Tiko unibody 3d printer review

The Tiko Printer: What Happens When You Innovate Too Much

Sometime in the very distant future, the Universe will become the domain of black holes. Energy and entropy will be compressed into minuscule quantum fluctuations. Even in this domain of nothingness, there will still be one unassailable truth: you should not buy a 3D printer on Kickstarter.

We’re no strangers to failed 3D printer crowdfunding campaigns. Around this time last year, backers for the Peachy Printer, an inordinately innovative resin printer, found out they were getting a timeshare in Canada instead of a printer. This was unusual not because a crowdfunding campaign failed, but because we know what actually happened. It’s rare to get the inside story, and the Peachy Printer did not disappoint.

For the last few months, we’ve been watching another crowdfunding campaign on its long walk to the gallows. The Tiko 3D printer is another 3D printer that looks innovative, and at the time of the crowdfunding campaign, the price couldn’t be beat. For just $179 USD, the backers of the Tiko printer would receive a 3D printer. Keep in mind the Tiko launched nearly two years ago, when a bargain-basement printer still cost about $400. Fools and money, or something like that, and the Tiko 3D printer campaign garnered almost three million dollars in pledges.

Now, after almost two years of development, Tiko is closing up shop. In an update posted to the Tiko Kickstarter this week, Tiko announced they are laying off their team and winding down operations. It’s a sad but almost predictable end to a project that could have been cool. Unlike so many other failed crowdfunding campaigns, Tiko has given us a post-mortum on their campaign. This is how the Tiko became a standout success on Kickstarter, how it failed, and is an excellent example of the difference between building one of something and building ten thousand.

Why the Tiko Was a Hit

The Tiko printer was an easy sell. All you had to do was look at your favorite tech blog and see someone was selling a 3D printer for less than one hundred dollars. Yes, that was the super early bird price, but that’s cheap for a 3D printer. In 2015, unimaginably so. The regular price, and what non-early bird Kickstarter backers paid, was only $179 USD. Even today, with the machinations of dozens of factories in China, this is a very inexpensive price point. In fact, only with the upcoming release of Monoprice’s $150 delta printer will we see a printer that is as capable while still being this inexpensive.

Yes, that was the super early bird price, but that’s cheap for a 3D printer. In 2015, unimaginably so. The regular price, and what non-early bird Kickstarter backers paid, was only $179 USD. Even today, with the machinations of dozens of factories in China, this is a very inexpensive price point. In fact, only with the upcoming release of Monoprice’s $150 delta printer will we see a printer that is as capable while still being this inexpensive.

The astonishing economy of the Tiko leads to an obvious question. How did the Tiko team plan to build a 3D printer and send it out the door for less than $200? Even today, sourcing and building the most bare bones i3 clone will cost more than that. In 2015, the costs were even higher.

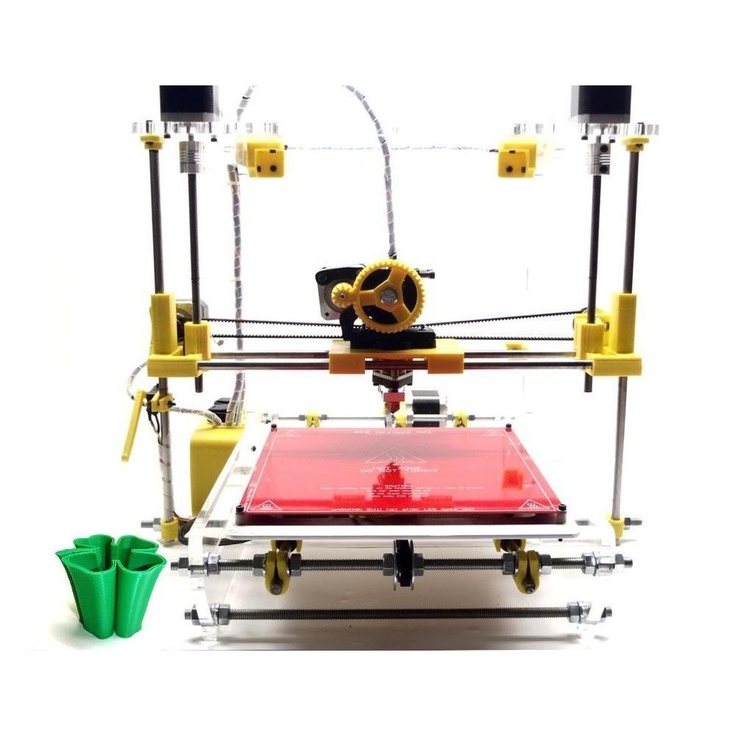

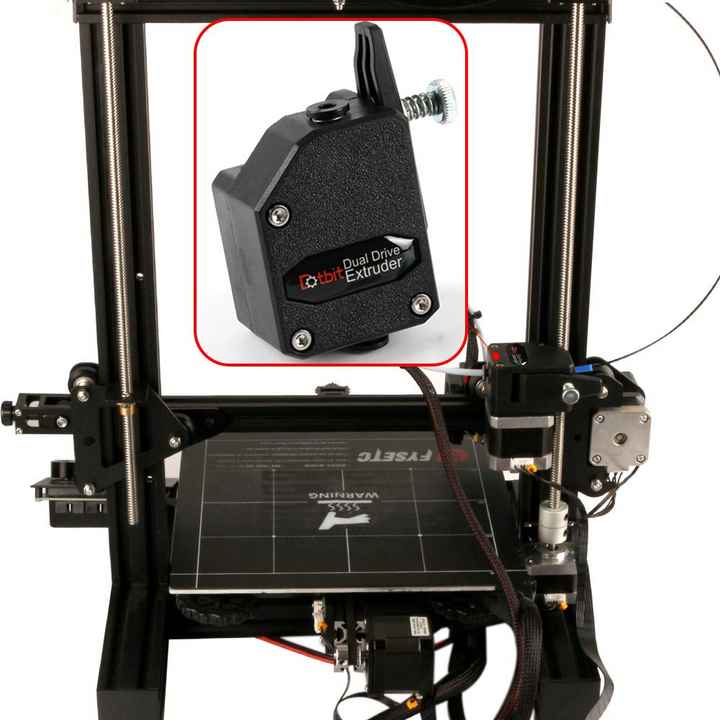

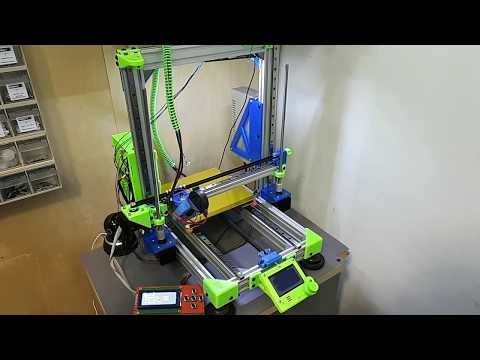

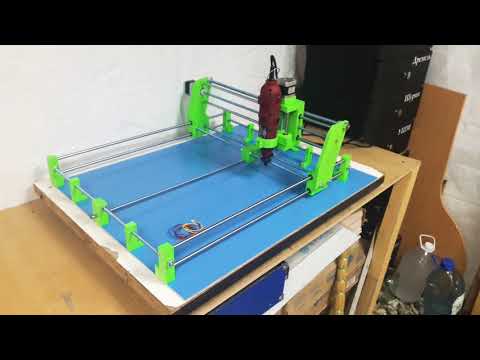

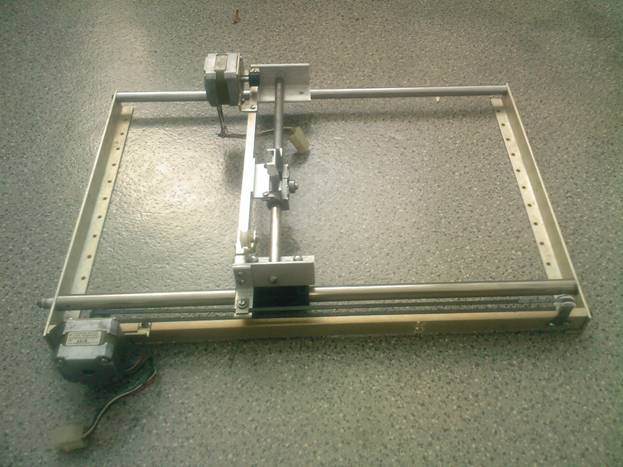

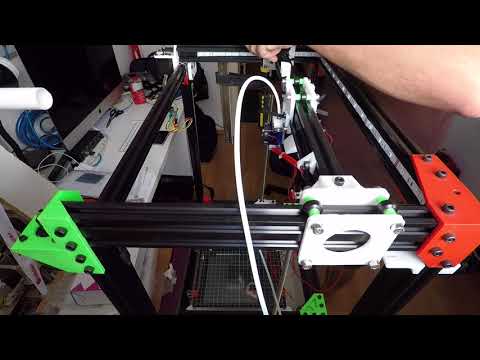

Tiko’s unibody construction. By building a linear motion system into the enclosure, Tiko significantly reduced the cost of their bill of materials.The answer comes from something that sounds like it’s glomming onto Apple ad copy: unibody construction. The body of the Tiko is a single part with an integrated c-channel used as the linear rails of this delta bot. This unibody construction is, quite simply, ingenious. If you’ve ever assembled a RepRap Mendel, or any of the other threaded rod printer monstrosities from back in the day, you know the frame of a 3D printer is what makes or breaks the build. By using an extrusion with integrated rails, the Tiko team brought the cost of a frame down while making their assembly easier. From a manufacturing standpoint, Tiko’s unibody construction is brilliant, and we won’t be surprised when we see another delta bot with the same sort of enclosure.

The body of the Tiko is a single part with an integrated c-channel used as the linear rails of this delta bot. This unibody construction is, quite simply, ingenious. If you’ve ever assembled a RepRap Mendel, or any of the other threaded rod printer monstrosities from back in the day, you know the frame of a 3D printer is what makes or breaks the build. By using an extrusion with integrated rails, the Tiko team brought the cost of a frame down while making their assembly easier. From a manufacturing standpoint, Tiko’s unibody construction is brilliant, and we won’t be surprised when we see another delta bot with the same sort of enclosure.

At its very core, Tiko was innovative. This is a 3D printer that was built around standardized manufacturing processes. Yes, building a ‘unibody’ 3D printer will require a significant capital investment to get the first printer off the assembly line. Once that’s done, though, the creators of the Tiko printer would have a viable product that could be manufactured for far less than their competitors.

Why the Tiko Failed

Tiko put a lot of innovation into their unibody frame. Unfortunately, they decided to extend that innovation to the rest of the printer. Even before the Tiko Kickstarter was a week old, the 3D printer forumheads had questions about the Tiko printer.

The usual method for linear motion in a 3D printer is a stepper motor. NEMA 17 stepper motors are par for the course. The historical pricing of NEMA 17 motors is itself interesting: back in 2008, before the RepRap project came to fruition, it wasn’t unrealistic to spend $40 on a single NEMA 17 motor with a driver. Now, you can pick up the same parts for less than half that cost.

Instead of relying on the ecosystem that has enabled very inexpensive printers, Tiko chose to go their own way. They used cheaper but much lower torque stepper motors on their printer. This would cause severe issues with the printer. Of the over four thousand units Tiko shipped, there were far too many reports of layer shifting and missed steps than you would expect. In the most severe cases, the Tiko printer could not print a simple cube.

In the most severe cases, the Tiko printer could not print a simple cube.

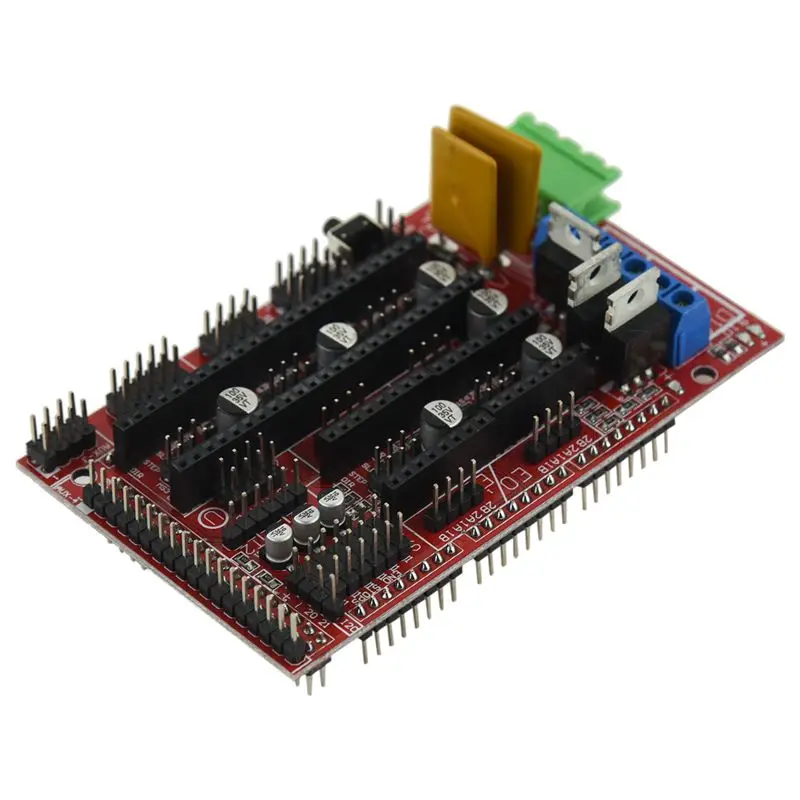

Even in the electronics, Tiko strove for innovation.

Right now, the state of electronics for 3D printers is heavily derived from the original RepRap projects. Derivatives of the Arduino Mega, using the ATmega2560 and ATmega32u2 microcontrollers, are the norm. The new LulzBot Brain Box uses a RAMBo board with this microcontroller. The electronics for the vast majority of 3D printers is derived from those initial 3D printer experiments, and that means a decade of technical debt.

Tiko advertised WiFi printing during their Kickstarter campaign. Right now, the easy way to do a WiFi printer would be a standard ATmega-based controller board with an ESP8266 WiFi module. This would be easy, but it wouldn’t be cheap. Instead of the easy solution, Tiko turned to a neat WiFi-enabled microcontroller released by Texas Instruments. The CC3200 gave the Tiko a powerful ARM Cortex-M4 microcontroller and WiFi. Given the smooth acceleration found in even the cheapest ARM controller boards, this is a win.

The CC3200 gave the Tiko a powerful ARM Cortex-M4 microcontroller and WiFi. Given the smooth acceleration found in even the cheapest ARM controller boards, this is a win.

But there’s a reason everyone keeps using older Arduino-based controller boards. Nearly all the firmware for 3D printers is built around the Arduino Mega. Building a printer controller board around a relatively new part means building everything from scratch. This is development time Tiko didn’t have, and engineering time Tiko couldn’t afford.

Despite this, Tiko actually managed to build and ship over four thousand printers. Given Tiko took in nearly three million dollars from 16,000 Kickstarter backers, this doesn’t sound like much. Consider the decisions Tiko made, and it’s remarkable. They had ordered their complete BOM before a prototype was finalized. The decision to use cheap stepper motors led directly to the very poor performance of the finalized design. The efforts to fix hardware problems in software were not effective. Eventually, Tiko had too much technical debt to pay off. It certainly didn’t help that this was a 3D printer selling for a bargain-basement price, either. There’s only so much margin on a $200 printer, and from the start there wasn’t much left over for the engineering needed to make a good, cheap 3D printer.

Eventually, Tiko had too much technical debt to pay off. It certainly didn’t help that this was a 3D printer selling for a bargain-basement price, either. There’s only so much margin on a $200 printer, and from the start there wasn’t much left over for the engineering needed to make a good, cheap 3D printer.

The Future of Tiko

By the end of 2016, Tiko was effectively dead. Last week, they gave up, shutting down production, and refusing to refund backers. Tiko has even refused refunds on shipping costs, a move that led to an online petition and — get this — a Kickstarter campaign to start a class action lawsuit against Tiko. Tiko is dead, although they are actively pursuing additional investors.

Far too often we look at Kickstarters from an engineering perspective. What’s missing in these discussions is a look at Kickstarters from a business perspective. What Tiko has done is out-innovated themselves. They came up with a rather remarkable system for the frame of a 3D printer, but one that isn’t quite right for a hardware startup. They developed brand new hardware for the 3D printer community but backed themselves into a corner when their engineering team couldn’t keep up. They spent all their money buying components before their design was finalized. These aren’t poor engineering decisions, they’re poor business decisions.

They developed brand new hardware for the 3D printer community but backed themselves into a corner when their engineering team couldn’t keep up. They spent all their money buying components before their design was finalized. These aren’t poor engineering decisions, they’re poor business decisions.

Twelve thousand people have spent $200 (plus about $60 in shipping) on a printer they won’t receive. Four thousand people have a printer that doesn’t live up to their expectations. The Tiko team has a three million dollar failure hanging over their heads. No one is happy with this situation. Yet it can all be traced back to a single problem. This is what you get when you innovate too much.

5 Best Tiko 3D Printer Review – Alternatives 2022

On March 30, 2015, a Kickstarter project was opened to create a revolutionary new 3D printer. One month later, in April 2015, the Kickstarter had raised $2,950,874 from 16,538 backers who put up at least $179 each. Shipping was estimated to start in November 2015, approximately seven months later. The printer was going to be known as the Tiko Unibody 3D Printer.

The printer was going to be known as the Tiko Unibody 3D Printer.

The designers of this printer were visionaries in every sense of the word. The Tiko 3D printer what the creators of the term "state-of-the-art" had in mind when they coined the phrase. Here are some of the planned specifications.

- The maximum print volume was supposed to be 138.3 cubic inches.

- The shape of the print area wouldn't have been the usual rectangle or circle. Instead, it would have been triangular but with rounded corners. The height would have been 4.9 inches. If you were printing something with a cylindrical shape, the diameter of that cylinder could have been as large as 4.9 inches.

- The layer resolution was supposed to be 50 to 250 microns.

- The printing zone would have been enclosed.

- The print bed would have been made of a flexible plastic. That would have made it easy to pop off the printed item without damaging it.

- Tiko would have been able to connect to Wi-Fi so that you could print from virtually anywhere, including a smartphone.

If Wi-Fi was not available, you could have used the printer to create a wireless access point. This would have let you print directly from your computer to the printer.

If Wi-Fi was not available, you could have used the printer to create a wireless access point. This would have let you print directly from your computer to the printer. - If the unit was ever jarred or moved while printing, a built-in accelerometer would have sensed this and shut the Tiko down automatically.

- The accelerometer would have also had a role in the automatic calibration process.

This was your big chance to participate in the development of cutting-edge technology. For a mere $179, you could have contributed to a Kickstarter project and gotten a new type of 3D printer, one that would have made IT history.

The first shipment (from Hong Kong) went out in December 2016. That was 13 months after the initial expected ship date. Those units, once they were set up by the new owners, had problems. By February 22, 2017, the project was over. The Tiko 3D printer became someone’s broken dream. There were subsequent efforts to revive the brand, but nothing came of them. In the end, the biggest problem was probably not the design or planning. It was probably that the project was underfunded and couldn’t survive the bad times.

In the end, the biggest problem was probably not the design or planning. It was probably that the project was underfunded and couldn’t survive the bad times.

Even though their $179 investment was gone, those who contributed to the Tiko Kickstarter project were offered an inexpensive way to acquire a 3D printer. The CEO of M3D offered anyone who lost money on the Tiko Kickstarter the opportunity to purchase a Micro 3D Printer for a discounted price of $199. It was a good deal for anyone who accepted the offer and a smart way for M3D to expand its customer base.

There are plenty of other options available for those who were hoping to purchase a Tiko 3D printer. We will list some of those alternatives for you. But first, here is some background information on 3D printers.

| Preview | Product | Price | |

|---|---|---|---|

Monoprice Mini Delta v2 3D Printer (110 x 120mm) Heated Build Plate,. .. .. | $244.56 | Buy on Amazon | |

| M3D Micro+ Desktop 3D Printer for Home, Work, and School Use, Includes... | Buy on Amazon | ||

| Promotion! Print-Rite CoLiDo Delta 3D Printer Kossel Kit D1315 Plus... | Buy on Amazon |

Image by Karolina Grabowska from Pixabay

The printers we reviewed were chosen based on price. We were looking for printers at a price close to the $179 that would have been spent on the Tiko. Quite a bit of time has passed since the beginning of the Tiko project. In that time, technology has marched on. It is reasonable to expect that since then, prices have dropped, and functionality has increased. It is interesting to see how some of the ideas in the Tiko design have made it into currently available printers.

We were looking for printers at a price close to the $179 that would have been spent on the Tiko. Quite a bit of time has passed since the beginning of the Tiko project. In that time, technology has marched on. It is reasonable to expect that since then, prices have dropped, and functionality has increased. It is interesting to see how some of the ideas in the Tiko design have made it into currently available printers.

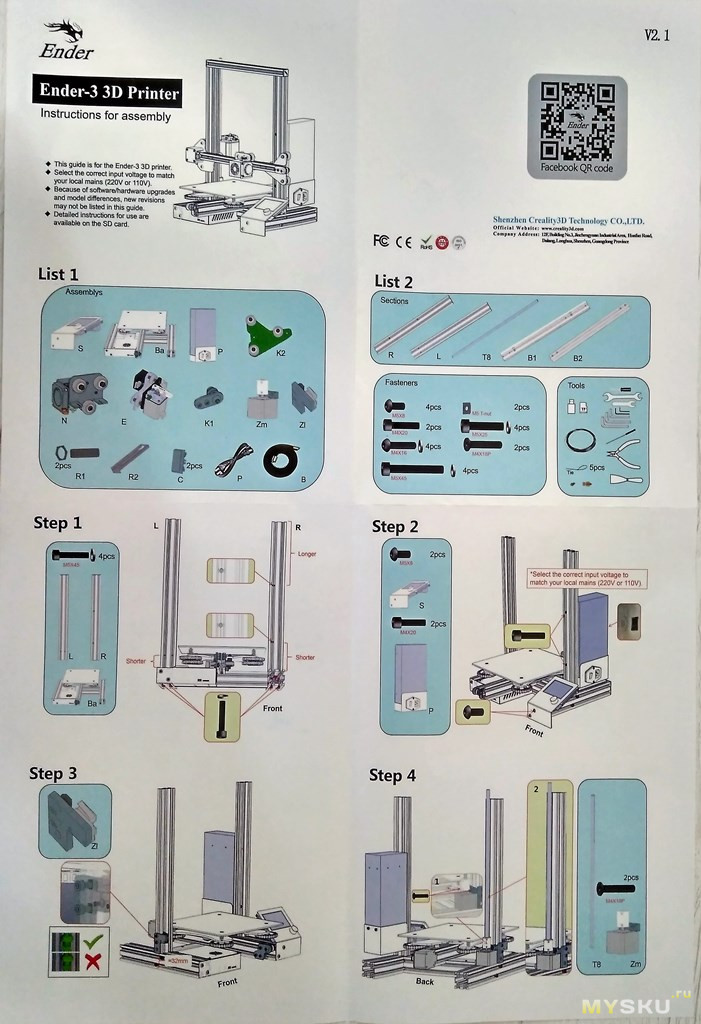

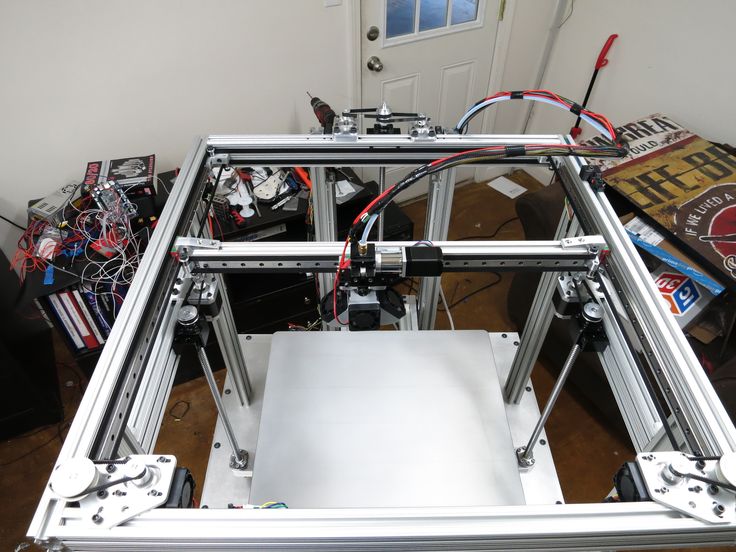

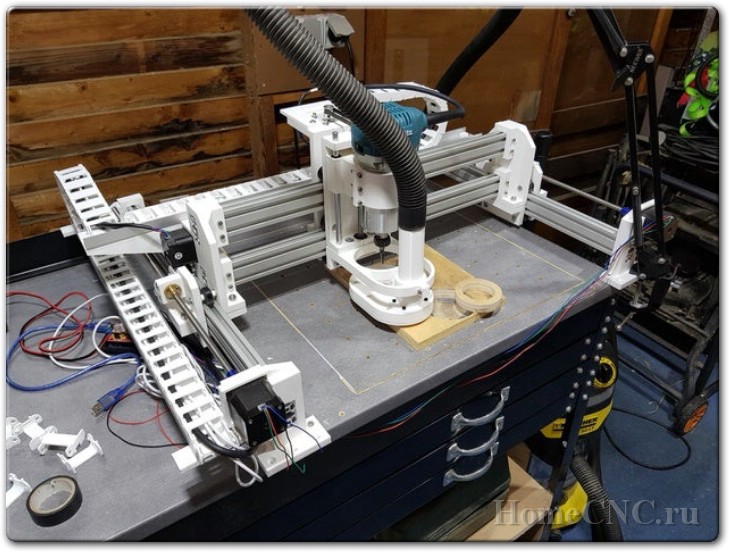

All the printers reviewed here are delivered completely assembled. There are many more available in this price range that require assembly. Some even come in the form of a kit, which sounds like an extreme form of assembly. If you are good with your hands, have a sense of adventure and have the patience of a saint, you might do well to find a kit. This will give you lot more printer for the money.

Overall Price Range of This ProductImage by Lutz Peter from Pixabay

In general, the cost of filament-based 3D printers ranges from the low hundreds to many thousands of dollars. Because we are looking to replace a $179 Tiko printer, we have decided to limit our price range to between $150 and $350.

Because we are looking to replace a $179 Tiko printer, we have decided to limit our price range to between $150 and $350.

Monoprice Mini Delta 3D Printer

Monoprice Mini Delta v2 3D Printer (110 x 120mm) Heated Build Plate,...

- Touchscreen Control, Updated Firmware and UI: You spoke and we listened. Larger icons, clear and concise instructions,...

- Fully assembled: the mp mini delta 3D printer comes fully assembled, ready to print out of the box

- PoloPrint Pro Wi-Fi Connection: Connect to the printer over Wi Fi using the updated PoloPrint Pro app for iOS or...

Price | $159 |

Setup | Assembled |

Interface | Wi-Fi, USB, microSD |

Display | LCD |

Technology | FFF |

Print Area | 4. |

Enclosed | No |

Heated Bed | Yes |

Bed Leveling | Auto |

Nozzle Size | .04 mm |

Extruders | 1 |

Software Inc. | Cura, supports Windows XP or later, Mac OS X (10. |

Resolution | 50 micron |

Dimensions | 14.2” x 10.4” x 16.9” |

Weight | 30.6 lbs |

Includes | USB cable, microSD card, power adapter, cord |

Where To Buy | Monoprice, Amazon |

Warranty | 30-day money back guarantee, one year for repair of manufacturer’s defects |

This low-end printer has it all. It works right out of the box and, except for its lack of enclosure, it has all the great features of higher-end systems. Wi-Fi connectivity allows you to cut the leash to your computer. It only addresses smaller print projects, but if you can work with that limitation, this printer is for you. This model is also worth considering if you are looking to buy your first 3D printer.

It works right out of the box and, except for its lack of enclosure, it has all the great features of higher-end systems. Wi-Fi connectivity allows you to cut the leash to your computer. It only addresses smaller print projects, but if you can work with that limitation, this printer is for you. This model is also worth considering if you are looking to buy your first 3D printer.

- Wi-Fi interface

- SD card

- Excellent features at a low cost

- Heated bed

M3D Micro+ Desktop 3D Printer for Home, Work, and School Use, Includes...

Price | $349 |

Setup | Assembled |

Interface | USB |

Display | No |

Technology | FFF |

Print Area | 4. |

Enclosed | No |

Heated Bed | No |

Bed Leveling | Auto |

Nozzle Size | 0.35 mm |

Extruders | 1 |

Software Inc. | M3D |

Resolution | 50 to 350 microns |

Dimensions | 7. |

Weight | 4.4 lbs |

Includes | M3D software, USB cable, power adapter |

Where To Buy | Amazon, M3D website |

Warranty | Three months for manufacturer’s defects |

- Lightweight

- No Display

da Vinci Mini Wireless 3D Printer

No products found.

Price | $200 |

Setup | Assembled |

Interface | USB, Wi-Fi |

Display | No |

Technology | FFF |

Print Area | 5. |

Enclosed | No |

Heated Bed | No |

Bed Leveling | Auto |

Nozzle Size | .04 mm |

Extruders | 1 |

Software Inc. | XYZware, supports Windows 7 and above, Mac OSX 10. above |

Resolution | 100 microns |

Dimensions | 15.4” x 13.2” x 14.2” |

Weight | 18 lbs |

Includes | Starter filament |

Where To Buy | XYZ Printing, Amazon |

Warranty | Undetermined |

This is another excellent entry-level printer that works right out of the box. Wi-Fi connectivity is a big plus, as is that automatic bed-leveling feature. The resolution of 100 microns is good, but not great. It only runs filaments available from XYZ Printers. The proprietary XYZware software is provided.

Wi-Fi connectivity is a big plus, as is that automatic bed-leveling feature. The resolution of 100 microns is good, but not great. It only runs filaments available from XYZ Printers. The proprietary XYZware software is provided.

- Wi-Fi interface

- Uses only XYZ Printing filaments

- Resolution

HopeWant Desktop 3D Printer

No products found.

This seems to be a good entry-level printer. Remove it from the shipping carton, and it’s ready to go. It prints either from the computer or the SD card (TF card).

- SD Card

- Price

- No Display

- Resolution

Print-Rite CoLiDo Delta 3D Printer

Promotion! Print-Rite CoLiDo Delta 3D Printer Kossel Kit D1315 Plus...

- Fast print: Delta design, 3 axles moving at the same time, 30% faster than XYZ printing technology

- 0.

05 mm layer resolution printing quality, two times more precise than other low cost 3d printers, which usually print...

05 mm layer resolution printing quality, two times more precise than other low cost 3d printers, which usually print... - Ready to print, fully assembled and calibrated. Compact design with premium quality parts, portable machine with...

Price | $269 |

Setup | Assembled |

Interface | USB |

Display | No |

Technology | FDM |

Print Area | 5” diameter x 5. |

Enclosed | No |

Heated Bed | No |

Bed Leveling | No |

Nozzle Size | .04 mm |

Extruders | 1 |

Software Inc. | Repetier-Host, supports Windows 7 and above, Mac |

Resolution | 50 microns |

Dimensions | 9. |

Weight | 12 lbs |

Includes | Flash drive, USB cable, adapter, filament |

Where To Buy | Amazon, CoLiDo |

Warranty | 30-day return policy, one-year international warranty |

The price of this unit is at the high end of our range but, as always, you get what you pay for. This printer is different from the others in that it is configured for a circular print area. It is easy to set up, and it prints quickly due to its three-axis parallel movement system. This is an excellent printer for a beginner, but the quality and consistency are good enough for professional applications. At 30 watts, it is economical to operate.

This is an excellent printer for a beginner, but the quality and consistency are good enough for professional applications. At 30 watts, it is economical to operate.

- Fast printing

- Low power

- No Display

- Resolution

The Monoprice Mini Delta 3D printer was the clear winner here. For a printer with its features, the price is almost unbelievable. Wi-Fi connectivity and use of SD cards to store print files make it very user friendly. The heated bed also makes this the only printer on the list that could be comfortably used in a professional setting.

Featured Image: Image by ZMorph4D from Pixabay

Last update on 2021-12-12 at 04:27 / Affiliate links / Images from Amazon Product Advertising API

TIKO 3D printer - controversial Kickstarter project

A small report on the purchase of a 3D printer (used) from the eBay site (America).

The Tiko 3D printer is a small and interesting machine.

Details under the cut.

Greetings to all visitors of the site 3dtoday.ru !

A short story about how I bought and completed the 3D printer of the famous startup Tiko 3D.

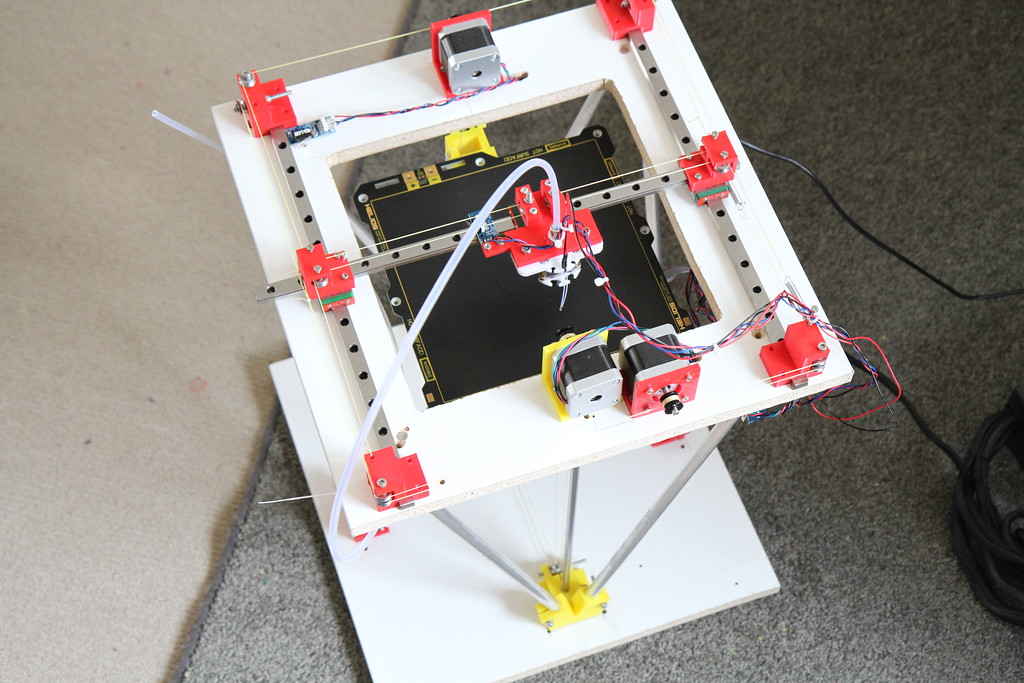

This is quite an interesting 3D printer with delta kinematics. Not without childhood diseases of course.

Tiko official website.

I have long wanted to participate in large crowdfunding companies. I occasionally participate in small ones. Especially in the field of various technologies.

I constantly monitor new startups with 3D printers and 3D printing. Now there is a fundraising for a small and inexpensive Geeetech E180A printer. As for the Tiko project specifically, The Unibody 3D Printer is one of the most successful projects at the start. Tiko raised over $2.9 million. There were over 16,000 backers.

Now there is a fundraising for a small and inexpensive Geeetech E180A printer. As for the Tiko project specifically, The Unibody 3D Printer is one of the most successful projects at the start. Tiko raised over $2.9 million. There were over 16,000 backers.

Project page on kickstarter

I didn't manage to buy it as a backer. The last opportunity to deposit funds was closed at the beginning of this year. The guys collected much more than they had planned and, to celebrate, began to spend money. They launched mass production of printers ... not completely correcting children's sores. For example, the lack of airflow. Well, there were certain problems with accelerations and inertia at high speeds - the printer still "specializes" for printing up to 30 mm / s , although it is clear that it can be more.

I had to look for one of the used printers. There are quite a lot of them (there were) - the backers refuse, they don’t know how to get rid of the received device. There were several options on eBay, at very low prices. It was possible to take for a quarter or half the price of a printer in excellent condition.

There were several options on eBay, at very low prices. It was possible to take for a quarter or half the price of a printer in excellent condition.

Here is the lot I won.

The seller is one of the first backers, a firefighter from Cloverdale, California, who bought and was upset because he could not print on the printer. The printer had a minimal gap, a virtually untouched native spool of filament.

At the moment (at the time of the publication of the review) - it was not possible to buy a printer on eBay or on the official website (out of stock). In the title of the review, I indicate the lot, which I also bought.

But there are other interesting options , for example, M3D Micro - a similarly inexpensive device with children's "sores", around $100. Can be taken for a child or as a first printer. Similar to the Tiko 3D, the M3D Micro's pros are its small size and good looks (and it's easier to ship).

Characteristics:

Brand: TIKO

Model: Unibody 3D Printer

Type of kinematics: deltabot

Construction area: Diameter 125 mm. Height 125mm

Height 125mm

Features: supporting case, Wi-Fi hotspot, built-in slicer.

Adhesion: polymer backing.

Effector: steel+ceramic, 0.4mm

Materials: PLA/ABS.

Dimensions: 222 x 235.9 x 450mm

A small infographic from the official site: the main functions that startups relied on are indicated.

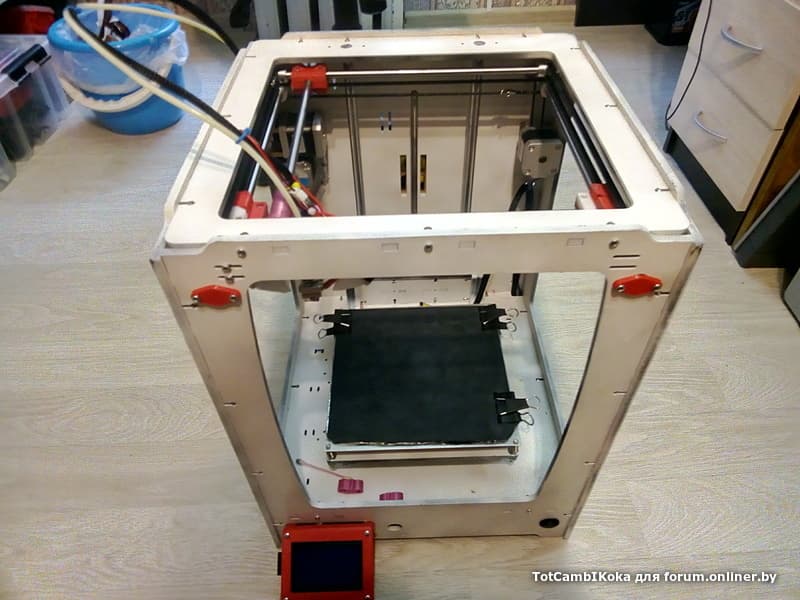

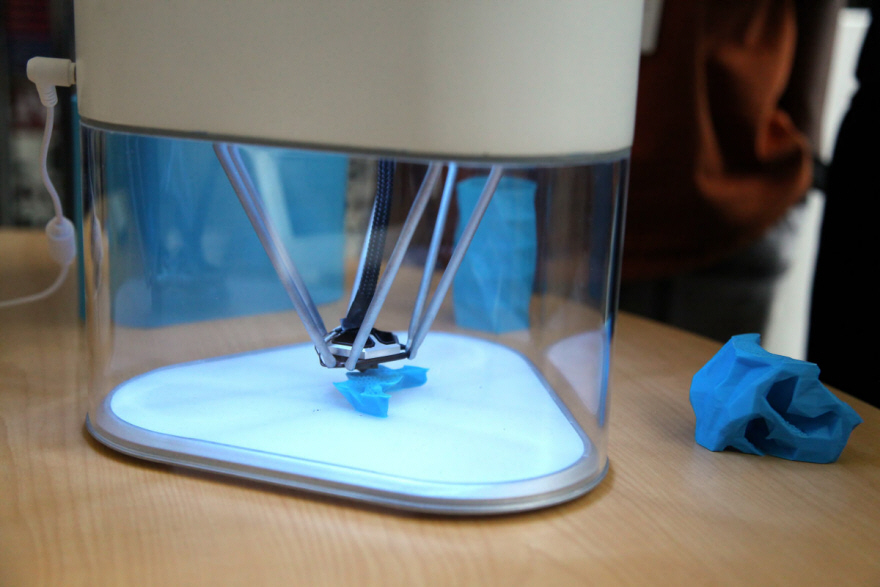

Externally, the TIKO 3D printer looks like a white plastic tower with a transparent insert. The coil is located at the top under the cover. The whole structure is fixed on the supporting white part of the body. Removable underlay. There is no heating or cooling.

Unibody dimensions and build area illustration

Done right, this is a good printer. Of course, not everything is smooth with him, but we will try to cope.

I was looking for a suitable lot for a long time (there were three options during the summer months). But there were no problems to win the lot - not the most popular product.

Purchased the printer through an intermediary forwarder (details at the end).

After about 20 days (painful waiting, especially for the results of customs clearance) I received a huge box.

Inside original packaging with printer, printer in foam shell.

“Shell” repeats the shape of the printer - very good packaging.

Separately, I will highlight the instructions - very detailed.

There was also a backer's card and a DVD.

There was a separate power source in the cell - an adapter for 12V (2.5A)

Spool with native blue PLA filament has been installed in the compartment at the top.

Spool is almost intact. True, plastic for six months in printed form has already begun to crack and break.

Cell for the coil

Unpacking the printer, checking the condition

Delivered whole))) The printer deservedly takes its place on the desktop. It looks like the rest of the office equipment - very good. At least the design is head and shoulders above that of Pryush.

Manufacturer's label. The basic information is carefully indicated, up to the connection address.

A photo of the printer on the desktop. Connects via Wi-Fi.

I will tell you in detail about the design.

The main focus of the developers is minimalism and lightness of construction.

Minimal effector: composite+ceramic. It heats up quickly, does not require blowing the thermal barrier.

The extruder motor is centrally located on the main body.

Carriages are lightweight, made of flexible plastic such as high impact polystyrene (or similar). You can take it off and put it back on with almost no effort.

Guides (3 pcs) - plastic "rails".

Uses small 12 volt BYJ-48 motors.

The motors move on the rack. Lubrication is present.

Please note: the limit switch is mounted on the carriage itself.

Power connector

Rods and effector - everything is as light as possible.

The backlight is dynamic, strong enough. The LEDs are arranged in a ring on the board.

All harnesses are plugged in. A flexible cable goes to the hotend.

Bowden tubes with fittings. Can be disassembled, disconnect the tube for maintenance. Made very thoughtfully.

The print base has a special plastic pad for adhesion.

Print marks from previous owner visible.

The Tiko board is very specific. It has Wi-Fi and a slicer on board.

All parts of the printer - the design turned out to be very technological.

We connect the printer to the outlet, we are waiting for the software to download (after downloading, the backlight turns on).

To connect to the printer, you need to select the Tiko Wi-Fi network and then you need to type in the browser line:

print.tiko/editor or - 192.168.1.1 .

Connect from a smartphone in the same way.

When turned on, the printer thinks for a while, then starts blinking in greeting.

Loading the model (Add object)

You can also use the manual options (menu on the left). This is the heating of the nozzle, the loading and unloading of the filament.

Insert the filament into the tube and push it all the way into the extruder mechanism.

Press Load filament and wait for the end

You can extrude a little to check

The result of extrusion

Unloading is similar - Unload filament

Select a model, press print

The slicer is working. You can print. Don't forget about calibration. When printing, you can skip the calibration step (or run it automatically).

Print settings

Printing in progress

To stop printing, you can lift and tilt the printer

When accessed from a smartphone, the same pages open. And slicing does not "strain" the smartphone.

It is extremely convenient to perform calibration from a smartphone - it is easier to control and adjust the nozzle manually

Before printing, select the option of manual calibration (or automatic)

The meaning is to alternately set the height (touch) of the nozzle on the table surface.

Use the ▲ and ▼ keys to adjust the nozzle close (well, or under the paper) to the substrate.

Press Done for each step (3 dots).

The printer moves to the next point.

Finishing and parking

Calibration completed

You can send the first model to print.

When I turned on the printer, I had a series of beeps and an error "301" - auto-home failure. It was necessary to correct one of the engines on the rail. By the way, they install almost effortlessly.

Loading filament. Here I encountered the fact that the old filament was present (and two colors at once). The former owner printed with silver filament, which was pushed heavily through the nozzle. I had to clean it by hand.

It is necessary to push through the old filament, which remained in the area after the extruder - the former owner could not cope, he apparently had a clogged nozzle or tube.

Loading did not go through normally, apparently there were pieces of the old filament inside.

Disconnect the tubes from the extruder (there is a simple clamp) and push through.

I pushed mine by hand with the nozzle warmed up.

Until I pushed out all the remnants of native plastic, and mine appeared (green).

Now standard loading

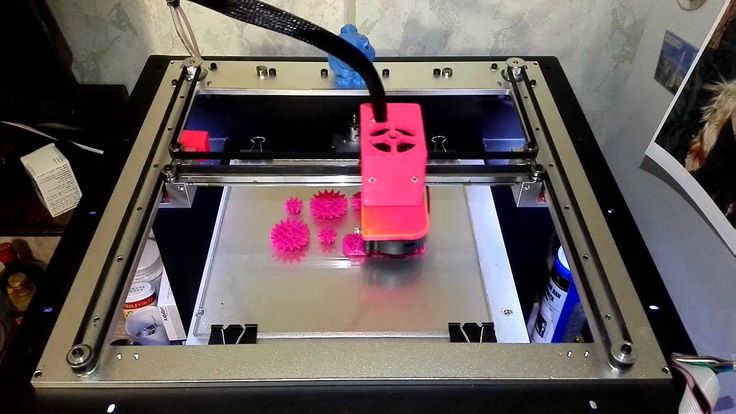

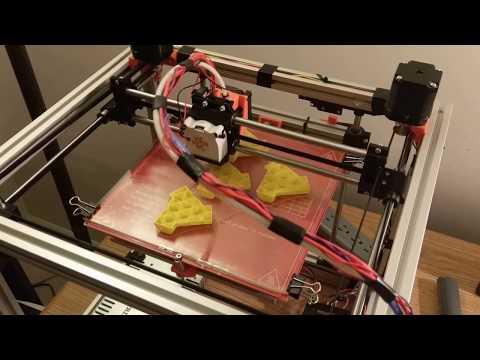

First print.

Raft does not turn off on models (Gcode editing only)

It can be seen that the printer does not have enough airflow. The plastic is starting to sag.

By the way, one of the pieces of the 'native' blue plastic got on the photo - it broke and such pieces got stuck in the tubes. Apparently forced to sweat the first owner.

Printing a test cube

The cube turned out better.

Calibration steps.

By the way, the Z-hope option is enabled. The printer raises its head slightly when moved.

Top slightly smeared from overheating.

Again it is clear that there is not enough airflow for PLA.

Pay attention to the printer modification models on thingiverse, in particular to this collection. The easiest way to implement this is with tubes and a small turbine or compressor.

You can print the tube holder for the effector.

This is what it looks like assembled. Tubes can be used silicone with an outer diameter of 6 mm (as from an aquarium).

Additionally, you can print a tee for pipes (one inlet, and three pieces are blown).

An aquarium compressor or turbine can be used for blowing.

I used a 12V impeller with a tube adapter.

It blows quite well, but I would like more

Pre-printed some splitters.

The tubes are threaded into the holders on the effector.

Alternatively separate nozzles can be used.

The hot end of the printer is best insulated with silicone tape or Kapton.

After installing the blower with a turbine, I started printing again.

That's what happened. For PLA, the print quality has increased to an acceptable level

For comparison, both models: on the green (without blowing), the edges are smoothed due to the lack of blowing of the model during printing

And similarly "native" Tiko test model. The print quality has grown)))

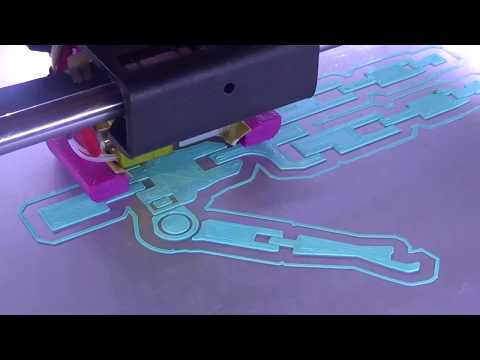

Here are a couple of printed models.

Hare Flat Figurine

The print quality is quite tolerable, especially for a $100 printer.

Frog

I will note some hairiness. Still, the turbines are not enough, I will put the compressor from the aquarium (larger and quieter).

Print animation))))

Quite an entertaining process.

Pins:

Fairly good budget 3D printer with excellent price/quality ratio. The guys from the startup Tiko got almost . Almost - because improvements are required.

Pros : Great balance between price and features. There is a built-in slicer (a huge plus when controlled from a smartphone / tablet), there is Wi-Fi, backlight, some functions such as turning off the printer by tilting and auto-calibration.

Cons : Due to the servo drives used in the design, the printer turned out to be very slow, the carriages and motors need to be heavier. And given that there is no more than complete airflow in the drain, it is difficult to print PLA with good quality. Improvements and treatment of "childhood diseases" of the printer are required.

And given that there is no more than complete airflow in the drain, it is difficult to print PLA with good quality. Improvements and treatment of "childhood diseases" of the printer are required.

Regarding shipping: on the one hand, the price is decent, on the other hand, it is an opportunity to get a printer for half the price.

Details of the reseller I used and the shipping process

The printer, like most Kickstarter startups, was sold in America. To bring to the Russian Federation, you need to either negotiate with the seller (not everyone agrees), or use the services of an intermediary. I have been looking for a suitable one for a long time (the weight of the printer is about 5.5 kg, the dimensions are also decent - this directly affects the cost of delivery). I turned to intermediaries with a question about the possibility of sending exactly a 3D printer, in packaging, transport tariff, as well as with a question about the declaration and customs clearance.

The cheapest was Pochtoy . In agreement with the support of Pochtoy.com, the declaration indicated the name simply TIKO printer , without 3D (this is an extra clue for customs).

Pochtoy reseller site We register, we get the address, we indicate the address in our Ebay account.

We make a purchase (payment) in our name, but to the Pochtoy.com warehouse.

After receiving the goods, check in your account (photos of appearance).

Money:

Price calculator. Delivery of such a voluminous and heavy cargo as a 3D printer costs a little more than $50 (see there are different tariffs, it is better to take a cheaper one - it takes longer, but customs is easier). When ordering, I used the code: GADGETUSA ($5 per account), in my opinion, is still valid.

Useful links:

Tiko 3D official website Official site forum Project page on kickstarter Acquisition and setup experience from rubyfox Models for printer modifications on thingiverse Discount calendar

Overview of the budget 3D printer Monoprice Select Mini

3DPrintStory Reviews Overview of the budget 3D printer Monoprice Select Mini

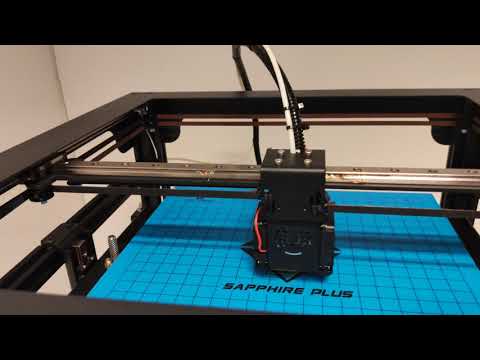

Prices for desktop 3D printers continue to fall. There were times when a $600 3D printer was a delight and a desire to order it as soon as possible, but technology does not stand still, and developers and manufacturers are looking for new options to lower the price even lower. This review is dedicated to one of the budget 3D printers costing about $200 - Monoprice Select Mini.

There were times when a $600 3D printer was a delight and a desire to order it as soon as possible, but technology does not stand still, and developers and manufacturers are looking for new options to lower the price even lower. This review is dedicated to one of the budget 3D printers costing about $200 - Monoprice Select Mini.

It is worth noting that this inexpensive model breaks established traditions and did not start with Kickstarter, unlike others like M3D Micro, Tiko, OLO / ONO and Trinus, which attracted the attention of consumers and investors thanks to crowdfunding platforms (by the way, this is really an effective development strategy for small startups, but there is often a mismatch between expectations and the final product).

Monoprice is different. This is an American company that did not particularly bother with the development and production of its own 3D printer, but simply imported the Malyan M200 from China, hung its logo on it and put an attractive price of $199. What if you got a defective 3D printer? No problem, send it back and they will replace it for you.

What if you got a defective 3D printer? No problem, send it back and they will replace it for you.

A reasonable question arises: can such a cheap 3D printer compete with Ultimakers or Printrbots? And is it even worth comparing? We will try to answer these and other questions in the review below.

Features Monoprice Select Mini

- Available;

- Robust design;

- Easy to use;

- Predictable 3D printing at low speed;

- Works with any slicing software and standard 3D printing materials;

- Amenable to improvements and upgrades;

- I think we already mentioned the price?

Disadvantages Monoprice Select Mini

- Difficult to calibrate;

- Prints poorly at high speeds;

- Print table not protected;

- Faulty power supply;

- WiFi module not active;

- Unstable nozzle temperature;

- Strange quirks...

Short Verdict

The Monoprice Select Mini is a great 3D printer for the price. There is a heated table, easy to operate if you do not use high speeds, stable 3D printing quality.

There is a heated table, easy to operate if you do not use high speeds, stable 3D printing quality.

Naturally, there are disadvantages. During operation, the temperature of the nozzle may change, and at high speeds, 3D printing errors occur. The calibration process takes a lot of time and the first time you have to tinker. Well, the most interesting thing is that the power supply burned out after 12 hours. But the latter, incorrect, can be attributed to an accidental marriage.

Despite all the shortcomings, the Monoprice Select Mini is a wonderful little 3D printer with many great features. In general, it performs in accordance with the information in the technical specifications, and the quality of the 3D printing even exceeded our expectations.

If you are not afraid to take it apart / put it back together, then you can do a few upgrades. The first thing to do is to replace the hotend and update the firmware to activate the WiFi module ( be careful! These upgrades have not been tested as part of this review and may damage your 3D printer! ). You can install the glass on the print table. Even with these upgrades, the price will still remain acceptable.

You can install the glass on the print table. Even with these upgrades, the price will still remain acceptable.

Would you recommend the Monoprice Select Mini as your first 3D printer? Yes, definitely.

Specifications and features Monoprice Select Mini

Monoprice Select Mini workspace 120 x 120 x 120 mm. The maximum resolution of 3D printing is 100 microns. Heated table. The 3D printing speed is 55 mm/s.

You can upload your 3D model via micro SD card or USB. The manual states that compatible slicing programs are Cura, Repetier-Host, ReplicatorG, and Simplify3D. This means that the Monoprice Select Mini recognizes the standard G-code, and this 3D printer is not tied to any particular software. Cura was used during testing for this review.

Monoprice Select Mini doesn't limit you in the media you use. You can print with any standard 1.75 filament using PLA or ABS thermoplastics. In our case, PLA plastic from ColorFabb was used.

These two things - freedom to choose software and filament - are very important in this price range, because manufacturers like M3D Micro and XYZprinting, which are Monoprice's main competitors in this niche, tend to use proprietary software and their own materials for 3D printing .

Unpacking and installation of the Monoprice Select Mini

Installation of the Monoprice Select Mini is quite simple. You can start typing within 20 minutes.

Inside the box you will find a 3D printer, a power supply, an imbus wrench for calibrating the table, a plastic spatula for scraping off the rest of the material from the table after printing, a 256 mb micro SD card and a micro USB cable.

One piece of paper contains basic instructions and a link to a website where you can download the full version.

You will also find a rectangular steel sheet, the purpose of which is not clear at first. It turns out that this is a coil holder that is attached to the side of the main unit.

It is important to note that the Monoprice Select Mini kit does not include media test samples. So stock up on filament with a diameter of 1.75 mm.

You can use the wheel to adjust. The menu is well structured and easy to understand. You can start the calibration process, preheat the extruder and feed the filament.

Calibration can be somewhat difficult. In theory, it should be carried out even before shipment, in production, and you should have a piece of paper between the nozzle and the printing table. If it doesn’t work, then hex keys will come in handy here. It will be necessary to try and tighten the screws at the corners of the table so that the sheet still passes.

At this stage, the first important shortcoming of this model becomes clear. The printing table is made of aluminum and does not have a special protective film or coating on it. So stock up on blue 3D printing tape or install glass right away. Otherwise, the table will wear out very quickly and you will have to change it.

Well, one more bug that got out in our particular case. The power supply burned out after 12 hours of use. Foaming it was not difficult, but it was very unpleasant. You can probably throw it off for marriage, but in any case, be prepared for a similar turn of events.

Design and build quality of the Monoprice Select Mini

Very pleased with the build quality of the Monoprice Select Mini. The construction is strong, reliable, with a steel sheet metal case that hides all the electronics. So don't worry about shipping damage.

The construction is strong, reliable, with a steel sheet metal case that hides all the electronics. So don't worry about shipping damage.

This 3D printer uses deposition modeling technology. The classical Cartesian coordinate system is used. The design is similar to Printrbot Simple. One cooler is used to cool the nozzle. It is likely that problems may arise during 3D printing with unusual materials.

The extruder has a diameter of 0.4 mm and can be heated up to 230°C. We have not been able to test how easy it is to change, but in the long run this is an important factor as the nozzle will still need to be changed over time.

Monoprice Select Mini Print Quality

Models will already be preloaded on the micro SD card. They are supposed to be optimized for 3D printing on the Monoprice Select Mini. So before uploading our own models, we printed test ones.

The cat was printed first. The resolution was 200 microns. Everything went well until the last layers. The upper part of the paw and ears could not be printed even once. There were 3 attempts in total.

The upper part of the paw and ears could not be printed even once. There were 3 attempts in total.

G-code analysis in Simlify3D shows that the table accelerates up to 55mm/s during the last layers. That is why the error was repeated. Quite a strange decision of the company - to provide a test model, which a priori will be printed with errors...

The second model that we printed is a test elephant. The resolution was also 200 microns and 10% infill. There were no problems! The result is excellent and you can see it in the photo below.

Next we moved on to our own models. We used Cura for slicing. This article reveals the excellent Cura settings for 3D printing on the Monoprice Select Mini and we used them.

We printed a classic 3DBenchy and Graphica model: a MEGA Ghost with 200 micron resolution and 10% infill, a V29 whistle with 200 micron resolution and 100% infill, and another 3DBenchy model with 100 micron resolution and 10% infill.

The simple 200 micron models worked out well. There are no special problems with small protrusions and holes, although there are sagging. The layers are laid evenly along the X and Y axes.

The V29 whistle sounds as loud as intended, which means the partitions were printed correctly. The Graphica Mega Ghost with its long tongue also printed correctly. The hinge glided smoothly. The

3DBenchy at 100 microns worked well too. When you look at the photo, don't forget that this is a $19 3D printer.9.

We have noticed that most errors in 3D printing occur when the spool of filament clings or there is not enough adhesive coating on the printing table. This cannot be attributed to the shortcomings of the Monoprice Select Mini itself, since this is a global problem for all FFF printers.

During operation, the print table may block access to the control wheel. This point is implemented in the design is not very ergonomic.

Another disadvantage is that the nozzle temperature has an error in the region of 5°C. For example, when the 3D printing temperature is set to 215°C, it jumps between 213°C and 217°C on the control panel.

For example, when the 3D printing temperature is set to 215°C, it jumps between 213°C and 217°C on the control panel.

This does not particularly affect printing with PLA plastics, but may have a negative effect during 3D printing with materials that are more sensitive to temperature changes.

Finally, we printed a Low Poly Moai bust. We scaled the model by 50% and printed with 100 micron settings and 30% infill. It turned out well on the whole, the only small marriage is the influx of material on the chin. By the way, we observed the same effect when printing 3DBenchy with resolution settings of 100 microns.

Life hacks and upgrades Monoprice Select Mini

A few words about upgrading the Monoprice Select Mini 3D printer. There are no official upgrades! But here are a few options that you can try to implement on your own.

In our opinion, it is necessary to deal with the temperature of the extruder, make it more stable. For example, you can implement a PID temperature controller.

3” x 4.3” x 4.7”

3” x 4.3” x 4.7” 6 64-bit)

6 64-bit) 3” x 4.5” x 4.6”

3” x 4.5” x 4.6” 3” x 7.3” x 7.3”

3” x 7.3” x 7.3” 9” x 5.9” x 5.9”

9” x 5.9” x 5.9”  8 and

8 and 9” high

9” high 9” diameter x 17.5 high

9” diameter x 17.5 high