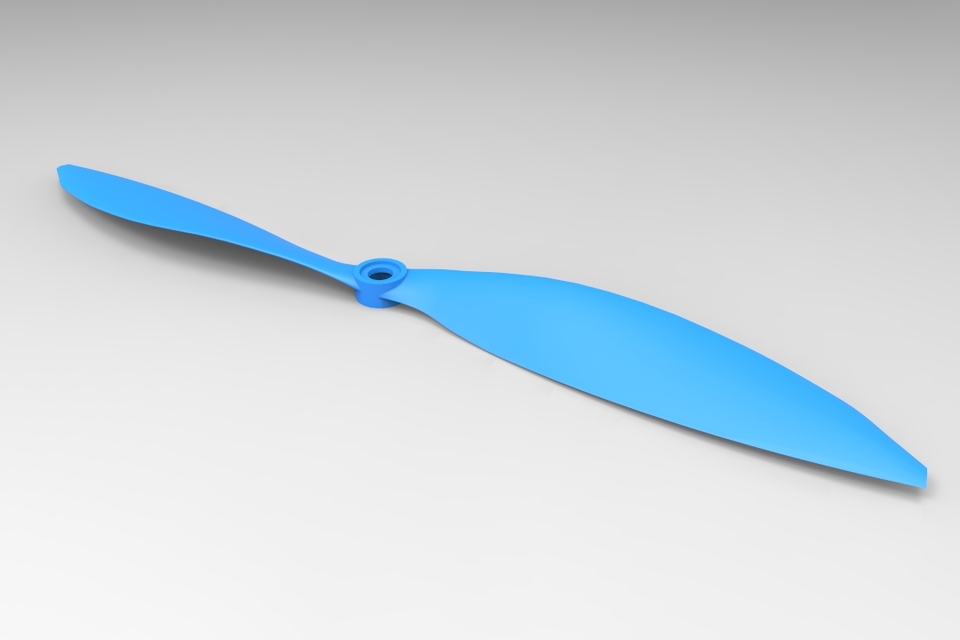

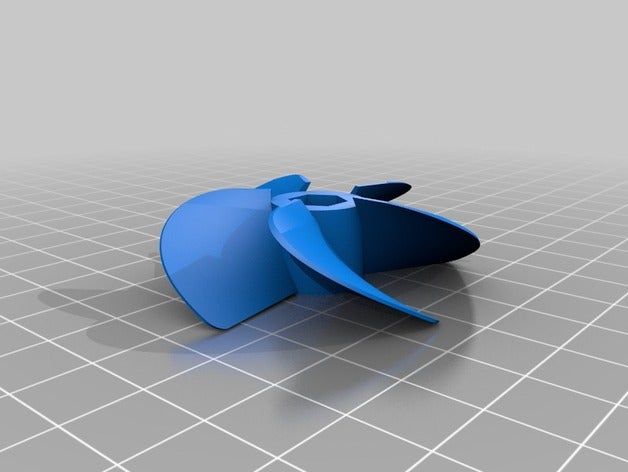

3D print drone propeller

Top Notch 3D Printed Drone Propellers Supplier

We have an idea of how important it is to control your drone’s steady or rotary motion in the air. That is why we are here with the premium quality 3D printed drone propeller services worldwide.

Therefore, we mark the industry with a tag in the production of leading products.

21+ Years

Manufacturing experience

72M+ Parts

We had finished

2300+ Clients

Over the world

99.9%

Satisfaction

Durable 3D Printed Drone Propellers

If you’re looking for a platform that can increase the efficiency of your 3D drone, DEK can be the only solution for you! In China, it is considered one of the leading platforms that provide 3D printing drone prototypes without compromising the quality and working efficiency of the device.

Get Reasonable Priced 3D Printing Drone Propellers

We have won the trust of our customers by providing them with a long list of the best services at reasonable prices. You don’t have to roam around to choose the platform that can assist with budget-friendly services.

You can head directly to DEK. Our professionals are always ready to help you.

Loot at Demanding Printing Services Below

SLA 3D Printing

If you want to create large drone models that stand out of the box in the drone industry, you can go for SLA printing technology at DEK. This industrial printing technology is mainly used to intricate the complex geometries, producing quality products with a high surface finish.

SLS 3D Printing

One of the most demanding additive manufacturing techniques known as selective laser sintering is also used to produce the 3D printed drone propellers. However, the source of illumination, in this case, is the laser. It is mainly used to sinter the material on the product for creating a print.

MJF 3D Printing

Depending on the material properties, we have not included multi-jet fusion printing in the list of our services. You can use this printing technique to deal with thermoplastic polymers, which are integrated into granular forms. There is also layering of prints on the surface of the object.

You can use this printing technique to deal with thermoplastic polymers, which are integrated into granular forms. There is also layering of prints on the surface of the object.

DLP 3D Printing

Digital laser printing corresponds with the use of a leading digital printer that generates high frequencies. This fast laser is used to fuse the powder on the surface, thereby leading to 3D printed drone propellers. In addition to this, there is also a layer of powder on the top.

FDM 3D Printing

We are adding Fused Deposition Modelling to fulfill the needs of those who want an extrusion printing technology for the 3D printed drone propeller. In this printing, a filament is used, which is then pushed into the hot extruder for better working. The extruder is heated first and then used.

Polyjet 3D Printing

If you are looking for the manufactured product’s accuracy and precision, you can select Polyjet printing for sure. The primary reason behind this action is the production of smooth and accurate parts. DEK has all technologies that are implemented in this method of printing.

The primary reason behind this action is the production of smooth and accurate parts. DEK has all technologies that are implemented in this method of printing.

SLM 3D Printing

We have also provided a solution to the customers who demand printing of the objects with 99.9% relative density. SLM is considered the best option in this case. You can make the net-shaped parts without consuming more time. Metallic powders are used in this process.

Recent projects we finished

Before you, we have successfully manufactured 72M+ different parts.

Why choose us?

Working with market leaders in the On-demand manufacturing industry, without the busyness and risk.

High Precision

People looking for the precise 3D printed drone propeller give all your needs to DEK for better precision. You don't have to search any further. We are here to serve you.

Excellent Quality

The availability of raw material industries has ensured the use of quality materials to get excellent quality. At DEK, we always pay attention to getting you premium quality services.

At DEK, we always pay attention to getting you premium quality services.

Low Cost

If you're running out of your budget, you can ask DEK to provide you with the best printing services without demanding more. We will plan packages according to your budget.

Quick Turnaround Time

The delivery and turnaround times are available at DEK. All you need to do is to contact DEK since we provide on-time services.

Business Partnership

We work on the strategy of a business partner to provide constant business support to those who want a healthy business plan.

24x7 Services

We are open to a conversation regardless of the time, day, and even year. You can contact our professionals without any concerns.

Quality is our top priority

“QUALITY COMES NOT FROM INSPECTION, BUT FROM IMPROVEMENT OF THE PRODUCTION PROCESS.”

-DR. W. EDWARDS DEMING

To DEK, Dr. Deming’s textbook remark is not a theory, but a practice we have been conducting every day. We use advanced production technologies and strict control systems to ensure high quality. More importantly, the quality-oriented attitude has been so entrenched in the mind of every single employee.

Deming’s textbook remark is not a theory, but a practice we have been conducting every day. We use advanced production technologies and strict control systems to ensure high quality. More importantly, the quality-oriented attitude has been so entrenched in the mind of every single employee.

We never stop improving

“We use advanced 3D printing technologies and strict control systems to ensure high quality. More importantly, the quality-oriented attitude has been so entrenched in the mind of every single employee.”

-Austin, GM of DEK

In DEK, we never stop improving the quality of our product. This is how we differentiate ourselves from the competition and is also why we can remain on top of the game for so many years.

Will you optimize the design?

Yes, we will analyze your 3D files and make recommendations suitable for 3D printing.

Do you provide surface finishing services?

Yes, we can perform surface finishes such as sanding, polishing, and coloring on the 3D printed parts.

Do you provide parts assembly services?

Yes, after printing the parts, if necessary, we can assemble them.

How long does it take to print?

Generally within 1-3 days, depending on your requirements, such as quantity, material, surface finishing, etc.

How to pack?

The product will be wrapped with foam cotton to avoid bumps, and then placed in a reinforced 5-layer corrugated box.

How to transport to our company?

For small-sized goods, we will deliver them directly to you via DHL, FedEx, UPS, TNT. It usually takes 3-7 days.

It's our honor to be their best partner

It was pretty challenging for me to get a reliable manufacturer for my 3D printed drone propeller services. But Luckily, I somehow got to know about DEK. They assisted me every time I needed help. Plus, their professionals give genuine suggestions about business.

James P.

DEK has been the most supportive platform for my printing company. As a newbie in the industry, I contacted them. They made sure to help me out wherever I got stuck. Give them a try! With their assistance and support, I'm offering my products worldwide.

Robert L.

KyronMAX Winner: Ultra-Quiet UAV Propeller Enabled with 3D Printing - 3DPrint.com

A couple weeks ago, the Cincinnati, Ohio-based grocery chain Kroger made its first drone delivery less than 30 minutes from my home in Dayton, flying one mile from Centerville’s Kroger Marketplace to City Hall and delivering two bags of rice, along with a piece of fabric from the Wright Brothers’ 1903 flyer; we’re very proud of our “first in flight” heritage around here. Drones, or unmanned aerial vehicles (UAVs), can be used for all sorts of tasks, from delivering groceries, food, medical supplies, and even spare parts to surveillance, search and rescue missions, clearing land mines, and fighting fires, and 3D printing is often used to make or customize them.

This winter, global engineering community and platform Wevolver announced a partnership with Mitsubishi Chemical Advanced Materials (MCAM) to launch the KyronMAX Design Challenge, and we recently learned that the winner is an ultra-quiet UAV propeller, and that 3D printing played a part in the design.

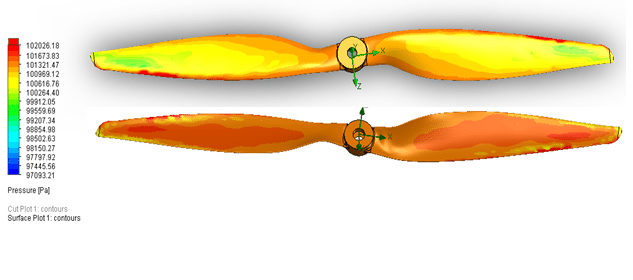

The goal of the challenge was to create a design that uses MCAM’s KyronMAX range of high-strength carbon fiber-based composite materials to solve a manufacturing or engineering challenge, and a team of engineers from Canadian aerospace startup Delson Aeronautics won for its Ultra-Quiet Unmanned Aerial Vehicle (UAV) Blades, which promise to decrease propeller noise by an astonishing 50%, so that obnoxious buzzing sound you typically hear with drones will be no more.

In order to handle heavy loads, and be flexible enough to avoid any damage, drone propellers need to be able to generate a significant amount of lift, and herein lies the challenge that the Delson team decided to solve—finding cost-effective, lightweight, and manufacturable materials to make UAV propellers that also feature the necessary amount of flexibility, strength, and stiffness is no easy feat. Additionally, when a drone propeller spins faster to generate more thrust, the noise also goes up.

Additionally, when a drone propeller spins faster to generate more thrust, the noise also goes up.

Delson engineers Michael Deloyer, Eitan Rotbart, and Ammar Jessa thought that MCAM’s injection molding technology and structural thermoplastic KyronMAX materials, with their increased mechanical properties, could help them create a better UAV propeller, and one with reduced sound as well.

Graph showing sound pressure level vs. thrust. Image courtesy of Delson Aeronautics.

When it comes to injection molding, CNC machining is often required, and depending on the complexity and size of the parts you’re making, this can really drive up costs. This isn’t as much of an issue when you’re manufacturing large batches, since the individual cost per part goes down as the number you’re making goes up, but it’s really not practical to use it for prototyping, testing, and small batch manufacturing.

Delson knew that MCAM’s KyronMAX platform could help them here, as it uses a technology called SPRINT (Soluble PRinted INjection Tooling), which involves AddiFab’s Freeform Injection Molding (FIM) process and 3D prints soluble mold inserts using photopolymer resin. Once you’ve got the 3D printed mold inserts, they can be put into the main metal mold base and then injected with molten plastic; the soluble mold is later washed in a solution that dissolves and exposes the completed plastic part, which is said to be both strong yet lightweight, as well as more affordable.

Once you’ve got the 3D printed mold inserts, they can be put into the main metal mold base and then injected with molten plastic; the soluble mold is later washed in a solution that dissolves and exposes the completed plastic part, which is said to be both strong yet lightweight, as well as more affordable.

It takes just days, rather than months, to complete this process, and SPRINT also makes it possible to create complicated geometries without having to use sliding mold surfaces or complicated cam devices. In addition, KyronMAX materials, when they’re used for injection molding, can supposedly produce parts that are 40% lighter than aluminum and 75% lighter than steel. All in all, the Delson team was able to produce tough propellers with the aesthetic finish and surface qualities of injection molding and the lead time and design freedom of AM.

As the winner of the KyronMAX Design Challenge, Delson Aeronautics has received $25,000 worth of design and manufacturing support from MCAM to help develop their ultra-quiet propellers and bring the product to the commercial market.

“The team is very excited to have kicked off the program with Mitsubishi Chemical Advanced Materials and Wevolver,” said Deloyer, the Founder of Delson Aeronautics. “Their support will help show what the Delson blades are capable of and the impact they can have on the future of the UAV industry. The prize has greatly increased interest from UAV manufacturers and we are now discussing potential collaborations to help bring these blades to market.”

Delson Aeronautics test their ultra-quiet blades.

The Delson team will continue to work closely with MCAM engineers to build and test out the propeller blades, with a product release already scheduled for later this year. You can follow the project here, as their progress will be documented all the way through to the final stage of commercialization.

(Source/Images: Wevolver)

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d print molds • 3d printed injection molds • blades • carbon fiber composites • commercialization • Delson Aeronautics • drone • drone design • Freeform Injection Molding • injection molding • KyronMAX • KyronMAX Design Challenge • MCAM • Mitsubishi Chemical Advanced Materials • mold inserts • propellor • Soluble PRinted INjection Tooling • SPRINT • UAV • unmanned aerial vehicle • wevolver

Please enable JavaScript to view the comments powered by Disqus.

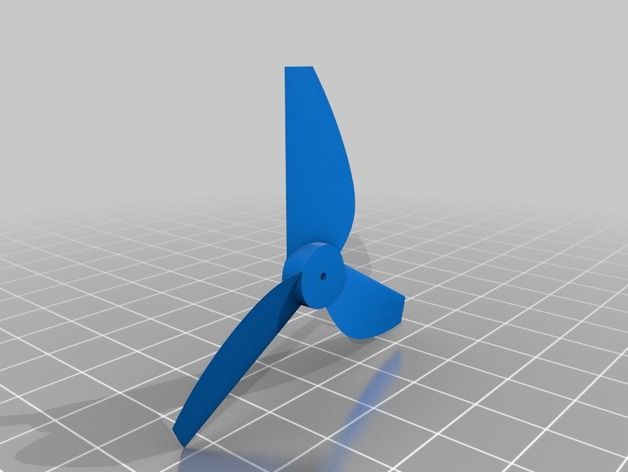

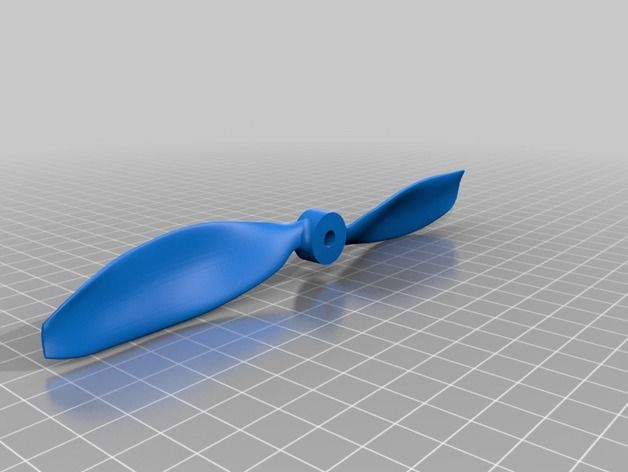

3D Printer Drone and Quadcopter Models

This article is an introduction to 3D Printing your own quadcopter drone. You will get acquainted with some basic principles of drone building, and we will describe some points step by step. The task will be relatively simple, since the description will be detailed.

What we need to get started

In addition to the 3D printer, we will need some non-printable parts such as a motor, batteries or accumulators, some electronics, sensors, a remote control and a knack to put it all together. nine0003

nine0003

Why print a drone?

Actually, we will be printing the frame and body structure. Sometimes propellers can be printed. Why is it important? Because drones fall and break. Especially if you are a beginner pilot. This picture shows everything clearly:

If we 3D print parts, we will have an almost infinite supply of spare parts, which will make it easier to survive pilot training and regular plane crashes. Apart from the fact that the quadcopter will be easier to repair, a homemade drone will allow you to get a better feel for its inner workings and mechanics. nine0003

And one more important point: 3D printing allows you to quickly develop parts according to your own project. Let's say you have purchased a new camera and want to install it on your quadcopter. Then you just open up your favorite 3D modeling program and end up printing out the part and testing it. Make changes, print again, etc.

What is a quadcopter drone?

A quadcopter is a multi-rotor helicopter that rises and moves with four main rotors and does not have a tail rotor. This is the most common type of amateur radio-controlled drones. nine0003

This is the most common type of amateur radio-controlled drones. nine0003

Small in size and highly maneuverable, these quadcopter drones can fly both indoors and outdoors. In addition, at this size, quadcopter drones are cheaper than conventional helicopters and more reliable due to their simple design.

Here is a detailed overview of the details of a commercially available high-end quadcopter drone used for aerial photography.

Almost all parts that are not motor or electronics can be 3D printed. The printed version of the drone looks a little different. nine0003

3D printed Crossfire quadcopter. Link to the project: http://www.thingiverse.com/thing:32281

In addition to the visual and aesthetic differences, the printed version has the advantage of being easy to update and modular. In the next video, Dennis Baldwin talks in detail about his quadcopter.

How to Print a Quadcopter Drone

If you want to build your own drone, we offer several entry points to the project. Here is a detailed guide to 3D printed quadcopter:

Here is a detailed guide to 3D printed quadcopter:

http://www.instructables.com/id/3D-Printed-Quadcopter-with-Arduino/?ALLSTEPS

Titch Micro Drone

https://www.myminifactory.com/object/ 38967

Brushed Y6 Micro Quad

https://www.myminifactory.com/object/brushed-y6-micro-quad-31348

Millennium Falcon Drone Shell

https://www.myminifactory.com/object/millennium-falcon-drone-shell-10144

Micro 105 FPV Quadcopter

https://www.myminifactory.com/object/micro-105-fpv-quadcopter-21362

Micro 105 FPV Quadcopter

https ://www.myminifactory.com/object/3drobotics-iris-19615

Hexacopter drone

https://www.myminifactory.com/object/hexacopter-drone-19600

And this is the instructions for building an H-shaped drone:

http://www. instructables.com/id/Make-an-H-Quadcopter-with-3D-printing/?ALLSTEPS

instructables.com/id/Make-an-H-Quadcopter-with-3D-printing/?ALLSTEPS

Printed remote control

If you want to 3D print

insectoid ornithopter on a 3D printer

9002 Detailed Guide to the Insectoid Ornithopter:http://www.instructables.com/id/3D-Printed-Ornithopter-Micro-UAV-Drone/

Regulations

Please be aware that there are a number of laws governing the flying of amateur drones and drones, they are different everywhere and it is important to get acquainted with them. Safety is also important! High-flying objects with propellers rotating at high speed in the hands of inexperienced pilots can cause considerable damage to people and property.

How to fly the quadcopter drone? nine0044

Youtube is full of instructional videos about this, they can be your starting point. Once you get the hang of it, you can do fun things like cockpit drone racing.

From the screw!

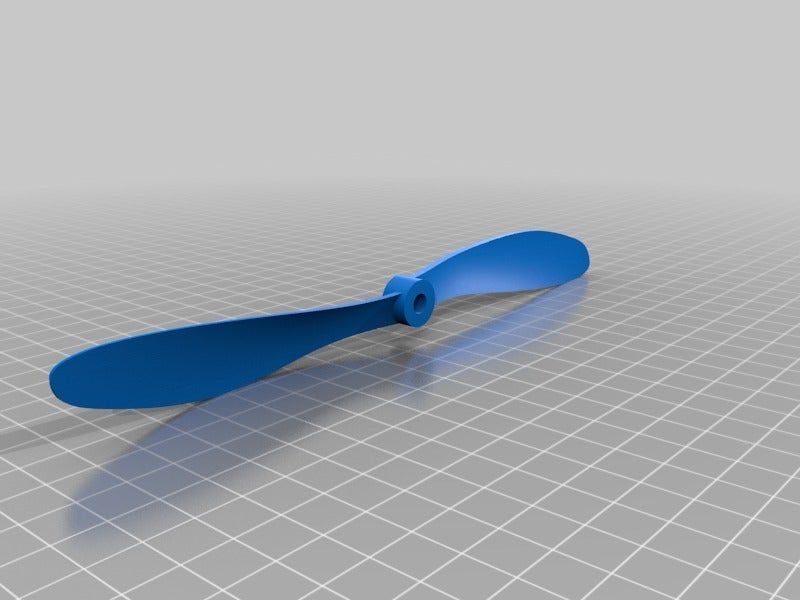

STL file RC drone propeller・3D printer model to download・Cults

Archimedean auger

2.84 €

Crane hook

€1.90

Signet ring

1,90 €

Canoe

4.74 €

Merkaba star wire frame

0,95 €

Medieval Viking helmet

3,79 €

Frame pyramid

0.95 €

Badge with the image of the heart of Ukraine

0,95 €

Best 3D Printer Files in the Gadget Category

Fiat 600 Scale Model

2. 10 €

10 €

Beer Tree Crown Cork Party

Free

Cable holder, cable clip, cable management, audio cable, storage

Free

Smartphone bike holder

Free

Wall holder for guitar

2,50 €

Complaint Button II: Hammer Time

Free

Cement mixer with print

Free

nine0043 Pocket drone h40CH caseFree

Bestsellers in the Gadget category

Brush conditioner

2.28 €

CYLINDER WALL/PISTON 2-STROKE

0,89 €

stock ALLIGATOR 2 AR15

2,50 €

nine0043 Pringles box1,50 €

Renewed bone finger

6. 40 €

40 €

The Thing - charging stand for Airpod and Apple Watch

14.22 €

Keyfob application

€3.50

ENGINE BLOCK - WALL KEY HANGER

€1.79

trx4m lift kit

1.19 €

FLEXI GIRAFFE

0,93 €

Inner fenders Trx4m Bronco

7.58 €

Seal of the V8 engine in place

1.76 €

Italian hand

1 €

Spear Draupnir with several greaves and ring | Spear of Kratos | By CC3D

10.20 €

Bambu AMS Color 2 tier rack (for 2 AMS units 1 top 1 bottom)

2.