Upcoming 3d printers

Creality Ender 3 S1 Pro Review: All the Bells and Whistles

When you purchase through links on our site, we may earn an affiliate commission. Here’s how it works.

No upgrades needed. This Ender 3 has it all.

Editor's Choice

(Image: © Tom's Hardware)

Tom's Hardware Verdict

Creality took its most popular budget 3D printer and decked it out with all the upgrades, saving you time, and even a little money.

TODAY'S BEST DEALS

Pros

- +

Quality prints

- +

Easy assembly

- +

Auto bed leveling

- +

Direct drive

- +

Touch Screen

Why you can trust Tom's Hardware Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

Today's best Creality Ender 3 S1 Pro deals

$399

View

$499

$449

View

Reduced Price

$460

View

The Creality Ender 3 S1 Pro is quite a mouthful, but it’s also quite a printer. Shortly after announcing the deluxe Ender 3 S1, Creality inexplicably added even more features to their trusty workhorse and dubbed it the “pro” version.

None of these new features will make you throw your S1 in the garbage, but they are enticing if you’re stepping up from an Ender 3 Pro or V2 model. Ready to compete with the best 3D printers on the market, the Ender 3 S1 Pro comes with Creality’s first all metal hotend, a PEI flex plate, a touch screen, an improved spool holder and a built-in light kit.

That’s on top of core improvements already introduced in the S1 version, such as a direct drive, dual Z axis, auto bed leveling, and a slot for a full sized SD card.

Retailing at $479 on Creality’s website , this printer is a far cry from its budget minded roots. It’s still $360 cheaper Prusa MK3S+ kit, but nearly twice the price of basic Ender 3s still on the market. Those bargain basement Enders are still popular because they are so easily upgraded. Nearly everything that comes on an Ender 3 S1 Pro can be added to a classic Ender 3, if you’re willing to spend at least $350 in parts and add them to the old printer yourself (which is a hassle and costs more if you don’t already own an Ender 3).

Nearly everything that comes on an Ender 3 S1 Pro can be added to a classic Ender 3, if you’re willing to spend at least $350 in parts and add them to the old printer yourself (which is a hassle and costs more if you don’t already own an Ender 3).

- Creality Ender 3 S1 Pro at GeekBuying for $399

Specifications: Ender 3 S1 Pro

Swipe to scroll horizontally

| Machine Footprint | 6490 x 455 x 625 mm (19.2 x 18 x 24.5 inches) |

| Build Volume | 220 x 220 x 270 mm (8.5 x 8.5 x 10.5 inches) |

| Material | PLA/PETG/TPU/ABS |

| Extruder Type | Direct Drive |

| Nozzle | .4mm (Interchangeable) |

| Filament Runout Sensor | Yes |

| Bed Leveling | CR Touch |

| Connectivity | SD card, Type-C USB |

| Interface | Color Touch Screen |

Creality Ender 3 S1 Pro: Included in the box

(Image credit: Tom's Hardware)The Ender 3 S1 Pro comes with everything you need to get your printer set up. You get tools to build and maintain the printer, side cutters, a metal scraper, a nozzle cleaner, a spare nozzle, an extra Z limit switch, and a full sized SD card with a USB adapter. There’s also a small sample of white PLA to print your first model.

You get tools to build and maintain the printer, side cutters, a metal scraper, a nozzle cleaner, a spare nozzle, an extra Z limit switch, and a full sized SD card with a USB adapter. There’s also a small sample of white PLA to print your first model.

The SD card has two short videos, one on assembling the printer, and another on how to level it. You also get a PDF copy of the manual, a copy of Creality Slicer 4.8.0 and models in both pre-sliced .gcode and .stl format.

(Image credit: Tom's Hardware)The Ender 3 S1 Pro is quite a bit flashier than the old Ender 3s, but only slightly different from the previous S1.

The Ender 3 S1 Pro has a modern look, with an all-in-one design, smooth metal frame and flat cables. It has Creality’s newest direct drive, the all metal Sprite, which not only improves performance, but does away with the need for a Bowden tube.

The direct drive is an all metal, dual gear unit that works beautifully. It’s a little industrial looking compared to the rest of the machine, but the lack of plastic housing serves to cut down on weight. It’s a titanium heat break allows it to heat up to a toasty 300 degrees. This allows us to print more materials, but more important, cuts down on nasty clogs from burnt PTFE tubes.

It’s a titanium heat break allows it to heat up to a toasty 300 degrees. This allows us to print more materials, but more important, cuts down on nasty clogs from burnt PTFE tubes.

The Creality Sprite extruder is shipped unmounted and attaches with a few easy to reach screws. It’s meant to be simple to remove, so you can swap it with a laser kit , purchased separately. We’ll be reviewing the laser at a later date.

(Image credit: Tom's Hardware)I’m still not loving the awkward front-mounted parts cooling fan, which makes it hard to watch your first layer go down. The machine also comes with a run out sensor mounted near the spool holder and power loss recovery.

Like the S1, the Ender 3 S1 Pro has a CR Touch for auto bed leveling, but kept the bed’s flexible springs and knobs. Should the CR Touch fail completely, or you just hate easy bed leveling, Creality included a Z limit switch you could add to convert it back to manual.

A final intriguing addition is a dual Z axis upgrade, something normally reserved for larger printers. The two lead screws are kept in sync with a belt for added security. The extra Z axis ensures smoother prints by giving the X gantry more support.

The two lead screws are kept in sync with a belt for added security. The extra Z axis ensures smoother prints by giving the X gantry more support.

I was most excited to see my favorite upgrade – a PEI coated steel flex plate. The PC coated plate on the S1 was both too sticky and too floppy, and damaged a few vase mode prints.

(Image credit: Tom's Hardware)If you’ve used any Creality machine in the past, the new touch screen will throw you for a loop. The layout is completely different from all the old versions with a complex text menu that, honestly, doesn’t make a lot of sense in places. For example, the automatic preheat buttons are hidden under “manual” and bed leveling is stashed under settings.

(Image credit: Tom's Hardware)Assembling the Creality Ender 3 S1 Pro

(Image credit: Tom's Hardware)The Creality Ender 3 S1 Pro is mostly pre-assembled and comes together with a handful of neatly labeled bolts and screws. Creality learned from the S1 and made the paper manual much larger. If you find video easier to follow, you can watch a good assembly video on the included SD card.

If you find video easier to follow, you can watch a good assembly video on the included SD card.

I installed the gantry first. It fits into slots on the base unit and is held in place with 2 screws and 2 bolts on each side. Then I fitted the hotend assembly onto the X gantry with four screws. The control screen bolts to the side with 3 screws and the spool holder snaps into place on the top.

Wiring is very simple as everything is already attached to the frame and only needs to be plugged in.

Last, flip the power supply switch to match your main household electric, which is 115V in the U.S. Creality placed a giant sticker to make sure you don’t overlook the hidden switch.

(Image credit: Tom's Hardware)Leveling the Creality Ender 3 S1 Pro

(Image credit: Tom's Hardware)The Ender 3 S1 Pro comes with a CR Touch installed, Creality’s version of the popular BL Touch. It physically taps the build surface with a metal probe and works with both metal or glass surfaces.

To level the printer for the first time, select Level from the settings menu. Click Start and the printer will immediately go into its leveling routine without preheating and tap 16 points around the bed.

(Image credit: Tom's Hardware)Now go back to the previous menu and click “Auto Level” to set the Z offset by sliding a piece of paper under the nozzle. Move the Z offset up or down until the nozzle just scrapes the paper. The printer I tested did not need to adjust the Z, it was perfect the first time.

If the CR Touch is unable to level the bed, you will need to do a manual level. Directions for this are in the manual.

Loading Filament on the Creality Ender 3 S1 Pro

(Image credit: Tom's Hardware)The Creality Ender 3 S1 Pro is the first Ender to include a filament loading routine in the control panel. This is located under Ready → In/Out. Click the nozzle icon, enter a number of millimeters you’d like to advance. 20 is a good place to start. If the nozzle is not hot, the Ender 3 S1 Pro will automatically warm up to 200 degrees, then advance the filament.

If the nozzle is not hot, the Ender 3 S1 Pro will automatically warm up to 200 degrees, then advance the filament.

To unload material, just reverse the process.

Preparing Files / Software for Creality Ender 3 S1 Pro

(Image credit: Tom's Hardware)The Ender 3 S1 Pro comes with a copy of Creality Slicer 4.8.0, which is simply an older version of Cura with Creality branding and every printer its ever made pre-loaded. PrusaSlicer is another popular alternative that’s also free and some consider easier to use.

The latest version of Cura (5.0) doesn’t have a profile for the Ender 3 S1 Pro, but you can use the profile for the Ender 3 Pro and adjust the build height to 270. PrusaSlicer has a profile for the Ender 3 S1, which has the same build size.

Printing on the Creality Ender 3 S1 Pro

The Creality Ender 3 S1 Pro printed wonderfully right out of the box. My first print was a pre-sliced Cat from the SD card – which was also the test print supplied with the S1. I turned out exactly the same, including the same little stray bit of filament on the mouth. This is printed using the sample filament.

I turned out exactly the same, including the same little stray bit of filament on the mouth. This is printed using the sample filament.

I like to test bed adhesion with a print in place model, like a flexi toy. This dolphin from Flexi Factory fit the bill and printed very cleanly. I did a manual color swap just to use up some final scraps of PLA. This is printed in Inland Turquoise PLA and Matterhackers Pro Series Blue PLA. This took 3 hours and 55 minutes at a .2mm layer height and 60mms speed.

Model by Flexi Factory (Image credit: Tom's Hardware)I wanted to test TPU in an interesting way, so I ran this really cool coaster set from Trilobyte3D. It won a contest on Printables.com for, you guessed it, coasters! This is a three part print, with the leaves printed in TPU laying flat, then the stem and pot printing separately without supports. The leaves are made from Matterhackers Translucent Green TPU and come off the stem to place under your drink. The stem is Emerald City Green Silk from Polyalchemy Elixir and the pot is Protopasta Recycled PLA in Still Colorful 11. Everything was printed individually at a standard .2mm layer height, and the whole project took 19 hours and 45 minutes of printing time.

The stem is Emerald City Green Silk from Polyalchemy Elixir and the pot is Protopasta Recycled PLA in Still Colorful 11. Everything was printed individually at a standard .2mm layer height, and the whole project took 19 hours and 45 minutes of printing time.

I’ve been looking for practical prints, and found it with this credit card cutlery model from jq910. I used Keene Village Edge Glow Glass PETG. It’s only a nine layers thick, but still quite sturdy. This printed in 36 minutes with a .2mm layer height and 60 mms speed.

Model by jq910 (Image credit: Tom's Hardware)To see just how big I can print with an Ender 3 S1 Pro, I took this Twisted Cloud Vase by PressPrint and expanded it 200% until it filled the bed. Then I ran it in Blue/Purple Evyone Matte Dual-Color PLA . It’s a vase mode print, so it only took 7 hours and 36 minutes at a .2mm layer height and 60 mms speed.

Model by PressPrint (Image credit: Tom's Hardware)The Ender 3 S1 Pro is a fantastic printer and a refreshing change of pace from its bare-bones beginnings. It’s easy to assemble and the CR Touch leveling system worked perfectly without a need to make any adjustments. The new PEI coated flex plate is great and all the little upgrades from light kit to all metal hotend make this printer feel like a complete consumer grade product. This isn’t a science project to stick out in the shed, it’s a real piece of hardware to sit proudly on your desk.

It’s easy to assemble and the CR Touch leveling system worked perfectly without a need to make any adjustments. The new PEI coated flex plate is great and all the little upgrades from light kit to all metal hotend make this printer feel like a complete consumer grade product. This isn’t a science project to stick out in the shed, it’s a real piece of hardware to sit proudly on your desk.

Retailing at $479, the S1 Pro has everything you need in a 3D printer, and more features than a lot of the competition. However, if you want the deluxe Ender experience and don’t need an all metal hotend, you can save a few bucks by getting the Ender 3 S1. Another feature packed printer we like is the Anycubic Kobra, priced at $319, it’s an Editor’s Choice and our pick for Best Printer for Beginners.

Creality Ender 3 S1 Pro: Price Comparison

$399

View

$499

$449

View

Reduced Price

$460

View

powered by

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing.

3D Printers - Press Releases - Guides

CoreTechnologie and Weirather Join for Open SLS System

Software company CoreTechnologie has partnered with machine specialist Weirather to develop an open system for SLS 3D printing of high-quality plastic parts. With... read more »

2 weeks ago

3D Printers

Creality Launches Huge CR-M4 – The Next Big Thing in Quality Printing

Creality has just released its new FDM 3D printer, the CR-M4, with rigid stability and a HUGE build volume. The CR-M4 is being... read more »

1 month ago

3D Printers

Printing with Quantica’s NovoJet Technology – A Closer Look

A few weeks ago we took our first look at the new multi-material jetting printer from Berlin-based 3D printing company Quantica. The company... read more »

2 months ago

3D Printers

3D Systems Partners with WeMatter for Small Footprint SLS

SLS machines are typically fairly hefty things and are often a wee too big for your average small workshop or office space. But... read more »

But... read more »

3 months ago

3D Printers

Carima to Exhibit New C-CAT Tech at Formnext 2022

Seoul-based 3D printer company Carima has been advancing printer technology in South Korea since the year 2000, and in that time they have... read more »

3 months ago

3D Printers

Quantica Introduces New Open Desktop System for Multi-Material Printing Development at Formnext

Berlin-based 3D printer manufacturer Quantica has announced the release of their latest machine aimed at users in the R&D domain. Their latest printer... read more »

3 months ago

3D Printers

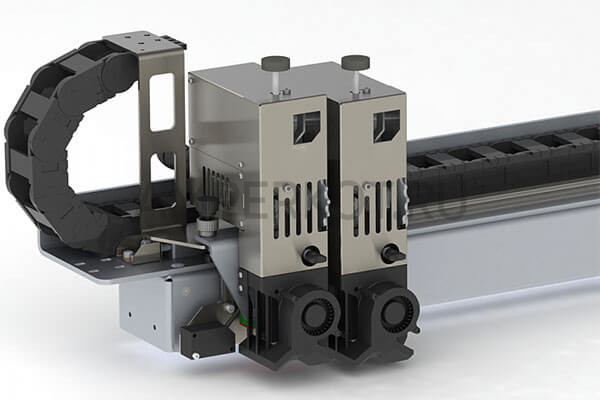

Mizar M Printer Features Dual Hotends for More Multi-color Modes

Traditional monochrome printing has been difficult to meet the creative needs of 3D printing enthusiasts, and mixed-color printing has become the future trend. ... read more »

... read more »

3 months ago

3D Printers

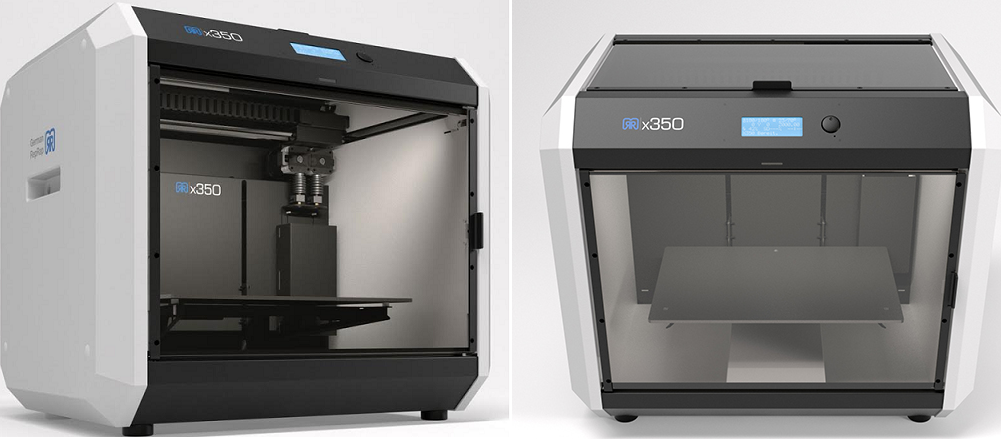

Modix Announces their Next Generation of BIG 3D Printers

Modix are known for their cost-effective, sturdy, large format filament extruding 3D printers. They range in size from the BIG-60 (60cm x 60... read more »

3 months ago

3D Printers

See UnionTech’s New Printers at Formnext

UnionTech, manufacturer of industrial printers, will be unveiling some new additions to their growing range of resin printer systems at the upcoming Formnext... read more »

3 months ago

3D Printers

Creality Launches Ender-5 S1

Creality has announced the launch of the Ender-5 S1, the latest (and greatest) of the best-selling Ender series at the price of $559... read more »

4 months ago

3D Printers

Halloween Bargains on HALOT-ONE Series from Creality

It’s approaching that spooooky time of year again, and Creality is slashing the prices of their HALOT-ONE series of resin printers like a. .. read more »

.. read more »

4 months ago

3D Printers

Cerambot Launches Huge Multi-material Printer on Kickstarter

Back in April 2021 we took a look at Chinese printer company Cerambot’s ceramic printer the Eazao, which enabled the printing of ceramics... read more »

4 months ago

3D Printers

Thermoset 3D Printer for Seals and Grommets Hits Shelves

Chromatic 3D Materials has developed a system for printing ultra-smooth elastomers for use as gaskets and seals. Their Chromatic RX-AM materials and technology... read more »

4 months ago

3D Printers

Stanford Engineers Reveal Multi-material iCLIP Printer

The team of Stanford researchers behind the rapid CLIP (continuous liquid interface production) resin printer technology have unveiled a multi-material version of the. .. read more »

.. read more »

5 months ago

3D Printers

Geeetech THUNDER Kickstarter Campaign Officially Begins

The Geeetech THUNDER Kickstarter campaign has officially started today, and we are going to look at the deal on offer. The THUNDER will... read more »

5 months ago

3D Printers

Anycubic Celebrates 7th Anniversary with Revolutionary 3D Printer Launch

Anycubic is celebrating its 7th anniversary on 2nd September 2022 with a new online product launch. Let’s take a look at the special... read more »

6 months ago

3D Printers

Hands-On Review: Anycubic Photon D2

Hands-On Review Anycubic Photon D2 Resin printers are all the rage right now and Anycubic isn’t going to miss out. We recently reviewed... read more »

6 months ago

3D Printers

Ender-3 Neo, Ender-3 V2 Neo and Ender-3 Max Neo, Which Is The Best Ender For You?

Officially launched in 2018, the Ender-3 series has raised the bar for budget 3D printers and become the choice of many, from professionals. .. read more »

.. read more »

6 months ago

3D Printers

Geeetech THUNDER Coming to Kickstarter

FDM printers aren’t always the fastest things in the world, often taking hours upon hours to deliver prints. Geeetech has a new printer... read more »

6 months ago

3D Printers

Anycubic Contributes to T°Red’s Olympic Cycling Project

Anycubic has recently entered the 3D printed cycling hardware arena by sponsoring Italian bike manufacturer T°Red. Specifically the printer manufacturer has been collaborating... read more »

6 months ago

3D Printers

what lies ahead for 3D printing

The prospects for 3D printing

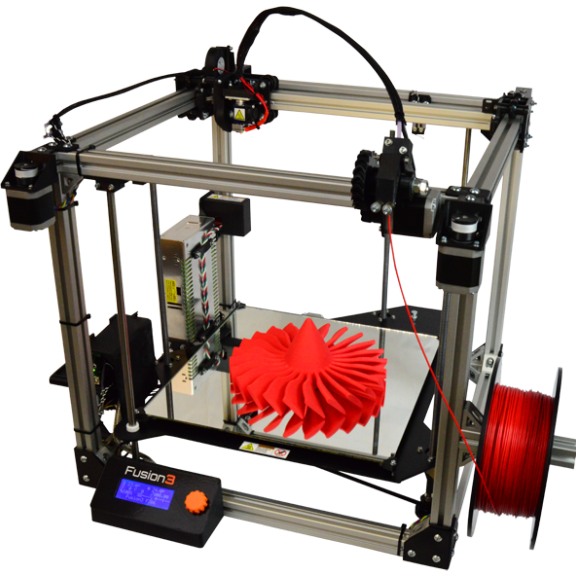

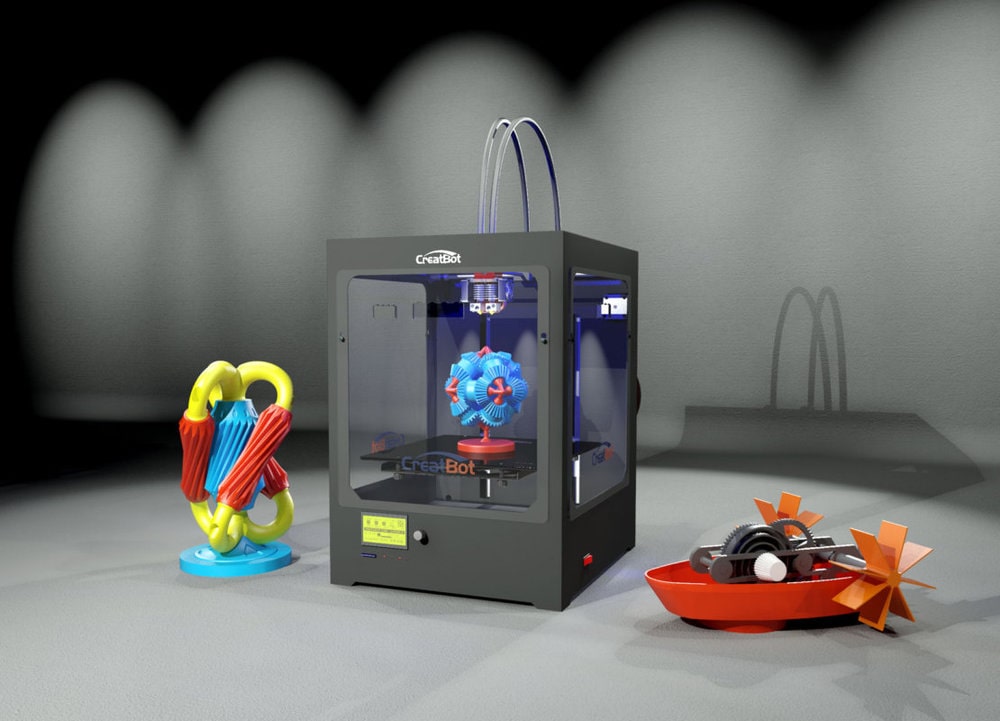

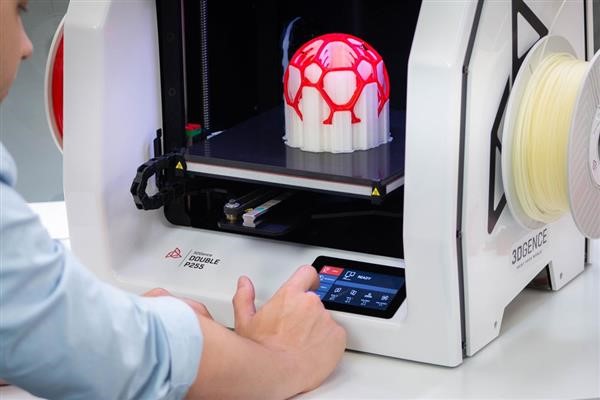

Even now, the prospects for 3D printing are extremely promising. Scientists are actively developing existing 3D printing techniques, developing new technologies and types of materials, and finding new areas of application. Many call 3D printing the technology of the future, and for good reason. The technique is able to completely turn the usual way of life, changing the way most things are produced. In fact, a 3D printer is a real multifunctional factory, small and compact. Due to this, the future of 3D printing can definitely be called successful.

Many call 3D printing the technology of the future, and for good reason. The technique is able to completely turn the usual way of life, changing the way most things are produced. In fact, a 3D printer is a real multifunctional factory, small and compact. Due to this, the future of 3D printing can definitely be called successful.

3D printers can significantly reduce production costs, thereby reducing the cost of products. Judging by the growing trend towards the popularization of 3D technologies, raw materials for 3D printing will become the main commodity unit in the future. In general, the prospects for 3D printing are defined for many areas. And now we will try to reveal them as much as possible.

The Future of 3D Printing

If you try to imagine the future of 3D printing, your imagination paints a rather interesting picture. Given the great interest of scientists in the 3D bioprinting technique, which is one of the most promising 3D printing technologies, the production of artificial organs on a 3D printer is not far off. It is also safe to say that the future of 3D printing will bring us dramatic changes in areas such as:

It is also safe to say that the future of 3D printing will bring us dramatic changes in areas such as:

- Construction. 3D printing of houses, or contour construction, attracts many with its futurism and simplicity. The first steps in this direction have already been taken. The pioneers in 3D printing of houses were the Chinese, followed by the government of Dubai who discovered contour building. The first 3D printed office building has already been built in this city of the future, and an entire block is planned to be printed in the near future. And just recently, the first printed house in Europe was created on a 3D printer;

- Electronics. When listing the prospects for 3D printing, this point should be given special attention. Scientists believe 3D printing of electronics is the future of digital device manufacturing, and with good reason. Graphene properties and its application in additive manufacturing are currently being actively researched. A huge breakthrough in this area is the creation of a graphene battery with an unlimited service life on a 3D printer;

- Automotive and aerospace industry.

The future of 3D printing is largely based on its ability to reproduce almost any element of varying complexity. In this regard, 3D printing is already widely used in the development of aircraft, machines and satellites. The ISS even has its own 3D printer, not to mention a number of successful 3D printing of cars.

The future of 3D printing is largely based on its ability to reproduce almost any element of varying complexity. In this regard, 3D printing is already widely used in the development of aircraft, machines and satellites. The ISS even has its own 3D printer, not to mention a number of successful 3D printing of cars. - Pharmaceutical industry. Yes, yes, you can imagine. The future of 3D printing is in the manufacture of tablets and other medicines. This is confirmed by epilepsy pills legalized in the USA, made according to a special technique. The essence of this perspective of 3D printing is the gradual release of active substances, so that instead of many tablets, you can drink just one.

- Food industry. 3D food printers are gradually gaining space in cafes and restaurants. While this is probably one of the most raw 3D printing technologies out there, it has potential. Food 3D printers are especially interesting for the possibility of making food for astronauts, as well as the freedom to display culinary talent.

This is confirmed by the amazing 3D-printed desserts of our compatriot.

This is confirmed by the amazing 3D-printed desserts of our compatriot.

Other questions and answers about 3D printers and 3D printing:

- Finance Which 3D printer manufacturers are best?

- Finance Which 3D printer is better to buy?

The future of 3D printers

Now let's try to imagine the future of 3D printers. There are several important points to be noted here. Below we list the most likely scenarios for the future of 3D printers.

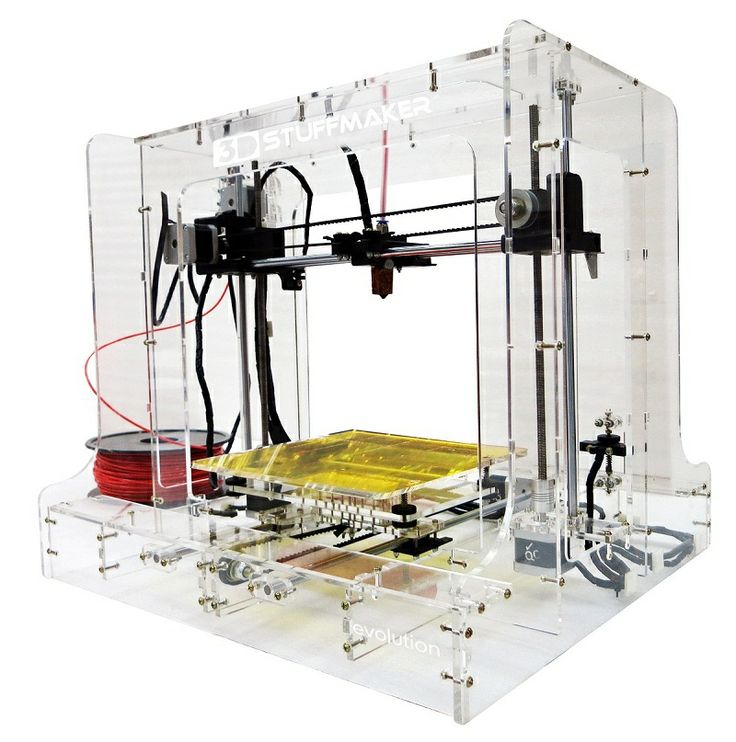

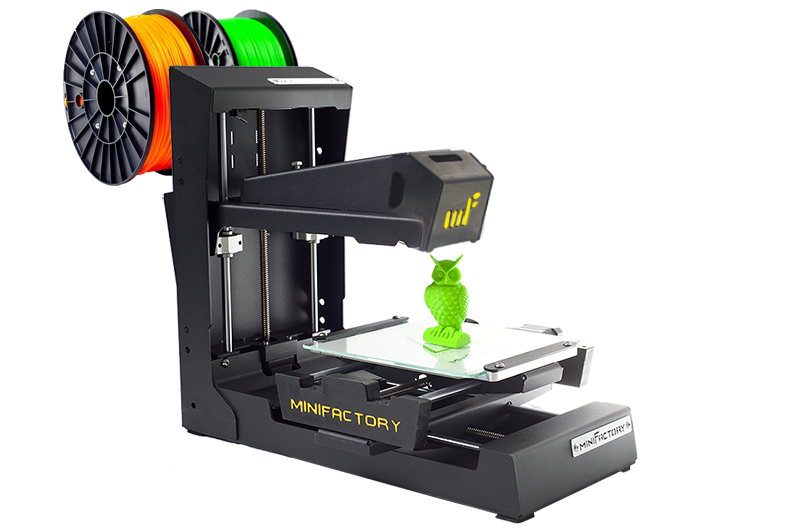

- Improving the reliability and quality of devices. Surely, many users are looking forward to this, because most of the existing models of 3D printers cannot boast of uninterrupted operation and the absence of printing errors;

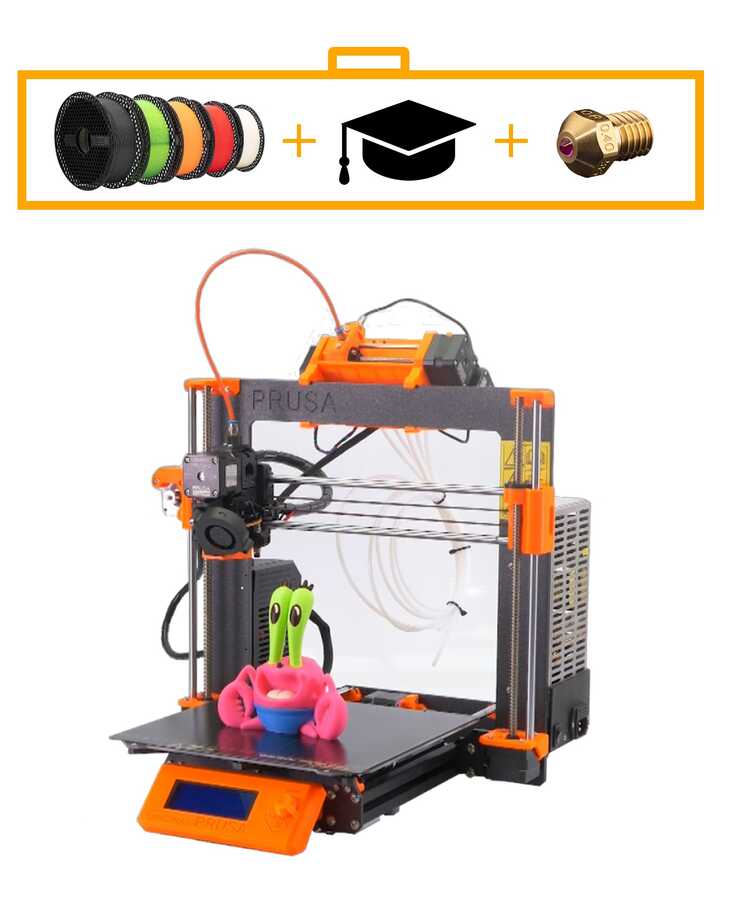

- Large-scale distribution. It is certain that the future of 3D printers will please us with their popularization. Even now, one can observe a growing trend towards the use of 3D printing in almost all areas of industry. In parallel with the fact that more and more users learn about the possibilities of technology, the demand for desktop 3D printers is also growing;

- Availability.

In continuation of the previous paragraph, it is worth noting that the growing demand for 3D printers will lead to lower prices for these devices. The use of 3D printing for domestic purposes is gaining momentum, which brings new equipment manufacturers to the market. Naturally, such a step will entail a reduction in the cost of devices;

In continuation of the previous paragraph, it is worth noting that the growing demand for 3D printers will lead to lower prices for these devices. The use of 3D printing for domestic purposes is gaining momentum, which brings new equipment manufacturers to the market. Naturally, such a step will entail a reduction in the cost of devices; - Enlargement of the construction area. 3D printing of large-sized objects has long occupied the minds of developers. Of course, this applies to industrial 3D printers, because the functionality of 3D printing at this scale will allow you to create full-fledged components, for example, cars and aircraft;

- Expanding the range of available materials. The future of 3D printers depends a lot on 3D printing materials, because more means more possibilities. The development of special equipment and related materials is being carried out by many companies, and news about the release of new polymers is constantly appearing.

3D technologies of the future

Summing up, it remains to consider only 3D technologies of the future. These include various futuristic scenarios that, to one degree or another, are already beginning to develop today. These include the technique of virtual reality, 3D scanning to create the perfect clothes and shoes, 3D printed makeup, and more. In a way, 3D technologies of the future also include bioprinting. By the way, scientists are talking about building the first 3D printed settlement on the Moon and Mars, so the prospects for 3D printing are also relevant outside the Earth.

These include various futuristic scenarios that, to one degree or another, are already beginning to develop today. These include the technique of virtual reality, 3D scanning to create the perfect clothes and shoes, 3D printed makeup, and more. In a way, 3D technologies of the future also include bioprinting. By the way, scientists are talking about building the first 3D printed settlement on the Moon and Mars, so the prospects for 3D printing are also relevant outside the Earth.

This was a list of the main scenarios for the future of 3D printing. Let's see how they are destined to come true. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.

Our store offers a wide range of 3D printers, 3D scanners, 3D plastics and resins, as well as other accessories at the best prices on the Ukrainian market with delivery to all cities (Kharkiv, Nikolaev, Dnepropetrovsk, Lviv, Zaporozhye, Kherson, Donetsk, Odessa ). We also provide 3D printing, 3D scanning and 3D modeling services. For all questions, please contact us in any way convenient for you. Contacts are listed here. We look forward to collaborating!

We also provide 3D printing, 3D scanning and 3D modeling services. For all questions, please contact us in any way convenient for you. Contacts are listed here. We look forward to collaborating!

Back to Home

Perspectives, development and the future of 3d printers

3D printing is an extremely promising technology that has the potential to change how many things are made. In addition, the use of 3D printers will significantly reduce the production time of various products and reduce their final cost. Let's consider in which areas the use of 3D printing is most promising, what is the future of this technology and how quickly it will develop.

Relevance of 3D printing

3D printing technology is relevant due to its ease of use and saving time spent on the production of various types of products.

Printing of 3D objects also provides high-precision reproduction of the necessary shapes and details of a particular object. At the same time, manual labor is practically reduced to zero, which means that the cost of the operator and maintenance of the 3D printer will be minimal. Subsequently, this will reduce the cost of the finished product.

Subsequently, this will reduce the cost of the finished product.

Thanks to these benefits, 3D printing is successfully used in many industries and everyday life.

The promise of 3D printers in various fields

3D printing technology has quite a lot of promise when applied correctly. The following areas of activity are most in need of 3D printing services:

- Construction. In the construction industry, 3D printing can be a powerful addition to traditional construction methods. Since this technology does not require the involvement of a large number of people to perform hard work. A few operators and craftsmen are enough to service the construction 3D printer. The first successful experiments in the manufacture of building parts and the construction of houses have already been carried out in China and the United Arab Emirates.

- Electronics. In the manufacture of digital devices, 3D printing will reduce the time for the manufacture of labor-intensive parts, microcircuits and hardware electronics.

In particular, 3D printing is already developing the first samples of graphene batteries that have an unlimited service life.

In particular, 3D printing is already developing the first samples of graphene batteries that have an unlimited service life. - Mechanical engineering and automotive industry. In this area, with the help of three-dimensional printing, experimental models of future spare parts and parts are created, which later allow the production of products of perfect quality. This is possible due to the detailed study of a three-dimensional object during its creation and printing of a finished computer model, which has a high level of detail.

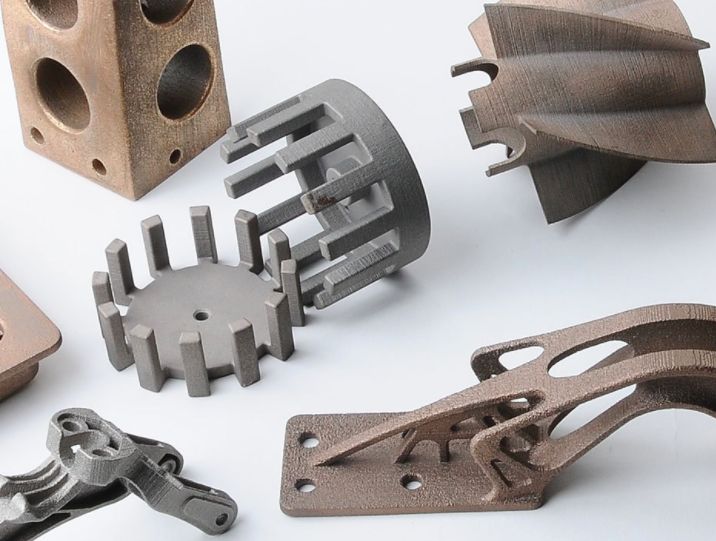

- Aerospace industry. The use of 3D printing in this industry is explained by the ability to create innovative designs of any complexity. Details of satellites, rockets and other space objects are printed from metal, polymers and other types of heavy-duty materials.

- Medicine and pharmaceuticals. In medicine, 3D printing technology is extremely important. Therefore, in this industry it is studied in great detail. With the help of a 3D printer, it is possible to print prototypes of human organs, prostheses, bone tissue implants.

Even the first steps are being taken to develop and print real organs that will take root well in the human body. In the pharmaceutical industry, 3D printing is mainly used to create tablets that will gradually release active substances after ingestion.

Even the first steps are being taken to develop and print real organs that will take root well in the human body. In the pharmaceutical industry, 3D printing is mainly used to create tablets that will gradually release active substances after ingestion. - Advertising. For advertising purposes, 3D printers print prototypes of various products, demonstration and handouts.

- Food industry. 3D food printers are especially interesting because they allow you to create edible objects from familiar foods. 3D printing makes it possible to create unique decorations and complex multi-color objects with high detail.

The future of 3D printing

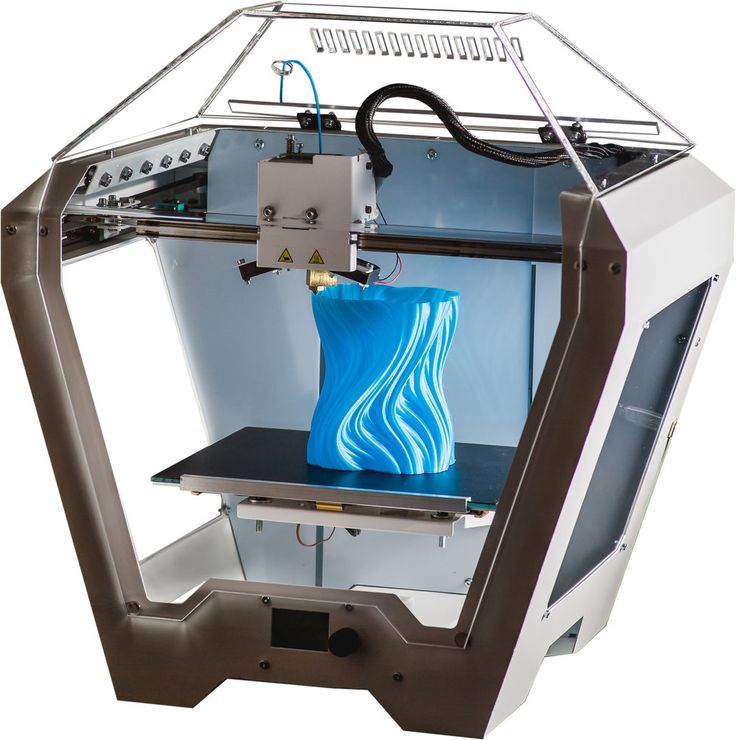

3D printing, if properly developed and explored, will be more accessible in the future. Since 3D printers will be common as a work unit in many areas. At the same time, prices for such equipment are likely to fall. Since they will be produced by various companies in large quantities to satisfy the demand of all buyers.

The growing demand for 3D printing will lead to the development of new types of 3D printers and materials for creating products.

Also for larger 3D printing, large-scale equipment will be created that will allow printing very large products for construction needs, engineering and other industries.

Unexpected possibilities of 3D printing

In addition to the standard creation of three-dimensional objects, the development and 3D printing of unique and customized products is also available on a 3D printer. Their shape, structure and design features are limited only by the user's imagination. It is possible to produce unusual products. For example, non-melting ice sculptures, curly perfectly fried pancakes or fine jewelry.

Who is the future of 3D printing?

Primarily, the future of 3D printing depends on inventors who create new types of printers and develop new printing technologies depending on the type of material used. Most often, 3D printing novelties appear in research centers, industrial enterprises and technical departments of various universities. This is due to the fact that people working in such institutions are interested in the development of new technologies. Since innovation will help to improve and improve the processes of creating products in specific areas. In addition to researchers and students, a large number of developments are carried out by children and 3D printing enthusiasts. For example, the invention of the first 3D-printed prosthesis belongs to 17-year-old Easton LaChapelle.

This is due to the fact that people working in such institutions are interested in the development of new technologies. Since innovation will help to improve and improve the processes of creating products in specific areas. In addition to researchers and students, a large number of developments are carried out by children and 3D printing enthusiasts. For example, the invention of the first 3D-printed prosthesis belongs to 17-year-old Easton LaChapelle.

In addition to inventors, organizations that sponsor new developments are also responsible for the continued development and improvement of printing techniques.

Help. Three companies are considered the most famous in the field of 3D printing: Shapeways, Sculpteo and Materialize. They are engaged in the professional development and release of new models of 3D printers, materials, as well as the improvement of existing technologies and the creation of new ones.

What's in store for 3D printing in the next few years?

Experts in the field of 3D printing in 2021 make the following forecasts for its development:

- The spread of 3D printing will be massive.

Studios for creating three-dimensional objects will be distributed in much the same way as studios for photocopying and printing materials. 3D printing will be carried out both on standard models and on individual projects.

Studios for creating three-dimensional objects will be distributed in much the same way as studios for photocopying and printing materials. 3D printing will be carried out both on standard models and on individual projects. - Small-scale production of various products will completely switch to 3D printing technology. This will help to significantly reduce the price of finished products.

- Medical scientists will master the creation of full-fledged and fully compatible organs on a 3D printer, which will be printed from dividing human cells.

- With due diligence confirming the safety of 3D printing for construction purposes, many companies in the industry will start using powerful industrial printers to create the required building elements. At the same time, the time to build houses will be reduced and the proportion of hired workers who perform hard work will decrease.

A revolution in materials

A standard 3D printer uses plastic materials as a filament. However, technology development continues at an accelerated pace. Thanks to this, innovative materials appear on the market, such as:

However, technology development continues at an accelerated pace. Thanks to this, innovative materials appear on the market, such as:

- Metal powder. This material is mixed with a polymer during printing and is used in the technology of laser sintering of metals. Products printed from a mixture of polymer and metal powder have increased strength comparable to real metal.

- Graphene. This carbon material is being used experimentally to develop a new composite. Ideally, a 3D-printed graphene sheet would be one molecule thick. By weight, the material will be lighter than air, but its strength properties will be very high - the sheet is ten times stronger than steel.

- Ceramic foam. Such material has flexible characteristics that can be changed depending on the purpose of use. From ceramic foam on a 3D printer, you can print both a very light figure and a heavy monument. In theory, development already exists. But it requires a series of tests and stabilization of functional properties.

Learn more