expensive powders, vacuum chambers and lasers. The device draws with metal in the air, allowing you to create elegant interlaced designs. nine0003

Jewelry

Beautiful and functional

A clear demonstration of the precision of 3D printing is its application in jewelry. It should be said right away that not all technologies are suitable for this task. Widespread FDM printers are attractive due to their cost-effectiveness, but in terms of print quality they do not reach the standards of jewelry production. The most popular choice is laser (SLA) and projector (DLP) stereolithography - installations using these technologies allow printing photopolymer parts of extraordinary accuracy. Such products are used as master models when creating jewelry casting molds, greatly simplifying the production process. nine0003

It should be said right away that not all technologies are suitable for this task. Widespread FDM printers are attractive due to their cost-effectiveness, but in terms of print quality they do not reach the standards of jewelry production. The most popular choice is laser (SLA) and projector (DLP) stereolithography - installations using these technologies allow printing photopolymer parts of extraordinary accuracy. Such products are used as master models when creating jewelry casting molds, greatly simplifying the production process. nine0003

But there is also an option for direct additive manufacturing of jewelry: laser sintering and melting technologies make it possible to create finished products from metal powder, including precious metal powders. True, the cost of such installations and materials is often too high for widespread use even by jewelers.

Construction

3D printing of buildings will help solve housing problems experimenting with the construction of concrete "boxes". True, these attempts are still quite primitive, because a real house will also need infrastructure - drainage, wiring ... Andrey Rudenko's attempts to build a full-fledged house are very promising. Andrey designed his own printer capable of printing with commercially available cement mixtures. Moreover, he already had competitors. Thus, the BetAbram company plans to put on sale printers for printing buildings up to 16x9m. The issue price is about $44,000 for the largest of the three models. True, "more" is not necessarily "better". Spanish developers are trying to go in the direction of miniaturization of 3D construction printers, creating robots that can use already built building elements as a working support.

True, these attempts are still quite primitive, because a real house will also need infrastructure - drainage, wiring ... Andrey Rudenko's attempts to build a full-fledged house are very promising. Andrey designed his own printer capable of printing with commercially available cement mixtures. Moreover, he already had competitors. Thus, the BetAbram company plans to put on sale printers for printing buildings up to 16x9m. The issue price is about $44,000 for the largest of the three models. True, "more" is not necessarily "better". Spanish developers are trying to go in the direction of miniaturization of 3D construction printers, creating robots that can use already built building elements as a working support.

Which method will be the most practical, time will tell. But if any of them succeeds, the construction industry can make a qualitative breakthrough, expressed in increased savings, safety and speed of building construction. nine0003

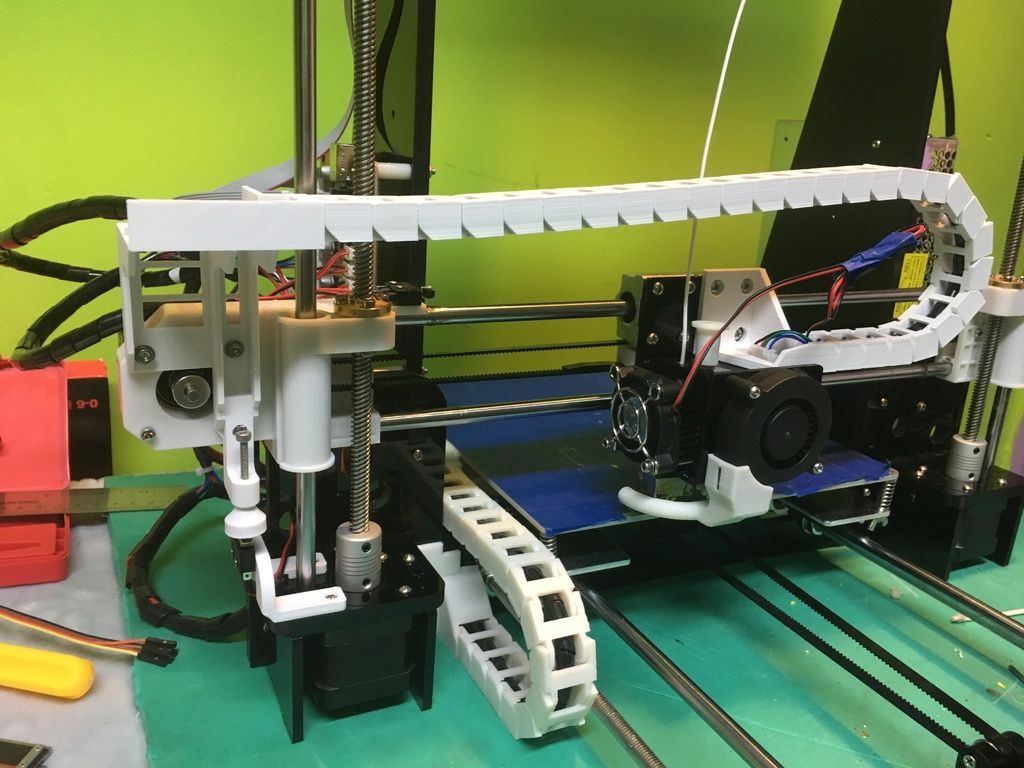

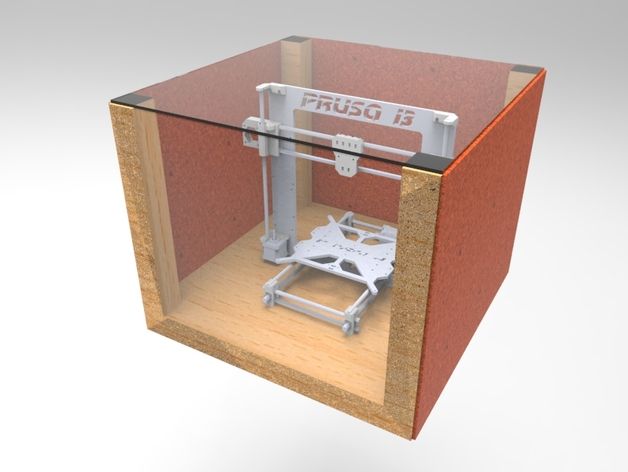

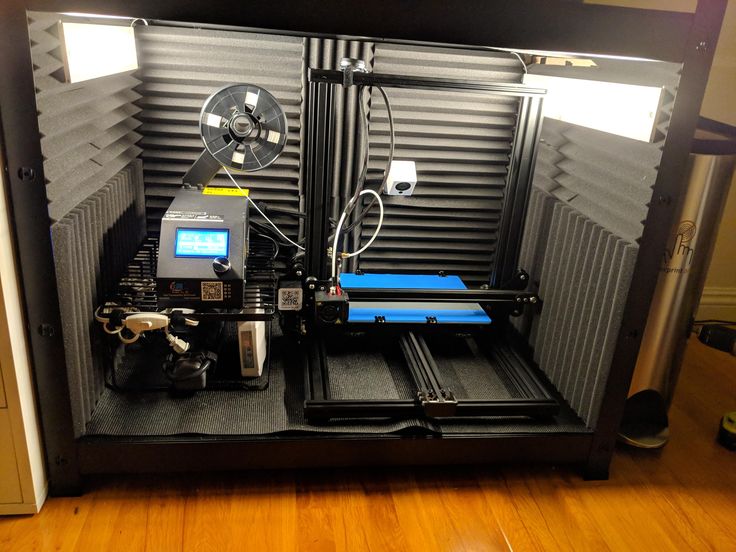

3D printers

What else can I print with a 3D printer? Another 3D printer! Even if not entirely yet: the necessary electronic and electromechanical components are not yet subject to printing, but this is only a matter of time. Almost all materials used or close analogues have already been tested by various additive manufacturing methods. It remains only to wait for the appearance of machines capable of using the full range of consumables. Then the RepRap project, which gave impetus to the development of compact self-replicating 3D printers, will come to a logical conclusion. nine0003

Almost all materials used or close analogues have already been tested by various additive manufacturing methods. It remains only to wait for the appearance of machines capable of using the full range of consumables. Then the RepRap project, which gave impetus to the development of compact self-replicating 3D printers, will come to a logical conclusion. nine0003

Article prepared for 3DToday.ru

Top 10 uses for 3D printing

As people in the know say, the main problem with 3D printing is that no one knows why it is needed. Unfortunately, for the majority of Russians, additive technologies still remain something mysterious and incomprehensible, despite their growing popularity around the world. In fact, household 3D printers are quite easy to use, and quite successfully produced by Russian companies at quite affordable prices. Industrial devices are very expensive, but their potential cannot but impress. Let's look at what can and should be printed using the ten most striking examples of the use of 3D printers in everyday life and industry. nine0003

nine0003

Medical

The most promising direction for 3D printing in general is piece or small-scale production. If consumer goods are easier and cheaper to cast and stamp, then customized products are more profitable to print, because 3D printing allows you to go from a digital model directly to production, without requiring the manufacture of expensive tooling. Sometimes, however, it is simply impossible to do without piece production. Excellent examples are children's prostheses, which need to be constantly changed as the child grows. The idea of prosthetics has become widespread around the world, with some fully capable mechanical versions costing as little as $50, while custom-made prostheses can cost as much as $50,000. The most famous domestic project in this direction was Can Touch, founded by Vladimir Rumyantsev with the support of the W.E.A.S. robotics. Designers are helped by 3D scanners used to obtain a three-dimensional drawing of a limb. Then the prosthesis is printed according to the obtained dimensions and outlines. Recently, the company has been using professional 3D printers for higher quality surfaces, but fully functional and very cheap versions can be obtained using consumer printers. nine0003

Then the prosthesis is printed according to the obtained dimensions and outlines. Recently, the company has been using professional 3D printers for higher quality surfaces, but fully functional and very cheap versions can be obtained using consumer printers. nine0003

But dentures are just the beginning. There is a special direction in additive manufacturing called bioprinting. Its essence lies in the 3D printing of three-dimensional structures with living cells and biodegradable materials that serve as a scaffold or "matrix" for the cell mass. Of course, it is possible to grow a cell mass in a test tube, but only bioprinting can create a fully functional organ from several tissues and with a network of blood vessels, and even suitable for transplantation. Work in this direction is already underway, although complex organs have not yet been obtained. The most advanced example can be considered the experiments of the Russian company 3D Bioprinting Solutions, which printed the thyroid gland, which was then successfully implanted in an experimental mouse. But the American company Organovo already produces liver tissue used as samples for testing new drugs for efficacy, toxicity and side effects without the participation of bipedal test subjects. nine0003

But the American company Organovo already produces liver tissue used as samples for testing new drugs for efficacy, toxicity and side effects without the participation of bipedal test subjects. nine0003

Sometimes it is not necessary to print a new organ to save a life. You can fix an existing one. A vivid example was the operation performed by surgeons of the St. Petersburg State Pediatric Medical University. Doctors had to save a baby born with a complex heart defect. In order to understand the structure of the defect, the doctors printed an exact model of the heart from tomographic images and worked out all the details before proceeding with two complex operations. The story ended happily: the boy went to a quick recovery. nine0003

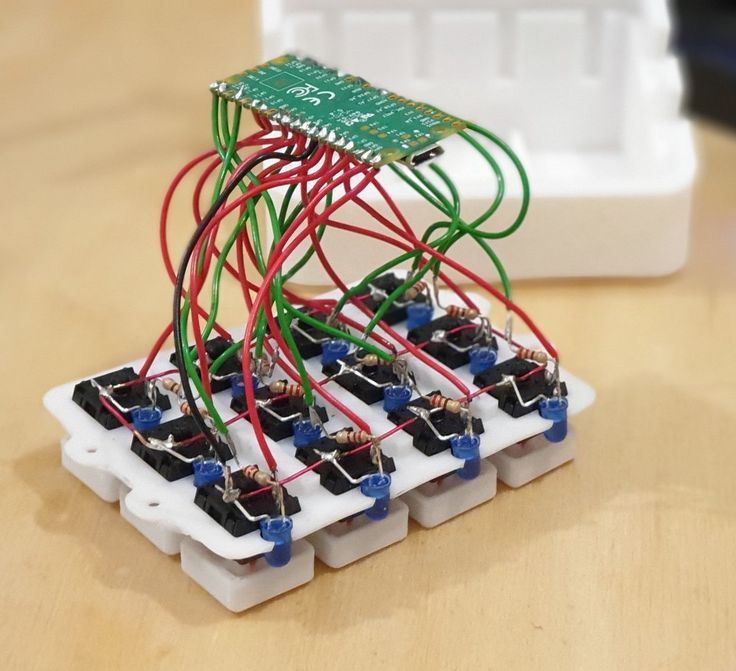

Robotics

We already mentioned prostheses, but what about full-fledged robots? Easy. There are actually a lot of options, but the development of Siemens is interesting because it is based on 3D printed robots that act as 3D printers! As conceived by the creators, such devices should serve as a production swarm like ants or bees. A group of machines follows common algorithms by printing new objects using onboard 3D printers.

A group of machines follows common algorithms by printing new objects using onboard 3D printers.

Such "robo-spiders" work on batteries, remembering their position in space and relative to each other. When the batteries are low, the spider robot calls a fully charged shifter, and he goes to rest and recharge. The developers believe that the industrial version of such a swarm will be able to produce truly large-sized objects like buildings or ship hulls.

Construction

True, buildings can be printed now. There are not many construction 3D printers yet, but they are already showing interesting results. The essence of the process, as a rule, comes down to layer-by-layer printing of walls from a specially formulated cement mixture. The recipe for the mixture is very important, as it needs to set quickly enough to not be crushed by subsequent layers. On the other hand, drying too quickly will prevent the layers from setting to each other. The resulting hollow walls serve as a kind of fixed formwork, into which you can insert insulation, reinforcement, conduct communications, and for greater strength, fill the remaining cavities with concrete and get a monolithic structure. The advantage of this technology over the usual formwork is the ability to create all sorts of hitherto unthinkable shapes - rounded, spiral, etc.

The resulting hollow walls serve as a kind of fixed formwork, into which you can insert insulation, reinforcement, conduct communications, and for greater strength, fill the remaining cavities with concrete and get a monolithic structure. The advantage of this technology over the usual formwork is the ability to create all sorts of hitherto unthinkable shapes - rounded, spiral, etc.

An excellent example is the work of Andrey Rudenko, who printed a miniature castle in the illustration. Andrey recently took on a very serious project by printing an extension to a hotel complex in the Philippines. And the dexterous Chinese at WinSun have already printed the five-story building, although they completed the project piecemeal, assembling the printed panels on site.

Automotive

In just a few years, you'll notice a new car pulling out of your neighbor's garage every time. How can this be? The answer is simple: he prints them. Automotive parts production has quickly become one of the favorite destinations for DIY printers or "makers". Is it worth waiting for delivery or scouring the shops for a broken handle or a hood ornament torn off by a bully when they can be printed? At the same time, printed products cost mere pennies, while spare parts from dealers can be quite expensive. For printing, you can use ABS plastic - the same one from which most plastic trim elements are made. But the automotive 3D printing career didn't end there. nine0003

Is it worth waiting for delivery or scouring the shops for a broken handle or a hood ornament torn off by a bully when they can be printed? At the same time, printed products cost mere pennies, while spare parts from dealers can be quite expensive. For printing, you can use ABS plastic - the same one from which most plastic trim elements are made. But the automotive 3D printing career didn't end there. nine0003

When MarkForged introduced a special 3D printer that allows printing with plastic and carbon fiber composites, 3D printed parts began to appear even on Formula 1 cars. And the American company Local Motors went even further and created a car with a 3D printed body. Now even Toyota is working on its version of the 3D printed machine.

Space

Those born to fly should not crawl, and astronauts love high-tech gadgets. A space 3D printer suggests itself! The first such device, similar to bar desktop machines available on Earth to anyone, was launched into orbit in September 2014. The Made in Space 3D printer has been successfully tested in zero gravity and has already returned to its home planet, and it has been replaced by a more advanced version. nine0003

The Made in Space 3D printer has been successfully tested in zero gravity and has already returned to its home planet, and it has been replaced by a more advanced version. nine0003

And yes, like motorists, astronauts intend to use 3D printing to produce spare parts. The logic here is simple: why carry a complete set of parts and tools into orbit when they can be printed as needed from the relatively small stock of materials on board the station? The latest Made in Space project, still conceptual, involves 3D printing of engines and onboard equipment on asteroids using improvised materials. What for? To deliver a huge block of valuable raw materials to low Earth orbit, where it can be used to build new orbital structures or lower to Earth. nine0003

Although everyone has their own worries: Italian astronauts do not start their day without a cup of espresso brewed with a special coffee machine. And in order to prevent the drink from spreading throughout the station, 3D-printed cups of a special shape are used to hold the liquid due to surface tension. And quite recently, a Russian satellite, manufactured by specialists from the Tomsk Polytechnic University, arrived on board the ISS. The design of the satellite is partially made using 3D printing.

And quite recently, a Russian satellite, manufactured by specialists from the Tomsk Polytechnic University, arrived on board the ISS. The design of the satellite is partially made using 3D printing.

Aircraft

Wait a minute, what other 3D printed engines? Is it possible? Quite, and additive manufacturing is successfully used in many areas of mechanical engineering, including the aviation and space industries, where 3D-printed engine parts are quickly becoming commonplace. It's all about 3D printing methods such as selective laser sintering (SLS) and deposition welding (SLM). These methods allow you to create high-precision parts, consisting entirely of metals and alloys. nine0003

The raw materials used are finely dispersed powders heated almost to the melting point and then sintered or fused along predetermined contours using ultra-precise lasers. Although there were initially some doubts about the strength of such products, numerous experiments dispelled fears: the density of the parts obtained is almost the same as cast counterparts, and the ability to manufacture the most complex components as a whole makes it possible to avoid the formation of weak zones that usually appear at the site of welds. nine0003

nine0003

3D printed engine parts, up to injectors, are already being used on SpaceX devices, Airbus is actively and successfully testing 3D printed parts of engines and supporting structures of airliners, and 3D printed swirlers created by the All-Russian Research Institute of Aviation can be considered a domestic example. Materials (VIAM) for promising PD-14 engines currently undergoing flight tests.

Industrial Design

Although complex, expensive metal-printing systems are used to make motors, plastic 3D printers are the most used in industry. They are used not so much for the manufacture of finished products as prototypes. Initially, 3D printing technology was called so - rapid prototyping. 3D printers make it possible to produce high-precision prototype parts, gadget cases, architectural models, and even shoes. Finished products not only serve for visual visualization, but also allow you to try on the components to be assembled. The latter option is used by the developers of the Armata tanks. Because prototyping requires no tooling, and the design itself can be quickly digitally modified and reprinted, 3D printing for prototyping results in significant time and cost savings in R&D. nine0003

Because prototyping requires no tooling, and the design itself can be quickly digitally modified and reprinted, 3D printing for prototyping results in significant time and cost savings in R&D. nine0003

At the same time, 3D printing is for all ages. While serious engineers are designing tanks and aircraft, their young colleagues are increasingly using 3D printing to teach modeling and design skills. Inexpensive user-level 3D printers are increasingly being used in schools and clubs, and youth creativity centers are being created throughout Russia, where future engineers can try out additive manufacturing technologies on their own.

Guns

Of course, 3D printing hasn't gone unnoticed by gun enthusiasts either, causing a lot of headaches for regulators around the world. It all started with the Liberator project by an American gun fighter named Cody Wilson. A simple plastic gun can be printed on any home 3D printer, the only metal element is a nail used as a striker, and the likelihood of an explosion and resulting injury to the shooter is higher than the chance of a successful shot. nine0003

nine0003

It turned out to be almost impossible to fight the distribution of free files with a 3D model of a pistol, but these were just flowers. Berries followed in the form of a 3D-printed receiver for AR-15 automatic carbines - the actual analogues of the M-16 assault rifle, which is in service with the United States and many other countries of the world. The fact is that it is the lower part of the receiver that is subject to registration and accounting, since the serial number is stamped on it, and all other parts can be bought at any weapons store. The box, on the other hand, does not carry high loads, and it is quite possible to print it from plastic, and then assemble an unaccounted for, unregistered rifle. Gun printing quickly fell under a local ban, and the aforementioned MarkForged company even refused to sell Cody their printer that prints with high-strength composites. nine0003

Although, sometimes there are quite legal projects, such as fully functional 3D printed replicas of the Colt 1911 pistol, released in a limited edition by Texas-based weapons company Solid Concepts. Be that as it may, 3D printing of weapons in Russia will result in at least a criminal article for illegal storage and distribution, and therefore the experience of Cody Wilson should not be adopted.

Be that as it may, 3D printing of weapons in Russia will result in at least a criminal article for illegal storage and distribution, and therefore the experience of Cody Wilson should not be adopted.

Ornaments

What about fake weapons? This option is allowed by law and is quite affordable even on household 3D printers. And not only weapons, but also all kinds of armor, jewelry and accessories. From glowing "plasma" swords from the popular game Halo to full-fledged Star Wars stormtrooper costumes, cosplay fans create the most colorful examples illustrating the possibilities of 3D printing. nine0003

In fact, MakerBot founder Bree Pettis demonstrated the feasibility of large-scale 3D printing with the Replicator Z18 3D printer in the most graphic way possible - wearing a fully printed helmet on his head in front of an audience of enthusiastic printers.

But with the help of 3D printing, you can create not only toy decorations, but also real ones. Jewelers around the world are increasingly turning to 3D modeling and printing blanks, on the basis of which molds are made for casting precious metal jewelry. For such projects, high-precision stereolithographic printers are used, printing with resins that harden under the influence of lasers or light projectors. nine0003

Jewelers around the world are increasingly turning to 3D modeling and printing blanks, on the basis of which molds are made for casting precious metal jewelry. For such projects, high-precision stereolithographic printers are used, printing with resins that harden under the influence of lasers or light projectors. nine0003

3D Printers

Finally, 3D printers can print… 3D printers! Among the makers there is a term "RepRap", which stands for something like "self-replicating 3D printer". In fact, the simplest 3D printer is nothing more than a numerically controlled machine - a set of rails, bearings, mounts and printheads controlled by a relatively simple computer controller.

Many of the structural elements (mounts, legs, corners and even printhead housings) are made of plastic, so why not print them on another 3D printer? This is exactly what real makers do, and many of the leading companies like MakerBot, Ultimaker or the Russian PICASO grew out of such home-made projects and still use 3D printed parts in the design of their branded printers.