Rize 3d print

RIZE 3D closes its doors, replaced by ‘next chapter’ company Palitra

0Shares

Boston-based industrial polymer 3D printer manufacturer RIZE 3D has announced it has ceased operating.

A post on the company’s website says the time has come to “close that chapter” on RIZE 3D, with a new company, Palitra, established to offer support for existing customers.

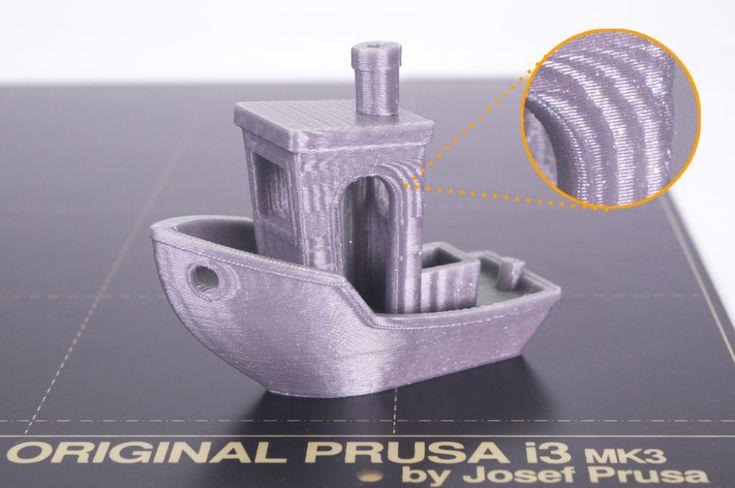

RIZE 2XC 3D printer. Photo via RIZE.Full-color 3D printing

RIZE was founded in 2014 by Eugene Giller, a previous employee of ZCorp which has since become 3D printer manufacturer 3D Systems. Having amassed extensive knowledge and experience within binder jetting, Giller set out to improve the powder handling aspect of the technology and improve the ease of post-processing.

Working with his team of engineers, Giller combined material jetting with FFF to develop RIZE’s Augmented Polymer Deposition (APD) process, which formed the basis of the firm’s RIZE One 3D printer, commercially introduced in 2017.

Designed around the motto of “zero post processing”, the RIZE One was capable of reducing turnaround time by 50 percent, cutting costs, and improving part strength. Supports on the 3D printed parts could be simply snapped off by hand, and the technology also enabled parts with color gradients, with space for full-color spectrum developments.

The RIZE One has previously been used by the US Army’s Armament Research, Development and Engineering Center (ARDEC) for the on-demand manufacturing of spare parts and tools, and by IRA Green Inc (IGI), a contract manufacturer of military insignia, to produce fixtures at lower costs. The firm’s technology reportedly saved IGI over $120,000 in production costs per year and “completely transformed” its production process.

The company went on to release its full-color 3D printer, the XRIZE, at the end of 2018, as well as what it claimed to be the first 3D printed Digitally Augmented Parts (DAP) to counter 3D printed piracy and counterfeits.

RIZE 3D closes its doors

The company’s social media channels have been quiet for several months, and the company has now broken its silence with the announcement that it has shut down. The statement on the firm’s website says:

“RIZE is no longer functioning as a company but don’t worry! Eugene Giller founded RIZE with one mission – to bring functional prototyping to the masses with advanced features like composite materials & full-color printing.

“Thanks to the incredible core team who worked tirelessly to create a technology ecosystem unlike any other filament 3D printer in the world, his vision became reality.

“While we are incredibly thankful for everything RIZE was able to accomplish, it was time to close that chapter to keep the initial vision alive. Welcome to the next chapter. Welcome to Palitra!”

The new company, Palitra, has been established to provide support to existing RIZE customers for the equipment they have purchased and to supply filaments previously provided by RIZE. The firm is currently “working on a new online store”, and in the meantime, customers can contact Palitra to order their filament.

The firm is currently “working on a new online store”, and in the meantime, customers can contact Palitra to order their filament.

Palitra’s website states the company is “just getting started”, and plans to serve existing RIZE customers with full-color 3D printing services and license its core technology to expand its reach.

RIZE 3D did not provide a reason for its closure in its statement. 3D Printing Industry has reached out to the company for comment, and we will keep our readers updated on Palitra’s future direction.

RIZE 3D’s closure follows the recent shut down of automotive OEM Local Motors, manufacturer of the partially 3D printed ‘Olli’ autonomous vehicle, and 3D printing service provider Voodoo Manufacturing, which succumbed to financial pressures from the Covid-19 pandemic midway through 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows RIZE 2XC 3D printer. Photo via RIZE.

Tags 3D Systems ARDEC Augmented Polymer Deposition Eugene Giller IRA Green Local Motors Olli Palitra Rize 3D Rize One Rize Xrize US Army Voodoo Manufacturing ZCorp zero post processing

Hayley Everett

Hayley is a Technology Journalist for 3DPI and has a background in B2B publications spanning manufacturing, tools and cycling. Writing news and features, she holds a keen interest in emerging technologies which are impacting the world we live in.

RIZE Ships the RIZE 7XC 3D Printer to Make Large Format Additive Manufacturing Easy, Durable and Efficient

CONCORD, Mass.--(BUSINESS WIRE)--RIZE, Inc. , an Additive Manufacturing 2.0 company bringing industrial 3D printing to all users and a World Economic Forum (WEF) 2020 Technology Pioneer, has shipped the RIZE 7XC large format 3D printer. When massive part size and industrial strength and other properties are needed for printing parts, jigs, tooling and fixtures, the RIZE 7XC delivers a time to part advantage, and helps manufacturers assure they have agile supply chains to sustain them in the new normal – safely, sustainably, and affordably. It is available immediately starting at $USD 19,995.

, an Additive Manufacturing 2.0 company bringing industrial 3D printing to all users and a World Economic Forum (WEF) 2020 Technology Pioneer, has shipped the RIZE 7XC large format 3D printer. When massive part size and industrial strength and other properties are needed for printing parts, jigs, tooling and fixtures, the RIZE 7XC delivers a time to part advantage, and helps manufacturers assure they have agile supply chains to sustain them in the new normal – safely, sustainably, and affordably. It is available immediately starting at $USD 19,995.

“Our customer, a major electronics manufacturer, used the RIZE 7XC to create large jigs called nests for their automotive electronics assembly processes – parts that need high strength and durability,” said Roberto Jacobus, director general at Industrias VIWA, a manufacturing and additive technology provider in Jalisco, Mexico and a pioneer in hybrid 3D printing and CNC machining solutions. Nests measured 32 cm x 28 cm, and were created using RIZIUM carbon fiber material. “Using the RIZE 7XC 3D printer, our customer built nests in just 2 or 3 hours that formerly took over a week to make with traditional machining processes. Since new jigs inevitably undergo design changes after testing, printing them on the 7XC significantly accelerates the introduction of new products and improvements in the customer’s manufacturing line.”

“Using the RIZE 7XC 3D printer, our customer built nests in just 2 or 3 hours that formerly took over a week to make with traditional machining processes. Since new jigs inevitably undergo design changes after testing, printing them on the 7XC significantly accelerates the introduction of new products and improvements in the customer’s manufacturing line.”

“The nests already have outlasted the previous jigs that were made in an ABS material on another 3D printer,” Jacobus continued. “Our customer really appreciated how easy and fast materials can be swapped, pointing out the printer’s step by step voice guidance.”

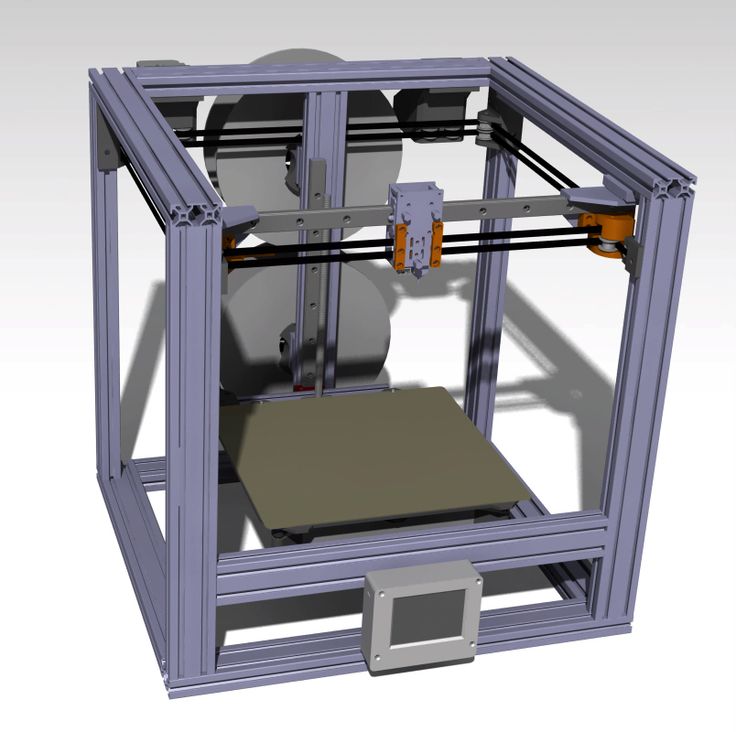

With a massive build size of up to 370mm x 390mm x 450mm, the RIZE 7XC was developed jointly with Sindoh Co, Ltd. to leverage Sindoh’s 7X large-format dual-nozzle 3D printing platform and supported materials, along with RIZE’s innovative RIZIUM composite materials including RIZIUM Glass Fiber and RIZIUM Carbon Fiber. By enabling the rapid creation of large parts and complex geometries on demand, far faster and at lower cost than molding, milling and casting, the RIZE 7XC provides teams with an affordable way to generate parts with high tensile strength and thermal dimensional stability, along with chemical and moisture resistance.

As the fourth member of RIZE’s family of safe, affordable 3D printers, the RIZE 7XC was developed with RIZE’s hallmark health and safety commitment, for printing anywhere without ventilation, yet with a Z-resolution of 50 microns that enables demanding geometries and superior surface finishes. Its composite-enhanced dual extruders enable a Z-resolution of 50 microns suitable for demanding geometries and a superior surface finish. Features such as active auto-leveling and internal insulation help assure superior mechanical properties, while RIZE’s commitment to sustainability means minimal post-processing, with supports that peel away quickly and easily without chemicals or tools.

The RIZE 7XC is the second deliverable of the RIZIUM Alliance, where other 3D printing industry partners can implement safer, sustainable, recyclable 3D printing on a variety of platforms, such as the RIZE 7XC and the smaller format, color-compatible RIZE 2XC.

“Sindoh is delighted to partner with RIZE to apply the company’s innovative materials and technologies to our proven 7X large-format 3D printing platform,” said Osung Kwon, COO of Sindoh Co. , Ltd. “Organizations are ready to apply additive manufacturing techniques when small runs require strong, highly durable parts. Thanks to our cooperative R&D efforts, the new RIZE 7XC makes large-scale additive manufacturing even simpler, more sustainable and cost-effective.”

, Ltd. “Organizations are ready to apply additive manufacturing techniques when small runs require strong, highly durable parts. Thanks to our cooperative R&D efforts, the new RIZE 7XC makes large-scale additive manufacturing even simpler, more sustainable and cost-effective.”

“The RIZE 7XC makes additive manufacturing capability rugged enough for industrial 3D printing needs, yet safe and affordable, too,” said Andy Kalambi, CEO of RIZE. “Finally manufacturers can apply the promise of additive manufacturing to creating agile and distributed supply chains where the ability to generate a needed part, tool, jig or fixture takes a fraction of the time of traditional processes.”

For more information on RIZE’s family of products, visit www.rize3d.com.

About Sindoh

Sindoh is a 3D printing market leader in Korea and is now expanding to the global market. Founded in 1960, Sindoh’s technology and solutions provide sustainable and reliable hardware products in term of the quality and efficiency. Headquartered in Korea, with a broad range of 3D printer products will empower industrial standards in 3D printing industry. For additional information, please visit: http://3dprinter.sindoh.com

Headquartered in Korea, with a broad range of 3D printer products will empower industrial standards in 3D printing industry. For additional information, please visit: http://3dprinter.sindoh.com

About RIZE

RIZE Inc. is an Additive Manufacturing 2.0 company based in Concord MA focused on enabling sustainable and inclusive innovation with safe, affordable, and full color 3D printing. RIZE is the only 3D printing firm named to the World Economic Forum 2020 Technology Pioneers list and is known for its commitment to sustainable practices in 3D printing. It is also the first 3D printing company in the world to receive the UL GREENGUARD certification for health and safety for its printers, materials and inks.

RIZE’s unique patented 3D printing technology enables production of full color, functional parts in homes/offices/factories/point-of-care settings using safe, non-toxic materials that are engineered for strength and durability. Applications include full color functional prototypes, medical models, customized tools and fixtures and urban lifestyle items.

RIZE designs, manufactures, and distributes complete additive manufacturing systems which include hardware, software and composite polymer materials and functional inks. RIZE serves three customer segments – academia, life sciences and industrial manufacturing – with marquee customers including NASA, Festo, Rutgers University, Virginia Tech, American Axles, Zimmer Biomet, and Merck. www.rize3d.com.

90,000 RIZ offers a desktop 3D printer for printing with compositional filamentsNews

Subscribe to the author

Subscribe

I do not want

1

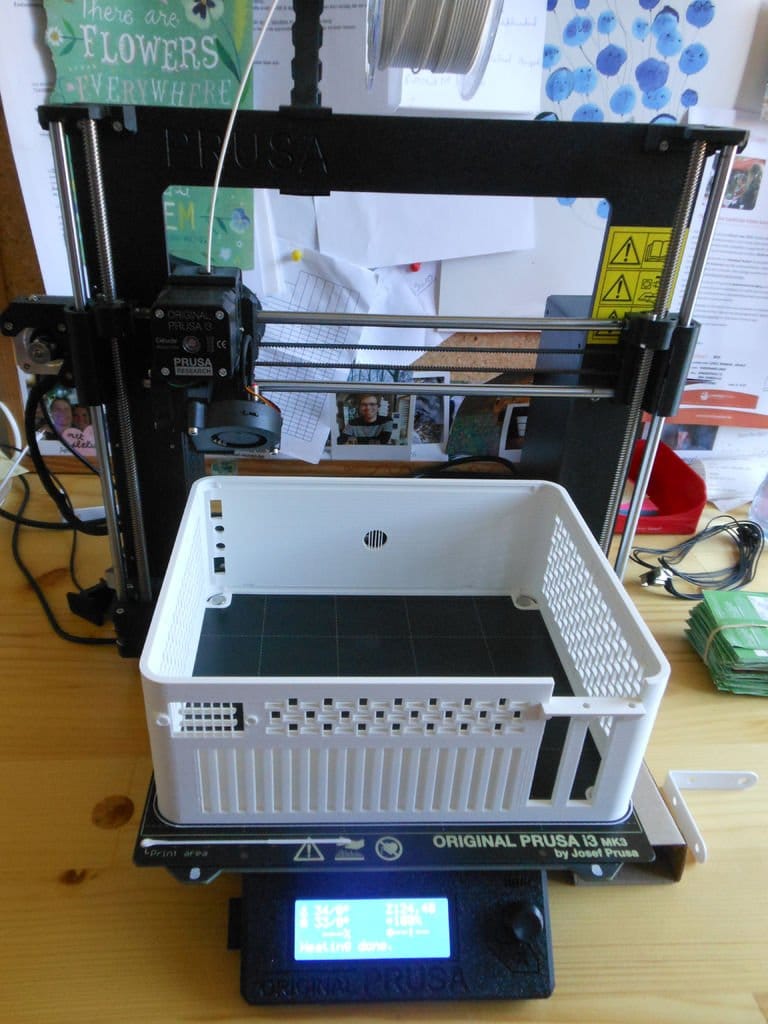

Boston company RIZE announced the RIZE 2XC desktop 3D printer, optimized for the 3D-printing compositional compositional compositional compositions materials with carbon and fiberglass filler.

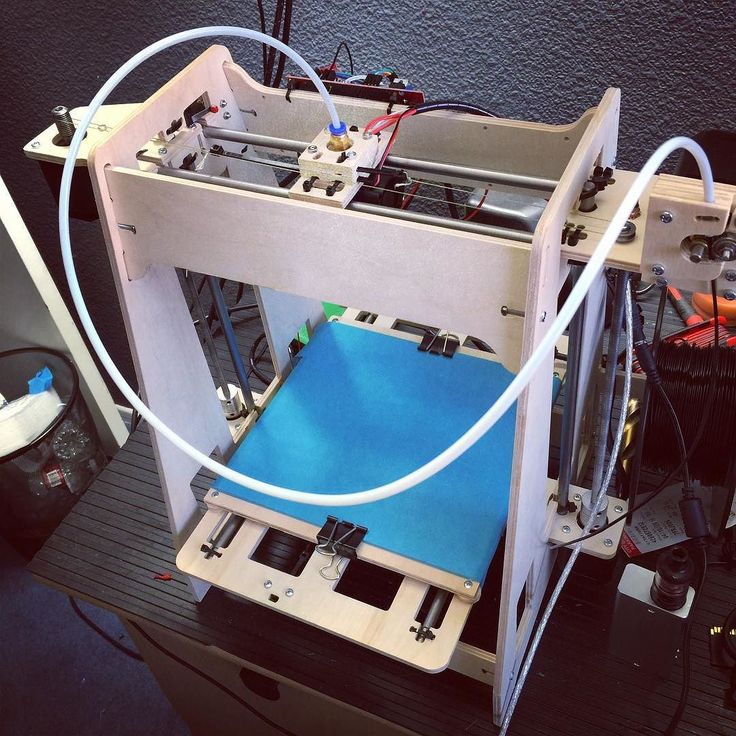

The Rize 2XC 3D printer is a modification of someone else's development, namely the desktop dual-extruder additive system manufactured by the South Korean company Sindoh. The system is equipped with two independent X-axis extruders and wear-resistant nozzles, which are necessary for working with highly abrasive composite materials.

The system is equipped with two independent X-axis extruders and wear-resistant nozzles, which are necessary for working with highly abrasive composite materials.

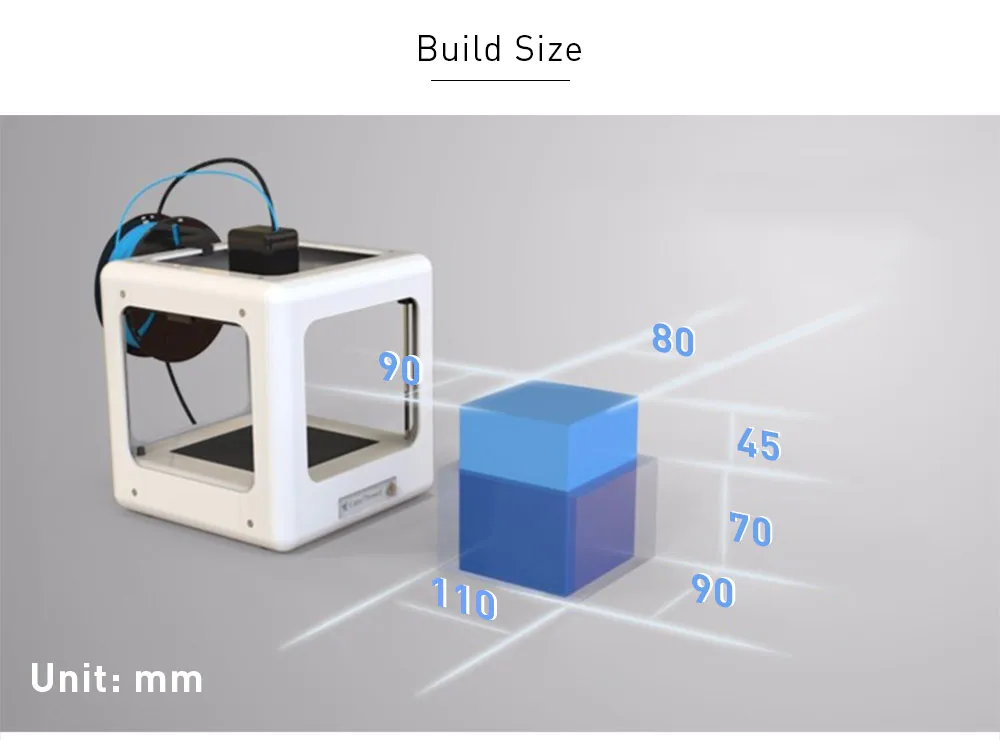

The size of the construction area is 228x200x300 mm, the thickness of the applied layers is adjustable within 50-400 microns. Printing is carried out on a flexible removable table, which facilitates the separation of finished products. The 3D printer is equipped with a wireless communication module (Wi-Fi) in addition to USB and Ethernet, as well as a voice guidance system. The device is equipped with an LED backlight and a camera for remote monitoring and control of workflows using the 3DWOX mobile application.

Rize offers two composite engineering filaments filled with carbon and fiberglass. The fiberglass variant is not yet on sale, but is expected soon. The second extruder can be used to print easily detachable support structures with the special Rizium Support filament. The company says the proprietary materials are designed with a focus on reducing VOC emissions and are safe for office use.

The fiberglass-filled filament will also be compatible with XRize's proprietary 3D printers: these systems combine layer-by-layer fusing of a rod with inkjet 3D printing, which is used to apply a separating ink that facilitates the removal of support structures and enables full color 3D printing.

Rize 2XC differs from more advanced branded systems by increased affordability: if basic Rize One 3D printers and color XRize are priced at $26,000 and $55,000, respectively, then Rize 2XC can be reserved for $3 995. Additional information is available on the official website at this link.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

Article comments

More interesting articles

eight

Follow author

Follow

Don't want to

The F2 Gigantry system will enable manufacturing companies, in particular aerospace companies, to. ..

..

Read more

6

Subscribe to the author

Subscribe

Don't want to

The Salyut production complex of the United Engine Corporation is planning the next...

Read more

sarkazm

Loading

04/01/2016

39838

68

Subscribe to the author

Subscribe

Don't want

News from the world of printing in a short line

FDplast announced the release of a free...

Read more

Review of the new hybrid 3D printer Rize One

Fast and efficient | Industrial grade 3D printer | Safe in the office and at work | Specifications | Materials | Software

In modern devices, parts made of several materials with different mechanical, electrical and chemical properties are increasingly used. APD technology, developed by Boston-based startup Rize, connects the two to create unparalleled, innovative products for consumers.

APD technology, developed by Boston-based startup Rize, connects the two to create unparalleled, innovative products for consumers.

The Rize™ One is a revolutionary 3D printer that for the first time combines two separate technologies, FDM and piezo inkjet, in one device. Rize One delivers products with maximum isotropic strength – twice as strong as ABSplus, polycarbonate and carbon fiber reinforced plastics (Z-axis). Objects printed by Rize 3D printer are waterproof, have a high heat distortion temperature, are sterilizable, and are resistant to acids, acetone, alcohol, etc.

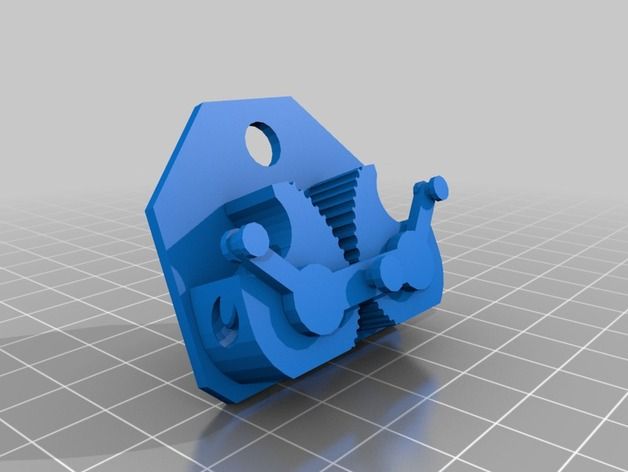

This breakthrough was made possible by a patented technology called Augmented Polymer Deposition (APD). It enables multi-material 3D printing with minimal post-processing, as well as the use of safe, non-toxic and recyclable materials. APD technology is based on the simultaneous extrusion of a proprietary composition of engineering and medical thermoplastics and the inkjet spraying of functional compounds (“ink”) on those areas where it is necessary to change the properties of the thermoplastic at the voxel level. This allows Rize Release One ink to be sprayed between the backing material and the product for quick, easy, clean and safe manual removal of support immediately after printing is complete, as well as graphics ink to apply text and images to the inside and outside surfaces of parts.

APD technology is based on the simultaneous extrusion of a proprietary composition of engineering and medical thermoplastics and the inkjet spraying of functional compounds (“ink”) on those areas where it is necessary to change the properties of the thermoplastic at the voxel level. This allows Rize Release One ink to be sprayed between the backing material and the product for quick, easy, clean and safe manual removal of support immediately after printing is complete, as well as graphics ink to apply text and images to the inside and outside surfaces of parts.

Rize One combines the strength, safety and speed of 3D printing to produce replacement parts, special tools, fixtures and templates, and finished products at a low cost and with consistent quality. All this provides:

- faster time to market;

- cost reduction;

- production optimization;

- reduction of manufacturing defects;

- increase in productivity and accuracy of products;

- improvement of design solutions.

Boston startup Rize team with their revolutionary development

Fast and efficient

- The only 3D printer with virtually no post-processing required. Minimizes the time-consuming operation of removing support and reduces the time to receive the finished product by up to 2 times, compared with other systems. The

- Rize One pays for itself in months with reduced post-processing, material and equipment costs.

- Unique software reduces production time and allows unoptimized files to be printed automatically.

Industrial grade 3D printer

- Provides sealed, isotropic products that are stronger than polycarbonate and twice as strong as ABSplus plastic.

- Products have a high heat distortion temperature and are suitable for sterilization.

- Products have high chemical resistance.

- Allows you to print multiple items at the same time.

- Ability to 3D print high-definition text and images on products.

Safe in the office and at work

- Unlike other desktop 3D printers, the Rize One is completely safe in the office with no harmful particle emissions or harmful or messy post-processing.

- All materials used in the Rize One 3D printing process are safe and recyclable.

- The printer is compact enough to be installed in an office and does not require special operating conditions or special disposal procedures.

Specifications

- Max. product dimensions: 300 mm x 200 mm x 150 mm

- Layer thickness: 0.25 mm (250 µm)

- Workstation: 64-bit Windows 7, 8, or 10; x64 9 processor0110

- Network connection: Ethernet 10/100 or USB stick

- Dimensions, HxWxD: 543 mm x 915 mm x 644 mm

- Weight: 61 kg

- Power Requirements: Universal Power Supply 100-240 VAC, 750 W

- Air temperature: 15-30 C

- 20% - 60% r.h. humidity

- Compliance: FCC, RohS, NRTL

- Special site requirements: None

Materials

First of all, unlike other 3D printing technologies, all materials used in APD technology are completely safe for use in the office without special ventilation, gloves and disposal equipment and are environmentally friendly.

Rizium One

Details printed on Rize One are extremely durable

A self-developed composition of engineering and medical thermoplastics, which allows to obtain sealed isotropic products that are stronger than polycarbonate counterparts, products reinforced with carbon fiber or nylon, and twice as strong as ABSplus products. Rizium One products have a high heat distortion temperature and are suitable for sterilization. They also have high chemical resistance, including alcohol, acetone and acids.

Release One Ink

Release One's repulsive ink sprays between the product and the support and loosens the bond between them, making support removal easier and faster than other 3D printing technologies.

Graphic ink

Allows you to put text and images on products.

Software

The process of preparing CAD files for 3D printing can be complex, tedious and time-consuming. Therefore, many engineers purchase special file optimization software in addition to CAD. But even such programs require additional time and experience to get files ready for 3D printing.

Therefore, many engineers purchase special file optimization software in addition to CAD. But even such programs require additional time and experience to get files ready for 3D printing.

This problem is well known to co-founder and software engineer Leonid Raiz, creator of Revit and Pro/Engineer, the pioneering 3D CAD system that formed the basis of the very first 3D printers. Driven by the desire for hassle-free 3D printing, the Rize development team, led by Leonid, created a software that simply clicks “Print” to build a product.

The sophisticated and intelligent Rize software automatically detects and corrects imperfections in imported 3D files, such as incomplete surfaces or surface mismatches. With Rize's slicer's ability to handle flawed 3D files, you can 3D print them with unprecedented speed and ease. Rize helps you send files created with the software package you normally use to your 3D printer.

It can be argued that by creating this software, the Rize team has significantly relaxed the limitations still inherent in many 3D design systems.

/cdn0.vox-cdn.com/uploads/chorus_asset/file/8170811/passivdom_autonomous_house_designboom_03_16_2017_818_001_818x544.jpg)