Relativity 3d printer

Relativity Space

Scroll

FACTORY OF

THE FUTURE

ROCKETS BUILT AND FLOWN IN DAYS

Relativity's proprietary Factory of the Future centers on Stargate, the world’s largest metal 3D printers, that create Terran 1, the world’s first 3D printed rocket, and the first fully reusable, entirely 3D printed rocket, Terran R, from raw material to flight in 60 days. Relativity’s Stargate printers’ patented technology enables an entirely new value chain and innovative structural designs that make Terran 1 and Terran R possible. By developing its Factory of the Future and rockets together, Relativity accelerates its ability to improve design, production, quality, and speed.

Zero fixed tooling and radical part count reduction

LEARN ABOUT TERRAN

POWERING THE STARGATE PRINTER

METALLURGY

Relativity developed multiple proprietary alloys custom designed for 3D printing to meet mission-critical performance.

UNIFORMITY

Parts are inspected during and after printing to ensure they meet the highest standards of uniformity and quality.

THE FUTURE IS 3D PRINTEDFor 60 years, aerospace manufacturing has relied on large factories, fixed tooling, complex supply chains, and extensive manual labor to build costly rockets comprised of 100,000+ parts in 2 years or longer.

To accelerate innovation in the industry, Relativity built its Factory of the Future, the first aerospace platform to automate rocket manufacturing, vertically integrating intelligent robotics, software, and data-driven 3D printing technology. Incorporating Stargate, the world’s largest metal 3D printer with AI-driven controls, our Factory of the Future continuously optimizes production, resulting in greatly compounded quality and time improvements, lower costs, and product designs previously not possible.

Relativity is an application-layer 3D printing company that is starting with rockets, and will extend its Factory of the Future to all of aerospace.

Rigid Factories, Fixed

tooling & HIGH Labor Costs

100,000+ Part Count

24 Month Build Time

48 Month Iteration Time

Complex Supply Chain

High Physical Complexity

ADAPTABLE, SCALABLE

AUTONOMOUS ROBOTICS

<1,000 Part Count

2 Month Build Time

6 Month Iteration Time

Simple Supply Chain

Software Defined Factory

CHANGING THE WAY ROCKETS ARE BUILT AND FLOWN

Custom designed

for printing

- High strength alloys specially designed for Stargate printers

- Physical properties designed to meet mission-critical structural requirements

- In-house material characterization lab for quickly iterating on new alloy development

- Relativity developed multiple proprietary alloys custom designed for 3D printing to meet mission-critical performance

- Parts are inspected during and after printing to ensure they meet the highest standards of uniformity and quality.

UNIFORMITY

REAL-TIME QUALITY CONTROL

AND PART INSPECTION

- Intelligent data-driven manufacturing

- Machine learning control algorithms

- Collaborative additive and subtractive process enables complex geometry

Collaborative robotics

and path planning

- Verification and validation data captured during manufacturing

- Flexible and highly scalable system architecture

- Cloud-based manufacturing simulation and training

Careers

Scroll

CAREERS

CAREERS

View Open Positions

Relativity team members at our hanger at Launch Complex 16 in Cape Canaveral, FL

Celebrating World Creativity and Innovation Day 2022, Long Beach, CA Headquarters

Propulsion Test Technician working on our engine at our test facility in Stennis, MS

GO/NOGO polling from the control room at Cape Canaveral, FL

2022 Aerospace Games in Long Beach, CA

You're a multihyphenate human who thrives where engineering meets creativity. And we at Relativity defy labels, exceed expectations, and push through boundaries. From day one, you'll get to work on cutting-edge technology and solve complex problems in creative ways that haven't been done before. By creating the world's largest metal 3D printers, Relativity is taking 3D printing to new heights, starting first by creating orbital rockets, Terran 1, the world's first 3D printed rocket and Terran R, the first fully reusable, 3D printed rocket. With the ultimate goal of building humanity's multiplanetary future, Relativity is expanding the possibilities of the human experience by upgrading humanity's industrial base on both Earth and Mars. Want to create new worlds while protecting our own? Join our team and help create the future of manufacturing.

And we at Relativity defy labels, exceed expectations, and push through boundaries. From day one, you'll get to work on cutting-edge technology and solve complex problems in creative ways that haven't been done before. By creating the world's largest metal 3D printers, Relativity is taking 3D printing to new heights, starting first by creating orbital rockets, Terran 1, the world's first 3D printed rocket and Terran R, the first fully reusable, 3D printed rocket. With the ultimate goal of building humanity's multiplanetary future, Relativity is expanding the possibilities of the human experience by upgrading humanity's industrial base on both Earth and Mars. Want to create new worlds while protecting our own? Join our team and help create the future of manufacturing.

As a partner of NASA’s Stennis Space Center and the U. S. Air Force, Relativity operates multiple production, test, and launch sites across the country. Whether you want to work at our headquarters in California, our testing facilities in Mississippi, or our launch complex in Florida, Relativity has a spot for you.

S. Air Force, Relativity operates multiple production, test, and launch sites across the country. Whether you want to work at our headquarters in California, our testing facilities in Mississippi, or our launch complex in Florida, Relativity has a spot for you.

View All Locations

AUDACITY

Challenge convention in pursuit of an expansive future.

RELENTLESSNESS

Focus on achieving intentionally meaningful results.

WONDER

Approach the world with awe and a deep desire to create.

Humanity

Expand possibilities for the human experience in this world – and beyond.

We are committed to our team member’s health, well-being, and growth.

We offer high-quality care plans for health, dental, and vision, and provide an additional stipend for employee wellness.

COMPETITIVE COMPENSATIONIn addition to receiving a competitive salary and 401(k), team members are eligible to receive equity.

WORK / LIFE INTEGRATIONWe observe 11 company holidays and have a generous PTO policy.

TEAM CAMARADERIEOur team connects and recharges with monthly lunches, game nights, holiday celebrations, and offsite events.

Parental Leave and Family Building

We offer generous parental leave and provide a $10,000 stipend for fertility, adoption, and other family-building benefits.

LEARNING AND DEVELOPMENT

Our $2,000 annual learning stipend allows you to develop your professional skills and accelerate your career. We also have constant training opportunities, company Lunch and Learns, and access to industry conferences.

We look forward to welcoming you and building a multi-planetary future – for everyone!

We believe empowering people from different backgrounds, identities, and perspectives will advance our mission and enable us to build the highest-performing team possible. Diversity, equity, and inclusion are integrated into Relativity’s DNA, and we continuously take steps to advance our culture of belonging internally and externally.

Through our Inclusion Champion Program and Inclusion 30 Conversations, our team members advocate for DEI and consistently drive our mission forward. By partnering with organizations like the Los Angeles’ Racial Equity & Newly Empowered Workplaces (RENEW) Task Force, Aerospace 2030, and the City of Long Beach’s Space Beach Mentorship Program, we seek to inspire and build a more inclusive future for aerospace.

Relativity team. Pride celebration at Long Beach, CA Headquarters

Full-time positions are listed below. Students can view the list of internships here.

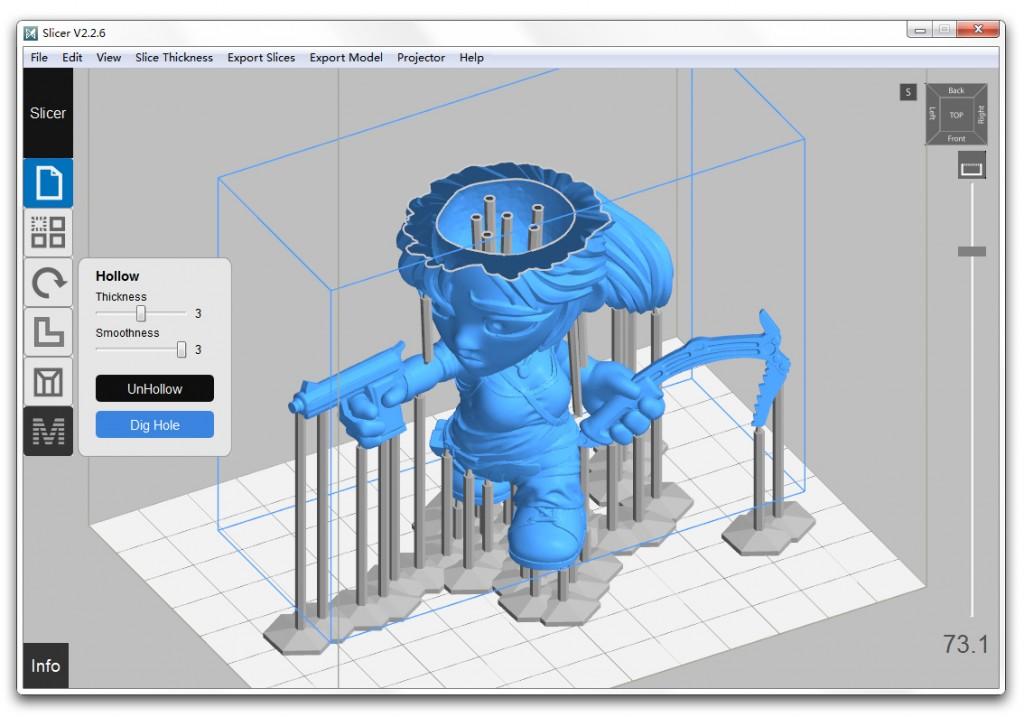

Classification of 3D printers (7 3D printing technologies) / Sudo Null IT News what principles are laid down in 3D printing technology, what materials are used and, ultimately, what technology is better to use to obtain a certain result, whether it is a titanium part or a master model for subsequent replication.

The article is based on the book Fabricated: The New World of 3D printing

I. Those who extrude or pour or spray something

1) FDM (fused deposition modeling) printers that extrude some material layer by layer through a nozzle-dispenser, I will not paint in detail, we all know about them. All makerbot-like printers + Stratasys printers + various culinary printers (using icing, cheese, dough) + medical ones that print with “living ink” (when any set of living cells is placed in a special medical gel that is used further in biomedicine)

All makerbot-like printers + Stratasys printers + various culinary printers (using icing, cheese, dough) + medical ones that print with “living ink” (when any set of living cells is placed in a special medical gel that is used further in biomedicine)

2) Polyjet technology was invented by the Israeli company Objet in 2000. Stratasys bought them in 2012. The essence of the technology: the photopolymer is fired in small doses from thin nozzles, as in inkjet printing, and immediately polymerizes on the surface of the manufactured device under the influence of UV radiation. An important feature that distinguishes PolyJet from stereolithography is the ability to print with various materials.

Advantages of the technology: a) layer thickness up to 16 microns (blood cell 10 microns) b) prints quickly, as the liquid can be applied very quickly. Disadvantages of the technology: a) prints only using a photopolymer - a highly specialized, expensive plastic, usually sensitive to UV and quite fragile.

Application: industrial prototyping and medicine

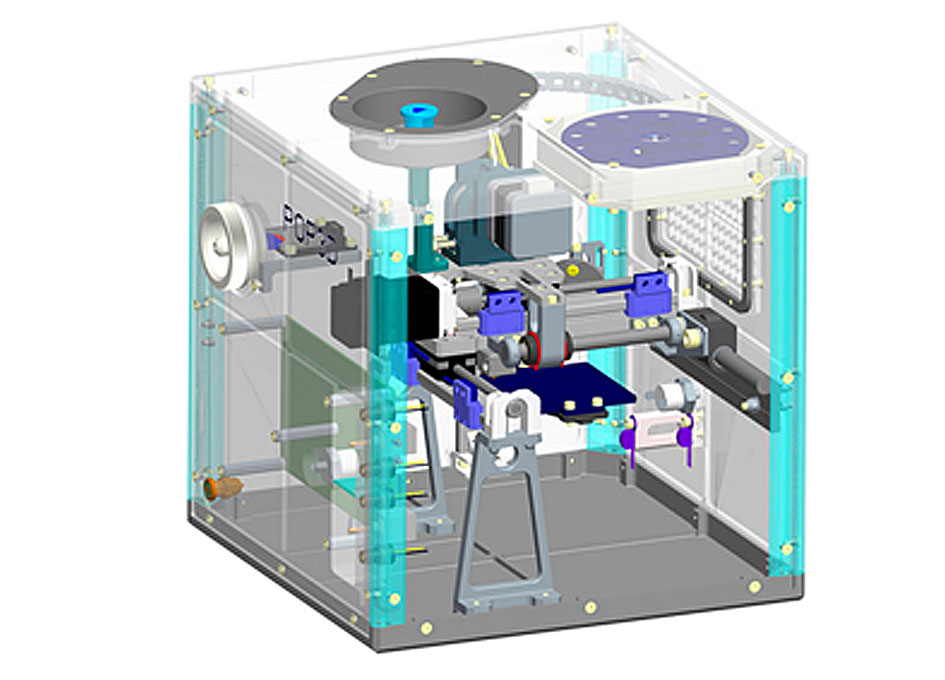

3) LENS (LASER ENGINEERED NET SHAPING)

The material in powder form is blown out of the nozzle and hit by a focused laser beam. Part of the powder flies past, and the part that falls into the focus of the laser is instantly sintered and layer by layer forms a three-dimensional part. This technology is used to print steel and titanium objects.

Since only plastic objects could be printed before the advent of this technology, no one took 3D printing particularly seriously, and this technology opened the door for 3D printing to the “big” industry. Powders of different materials can be mixed and thus obtained alloys, on the fly.

Application: e.g. titanium blades for turbines with internal cooling channels. Equipment manufacturer: Optomec

4) LOM (laminated object manufacturing)

Thin laminated sheets of material are cut with a knife or laser and then sintered or glued into a three-dimensional object. Those. a thin sheet of material is laid, which is cut along the contour of the object, thus one layer is obtained, the next sheet is laid on it, and so on. After that, all sheets are pressed or sintered.

Those. a thin sheet of material is laid, which is cut along the contour of the object, thus one layer is obtained, the next sheet is laid on it, and so on. After that, all sheets are pressed or sintered.

In this way, 3D models are printed from paper, plastic or aluminum. Aluminum models are printed using thin aluminum foil, which is cut along the contour layer by layer and then sintered using ultrasonic vibration.

II. Those who sinter or glue something

1) SL (Stereolithography) Stereolithography.

There is a small bath with liquid polymer. The laser beam passes over the surface, and at this point the polymer polymerizes under the influence of UV. After one layer is ready, the platform with the part is lowered, the liquid polymer fills the void, then the next layer is baked and so on. Sometimes the opposite happens: the platform with the part rises, the laser is accordingly located below ...

After printing with this method, post-processing of the object is required - removal of excess material and support, sometimes the surface is polished. Depending on the required properties of the final object, the model is baked in the so-called. ultraviolet ovens.

Depending on the required properties of the final object, the model is baked in the so-called. ultraviolet ovens.

The photopolymer is often toxic, so when working with it, you need to use protective equipment and respirators. Maintaining and maintaining such a printer at home is difficult and expensive

Advantages: fast and accurate, accurate to 10 microns. To sinter the photopolymer, a laser from a Blu-ray player is enough, thanks to which cheap yet accurate printers using this technology (e.g. Form1) appear on the market.

2) LS (laser sintering)

Laser sintering. Similar to SL, but instead of a liquid photopolymer, a powder is used that is sintered by a laser.

Advantages: a) it is less likely that the part will break during the printing process, since the powder itself acts as a reliable support b) materials in powder form are quite easy to find on sale, including: bronze, steel, nylon, titanium

Disadvantages: a) the surface is porous b) some powders are explosive, therefore they must be stored in chambers filled with nitrogen c) sintering takes place at high temperatures, so the finished parts cool for a long time, depending on the size and thickness of the layers, some objects can cool up to one day .

3) 3DP (three dimensional printing)

Invented in 1980 at MIT by Paul Williams, the technology has been sold to several commercial organizations, one of which is zCorp, now taken over by 3D Systems.

An adhesive is applied to the material in powder form, which binds the granules, then a fresh layer of powder is applied over the glued layer, and so on. The output, as a rule, is a sandstone material (similar in properties to gypsum)

Advantages: a) since glue is used, paint can be added to it and thus colored objects can be printed b) the technology is relatively cheap and energy efficient c) it can be used at home or office c) it can be printed using glass powder, bone powder, recycled rubber, bronze and even sawdust. Using a similar technology, you can print edible objects such as sugar or chocolate powder. The powder is glued together with special food glue, dye and flavoring can be added to the glue. As an example, the new 3D printers from 3D systems, which were demonstrated at CES 2014 - ChefJet and ChefJet Pro

Disadvantages: a) a rather rough surface is obtained at the output, with a low resolution of ~ 100 microns b) the material must be post-processed (baked) to give it the necessary properties.

I hope the material will be useful to you.

Additions are accepted.

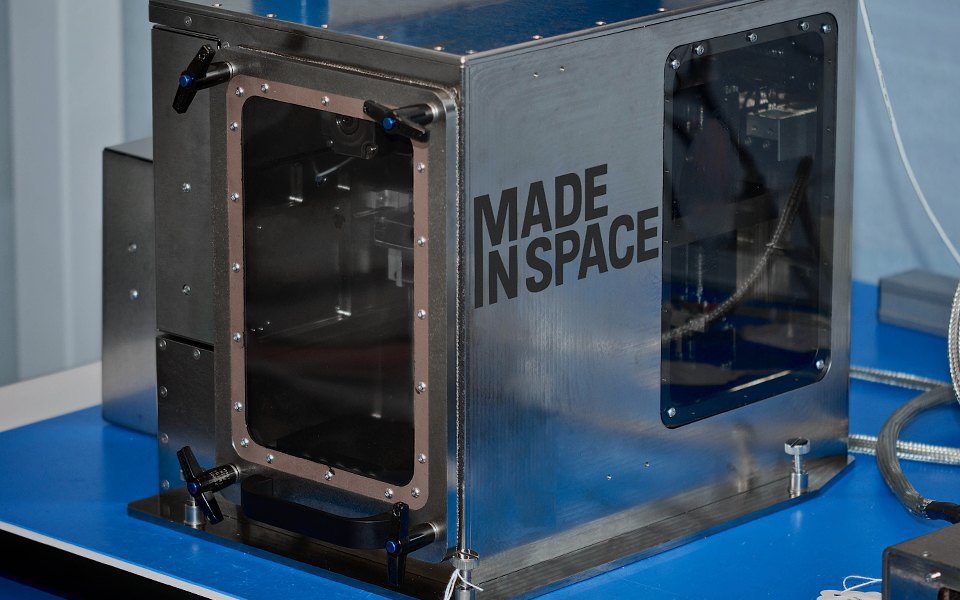

3D printer taught to detect printing defects in time

American researchers have created an algorithm that can monitor the compliance of the object printed on the 3D printer with the original model. The camera-assisted system evaluates the condition of an item during critical printing steps and can stop the process if defects are found, the developers say in a magazine Procedia Manufacturing .

Most 3D printers do not have a print tracking system and in some cases can even continue printing after the filament is used up. Because of this, in the case of printing large and complex parts, the printer can waste time and materials that could be saved with a tracking system.

Ugandhar Delli and Shing Chang of the University of Kansas have developed a 3D printer system that automatically evaluates the print status. The system consists of a camera and lighting mounted on a 3D printer, and a control algorithm. After the user creates a 3D model of an object, it is supplemented with several control points - printing stages, in which the shape of the object changes greatly and the probability of error is higher. The authors chose this particular scheme of work, because otherwise the printer would have to stop printing and take the extruder to the side after each layer, and this would significantly reduce the printing speed.

After the user creates a 3D model of an object, it is supplemented with several control points - printing stages, in which the shape of the object changes greatly and the probability of error is higher. The authors chose this particular scheme of work, because otherwise the printer would have to stop printing and take the extruder to the side after each layer, and this would significantly reduce the printing speed.

After the printer has retracted the print head and allowed the camera to capture an image of the partially printed part, the algorithm starts processing the image. Initially, it is divided into a square grid of four by four regions, and for each region of the image, the algorithm calculates the average color value. This is followed by a two-stage analysis. First, the algorithm compares the colors of the areas, and if at least four of them differ from the standard by ten percent, this may mean a noticeable difference in print quality from the planned one.

The image is then passed to a machine learning algorithm based on the support vector machine. The researchers created two trained models for it, corresponding to “high-quality” and “poor-quality” items. The task of the algorithm is to classify the input images and assign them to one of these two categories. If the conclusions of both algorithms matched, it is likely that a failure occurred during the printing process and it is more profitable to stop it so as not to waste time and materials.

The researchers created two trained models for it, corresponding to “high-quality” and “poor-quality” items. The task of the algorithm is to classify the input images and assign them to one of these two categories. If the conclusions of both algorithms matched, it is likely that a failure occurred during the printing process and it is more profitable to stop it so as not to waste time and materials.

Researchers note that their development has two drawbacks. First, the system requires you to stop printing, which increases the printer's operating time. Secondly, while the system is equipped only with a camera that shoots an object from above. In the future, the authors plan to add side cameras to it, which will allow the system to see defects in different parts of the structure.

Usually 3D printer developers struggle with defects, but sometimes they deliberately create them. Last year, American engineers developed a method to protect 3D printed products from copying and forgery.