3D printing skyscrapers

6 of the World’s Most Impressive 3D Printed Buildings

Photo: Kamp C & Jasmien Smets

Over the last few years, 3D printing, also known as additive manufacturing, has been gaining popularity in construction and architecture. As the technology matured, it’s position changed from a curiosity to a viable tool of the building trade, with companies producing and selling 3D-printed structures around the world.

In construction technology, additive manufacturing is still considered an emerging technology. Still, it’s already shown great promise for its ability to slash budgets and shorten building times. Some printers are even capable of creating an entire structure from scratch in less than a day and at a fraction of the cost of conventional construction methods.

3D printing is also considered a very real potential solution to humanitarian issues like the global housing crisis. In parts of the world where a roof over your head is far from a guarantee, the ability to quickly and inexpensively produce a livable structure has enormous potential, like this entire 50-home 3D-printed community in Mexico.

The following six 3D-printed structures showcase what can be accomplished with this technology and might offer a glimpse of the global housing landscape in the years ahead.

WinSun’s 3D-Printed Apartment Block, Jiangsu Province, ChinaPhoto: WinSunChinese company WinSun Decoration Design Engineering Co. is no stranger to testing the limits of 3D printing. Having already built 10 3D-printed houses in under 24 hours, it quickly gained the distinction of building the world’s tallest 3D-printed structure, a 5-story apartment block it completed back in 2015.

According to ArchDaily, the apartment building was made using a 20-feet tall, 33-feet wide, and 132-feet long 3D printer. Ir brought the structure to life layer by layer using a mixture of glass fiber, steel, cement, hardening agents, and recycled construction waste. The individual building sections were then pieced together, much like any other modular construction project. At the same time, WinSun built an 1,100 square-meter mansion, fully decorated inside and out. ArchDaily writes that a Taiwanese real estate company ordered 10 of the prototype mansions. Each will cost about $160,000 to build.

ArchDaily writes that a Taiwanese real estate company ordered 10 of the prototype mansions. Each will cost about $160,000 to build.

At the time, Ma Rongquan, China Construction No. 8 Engineering Bureau’s chief engineer, said in a news conference that he hoped the projects would pave the way towards more unified standards around 3D-printed construction.

“These two houses are in full compliance with the relevant national standards. It is safe, reliable, and features a good integration of architecture and decoration. But as there is no specific national standard for 3D printing architecture, we need to revise and improve such a standard for the future,” he said.

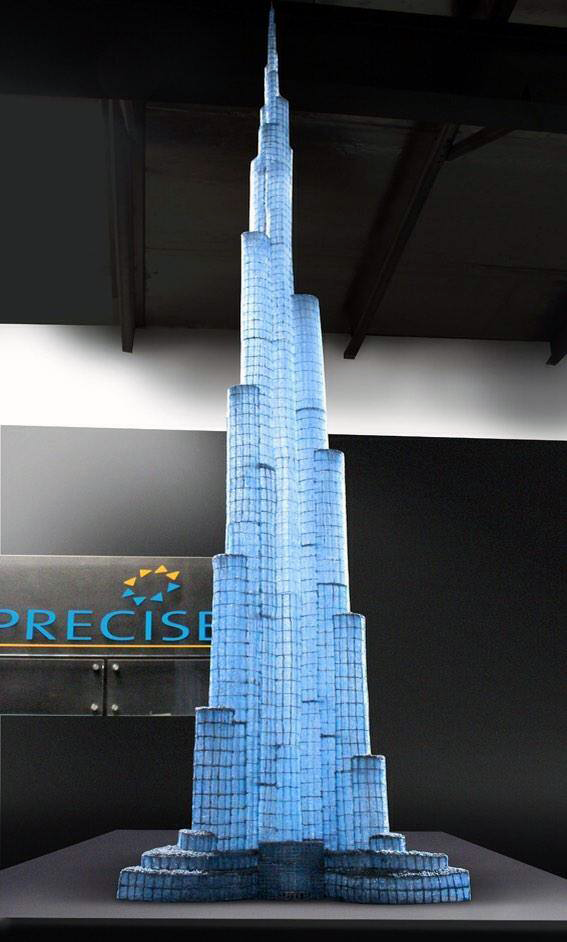

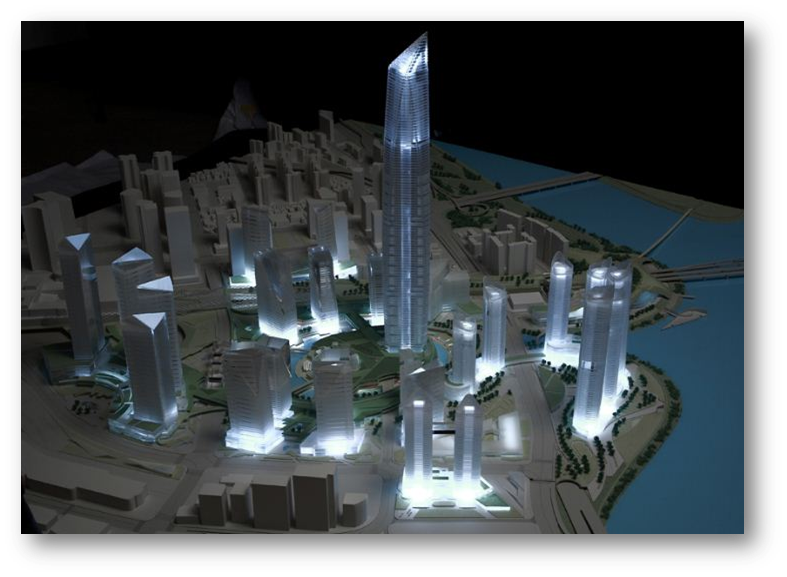

Municipal Building, Dubai, United Arab EmiratesPhoto: Apis CorNot to be outdone, Dubai opened the world’s largest 3D printed building in early 2020, a 6,900 square-foot administrative building for the Dubai Municipality. Dubai has long been known to aim for the impossible when it comes to construction. After all, it’s already the home of Burj Khalifa, the world’s tallest building, which towers over the desert landscape at over half a mile high.

After all, it’s already the home of Burj Khalifa, the world’s tallest building, which towers over the desert landscape at over half a mile high.

For the municipal building project, Dubai collaborated with Boston-based Apis Cor, the company known for building a 3D printed house in Russia in under 24 hours, according to SingularityHub. The building’s structure is much like a conventional building, made of precast concrete and reinforced with rebar and concrete. Contractors were brought in to add touches like windows and a roof after the structure came together.

Dubai has grand plans for 3D printing technology. It’s aiming to create as much as one-quarter of all new buildings using the method by 2030. SingularityHub writes that it’s part of the government’s plan to reduce building costs and save time on construction projects.

Two-Story Detached House, Beckum, North Rhine-Westphalia, GermanyPhoto: Mense-KorteBuilder PERI GmbH and designer MENSE-KORTE ingenieure+architekten collaborated on the first-ever 3D printed house in Germany, a two-story building with approximately 860 square feet of livable space per floor, according to ArchDaily.

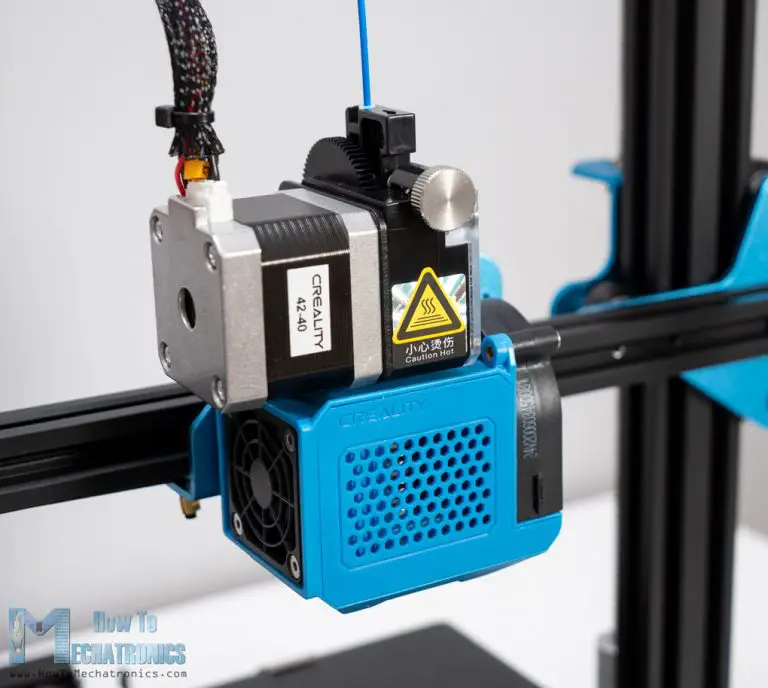

The project uses a special 3D printer called BOD2, pioneered by Danish manufacturer COBOD. The machine allows the addition of pipes and other internal building components, even while the printing is underway. It can print up to 10 square-feet of double-skin wall in just 5 minutes, ArchDaily writes, and only needs to be calibrated once before getting to work on each section.

“The concrete printing process affords us, designers, a high degree of freedom when we are designing buildings. With conventional construction methods, this would only be possible at a great financial cost. With our printed residential building in Beckum, we are demonstrating the potential of the construction printing process,” said Waldemar Korte, partner MENSE-KORTE ingenieure+architekten.

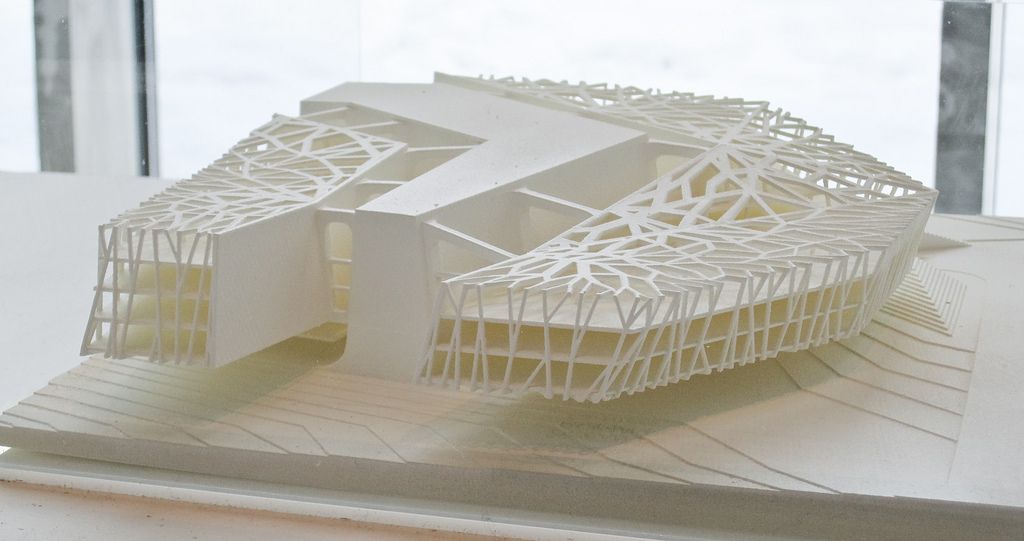

3D-Printed Office Building, Dubai, United Arab EmiratesPhoto: Gulf NewsBefore Dubai became the home of the world’s largest 3D printed building, it had already been known for the world’s first 3D-printed office building. According to Architect Magazine, the 2,600 square-foot office complex houses the Dubai Future Foundation (DFF) headquarters. Each building is made of individual concrete components, which were printed in Shanghai and shipped to Dubai for placement. To complete the job, Dubai enlisted the help of WinSun’s enormous 3D printer, measuring 120-feet long, 40-feet wide, and 20-feet high.

According to Architect Magazine, the 2,600 square-foot office complex houses the Dubai Future Foundation (DFF) headquarters. Each building is made of individual concrete components, which were printed in Shanghai and shipped to Dubai for placement. To complete the job, Dubai enlisted the help of WinSun’s enormous 3D printer, measuring 120-feet long, 40-feet wide, and 20-feet high.

According to Architect Magazine, the firm said the combination of 3D printing and modular assembly reduced labor costs by 50%–80% and construction waste by 30%–60%. The building, which first opened for business in the summer of 2016, was designed by Gensler for the United Arab Emirates National Committee.

“This paves the way for a future where 3D printing can help resolve pressing environmental and urbanization issues, and it allows us to deliver highly customized spaces for our clients in a much shorter time frame,” Gensler principal Richard Hammond told Architect Magazine in a statement.

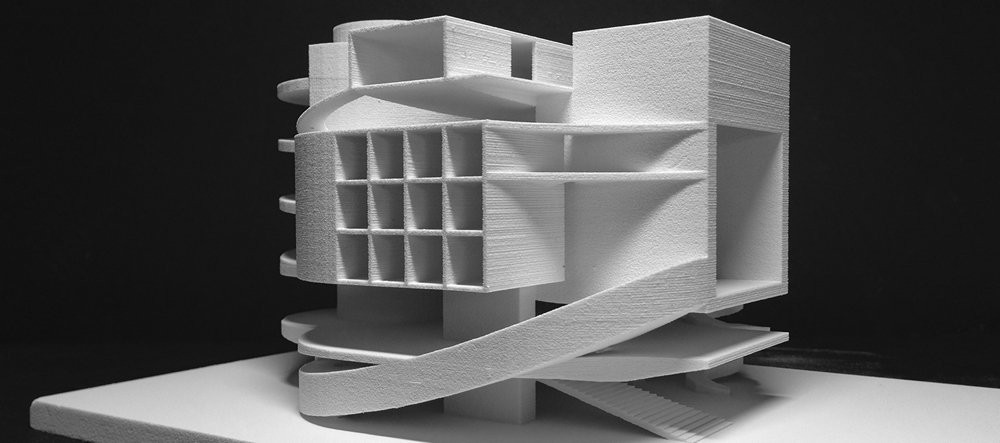

3D-Printed House Prototype, Antwerp, BelgiumPhoto: Kamp C & Jasmien SmetsThis past summer, Kamp C erected a 3D-printed two-story house in Belgium, according to New Atlas. The house is just shy of 1,000 square feet and was made using the same COBOD BOD2 printing technology as the detached house in Germany. The printer measures 32 by 32 feet and extrudes a cement-like mixture in individual layers until the structure is complete. After it was done, human contractors added windows and other essential elements.

The house is just shy of 1,000 square feet and was made using the same COBOD BOD2 printing technology as the detached house in Germany. The printer measures 32 by 32 feet and extrudes a cement-like mixture in individual layers until the structure is complete. After it was done, human contractors added windows and other essential elements.

This project took around three weeks to complete, but Kamp C told New Atlas it would reduce the building time to under two days. The building includes an entrance hall, two conference rooms, and a kitchen and is outfitted with modern amenities, including heated floors, solar panels, and a heat pump.

Project manager Marijke Aerts told New Atlas that 3D printing technology for the project saved approximately 60% on time, budget, and materials.

14Trees’ Affordable, Sustainable Buildings, Malawi, AfricaPhoto: 14TreesAffordable housing isn’t a given in many places. 14Trees, a joint venture between CDC Group and cement producer LafargeHolcim, is looking to improve residents’ quality of life by increasing the availability of affordable homes and school buildings around Africa.

Starting in Malawi, 14Trees has begun producing its sustainable and affordable structures, once again using COBOD’s BOD2 3D printer, according to 3D Printing Media Network. The printer’s enormous size requires two human operators, so COBOD sent experts to Malawi to ensure local workers’ proper training.

“We are very encouraged by the fact that 14Trees now has brought our technology to beneficial use in Africa, and we are impressed by the speed they manage to achieve for the printing of the walls of the first buildings, COBOD Founder and General Manager Henrik Lund-Nielsen told 3D Printing Media Network.

“The shortage of affordable housing and schools in Africa is overwhelming, and we do believe that our technology can play a vital role in solving this, not at least by increasing the speed of execution.”

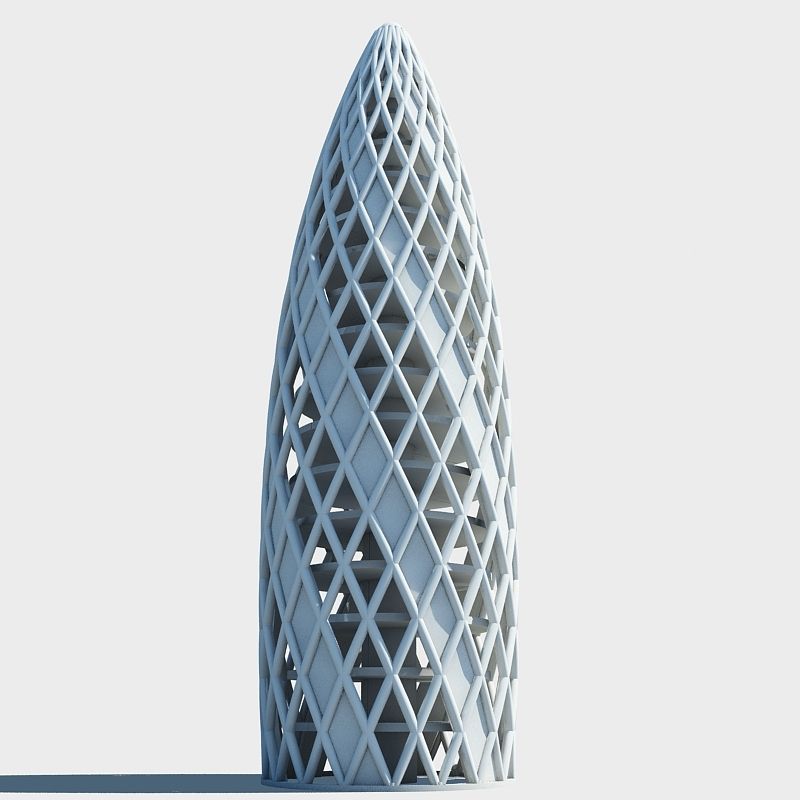

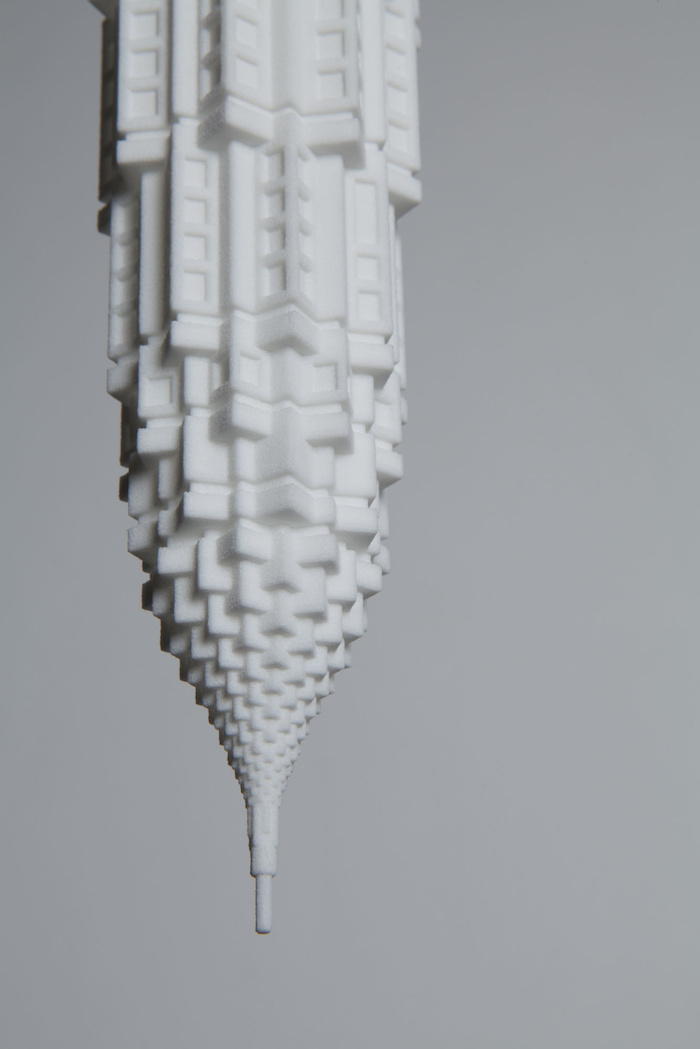

Skyscraper best STL files for 3D printing・Cults

Ramesses Great pyramid under construction 5

€17.20

Galactic Senate Ship

€19. 50

50

Dark Cyberpunk City 2

€20.64

Dark Cyberpunk City 1

€19.50

Sci-fi Opera Skyscraper

€13.76

Thors Hammer Sci-Fi Cityscape 1 Kit bash

€20.64

Scifi Skyscraper building for 6mm gaming

Free

Alien Spine Tower 1

€13.76

CHANCELLOR FLOATING CITY 2

€25.23

Cyberpunk Emperor Towers Split Dimensions Kit bash 2

€25.23

Chancellor Floating city 1

€17.20

Loft Test 12 (AKA Frost Tower San Antonio)

Free

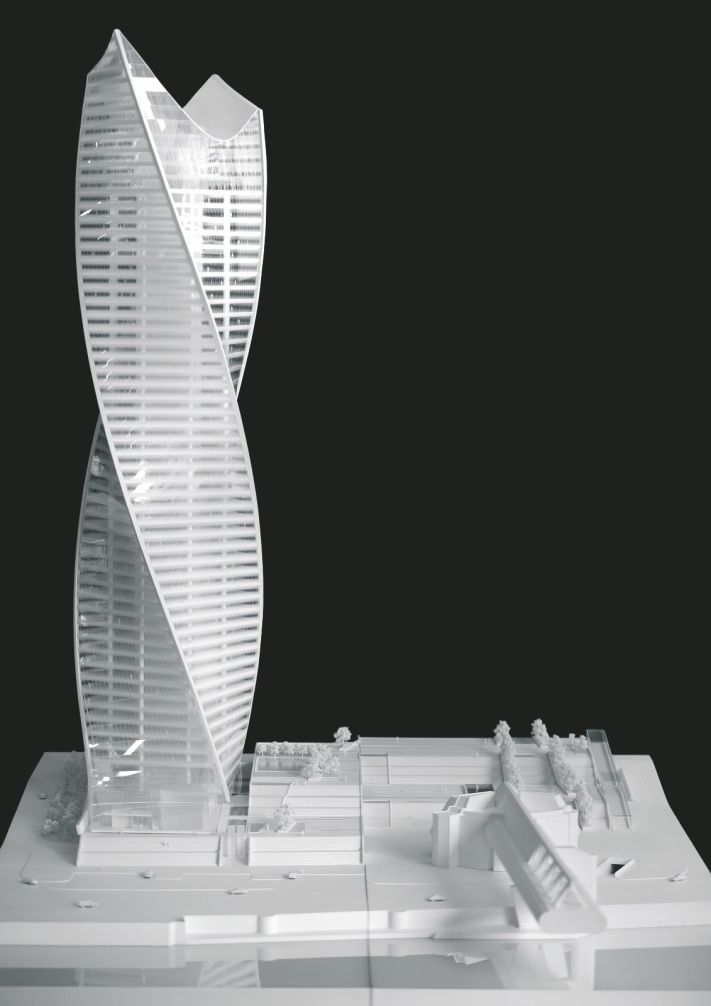

twisted skyscraper

Free

Sci-Fi Cyberpunk temples Dark

€50. 46

46

Sci-Fi dark Cyberpunk Shogun Towers 4 Kitbash

€25.23

Sci-Fi dark Cyberpunk Shogun 2 Kitbash

€25.23

Sci-Fi dark Cyberpunk temples With ship 2 Kitbash

€20.64

Sci-Fi dark Cyberpunk temples With ship Kitbash

€25.23

Sci-Fi dark Cyberpunk Mass Halls Kitbash

€20.64

Sci-Fi dark Cyberpunk Tower Kitbash

€24.08

Sci-Fi dark Cyberpunk temples 3 Kitbash

€19.50

Sci-Fi dark Cyberpunk temples 2 Kitbash

€28.67

Sci-Fi dark Cyberpunk temples Kitbash

€25.23

Sci-Fi dark Platforms 8 Monoliths

€25. 23

23

Sci-Fi dark Platforms 6 Monoliths

€17.20

Sci-Fi dark Platforms 3 Monoliths

€18.35

Sci-Fi dark Platforms 2 Monoliths

€10.32

Sci-Fi dark Platforms 13

€9.17

Sci-Fi dark Platforms 12

€9.17

Sci-Fi dark Platforms ship version 2

€9.17

Sci-Fi dark Platforms Ship

€8.03

Sci-Fi dark Platforms 10

€10.32

Sci-Fi dark Platforms 9

€13.76

Sci-Fi dark Platforms Decepticon base

€18.35

Sci-Fi dark Lord Platforms Base kitbash

€19. 50

50

Sci-Fi dark Platforms City kitbash

€17.20

Sci-Fi dark Platforms Floating 3 Versions

€17.20

Sci-Fi dark Platforms Floating Kitbash 2

€16.06

Alien Missile Defense base kit bash 1

€13.76

Sci-Fi dark Platforms City

€9.17

Sci-Fi dark Platforms Floating 3

€14.91

Sci-Fi dark Platforms Floating 2 designs

€13.76

Sci-Fi dark Platforms Floating 6

€12.61

Sci-Fi dark Platforms Floating 5

€9.17

Sci-Fi dark Platforms Floating 4

€8. 03

03

Sci-Fi dark Platforms Floating 2

€10.32

Sci-Fi dark Platforms Floating

€11.47

Sci-Fi dark Platforms 8

€9.17

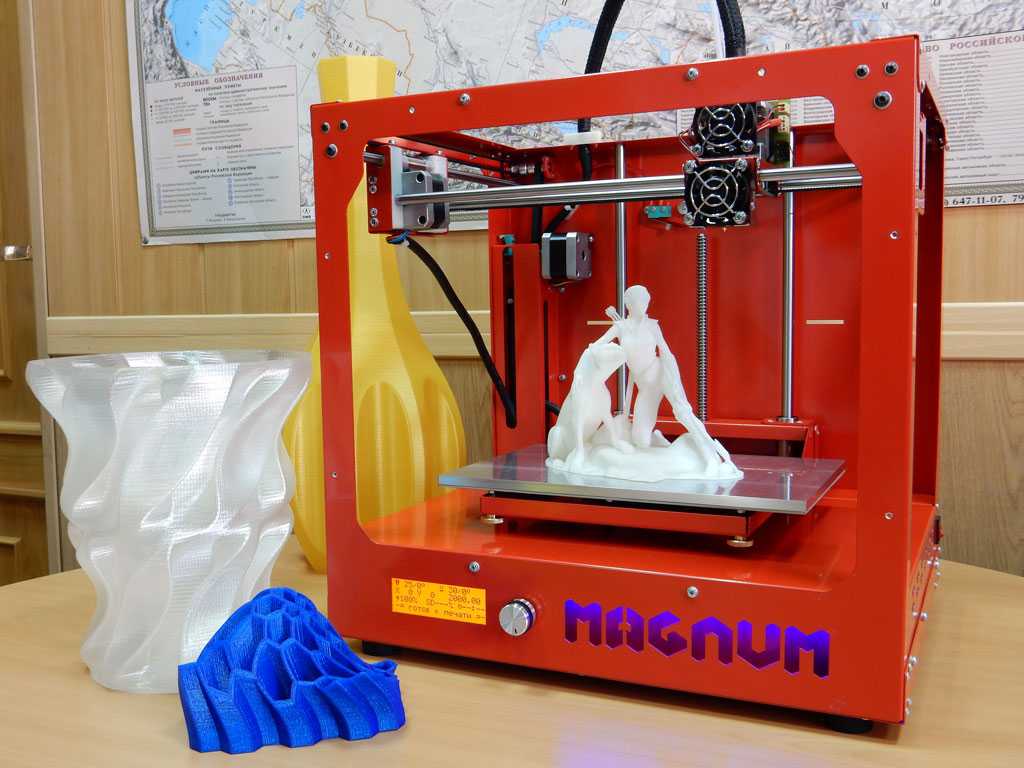

What's new in the world of 3D printing? March News Review

3D printing is one of the fastest growing areas. It's hard to keep up with all the news here. Therefore, we have prepared for you a selection of the latest 3D printing news for the first half of March.

Metal filament 3D printed bicycle frame

A team of MX3D engineers from the Netherlands 3D printed an Arc bicycle frame using a welding 3D printer. The printer uses a metallic filament and the resulting construction is stronger but heavier than conventional frames. MX3D team prophesies great future use 3 D printing in architecture. Among their projects is a very ambitious plan to print a bridge in the center of Amsterdam.

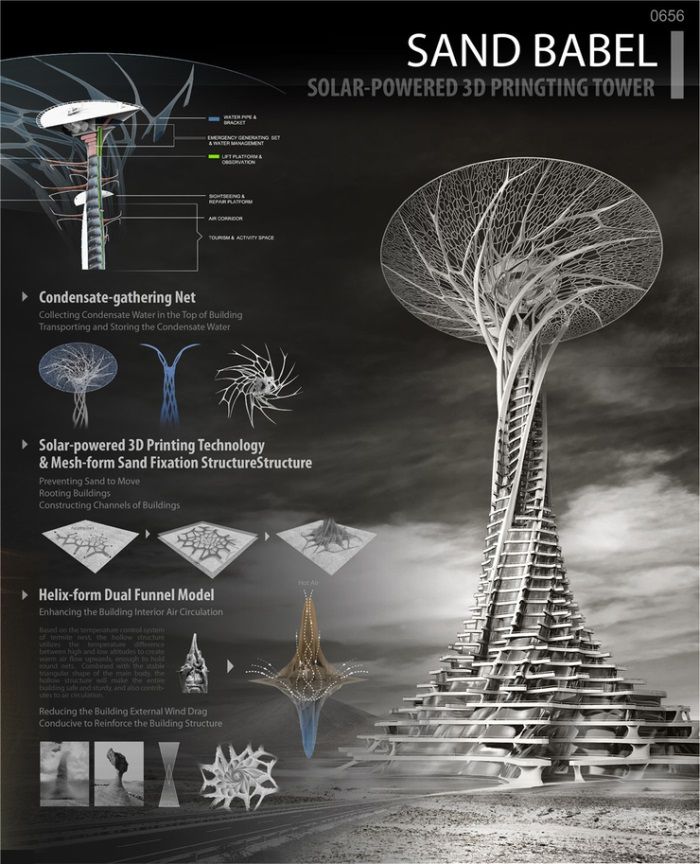

First millions invested in 3D printing of skyscrapers

Singapore also plans to introduce 3D printing for architecture, in particular for housing construction. According to 3D printing news, the technology will allow the creation of concrete blocks on special 3D printers. So far, $107 million has already been invested in the technology. The introduction of this technology will open up new opportunities for creating social housing. nine0007

Candy 3D printer launched in Dubai

Fortunately, there is also edible thread for printing 3 D printing - two 3D printers have been launched in Dubai that allow you to create candy. Read more about this news in our article on the website.

Carbon3D has developed continuous printing technology

CLIP is a very interesting printing technology of the future that allows continuous printing of a product. A platform is lowered into a tank filled with liquid polymer, on which an object is formed. Liquid polymer hardens thanks to UV light that the print head should emit.

Liquid polymer hardens thanks to UV light that the print head should emit.

Continuous Liquid Interface Production allows you to increase the speed of printing and the level of detail of objects. The technology was developed by Carbon3D, which recently signed a cooperation agreement with Kodak. It is quite possible that soon the world will see new printers with this technology.

Patented 3D printing using levitation

Boeing patented a new 3D printing technology using acoustic and magnetic levitation . The new technology will make it possible to create one-piece complex objects and significantly speed up the process of creating aircraft parts. Read more about this in our article.

A dog had a successful bone implant surgery based on a 3D model

Previously, 3D modeling was widely used to create bone prostheses and even new organs for humans. Today, with the help of 3D printing, helping our little friends has become even easier. The story of the three-legged border collie Ziggy from Australia touched the whole world. The absence of one paw led to an increase in the load on the remaining limbs, as a result of which he began to experience pain and he needed surgery. Veterinary School scientists studied the front paw in detail and recreated it using 3 D-simulation. Soon the dog will be able to walk freely, but for now he uses a wheelchair.

The story of the three-legged border collie Ziggy from Australia touched the whole world. The absence of one paw led to an increase in the load on the remaining limbs, as a result of which he began to experience pain and he needed surgery. Veterinary School scientists studied the front paw in detail and recreated it using 3 D-simulation. Soon the dog will be able to walk freely, but for now he uses a wheelchair.

Created an orthosis for sports

The next application of 3D modeling in medicine is the creation of orthoses. Using a 3D model of a hand, scientists at the University of Wrocław designed an orthosis that helped a man with paresis play sports. Until recently, this syndrome significantly reduced the quality of life of people. Such an orthosis not only allows you to maintain a high level of vitality, but also to engage in power loads. nine0007

Planned to send a 3D printer into space

A 3D printer developed by the American company Made in Space has attracted the attention of NASA. This printer allows you to print in zero gravity. Together with Israeli artist Eyal Gever, NASA is initiating a new project "# Laugh ". Its goal is to refine the 3D printing process in zero gravity. The successful implementation of the project will greatly facilitate the life of astronauts on the ISS - they will be able to independently print the necessary parts in the event of a breakdown, without waiting for delivery from Earth. nine0007

This printer allows you to print in zero gravity. Together with Israeli artist Eyal Gever, NASA is initiating a new project "# Laugh ". Its goal is to refine the 3D printing process in zero gravity. The successful implementation of the project will greatly facilitate the life of astronauts on the ISS - they will be able to independently print the necessary parts in the event of a breakdown, without waiting for delivery from Earth. nine0007

Nanosatellite from Russia goes into space

The first satellite body was created in Tomsk using 3D printing. Its dimensions are 30×10×10 cm. The nanotreader will go into space on March 31 aboard the Progress MS-2 cargo spacecraft.

Employees of the Tomsk Polytechnic University note that thanks to 3D printing, they managed to achieve a significant reduction in the cost of manufacturing satellites.

Soon 3D printing will be integrated into all areas of our lives. nine0007

Visit our blog and be the first to know the news 3 D print!

3D printed houses and 4 more engineering trends that will make our world a better place

January 19 Technologies

One smart fabric T-shirt keeps you warm when it's cold and cool when it's hot. And multi-storey farms will save kilometers of fields. Find out how other engineers will change our lives in the very near future.

And multi-storey farms will save kilometers of fields. Find out how other engineers will change our lives in the very near future.

Trend 1: Development of green fuels to help reduce our carbon footprint

Illustration: Scharfsinn/ShutterstockThe progressive world is seriously engaged in the transition to clean and renewable energy sources for transport. The roads are filled with electric vehicles, but this is not enough for engineers. They are working with might and main to improve hydrogen engines. Green hydrogen is already considered the main alternative to diesel fuel, and scientists have found a way to produce it in an environmentally friendly way. To do this, electrolysis of water is used, and the energy necessary for the reaction comes from a renewable source. The method allows you to get rid of 830 million tons of harmful carbon dioxide emissions per year. nine0007

Many auto giants are already producing cars with hydrogen engines. Next up is aviation. Airbus is actively working on the creation of "green" aircraft, and in the United States they plan to make the world's first manned hydrogen-fueled helicopter. However, experts say that "green" hydrogen will be able to compete with its non-environmentally friendly counterparts no sooner than in 10 years. At the same time, the EU, Australia, the USA and other countries have already begun to develop hydrogen energy, and Japan even made it a state priority back in 2017. In this industry, engineers will definitely have something to do. nine0007

However, experts say that "green" hydrogen will be able to compete with its non-environmentally friendly counterparts no sooner than in 10 years. At the same time, the EU, Australia, the USA and other countries have already begun to develop hydrogen energy, and Japan even made it a state priority back in 2017. In this industry, engineers will definitely have something to do. nine0007

Trend 2: food production optimization - vertical farms for fruits and vegetables

Building skyscrapers once solved the problem of urban density. Now engineers are transferring this idea to agriculture and suggest building farms not in breadth, but up - multi-story beds instead of kilometers of fields. A vertical agricultural farm is an automated complex with artificial lighting, air conditioning, heating and sterile air. There is usually a closed irrigation system: you can reuse the evaporated moisture and save up to 90% water. Such an engineering miracle will allow farming even in the center of the city. And also in areas of arid climate and harsh conditions of the Far North.

And also in areas of arid climate and harsh conditions of the Far North.

Fruits and vegetables from such farms are no worse than from ordinary ones. And maybe even better: they do not contain pesticides and pests, because fertilizers and chemicals are not used in production. According to experts, by 2025 vertical farms will become a normal phenomenon for large cities in developed countries. Today, unusual farming is most actively developing in the USA, Germany, China and Japan. Even Amazon CEO Jeff Bezos appreciated the technological trend and rushed to invest in a startup that works with vertical farms. nine0007

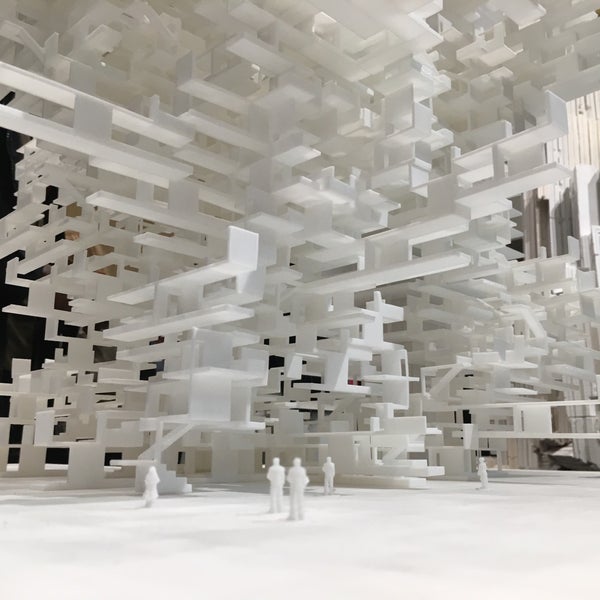

Trend 3: Development of modeling and computer engineering

Illustration: Jenson/Shutterstock Competition among manufacturers is growing at a furious pace, processes in enterprises are becoming more complex, costs and risks are increasing. Computer engineering helps to keep up with progress and reduce costs. These systems allow you to design digital models of products and processes of the entire production cycle.

Such technologies turn out to be more economical than real prototypes - virtual models do not require materials, only calculations on a computer screen. In the production of goods, modeling reduces the percentage of product defects, because many errors are eliminated at the design stage. Today, these technologies are successfully used in mechanical engineering, metallurgy, biomedicine, architecture, design, and even in the aerospace industry. In October last year, Elon Musk opened the fourth Tesla Gigafactory in Berlin. It plans to produce 500,000 cars a year. Of course, such volumes of production will be provided, among other things, by computer engineering. By the way, Russian universities have begun to train valuable specialists of this profile. nine0007

Trend 4: building buildings with 3D printing

With the use of a 3D printer, it has become possible to build houses in a matter of days. The largest building in the world "printed" in Dubai. This is the result of the work of a startup with Russian roots, which back in 2017 “built” a 38-meter house in Stupino, Moscow Region, on its own 3D printer in just 24 hours. The area of the building in the UAE is 641 square meters, it got into the Guinness Book of Records and brought entrepreneurs a million dollars. According to the plans of the Dubai authorities, by 2030 a quarter of city buildings will be built using 3D printers. nine0007

The area of the building in the UAE is 641 square meters, it got into the Guinness Book of Records and brought entrepreneurs a million dollars. According to the plans of the Dubai authorities, by 2030 a quarter of city buildings will be built using 3D printers. nine0007

The technology reduces construction costs by a factor of six and also reduces waste at the construction site. In the field of 3D printing of buildings, another direction is also relevant for engineers - the creation of new materials. For example, at the University of South Wales, they were able to figure out how to use LED rays to repair plastic printed on a 3D printer. Experiments have shown that the found method restores the material and, in addition, makes it stronger. A useful bonus of the discovery is concern for the environment, because the solution reduces the amount of plastic waste. nine0007

Trend 5: Making clothes out of smart fabrics

Who would have thought that engineers would take up the production of clothing materials in earnest. Fiber optics, metals, conductive polymers and other components have replaced traditional cotton and wool. For example, new synthetics can absorb sweat and not get heavy, and waterproof fabrics perfectly protect against bad weather - this will not surprise anyone.

Fiber optics, metals, conductive polymers and other components have replaced traditional cotton and wool. For example, new synthetics can absorb sweat and not get heavy, and waterproof fabrics perfectly protect against bad weather - this will not surprise anyone.

Now there is an active development of special - smart - materials that are able to adapt to environmental changes. For example, change color, “turn on” water resistance, antibacterial and other properties. Smart clothes will help you not to freeze in the cold and not overheat in the heat. Adaptive fabric was invented at the University of Maryland. It reacts to the temperature of the human body and decides whether to warm or cool the body. Smart fabrics can even make the work of doctors easier. Sensors and sensors in such materials make it possible to monitor the health of patients and capture the symptoms of certain diseases. nine0007

Engineers make our world better and more convenient. The profession will be in high demand in the next decades, so many schoolchildren and students want to build a career in this industry.