3D printing in construction pdf

[PDF] Construction 3D Printing | Semantic Scholar

Review of Emerging Additive Manufacturing Technologies in 3D Printing of Cementitious Materials in the Construction Industry

Additive manufacturing is a fabrication technology that is rapidly revolutionising the manufacturing and construction sectors. In this paper, a review of various prototyping technologies for printing…

Effect of Delay Time on the Mechanical Properties of Extrusion-Based 3D Printed Concrete

- Taylor Marchment, Ming Xia, E. Dodd, J. Sanjayan, B. Nematollahi

Materials Science, Engineering

- 2017

The extrusion-based 3D printing method is one of the main additive manufacturing techniques used in the construction industry which is capable of producing large-scale building components with…

An overview of critical success factors for implementing 3D printing technology in manufacturing firms

Additive manufacturing, also known as 3D printing or digital fabrication technology, is a process of accumulating deposited layers to form solid 3D objects from 3D models in digital fi les. 3D…

Current progress of 3D concrete printing technologies

- B. Nematollahi, Ming Xia, J. Sanjayan

Materials Science, Engineering

- 2017

The construction industry is expected to go through large transformations since construction automation is anticipated to drastically alter standard processing technologies and could lead to possible…

Applicability of using the 3D concrete printing technology in Sudan

- Ruaa Elnaeem, Mohammed Taglsir

Engineering

- 2021

It has been concluded that applying 3DCP technology in Sudan is possible and could be effective in the low-cost housing projects.

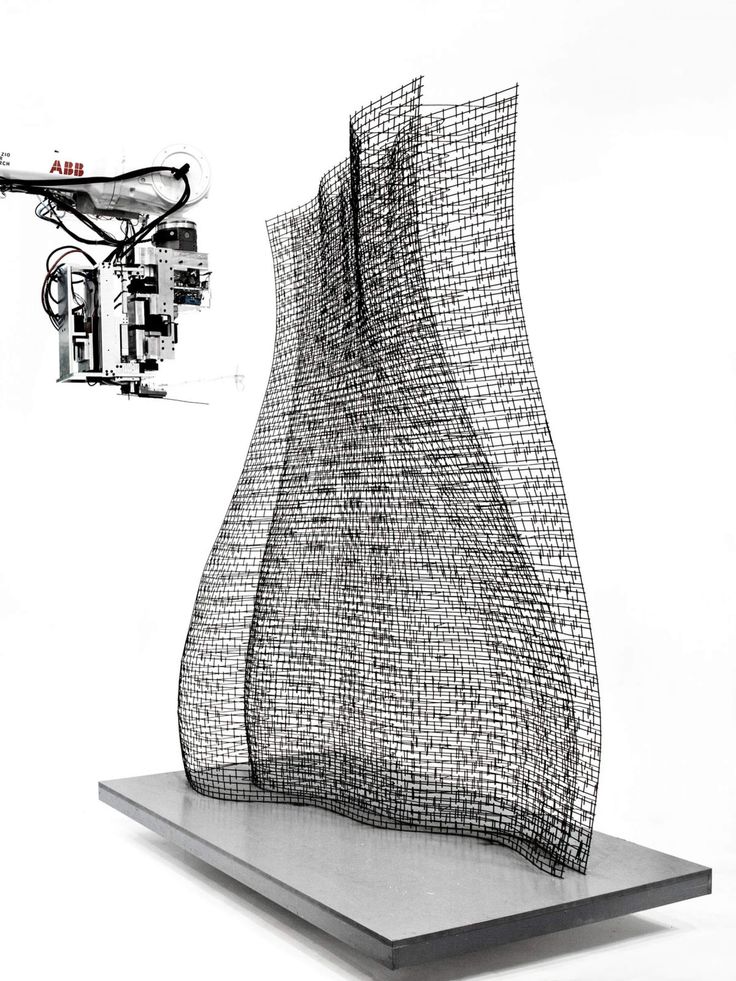

Optimisation of different concrete mix designs for 3D Printing by utilising 6DOF industrial robot

- Pshtiwan Shakor, Jarred Renneberg, S. Nejadi, G. Paul

Materials Science, Engineering

- 2017

Additive Manufacturing (AM) technologies are becoming increasingly viable for commercial and research implementation into various applications. AM refers to the process of forming structures layer…

AM refers to the process of forming structures layer…

Additive printing for civil infrastructure: Assessing concrete mix design, printability and nozzle effects

- G. Deivanai, K. Manikandan

Materials Science

- 2020

The need to automate the construction process for civil infrastructures has been perpetually propelled by the reported number of detrimental site accidents, enormous time, and material wastages in…

3D printed construction and implementation in Cyprus: Discussion and overview

- Mohamed Elasad, Dinmukhamed Amirov

Materials Science

- 2020

The article describes the construction technology using three-dimensional printing. The use of 3D printing allows the engineers to implement architectural projects of any complexity, to reduce the…

A Study into the Effect of Different Nozzles Shapes and Fibre-Reinforcement in 3D Printed Mortar

- Pshtiwan Shakor, S. Nejadi, G.

Paul

Paul Materials Science, Engineering

Materials

- 2019

This paper investigates the properties of 3D printed fibre-reinforced cementitious mortar prisms and members in conjunction with automation to achieve the optimum mechanical strength of printed mortar and to obtain suitable flowability and consistent workability for the mixed cementitious bricks during the printing process.

Technology of 3D Print in Field of Renovation of Architectural Structures and Historical Buildings

The article analyzes possibilities of using additive manufacturing in the building industry, especially in the field of reconstruction of building structures. On concrete examples, growing potential…

3D-Printing Technology in Construction: Results from a Survey

Abstract

Purpose

The purpose of this paper is to study the introduction of 3D-printing of concrete in the construction sector.

Design/Methodology/Approach

A survey was conducted to collect professional view on ongoing innovations in the construction sector, including 3D-printing. Participants were selected among the members of Norwegian networks for project and construction management research.

Findings

The survey highlighted effective leadership, collaboration with partners and industry-academia collaboration as primary enablers of innovation. Few of the respondents to the survey have used 3D-printing technologies.

Research Limitations/Implications

It is difficult to obtain representative samples in this type of research, including this study. The study can be seen as a snapshot of attitudes in the sector.

Practical Implications

3D-printing appear as a potentially interesting technology, especially for unstandardized construction components. Further work is needed to materialise the expectation for technological development in the construction sector.

Further work is needed to materialise the expectation for technological development in the construction sector.

Originality/Value

Most research on 3D-printing has focused on demonstrating technical potential. This study adds a practitioners’ perspective, with a large dose of pragmatism.

Keywords

- 3D-printing

- Concrete

- Implementation

- Additive

- Hybrid additive/Subtractive manufacturing

- HINDCON

Citation

Olsson, N.O.E., Shafqat, A., Arica, E. and Økland, A. (2019), "3D-Printing Technology in Construction: Results from a Survey", Lill, I. and Witt, E. (Ed.) 10th Nordic Conference on Construction Economics and Organization (Emerald Reach Proceedings Series, Vol. 2), Emerald Publishing Limited, Bingley, pp. 349-356. https://doi.org/10.1108/S2516-285320190000002044

2), Emerald Publishing Limited, Bingley, pp. 349-356. https://doi.org/10.1108/S2516-285320190000002044

Publisher

:Emerald Publishing Limited

Copyright © 2019, Nils O.E. Olsson, Ali Shafqat, Emrah Arica, Andreas Økland.

License

Published in the Emerald Reach Proceedings Series. Published by Emerald Publishing Limited. This article is published under the Creative Commons Attribution (CC BY 4.0) licence. Anyone may reproduce, distribute, translate and create derivative works of this article (for both commercial and non-commercial purposes), subject to full attribution to the original publication and authors. The full terms of this licence may be seen at http://creativecommons.org/licences/by/4.0/legalcode

1. Introduction

This paper studies 3D-printing of concrete in the construction sector. As an innovative technology, 3D-printing offers interesting opportunities for the construction industry, such as increased flexibility and reduced operational costs. However, it is important to analyse and use the previous innovation experiences to increase the success potential of implementing the 3D-printing technology in the construction industry. The study is a part of the EU-funded research project HINDCON (2018).

However, it is important to analyse and use the previous innovation experiences to increase the success potential of implementing the 3D-printing technology in the construction industry. The study is a part of the EU-funded research project HINDCON (2018).

The aim of this study is to investigate the implementation of 3D-printing in the construction sector. The following research questions are set up:

2. On 3D-printing as an innovation in construction

The construction industry has evolved from a craftsmanship to an industrialised and service-oriented business, owing to the significant efforts in development and implementation of technological and organisational innovations over the past 70 years. Nevertheless, it is questionable if the introduced innovations have yielded their full potential and promises in the construction industry. Many studies show that construction industry has failed to adopt innovations to improve its performance as in other industries (World Economic Forum, 2016). The lack of stakeholder's involvement, high initial innovation costs, lack of risk funding, inherent conservative behaviour of organisations and initial non-profitability of innovations are some examples of barriers leading to fails in innovation (Ozorhon et al., 2013). As an innovative technology, 3D-printing and hybrid additive/subtractive manufacturing offers significant opportunities for the construction industry, such as increased flexibility and reduced operational costs. However, it is important to analyse and use the previous innovation experiences to increase the success potential of implementing the 3D-printing technology in the construction industry.

The lack of stakeholder's involvement, high initial innovation costs, lack of risk funding, inherent conservative behaviour of organisations and initial non-profitability of innovations are some examples of barriers leading to fails in innovation (Ozorhon et al., 2013). As an innovative technology, 3D-printing and hybrid additive/subtractive manufacturing offers significant opportunities for the construction industry, such as increased flexibility and reduced operational costs. However, it is important to analyse and use the previous innovation experiences to increase the success potential of implementing the 3D-printing technology in the construction industry.

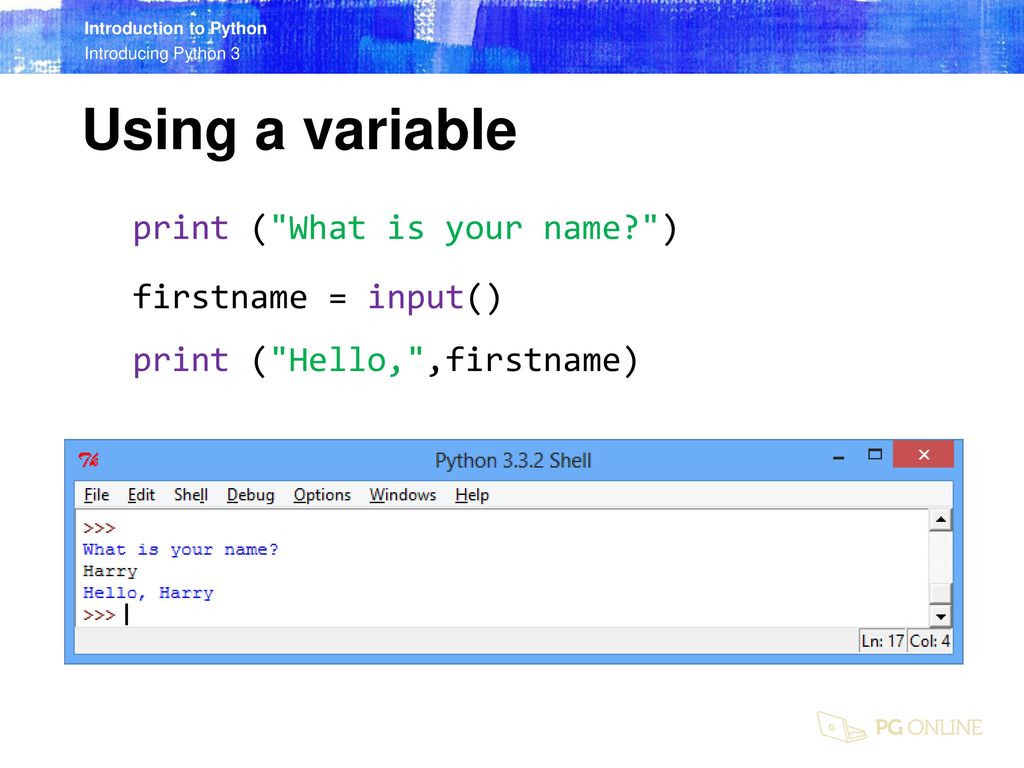

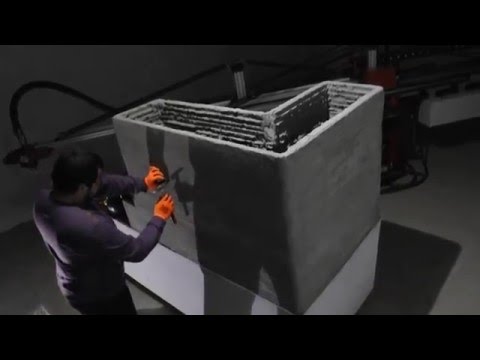

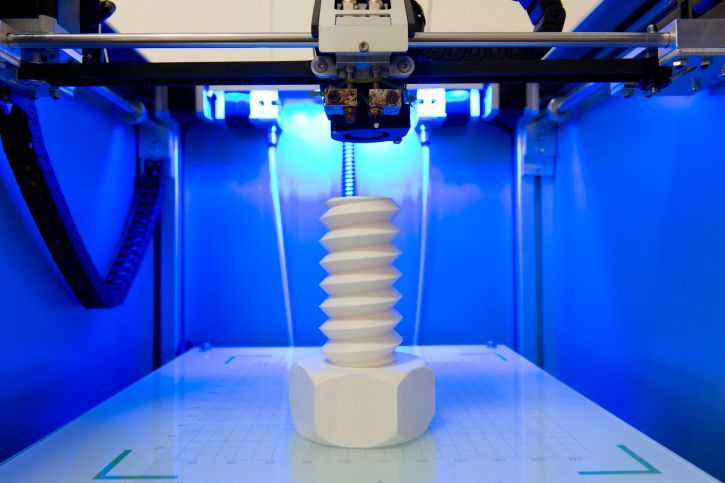

2.1. About 3D-printing and additive manufacturing

3D-printing is an automated, additive manufacturing process for producing 3D solid objects from a digital (i.e. CAD) model, where the 3D CAD model is sliced into a series of 2D layers that are later deposited by the printer to construct the model (Boothroyd, 1994). A more recent definition for 3D-printing is "the fabrication of objects through the deposition of a material using a print head, nozzle, or another printer technology" (American Society for Material and Testing 2009). The term "additive manufacturing" (AM) is more generally defined as: "the process of joining materials to make objects from 3D model data, usually layer upon layer" (American Society for Material and Testing, 2009). Additive manufacturing can deliver parts of intricate and complex geometries, built from tailored materials with near-zero material waste, while being applicable to a variety of materials (Bikas et al., 2016).

A more recent definition for 3D-printing is "the fabrication of objects through the deposition of a material using a print head, nozzle, or another printer technology" (American Society for Material and Testing 2009). The term "additive manufacturing" (AM) is more generally defined as: "the process of joining materials to make objects from 3D model data, usually layer upon layer" (American Society for Material and Testing, 2009). Additive manufacturing can deliver parts of intricate and complex geometries, built from tailored materials with near-zero material waste, while being applicable to a variety of materials (Bikas et al., 2016).

Three important aspects of additive manufacturing are: material, process, and design. The main categories of 3D-printing have been detailed by (Labonnote et al. 2016) solid-like, viscous-like, powder-like and liquid-like. More complete overviews on previous and current additive construction experiences can be found in (Perkins and Skitmore, 2015; Labonnote and Rüther, 2016 and Wu, Wang et al. , 2016).

, 2016).

PWC (2014) did a general about use of 3D-printing in manufacturing. It showed that about 25% of the companies were involved in prototyping using 3D-printing and 29% were experimenting how they can use it.

2.3. Drivers and barriers to use of 3D-printing in construction

A driver that supports the use of 3D-printing in construction is the significant customisation opportunities (Labonnote et al. 2016). Minimisation of waste (Berman, 2012) and improved carbon footprint (Achillas et al., 2015) are also interesting possibilities. There is a potential for cost-efficiency through high automation and reduced manpower requirement (www.3ders.org, 2014). Automation such as 3D-printing can reduce danger for human workers in harsh environments (Millsaps, 2015). 3D-printers also have quick deployability (Peter, 2015).

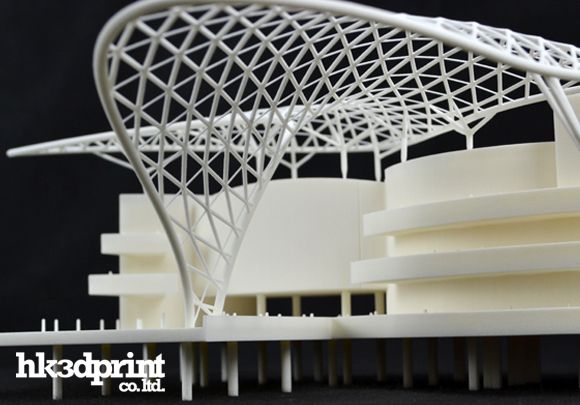

Issues that may serve as barriers include uncertainty regarding the size of demand for mass customisation and availability of high-strength printing materials. The literature also find it unclear whether 3D-printing could lead to reduced or increased construction cost (Wu, Wang et al., 2016). Owing to size limitation of existing 3D printers, it is difficult to print a multi-story building at a time (Gibson et al., 2002). However, users can print structural components piece-by-piece and then assemble them together as a real-scale building (Feng and Yuhong, 2014). Intellectual property issues have been raised in particular in connection with concerns that digital objects (including a digital file describing the construction of a given structure) can easily be copied and re-sold (Berman, 2012). There are also cyber security risks (Campbell et al., 2014).

The literature also find it unclear whether 3D-printing could lead to reduced or increased construction cost (Wu, Wang et al., 2016). Owing to size limitation of existing 3D printers, it is difficult to print a multi-story building at a time (Gibson et al., 2002). However, users can print structural components piece-by-piece and then assemble them together as a real-scale building (Feng and Yuhong, 2014). Intellectual property issues have been raised in particular in connection with concerns that digital objects (including a digital file describing the construction of a given structure) can easily be copied and re-sold (Berman, 2012). There are also cyber security risks (Campbell et al., 2014).

3. Research approach

The paper presents findings from a questionnaire on use and expectations for 3D-printing in construction industry. Based on initial literature studies, the first version of the questionnaire was developed, which involved several workshops with the authors and the HINDCON team members. The result presented here is related to the 3D-printing experiences and expectations in the construction sector. In the second phase of the survey, the questionnaire was piloted in three companies with follow-up interviews. The questionnaire was adjusted after the feedback. The third phase of the survey was to collect an e-mail list of potential respondents. Survey participants were mainly selected among the members of Norwegian networks for project and construction management research. The types of companies involved in the survey are engineering and construction management consultants, clients, building owners, architects and suppliers of pre-assembled modules. The list of potential respondents included 235 persons. The fourth stage of the survey was to launch the final version of the questionnaire. A total of 36 valid responses were received. The results of the survey are entered in Excel format for analysis and graphical presentation.

The result presented here is related to the 3D-printing experiences and expectations in the construction sector. In the second phase of the survey, the questionnaire was piloted in three companies with follow-up interviews. The questionnaire was adjusted after the feedback. The third phase of the survey was to collect an e-mail list of potential respondents. Survey participants were mainly selected among the members of Norwegian networks for project and construction management research. The types of companies involved in the survey are engineering and construction management consultants, clients, building owners, architects and suppliers of pre-assembled modules. The list of potential respondents included 235 persons. The fourth stage of the survey was to launch the final version of the questionnaire. A total of 36 valid responses were received. The results of the survey are entered in Excel format for analysis and graphical presentation.

The formal response rate was 15%. However, it was not realistic to receive answers from all as several organisations had more than one person listed, and the list covered a wide array of actors. We estimate that the response rate among realistic respondents was between 25 and 30%. The results are largely based on Norwegian companies, with a bias towards large actors in the construction industry and those with an interest in research and development. Reliability can be influenced by the selection criteria of respondents. However, the study can hopefully give indications of present thinking about 3D-printing, even though the quantifications are not based on a representative sample. Validity in the study was a main concern in the development for the survey and in the piloting with three companies.

We estimate that the response rate among realistic respondents was between 25 and 30%. The results are largely based on Norwegian companies, with a bias towards large actors in the construction industry and those with an interest in research and development. Reliability can be influenced by the selection criteria of respondents. However, the study can hopefully give indications of present thinking about 3D-printing, even though the quantifications are not based on a representative sample. Validity in the study was a main concern in the development for the survey and in the piloting with three companies.

4. Results about the use of 3D-printing

The results address two aspects of 3D-printing in construction. The first aspect is about present and expected degree of implementation, while the second aspect is about expected cost issues.

4.1. Implementation of 3D-printing

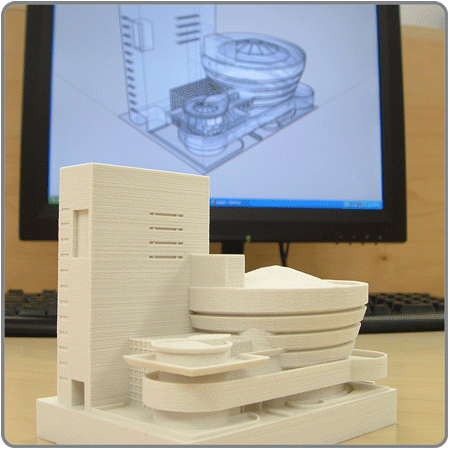

The questionnaire addressed the use and implementation of 3D-printing. Figure 1 indicates that most of the respondents had not used 3D-printing. Those who had used the technology had mainly used it for piloting and prototyping.

Those who had used the technology had mainly used it for piloting and prototyping.

Figure 1

Is your company involved in 3D-printing technology? N = 36 (more than one alternative could be selected)

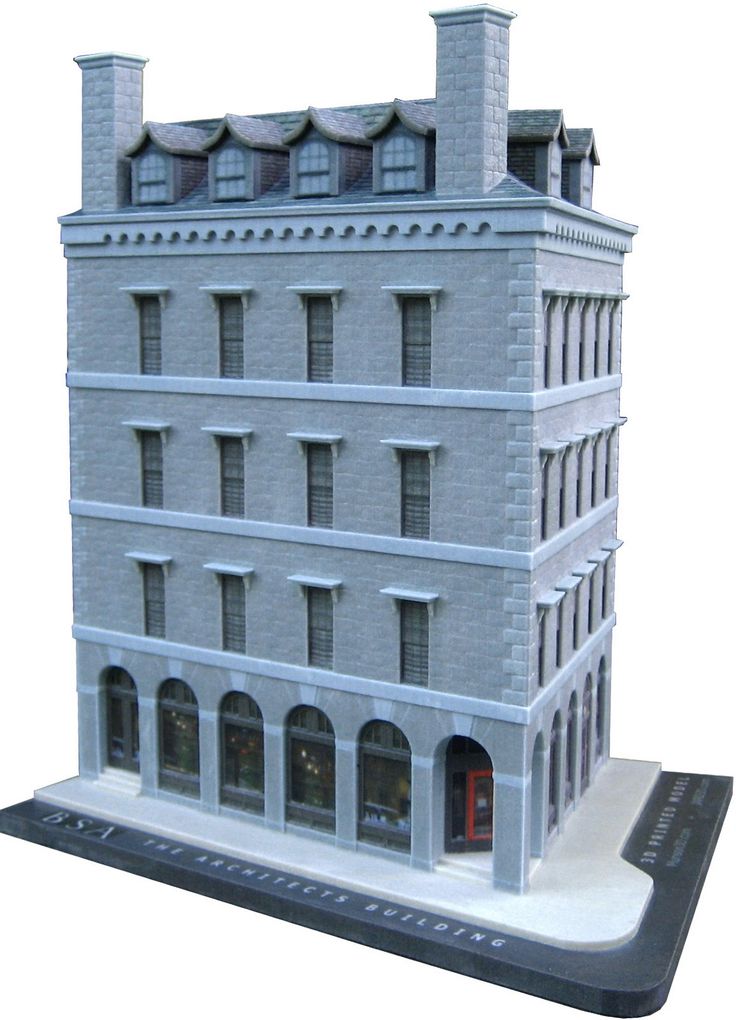

Figure 2 shows the expected areas of application of 3D-printing. Most respondents expected that 3D-printing would mainly be applied for small or complex parts, including decorations. However, some also believed in the production of building blocks.

Figure 2

In the near future (5 to 10 years), what do you expect to be the primary area for application of 3D-printing products in your company? N = 36 (more than one alternative could be selected)

Figure 3 indicate collaboration within the construction sector as a key success factor for implementation of 3D-printing, along with R&D funding.

Figure 3

How can 3D-printing technology be successfully implemented in the construction industry? N = 34 (more than one alternative could be selected)

Most of the respondents expect that it will take more than eight years for 3D-printing to be widely in use, as shown in Figure 4.

Figure 4

In how many years do you expect 3D-printing technology to be used widely in construction projects? N = 36

4.2. Cost issues

The survey also included questions about cost issues of 3D-printing. Figure 5 show that most respondents expected a high initial investment related to 3D-printing.

Figure 5

Do you think 3D-printing technology involves high initial investment? N = 35

In spite of the expected high investment, a majority of the respondents believed that 3D-printing would eventually be cost efficient (see Figure 6).

Figure 6

Do you think the use of 3D-printing technology in construction projects will be cost -efficient? N = 35

5. Conclusions

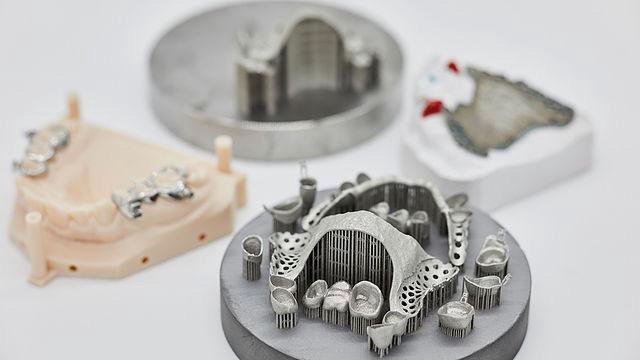

We have investigated the implementation of 3D-printing in the construction sector. The first research question addressed the status of implementation of 3D-printing technology in construction industry. Despite the positive expectations from 3D-printing technology, it has so far only been applied to a limited extent in the Norwegian construction industry, and mainly for piloting and prototyping. The study shows that 20% of the respondents use 3D-printing for prototyping, while a smaller part of the companies uses 3D-printing for ordinary production. In terms of materials, plastic and ceramic are now not only widely used in 3D-printing, but also a big development in 3D-printing of metals. In comparison, the study by PWC (2014) found that some years ago, 25% of manufacturing companies were involved in prototyping using 3D-printing. Our results imply that the Norwegian construction industry is behind but still on somewhat the same level as for manufacturing.

The study shows that 20% of the respondents use 3D-printing for prototyping, while a smaller part of the companies uses 3D-printing for ordinary production. In terms of materials, plastic and ceramic are now not only widely used in 3D-printing, but also a big development in 3D-printing of metals. In comparison, the study by PWC (2014) found that some years ago, 25% of manufacturing companies were involved in prototyping using 3D-printing. Our results imply that the Norwegian construction industry is behind but still on somewhat the same level as for manufacturing.

The second research question is related to expectations for 3D-printing in construction industry. The respondents expected not only high initial investments, but also that 3D-printing would prove to be cost efficient in the long run, with an implementation time of more than eight years. The reviewed literature was not conclusive about the future cost efficiency of 3D-printing (quite naturally, as the technology is in an early stage of development).

The companies in the survey believe that research and development funding for the 3D-printing technology along with collaboration between suppliers and contractors will facilitate its wide future implementation of 3D-printing in the construction sector. Regarding future use, the survey pointed to production of small or complex parts, including decorations as key potential applications of 3D-printing. This is in accordance to the literature, which highlighted the significant customisation opportunities, even though the literature also addressed uncertainty regarding the size of demand for mass customisation. Overall, the study conveys the impression of 3D-printing as a potentially interesting technology, especially for unstandardized construction components. The technology appears to still be at a testing stage. However, there is interest in the industry and we expect to hear more as the technology matures, and we gain more experiences.

References

Achillas, Aidonis, Iakovou, Thymianidis, and Tzetzis, 2015Achillas, C. , Aidonis, D., Iakovou, E., Thymianidis, M. and Tzetzis, D. (2015). “A methodological framework for the inclusion of modern additive manufacturing into the production portfolio of a focused factory.” Journal of Manufacturing Systems 37(1): 328–339.

, Aidonis, D., Iakovou, E., Thymianidis, M. and Tzetzis, D. (2015). “A methodological framework for the inclusion of modern additive manufacturing into the production portfolio of a focused factory.” Journal of Manufacturing Systems 37(1): 328–339.

American Society for Material and Testing, 2009American Society for Material and Testing (2009). “Standard terminology for additive manufacturing technologies”. West Consholhocken, US, ASTM International. F2792-12a.

Berman, 2012Berman, B. (2012). “3-D printing: The new industrial revolution.” Business horizons 55(2): 155–162.

Bikas, Stavropoulos, and Chryssolouris, 2016Bikas, H., Stavropoulos, P. and Chryssolouris, G. (2016). “Additive manufacturing methods and modelling approaches: a critical review.” The International Journal of Advanced Manufacturing Technology 83(1-4): pp. 389–405.

Boothroyd, 1994Boothroyd, G. (1994). “Product design for manufacture and assembly”. Computer-Aided Design, 26(7), pp 505–520.

(1994). “Product design for manufacture and assembly”. Computer-Aided Design, 26(7), pp 505–520.

Campbell, Tibbits, and Garrett, 2014Campbell, T. A., Tibbits, S. and Garrett, B. (2014). “The next wave: 4D printing - Programming the material world”. Atlantic Council, Washington DC.https://www.researchgate.net/publication/262818283_The_Next_Wave_4D_Printing_-_Programming_the_Material_World/download (accessed on 20 August 2018).

Feng, and Yuhong, 2014Feng, L. and Yuhong, L. (2014). “Study on the status quo and problems of 3d printed buildings in china.” Global Journal of Human-Social Science Research.

Gibson, Kvan, and Wai Ming, 2002Gibson, I., Kvan, T. and Wai Ming, L. (2002). “Rapid prototyping for architectural models.” Rapid prototyping journal 8(2): pp 91–95.

HINDCON, 2018HINDCON (2018) “Hybrid INDustrial CONstruction” http://www. hindcon3d.com, (accessed on 20 August 2018).

hindcon3d.com, (accessed on 20 August 2018).

Labonnote, Rønnquist, Manum, and Rüther, 2016Labonnote, N., Rønnquist, A., Manum, B. and Rüther, P. (2016). “Additive construction: State-of-the-art, challenges and opportunities.” Automation in Construction 72, Part 3: pp. 347–366.

Labonnote, and Rüther, 2016Labonnote, N. and Rüther, P. (2016). “Additive manufacturing: an opportunity for functional and sustainable constructions”, Smart and Sustainable Manufacturing. Lisbon, Portugal. https://www.researchgate.net/publication/309430330_Additive_manufacturing_An_opportunity_for_functional_and_sustainable_constructions, (accessed on 20 August 2018).

Millsaps, 2015Millsaps, B. B. (2015). “The Swarmscapers: Students create 3D printing robots capable of building in outlying areas”. www.3DPrint.com, (accessed on 20 August 2018).

Ozorhon, Abbott, and Aouad, 2013Ozorhon, B. , Abbott, C. and Aouad, G. (2013). “Integration and leadership as enablers of innovation in construction: Case study”. Journal of Management in Engineering, 30(2), pp. 256–263.

, Abbott, C. and Aouad, G. (2013). “Integration and leadership as enablers of innovation in construction: Case study”. Journal of Management in Engineering, 30(2), pp. 256–263.

Perkins, and Skitmore, 2015Perkins, I. and Skitmore, M. (2015). “Three-dimensional printing in the construction industry: A review.” International Journal of Construction Management 15(1): pp 1–9.

Peter, 2015Peter, B. J. (2015). “Spiderbot: Large Scale 3D Printer.” Retrieved November 2015, from http://www.bnpeters.com/spiderbot.html (accessed on 20 August 2018).

PWC, 2014PWC (2014). “Technology forecast: The future of 3-D printing”, http://usblogs.pwc.com/emerging-technology/the-road-ahead-for-3d-printing/pp (accessed on 20 August 2018).

World Economic Forum, 2016World Economic Forum (2016). “Shaping the future of construction a breakthrough in mindset and technology”. http://www3.weforum.org/docs/WEF_Shaping_the_Future_of_Construction_full_report__.pdf (accessed 20 August 2018).

http://www3.weforum.org/docs/WEF_Shaping_the_Future_of_Construction_full_report__.pdf (accessed 20 August 2018).

Wu, Wang, and Wang, 2016Wu, P., Wang, J. and Wang, X. (2016). “A critical review of the use of 3-D printing in the construction industry.” Automation in Construction 68: pp. 21–31.

www.3ders.org, 2014www.3ders.org. (2014). “Loughborough University teams up with Skanska to build commercial 3D concrete printing robot.” http://www.3ders.org/articles/20141121-loughborough-university-skanska-to-build-commerical-3d-concrete-printing-robot.html, (accessed on 20 August 2018).

Construction 3D printer, arm type

2019. - T 6. - No. 4 - go to the content of the issue... English

DOI : 10.15862/14SATS419 (https://doi.org/10.15862/14SATS419)

Full text of the article in PDF format ( file size: 544. 5 Kb )

5 Kb )

Link to cite this article:

N.Yu. Klindukh, E.S. Turysheva, I.K. Amuzin, E.S. Dremin, E.D. Bules, E.A. Manipulator-type construction 3D printer // Transport facilities. - 2019. - T 6. - No. 4. - URL: https://t-s.today/PDF/14SATS419.pdf DOI: 10.15862/14SATS419

Klindukh Nadezhda Yurievna

Siberian Federal University, Krasnoyarsk, Russia

Associate Professor

Candidate of Technical Sciences

E-mail: [email protected]

Turysheva Evgenia Sergeevna

Siberian Federal University, Krasnoyarsk, Russia

Associate Professor

Ph.D. Ivan Konstantinovich Amuzin

Siberian Federal University, Krasnoyarsk, Russia

Student

Master student 08.04.01.07 Integrated mechanization and automation of construction

E-mail: [email protected]

Dremin Yegor Sergeevich

FGAOU Siberian Federal University, Krasnoyarsk, Russia

Student

Medic art 04. 04.07 “Construction mechanization and automation of construction”

04.07 “Construction mechanization and automation of construction”

E-mail: [email protected]

9000 Bules Catherine 9003 "Siberian Federal University", Krasnoyarsk, Russia

Student

Master student 08.04.01.07 "Complex mechanization and automation of construction"

E-mail: [email protected]

Elizaveta Aleksandrovna Vorobieva

Siberian Federal University, Krasnoyarsk, Russia

Student

Master student 08.04.01.07 Integrated mechanization and automation of construction

E-mail: [email protected]

Keywords: markup; 3D printer; oscillatory process; vibration and current sensors; vibroforming; mixture density; compressive strength; amplitude; stepper motor current; dynamic loading

Download

Dear readers! Comments on articles are accepted in Russian and English.

Comments are pre-moderated and appear on the site after checking by the editor.

Comments that are not related to the subject of the article are not published.

Prospects for the development of 3D printing in construction

Authors : Lokhmutov Nikita Dmitrievich, Kulichkov Denis Vasilievich, Ermolaeva Veronika Viktorovna

Category : Information technology

Posted by in young scientist #23 (209) June 2018

Publication date : 11. 06.2018 2018-06-11

06.2018 2018-06-11

Article viewed: 1356 times

Download electronic version

Download Part 3 (pdf)

References:

Lokhmutov, N. D. Prospects for the development of 3D printing in construction / N. D. Lokhmutov, D. V. Kulichkov, V. V. Ermolaeva. - Text: direct // Young scientist. - 2018. - No. 23 (209). — S. 177-179. — URL: https://moluch.ru/archive/209/51318/ (date of access: 05.11.2022).

This article is devoted to the prospects for the development of 3D printing in Russia as a manufacturing element of the construction industry. The level of development of construction 3D printing in Russia and foreign countries is shown. Examples of the use of construction 3D printers in Russia and other countries are considered.

Keywords: 3D printing, construction 3D printer.

Development 3 D -Print

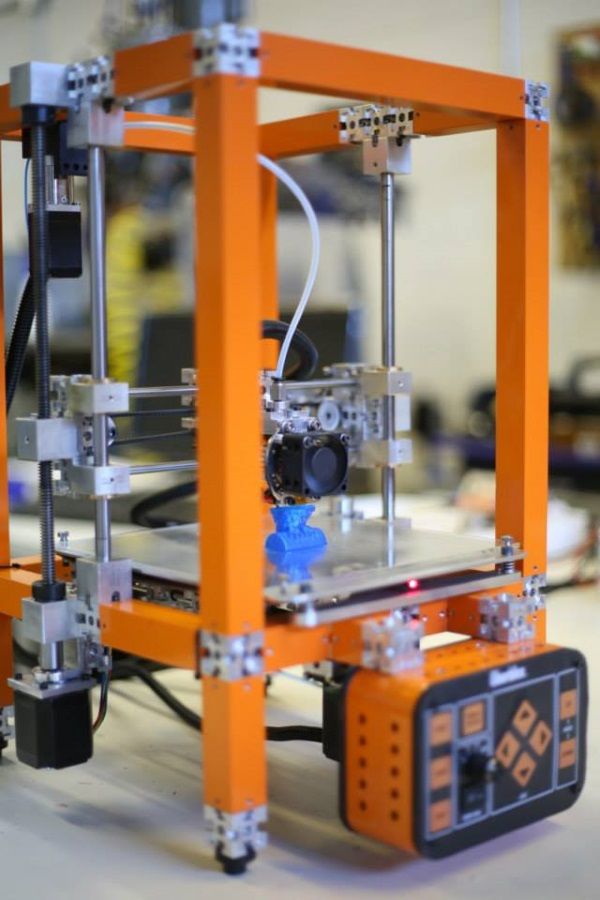

3D printing is done in several ways, using different materials, but each of the methods uses the technology of creating a layered solid object. 3D printing was invented by American researcher Chuck Hull. In 1986, he showed people his invention, to which he gave the name "installation for stereolithography." But over the years, Scott Crump invented the technology that powers all low-consumption 3D printers today. The technology was called FDM (Fusible Material Decomposition Modeling). In 2008, all 3D printers continued to use only ABS plastic as the main material. But Objet Geometries Ltd introduced a multi-material printer that same year. Today, the number of materials used in 3D printing has already exceeded 100, with biomaterials and concrete being the most interesting among new materials.

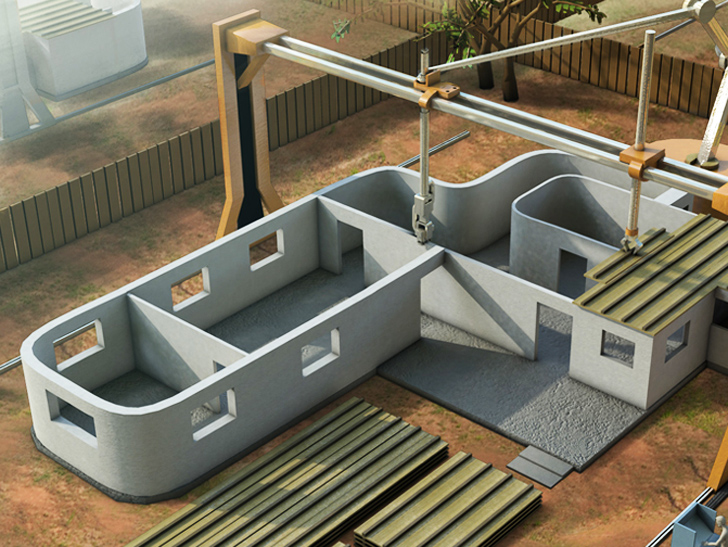

3 D - printing in construction

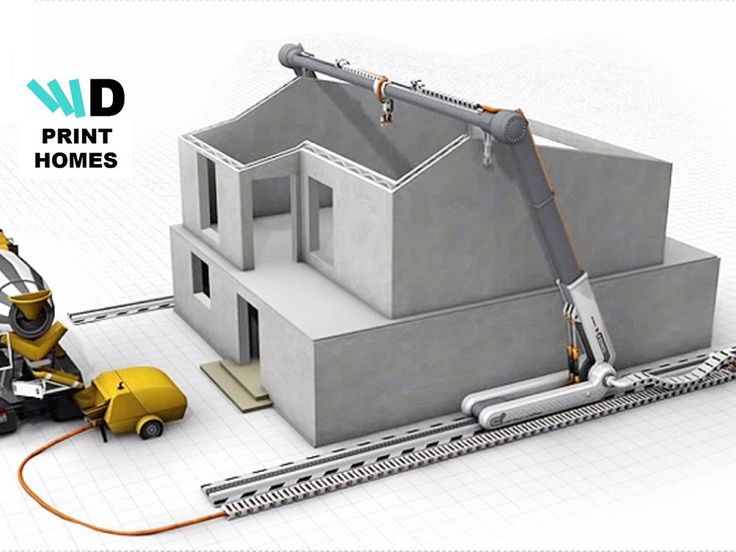

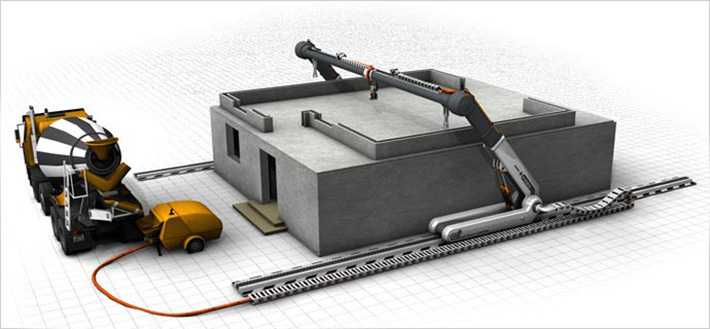

In 2014, active construction of buildings began using a 3D printer, concrete was used as the main material. In the same year, the Chinese company WinSun planned to build ten 3D printed houses, and they planned to build them in a day, subsequently they built another five-story house and a mansion. At the university with a technical direction, which is located in Eindhoven, in early 2015, work began on the creation of a 3D printer for making houses. During this time, the team made a small number of projects using a 3d printer, for example, bridges, small pavilions and, most importantly, began designing residential buildings. The buildings built in Eindhoven will have an unusual shape that can only be made with 3D printing. The partners of the university are working hard to make a design of high quality and reliability, which brings innovation to the usual design of houses in the Netherlands. The first tenants will be able to move into their new 3D-printed one-story houses in early 2019year, in the future it is planned to build multi-storey buildings. The details of the first houses will be made on the university's own 3D printer, the next goal of the engineers is to gradually transfer production to the construction site. The final house will be 3D printed directly on the construction site. Also in other countries, the use of this technology in construction has begun. As an example, New York City architects are using 3D printing to restore the look of historic buildings. The motivation for the EDG project was the desire to restore the facade design of a historic house on Fifth Avenue in New York City that was due to be demolished. The architects say that the classical ornaments on the facades are too difficult or even impossible to reproduce at the present time - which is why teams around the world do not often turn to the restoration of the remaining historical examples. A new technique using 3D printing makes it possible to create and embed elements of a facade ornament at a very low cost.

The first tenants will be able to move into their new 3D-printed one-story houses in early 2019year, in the future it is planned to build multi-storey buildings. The details of the first houses will be made on the university's own 3D printer, the next goal of the engineers is to gradually transfer production to the construction site. The final house will be 3D printed directly on the construction site. Also in other countries, the use of this technology in construction has begun. As an example, New York City architects are using 3D printing to restore the look of historic buildings. The motivation for the EDG project was the desire to restore the facade design of a historic house on Fifth Avenue in New York City that was due to be demolished. The architects say that the classical ornaments on the facades are too difficult or even impossible to reproduce at the present time - which is why teams around the world do not often turn to the restoration of the remaining historical examples. A new technique using 3D printing makes it possible to create and embed elements of a facade ornament at a very low cost. EDG hopes that the development can be applied to other cities and countries around the world. The technology brings back the feeling of “handmade” production and also democratizes the design process, making it accessible to all industries.

EDG hopes that the development can be applied to other cities and countries around the world. The technology brings back the feeling of “handmade” production and also democratizes the design process, making it accessible to all industries.

Development 3 D - print in Russia

In Russia in 2015, within the framework of the Machine Tool Building exhibition (Crocus-Expo), CJSC SPETSAVIA presented Russian developments and industrial samples of construction 3D printers. Less than two years later, in February 2017, a completely 3D-printed house was created in Stupino near Moscow. It was erected right on the construction site. And quite quickly, construction technology using 3D printing reached the regions. At the end of May 2018, Yaroslavl engineers made a diagnosis of the first construction 3D printer in Bulgaria. AMT-SPETSAVIA specialists demonstrated how to handle the equipment to the personnel of the purchasing company. In addition to managing the printer, the training program included the formation of G-codes, the selection of recipes from local materials and the preparation of mixtures for printing, routine maintenance of equipment, and test printing.

In addition to managing the printer, the training program included the formation of G-codes, the selection of recipes from local materials and the preparation of mixtures for printing, routine maintenance of equipment, and test printing.

As a result, a local construction company received an AMT S-6044 Long construction printer with a working field of 8x8 meters. The printer can print with standard cement based formulations M 300-500. The print speed is about 10 square meters. m / h in terms of a single-chamber wall.

Rice. one.

Also, AMT-SPETSAVIA 3D printers are already operating in Denmark, Kazakhstan, Moldova, and Uzbekistan. To date, the most famous project of the company is the 3D printing of a residential building in the Yaroslavl region.

3 D - printing on large objects

In the European organization for nuclear research CERN, 3D printing technologies are being introduced into the development of new materials and parts - since 2014, elements of the Large Hadron Collider have been produced using SLA technology using a 3D printer of their own design. Now CERN experts are exploring ways to 3D print metal, engineers are especially interested in magnetic superconductors and parts for working with radio frequencies.

Now CERN experts are exploring ways to 3D print metal, engineers are especially interested in magnetic superconductors and parts for working with radio frequencies.

Simufact Additive will partner with CERN to develop selective laser melting (SLM) 3D printing technologies. The Simufact team will provide CERN researchers with computer simulations to predict the results of 3D printing, enabling more efficient and cost-effective use of expensive parts. The Simufact Additive Platform is a digital tool integrated with the Materialize Magics software and has been on the market for over a year. The simulation is used by more than 60 customers, including the German manufacturer of precision components Toolcraft.

The value of Simufact simulations for engineers at CERN is obvious - predicting the results of 3D printing allows you to get perfect parts from expensive materials the first time. In addition to 3D printing, the Simufact Additive platform calculates the results of heat treatment, removal of support materials and the print platform, as well as other methods of processing metal parts.

Conclusion

3D printing has a wide range of applications in our lives. 3D printing can, if not solve, then help solve many global problems. The development of a building project of any complexity and its construction will take several times less time, and this technology will also allow in the future to build structures on other planets, in particular on Mars. For Russia, the technology of erecting buildings using a 3D printer is quite relevant. From February 1, 2017, all Russian citizens can apply for a “Far Eastern hectare”. With the help of 3D printing technology, it is possible to build a whole village in the Far East in a week. This technology, of course, has its drawbacks, including the high cost of equipment, but if we rationalize this industry a little, our future undoubtedly belongs to it. This article highlights only a part of the possibilities of 3D printing, it plays an equally important role in medicine and many other areas.

Literature:

- http://www.

3dpulse.ru

3dpulse.ru - https://en.wikipedia.org

Basic terms (automatically generated) : CERN, Russia, EDG, ABS, FDM, SLA, SLM, New York, main material, Eindhoven.

Keywords

3D printing, construction 3D printer3D printing, construction 3D printer

Similar articles

3D printer is the technology of the future | Journal article...

Core technologies ( SLA , SLS, DLP, EBM, HPM). Printing on 3D printers can be done in different ways, in

1) SLA - technology - laser stereolithography. Fusion Printing Technology ( FDM ) was designed by S. Scott...

Problems and prospects of creating the World Financial Center

. ..

.. New - York .

Basic terms (automatically generated): Russia , global financial center , Moscow, GFCI, financial market, government RF , creation, Russian Federation, international financial center , Central Bank.

Analysis of the change in the metaphorical image

of Russia ...The material of research are articles about relations between Russia and the world since July 2015 in English and American newspapers

the image of V.V. president of Russia - main threat in...

On- and off-trade channels as

main communication channels... Glenny M. Dark Market : cyberthieves, cybercops, and you, New York , NY: Alfred A. Knopf, 2011.

Knopf, 2011.

Basic terms (automatically generated tobacco products, healthy lifestyle): , Russia , tobacco consumption, cigarette, human health, harm of smoking.

Desktop 3D Printer | Article in the journal "Young scientist"

1) SLA - technology - laser stereolithography.

Basic terms (automatically generated): FDM , original material , ABS , SLS, PLA, PET, PCL, HDPE, DMLS, laser radiation.

The heyday of social advertising on the example of the United States | Article in the collection...

The main economic role of advertising in such an environment is to create artificial needs, to expand the market through

In a strip institutional ad in the New - York Times, the Chamber of Commerce appealed to Americans to "Save America!"

Evaluation of the economic efficiency of the implementation of cloud.

..

.. In the banking sector Russia , only in the last five years began to show interest in the cloud ABS .

- cost of development and implementation of the project; - involvement of external consultants; - initial purchases main SW

The role of northern-eastern trade route in the relationships of the...

Basic terms (automatically generated): XVII-XVIII, Russia , Moscow state, Russian geography, XII-XVII, XVI-XVIII, XVI centuries

XVII-XVIII centuries. and " Russia and Mongolia". Undoubtedly, the most valuable materials and conclusions are contained in the works of the well-known ...

Analysis of the system of production and consumption of clothing in fashion...

The Internet, as the main means of obtaining information from a modern person personifies

For example, New - the York SOLS company, which is one of the first to use three-dimensional

The current state of the baking industry Russia.

Similar articles

3D printer is the technology of the future | Journal article...

Basic technologies ( SLA , SLS, DLP, EBM, HPM). Printing on 3D printers can be done in different ways, in

1) SLA - technology - laser stereolithography. Fused deposition printing technology ( FDM ) was developed by S. Scott...

Problems and prospects of creating the World Financial Center

...New - York .

Basic terms (automatically generated): Russia , global financial center , Moscow, GFCI, financial market, government RF , creation, Russian Federation, international financial center , Central Bank.

Analysis of the change in the metaphorical image

of Russia . ..

.. Research material are articles on relationships Russia and the world since July 2015 in English and American newspapers

the image of VV Putin as President RF is still the most striking and controversial; president of Russia - main threat in...

On- and off-trade channels as

main communication channels ...Glenny M. Dark Market : cyberthieves, cybercops, and you, New York , NY: Alfred A. Knopf, 2011.

Basic terms (automatically generated): tobacco products, healthy lifestyle, Russia , tobacco consumption, cigarette, human health, harm of smoking.

Desktop 3D Printer | Article in the journal "Young scientist"

1) SLA - technology - laser stereolithography.

Basic terms (automatically generated): FDM , original material , ABS , SLS, PLA, PET, PCL, HDPE, DMLS, laser light.

The heyday of social advertising on the example of the United States | Article in the collection...

The main economic role of advertising in such an environment is to create artificial needs, to expand the market through

In a strip institutional advertisement in the New - York Times, the Chamber of Commerce appealed to Americans with the appeal: “Save, America! ".

Evaluation of the economic efficiency of the implementation of cloud...

In the banking sector Russia , only in the last five years began to show interest in the cloud ABS .

- cost of development and implementation of the project; - involvement of external consultants; - initial purchases basic software

The role of northern-eastern trade route in the relationships of the.