3D print hub

3D Printing Service UK | Instant Quotes Online

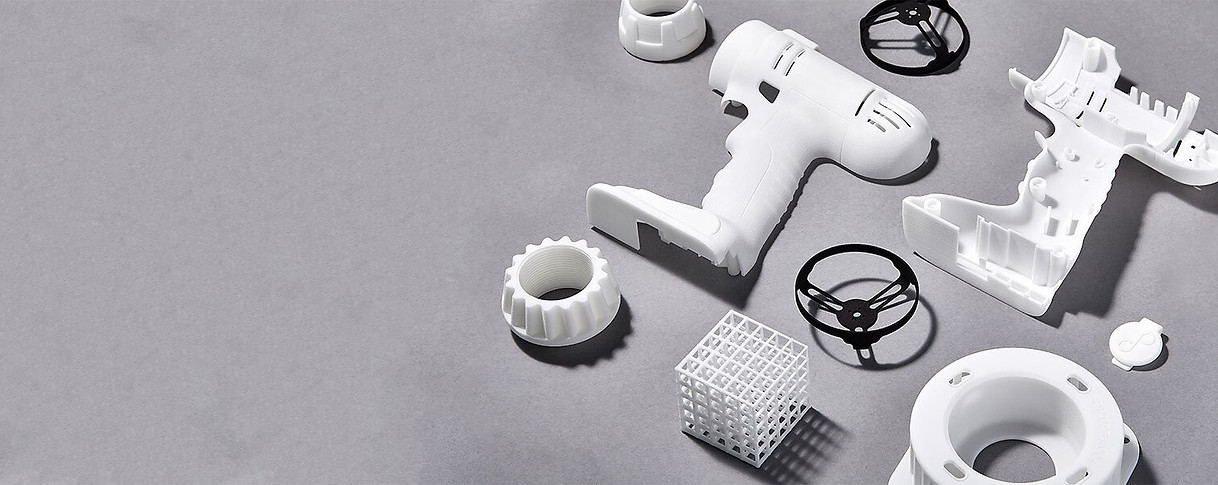

Our 3D printing capabilities

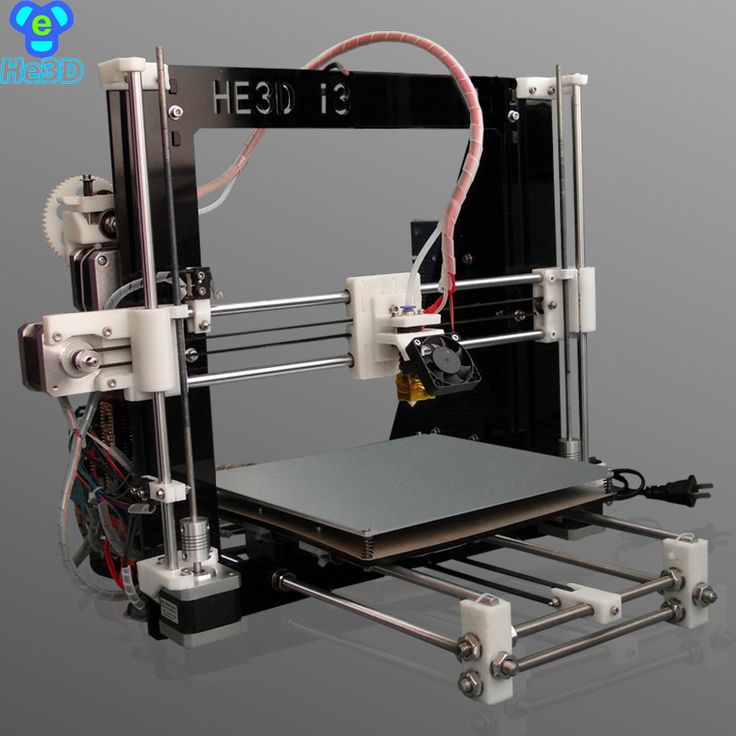

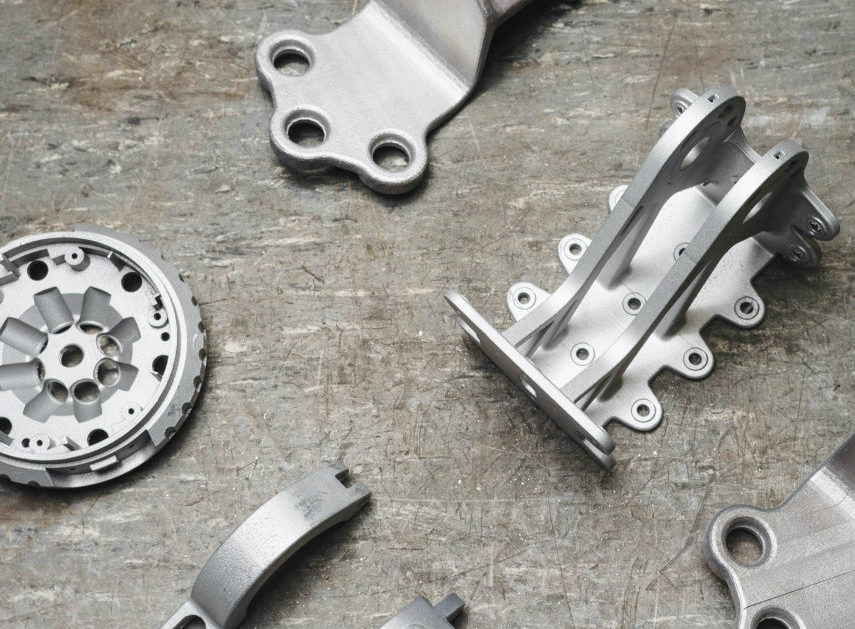

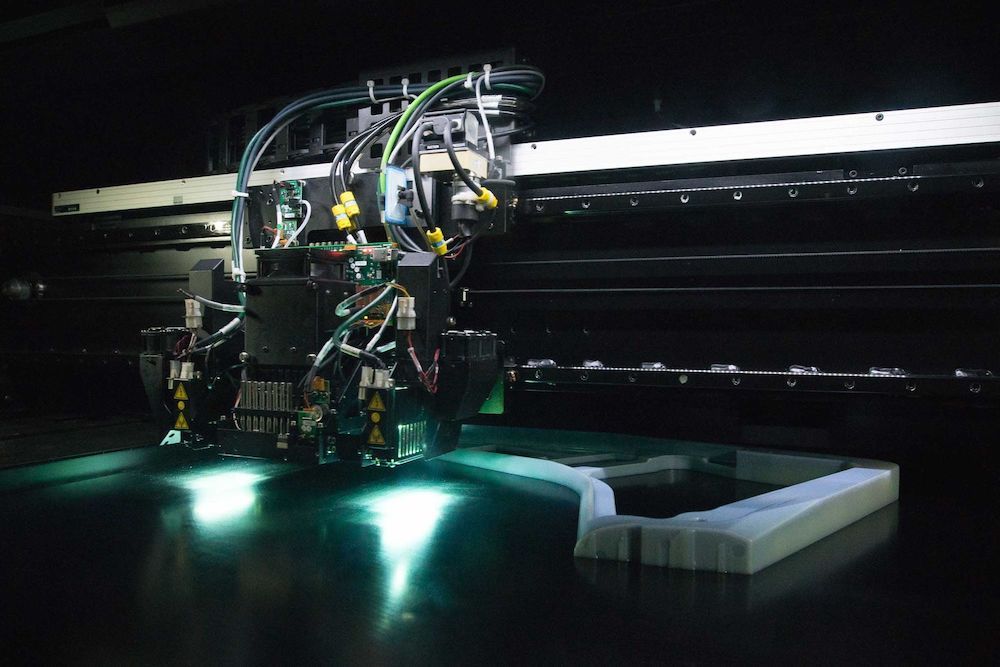

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

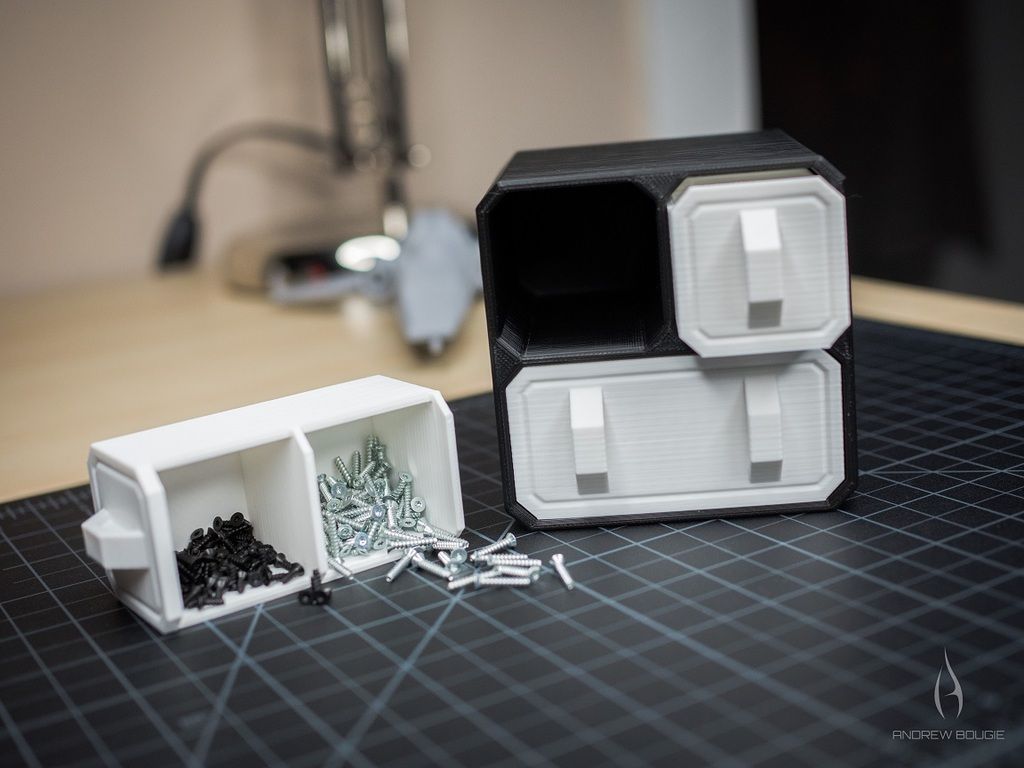

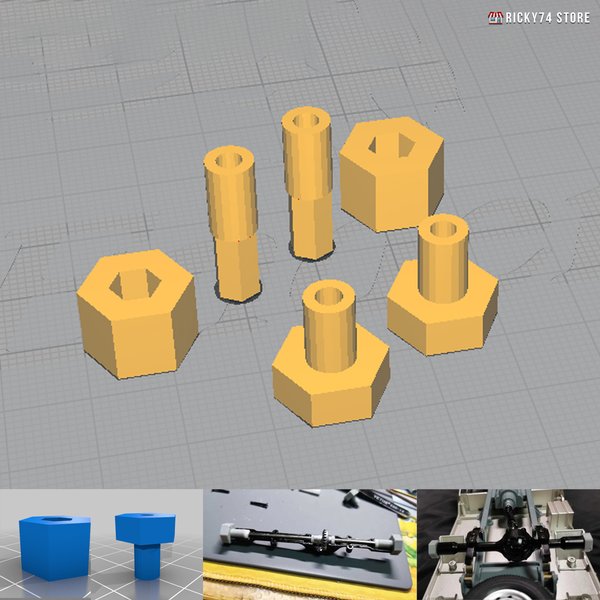

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. |

| Industry | Automotive |

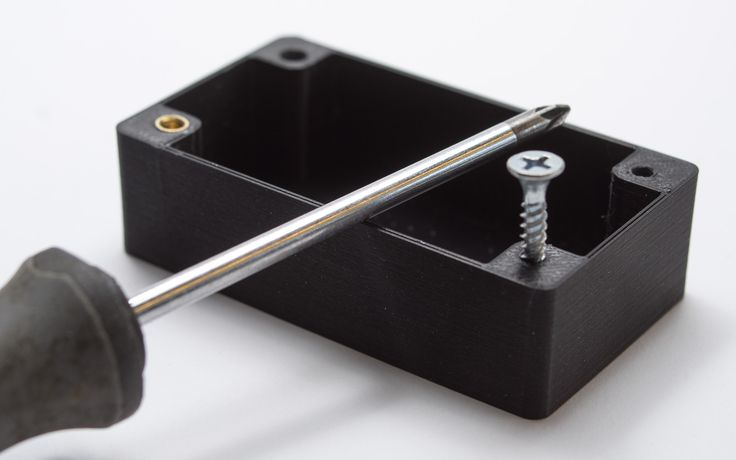

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

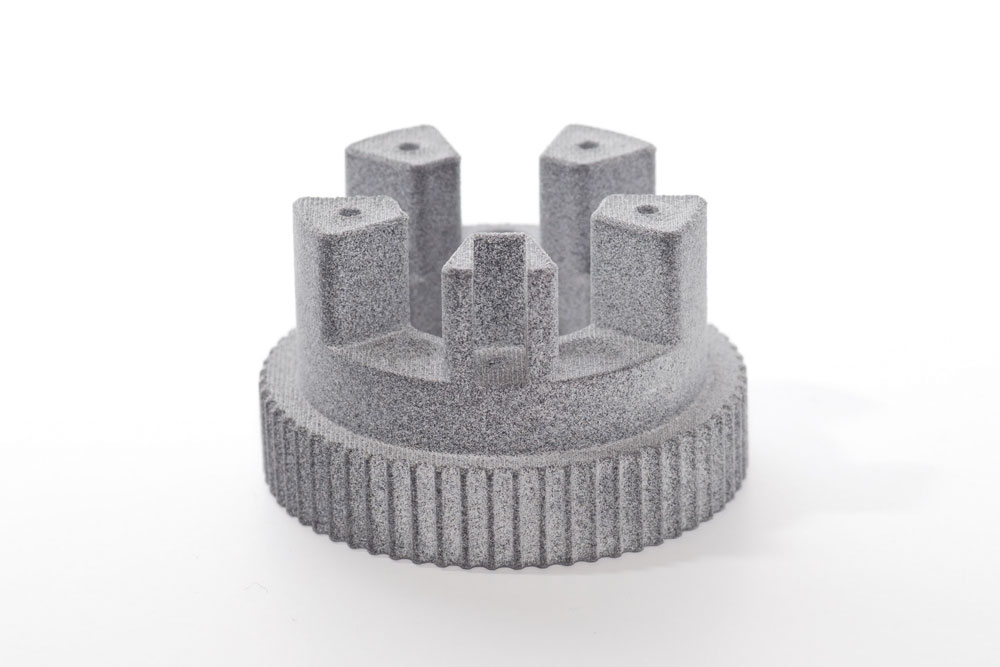

HP PA 12

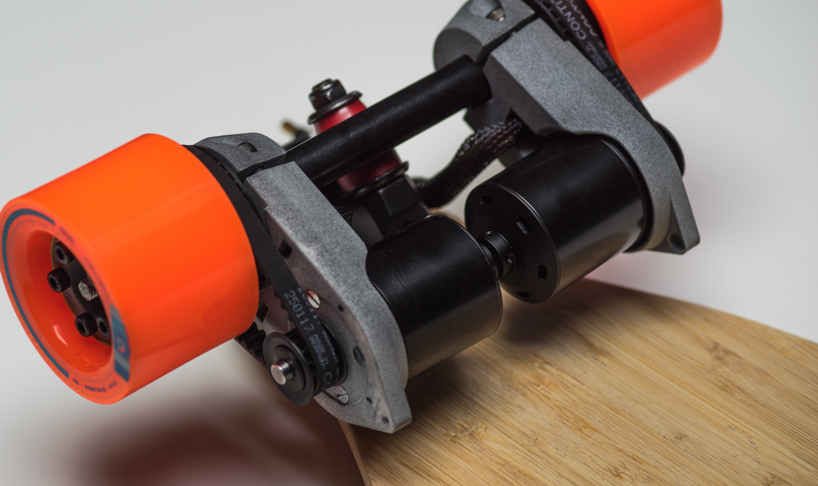

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

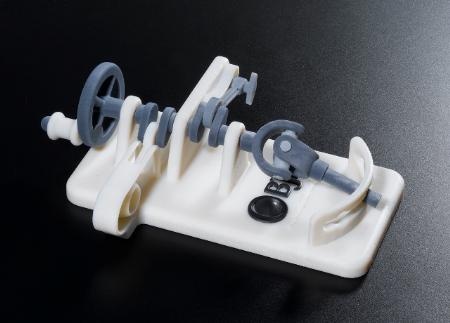

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

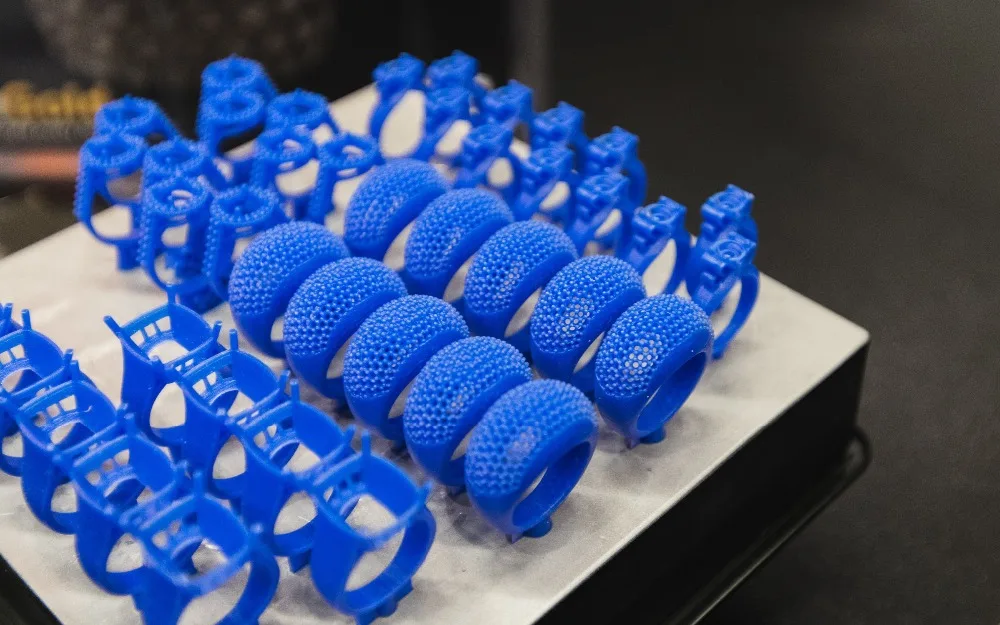

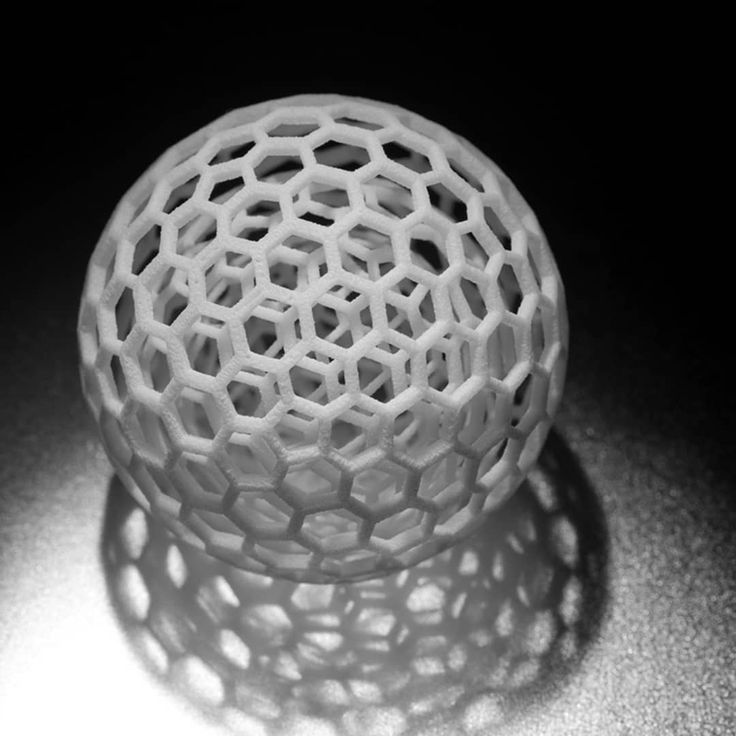

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

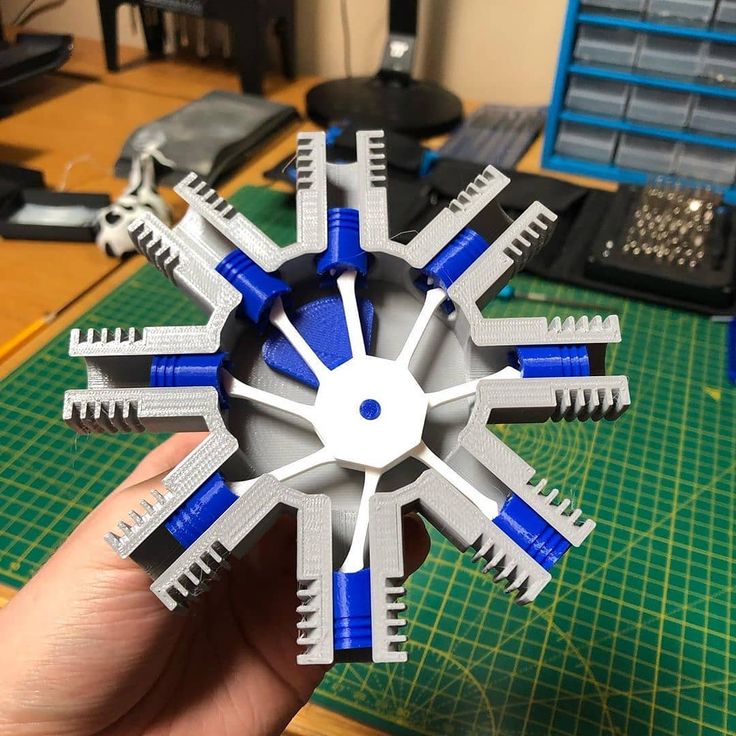

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc.

.

. -

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 129 customers are satisfied with our 3D printing service.

“Couldn't be happier, service and quality is brilliant.”

“Absolutely spot on! Will be using this again! ”

“This is my second order from this company and everything could not have been easier, communications were fast and the finished product was spot on. Will not hesitate to use them again.”

“Really good quality print Item arrived the day that was estimated Quick response time and really helpful/flexible”

“Speedy service, valuable advice. Excellent communication. highly recommended!”

“On time, design as expected. Many thanks!”

“Great help and solved issues fast and effect. A+”

“Very responsive and helpful, would highly recommend.”

“Great print and very speedy production and delivery.”

“Very helpful and friendly service would happily use this service provider again.”

“Thank you for the super quick service and response. ”

“The piece was perfect, exactly as I expected”

“Really quick service and I'm really pleased with the result. ”

”

“Excellent service and delivery even down to the care taken with the packaging. This was the first time I have used Hubs and I would highly recommend.”

“Good printer, well packaged, quick delivery. Recommended.”

“Thanks for an excellent service Felix! Very happy :)”

“Excellent service & communication. Parts quality even better than expected as well :) Couldn't be happier with the service I received :)”

“Brilliant . Many thanks Will share this with the Pebble community”

“Spot on service, really happy with the results”

“Again fantastic service and brilliant communication ”

“Very good experience. Excellent service, would certainly use again. very pleased”

“Great service, print quality and communication. Will be ordering again. ”

“The print was great quality and it shipped quickly, thanks!”

“Quality of the parts was great, good communication and prompt service. Would definitely use again for any future needs”

“I have no prior experience with 3D printed objects, but as far as I can tell this is a very clean print. The plastic is nice and flexible so it's not likely to snap under general use.”

The plastic is nice and flexible so it's not likely to snap under general use.”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near UK

Stoke Derby Birmingham

Manchester Sheffield Telford

Coventry Nottingham Bradford

Leeds

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

Best 3D Hubs alternatives for custom 3D printing

3D hubs is probably the first name that most people consider when they think of online 3D printing services. Indeed, 3D hubs has evolved over time into a professional online manufacturing service that includes CNC Machining, 3D printing, plastic mold injection and myriad other services offered by a global network of engineers associated with 3D hubs. But 3D hubs didn’t start out with a laser-focus on pro-manufacturing services.

Indeed, 3D hubs has evolved over time into a professional online manufacturing service that includes CNC Machining, 3D printing, plastic mold injection and myriad other services offered by a global network of engineers associated with 3D hubs. But 3D hubs didn’t start out with a laser-focus on pro-manufacturing services.

- In this article, we will be taking a look at some of the best alternative online 3D printing services available for custom 3D printing jobs.

- We’ll also consider what makes these online 3D printing services tempting for the average user.

Disclosure: This post contain affiliate links, we may earn advertising commissions for sharing products we know and love.

1. MakeXYZ

MakeXYZ.com is a unique proposition. The website’s primary focus is to connect users with local makers. Even the search box on the homepage defaults to location search instead of material or 3D printing technology search (which you can do by the way, just use the advanced search function).

The advantages of MakeXYZ primarily lie in its focus on local sourcing. By making sure to put local manufacturers near you in the spotlight, MakeXYZ makes it certain to reduce unnecessary freight costs, as well as to allow the customer to have somewhat of a better experience by connecting with someone nearby instead of from across the globe.

2. Fiverr

Fiverr is arguably the best way to connect directly with the right maker for CAD design and even printing and shipping. Fiverr, while not a standalone 3D printing service, it is one of the most economical ways to connect with service providers who offer such services.

See, Most affordable 3D printing service – Real use case example

You will be able to find a global market of service providers that specialize in designing, optimizing and cleaning up 3D printer files. And afterwards, you can simply search for 3D printers that would print your custom job and ship the 3D print to your address all for a transparent, decided-before-ordering price. And if you cannot seem to find the right 3D printing seller by searching, simply post a Custom job request and let the sellers contact you.

And if you cannot seem to find the right 3D printing seller by searching, simply post a Custom job request and let the sellers contact you.

3. Print a thing

Although the service itself is still in beta, print a thing has the makings of a good marketplace that puts ease-of-use front and center. Think of it as what 3D hubs would’ve looked like, had it maintained its community roots when growing up.

Print a thing allows a seamless web user experience, whereby you simply upload an STL file or a thingiverse URL; select the technology you want to use (right now they only offer FFF/FDM and SLA) and presto! The website spits out a checkout quotation.

Behind the scenes, Printathing.com relies on networking with 3D printers around the globe to form its “supplier network”, and based on internal algorithms, printathing then assigns your 3D print to what it considers the best maker for the job.

To the user, it all appears as if you merely order something online, and then it is sent to you in real life via the magic of 3D printing and logistics.

4. 3D Experience Make marketplace

The Make Marketplace is unique in that while it is run by Dassault Systems, a reputable name in the professional 3D design space. It still focuses on connecting customers directly with professional on-demand 3D printing and subtractive manufacturers.

As of writing, the Make Marketplace offers a selection of 119 unique service providers. The interface itself screams business instead of user-friendliness. But if you are in the market for pro-grade services but still want to have direct communication with your 3D printer, the Make marketplace may just be a good place to look.

5. Other Pro-grade on-demand manufacturing websites

Nowadays, almost all the 3D printer juggernauts run their own on-demand 3D printing websites. All these websites focus on pro-grade services, and they come with a suitably higher price per print. There is little in the way of differentiation between these services as they all tend to offer almost the entire spectrum of materials selection imaginable along with other subtractive manufacturing techniques as well.

- Sculpteo

- Shapeways

- Xometry

- i.Materialise

These websites represent the club that 3D hubs is now a part of. But if that is what you are after, then we recommend trying out all of them before ordering to make sure that you are satisfied with the premium that you would pay on these services.

6. CraftCloud by All3DP

Craftcloud itself is not an online 3D printing service, instead Craft Cloud is an online price comparison tool that connects to an ever-increasing number of online 3D printing services. By its very nature, Craftcloud offers some of the biggest material and technology selections of any website.

While you do lose the ability to connect with individual makers, Craftcloud offers a streamlined user-interface to offer customers the lowest possible quotations for their needs.

· Selection of materials

The first obvious benefit when using an online service, is the breadth of materials that you get to choose from.

Even if the service only offers FDM technology, the selection of filaments as well as the quality of filaments on-offer would generally far exceed what any enthusiast could practically use on their own.

Material choices range from normal PLA, to polycarbonate, nylon, ABS, metal and wood fill. Even powder metal 3D printing for engineering-grade functional prototypes. With the right online service, you can be sure to find the exact material that you want for your project.

· Availability of different 3D printing technologies

Almost all of these 3D hubs-like online 3D printing services get one thing right: by relying on a network of individuals and professionals, they are able to offer a vast range of different technologies to the customer.

It is also one of the few ways that average consumers can have access to higher-end 3D printing technologies like full metal 3D printing.

Choices ranging from FDM and SLA, to SLS, SLM, Metal-Jet printing and everything in between are actually quite commonplace now for on-demand 3D printing services. No matter your needs; with the right service and budget, you are sure to find exactly the right 3D printing technology.

No matter your needs; with the right service and budget, you are sure to find exactly the right 3D printing technology.

· Professional print quality

Most of us are decent at best when it comes to optimizing our 3D prints for quality of print. As a rule, enthusiasts balance printing quality with the cost of filament to be used as well as having to deal with other limiting factors such as ageing 3D printers or entry-level hardware.

Online 3D printing services on the other hand, are run as businesses, so the makers are always paying attention to the quality of output of their machines since it directly impacts their bottom-lines. If you want even more consistency and accurate results, then you could even opt for one of the professional on-demand additive manufacturing services online.

As a rather safe generalization, you would be getting much higher quality 3D prints with online 3D printing services than you would at home.

3D hubs is a household name these days for online pro-manufacturing services. But it wasn’t always this way. Even a few years back, 3D hubs was a bustling community network that allowed 3D printing enthusiasts and makers around the world to connect with one another to satisfy their 3D printing demands.

But it wasn’t always this way. Even a few years back, 3D hubs was a bustling community network that allowed 3D printing enthusiasts and makers around the world to connect with one another to satisfy their 3D printing demands.

Rewind time even just five years and there was NO alternative to 3D hubs. Not because no one else tried, but because the 3D printing community, by and large saw 3D hubs as their online home.

Changing times

But then, corporate goals at 3D hubs shifted quite dramatically over the last few years. 3D hubs went from being a marketplace that connected makers and enthusiasts around the world to a curated selection of affiliated makers at first, and then finally 3D hubs became one hub of pro-manufacturing services that we see now today.

Suffice to say, this left many a 3D printing maker as well as enthusiast with a sour taste. But thankfully, with time, many viable alternatives have emerged to 3D hubs.

The 3D printing world was left with a void when 3D hubs decided to change directions, but thankfully, with time and effort, the online custom 3D printing service business has never been more diverse nor healthier.

Tags: Custom 3D printing

MoreRead more

Read more

Read more

GLOBAL

GLOBAL

3d event

one million

one million

usd one million

one million

usd one million

one million

usd one million

one million

usd one million

one million

usd one million

one million

usd one million

one million

usd one million

one million

usd one million

one million

usd one million

one million

usd one million

one million

usd one million

one million

usd one million

one million

usd one million

one million

usd one million

one million

usd one million

one million

usd

Show case

3D EN

IS A

3500 M2

FARM FOR

3D PRINTING

|

Show case

3D EN

3D EN

+7 (495) 212-07-01+7 (495) 212-07-01

send

messages

We are always ready to answer your questions, please fill in the form

10 reasons to visit a prototyping center

Analytics and business

Rapid prototyping

Experts recommend

Author: Andrey Kombarov

Author: Andrey Kombarov

1. Supply chain management | 2. Large selection of materials | 3. Variety of colors and finishes | 4. Large format 3D printing | 5. Professional quality parts | 6. Cost reduction | 7. Save time | 8. Scalability | 9. Expert advice and assistance | 10. Services of professional designers

Supply chain management | 2. Large selection of materials | 3. Variety of colors and finishes | 4. Large format 3D printing | 5. Professional quality parts | 6. Cost reduction | 7. Save time | 8. Scalability | 9. Expert advice and assistance | 10. Services of professional designers

The 3D printing services business is growing faster than ever. This happens because more and more people are striving to realize their ideas by means of additive technologies. Many solo enthusiasts, research groups, and manufacturing companies are not interested in investing in 3D printers, but prefer to go to a prototyping center first.

Today, 3D printing services are based mainly on working with professional clients. Of course, orders are also carried out for individuals, but most of the market is the B2B segment.

Even if you have access to a 3D printer, sometimes it's better to hire an outside contractor. Let's say you need a part in a material or color you don't have, and you'd rather not buy the whole lot. It is much wiser to order the missing part, and not to purchase all the equipment and inventory that may not be needed in the future.

It is much wiser to order the missing part, and not to purchase all the equipment and inventory that may not be needed in the future.

We will look at ten reasons why additive manufacturing using a service can be more profitable.

Do you have projects that you would like to realize using 3D printing, 3D scanning or 3D modeling? Order a service from our company!

Leave a request

1. Supply chain management

Additive technologies have been improved over the years, and today they allow the production of both prototypes and final parts, especially when solving certain problems.

In general, the development and manufacture of a particular part can be expensive due to high tooling costs. 3D printing is an extremely flexible technology. Manufacture of many different products and refinement of their designs is no longer a complex problem, which makes additive manufacturing a reliable solution to problems with the active use of redesign.

Outsourcing 3D printing jobs saves costs and lead times © Leo Gregurić via All3DP

Today, many research groups and companies rely on 3D printing services as a supply chain. It is extremely useful for them to be able to easily create and deliver custom parts.

2. Large selection of materials

One of the strong selling points for 3D services is the variety of consumables (and technologies) on offer. Thanks to the constant introduction of innovations in this area, service providers are able to work with the latest developments, especially large companies.

Prototyping centers offer, as a rule, the three most popular additive technologies: FDM, SLA and SLS. Accordingly, polymer filaments or granules, photopolymer resin and plastic powders are used as consumables.

A wide range of options gives the customer the opportunity to obtain the material that is required for a particular project, based on mechanical and chemical properties and aesthetic requirements.

The variety of materials is practical not only for professional needs. The Professional 3D Services Center will also offer simple materials that may not be available to a private person. Buying a certain material and printing a product from it on your own can be more expensive than simply ordering the manufacture of a single part from this material.

iQB Technologies experts recommend an article: 9 products that are more profitable to make on a photopolymer 3D printer

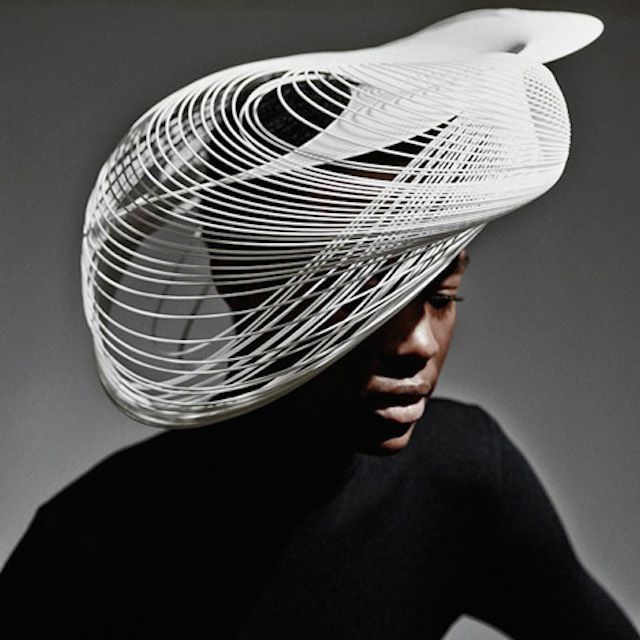

3. Variety of colors and finishes

With such a wide range of materials available, 3D printing service customers are not limited in their choice of colors and finishes. Creating the perfect combination for a specific task has never been easier.

Colors

FDM filaments (PLA, ABS, PETG, and others) are typically offered in a wide range of colors. The plastic granules from which the thread is made are easily dyed.

More advanced combinations of plastics in the form of filaments, such as polymer composites or nylon, are difficult to dye and their color range is not as rich.

With regard to SLA technology, various colors are available for photopolymers. True, there are not as many of them as for PLA. Methods like SLS use industrial grade nylon powder, which comes in white, black, or some color in between. This is also due to the difficulty of coloring.

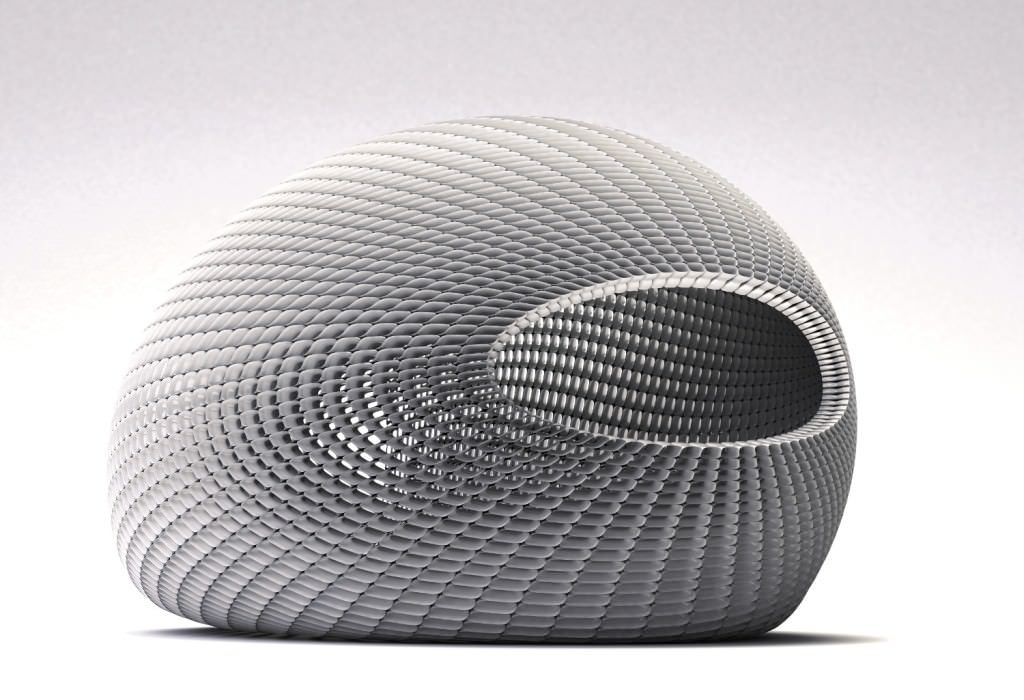

Technology available for full-color 3D printing © Hubs

There are full-color 3D printers that are ideal for creating visually appealing prototypes and teaching models, such as anatomy and geography. Given the high cost of professional machines, the ability to use technology that is not otherwise available through a 3D printing service is of great importance to the end user.

Finish

The surfaces of products created on a 3D printer can be subjected to various post-processing methods. Details are processed until the layers are completely indistinguishable and, as a result, look as if they were not printed at all.

But this is only the beginning. Processing can include sanding, polishing, galvanizing and painting, and many other finishes. Not every 3D printing material is suitable for all post-processing methods, and the service provider should explain this point to you when ordering.

Processing can include sanding, polishing, galvanizing and painting, and many other finishes. Not every 3D printing material is suitable for all post-processing methods, and the service provider should explain this point to you when ordering.

In addition to the huge selection of options, one of the biggest benefits of ordering a finishing service is quality and convenience. Post-processing can take a lot of time, and entrusting the work to professionals, you will be sure of a high-quality and reliable result.

4. Large Format 3D Printing

Sometimes you may need a large printer © WASP Team via Youtube

An additive manufacturing services company typically operates multiple 3D printers to meet high demand (and meet deadlines) and various other requests. This provides a number of advantages, among them - the flexibility of product sizes.

Sometimes splitting a large part into multiple sub-elements is not the best solution, so an additive setup with a large build platform is needed. An individual or company often does not have access to large 3D printers, while many 3D service providers do.

An individual or company often does not have access to large 3D printers, while many 3D service providers do.

5. Professional quality parts

3D printers are becoming more reliable, and even the most affordable technology is showing impressive accuracy. However, many products (say, jewelry) require more precise workmanship or tighter tolerances to ensure perfect compatibility (for example, functional units). The professional results offered by the 3D printing service guarantee consistently high-quality workmanship in terms of precision and finish.

Professional machines are more reliable in terms of repeatability. This is an important factor to consider when printing a large number of parts that require constant and tight tolerances.

But not only machines determine the final result. The people who work with 3D printers make a significant contribution to the production of professional quality parts. They have the knowledge and experience to advise you on how to best prepare your model, select the most suitable material, and finally create the final part.

A high-quality prototype created on an industrial SLA printer at the TWIZE Prototyping Center © TWIZE

6. Cost reduction

If you need to make something on a 3D printer, there are two options: either buy equipment and print the parts yourself, or order printing and receive finished products. Using a 3D printing service can save you money.

When a business is considering launching its own additive manufacturing, outsourcing through a service provider first makes sense. This will allow an individual or company to access 3D printing technologies while avoiding the cost of equipment, materials and maintenance. Once you understand that 3D printing meets the needs of your business, this may be the right time to start thinking about buying equipment.

There are other scenarios as well. Some businesses can save money in the prototyping phase by having them 3D printed before putting the final version into production through another process such as injection molding.

However, outsourcing a project can save a lot of money until a “tipping point” is reached, at which point the cost of acquiring the equipment becomes a worthy investment.

Considering starting a 3D services business?

We share our experience in the article 3D printing as a business: the most profitable concepts of the RP Center

We will consult and select ready-made solutions. Contact us!

7. Save time

When ordering 3D printing from a service provider, you don't have to worry about printer setup and maintenance. In fact, you make a payment and get the parts you need. Everything is done on a turnkey basis, and you don't have to think about all the additional costs associated with setting up, maintaining and operating the equipment.

3D printing of some parts may require time that you do not have © Leo Gregurić via All3DP

And even if you have printers, they may not be enough to print a large number of products in a short time. Since prototyping centers usually have a large stock of equipment, large batches can be produced very quickly.

Since prototyping centers usually have a large stock of equipment, large batches can be produced very quickly.

Of course, the order may take a long time, so choose the service wisely. But the turnaround time for an order (printing from standard media with standard post-processing) may well be shorter than the total time it takes to set up, maintain, and operate the related equipment. For many, this alone is enough to apply for a service to a contractor.

In addition, the production of an object on a 3D printer takes hours or days - this requires control, which not everyone can do.

8. Scalability

Since the advent of 3D printing, it has been described in the mainstream media as a slow process. What is usually meant is that additive manufacturing cannot compete with traditional methods such as injection molding when it comes to high volume production.

There is some truth in this, but it is important to understand that 3D printing is a very effective process in certain circumstances. When you need to produce large batches of the same parts, this is not the best option, but 3D printers are more than capable of producing in small and medium volumes.

When you need to produce large batches of the same parts, this is not the best option, but 3D printers are more than capable of producing in small and medium volumes.

This is especially beneficial when we are dealing with individual designs or iterations, that is, when classical methods involve much more time and money.

For this reason, 3D printing services in particular can provide scalable manufacturing solutions that meet the needs of even medium volume production. Small-scale production is possible in a garage or a small office, something larger is hardly imaginable, and this is where the use of a 3D printing service makes sense.

3D service providers can deliver scalable solutions © BMW Group

9. Expert advice and assistance

As already mentioned, 3D printing services are available to a large number of different customers. These can be both individuals who want to print a cartoon character figurine on a 3D printer, and world-famous corporations seeking to optimize their workflows. In any case, consultation is an important factor that can help close the deal.

In any case, consultation is an important factor that can help close the deal.

The additive manufacturing experts at the 3D Services Center can help customers determine the right course of action before launching a project. Working with the client on the specific needs of his project, he is explained the available options.

Identifying the exact applications for 3D printing as well as discussing technical issues and specifics (such as what material is best for the purpose) are all part of the consulting service. Sometimes good preparation based on consultation can save money as the project progresses. For large projects, this is certainly an important advantage.

10. Professional design services

Most 3D service companies expect you to already have a 3D model ready to print. Often this is the case, but some clients still need additional help. In cases where the customer needs to develop a part from scratch and he does not have 3D modeling experience, a service with the involvement of full-time professional designers will come in handy.