Uva 3d printing

University of Virginia 3D-prints living soil walls that sprout greenery

Rima Sabina Aouf | Leave a comment

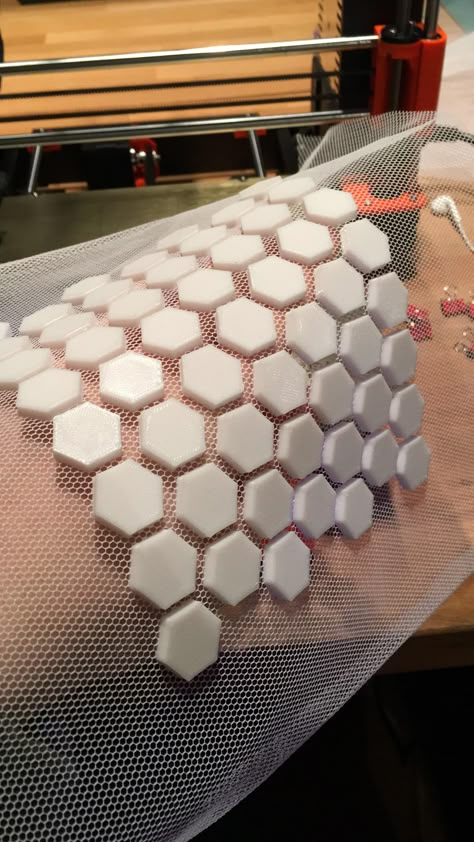

University of Virginia researchers have invented a method of 3D printing with seed-impregnated soil, which could be used to create walls and roofs teeming with plant life.

Prototypes built by the researchers start off looking like ordinary raw-earth structures. But over the course of a few days, they sprout and become covered in greenery, leading the University of Virginia (UVA) to compare them to "oversized Chia Pets".

Building elements such as green walls and roofs could be constructed using this method, bringing benefits like natural insulation, flood prevention and green spaces for people, pollinators and other animals, according to UVA.

UVA researchers have 3D-printed living walls that sprout greeneryBy combining soil and seeds into 3D-printable "soil inks", greenery could be built into the very fabric of architectural features rather than just layered on top.

This has the potential to reduce the need for more emissions-intensive building materials and replace them with a circular alternative, which the researchers say can be can be reused again and again.

"We are working with local soils and plants mixed with water," said Ehsan Baharlou, an assistant professor at UVA's School of Architecture. "The only electricity we need is to move the material and run a pump during printing."

"If we don't need a printed piece or if it isn't the right quality, we can recycle and reuse the material in the next batch of inks."

Ehsan Baharlou is one member of the research team. Photo by Tom DalyBuildings made with this technique have the potential to be carbon neutral or even carbon negative, as their plant covering would draw down carbon dioxide from the atmosphere.

"This method hypothesises to create an active ecological system that might store emitted carbon in 3D-printed soil structures through the process of photosynthesis," Baharlou told Dezeen.

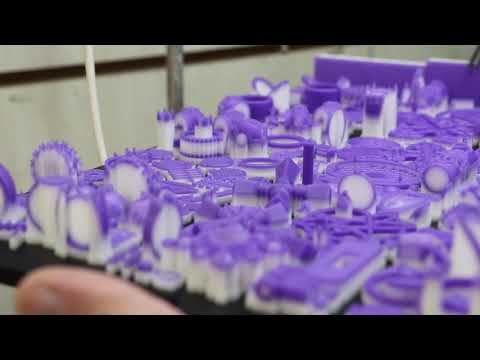

Initially, the UVA researchers used their method to create a series of small, self-supporting structures that resemble beehives and published them in the journal Additive Manufacturing.

The team developed 3D-printable "soil inks" made from raw earth and seedsAt that stage, their goal was to create structures that were solid enough to stand by themselves while also providing enough moisture and nutrients to support seed germination and seedling growth.

For the seeds, they chose to use stonecrop – a succulent plant that can survive with little water – as the extrusion process makes the soil compact and dry.

Blast Studio 3D prints column from mycelium to make "architecture that could feed people"

The researchers have since started printing larger objects such as low walls about a metre in height. Next, they will look at mounting the 3D-printing system on a moving robot that could enable the production of taller, more complex structures with multiple sides.

For this upcoming stage, the researchers will have to further develop the formula for their "soil inks" as they predict that the extra height will exacerbate problems such as soil cracking.

Plant life begins to grow on the structures in a matter of daysThe researchers also plan to experiment with using multiple material layers within a wall panel, allowing the dry inner wall to be insulated from the moist outer wall.

Other efforts to create living architecture through 3D printing have come from London-based Blast Studio, which has mixed mycelium with paper pulp to create an architectural column that can sprout mushrooms.

The photos are by Ehsan Baharlou unless otherwise stated.

Project credits

Research team: Ji Ma, David Carr, Ehsan Baharlou, Spencer Barnes, Leah Kirssin and Lizzie Needham.

Subscribe to our newsletters

Your email addressDezeen Debate

Our most popular newsletter, formerly known as Dezeen Weekly. Sent every Thursday and featuring a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

Sent every Thursday and featuring a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

Sent every Tuesday and containing a selection of the most important news highlights. Plus occasional updates on Dezeen’s services and breaking news.

Dezeen DailyA daily newsletter containing the latest stories from Dezeen.

Dezeen JobsDaily updates on the latest design and architecture vacancies advertised on Dezeen Jobs. Plus occasional news.

Dezeen AwardsNews about our Dezeen Awards programme, including entry deadlines and announcements. Plus occasional updates.

Dezeen Events GuideNews from Dezeen Events Guide, a listings guide covering the leading design-related events taking place around the world. Plus occasional updates.

We will only use your email address to send you the newsletters you have requested. We will never give your details to anyone else without your consent. You can unsubscribe at any time by clicking on the unsubscribe link at the bottom of every email, or by emailing us at [email protected].

We will never give your details to anyone else without your consent. You can unsubscribe at any time by clicking on the unsubscribe link at the bottom of every email, or by emailing us at [email protected].

For more details, please see our privacy notice.

Thank you!

You will shortly receive a welcome email so please check your inbox.

You can unsubscribe at any time by clicking the link at the bottom of every newsletter.

More images

UVA researchers develop 3D-printed structures made of soil and seeds | News

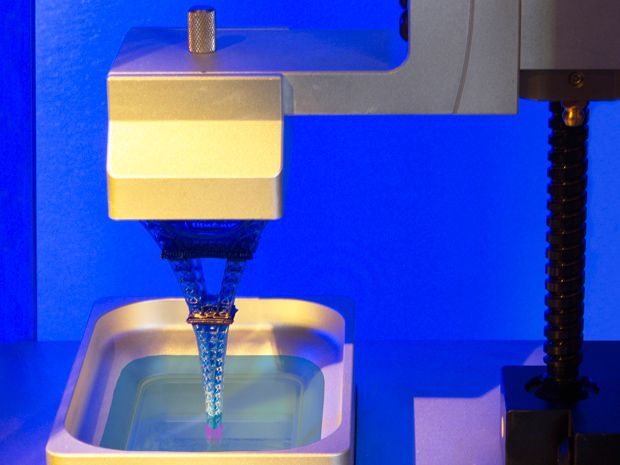

anchorUsing a 3D printer that squirts soil mixed with seeds, researchers are considering how they could build structures with walls and roofs infused with greenery, a little bit like the 1980s craze of Chia Pets. (Contributed photo courtesy of Dr. Ehsan Baharlou)

A research team out of the University of Virginia (UVA) has developed a new innovative and sustainable approach to building that utilizes the power of 3D printing to create structures made of soil implanted with seeds.

The team consists of Ji Ma, an assistant professor of materials science and engineering at UVA’s School of Engineering and Applied Science; David Carr, a research professor in the university’s Department of Environmental Sciences; Ehsan Baharlou, an assistant professor in the UVA School of Architecture; and recent UVA graduate Spencer Barnes, who earned his Bachelor of Science in aerospace engineering. Given the environmental benefits of integrating green spaces with buildings, the researchers wanted to investigate the possibility of developing complex structures made of natural materials themselves.

"Supported by the School of Architecture’s fabrication lab and a 3Cavaliers grant, Baharlou established an additive manufacturing fabrication system to 3D-print large structures. The centerpiece is an industrial robot with a 3- to 4-foot reach that can deposit materials customized to an architect’s desired objectives for a structure, such as space, function and geometry." Image and text courtesy of UVA. Photo credit: Tom Daly

Photo credit: Tom DalyTheir approach combines the speed, cost efficiency, and low energy demands of 3D printing with locally-sourced, bio-based materials. This method breaks away from the typical linear approach to design and construction, where raw materials are thrown away as waste at the end of their lives, into a circular one, in which construction materials can be recycled, resulting in reduced carbon emissions.

“We moved to soil-based ‘inks’ to derive additional benefits from circular additive manufacturing,” Baharlou said to UVA Today. “We are working with local soils and plants mixed with water; the only electricity we need is to move the material and run a pump during printing. If we don’t need a printed piece, or if it isn’t the right quality, we can recycle and reuse the material in the next batch of inks.”

Barnes was tasked with conducting experiments with soil-based inks. He used a desk-sized 3D printer to explore two approaches: printing soil and seed in sequential layers and mixing seed and soil before printing. Both approaches worked, and he produced a cylindrical prototype that resembled a Chia Pet. Baharlou then proposed 3D printing more complex structures, such as domes.

Both approaches worked, and he produced a cylindrical prototype that resembled a Chia Pet. Baharlou then proposed 3D printing more complex structures, such as domes.

Leah Kirssin, a UVA architecture graduate, and Lizzie Needham, a Master of Landscape Architecture graduate, who assisted on the project, tested how material comes out of the printer head without any additives to the soil mixture. They found that 3D-printed soil structures can support plant growth but are limited to plants that can survive with little water. They believe the reason behind this is due to how compact the soil gets when 3D printed, which makes the environment around the plant drier.

To identify possible plant options, Ma sought out Carr, who works as the director of Blandy Experimental Farm, an environmental science field station in Virginia’s Clarke County. He suggested plants that are naturally found in harsh settings, specifically the stonecrop, a succulent that thrives in dry, sunny locations and is commonly used in green roof settings.

The results of the study, “3D printing of Ecologically Active Soil Structures,” were published in the journal Additive Manufacturing earlier this year.

university of virginiabiomaterialsalternative materials3d printingcircular economysustainabilityresearchmaterial sciencebuilding materialsearth day

0003Name *

Telephone *

E-mail *

Desired budget

Deadline

Number of items *

Delivery available * AllowedNot allowed

Task description and product requirement *

Allow public publication of the announcement

Payment to the current account (for legal entities)

Examples of our work

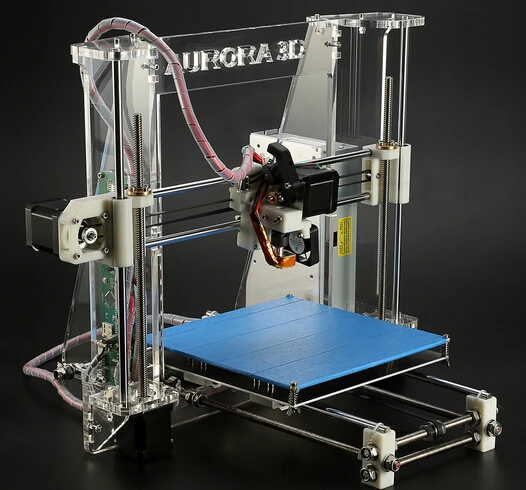

3D printing in Ufa

The VolPrint group of companies produces high-quality 3D shapes and forms in accordance with modern standards. 3D printing is a promising direction in the field of rapid prototyping of plastics and other raw materials. Advantages. The use of additive technologies in modern production, prototyping, modeling and other areas has advantages that make it possible to distinguish this technique from others. Among the main advantages we note: Wide operating vector. Printing enables customers to create a product for almost every industry - test samples, models or parts for presentations, practically functioning products. Fast production speed. Unlike common methods of obtaining primary samples, 3D printing reduces the process of their production to several hours. Extensive possibilities. With modern equipment, you can recreate all kinds of objects, you are not limited by anything. Variety of materials. We print not only from plastic, for example from other raw materials: rubber-like materials, photopolymers, etc.

3D printing is a promising direction in the field of rapid prototyping of plastics and other raw materials. Advantages. The use of additive technologies in modern production, prototyping, modeling and other areas has advantages that make it possible to distinguish this technique from others. Among the main advantages we note: Wide operating vector. Printing enables customers to create a product for almost every industry - test samples, models or parts for presentations, practically functioning products. Fast production speed. Unlike common methods of obtaining primary samples, 3D printing reduces the process of their production to several hours. Extensive possibilities. With modern equipment, you can recreate all kinds of objects, you are not limited by anything. Variety of materials. We print not only from plastic, for example from other raw materials: rubber-like materials, photopolymers, etc.

VolPrint services

Our company has been printing 3D products for more than 5 years. A successful combination of experience, good raw materials, personal equipment and high skill of employees, allows us to provide our customers with 3D printing services without sacrificing quality. High precision manufactured products, high production speed, own consumables - more than 5,000 loyal customers.

A successful combination of experience, good raw materials, personal equipment and high skill of employees, allows us to provide our customers with 3D printing services without sacrificing quality. High precision manufactured products, high production speed, own consumables - more than 5,000 loyal customers.

3D printing and modeling services

- Piece production

- 3D printing small series

- 3D printing of composite structures

- 3D printing layouts

- 3D printing of interior products

- 3D printing of large items

- 3D printed masks

- 3D printing of applicable gears

- 3D printing of souvenir and decorative items

- 3D printed enclosures

- 3D printing of casting molds

3D plastic printing in Ufa, 3D prototyping, plaster printing of any models

The company "3D Virtuoz" performs high-quality 3D printing of models of any complexity. Printing is carried out with ABS, PLA plastic on modern equipment Picaso Designer PRO 250, Zenit, MakerBot Replicator.

Souvenirs and advertising

Do you need to prepare a presentation layout or just want to print a three-dimensional logo of your company? With 3DVirtuoz it's possible! Make an order and print any souvenirs, voluminous layouts for theses and presentations, term papers, as well as any souvenir.

| | | | | |

| Lettering Any volumetric inscriptions, hashtags, names of children, friends, memorable dates and events, volumetric greeting cards. | Toppers Very beautiful and original cake and bouquet toppers. For birthday, wedding day and more. | Photo frames, metrics Photo frames with volumetric inscriptions, children's metrics with photos, photo frames, fridge magnets. | Signed watch We create original plastic clocks with any inscriptions and figurines. Wall and desktop, with and without an alarm clock. | Souvenirs, figurines Imagine being able to print out your favorite character from a computer game. |

To calculate the cost of printing, send your .stl file to our email: [email protected]

Prototyping

| Architecture

|