Best 3d printed houses

10 best 3D-Printed houses around the world

© wavyThe evolution of building materials has been quite an eventful journey. Across history and civilizations, new building materials have made their mark. This transition has resulted in immense possibilities, from using hay, tree barks, stone, timber, brick, mortar, or glass and steel. Materials have a great influence on the experiential quality of a space. In this process, different materials started to use in 3d printers. Today, we can create 3D-printed houses by using these technologies. Different materials provide a different range of thermal and acoustic comfort. Materials also vary based on the region and the specific climatic conditions. The variations in building materials thus strengthen the thought that “Change is the only constant”.

© Sika Sikacrete® 3DFor instance, the brick alone has undergone multiple evolutions. It has evolved from clay and sand bricks to fly ash bricks, hollow wooden bricks, etc. Thus, the genre of materials is very deep. Moreover, technological innovations have led to unconventional techniques and materials. This not only reduces the environmental impact but also increases the life span and strength of the building. This includes using materials like Bamboo, Reclaimed Wood, Recyclable Waste, Bitumen Materials, Tempered Glass, Crumb Rubber, etc. This list also includes new-age materials like Fiber Reinforced Polymer, Glass Fiber Reinforced Plastics, Bamboo reinforced plastics, etc. But 3D printed houses are the latest and most jaw-dropping innovation of the current times.

Yes, this is not just a technological marvel in the AEC industry but also the printing technology. But what has made 3D printing a new trend in the AEC industry?

Let’s have a glance.

How is 3D Printing Technology Growing in the AEC Industry?

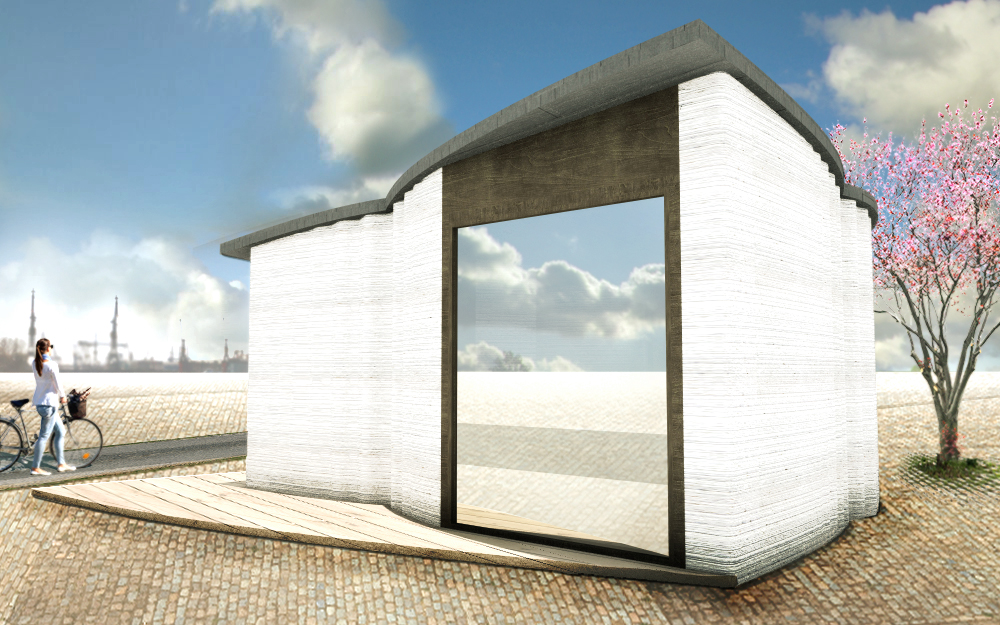

© news aktuell via AP ImagesA construction 3D printer employs a machine that builds houses by stacking the building material. This type of construction is termed “Construction 4.0”. In this technique, a paste material ejected through a tube. This includes materials like concrete or earth stacked in layers, thus creating a spatial volume.

This type of construction is termed “Construction 4.0”. In this technique, a paste material ejected through a tube. This includes materials like concrete or earth stacked in layers, thus creating a spatial volume.

This technology helps save time, effort, and material compared to traditional construction methods. But, 3D printing limited to the printing of walls and frames. Later, systems like windows, plumbing, etc., are conventionally installed. Despite these limitations, the technology is gaining traction owing to the minimal time required by the technology. This eliminates the time spent setting deep foundations, concrete settings, and other time-consuming methods involved in traditional constructions.

3D Printed Homes Across the Globe

Now that we have seen the potential of 3D printing in architecture and the advantages of 3D-printed construction, let us check out some 3D-printed homes that have pivoted the idea of housing technology worldwide.

Here’s an insightful list:

1. Bio-plastic micro-home© DUS Architects

Bio-plastic micro-home© DUS ArchitectsThis marvelous cabin structure was designed by DUS Architects using sustainable bio-plastics and is located in the Netherlands. Bio-plastic used as a core material to print and construct this 8 sq. meter. Micro cabin, a form of additive manufacturing typically used in household 3D printers, to create its geometric walls. The Bio-plastic can be easily recycled and repeatedly reprinted. Using this method makes this project environment-friendly in the true sense. The use of black material renders this micro cabin with a customizable and ornamental facade. This cutting-edge design show how it is strategically conceptualized to induce form optimization.

Moreover, bioplastic makes the micro cabin naturally insulated, eliminating the need for mechanical ventilation. This also highlights the innovation in materiality and energy consumption. The modular interiors also feature a plush 3D-printed bathtub, whereas the porch and steps in concrete open up the cabin into the park. Thus, creating an aesthetic transition between the built and the unbuilt.

Thus, creating an aesthetic transition between the built and the unbuilt.

In collaboration with 3D-printing specialists WASP, Italy-based studio Mario Cucinella Architects has developed this low-carbon impact housing prototype, which goes by the name Tecla. A spatial enclosure formed by two connected domes with a total area of about 60-square-meters. The large skylight at the top of each dome allows light to penetrate the space from the top, making the space well-lit naturally.

The combination of modern technology, locally-sourced clay as the building material, and the multileveled 3D printer showcases the intersection of functionality and aesthetics.

Two-Story Detached House is the first-ever 3D-printed house in Germany. It has a two-storied structure with approximately 860 sq. ft of habitable space per floor. This project is being built using the 3D printer called BOD2. It pioneered by Danish manufacturer COBOD. The key feature of this machine is that it facilitates the addition of pipes and other internal building service components while the printing is underway. Moreover, it can print up to 10 sq. ft of double-skin wall in a magical span of just 5 minutes.

It pioneered by Danish manufacturer COBOD. The key feature of this machine is that it facilitates the addition of pipes and other internal building service components while the printing is underway. Moreover, it can print up to 10 sq. ft of double-skin wall in a magical span of just 5 minutes.

Read more What is Concrete 3D Printing?

4. Project Milestone© 3dprintingmedia.networkDesigned as part of a design development that aims to be the world’s first 3D-printed rental property, this structure has become the first lived-in 3D-printed home in Europe.

This boulder-shaped home was designed by Studio Houben & Van Mierlo. It was developed as part of a research project with the Eindhoven University of Technology. The whole construction process has been a new learning experience, thereby broadening knowledge around the production of 3D-printed homes.

5. Gaia© 3dwaspPrinted using a mixture of local soil, chopped straw, and rice husks obtained from rice waste production. This 30-square-meter house is situated in Italy and was constructed by WASP.

This 30-square-meter house is situated in Italy and was constructed by WASP.

A unique amalgamation of 3D printing technology and traditional construction method can be seen here, where the structural walls are printed from the soil. At the same time, the cavities are filled with rice waste for better insulation. Rice husks are also being used in the interior to cover the walls and ceiling of the house as a form of natural plaster.

This inspirational design proves that agricultural waste could become a major construction and 3D printing resource, making this process sustainable.

East 17th Street Residences are designed to withstand extreme weather conditions in the US.

The construction was accomplished in 7 days. This includes a configuration of two-, three- and four-bedroom residences. So far, these cement-based homes have withstood an earthquake of magnitude 7.4 and severe winter storms. This shows how 3D printing construction is reliable and can withstand environmental disasters.

Casa Covina was designed as a design experiment in the San Luis Valley. The structure is formed by the interconnection of three cylindrical volumes or vaulted structures.

The hut was conceptualized to facilitate the co-existence of two individuals considering the coronavirus-led social distancing and isolation requirements. The adobe walls of Casa Covina are built using sand, silt, clay, and water are used to build. The structure is printed using a three-axis Selective Compliance Articulated Robot Arm.

The key highlight here is an inflatable pink roof which can be erected if it rains or snows. This great example of combining modern and ancient technology to create sustainable habitable solutions.

This two-storied house in Belgium is one of the first 3D-printed houses as one piece. Located in Westerlo, this home is eight meters tall and has a floor area of 90-sq. meters. The structure showcases the enhanced potential of 3D printing technology.

meters. The structure showcases the enhanced potential of 3D printing technology.

Designed as a low-energy consumption home, the design integrates energy-efficient provisions like ceiling and underfloor heating, solar panels, and a heat pump.

PassivDom House is probably among the most sustainable and energy-efficient 3D-printed houses. The entire house is designed to harness solar power. Whereas, from the moisture in the air, water generation is accomplished. This acts as an add-on facility. Built using a huge 3D printer in a factory in Nevada, PassivDom House is a perfect example of futuristic housing.

Furthermore, to clean and recycle water, the bathroom is designed technologically powered. Designed to use as few resources as possible, the house is ‘Off-grid’ in the true sense.

10. Curve Appeal© watgCurve Appeal is a dynamic 3D-printed house built from 3D-printed plastic, carbon-fiber panels, and glazed walls. The free-flowing forms and the parametric facade inculcates this structure with incredibly bold imagery compared to the other 3D-printed homes in the world. WATG designs this 1,000-square-foot residence. This structure printed using Branch Tecnchology’s freeform process and is the first of its kind. The dynamic curved facade is aesthetic and designed with optimum structural stability. The glazed facade lets light into the interiors, making the space naturally -lit. Moreover, the use of glass as a facade also induces a sense of transparency, merging the indoors with the outdoors. The entire structure is known for its net-zero energy.

The free-flowing forms and the parametric facade inculcates this structure with incredibly bold imagery compared to the other 3D-printed homes in the world. WATG designs this 1,000-square-foot residence. This structure printed using Branch Tecnchology’s freeform process and is the first of its kind. The dynamic curved facade is aesthetic and designed with optimum structural stability. The glazed facade lets light into the interiors, making the space naturally -lit. Moreover, the use of glass as a facade also induces a sense of transparency, merging the indoors with the outdoors. The entire structure is known for its net-zero energy.

The path-breaking revolutionary construction techniques coupled with innovative technologies such as solar carving and passive mechanical systems thus make Curve Appeal futuristic in the true sense.

3D Printed Houses: Top Projects from Around the World

3D printing news News 3D Printed Houses: A Closer Look at Completed Projects from Around the World

Published on July 29, 2022 by Carlota V.

As you may know, additive manufacturing is becoming increasingly important in the construction market. The new technologies make it possible to create more complex shapes, build walls faster, and reduce labor costs. Many construction companies have already started to 3D print buildings or houses. Be careful, however, with the term 3D printed house: In most cases, only the walls are made by a 3D concrete printer, that prints them layer by layer. That in itself is already quite an innovation that has made it possible to build homes in hard-to-reach, disadvantaged, or conflicted areas. These days, we are starting to see more and more 3D-printed houses being inaugurated and the first families are starting to move in. Yet, at this point, it is still difficult to assess the sustainability of such a structure, and only time will show if this manufacturing method is more viable altogether. However, we can already share with you some 3D printed house-projects that have been completed around the world.

A 3D Printed House in Japan

In less than 24 hours and for less than $25,500, the company Serendix designed this small house with 3D printed walls. Even if it’s hard to imagine that anyone could live in it, the project is still interesting and shows all the agility of 3D concrete printing. With a surface area of only 10 square meters, the structure has a honeycomb shape and no reinforcements. Serendix’s objective is to create emergency housing in times of crisis, as earthquakes and typhoons regularly hit the country. It took three hours to assemble the different 3D printed parts and a total of 23 hours and 12 minutes to get the final result.

Alquist 3D and the Virginia Project

U.S.-based Alquist 3D recently announced the launch of one of its new projects for 3D printing homes. Located in the state of Virginia, the 200 homes that make up the project will be created through additive manufacturing with the aim of reducing the overall cost of infrastructure in communities with economic problems. According to the company, which specializes in 3D printing houses with concrete, this initiative is intended to be one of the largest housing construction projects, with Pulaski and Roanoke being the first cities to be chosen for it, due to the growth in demand for housing that these areas have experienced in recent years. After completing the project for Habitat for Humanity, this new idea now aims to help the company expand further into the 3D construction market.

According to the company, which specializes in 3D printing houses with concrete, this initiative is intended to be one of the largest housing construction projects, with Pulaski and Roanoke being the first cities to be chosen for it, due to the growth in demand for housing that these areas have experienced in recent years. After completing the project for Habitat for Humanity, this new idea now aims to help the company expand further into the 3D construction market.

The Fibonacci House, the First 3D Printed House on Airbnb

The next house on our list is interesting not just for its design but because it holds the distinction of being the first fully 3D printed house to be listed on Airbnb. Twente Additive Manufacturing (TAM), one of the leading companies in concrete 3D printing, created this home in a spiral shape following the Fibonacci sequence, a famous mathematic sequence also known as the golden ratio that often occurs naturally, giving the home its name. The spiral allows for the progression of space from the wide-open exterior to the closed and warmer space in the tightest part of the spiral. The tiny home is available for rent for a minimum of two nights in Proctor, British Columbia, Canada on Airbnb for about $128 a night..

The tiny home is available for rent for a minimum of two nights in Proctor, British Columbia, Canada on Airbnb for about $128 a night..

Mvule Gardens is Africa’s Largest 3D Printed Housing Project

Continuing the trend of 3D printed houses being used for affordable housing, Mvule Gardens is a neighborhood consisting of 52 houses, it is Africa’s largest 3D printed affordable housing project. Built by 14Trees, a joint venture between Holcim, a global leader in sustainable construction solutions, and CDC Group, the UK Government’s impact investor, the project hopes to address the housing shortage in Kenya. The homes were built using the BOD2 printer from COBOD and a 3D printable dry mortar called TectorPrint from Holcim, ensuring that the houses are adequately strong and can be made with a reduced carbon footprint. Both two-bedroom and three-bedroom homes are available and 14Trees notes that they hope they will help to make green, low-income and affordable housing a reality for Africa.

Azure 3D Printed Homes for Sustainable Construction

With the goal to develop homes faster, more economically, and with less environmental impact, Ross Maguire and Gene Eidelman brought Azure 3D Printed Homes to life in 2019. By combining years of experience in building and developing properties all over the world, the company has already been able to 3D print several environmentally friendly houses. The company uses recycled waste materials to create the structure of the houses, which are then produced with a large-scale 3D printer in only 24 hours. Azure 3D Printed Homes offers a variety of backyard offices and homes, one example is its Azure Marina Model. This 360 SQ/FT studio consists of a bedroom, kitchen, and bathroom, and can be customized and ordered on the company’s website.

Habitat for Humanity Uses AM For Homes in Low-Income Areas

Atlanta-based nonprofit organization Habitat for Humanity has been able to support millions of people all over the world by helping to construct and preserve houses and shelters.![]() Last year, in 2021, the organization finalized its first house using 3D printing technologies. The 1,200-square-feet house that is located in Williamsburg, Virginia, was the first 3D printed house to be owner-occupied in the United States. To create the house, Habitat for Humanity partnered with 3D printing home construction company Alquist 3D, which used a large-scale 3D concrete printer to produce the house in only 28 hours. The home features a kitchen, three bedrooms, and two full bathrooms. The nonprofit also has been working on building 3D printed houses in other states including Arizona.

Last year, in 2021, the organization finalized its first house using 3D printing technologies. The 1,200-square-feet house that is located in Williamsburg, Virginia, was the first 3D printed house to be owner-occupied in the United States. To create the house, Habitat for Humanity partnered with 3D printing home construction company Alquist 3D, which used a large-scale 3D concrete printer to produce the house in only 28 hours. The home features a kitchen, three bedrooms, and two full bathrooms. The nonprofit also has been working on building 3D printed houses in other states including Arizona.

House 1.0, Europe’s First 3D Printed Tiny House

The House 1.0 is the first 3D-printed Tiny House in Europe. It was made by Danish 3D printing startup 3DCP Group using concrete 3D printers. The company’s goal with this house is to build better, faster, greener, and reduce the amount of effort required in the construction process. The Tiny House is designed to be as cost-effective as possible and to provide owners with all the necessary amenities despite its small size of only 37 m2.

SQ4D Puts the First 3D Printed House on the Market

SQ4D is a company that has completed the construction of the world’s largest known 3D printed house. The house, which was printed and built entirely on-site, is approximately 180 m2 in size and required only forty-eight hours of printing time, which was spread over a period of eight days. The materials used in the manufacturing process had a total value of less than $6000. The company continues to strive for innovation and plans to cut the printing time in half for subsequent projects in the future.

Prvok, the 3D Printed Houses in the Czech Republic

Whether in the countryside, in the city, or even on water, the 3D-printed house called Prvok was born in the Czech Republic and was created through the collaboration of Buřinka, a visionary company from the construction sector, and sculptor Michael Trpák. Built of concrete, the house can be printed in just 22 hours due to the printing speed of 15 cm per second – and with a size of 13.35 m x 3.5 m x 3.1 m. The robot arm thus produces a living area of 43 m2. With a total of three rooms – a bathroom with toilet, a living room with kitchen area, and a bedroom – the building can even be solidified on a floating hollow body, making it habitable on the water all year round.

Built of concrete, the house can be printed in just 22 hours due to the printing speed of 15 cm per second – and with a size of 13.35 m x 3.5 m x 3.1 m. The robot arm thus produces a living area of 43 m2. With a total of three rooms – a bathroom with toilet, a living room with kitchen area, and a bedroom – the building can even be solidified on a floating hollow body, making it habitable on the water all year round.

Viliaprint, the Project Combining AM and Conventional Construction

This project combines additive manufacturing and conventional techniques for building houses. The project called Viliaprint was inaugurated in June of this year in the French city of Reims, more precisely in the eco-district there called Réma’Vert. A total of five houses, with each having living spaces ranging from 77 to 108 m2, were built thanks to the collaboration of stakeholders. The promising project aims at improvements in social, economic, and sustainable aspects. In the 3D printing process, which did not take place directly on site, the designers behind the 3D printed homes placed particular emphasis on concrete that dries as quickly as possible after each layer is applied so that it can hold its own weight.

COBOD and PERI Partner for Incredible Houses Build Using AM

PERI is a company founded in 1969. In 2018, the group acquired a minority stake in COBOD, a leader in 3D design, and since then the two companies have been working together. In 2020, they built the first 3D-printed house in Germany and the largest apartment building in Europe. The house, printed in the Rhineland region of North Westphalia, is a 160-square-meter, two-story single-family home with three-layer insulated cavity walls. The COBOD BOD2 printer was used for the construction, which is characterized by its ability to extrude concrete at a speed of up to 100 cm per second, resulting in the desired project size, smooth and straight walls, and the highest quality requirements. With the CODOB printer, it is possible to build up to 300 square meters on 3 floors at an unprecedented speed. PERI firmly believes that 3D printing will one day, revolutionize the construction industry.

Project Milestone, the 5 3D Printed Homes in the Netherlands

This next housing project is located in the city of Eindhoven in the Netherlands. It consists of five 3D-printed concrete houses. Although the houses have already been sold, you can rent them from a real estate company. Each of them is made of 24 individual concrete pieces that took 120 hours to print layer by layer. These 24 pieces were then moved to the location where the house is currently located and assembled, attached to the foundations, and fitted with a roof, windows, and doors. The buildings have a futuristic design, which makes the houses look like they are abandoned, reminiscent of rocks in an oasis surrounded by trees. The houses meet the ultimate comfort needs and were built in a sustainable and energy-efficient way. The surrounding area is bright, yet quiet, and provides a great place to relax.

It consists of five 3D-printed concrete houses. Although the houses have already been sold, you can rent them from a real estate company. Each of them is made of 24 individual concrete pieces that took 120 hours to print layer by layer. These 24 pieces were then moved to the location where the house is currently located and assembled, attached to the foundations, and fitted with a roof, windows, and doors. The buildings have a futuristic design, which makes the houses look like they are abandoned, reminiscent of rocks in an oasis surrounded by trees. The houses meet the ultimate comfort needs and were built in a sustainable and energy-efficient way. The surrounding area is bright, yet quiet, and provides a great place to relax.

What do you think of these different projects? What is the impact of 3D printing in the construction sector? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

Construction 3D printing is waiting for a breakthrough The first construction projects using this technology appeared only in 2014.

We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed.

We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed. Construction is the world's number one market. And, if many technological innovations are being introduced in the field of high-rise construction, then little has changed in the field of low-rise construction over the past decades. The last 30 years have seen the availability of the Internet, mobile phones, mobile internet, robotics taken to a new level, etc., but when you get to a house construction site, you are unlikely to find many technological innovations. Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more.

Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more.

This Internet meme shows what happened to the cost of building materials in just a year. And the process is still going on. At the same time, there is a serious rise in the cost of labor, and there is an acute shortage of it. All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development.

Preparing to write an article, I turned to the founder of Arkon - Boris Kozlov y. Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

- Construction 3D printing appeared in 2014, but no mass introduction of this technology followed in 7-8 years. Why do you think this happened, and why is there a surge of new projects right now?

- It seems to me that the reason is the snowball effect. The technology had to mature, grow from a hypothesis to a pilot implementation, and finally to commercialization and scaling (what is happening now). In addition, it should be borne in mind that construction is one of the most conservative industries, where, unlike even aviation and the automotive industry, there is still an extremely low introduction of digital solutions and automation in the field of the production process itself - the construction itself.

The issue of regulation and certification also plays an important role - this process is long and creates an additional lag.

In 2014-2016 the first samples of building 3D printers and prototypes of printed buildings appeared. The concepts of various form factors of construction 3D printers and types of printing materials were tested.

In 2017-2018 in the world, the first notable investments were made in a number of construction 3D printing start-ups. Further, by 2020, these investments "rolled" in the form of reaching a certain level of technology maturity - the first commercial products (3D printers and houses) appeared.

Finally, in 2020-2022 it became clear that the hypotheses of the effectiveness of construction 3D printing were justified (cheaper, faster, more environmentally friendly), and large investments began in the industry. A striking example is the investment of GE (the French division of General Electric) in the Danish COBOD or the achievement of a capitalization of $ 2 billion by the American company ICON.

In 2022-2023 over 1,000 buildings will be printed worldwide already, scaling from single buildings/pilot projects to entire villages and major infrastructure/reinforced concrete implementations. In addition, in a number of countries, by now, a regulatory framework has been created or is being actively created for the introduction of additive technologies in the construction industry.

Thus, I believe that the specified time period is a fairly natural cycle of technology development, which is likely to experience exponential growth in the next decade.

According to ResearchAndMarket report, the global construction 3D printing market is valued at USD 354.3 million in 2022 and is projected to reach USD 11068.1 million by 2027, growing by 99.04%.

Various market processes affect the prices and behavior of participants in the global 3D construction printing market. They create price signals that are the result of changes in the demand and supply curves for a product or service. They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals.

They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals.

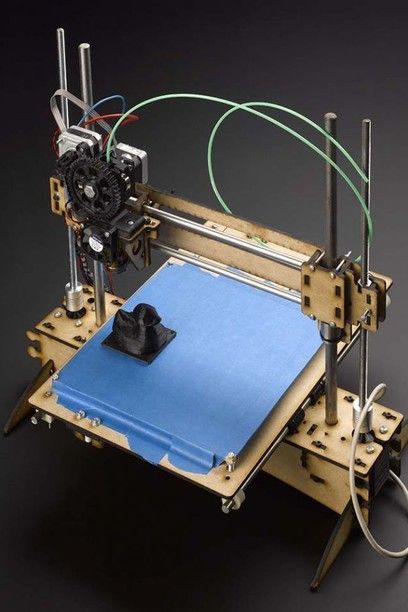

Now let's take a quick look at what the construction 3D printer is. Without delving too deeply into the technology, we can say that construction 3D printers are very similar to classic FDM/FFF printers that print with plastic, but instead of plastic, the material here is a cement mixture, which is fed directly into the nozzle and forms an object by layer-by-layer overlay. Printers are also portal, on the basis of a flying boom, with a robotic arm.

Pictured left is a construction printer based on a boom. The figure on the right is a gantry construction 3D printer

In the figure above, a construction 3D printer in the form of a robot arm installed on a mobile platform.

Everything changed completely when, in the summer of 2021, the American company ICON, which was trying to introduce 3D printing into the construction of various auxiliary facilities, signed a contract with one of the largest American developers, Lennar, to build a village of 100 houses in Texas and immediately became a unicorn , having received 200 million dollars of investments from several investment funds.

At the same time, the Danish company COBOD, created by the world's largest construction formwork company PERRI, began selling its gantry 3D construction printers and participating in construction projects around the world. In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

Few things unite developed, developing and poor countries, everywhere their problems and tasks, but Affordable housing shortage is a global agenda . If in poor countries there is an acute problem with the increase in the number of homeless people due to a lack of housing, as such, then in developing countries it is necessary to dramatically accelerate the number of new housing being built to meet the needs of a growing population. In developed countries, the problem is primarily in the cost of housing, which has risen in price to such an extent that it has become practically inaccessible to young people. And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse.

And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse.

At the same time, the trend towards "green agenda " is developing, reducing CO2 emissions, building with more environmentally friendly materials, etc. But, unfortunately, so far the construction industry is the absolute leader in CO2 emissions, as well as in the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples.

3D printed walls. Today, when we talk about 3D printing houses, we are talking about printing walls. Everything else (foundation, windows, doors, ceilings and roof) is done in the traditional way. 3D printed walls are built as fixed formwork, which significantly saves the amount of cement used , and this, in turn, reduces the cost of construction and reduces the environmental impact of cement production. In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

Eco-concrete with the addition of polymers is being actively developed, the production of which reduces CO2 emissions from 30% to 100%. The Apis Cor company mentioned at the beginning of the article, which built a house in the suburbs in 2015, is now based in hot Florida, plans to start using this material in its projects..jpg)

Another startup from Russia, Mighty Buildings, headquartered in California, initially relied on a polymer with the addition of mineral chips. And while the company doesn't build entire homes, it only makes wall panels, it has won numerous design awards, as well as a $400 million valuation in several investment rounds.

As a result, with a rough calculation, we can say that the total savings on the construction of walls can reach 30%, and the total cost of the house can be reduced by 10%. This is true for houses designed for conventional construction. And if you initially design with 3D printing, you can improve this ratio by optimizing the laying of communications, the ability to immediately print interior walls, bookmark niches for bathrooms, fireplaces, built-in wardrobes and kitchens, as was done in the house built by COBOD in Germany.

"There are spots on the sun." Despite all the advantages of construction 3D printing, has several significant disadvantages of . The main one is layering, which cannot be avoided at the current level of technology development.

The main one is layering, which cannot be avoided at the current level of technology development.

The photo above shows the layering of the 3D printed walls.

This task can be worked in several directions:

-

Ribbed walls can be plastered, painted and played with as a design element. That's how ICON does it in the US, for example their latest project House Zero is done that way and has won a number of design awards.

-

Use special "shutters" on the print head that allow smooth layers, as COBOD and other manufacturers do. The photo below shows that this does not ensure the complete absence of layering.

-

Fully sand the surface to get the usual smooth wall for plastering, painting, wallpapering or other finishing. It is possible, but it will require huge labor costs, which can reduce the overall efficiency of using 3D printing.

Pictured above is a 3D printed wall sanded smooth.

The second problem is the required temperature. Ideally, printing should take place at temperatures between +5C° and +30C°. Humidity is also important. Using additives, you can push these boundaries, but not indefinitely. At strong sub-zero temperatures, printing will be possible in the field only if the construction site is covered with a dome and the required temperature is reached inside with the help of heat guns. In conditions of intense heat, it is preferable to print at night. Another solution could be to print the wall panels in the shop and assemble them on site. Of course, each of these decisions will have a negative impact on the economic efficiency of the project.

Building 3D printing can be useful not only for the construction of houses . With its help, you can solve many other problems, and there its disadvantages will not matter. For example, the American concern GE uses COBOD printers to build towers for wind turbines in the shop. Ribbed surface and temperature restrictions in this case do not play any role. Construction takes place in the shop, after which the object is transported to the installation site.

Construction takes place in the shop, after which the object is transported to the installation site.

Construction 3D printing, or, as it is also called, additive construction, has just appeared, and I want to believe in its bright future. There are many prerequisites for this, but a lot still needs to be done for success. First of all, it is necessary to develop principles for designing houses for building 3D printing. Then it is necessary to attract top architects to create landmark projects, which can be followed by the mass introduction of a new and very promising technology. Construction 3D printing could help solve the global housing shortage and bring more automation to other areas of construction.

Alexander Kornveits

Expert in the field of additive technologies and 3D printing, head of Tsvetnoy Mir company

The best 3D printers for home, office or studio

? There is nothing surprising if such a thought periodically visited you. Today, 3D printing has gone beyond the geek toy it once was, and the 3D printer has become a truly useful device for many creative people. Such printers can be used not only to produce parts for all kinds of design projects, but also to print useful home appliances. In addition, the ability to print with consumables such as metal, rubber, or even biodegradable filaments means that finished products will be strong and durable. And if you are an experienced 3D artist or designer, you can combine your skills and the capabilities of a 3D printer to the maximum.

Today, 3D printing has gone beyond the geek toy it once was, and the 3D printer has become a truly useful device for many creative people. Such printers can be used not only to produce parts for all kinds of design projects, but also to print useful home appliances. In addition, the ability to print with consumables such as metal, rubber, or even biodegradable filaments means that finished products will be strong and durable. And if you are an experienced 3D artist or designer, you can combine your skills and the capabilities of a 3D printer to the maximum.

Be aware that not all 3D printers work the same way. Some use spools of plastic filament that is heated like a hot glue gun and then laid out in layers on the print bed. The print quality of such devices can be good, but some manual processing is often required to smooth out the layer lines. Some models use an LCD screen to shine light onto the resin, while other printers use a laser to solidify the melted resin.

If you do not want to do modeling, then the abundance of marketplaces with ready-made 3D models will allow you to get good results. Thingiverse, CG Trader and many other sites offer all sorts of models in .stl format that you can print with just a few clicks. Very often you can find free models.

Thingiverse, CG Trader and many other sites offer all sorts of models in .stl format that you can print with just a few clicks. Very often you can find free models.

Anycubic Vyper

Budget printer with good features

Price: $399.

Print volume: 245x245x260 mm.

Layer thickness: 100 µm.

Pros:

- self-levelling bed included,

- excellent level of detail,

- good print speed.

Cons:

- the need for self-assembly.

Anycubic's 3D printers are all good options, but as the most affordable FDM printer, the Vyper is the best deal. It has features not found in more expensive options, and produces prints with great detail and clarity, while doing so with minimal noise. The heated self-levelling print bed is a great feature, but adding a magnetic spring steel sheet to make it easier to remove prints is a win-win.

Ultimaker S3

Best solution for general 3D printing tasks

Price: $4,080.

Print volume: 230x190x200 mm.

Layer thickness: 20 µm.

Pros:

- double extruders make life easier,

- is an excellent self-leveling heated build platform.

Cons:

- not the cheapest option,

- noise level is higher than some other printers.

Ultimaker printers come in a variety of sizes and capabilities, but the Ultimaker 3 is the model we deliberately included in our list of the best 3D printers. A 3D printer has most of the features you want from larger brethren, including dual extruders and nozzles of various sizes. This means that you can print models that would be difficult to print using PVA plastic, which dissolves in water. The Ultimaker 3 also has a print progress camera, a great touch screen interface and a solid build. If you need to master large volumes of printing, then choose the advanced version, which is a little more expensive.

Elegoo Mars 2 Pro

Best Resin Printing Solution

Price: $329. 99.

99.

Print volume: 129x80x160 mm.

Layer thickness: 50 µm

Pros:

- excellent print quality at a reasonable price,

- fast printing at 1-2 seconds per layer.

Cons:

- self assembly required,

- Printing smoke can be annoying.

Elegoo is relatively new to the 3D printing market, but the original Mars printer made a good impression on the community. Mars 2 Pro only confirms the serious intentions of the manufacturer. The new 6” screen prints a layer in less than 2 seconds with no loss of clarity or blur, making this 3D printer one of the fastest resin printers around. In terms of prototyping speed, it's hard to beat unless you need larger objects, as the only real downside to the Mars 2 Pro is the small amount of printed assembly. Smoke when printing is typical for this type of printer.

Makerbot Replicator+

Universal 3D printer with FDM

Technology: 4500 dollars

Press volume: 295x195x165 mm

Layer thickness: 100 μm

Plus:

- 9009

- lots of connection options.

Cons:

- takes up more space than most competitors,

- is not the cheapest option.

Makerbot has been around for a long time and is probably the best-known manufacturer of consumer 3D printers. Even Anna Kendrick used it in space in the movie Stowaway. Experience in this area has allowed Makerbot to maintain a similar area to previous models, but increase the volume of printing and reduce the noise level. This model provides a large number of connectivity options, including Wi-Fi. The Makerbot Replicator+ even has a camera so you can watch what's going on remotely. Printing results are good and need only a little manual refinement, because this is an FDM printer. The Replicator+ is a great and reliable option if you are looking to purchase a 3D printer for your home office, school or workshop.

Anycubic Photon mono SE

Best choice for printing 3D miniatures

Price: $449.89

Print volume: 130x78x160 mm.

Layer thickness: 100 µm.

Pros:

- excellent level of detail,

- smooth surface.

Cons:

- pairs of highlights during printing can be unbearable,

- resin is expensive. Anycubic's

Photo Mono SE is a great choice if you like custom toys, collectibles or action figures from PC games as the detail on this printer is fantastic. Like other monochrome printers, it is fast enough. It only takes about a second to print one layer. The resin may have an unpleasant odor, but you can place the printer under an air exhaust cabinet. This is a small sacrifice for such a productive machine, which is really worth the money spent.

Markforged Onyx One

Best Metal Printer

Price: $4,794.

Print volume: 320x132x154 mm.

Layer thickness: 100-200 µm.

Pros:

- reliable and durable prints,

- all in one desktop case.

Cons:

- expensive,

- metal filament spools are expensive.

Onyx One prints out of durable metal, but the parts are actually carbon fiber. The main reason for choosing this technology is that although powdered metal filaments are available, they instantly destroy extruder nozzles, making the production of metal objects prohibitively expensive. Markforged solves this problem with a best-in-class desktop solution. So if you're looking for durable and reliable parts, this printer should be on your list. Just remember that a spool of filament can be quite expensive.

Creality Ender 3

Best Budget FDM 3D Printer

Price: $223.

Print volume: 220x220x250 mm.

Layer thickness: 100 µm.

Pros:

- high quality components,

- ease of use.

Cons:

- open chassis,

- The typing sound can be quite loud.

Ender's range of 3D printers is known for its superior performance at an affordable price. And Ender 3 is a perfect example of this. At this price, you would think that Black Friday lasts all year round. Creality has somehow managed to inject some of the highest quality components into Ender 3. The printer comes in kit form, which may not be to everyone's liking, but the assembly process actually gives you a good idea of how the printer works and can help with troubleshooting if there are any in the future.

At this price, you would think that Black Friday lasts all year round. Creality has somehow managed to inject some of the highest quality components into Ender 3. The printer comes in kit form, which may not be to everyone's liking, but the assembly process actually gives you a good idea of how the printer works and can help with troubleshooting if there are any in the future.

Formlabs Form 3

Best SLA Printer

Price: $3499.

Print volume: 145x145x185 mm.

Layer thickness: 15 µm.

Pros:

- easy replacement of material cartridges,

- No layer visibility.

Cons:

- expensive,

- additional costs for obtaining a medical version.

The Formlabs Form 3 and its predecessor Form 2 set the benchmark for SLA printers (3D printing technology based on the layer-by-layer curing of a liquid material under the action of a laser beam). And the FormLabs Form 3 is by far the best printer on the market. This is a rather expensive product, but the quality of the results speaks for itself. Products are obtained with invisible layers, and the printer itself is equipped with a system that allows you to remove the finished product without the use of cutters. In addition to the impeccable print quality, the big advantage here is the ease of use. Changing media is as easy as replacing a cartridge on a conventional printer. For a little more, you will have access to biomaterials for use in dentistry and medicine. Oh, and the PreForm software is simple and intuitive too.

This is a rather expensive product, but the quality of the results speaks for itself. Products are obtained with invisible layers, and the printer itself is equipped with a system that allows you to remove the finished product without the use of cutters. In addition to the impeccable print quality, the big advantage here is the ease of use. Changing media is as easy as replacing a cartridge on a conventional printer. For a little more, you will have access to biomaterials for use in dentistry and medicine. Oh, and the PreForm software is simple and intuitive too.

3Doodler

Best Portable 3D Printer

Price: $49.99

Pros:

- you can take it anywhere,

- no print volume limit.

Cons:

- expensive consumables,

- print quality is up to you.

One of the biggest limitations for 3D printing is the fixed volume. But since 3Doodler is a 3D printing pen, here you can print projects of any size. The cost of consumables can be quite high, especially if you are trying to model a car in 1:1 scale. What's more, it's fantastic fun to pick up a pen from a table top and draw lines in the air with plastic ink. The threads come in different colors, so you can consider it an added plus. But the downside is that you will have to rely only on yourself for printing accuracy, since the extruder is entirely in your hands, and not on rails. Several models are available, including 3Doodler Start (for kids) and a Pro version.

The cost of consumables can be quite high, especially if you are trying to model a car in 1:1 scale. What's more, it's fantastic fun to pick up a pen from a table top and draw lines in the air with plastic ink. The threads come in different colors, so you can consider it an added plus. But the downside is that you will have to rely only on yourself for printing accuracy, since the extruder is entirely in your hands, and not on rails. Several models are available, including 3Doodler Start (for kids) and a Pro version.

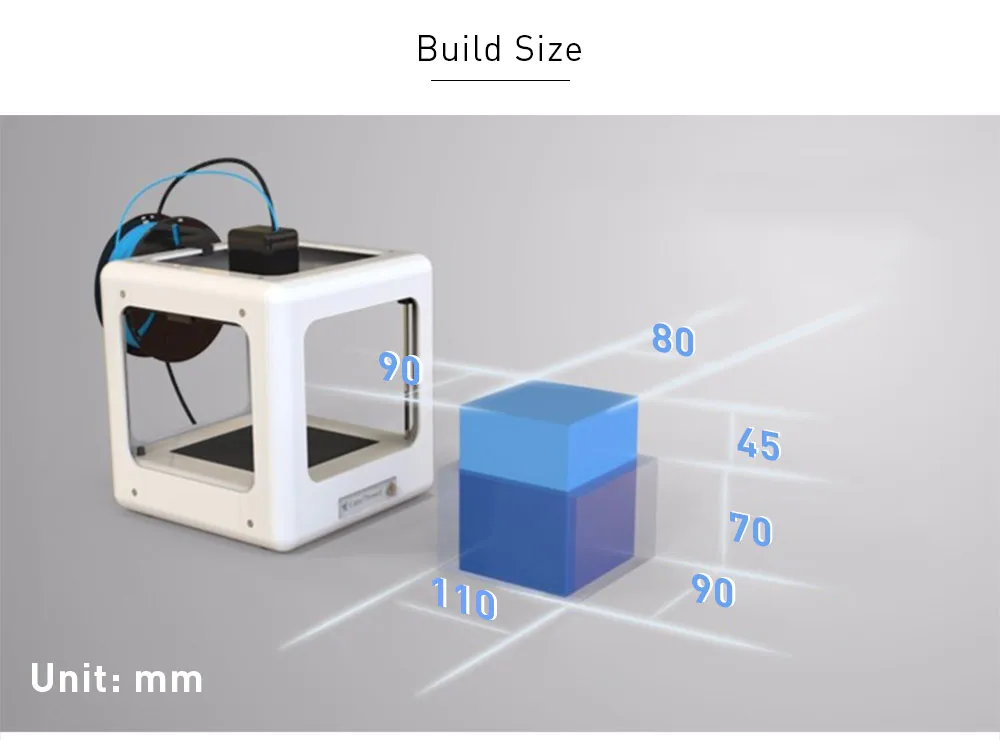

EasythreeD K5

Best budget option, safe for kids

Price: $99.99.

Print volume: 80x80x100 mm.

Layer thickness: 100-400 µm.

Pros:

- affordable entry point to 3D printing,

- fun and safety for kids.

Cons:

- tiny build platform,

- medium print quality.

It's hard not to love the EasythreeD K5 for its attractive looks and ease of use.