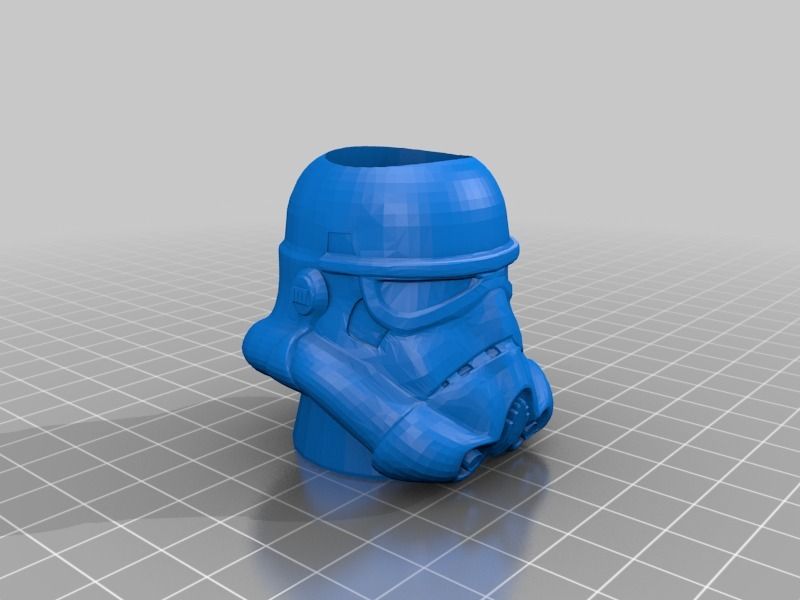

Storm trooper 3d print

Stormtrooper best 3D printing models・Cults

Stormtrooper

€1.50

Stormtrooper

€0.85

Stormtrooper

€1.20

Stormtrooper

€1

Stormtrooper

€1

Stormtrooper

€1.20

Stormtrooper

€1.20

R2D2

€1.20

R2D2

€1.20

Stormtrooper notebook cover / notebook cover

€4

Stormtrooper Christmas ornament

€1.28

CR90 Space Ship

€32.54

Skull Stormtrooper damaged head

Free

R2-D2 Star Wars

€1. 04

C3PO Star Wars

€1.04

Chewbacca Star Wars

€1.04

Star Wars SE-14R Blaster Stand

Free

Stormtrooper E-11 Blasttech Stand (stable one finally)

Free

Stormtrooper Bobblehead

Free

Captain Phasma - Star Wars Fanart

€19.46

Star Wars Endor Bunker Diorama/Playset

€4

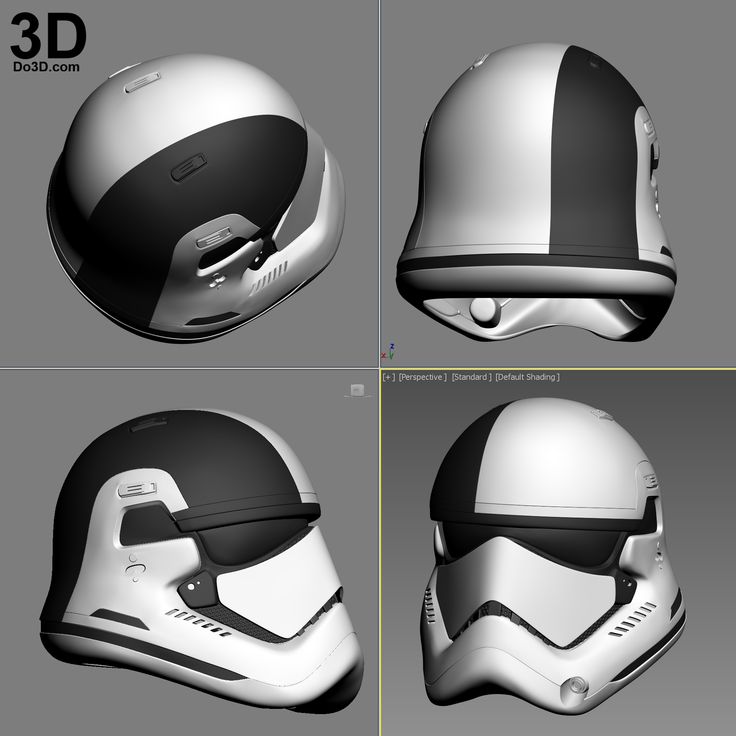

First Order Storm Trooper Helmet

€5.72 -50% €2.86

Monoprice Select Mini 3D V2 Stormtrooper control dial

Free

Stormtrooper 2D Wall Decor

€1. -35% €0.71 09

09

Athena Stormtrooper

Free

First Order Stormtrooper Helmet

€25.64

STORMTROOPER Rogue One Armor + helmet | Andor | Solo

€42.59

Stormtrooper helmet life size scale from Rouge one 3D print model

€15.28

Flexi Stormtrooper

€4.10

STAR WARS DOUBLE BIT: STORMTROOPER (EMPIRE)

Free

Mate dead trooper

€0.87

STAR WARS VINTAGE STORMTROOPER REMOVABLE HELMET, CUSTOM UNPRODUCED KENNER, HASBRO ACTION FIGURE, 3.75", 1/18, 5POA

€5.12

Westar M5 and DC-17 with holster for Black Series/SH Figuarts

€2. 35

35

Mandalorian Death Watch and Westar 35 Rifle for Black Series/SH Figuarts

€1.98

E-5 for Black Series/SH Figuarts

€1.98

EE-3 for Black Series/SH Figuarts

€1.31

Stormtrooper Octo

Free

DEATH TROOPER Helmet 1to1 scale 3d print

€15.28

Stormtrooper Angel - MOLD BATH BOMB, SOLID SHAMPOO

€3.08

STAR WARS VINTAGE AT-AT DRIVER REMOVABLE HELMET, CUSTOM UNPRODUCED KENNER, HASBRO ACTION FIGURE, 3.75", 1/18, 5POA

€5.12

mini at-at

€2

stormtrooper

€1.50

STAR WARS VINTAGE SNOWTROOPER REMOVABLE HELMET, CUSTOM UNPRODUCED KENNER, HASBRO ACTION FIGURE, 3.

75", 1/18, 5POA

75", 1/18, 5POA€5.12

Stormtrooper keyring

Free

Classic stormtrooper keyring

Free

Scout Trooper keyring

Free

Stormtrooper Keychain

Free

clone force

€1.50

Free 3D file Star Wars Imperial Stormtrooper Wearable Armor・3D printable object to download・Cults

Star Wars Darth Vader Helmet

Free

Batman Armored from Batman VS Superman Movie Full Armor

Free

Star Wars Patrol Trooper Wearable Helmet

Free

Doom 2016 Doomguy Helmet Wearable Part

Free

Star Wars Imperial Scout Trooper Wearable Armor

Free

Star Wars Clonetrooper Phase 1 Wearable Armor

Free

Iron Man War Machine Mark 4 Full Armor Wearable

Free

Star Wars Commander Cody Wearable Armor

Free

Best 3D printer files of the Various category

LOGO SOLEX

Free

100 Snowflakes

€2. 56

56

Bike Handlebar Button

€0.54

Secret design

Geocache Labyrinth

€1.20

Airsoft Micro Claymore

Free

UAZ BUKHANKA 452 RC BODY SCALER 267MM MST TAMIYA

€25

Super Mario Mushroom

Free

Best sellers of the category Various

Polestar 2 center console accessories

€7.09

Halloween Haunted House Lamp w 3d Moon-NO SUPPORT or PAINTING NEEDED

€4.57

The Black Phone Movie The Grabber 2 Part Mask 3 Styles Frown Smile Mouthless STL

€10.25

Polestar 2 cup holder

€5. 84

84

Ciberpunk 2077 Rebecca's Gun "Guts"

€4

Moving T-800 Terminator Skull

€15 -25% €11.25

RS-X-Bow "Government - 1911" style

€6.25

Gyarados - Articulated Seasnake

€1.50

Articulated Gyarados

€1.99

Adderini - 3D Printed Repeating Slingbow / Crossbow Pistol

€6.25

ItsLitho "Pure" personalized lithophane Christmas ball

€1.90

Chainsaw Man – Denji

€18.46

Wolf - Flexi Articulated Animal (print in place, no supports)

€2

Articulated Rayquaza Flexible Pokemon Dragon

€1

Gengar - Flexi Articulated Pokémon (print in place, no supports)

€2

Targaryen Crown - Viserys - House Of The Dragon

€9. 95

95

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

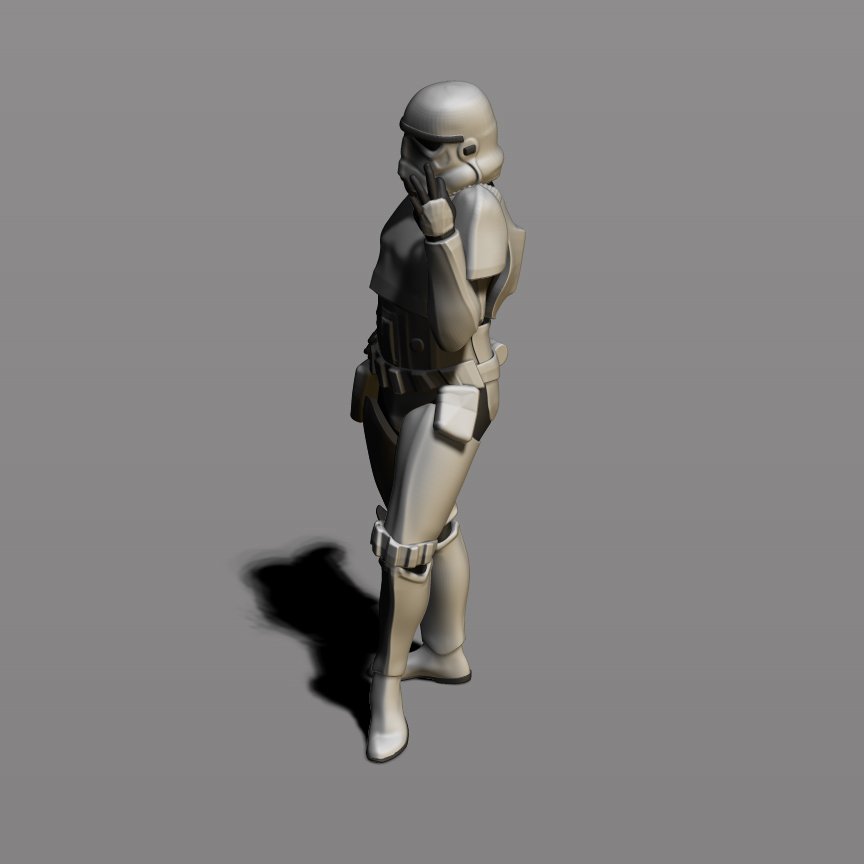

3D printed movable Star Wars Stormtrooper figurine - printable files included!

Report from the battlefield! Captain Phasma is leading a wave of attacks on the rebels! Defeating resistance is no easy task! The First Order needs to send a few more soldiers to join our fight!

Inspired by Autodesk Tinkerplay 3D Printer and my experience with Lego and Bionicles (leave a comment if you have any), this tutorial will show you how to build any custom figure! I love figurines with ball joints! I grew up with Bandai and Lego figurines and I love how easy they are to assemble and build! No need to constantly screw and unscrew something. I've tried traditional sculpting before, this is my attempt at making a figurine with CAD!

I've tried traditional sculpting before, this is my attempt at making a figurine with CAD!

Download the file and 3D print a stormtrooper figurine with realistic articulation! I hope you enjoy this guide and learn from it some tricks for 3D printing.

I am making this figurine as a Christmas present for my dear friend Susie! I want to make a decent photo-op figure for her! You can have different attitudes to the new Star Wars trilogy, but the design in the films is, as always, on top. Personally, from the first teaser, I really liked how the imperial attack aircraft looks.

Note: This article is a translation.

Step 1: Master TinkerPlay in 10 minutes!

First off, Tinkerplay is my dream toy printing software! Autodesk launched this application at the beginning of 2016, and as a 3D printing enthusiast, I was very happy to work with it.

The user interface (UI) is designed to be intuitive, easy to learn for both children and parents. Available on iOS, Android and Windows Store! I tried the Android app on my phone, but I prefer the desktop version. The app is so easy to use that it doesn't even start with a tutorial! Provides 10 character templates with unique limbs and body parts connected by ball joints. Select one of the templates and the guided build process will begin. The program has an interactive environment, customization of parts, inverse kinematics and the ability to copy and paste, as shown in my video.

The assembly process is strictly drag and drop. In addition to templates, the user can mix and match parts as they are available in two catalogs:

1) Parts from a specific character;

2) The same body parts from other characters.

Feel free to watch the video demo if you're interested!

Press the print button and you will see the approximate dimensions and weight of the figurine, these parameters are a general price indicator. You can have your figurine printed at your local 3D workshop.

You can have your figurine printed at your local 3D workshop.

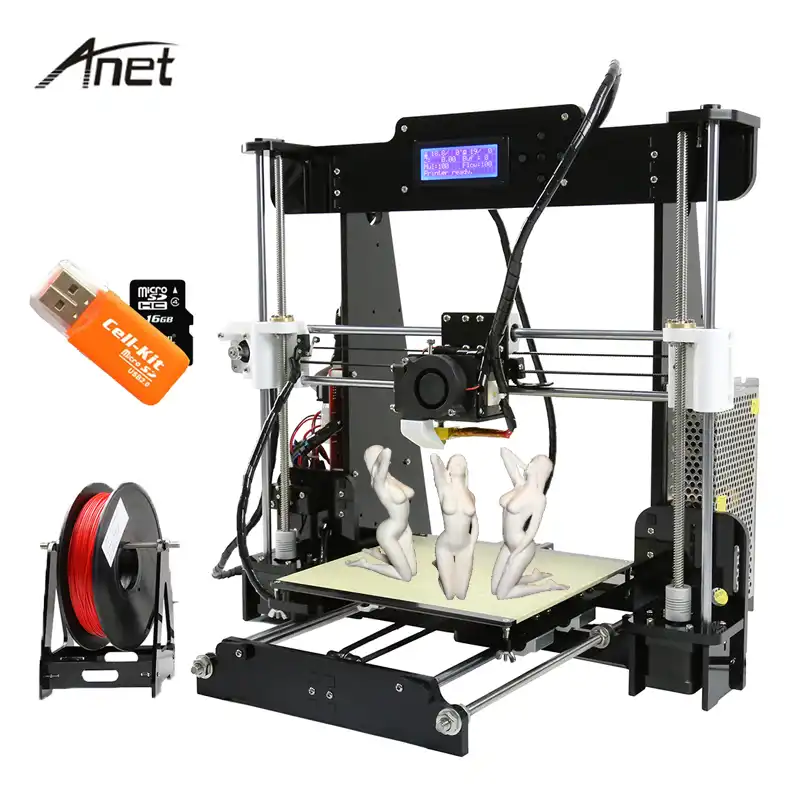

Unzip the STL files and load them into Blender, arranging them to match your printer! I installed mine on UPBOX at the university library. I printed this skeleton to test the printer and print file. Moving on to Maya! I hope in the future I will become a professional in Maya.

After printing, I cleaned the entire raft and support with pliers, assembled the skeleton and had some fun with it. The ball joints are very well articulated, with acceptable friction. He can take difficult poses, such as standing on one leg. A slight imperfection in print quality doesn't seem to affect functionality much!

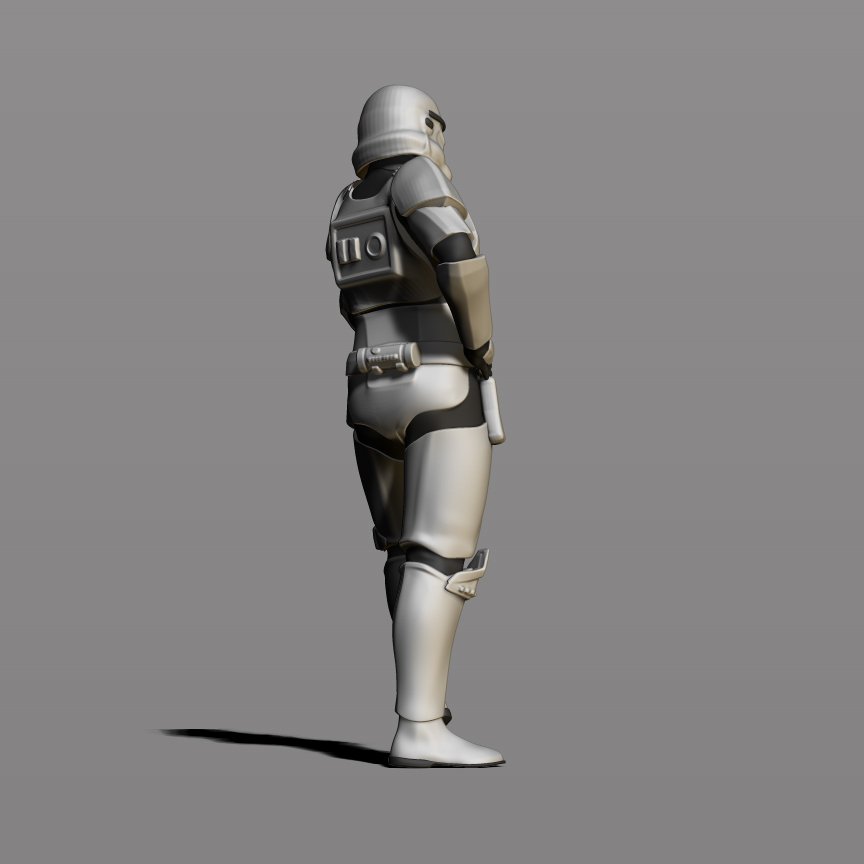

Step 2: 3D Modeling

This is the most creative part, you can model anything you want or download any game character you like on TurboSquid.

As a 3D artist, I will obviously model the stormtrooper myself. 3D modeling has been my passion for a few years now, I am so drawn to it, with more practice, I hope to get a proper postgraduate study and build a career on it! For beginners, I have the following tips:

1. Sculpt! put your brain to work with 3D shapes! (I tried paper clay figurine 2 years ago but it was too heavy and not hard enough, that was before I tried fimo.

2. Watch tutorial videos online! Long or short!

3. Watch disassembly

4. Follow digital artists on Instagram

5. Learn about topology and test your knowledge!0002 6. Post your work online! You will receive feedback, and you never know who will look at your work and where it will lead!

I've attached a timelapse of the process, I'm certainly not a pro (yet) but I hope you learn something!

Step 3: Tinkerplay modifications and refinement of the model

I sketched out the general scheme (see attached drawing) the main features are:

1. Double ball joints in the elbows and knees for higher bending angles;

Double ball joints in the elbows and knees for higher bending angles;

2. Hinges have 2 standard sizes instead of 1 as in tinkerplay to reduce weight.

I used an app called Camera Scanner, it's very handy and does the job. Autocorrect does indeed give the quality of the scanned image in most cases. Great for converting finished quality documents to PDF using your phone.

I roughly assembled the stormtrooper from a sketch in Blender. I then selected the ball joint from a .stl file that I exported from Tinkerplay. Scale to two sizes. Then I placed the joint on top and tested it. You can see me making a lot of adjustments to improve the articulation. After setting the connections and sockets in place, I began to connect them.

I then aligned the bone piece with the stormtrooper model. I made them overlap, they're not even connected. I decided to redo the connections. Some parts did not receive any support or raft at all, the basis of the seal was also shifted, some layers are visible sliding. It seems that the foundation was not fixed at the very beginning.

It seems that the foundation was not fixed at the very beginning.

Step 4: Test print

Strong slip can be observed

My initial approach to setting the bones inside failed due to generated support. I had to separate them.

Last successful print.

I doubted that everything would be fine from the very beginning, since this is a rather difficult thing to print. I expected that I might have to redo the model. I did a test print on the only printer I have access to. It was the printer in the university library. Unfortunately I have a 6 hour limit and can only print it in a very small size due to the complexity of the design.

It fails miserably due to size, ball joints have been disconnected. The printed base was not set properly, parts of my figure were shuffled like a deck of cards. There was a serious slip of the layers, it is clearly visible on the helmet. I just got unlucky.

Step 5: Modifications + Reprint

Position the taller part in the center and the less layered parts in the surrounding area to optimize timing and print head stability.

This is a skeleton demo, feel free to use this in your project.

The cylindrical part should normally stand upright due to the even distribution of thread around the circumference.

Right previous failed attempt

The fingers are difficult to orientate, this was my best attempt given the curvature of the shapes.

I separated the ball joint armature from the armor and reprinted it, I also realigned the parts so that the required support was minimal. You can also notice that I modeled the mesh in more detail... After fixing the printer and fixing its operational glitches, I finally got a working 3d printer. The print took 10 hours, the weight was about 100 g, and the cleaning of the prop and raft took more than an hour. I really wish I had my own 3d printer at home.

Modeling for printing is similar to modeling for games and graphics, but keep in mind some important differences:

- Use high-poly printing if necessary, as the printer does not usually work with bump maps or normal maps.

If you need more shape definition, add more geometry.

If you need more shape definition, add more geometry. - Mesh must be watertight and topologically connected.

- If that's not possible, make sure the two meshes overlap each other to a large extent (like the sternum and pelvis that I did).

Step 6: Assemble a stormtrooper and take down the rebels!

clear extraction from the grid, start with the parts located around, work inwards.

all parts are ready!

Roll the foam inward to secure the chest.

Looks like sushi.

It took me an hour to remove the part from the grid and support. Keep a swab with alcohol handy, I scratched my finger on the hard support. Freeing the part on the outskirts, move to the center, as you can see the head I took off the last

Then comes the real assembly. I'm testing the fitted parts. Because they are empty shells, the armor and some other parts dangle a little, such as the chest and thighs. I recommend adding kraft foam padding. If necessary, glue the shells to the appropriate places with hot glue.

I recommend adding kraft foam padding. If necessary, glue the shells to the appropriate places with hot glue.

As I already mentioned, the printer on which I printed this project had a number of problems. If the filament or printer fails a little, then the ball joints may not fit perfectly. If the parts do not fit, take a cutter and cut off the excess. Take a hot glue gun, put a drop of glue on the ball joint and rub it gently to apply a thin layer. The joints must be tight to lock in place and get difficult poses. Feel free to prime and sand the figurine to make it look cool and smooth.

Step 7 Flexibility

With more articulation than a mid-range action figure, my soldier is able to take such interesting poses. In particular, he has movable shoulder joints, not many figures refer to this subtle but important articulation. The stand on one leg is also a point of pride for me... I think the figure could be improved if the topology of the bones themselves was improved.

I hope you see how cool projects can grow from a creative mind and CAD!

Stormtrooper 3d printing files:

FYV6DI5IJHFFCF3.stl 184 Download

FAED2KBIJHFFC8R.stl 149 Download

Step 8: Service and Notes

I believe the strength of the seams will depend on the filament you use and the print resolution.

If the connection is not as tight as before, reprint the part or just rub with a layer of hot glue, as I mentioned, this may seem a little dishonest, but I think there is nothing wrong with it.

If you've read this far, thank you very much for following my experience with 3d printing. Thank you for your time and support Leave a comment and share this guide with your Star Wars-loving friends!

May the force be with you!

3D maniac or how I made a stormtrooper suit.

Hello everyone! It's finally time to write about the grandiose 3D printing of a complete attack aircraft suit.

The beginning of the story can be read here http://3dtoday.ru/blogs/byrdalak123/printprocessingreview-or-how-i-do-the-stormtrooper-costume/

The article will focus on the following:

- General history of printing

- Gluing parts + post-processing

- Print settings, technical points

- Connecting the suit, general conclusions and impressions

.

It all started with the fact that I won a Cheap 3d V300 printer and wanted to make my own suit on it. Unfortunately, there was not enough time for modeling, and I already wanted to use some kind of interesting costume in December last year at my big science shows. The choice fell on the attack aircraft, it most suited the script and it was decided to start printing it.

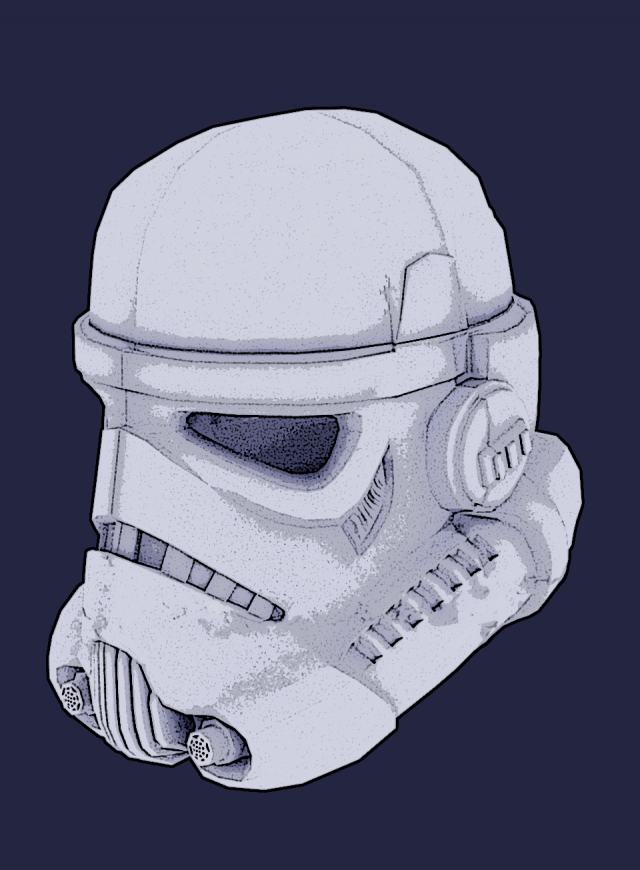

The stormtrooper helmet was pretty simple. Many people printed it, there are already honed stl models, everything is divided into parts that fit without problems in the field of my printer. There was also a description and gluing sequences, and the whole print is not very large, so here I went along already explored paths.

There was also a description and gluing sequences, and the whole print is not very large, so here I went along already explored paths.

But now, the helmet is printed, it's time for the costume. Everything turned out to be much more complicated here, since it was extremely difficult to find models in the public domain, and what I found turned out to be either with the wrong geometry, or did not look pretty enough and was very different from the original. I even thought about buying a model from American guys who sell professional costume models, already tested and cut. But still, I found a person in the states who printed the entire suit of an attack aircraft and posted a couple of photos and a short video with him. I contacted him and found out everything that was needed, and still found suitable stl.

Appropriate - this is very approximate, but more on that later. The main difference between my attack aircraft and the American one was that it was printed with ABS, and I haven’t tried much with it yet, but I’m good at making PLA parts, so the entire attack aircraft is PLA printing.

All models were on hand, and they were not from a single archive, but still some of the different ones found on the Internet. The main problem that I encountered is complete anarchy on a scale. All the details were in different scales and I often had to reprint some parts so that they looked normal and that I could move normally in them). Of course, the models had to be sawn for printing in parts (the print area does not allow you to print the sternum or dorsal part at once, although cheap 3d has a huge print area of 300x300x300).

Finally, the first parts began to be printed.

Of course, the amount of plastic required was brutal .... but more on that later.

Each piece was glued together using the proven method - Methylene Chloride. I dipped the edges for 5-6 seconds of the parts to be glued and connected. The connection is the strongest. The main thing when working with this reagent is gloves, a ventilated area, respiratory protection (I used 3M with all possible filters), eye protection from vapors is also desirable. Also, with the help of methylene, it was possible to remove the ribbing from the print itself, as well as to align the junctions.

Also, with the help of methylene, it was possible to remove the ribbing from the print itself, as well as to align the junctions.

Parts were printed exclusively with one plastic - FD Plast. Cheap and cheerful.

And there is a feeling that black was printed better than white. The walls were smoother and more glossy.

- Gluing of parts + post-processing

Gluing of parts was carried out at the expense of methylene chloride (which, by the way, costs a penny in comparison, if you take it from stores associated with 3D printing, I took it in Ruskhim). Dip each side to be glued for 5-6 seconds per 5-8 mm protrusion in methylene and then simply connect and hold for about a minute. Strong bonding occurs in 5-6 minutes. Full bonding - up to 5 hours.

The parts were then 'smoothed' with the same methylene and a lint-free cloth. I wetted the fabric and rubbed the part, leveling the layering.

IMPORTANT! I read somewhere about dipping the whole part (complete immersion in methylene) for a while. I'll tell you what happens in practice. If the part is not 'closed' on all sides (there are gaps in the internal structure - filling, then the part will most likely come to an end. The methylene will get so deep and dissolve everything making your model 'rubber' and warped. If you are sure that your entire model ' If the thickness of the closing of the model is small and the walls of the model are too small, then be sure that methylene also deforms your part, when taken out of the solution, there will be dents from your fingers, and then the model will generally twist So it's better to wipe the model.0003

I'll tell you what happens in practice. If the part is not 'closed' on all sides (there are gaps in the internal structure - filling, then the part will most likely come to an end. The methylene will get so deep and dissolve everything making your model 'rubber' and warped. If you are sure that your entire model ' If the thickness of the closing of the model is small and the walls of the model are too small, then be sure that methylene also deforms your part, when taken out of the solution, there will be dents from your fingers, and then the model will generally twist So it's better to wipe the model.0003

The parts were then dried. Then somewhere it is necessary - with sandpaper and again methylene. Further degreasing of parts, primer on plastic in 2-3 layers (slightly evens out, which is not wiped with methylene), then paint in 2-3 layers and at the end varnish, also in 2-3 layers. Of course you need to dry between layers.

The lacquer will give not only shine to the plastic, but also protect it from scratches, because even when touching a part on a part without lacquer, hello to scratches.

To be honest, since I had a lot of details and there was little time, somewhere I did not completely 'methylene' the part, and painted in 1-2 layers. Only the most visible parts were directly polished with methylene.

- Print settings, technical points

Print settings, studio!

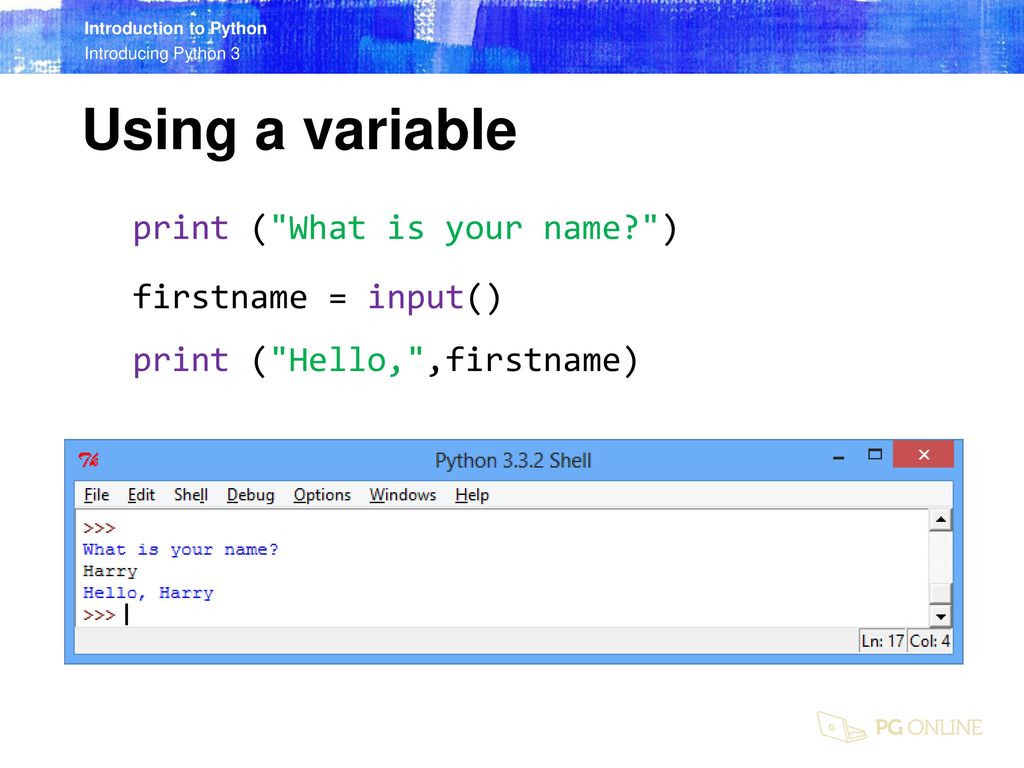

- SLICE via Cura

- Printing speed 50

- Moving extruder 110

- Filling 50

- layer thickness 0.2

- Filling up/bottom thickness 0.6

- Filling of the floor 25%

- Printing temperature 210 degrees

- Table temperature 70 degrees

- Sticking method - PVA glue

Printer: Cheap 3D V300

Plastic: FD plast PLA

The printing took place indoors, so there were no drafts.

Now I want to talk about the numbers associated with the costume:

3 broken glasses on which the models were printed (strong adhesion was plus the haste to tear the part off the table)

11 plastic spools of 750 gr.

7 kg weight suit with helmet

More than 50 days of printing

Suit consists of 50 parts

At all stages of printing - no clogging of the nozzle, no 'noodles' of the model, no distortion of the model during printing (delamination).

By the way, about the clogging of the nozzle - I use castor oil, which I pour onto a sponge and wrap the sponge around the rod in front of the extruder. Works, checked.

Printing took place in the office and for days, so the noise of the 'always printing monster' did not bother me))

- Suit connection, general conclusions and impressions

The suit is interconnected thanks to backpack straps and fastex (plastic tridents). The entire weight of the suit is held by the upper panels in front and behind, they are interconnected by thick disposable ties, from which there are already fastex straps. The straps are glued on hot glue and hold very cool! It is impossible to put on a suit by yourself, you need help.