3D inkjet printing

The 3D Inkjet Printing Process Explained

Simon Fried

Like many technical industries, the list of acronyms used to describe additive manufacturing processes and tools is extensive and will only grow over time. Among the long list of commercialized processes and those still in the research phase, inkjet printing is particularly unique for its adaptability and efficiency in printing fully functional products. The range of materials that can be used in inkjet printing and related processes is broad, allowing these systems to be used for additively manufacturing a variety of mechanical or electrical products.

The 3D inkjet printing process is similar to other 3D printing processes in that it proceeds through layer-by-layer deposition. Printing instructions in each layer are generated from a 3D mechanical model for your product, just as is done with popular fused deposition modeling (FDM) systems. However, this established additive manufacturing process is unique in that it is adaptable to a wide range of liquid materials or solid suspensions, providing conductive or insulating structures with high printing resolution. Compared to processes that involve the fusion of metal or plastic materials, inkjet printing requires no post-processing—the finished printing product will be fully functional as soon as it leaves the printing system.

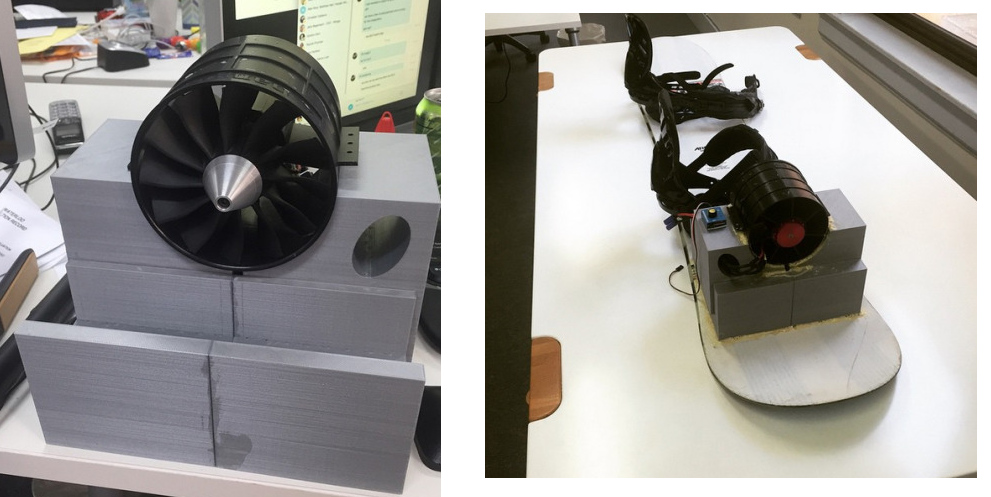

A 3D inkjet printing process can be used to print electronics with any geometry.

How the 3D Inkjet Printing Process Works3D inkjet printing is a low-temperature, low-pressure process that involves the deposition of liquid materials or solid suspensions. Polymers, dielectric nanoparticles, and conductive nanoparticles can be deposited with this process, making it adaptable to a broad range of materials. In this process, the printing material is extruded through a small nozzle within a print head. As the print head raster scans over a surface, multiple layers are built up in a layer-by-layer process.

Each deposited layer must be cured in between successive depositions, and the curing process will vary depending on the materials used to print your product. Inkjet 3D printing systems include equipment for curing each layer within the system. While the need to cure each deposited layer in between depositions may sound time consuming, the deposited layers are very thin and can be cured quickly, ideal at low temperature or with an optical process (such as exposure to infrared or ultraviolet light).

Inkjet 3D printing systems include equipment for curing each layer within the system. While the need to cure each deposited layer in between depositions may sound time consuming, the deposited layers are very thin and can be cured quickly, ideal at low temperature or with an optical process (such as exposure to infrared or ultraviolet light).

Printing resolution is an important parameter in any 3D printing system because this determines the smallest feature sizes and tolerances that can be reliably deposited with your system. The limiting factors that determine in the 3D inkjet printing process are the droplet size, which is determined by the size of the nozzle in the print head. In general, a smaller nozzle will provide a higher resolution (i.e., smaller printed features). The 3D inkjet printing process provides high-resolution conductive and insulating structures with a broad range of materials, making it ideal for additively manufacturing advanced PCBs with high interconnect density and high layer count.

Similar to other 3D printing processes, inkjet printing is complexity agnostic, meaning the printing time is nearly independent of product complexity. The time required to print a fully functional product depends solely on the time required to deposit the necessary amount of material and the curing time.

As a result, the cost structure only depends on the weight of the material being deposited and the energy consumed during deposition—costs in both of these areas are fixed. When printing complex multilayer and non-planar PCBs, all interconnects, mounting holes, and vias can be printed directly without additional machining steps. This reduces the total manufacturing time from weeks to hours with a highly predictable cost structure.

Once the printing process concludes, the finished product does not require any further post-processing. Contrast this with other processes, such as FDM, selective laser sintering, and powder bed fusion. These processes involve extrusion of molten materials through a print head, and the printed products tend to have some defects and ridges on the outer surface.

These processes involve extrusion of molten materials through a print head, and the printed products tend to have some defects and ridges on the outer surface.

Producing electronics and PCBs with a 3D inkjet printing process requires working with a conductive nanoparticle suspension for printing traces, as well as an insulating polymer for printing substrates. The use of conductive nanoparticles in an inkjet process carries several advantages for use in electronics, but these materials are ideal for 3D printing PCBs with an inkjet process. When combined with the appropriate insulating polymer, you’ll have the materials required to print fully functional PCBs with a 3D inkjet printing process.

Multiple materials can be printed with the right 3D inkjet printing system.

Selecting Materials in the 3D Inkjet Printing ProcessThe 3D inkjet printing process is highly adaptable to several materials that can be deposited and cured at relatively low temperature and ambient pressure. As liquid inks are extruded through a nozzle in this process, the system parameters (such as deposition pressure and temperature, as well as curing parameters) can be easily tuned to accommodate materials with different viscosities and curing requirements.

As liquid inks are extruded through a nozzle in this process, the system parameters (such as deposition pressure and temperature, as well as curing parameters) can be easily tuned to accommodate materials with different viscosities and curing requirements.

When 3D printing PCBs, there are several points to consider when selecting materials and the appropriate deposition system. Inkjet printing is unique compared to solid-state deposition processes in that it can be used for co-deposition of an insulating substrate and conductive elements simultaneously. As the range of available materials for these systems expands, the market should anticipate 3D inkjet printing of semiconductor devices and a variety of substrate materials that are ideal for operation in different frequency bands.

If you want to use the 3D inkjet printing process for the fabrication of complex PCBs, then you need an inkjet system that provides co-deposition of insulating and conductive materials with high throughput. The DragonFly LDM additive manufacturing system from Nano Dimension is ideal for in-house PCB prototyping or full-scale fabrication of complex electronics with a planar or non-planar architecture. Read a case study or contact us today to learn more about the DragonFly LDM system.

The DragonFly LDM additive manufacturing system from Nano Dimension is ideal for in-house PCB prototyping or full-scale fabrication of complex electronics with a planar or non-planar architecture. Read a case study or contact us today to learn more about the DragonFly LDM system.

Additive Manufacturing | 3d printing | inkjet

Simon Fried

A co-founder of Nano Dimension, Simon Fried leads Nano Dimension’s USA activities and marketing for this revolutionary additive technology. With experience working in the US, Israel, and throughout Europe, he has held senior and advisory roles in start-ups in the solar power, medical device, and marketing sectors. Previously, Simon worked as a consultant on projects covering sales, marketing, and strategy across the automotive, financial, retail, FMCG, pharmaceutical, and telecom industries. He also worked at Oxford University researching investor and consumer risk and decision making.

Mimaki 3D printer | MIMAKI

SCROLL

Superior 3D print results

compared with conventional methods

Mimaki offers the world's first 3D printer

with 10 million colors

and UV-curable inkjet printing

The 3D printer market growth continues to spread globally upon commencing from North America and Europe and its application is mainly entered in manufacturing industry and then penetrating to education, construction and medical business segment.

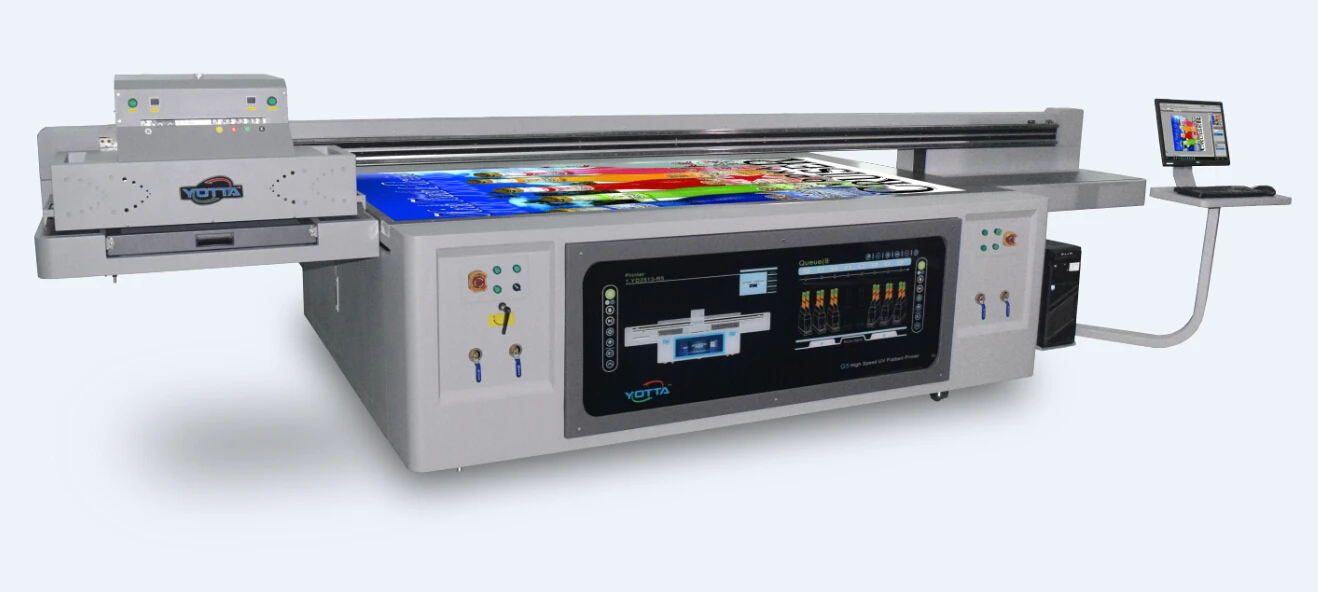

Mimaki 3D printer [3DUJ-553] has achieved the full color modeling with the capability of world first (*1) over 10 million colors based on our developed technology of 2D inkjet printers of professionals use.

We will propose a new business utilizing [3DUJ-553] as its having rich color expression is better suited to create a final product such as real object sign or building model, of which an extra coloring has been difficult after the completion of modeling.

Mimaki proposal for Sign Graphics market

Object signage by 3D printer is considerably effective to be remarked and understood easily with its presence by the combination of realistic 3 dimensional motif and 2D image.

[3DUJ-553] can express by more than 10 million different full colors and as well enhance the color reproducibility with the color adjustment employing the color profiles.

Mimaki proposal for Industrial Products market

Mimaki 3D printer, [3DUJ-553] can satisfy professionals exacting requirement to make full color and fine modeling of strong preference into the details and final products, for example, figure, 3D map and mock-up. And post processing like over coating and attachment of screws are also applicable.

Features of Mimaki 3D printer

Features of Mimaki 3D printer

Features of Mimaki 3D printer

Beautiful color expression

Beautiful color expression

Elaborate modeling expression

Elaborate modeling expression

Ink property

Ink property

Specifications

Specifications

USER STORIES

USER STORIES

Features of Mimaki 3D printer

Beautiful color expression

Elaborate modeling expression

Ink property

Specifications

USER STORIES

Sample gallery

Sample gallery

Sample gallery

Inquiry

Mimaki full color 3D printer [3DUJ-553] applied the UV curable inkjet system utilized Mimaki's original technology, which was amassed in our development and manufacturing for inkjet printers of professional use during a long period.

To learn more about our products, specifications and quotation, please contact below.

Inquiry contact form

*1: Survey as of August, 2017 by Mimaki Engineering

We use cookies in order to offer you a better experience in our website. By your continuation of browsing, we will regard that you have agreed to the use of cookies. More info

3D Inkjet Printing (3DP) – 3dprofy

Turch October 21st, 2014

3DP stands for Three-Dimensional Printing , and translates as three-dimensional printing. This technology is one of the varieties of systems for the additive construction of a product according to its CAD model and differs from numerous similar schemes in that the process is carried out according to the principle of a conventional printer - through print head nozzles. Thus, 3D inkjet printing is a natural continuation of the development of conventional 2D printing technologies. To date, it has achieved fairly good results, such as color printing. nine0003

nine0003

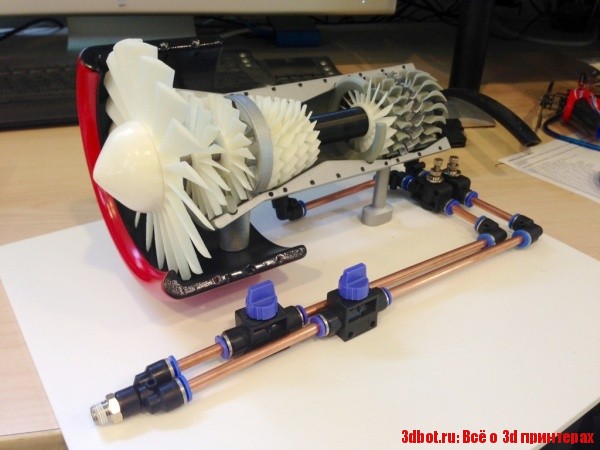

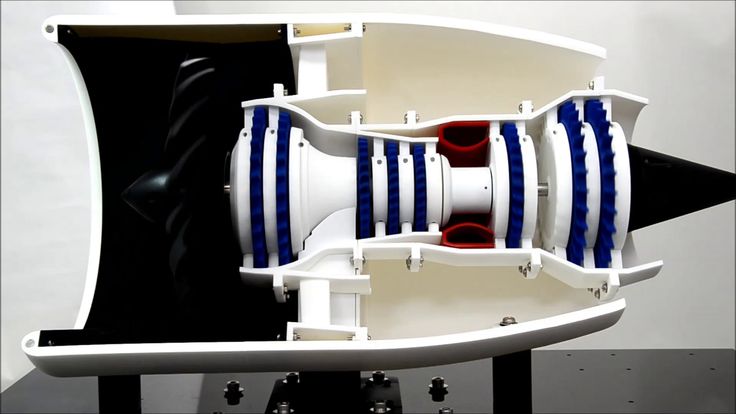

Products printed on the Z Corp's Spectrum Z510 color 3D printer

The history of the emergence and development of 3DP

For the first time, the idea of \u200b\u200brealizing equipment using this printing scheme was proposed by two students at the Massachusetts Institute of Technology Tim Anderson and Jim Bredt in 1993. It is thanks to them that the term 3D printing has spread around the world. And this is quite fair, because the first model of the device was a modification of a conventional 2D printer. Instead of ink, he used a special adhesive composition, which applied layer by layer to the surface of the bonded substance, the boundaries of the future three-dimensional product. nine0003

In 1995, Tim and Jim formed the Z Corporation, which brought this technology to market, improving it to such an extent that in 2012 3D systems Corporation wished to acquire it along with the company. Under her brand, former Z Corporation models are now sold worldwide.

One of the directions of the ExOne company (USA) is the production of 3D printers that use the same technology. This firm was founded in 2005 as a subsidiary of the Extrude Hone Corporation. Using the patents obtained by Anderson and Bedt, they launched a line of printers that even print metal products today. nine0003

3D inkjet printing technology

Today there are more than thirty 3D printing technologies, which in one way or another duplicate each other, although each has its own characteristics. The American Society for Testing and Materials (ASTM International) has divided 3D inkjet printing technologies into two categories:

- Material jetting - material jetting.

- Binder jetting Binder jetting. nine0027

In the first case, the building material itself is fed directly through the nozzles, which hardens after application. In the second, an adhesive is sprayed onto a thin layer of gypsum, polymer or metal powder. 3DP technology in its original form represented exactly the second method.

3DP technology in its original form represented exactly the second method.

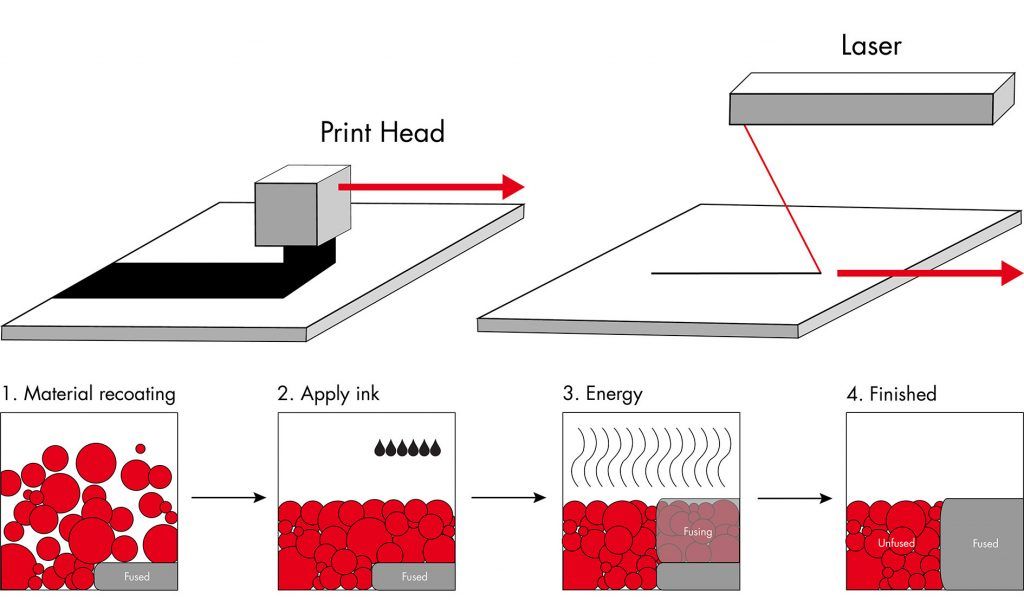

If we consider it in more detail, then printing occurs in the following way:0003

- To begin with, a CAD model is loaded into a computer connected via an Ethernet cable to the printer, which is “cut” into layers, about 0.1 mm thick.

- Next, a thin layer of powdered material (gypsum, polymers, sand, metal) is applied with a roller on a special platform.

- The print head sprays the binder (glue, water, special mixture) along the coordinates of the boundaries of the first layer received from the computer. nine0024 After that, the platform with the model is lowered by the thickness of the layer down, and the chamber with the building material is lowered by the same distance.

- Next, the roller unrolls the next layer and the process repeats.

- After the end of 3D printing, the product is removed from the powder layer and thoroughly cleaned of its residues.

When making models from metal powder, a firing process in a special furnace is added. Let's take a closer look at this process.

The figure above shows 4 stages of his stage:

- First, according to the above scheme, the so-called "green model" is formed from the matrix powder and binder (1,2).

- Next, the article is placed in an oven filled with a protective gas, usually nitrogen.

- When the temperature rises to 1000-1100 degrees, the binder is removed, and the free space around the powder particles is impregnated with bronze (or other metal) previously placed next to the "green" model. This process is called infiltration. nine0032

- Gypsum-based products are quite fragile and can only be used in a narrow field of activity. As a mold, it can only be used once, after which it is destroyed. nine0027

- When working with gypsum powders, a lot of dust is generated, so a good extraction is necessary.

- High speed of building parts - about 6 mm in height per hour, with a working area of 780 x 400 mm it will be 1780 cm3, which is an order of magnitude superior to laser rapid prototyping technologies.

- Relatively low cost of consumables.

- 1 CJP Technology

- 2 Process

- 3 Materials

- 4 Application

- 5 Other additive manufacturing technologies

Materials used for 3DP printing and their cost

Gypsum has traditionally been used in 3D printing, and water played the role of a binder in this case. However, technology has stepped forward and, as is clear from the previous section, metals (bronze, copper), sand and polymer mixtures are now also used. Dyes are mixed into the binder, which makes it possible to carry out color printing on such a 3D printer.

Dyes are mixed into the binder, which makes it possible to carry out color printing on such a 3D printer.

The cost of the simplest powders is on average 600-700 euros for a 10 kg bucket (8200 cm3), the price of the binder is about 660 euros for 3.8 liters. nine0003

Characteristics of finished products and their application

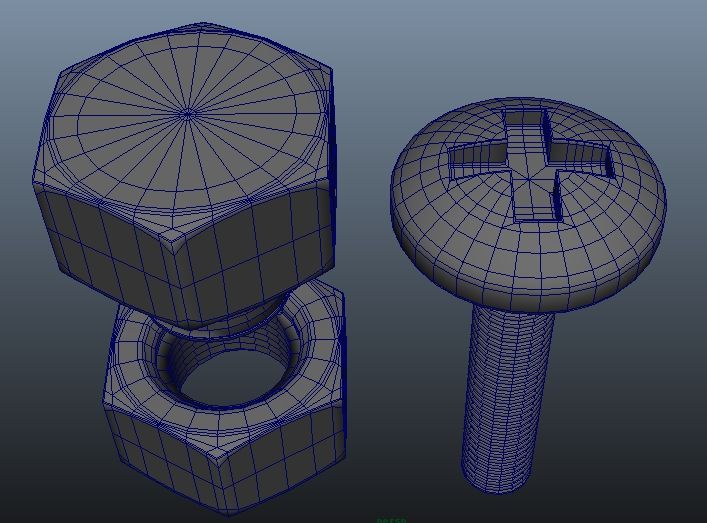

Models made of gypsum and polymers are not too strong to be used in the production cycle as a mold, however, they are quite suitable for rapid visualization of prototypes of various parts and products . It can also be used in various architectural and design works or in the manufacture of souvenirs.

Products using metals have better properties, however, their strength is still at an average level: tensile strength 610 MPa, hardness HRC = 10-20. nine0009 Such characteristics are quite suitable for the manufacture of plastic injection molds, which can withstand from 200 to 500 thousand production cycles. They are also used to make parts that work under friction conditions - shafts, bushings, gears, etc.

Disadvantages

Advantages

ExOne offers the following 3D printer models:

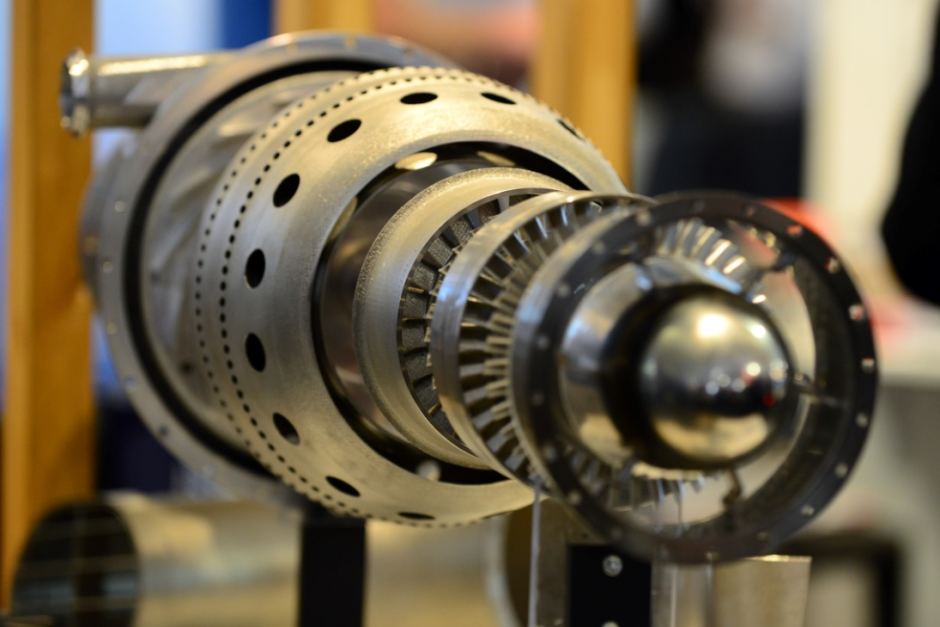

M-Flex printer model from ExOne.

Results

Printers using inkjet 3D printing technology is one of the possible solutions to implement the problem of rapid prototyping. It should be noted that despite some shortcomings, it still found a place in the market today and continues to develop actively along with many of its competitors.

Color Inkjet (CJP)

CJP Technology

Color Inkjet Printing (CJP) is a type of 3D inkjet printing (3DP) proprietary technology from 3D Systems.

Process

3D Systems ProJet 660 Professional CJP Printer

As with 3D inkjet printing (3DP), CJP technology involves the application of thin layers of powdered consumables, followed by the selective application of a binder polymer. A distinctive feature of the technology is the use of multi-colored connecting elements, which allows you to create complex color 3D models. nine0003

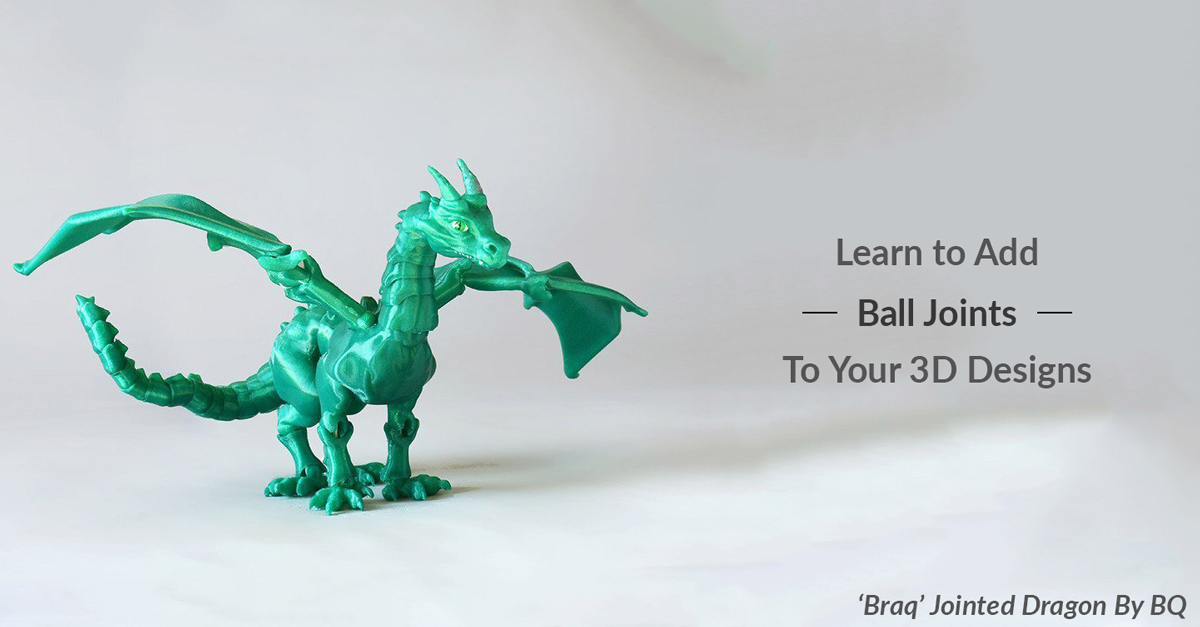

Unused materials are not removed from the working chamber during the process, but serve as a support for subsequent layers, which allows you to create objects of high geometric complexity. However, at the end of the print cycle, the residual powder can be collected and reused.

However, at the end of the print cycle, the residual powder can be collected and reused.

Materials

Colored tires created with a 3D Systems ProJet 660 CJP printer

Plastics with various mechanical properties that mimic rubber, impact-resistant thermoplastics and other materials are used as consumables. nine0003

For example, 3D Systems CJP printers use VisiJet PXL media impregnated with ColorBond (to strengthen color models), StrengthMax (high strength impregnation for functional models), or Salt Water Cure (environmentally friendly impregnation to increase the strength of surface layers).

Application

Color inkjet (CJP) dolls used in the ParaNorman cartoon

Color inkjet printing (CJP) technology is mainly used for prototyping products of complex geometric shapes and colors, as well as for the production of small batches finished products.