3D printing lunar base

Building a lunar base with 3D printing

Enabling & Support31/01/2013 147006 views 489 likes

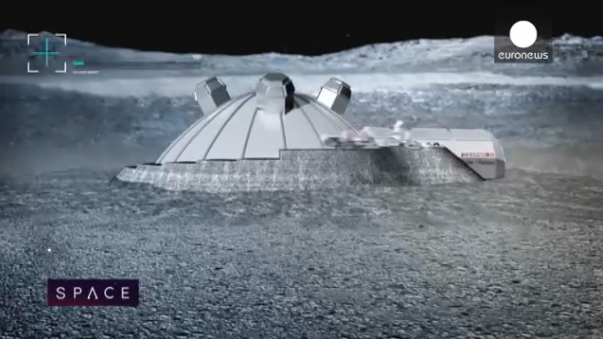

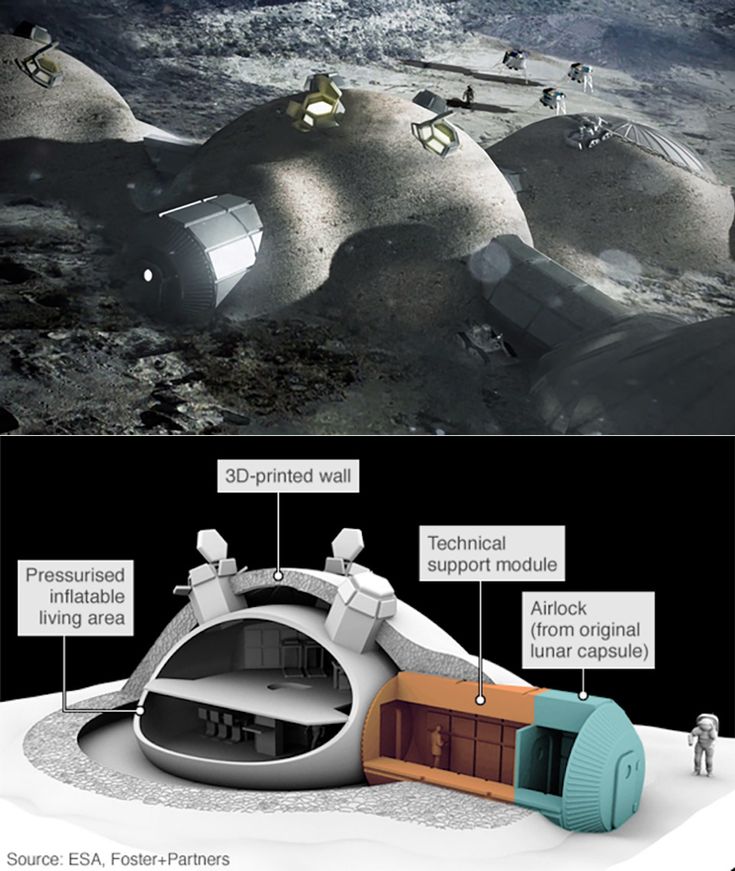

Setting up a lunar base could be made much simpler by using a 3D printer to build it from local materials. Industrial partners including renowned architects Foster + Partners have joined with ESA to test the feasibility of 3D printing using lunar soil.

“Terrestrial 3D printing technology has produced entire structures,” said Laurent Pambaguian, heading the project for ESA.

“Our industrial team investigated if it could similarly be employed to build a lunar habitat.”

Foster + Partners devised a weight-bearing ‘catenary’ dome design with a cellular structured wall to shield against micrometeoroids and space radiation, incorporating a pressurised inflatable to shelter astronauts.

A hollow closed-cell structure – reminiscent of bird bones – provides a good combination of strength and weight.

1.The base’s design was guided in turn by the properties of 3D-printed lunar soil, with a 1.5 tonne building block produced as a demonstration.

“3D printing offers a potential means of facilitating lunar settlement with reduced logistics from Earth,” added Scott Hovland of ESA’s human spaceflight team.

“The new possibilities this work opens up can then be considered by international space agencies as part of the current development of a common exploration strategy.”

Multi-dome base being constructed“As a practice, we are used to designing for extreme climates on Earth and exploiting the environmental benefits of using local, sustainable materials,” remarked Xavier De Kestelier of Foster + Partners Specialist Modelling Group. “Our lunar habitation follows a similar logic.”

The UK’s Monolite supplied the D-Shape printer, with a mobile printing array of nozzles on a 6 m frame to spray a binding solution onto a sand-like building material.

3D ‘printouts’ are built up layer by layer – the company more typically uses its printer to create sculptures and is working on artificial coral reefs to help preserve beaches from energetic sea waves.

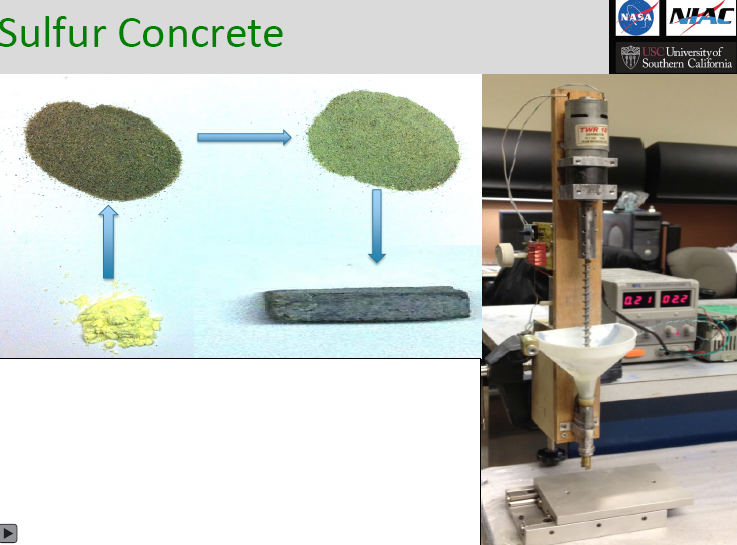

“First, we needed to mix the simulated lunar material with magnesium oxide. This turns it into ‘paper’ we can print with,” explained Monolite founder Enrico Dini.

“Then for our structural ‘ink’ we apply a binding salt which converts material to a stone-like solid.

“Our current printer builds at a rate of around 2 m per hour, while our next-generation design should attain 3.5 m per hour, completing an entire building in a week.”

3D-printed lunar base designItalian space research firm Alta SpA worked with Pisa-based engineering university Scuola Superiore Sant’Anna on adapting 3D printing techniques to a Moon mission and ensuring process quality control. The effect of working in a vacuum was also assessed.

The effect of working in a vacuum was also assessed.

“The process is based on applying liquids but, of course, unprotected liquids boil away in vacuum,” said Giovanni Cesaretti of Alta.

“So we inserted the 3D printer nozzle beneath the regolith layer. We found small 2 mm-scale droplets stay trapped by capillary forces in the soil, meaning the printing process can indeed work in vacuum.”

3D-printed sculptureSimulated lunar regolith is produced for scientific testing by specialist companies, typically sold by the kilogram. But the team required many tonnes for their work.

“As another useful outcome, we discovered a European source of simulated lunar regolith,” added Enrico.

“Basaltic rock from one volcano in central Italy turns out to bear a 99.8% resemblance to lunar soil.”

“This project took place through ESA’s General Studies Programme, used to look into new topics,” Laurent commented.

“We have confirmed the basic concept, and assembled a capable team for follow-on work.”

Lunar south poleFactors such as controlling lunar dust – hazardous to breathe in – and thermal factors will require further study.

3D printing works best at room temperature but over much of the Moon temperatures vary enormously across days and nights lasting two weeks each. For potential settlement, the lunar poles offer the most moderate temperature range.

Thank you for liking

You have already liked this page, you can only like it once!

Could the first lunar habitat be 3D-printed with moon dust?

Written by By Rebecca Cairns

The last time a person stepped foot on the moon was 1972. Now, the moon is back on NASA's space agenda. This time around the agency isn't just visiting -- it's planning to stay.

With its Artemis missions starting next year, NASA aims to have astronauts on the moon in 2024 and anticipates a permanent lunar base by the end of the decade. This would be the first habitat ever constructed on an extraterrestrial surface, and the challenges are unprecedented.

Sending a large quantity of construction materials to the moon would be expensive and time-consuming. But Texas-based startup ICON says it has a sci-fi solution -- 3D printing a lunar base from moon dust.

ICON is working with NASA to develop technology that can turn moon dust into a concrete-like material, says co-founder and CEO Jason Ballard. Moon dust, also known as lunar regolith, is the sand-like topsoil that covers the moon's surface, formed from minerals and tiny shards of glass created over millions of years as meteoroids hit the moon. It's sharp, abrasive, and extremely clingy -- the Apollo astronauts found it stuck to everything, including their space suits. There's plenty of it, which means there's a huge supply of raw materials if ICON is successful.

BIG's concept for Project Olympus includes donut-shaped buildings which could be entirely constructed with ICON's 3D printer. Credit: Bjarke Ingels Group / ICON

The initiative is named Project Olympus after the largest-known volcano in the solar system -- aptly conveying the mountain-sized challenge the team faces. But Ballard isn't just shooting for the moon. By designing a lunar habitat, he hopes to make construction on Earth cleaner, faster and cheaper, too.

Project Olympus

ICON has been using 3D printing technology to build social housing in Mexico and Texas, since 2018. Using a concrete-based mixture called lavacrete, its Vulcan printer can print around 500-square-feet in 24 hours.

But the moon is a "radically different world," says Ballard. From Earth, it looks like a serene, smooth, silver orb but it is subject to high levels of radiation, violent moonquakes, extreme temperature swings and frequent strikes by micrometeorites that crash through its thin atmosphere, he says.

And turning moon dust into building material is another huge challenge. The team is experimenting with small samples of moon dust in a lab -- working out how to change its state with microwaves, lasers and infrared light, while using "little to no additives," says Ballard.

The research area in ICON's proposed lunar structure is illuminated with smart lights that simulate day and night on Earth, to help astronauts retain a normal sleep-wake cycle. Credit: Bjarke Ingels Group / ICON

ICON worked with two architectural firms, Bjarke Ingels Group (BIG) and Space Exploration Architecture (SEArch+), to explore the possibilities of 3D printing technology.

The team studied habitats in extreme environments, including the McMurdo Station in Antarctica and the International Space Station, and used their findings to create a range of lunar design concepts, says Ballard.

The architects had to consider how to create an environment that is safe as well as comfortable to live in, says BIG founder Bjarke Ingels.

The proposal by SEArch+ features a tall, multi-story structure with protective 3D-printed petals shielding a core that would be built on Earth, while BIG designed a circular structure which could be entirely printed on the moon.

BIG's design includes a visible membrane of water padding the walls of the bedroom -- "a good insulant against radiation," says Ingels -- which will give astronauts extra protection while they sleep.

The radiation means that windows must be kept to a minimum, so Ingels carefully chose the location of the building's only one -- which always faces Earth.

SEArch+ imagined a base "that will allow astronauts to frequently come and go from the surface," with landing pads, roads, sheds and habitats says co-founder Rebeccah Pailes-Friedman. Credit: SEArch+ / ICON

A "double shell" structure and exterior latticework, which can be packed with loose lunar dust, provide additional protection from radiation and meteorites, says Ingels.

In addition to living and working spaces for astronauts, the lunar base would need to incorporate landing pads, roads and storage sheds. Human presence in space has been "dominated by engineering" so far, says Ingels. With multiple industries working together he hopes that the first permanent structure on the moon can be "aspirational" in design as well as an engineering marvel.

Human presence in space has been "dominated by engineering" so far, says Ingels. With multiple industries working together he hopes that the first permanent structure on the moon can be "aspirational" in design as well as an engineering marvel.

A gateway to the galaxy

NASA began exploring 3D printing as a possible space construction technology with the launch of the 3D-Printed Habitat Competition in 2015. Both SEArch+ and ICON took part in the initiative, with SEArch+ placing first for its design of the Mars X House.

With the Artemis missions launching next year, NASA's first step towards a lunar habitat is the "Gateway," a space station in the moon's orbit, says spokesperson Clare Skelly. Astronauts will live and work on the Gateway and shuttle to the moon, staying in their landers for up to a week.

ICON's 3D-printer, Vulcan, draws the outline of the building one layer at a time. It can print up to 500 square feet in 24 hours. Credit: ICON

Its goal, however, is a permanent base, from which to explore the moon in more depth and and test technology for human survival in space. NASA wants to construct facilities to house four astronauts for up to a month, says Skelly. It's an essential first step to Mars -- and beyond.

NASA wants to construct facilities to house four astronauts for up to a month, says Skelly. It's an essential first step to Mars -- and beyond.

Skelly says it has not yet been decided if the lunar habitat will be constructed using 3D printing, but "NASA could award ICON additional funding" and might give the company the opportunity to test its technology on the lunar surface.

Using moon tech on Earth

Ballard is optimistic about the technology's Earthbound potential, too. He believes the findings from Project Olympus could help to solve the global housing crisis.

As a relatively new technology, there's little definitive data on the advantages of 3D printing in construction. However, a 2020 review notes that it could reduce construction waste by 30% to 60%, labor costs by 50% to 80%, and construction time by 50% to 70% which would make building cheaper, faster and more sustainable.

ICON's first 3D construction project was a collaboration with non-profit New Story in Mexico, to build a social housing community for people who had lost their homes in natural disasters. Credit: Joshua Perez / ICON

Credit: Joshua Perez / ICON

While the technology is largely used on bespoke projects right now, Ballard hopes that the possibility to use "rawer, more direct, local materials" could open up more opportunities for 3D construction -- which could be transformative for some of the 1.6 billion people still in need of adequate housing on Earth.

"It's kind of a funny thought," he says, "but it just may turn out that the answers to our problems on Earth are on the moon or Mars."

Moon base 3D printed from lunar soil / Sudo Null IT News It is on such a project that the European Space Agency (ESA) is working in collaboration with renowned architect Norman Foster.

Human colonization of the Moon is no longer a utopian fantasy, but a promising goal. People do not want to build a base on the Moon “for show” - it can bring tangible benefits. The moon also has a variety of minerals, including metals valuable for industry: iron, aluminum, titanium. In the surface layer of soil (regolith), an isotope 9, rare on Earth, has been accumulated0007 helium-3 , which can be used as fuel for advanced thermonuclear reactors. Deep vacuum and the availability of cheap solar energy open new horizons for electronics , foundry , metalworking and materials science . The moon, due to its impressive landscapes and exoticism, would be an attractive object for tourists.

Deep vacuum and the availability of cheap solar energy open new horizons for electronics , foundry , metalworking and materials science . The moon, due to its impressive landscapes and exoticism, would be an attractive object for tourists.

ESA is therefore experimenting with various approaches that could enable construction on our planet's satellite in the future. At this stage, with the help of industrial companies, ESA is developing a project for a 3D lunar base from space soil.

“On Earth, full-fledged structures are already being created using 3D printing. Our fellow industrialists have tried to see if it is possible to build a safe environment for humans on the Moon in a similar way.”Foster + Partners, led by renowned architect Norman Foster, creator of London's famous Gherkin skyscraper and other buildings, has proposed hinged "domes" as a supporting structure. The special structure of their walls will protect the inhabitants from micrometeorites and cosmic radiation.

The astronauts will live inside the dome, in an inflatable "cocoon". The hollow structure, reminiscent of the bones of birds, should be a good compromise between strength and lightness. The base model is designed for 3D printing from a one and a half ton bar of lunar soil.

“3D printing could potentially enable the construction of a lunar settlement without massive supplies of materials from Earth.

The new possibilities this idea opens up can be taken into account by the international space agencies in the context of their own lunar exploration projects.”added Scott Hovland, ESA's manned flight manager.

“On Earth, we have already adapted to building in extreme conditions and have learned to take advantage of a particular environment, focusing on local natural materials. We are guided by the same logic in the lunar project”explains Xavier de Questellier of Foster + Partners.

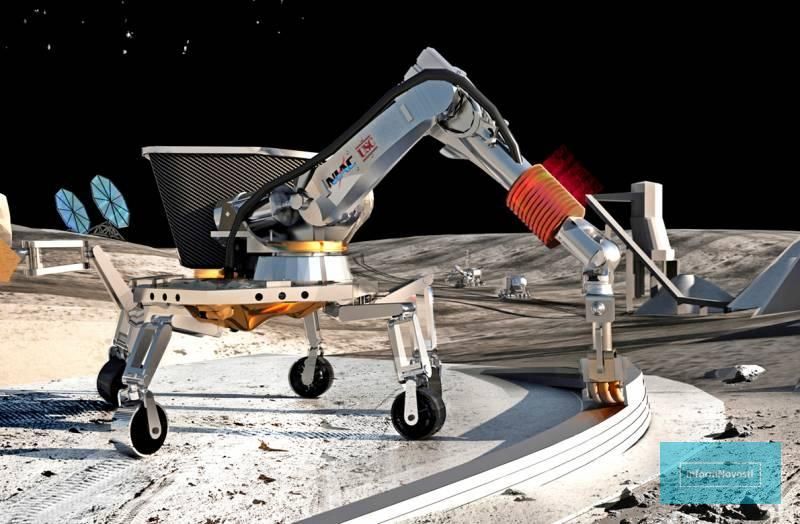

Lunar Base 3D PrinterThe D-Shape printer that prints the base has a 6 meter frame nozzle array that sprays an adhesive solution onto the sand-like building material. 3D prints are made in layers. Monolite is now using it on artificial coral reefs to create protection against the destruction of powerful sea waves.

“We first mixed our model lunar soil with magnesium oxide. This is the “paper” that we can print on. Then we apply our "ink" - a special saline solution that holds the "paper" together into a solid structure.

Right now our printer is printing at about two meters per hour, but the next generation printer will already be able to reach 3.5 meters per hour, so the whole building can be completed in a week.”Enrico Dini, founder of Monolite, explains.

The adaptation of the "terrestrial" printer to space work was carried out by the Italian space company Alta SpA in collaboration with the technical university Scuola Superiore Sant'Anna in Pisa.

Particular attention was paid to the peculiarities of working in a vacuum: after all, under these conditions, the liquid will instantly boil.

“To avoid this, we place nozzles under the regolith layer. We have found that 2mm droplets are successfully retained in it by capillary forces, so the printing process can take place in a vacuum.”, explained Giovanni Cesaretti, Alta employee.

An interesting side result of the work was the discovery of a source of "lunar" soil in Europe. In general, regolith is produced and sold by specialized companies in kilogram quantities, but this project needs tons of it.

The solution was found in the Apennines. The basalt rock of a dormant volcano in central Italy was 99.8% identical to the lunar soil.

The validation of the concept itself has now been completed, further work is still ahead. Other threats must be taken into account: lunar dust dangerous for people to inhale, the temperature features of the Moon.

3D printing works well at room temperature, but due to the absence of an atmosphere on the moon, the difference between night and day temperatures is very large. Only the poles differ in a more “mild” climate.

Moon dust 3D printer

CosmonauticsTechnology

09/08/2019

3,699 2 min read

Building a moon base is a real challenge. To avoid the transfer of heavy materials from the earth, scientists are developing the possibility of using lunar dust in special 3D printers. They should be able to print building blocks directly on the spot - the so-called additive manufacturing.

Ross Friel, senior lecturer at Halmstad University, leads a team of researchers working on autonomous additive manufacturing (also called 3D printing) that can be used on the moon.

Earth's resources are limited, so our continued existence requires that we look beyond our planet. There are endless resources in space.

To be able to explore, both inside and outside, our solar system, a lunar base is needed that can serve as a "springboard" for space travel. According to Ross Friel, it is economically and technically advantageous to use the Moon as a launch pad because of its low gravity, extremely thin atmosphere and clear skies, and the ability to use hydrogen and oxygen from lunar ice for rocket fuel.

The task of building a moon base

Building a moon base is not an easy task. The building material must withstand and protect people and scientific instruments from harmful cosmic radiation and meteoroids. It is impossible to transport heavy concrete from the Earth to the Moon - it is too expensive. Therefore, being able to use materials already on the Moon to create building blocks and other useful components such as spare parts could be a better solution.

Lunar dust, i.e. fine gravel on the Moon called lunar regolith, is a natural ceramic material - much like volcanic ash on Earth.

In our study, we used material from the earth with properties similar to moon dust. Real dust is hard to come by, says Ross Friel.

3D printer on the moon

By melting moon-like material from the earth, you can print various types of structures on a specially designed 3D printer, such as cubes, filter elements and screws, directly on the surface of the moon.

By melting material from the earth, which has properties similar to moon dust, various types of textures can be printed using a specially designed 3D printer. The figure shows: a) compact cubes, b) a potential filter structure, c) a screw and nut showing the accuracy of printing, and d) a building block in the form of a puzzle piece as a first step towards interconnected building components to create compact material structures directly on the moon. . Illustration: Halmstad UniversityIn the coming years, researchers will continue to develop technology for a stand-alone 3D printer capable of operating on the moon.

Learn more