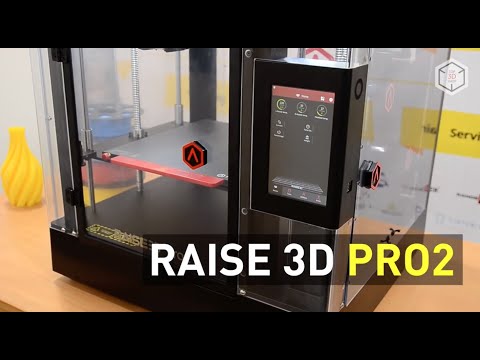

Raise3D pro2 3d printer

Dual Extruder 3D Printer | Pro2 Series Starting at $3,999

Dual Extruder 3D Printer | Pro2 Series Starting at $3,999Search for:

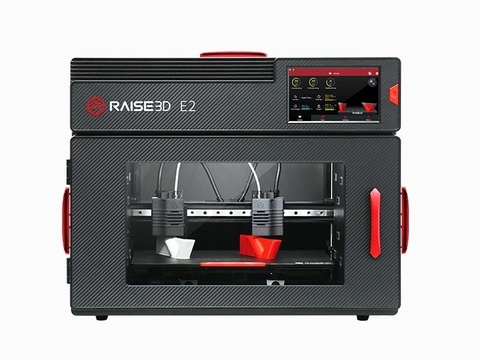

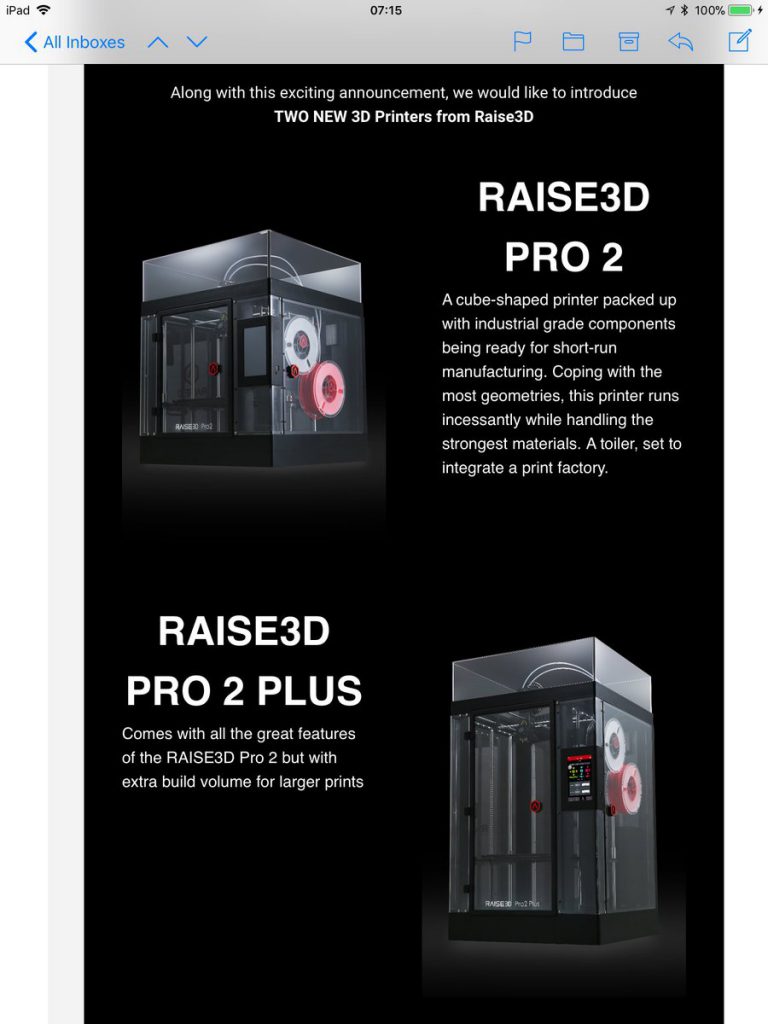

Dual Extruder 3D Printers from Raise3D

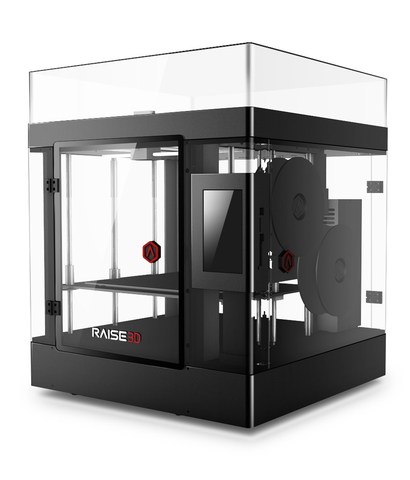

Raise3D’s award-winning Pro2 Series is recognized as a benchmark and gold standard for professional 3D printing applications and 24/ 7 reliability. From Raise3D’s Pro2 Series is the Pro2 and the Pro2 Plus, dual extruder 3D printers with high-resolution, for manufacturing and rapid-prototyping projects of varying sizes.

The Pro2 Series has a metal build plate for even heat distribution, along with a full metal frame for smooth movement and precise positioning, and is compatible with a variety of 3D printing materials. The Pro2 Series is complete with precaution measures to save work, a 7-inch touch screen for efficient monitoring of the 3D printing process, and a HEPA air filter. As with all 3D printers from Raise3D, the Pro2 Series can pair with: ideaMaker, a 3D slicer software, ideaMaker Library, a platform for sharing 3D printer files with those in the Raise3D community, and RaiseCloud, a cloud-based 3D printing management platform. Finally, as with all Raise3D products, the Pro2 Series is both ISO 9001 and ISO 14001 certified.

Raise3D’s award-winning Pro2 Series is recognized as a benchmark and gold standard for professional 3D printing applications and 24/ 7 reliability.

CertificationsThe Pro2 Series is CE, CB, RoHS and FCC certified.

Please visit here for the details of each certificate.

Printer DetailsThe Pro2 dual extruder 3D printer can print up to 12 x 12 x 11.8 inch | 305 x 305 x 300 mm. The Pro2 Plus 3D printer can print up to 12 x 12 x 23.8 inch | 305 x 305 x 605 mm.

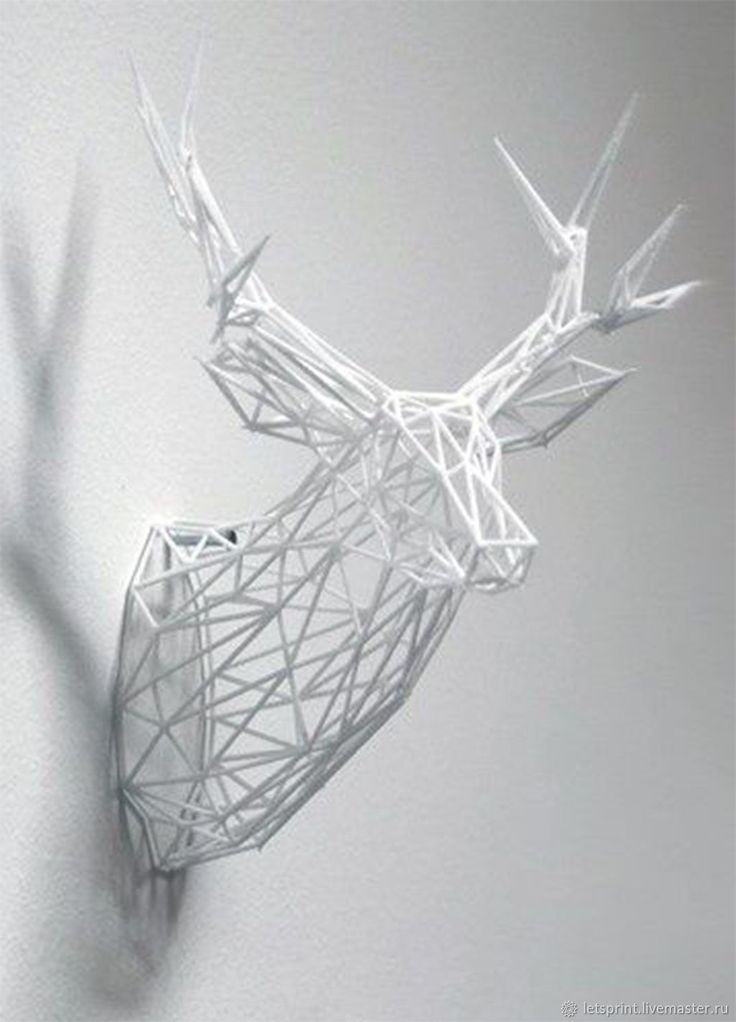

This flexibility allows the Pro2 Series to produce various kinds of tools, parts, and components. Some uses for 3D printers with this kind of build volume is in creating 3D printed tools to make professional manufacturing and rapid-prototyping more efficient.

Some uses for 3D printers with this kind of build volume is in creating 3D printed tools to make professional manufacturing and rapid-prototyping more efficient.

Download spec table

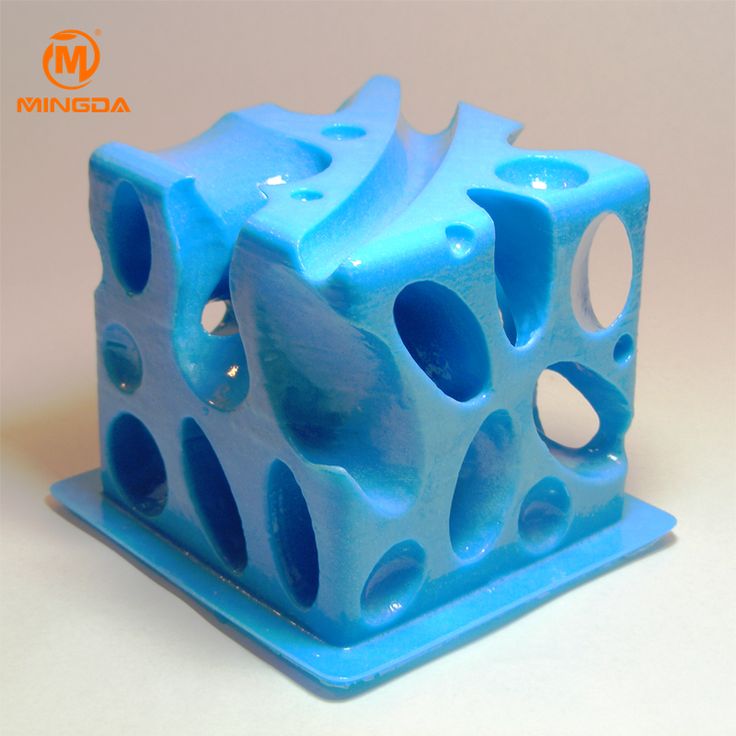

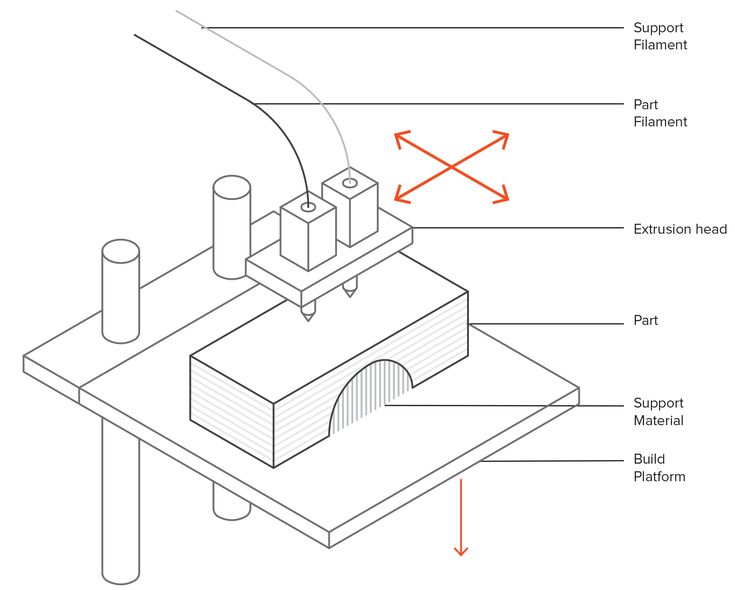

What is a dual extruder 3D printer?A dual extruder 3D printer can produce 3D printed objects with different kinds of 3D printing materials (also known as filaments) and colors within a single print job.

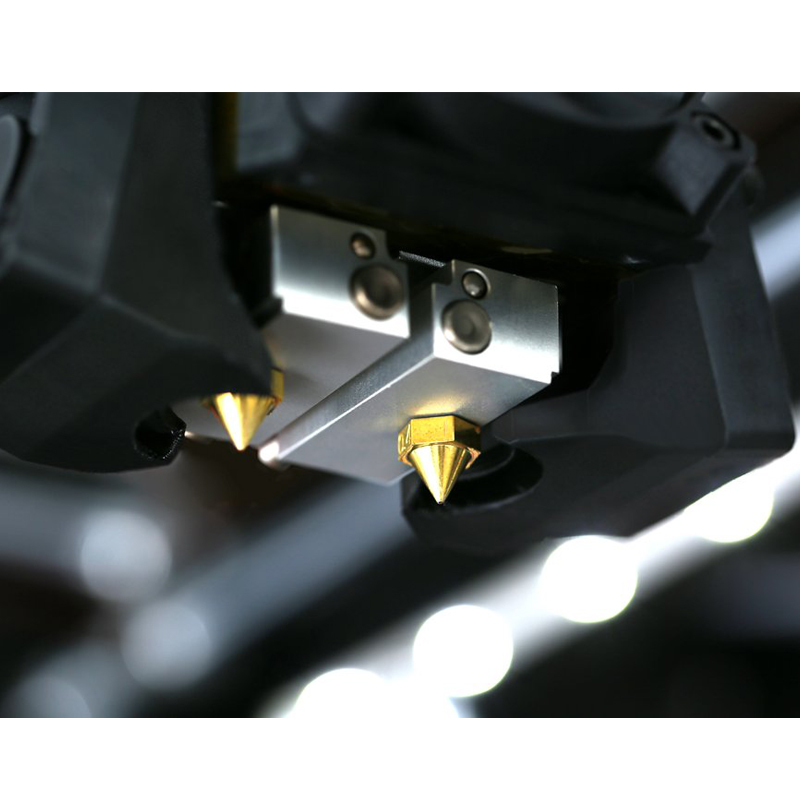

What are the dual extruders for?Dual extruders enable the 3D printer to produce objects with multiple filaments, such as a water-soluble 3D printing material, and multiple colors.

Technical DetailsHigh repeatability

Lightning speed

1.5 mm lifting distance

Compatible with flexible filamentsWhy is high repeatability good for a 3D printer? What does high reliability mean?

3D printing is a process where an object is built up by thin layers. The 3D printer needs to move back and forth along the length of the model to create those thin layers. If the printer loses its position during that back-and-forth motion, the 3D printing process will no longer be aligned, and the 3D printed object will be ruined. The high repeatability and reliability ensure the printer does not become misaligned during the back-and-forth movements.

The 3D printer needs to move back and forth along the length of the model to create those thin layers. If the printer loses its position during that back-and-forth motion, the 3D printing process will no longer be aligned, and the 3D printed object will be ruined. The high repeatability and reliability ensure the printer does not become misaligned during the back-and-forth movements.

What does lightning speed mean?

Lightning speed refers to the overall amount of time the 3D printer takes to print an object. However, this speed is heavily influenced by the type of project being printed and how quickly the printer can switch directions during the back-and-forth movement. Having a <1 second switch time means the Pro2 Series can change directions while printing an object. This shortens the overall time needed to complete a 3D printing process. Keep in mind, the general time savings will still be influenced by the project type.

Why is a 1. 5 mm lifting distance beneficial to a 3D printer?

5 mm lifting distance beneficial to a 3D printer?

Lifting distance refers to the clearance between the idle printing nozzle and the object being printed. There needs to be some distance between both to ensure the printer’s nozzle does not interfere with the printing. The 1.5 mm lifting distance on the Pro2 Series maintains enough distance between the idle nozzle and the model to not affect the printing process.

Capable of Printing a Variety of Filaments Up to 300℃PLA/ ABS/ HIPS/ PC/ TPU/ TPE/ PETG/ ASA/ PP/ PVA/ Nylon/ Glass Fiber Infused/ Carbon Fiber Infused/ Metal Fill/ Wood Fill

Buy Filaments

Material Compatibility Metal Build Plate HEPA Air Filter Touch Screen & Software Monitoring Precaution Measures Full Metal Frame

The Pro2 Series is compatible with a variety of 3D printing materials (known as filaments) to meet project requirementsDepending on the project goals, more than one 3D printing filament is necessary to accommodate varying structural or functional requirements (some such requirements include flexibility, and strength). Sometimes multiple filaments are required within the same print job. Having a 3D printer that is compatible with different filament types is both cost-saving and practical for print jobs multiple filaments.

Sometimes multiple filaments are required within the same print job. Having a 3D printer that is compatible with different filament types is both cost-saving and practical for print jobs multiple filaments.

The build plate is a heated, flat surface in every 3D printer where all projects are printed. An even heat surface on a build plate is crucial for creating high-quality 3D printed parts. It also ensures that all 3D printing filaments are not damaged due to unequal heat distribution.

HEPA air filtration removes toxic particles released during the 3D printing processThe Pro2 Series has HEPA air filtration to clean the air of any particles (including nano-particles) released during the 3D printing process. The HEPA air filter works effectively in classrooms, offices, and in large and small workspaces. The Pro2 Series’ HEPA air filtration operates silently, designed to work quietly in the background of any workspace.

The Pro2 Series’ HEPA air filtration operates silently, designed to work quietly in the background of any workspace.

The Pro2 Series’ 7-inch touch screens allow users to interact with the printer directly. It also provides on-screen assistance and visual model selections to simplify operating and monitoring the 3D printer and 3D printing process. As with all Raise3D 3D printers, the Pro2 Series is compatible with ideaMaker, a 3D slicing software, and RaiseCloud, a cloud-based 3D printing management platform. This wireless connection allows users to keep track of every print job while on the move.

Precaution measures are installed to save work in case the 3D printing material runs out or if there is a power outagePower loss can cancel and ruin an ongoing 3D printing project. However, the Pro2 Series’ power loss secures the 3D printing process in an unexpected power outage. In addition, the filament run-out sensor on the Pro2 Series extruders prevents ruined print jobs due to running out of filament.

In addition, the filament run-out sensor on the Pro2 Series extruders prevents ruined print jobs due to running out of filament.

High-quality 3D printing comes from high-quality 3D printers. The Pro2 Series uses a full metal frame to create a specific motion system that allows the machine to smoothly glide as it prints. This motion system works with precise positioning to ensure 3D print jobs are as accurate as possible. Interchangeable nozzles allow the Pro2 Series to print at different levels of detail.

Raise3D EcosystemPair ideaMaker and RaiseCloud with any of our 3D printers to create a Raise3D ecosystem for the best efficiency when 3D printing.

ideaMakerideaMaker is a free 3D slicing software from Raise3D, compatible with Raise3D printers and third-party printers.

Learn More

RaiseCloudRaiseCloud is a cloud-based 3D printing management platform capable of remotely monitoring the printing process and organizing print jobs for more efficient 3D printing.

Learn More

ideaMaker LibraryideaMaker Library provides users with slicing profiles for various filaments, including Raise3D filaments and OFP certified filaments, simplifying the settings of printing parameters for different filaments.

Learn More

Raise3D AcademyAccess Raise3D Academy for step-by-step guides and “how-to” articles, covering topics ranging from setting up and giving maintenance to the 3D printer to performing 3D printing.

Learn More

Raise3D SupportContact Raise3D’s Support Center with any questions regarding a specific printer.

Learn More

Pro2 Series Technical Specifications

DownloadPro2

Pro2 Plus

GENERAL

Build Volume (W × D × H)

Single Extrusion Print: 12 × 12 × 11.8 inch/ 305 × 305 × 300 mm

Dual Extrusion Print: 11 × 12 × 11.8 inch/ 280 × 305 × 300 mm

Single Extrusion Print: 12 × 12 × 23.8 inch/ 305 × 305 × 605 mm

Dual Extrusion Print: 11 × 12 × 23.8 inch/ 280 × 305 × 605 mm

Machine Size (W × D × H)

24.4 × 23.2 × 29.9 inch/ 620 × 590 × 760 mm

24.4 × 23.2 × 43.5 inch/ 620 × 590 × 1105 mm

Print Technology

FFF

Print Head System

Dual-head with electronic lifting system

Filament Diameter

1. 75 mm

75 mm

XYZ Step Size

0.78125, 0.78125, 0.078125 micron

Print Head Travel Speed

30–150 mm/s

Build Plate

Heated aluminum build plate with magnetic holding

Max Build Plate Temperature

110ºC

Heated Bed Material

Silicone

Build Plate Leveling

Pre-calibrated leveling

Filament Run-out Sensor

Available

Supported Materials

PLA/ ABS/ HIPS/ PC/ TPU/ TPE/ PETG/ ASA/ PP/ PVA/ Nylon/ Glass Fiber Infused/ Carbon Fiber Infused/ Metal Fill/ Wood Fill

Layer Height

0. 01-0.25mm

01-0.25mm

Nozzle Diameter

0.4 mm (Default), 0.2/ 0.6/ 0.8/ 1.0 mm (Available)

Max Nozzle Temperature

300ºC

Connectivity

Wi-Fi, LAN, USB port, Live camera

Noise Emission (Acoustic)

<50 dB(A) when building

Operating Ambient Temperature

15-30ºC, 10-90% RH non-condensing

Storage Temperature

-25℃ to +55℃, 10-90% RH non-condensing

Filter

HEPA filter with activated charcoal

Technical Certifications

CB, CE, FCC, RoHS

Net Weight

50. 2 kg

2 kg

59.3 kg

Gross Weight (Carton Only)

62.7 kg

71.8 kg

Gross Weight (Carton with Pallet)

70.5 kg

79.6 kg

ELECTRICAL

Power Supply Input

100-240 V AC, 50/ 60 Hz 230 V @ 3.3 A

Power Supply Output

24 V DC, 600 W

SOFTWARE

Slicing Software

ideaMaker

Supported File Types

STL/ OBJ/ 3MF/ OLTP

Supported OS

WINDOWS/ macOS/ Linux

Machine Code Type

GCODE

PRINTER CONTROLLER

User Interface

7-inch Touch Screen

Network

Wi-Fi, Ethernet

Power Loss Recovery

Available

Screen Resolution

1024 × 600

Motion Controller

Atmel ARM Cortex M7. 400 MHZ FPU

400 MHZ FPU

Logic Controller

NXP i.MX6, Quad core 1 GHz ARM processor

Memory

1 GB

Onboard Flash

16 GB

OS

Embedded Linux

Ports

USB 2.0 × 2, Ethernet × 1

Raise3D Pro2 3D Printer | MatterHackers

The Raise3D Pro2 Series 3D Printers

The Raise3D Pro2 3D printer takes the same amazing form of the Raise3D N2 and gives you even more! You get these same great features standard:

- Superb Build Volume

- Dual Extrusion

- Wireless Connectivity

- Fully Enclosed

- 7" Full-Color Touchscreen

- Print Recovery

- V3 Hotend Capable of Temperatures up to 300° C

With the Pro2, you also get these amazing NEW features:

- Magnetic Swappable Print Bed System

- Built-In Remote Monitoring Camera

- 32-Bit Motherboard Controller

- High-Quality Optical X, Y and Z Axis Endstops

- Improved Extruder Motors with Filament Runout Sensors

- Super High-Resolution 3D Printing - Down to 0. 01mm Layer Thickness

01mm Layer Thickness

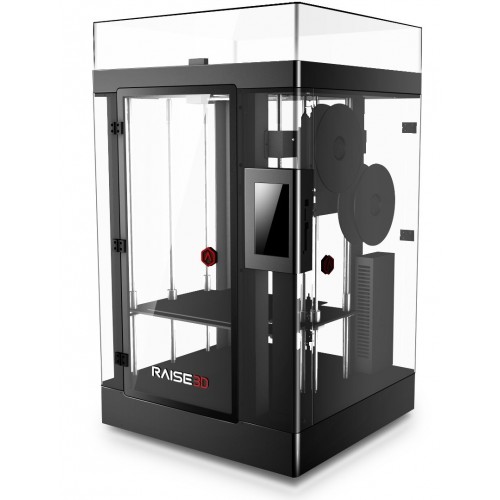

Massive, Fully Enclosed Build Area

The new Pro2 from Raise3D has a superb build volume - 12inx12inx11.8inches, making 3D printing in much larger scale than other similarly priced 3D printers no problem. Because it is fully-enclosed, temperatures remain much more stable, so printing with ABS and other temperature sensitive filaments is no problem. The enclosure also makes the Pro2 safer for beginners to work with, and it keeps curious fingers out of harm's way at schools.

The Pro2 includes a new cooling fan with a HEPA filter. Not only can the fan be controlled independently for more or less cooling, it traps over 90% of all contaminants, keeping dust and debris out of the air.

7" Full-Color Touchscreen

The Pro2 is equipped with a huge, 7" capacitive touchscreen, allowing the user to calibrate, download, monitor and modify 3D prints without a computer. With 2 USB ports, WiFi and Local Area Network connectivity, options for inputting designs are limitless. The interface also shows progress on 3D print jobs, so workgroups gain more insight into projects and keeps design teams moving in the right direction.

The interface also shows progress on 3D print jobs, so workgroups gain more insight into projects and keeps design teams moving in the right direction.

Emergency Print Recovery

If the power goes out, or the printer is accidentally unplugged during a print, it will save the previous location of the tool head during the print and allow the print to continue once power is restored. No more lost prints because of mother nature or butter fingers.

Unlimited Material Choices

The Pro2 hotend is capable of reaching a blistering 300°C, and the swappable heated print bed is capable of reaching temperatures of 110°C, so any and all filaments are supported!

-PLA -TPU -PETG

-ABS -NYLON -Metal infused PLA*

-HIPS -TPE -Wood PLA

-PC -FLEX -Carbon Fiber Reinforced*

*Required Hardened Nozzle

New and Improved Motherboard

The new ARM Cortex M7 32-bit controller allows for amazing accuracy while maintaining high-speeds for all 3D printing tasks. Made with industrial grade components, the Pro2 Plus delivers silky smooth movement and superior-quality 3D prints at any resolution.

Made with industrial grade components, the Pro2 Plus delivers silky smooth movement and superior-quality 3D prints at any resolution.

New Extruder with Filament Run-Out Sensor

The improved, dual-gear driven extruder lowers the possibility of slipping, giving better grip for all filament types, as well as more reliable extrusion overall. The extruder redesign makes it almost 50% faster. The dual extruder also includes receding nozzles - the nozzle that is not in use recedes until needed again. This also gives the Pro2 models even more speed to finish prints.

The filament run-out sensor gives 3D prints another chance at success by informing the user remotely that a project needs more filament. Once it is replaced, the print can resume without having to start all over again.

Improved Build Plate System

The aerospace-grade print bed is removable and has an upgraded 4+9 point lock system to prevent slippage. With a silicone heated pad under the main removable plate, heat distribution is excellent, with less warping along and extreme ease-of-use. Replacement of the print bed is also extremely easy and can be supplemented with additional print beds for more technical applications of additional surfaces - borosilicate, garolite, and other materials.

Replacement of the print bed is also extremely easy and can be supplemented with additional print beds for more technical applications of additional surfaces - borosilicate, garolite, and other materials.

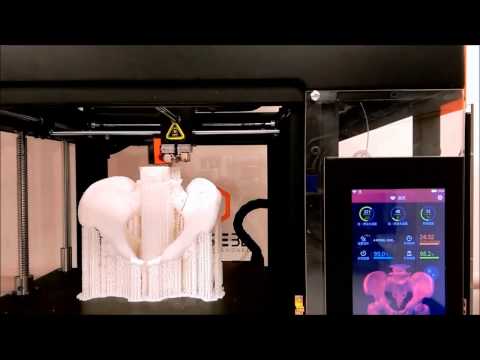

Built-In Live Camera

Now included with the Pro2 models is a built-in, high-resolution camera for remote monitoring. Get a look at your projects whether you are home or not!

Raise Shield Protects Your Printer, Letting You Focus on What's Important

Raise3D printers such as the Pro2 and Pro2 Plus come with a 1 year Limited Warranty, that covers non-electronics and non-consumables. By purchasing the Raise Shield warranty service for Raise3D 3D printers, your warranty coverage is upgraded to cover all manufacturer defects, including electronic components that 1 year. Consumables and cosmetic imperfections are not included in the Raise Shield coverage.

This can be extended to cover 2 or 3 years, depending on your checkout option.

Technical Specifications- Print Technology: FFF

- Build Volume (WxDxH):12x12x11.

8inch (305x305x300mm)

8inch (305x305x300mm) - 11x12x11.8inch (280x305x300mm) - Dual Extrusion

- Machine Size: (WxDxH): 24.4x23.2x29.9inch (620x590x760mm)

- Print Head: Dual-Head with electronic lifting system

- Filament Diameter: 1.75mm

- X/Y/Z Step Size: 0.78125, 0.78125, 0.078125 micron

- Print Head Travel Speed: 30 - 150 mm/s

- Build Plate: Heated Aluminum Build Plate with Magnetic Base

- Build Plate Material: Aluminim, with Silicone Safety Handle

- Max Build Plate Temperature: 110°C

- Build-Plate Leveling: Pre-Calibrated Leveling

- Supported Materials: PLA, ABS, HIPS, TPU, PC, NYLON, TPE, FLEX, PETG, Metallic PLA, Wood PLA, Carbon Fiber Reinforced Materials

- Nozzle Diameter: 0.20mm, 0.40mm, 0.60mm, 0.80mm, 1.00mm

- Max Nozzle Temperature: 300°C

- Operating Sound: 50 dB

- Connectivity: WiFi, LAN, USB Port

- Monitoring: Live Camera

- Power Supply Input: Universal 100-240 V AC, 50/60 Hz

- Power Supply Output: 600 Watts, 24 V DC

Printer Controller and Software

Slicing Software: ideaMaker

Supported File Types: STL, OBJ

Supported OS: Windows/iOS/Linux

Machine Code Type: gCode

User Interface: 7" Touch Screen

Network: Ethernet 802. 11b/g/n WiFI 2.4GHz/5GHz

11b/g/n WiFI 2.4GHz/5GHz

Resume Print after Power Outage: Second Generation

Screen Resolution: 1024x600

Motion Controller: ARM Cortex M7.400MHZ FPU

Logic Controller: Freescale imx6, Quad Core 1GHz ARM Processor

Memory: 1 GB

Onboard Flash: 8 GB

OS: Embedded Linux

Ports: SD Cardx1, USB 2.0x2, Ethernetx1

What's in the Box

- Raise3D Pro2 3D Printer

- Power Cable

- Hex Wrench Set

- Build Plate

- Raise3d Premium PLA Filament Spool x2

- 1kg Spool of White PLA

- 1kg Spool of Red PLA

- USB Stick

- Heat Resistant Gloves

- Filament Holder x2

- Spatula

- Nozzle Cleaning Kit

- Tweezers

- Replacement Fuses

- Replacement Thumb Screws

- Additional Replacement Components

Raise 3D Pro2 Plus

New Pro2 Series 3D Printers

Features and Benefits - Raise3D Pro2 Plus

Dual extruder with electronic lift

Prints even the most complex designs. Faster printing. Prints with various materials.

Reprint Accuracy (Incredibly fast switching between extruders (1.5mm lift height.

Over 100,000 reliability tests. nine0015

When Just a Large Print Area Isn't Enough

Reliability 24/7 thanks to high-strength aluminum frame.

Large range of materials

by heating up to 300℃

PLA / ABS / HIPS / PC / TPU / NYLON / TPE / FLEX / PETG / BRONZE / WOOD / CARBON

A high resolution

Sophisticated mechanics for superior print quality and model detail. nine0005

Unsurpassed layer resolution

Layer thickness 0.01 mm

Replacement nozzles

0.2 mm nozzle for high detail

Precise positioning

0. 0125 mm X/Y positioning

0125 mm X/Y positioning

Unique user interface

7-inch touch screen

Visual interface / Quick view / Visual display of the printing process / Full control of all printing parameters

Next Generation Resume System

You will never lose your print results.

“I accidentally unplugged the printer while I was vacuuming the room. At that time, the model had already been printed for 96 hours, there were only 2 hours of printing left.

When I saw this, I was ready to scream in horror, but turned the printer back on and he offered to continue printing. Raise3D literally saved me!” nine0014 Sean Robinson

Wireless management and printing

Work more efficiently with ideaMaker by wirelessly connecting to your Pro 2 printer

New generation position control device

High reliability. Precise current control. Smooth movements. Perfect thermal insulation properties.

Precise current control. Smooth movements. Perfect thermal insulation properties.

400MHz ARM Cortex-M7 32bit RISC FPU. nine0014 Industrial grade components.

Autonomous motor driver.

Control system with 256 micro steps.

New extruder with filament end sensor

Better thread grip. No slippage. More reliable printing.

Double driven.

4 times the performance.

Smooth and sensitive optical filament end sensor.

New air filter nine0003

Environmentally friendly.

The silent protector of your health.

Absorbs >91% of harmful particles

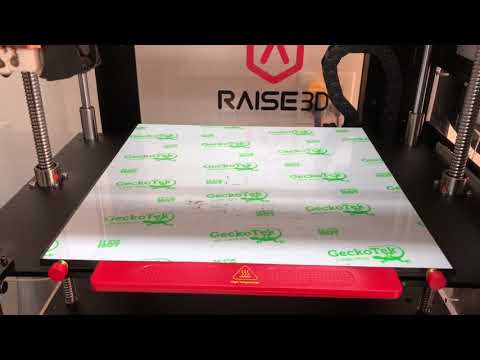

New platform

Good adhesion.

Uniform heating.

Longer service life.

Sturdy and easy to use.

Modern materials.

Silicone table warmer.

Aluminum platform with magnetic holders. nine0014 Improved 4+9 table attachment system.

nine0014 Improved 4+9 table attachment system.

Raise3D Pro2 – a new acquaintance. Read article

In mid-2018, Raise3D announced that it was releasing a new line of Pro2 3D printers. Everyone is well acquainted with the devices of this manufacturer's N-series, which have proven themselves well. The company itself, despite its young age (it has been operating since 2015), has already earned a positive reputation. And the main focus is on feedback, that is, the developments carried out by Raise3D employees in Shanghai are based on feedback, recommendations and wishes from users of 3D printers of this brand, in particular the N series. And the new Raise3D Pro2 and Pro2 Plus became the results of these works. And therefore, we will give a comparative description in accordance with the previous generation - Raise3D N2. nine0005

Raise3D Pro2 - exterior and interior

Visually, Raise3D Pro2 differs little from N2. However, there are still changes. The developers did not change the frame, but the case itself acquired some goodies. The first is a door with magnets. Recall that in N2 it was fixed on a latch. Magnets are undeniably more convenient.

The first is a door with magnets. Recall that in N2 it was fixed on a latch. Magnets are undeniably more convenient.

Second, there are holes in the spool compartment in the door. They are closed with plugs, but allow you to work with large coils without leaving the door open. Also a convenient innovation, especially considering that the equipment is focused on printing large items. nine0005

There are also changes inside. Raise3D Pro2 has got a HEPA filter. Now, even when printing with ABS plastic, unpleasant odors are felt much less.

The mechanics in N2 can be said to be perfect, so the Pro2 kinematics were left unchanged, at least not key ones. But the limit switches were still changed to more serious optical ones - a small step into the future.

In the previous model, the table was glass, in Pro2 it was made of aluminum and equipped with BulidTalk's proprietary adhesive surface on top. The fixation of the table is also on magnets and additionally on screws. Clothespins that the extruder could catch on are removed. nine0005

Clothespins that the extruder could catch on are removed. nine0005

Directly at the factory, each table is carefully checked for evenness. For this, a special test was invented, and it is printed, and its results are visible to you. By the way, you need to remove them before calibration and the first print.

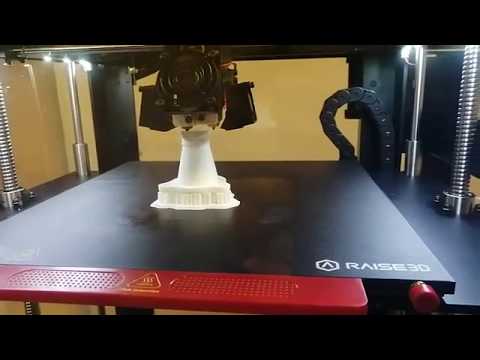

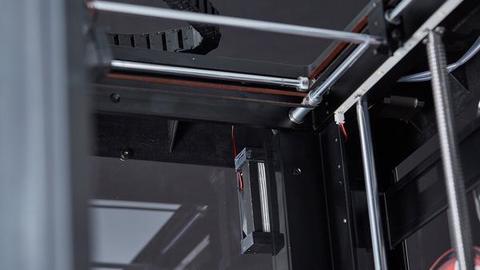

So what has changed significantly? Of course, the extruder is the heart of any FDM 3D printer. Dual extruder printing has some inherent problems. As I recall, in N2 it was necessary to ideally set the nozzles in relation to each other, but even in this case, the likelihood that one would interfere with the other, or even the model would simply be knocked down, was very high. nine0005

Pro2 is equipped with a system that raises the nozzles using a servo. The inactive nozzle rises literally a few millimeters during printing, but this is enough to ensure safe printing in terms of interference.

The only thing is that the calibration has become somewhat more complicated. But this is more than offset by the fact that the main problems of dual-extruder printing have been resolved, and the system itself has become more convenient.

But this is more than offset by the fact that the main problems of dual-extruder printing have been resolved, and the system itself has become more convenient.

In the N2, the extruder and with it the model were cooled by two fans. In the Pro2, the extruder is cooled by a large heatsink, and two small fans are provided to blow the model. Now you can adjust the airflow or turn it off altogether. nine0005

The developers have completely redesigned the plastic feed mechanism. Parts and mechanisms have been reduced and made lighter. As a result, the entire print head is lighter. Changing this indicator made it possible to print faster while maintaining the quality of the finished surface. Added the ability to adjust the clamping mechanism. This will be just an indispensable feature when working with whimsical materials such as flex and rubber.

There is a sensor on the top of the feed mechanism that will read the presence of filament. When finished, printing will be automatically paused. nine0005

nine0005

Pro2 is equipped with a camera that allows you to remotely monitor the printing process and record time-lapses.

But the developers decided to part with the battery, although the resume printing function was left, but the principle has changed somewhat. When the power is turned off, the printer pauses, non-volatile memory is activated, which, when the power is turned on, allows you to start printing from the right moment.

Of course, improvements have also affected the “brains”. All innovations required the installation of a more powerful board, which was done. As for electronics, the numbers will tell you better here:

- 400MHz ARM Cortex-M7 32bit RISC FPU.

- Autonomous motor driver.

- Control system with 256 micro steps.

Calibration

The Pro2 test sample is pre-production, so it has a large number of printed parts. In production models, they will be cast. From the factory, the model comes with an already calibrated table plane, and the nozzle will have to be calibrated by setting the distance between it and the table.

Send the extruder home first, then the table, in that order. Since the position of the extruder "in the house" is slightly out of the plane of the table, even if the table is raised a little high, the extruder will not crash into it. nine0005

You can use the feeler gauge that comes with the kit to set the gap. Calibration should be carried out only on a “cold” one, that is, neither the table nor the extruder needs to be heated.

Table height adjustment is carried out by means of a pin that closes the optical limit switch along the Z axis.

Nozzles are more difficult to calibrate. On N2, one bolt was simply unscrewed, and on Pro2 it will be necessary to remove the fan.

The mechanics of switching extruders is not complicated. Extruders with eccentrics are spring-loaded and driven by a servo drive. As a result, there are only two positions to the left to the maximum or to the right to the maximum. nine0005

For calibration, both extruders are first heated, then the desired extruder is lowered. Next on the screen you need to select the desired extruder and start extrusion. Then the bolt on the extruder is unscrewed, which will allow you to adjust its position in height. Do the same with the second extruder. This is how calibration is done.

Next on the screen you need to select the desired extruder and start extrusion. Then the bolt on the extruder is unscrewed, which will allow you to adjust its position in height. Do the same with the second extruder. This is how calibration is done.

Software

The work is carried out in the ideaMaker program. Some functions and new ready-made profiles have been added to the software, as many users prefer to use the ready-made settings. In particular, the new profile - "ultra quality" will allow you to print with a layer thickness of only 0.05. nine0005

Another useful feature is auto-registration of models in two-color printing. Previously, this task had to be handled manually.

Fine tuning is also available. There is an acceleration factor. Models on the table have the ability to ungroup, and then print them simultaneously, but for each set different parameters, including the layer thickness.

The Pro2 OSD also has new features - advanced settings, among which are acceleration, extruder offset and others. When printing, these settings will be higher in priority than those that the slicer will have, and if you use several 3D printers at once, then the setting can be done once and not toil with the constant preparation of the file. nine0005

When printing, these settings will be higher in priority than those that the slicer will have, and if you use several 3D printers at once, then the setting can be done once and not toil with the constant preparation of the file. nine0005

3D printing

We used the original branded Raise plastic for testing. The print quality is top notch.

In the process of printing was used soluble plastic for supports - PVA. Since the main purpose of Raise3D Pro2 is industrial, cases for the board, the battery of the screwdriver were also chosen for printing, but not without toys, vases and other trifles.

The Pro2 handled everything flawlessly.

To sum up…

So, Raise3D Pro2 is really made on the basis of N2, all significant wishes and comments of consumers were heard, which is very gratifying. In general, it's nice to know that the feedback works, because the Pro2 is actually more convenient than its predecessors.

With Raise3D Pro2, you can modernize your production, make it more modern and efficient, and reduce the cost of launching new products.