Monoprice maker select plus 3d printer firmware

Need help with 3d printing upgrade - Monoprice Maker Select Plus to Marlin firmware

Log in Register

JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding.

- Status

- Not open for further replies.

- Add bookmark

- #1

I've had a very frustrating weekend - a lot of "two steps forward, one step back" results. I've got a Monoprice Maker Select Plus, and I want to be able to program pauses for filament changes into my Gcode. The firmware that it comes with does not seem to support this, but most of the current firmwares do.

With some research, I settled on Marlin - it was the firmware that was most talked about favorably on Reddit. I got the information I needed, I downloaded the files I needed, and I procrastinated for a few weeks, because I know how painful firmware updates can be if the stars aren't aligned perfectly.

Well, that's what happened here. First I had trouble reattaching the thin video cable to the LCD panel (after adding a small mod to hold the LCD at a slight angle, instead of just vertical). Installing the cable incorrectly resulted in some odd side-effects, but once I got it mounted right, the printer worked fine again.

Then I went to install the LCD panel's firmware - separate from the main firmware, because this is, despite evidence to the contrary, still a hobbyist market, not a full professional market - and realized that I needed a different SD card than what I had. Got that, installed the files, still didn't work - because I hadn't formatted the SD card in precisely the manner that the hardware required. Formatted the SD card, reinstalled the files, and voila, the video screen's updated.

Got that, installed the files, still didn't work - because I hadn't formatted the SD card in precisely the manner that the hardware required. Formatted the SD card, reinstalled the files, and voila, the video screen's updated.

But that firmware update doesn't mesh well with the main board's firmware, so my printer is DOA until I can get the firmware update done. Try it one way (with Cura) - that didn't work. Ask for help on Reddit, get no responses at all. Try it another way (with the Wanhao-specific Cura) - that sort of worked, but not really. Check in on Reddit again, and I've gotten one reply, which actually did give me a little info that helped me look in the right direction.

Installed the firmware via Arduino IDE (which I'd avoided because I have no experience with Arduino, and thought that'd involve spending money to buy an Arduino), and that seems to have worked... except I still can't use it.

At this point, the Marlin menu does come up properly (instead of going to a secondary menu and being completely unresponsive). But when I go to a submenu, it does not give me accurate information (the Print page shows no Gcode files to print, even though the HD Card has dozens), and I'm unable to navigate further - both additional options and the BACK button blink when they're touched, but don't actually do anything.

But when I go to a submenu, it does not give me accurate information (the Print page shows no Gcode files to print, even though the HD Card has dozens), and I'm unable to navigate further - both additional options and the BACK button blink when they're touched, but don't actually do anything.

So I'm at a loss here. I have no idea how to fix this problem, /r/3dprinting is surprisingly unhelpful (I even got a downvote for asking for help, apparently), and I can't find any place - support forums, Skype or Discord discussion channels, ANYTHING - that could help me, point me in the right direction, and get me printing again.

So... where can I go to get this sort of assistance? Do I need to bite the bullet and go to one of the Los Angeles Maker Space labs and take the printer along for the ride, or is there some online support site or forum or chat channel that would be of use for me?

- Add bookmark

- #2

Honestly the Maker Select Facebook group is probably your best option. They deal with printer problems all the time.

They deal with printer problems all the time.

- Add bookmark

- #3

Thanks, Tegid. I've applied to that group (Monoprice Maker Select Plus Owners).

- Add bookmark

- #4

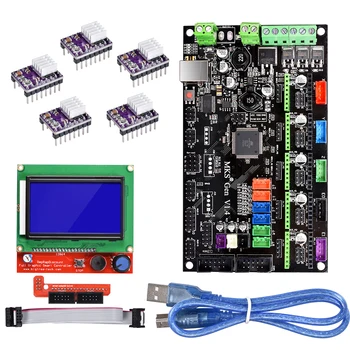

Which firmware are you installing? I've seen both i3Plus+ and ADVi3pp online, but it looks like i3Plus+ hasn't seen any updates in almost a year.

I'm planning to update my Select Plus to ADVi3pp soon-ish, mainly to enable missing safety features, but also to switch the extruder thermistor profile to the correct one for a Titan Aero. Now that my home project schedule is opening up again and the to-be-printed queue is piling up, it might be time...

For what it's worth, I've been able to get filament change pauses to work on my stock firmware. I'm using Octoprint on a Pi3 to control my printer though, instead of shuffling an SD card around.

- Add bookmark

- #5

I finally got some input on Reddit, and it looks like I should be able to finish the upgrade either tonight or later this week.

To answer your question, Ominous, I'm trying to use the ADVi3++ fork of Marlin, for exactly the reason you mentioned.

What I've gone through:

- Updating from standard Cura doesn't work (at all - it opens a mini-window for updating, and sits there with an empty bar forever).

- Updating from Wanhao-specific Cura doesn't work (it properly detects the system, starts to update, then declares that the update failed, and fills the progress bar anyway).

- Updating with Arduino IDE seems to work, but really doesn't. As mentioned above, the main menu works, but it stops responding (other than buttons flashing to show that they've been pressed) in the sub-menu pages.

The guy who is helping me on Reddit said that the method that worked for him in the end is using Octopi, which I haven't tried yet. He said that all of the Beta 2 updates were twitchy, and he's going to be doing Beta 3 (which releases today?) in the next few days and let me know.

- Add bookmark

- #6

Now I'm home again, and a little more info made me realize that I had the ADVi3++ Beta 2.0 for the LCD panel, but Beta 3.0 for the mainboard. So I was excited, thinking that maybe that was my problem - not having the same version on both.

Sadly, while that was the case, updating both to Beta 3.0 still has the same problem.

Part of me wants to step back to Beta 2.0 for both, but part of the reason I want to upgrade in the first place is the M600 command (Pause for filament change), which isn't available before Beta 3.0.

- Add bookmark

- #7

Nekojin said:

I finally got some input on Reddit, and it looks like I should be able to finish the upgrade either tonight or later this week.

To answer your question, Ominous, I'm trying to use the ADVi3++ fork of Marlin, for exactly the reason you mentioned.

What I've gone through:

- Updating from standard Cura doesn't work (at all - it opens a mini-window for updating, and sits there with an empty bar forever).

- Updating from Wanhao-specific Cura doesn't work (it properly detects the system, starts to update, then declares that the update failed, and fills the progress bar anyway).

- Updating with Arduino IDE seems to work, but really doesn't. As mentioned above, the main menu works, but it stops responding (other than buttons flashing to show that they've been pressed) in the sub-menu pages.

The guy who is helping me on Reddit said that the method that worked for him in the end is using Octopi, which I haven't tried yet. He said that all of the Beta 2 updates were twitchy, and he's going to be doing Beta 3 (which releases today?) in the next few days and let me know.

Click to expand...

It does sound like your LCD update went okay, but that the Marlin update failed. It's been a long time since I used it - does the Arduino IDE have any detailed log files somewhere you can look at? That might help direct you on what to troubleshoot.

I have an 8GB microSD on the way from Amazon (I understand why that's a limit, but they're getting harder to find!), and when it arrives I need to decide which version of ADVi3pp to install. I'm probably going to try the most recent stable release first (2.1), and once I've got that installed and working, then see if I can poke at upgrading to 3.0.

I have OctoPrint running on a Pi connected to my printer, and I've got a Linux laptop with both avrdude and the Arduino IDE installed, so I've got a few options. Worst case, I've got an AVR programmer (AVRISPmkII) and it looks like the board has a standard ISP header to plug into.

EDIT: Looking at the Facebook page for ADVi3pp, it appears that Cura 3. 3.x on Win64 is known-broken for updating. Supposedly Cura 3.2.1 works though.

3.x on Win64 is known-broken for updating. Supposedly Cura 3.2.1 works though.

- Add bookmark

- #8

OminousPonderer said:

It does sound like your LCD update went okay, but that the Marlin update failed.

It's been a long time since I used it - does the Arduino IDE have any detailed log files somewhere you can look at? That might help direct you on what to troubleshoot.

Click to expand...

Not that I can find. The two directories that it creates, Arduino and ArduinoData, don't have anything useful. No logs that I can see. =>_>=

- Add bookmark

- #9

So far, no help. The one person on Reddit has dried up, and I've gotten ZERO response in the Facebook discussion. :/ I've even asked Monoprice for information on the cable, and asked the Los Angeles Maker group if they would be able to help, and gotten no response from either.

The one person on Reddit has dried up, and I've gotten ZERO response in the Facebook discussion. :/ I've even asked Monoprice for information on the cable, and asked the Los Angeles Maker group if they would be able to help, and gotten no response from either.

I guess I'll have to try to install 2.1 and see if that works. If it still has the same problem, then it's probably the cable. Which is an even thornier problem, since I can't find a single store online that sells that cable, much less a slightly longer version.

- Add bookmark

- #10

Nekojin said:

So far, no help.

The one person on Reddit has dried up, and I've gotten ZERO response in the Facebook discussion. :/ I've even asked Monoprice for information on the cable, and asked the Los Angeles Maker group if they would be able to help, and gotten no response from either.

I guess I'll have to try to install 2.1 and see if that works. If it still has the same problem, then it's probably the cable. Which is an even thornier problem, since I can't find a single store online that sells that cable, much less a slightly longer version.

Click to expand...

My 8GB microSD showed up yesterday, and hopefully I'm going to take a poke at this tonight. I'm starting with 2.1, since that's at least considered "release" quality. If I get that installed and working, I'll try 3.0beta3.

I haven't opened mine up yet to look at the cable in question. From your original post, it sounds like there's at least some communications happening, so it doesn't sound to me like you've damaged the cable. I'd be more likely to blame the main board update silently failing based on what you've posted, or even a failed LCD update.

I'd be more likely to blame the main board update silently failing based on what you've posted, or even a failed LCD update.

I'll try to update after my attempt tonight - contingent on getting the kiddo into bed with minimal issues...

- Add bookmark

- #11

I was able to flash the LCD data and the firmware for 2. 1... For the LCD data, I used the .img file available on github, and used Win32DiskImager to write it to my microSD. That went okay, and took about 30 seconds total.

1... For the LCD data, I used the .img file available on github, and used Win32DiskImager to write it to my microSD. That went okay, and took about 30 seconds total.

Then I flashed the firmware. I used Firmware Updater from Octoprint (which uses avrdude under the hood) to flash the 2.1 firmware .hex file from github. That wrote and verified okay, and it booted up to the 2.1 UI immediately. I then flashed 2.1 again, but this time it was a .hex file I compiled in Arduino IDE, because I have a Titan Aero hotend/extruder which uses a different thermistor profile. Again, no issues using Octoprint/firmware updater. After poking around the screens, I ran a PID tune. Everything appears to be working.

Later this evening I'll try installing 3.0beta3, and report back on how that went. If that flash succeeds, I'll try a test print of a calibration cube.

- Add bookmark

- #12

I was able to flash 3. 0beta3 and the corresponding LCD data. PID tuning, extruder steps calibration, and manual bed levelling were successful. Currently printing a calibration cube to check X/Y/Z steps/mm and test the overall printing.

0beta3 and the corresponding LCD data. PID tuning, extruder steps calibration, and manual bed levelling were successful. Currently printing a calibration cube to check X/Y/Z steps/mm and test the overall printing.

One thing I noticed was that 2.1 showed me the GCODE files on my SD card, but 3.0beta3 did not... it only showed the single folder I have on the card. Not a big deal for me, since I'm using Octoprint, but it may be a bug in 3.0.

Are you able to get into the Info->Versions screen at all? What's it showing there?

- Add bookmark

- #13

OminousPonderer said:

Are you able to get into the Info->Versions screen at all? What's it showing there?

Click to expand.

..

Info screen only shows four options - Steps, Feedrate, Acceleration, and Jerk. Clicking on most of them does nothing*. Pressing Steps takes me to a movement panel (Move page), but the buttons there do nothing*.

* except blink the button to acknowledge that I pressed it.

- Add bookmark

- #14

Nekojin said:

OminousPonderer said:

Are you able to get into the Info->Versions screen at all? What's it showing there?

Click to expand.

..

Info screen only shows four options - Steps, Feedrate, Acceleration, and Jerk. Clicking on most of them does nothing*. Pressing Steps takes me to a movement panel (Move page), but the buttons there do nothing*.

* except blink the button to acknowledge that I pressed it.

Click to expand...

It sounds like your LCD update may have gone wrong, as that isn't the right content for the Info screen. I'd try reflashing the LCD. If you used the basic .zip the first time, try using the .img.zip version this time, as that worked correctly for me.

Here's the screens I see for 3.0beta3 in order:

ADVi3++ screens by OminousPonderer, on Flickr

ADVi3++ screens by OminousPonderer, on Flickr

ADVi3++ screens by OminousPonderer, on Flickr

- Add bookmark

- #15

Is there a way to wipe the LCD's memory to flash it fresh, or is that assumed to be automatic?

- Add bookmark

- #16

I did the 2. 1 patch, and that seems to have worked. I'll let you know!

1 patch, and that seems to have worked. I'll let you know!

Edit: Now printing, looks good!

Extra Edit: (This is a terrible picture, because I just plain suck at taking pictures)

- Add bookmark

- #17

Nekojin said:

Is there a way to wipe the LCD's memory to flash it fresh, or is that assumed to be automatic?

Click to expand.

..

I'm pretty sure it's an automatic wipe on flash. The reason I suggested reflashing it is from what I can tell, the LCD flash process is finicky, and very picky about file systems and file layouts. I think the display navigation is pretty self-contained on the LCD MCU, so if you're not getting the correct displays from various buttons, it would be a good reason to suspect the LCD flash. That's why I was recommending the .img LCD update - the filesystem is all set up and "known good" on that one.

I'm glad 2.1 worked! Potato-quality pictures are normal - as long as the relevant info is conveyed, the rest is just presentation. It's more important that you're printing.

I haven't played around with M600 yet. I first need to spend a while tuning my printer in more depth than I have in the past. I know it's capable of better than what I'm getting now, I just haven't had the time to dedicate to it.

- Add bookmark

- #18

By the way, if you're still looking for the display cable, it should be a pretty generic item. ADVi3++'s author has a blog page with everything he knows about the Duplicator i3 Plus, which includes a link to a sample cable.

ADVi3++'s author has a blog page with everything he knows about the Duplicator i3 Plus, which includes a link to a sample cable.

- Add bookmark

- #19

Nekojin said:

I did the 2.

1 patch, and that seems to have worked. I'll let you know!

Edit: Now printing, looks good!

Extra Edit: (This is a terrible picture, because I just plain suck at taking pictures)

Click to expand...

Needs more light! It will sharpen right up with better lighting. But it looks pretty good for a 3D Printing Brick! Glad it's at least working again, even if it doesn't work at the firmware you are aiming for.

- Add bookmark

- #20

I ran into another problem last night. In the default Repetier firmware, it was possible to pause a print, leave that menu section to move the head and change filaments, then return to the print menu and resume. In this ADVi3++ version 2.1, once you leave the active print page (called the SD Print page in the manual), there's no way to get back to it. I can pause the print, I can move the head, but there's no way to get back and Resume. :facepalm:

I may have to dip my hands into editing the code for that. I'm not a topnotch programmer (and certainly don't have any significant experience in that language), but I've always had a talent for reading code and figuring out how to modify.

- Add bookmark

- #21

Nekojin said:

I ran into another problem last night.

In the default Repetier firmware, it was possible to pause a print, leave that menu section to move the head and change filaments, then return to the print menu and resume. In this ADVi3++ version 2.1, once you leave the active print page (called the SD Print page in the manual), there's no way to get back to it. I can pause the print, I can move the head, but there's no way to get back and Resume. :facepalm:

I may have to dip my hands into editing the code for that. I'm not a topnotch programmer (and certainly don't have any significant experience in that language), but I've always had a talent for reading code and figuring out how to modify.

Click to expand...

If you haven't already looked at it, I highly recommend Octoprint. It's both less work than SD card printing and more functionality. I've used Cura's "pause at z-height" modifier with it for very basic color changes (print last 2mm of print in different color) and it has worked well for that. Add a PI camera module, and you've got a good way to keep an eye on it while in another room.

That being said, if the printer/LCD firmware works the way I think it does, you're probably going to be working on the LCD side of things. It sounds like there's just no path in the LCD menu structure to get back to the "current print" screen without starting a new print.

Maybe open a bug or feature request on ADVi3++'s github page with steps to reproduce. It's possible that has been solved in 3.0, as there's been a lot of changes to the LCD screens since 2.1.

- Add bookmark

- #22

OminousPonderer said:

Nekojin said:

I ran into another problem last night.

In the default Repetier firmware, it was possible to pause a print, leave that menu section to move the head and change filaments, then return to the print menu and resume. In this ADVi3++ version 2.1, once you leave the active print page (called the SD Print page in the manual), there's no way to get back to it. I can pause the print, I can move the head, but there's no way to get back and Resume. :facepalm:

I may have to dip my hands into editing the code for that. I'm not a topnotch programmer (and certainly don't have any significant experience in that language), but I've always had a talent for reading code and figuring out how to modify.

Click to expand...

If you haven't already looked at it, I highly recommend Octoprint. It's both less work than SD card printing and more functionality. I've used Cura's "pause at z-height" modifier with it for very basic color changes (print last 2mm of print in different color) and it has worked well for that.

Add a PI camera module, and you've got a good way to keep an eye on it while in another room.

Click to expand...

With the Repetier stock firmware, the "pause at z-height" didn't work. I haven't had a chance to mess with it at all since then. It's entirely possible that's all I need now - although, last I heard, Pause at Z-Height only did a PAUSE, not a nozzle move (which is the entire problem, of course). This is entirely the reason I wanted the M600 command - it's a pause and move the head away for a filament change, then returns to the print location to resume. Which Repetier did well, but you had to do it manually, which meant watching the print closely (instead of, say, playing games) until I got to that step.

That being said, if the printer/LCD firmware works the way I think it does, you're probably going to be working on the LCD side of things. It sounds like there's just no path in the LCD menu structure to get back to the "current print" screen without starting a new print.

![]()

Click to expand...

Right. There should be an If/Then detection to see if there's a print already in progress, and if so, to move you back to the right menu, instead of putting you at the .GCODE list.

Maybe open a bug or feature request on ADVi3++'s github page with steps to reproduce. It's possible that has been solved in 3.0, as there's been a lot of changes to the LCD screens since 2.1.

Click to expand...

Yeah... I'll have to mess with 3.something again. I don't want to be spending more time with the printer out of commission, though - I've got a lot of things that I want to get printed before the 25th (a gaming convention). But the current situation is untenable, and it'd be poor form for me to issue a feature request or bug report on something that's already fixed.

- Status

- Not open for further replies.

Jump to latest Follow Reply

Jump to latest Follow Reply

Monoprice Maker Select Plus 3D printer mods

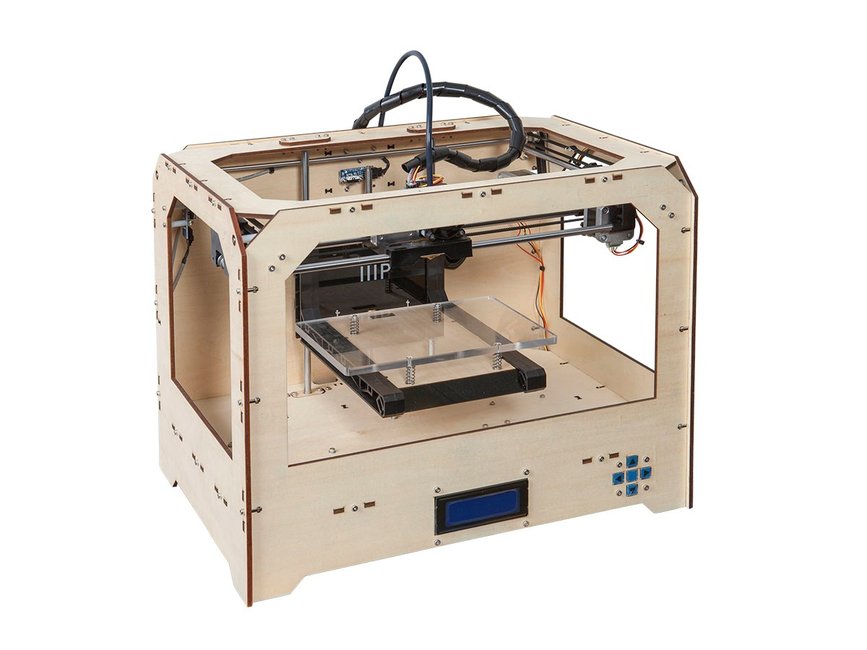

About a month ago I bought a 3D printer, the Monoprice Maker Select Plus. This is a rebrand of the Wanhao Duplicator i3 Plus, and is also rebranded by several other manufacturers, including Aldi supermarkets in Australia. Yes, really.

3D printers run a wide range, from “build the frame yourself and buy a hundred off-the-shelf parts”, to kits which include all the parts but require full assembly, to “spend a few grand, plug it in and turn it on”.

I picked the Monoprice model because it’s nearly fully assembled, requiring about 15 minutes of assembly to attach the two main components together, and it is well reviewed as producing decent prints out of the box. This is an important consideration for a first 3D printer, and I was very lucky to have my first few prints go perfectly, so I had an idea what the process should look like, to compare when things are going wrong.

And they will go wrong. No 3D printer will be completely foolproof, and all require various levels of troubleshooting. For all that I’ve learned in the last month, I feel confident that if I buy another printer, a kit would be easy and a completely-from-scratch build would be possible. (From what I’ve seen, 3D printers are like cats: people who have more than zero usually have more than one. Some even have their houses overrun by them.)

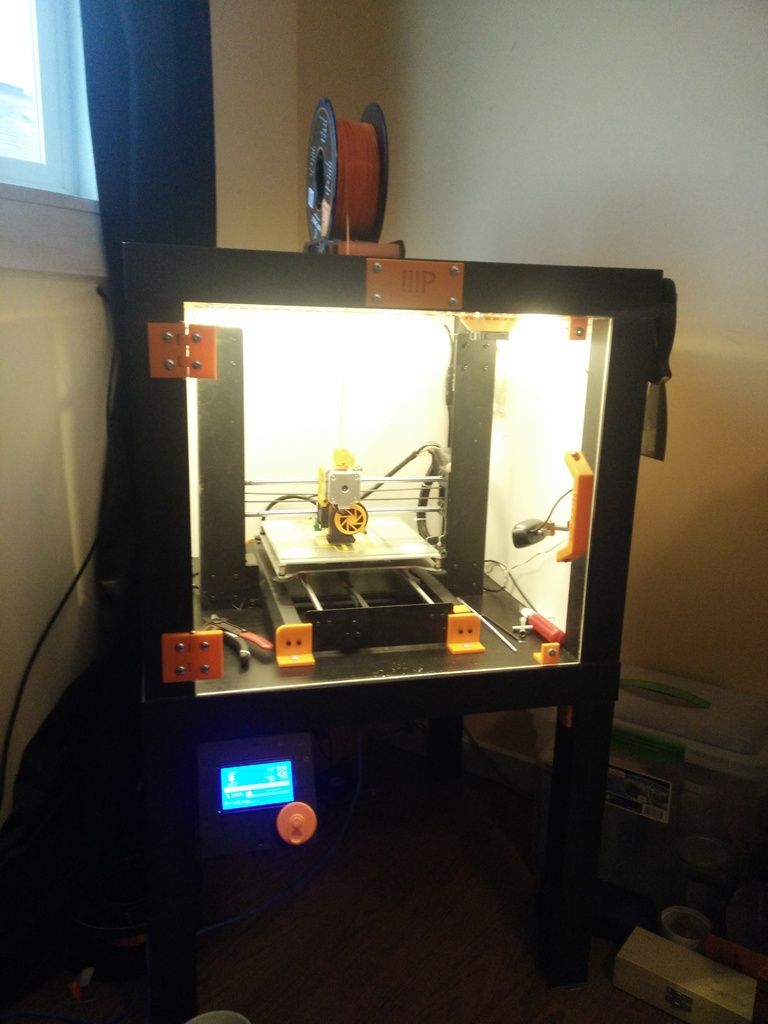

The second important factor in choosing the Monoprice is there is a lot of potential for customization, with a large community of Wanhao i3 owners. And oh boy, have I modded it in the last month. Strictly speaking, none of what I’ve done below is necessary, but this is a hobby, and all of it was fun.

- Printed a filament guide arm just below the spool holder. This was actually my first “mod” and was done with the sample black filament which came with the printer (and I used much of it).

- Added a Z brace, which helps avoid movement of the vertical frame and theoretically reduces the chance of ghosting on prints.

It also allows you to minutely adjust the torsion flex of the frame as a whole. This is one of the most impressive cost-to-looks ratio mods, and consisted of a 1 meter threaded rod ($3) split in two, about $3 worth of nuts and bolts, and a large amount of printed parts. The corners also double as a larger base to attach rubber or cork feet.

- Printed a lenth extension to the spool holder arm. The spool holder which comes with the printer isn’t wide enough to fit most common spools, which I think is one of the few outright flaws of the i3 Plus (albeit a small and easily corrected flaw).

- Printed an LCD extension panel, which tilts the viewing angle up slightly, and allows access to the LCD’s internal diagnostic MicroSD card (see below).

- Replaced the printer’s firmware with ADVi3++. The original firmware was decently capable, but was based on an older version of Marlin. ADVi3++ is based on the latest version, has extra features such as guides for filament length adjustment, and quality of life improvements such as temperature readings on the main menu.

This involved upgrading the firmware on the internal main board itself via USB, as well as upgrading the LCD’s firmware via a MicroSD slot on the side of the LCD. (Yes, the LCD has its own microcontroller.)

-

- Update (2019-06-16): I am no longer recommending ADVi3++ as, while the source code is still open source, the author is now charging for the firmware binaries as well as much of the documentation, including how to compile the source. The author is within his rights to do this, but I disagree with it.

- Replaced the cold block fan (which prevents the molten filament in the hot end from flowing back up and jamming) with a direct replacement. The original one started making a loud noise after a few weeks of use, and is a known problem. Thankfully direct replacements are a few dollars on Amazon.

- Replaced the 40mm part cooling fan with a 50mm blower fan. There are many more efficient part cooler mods such as the DiiiCooler or the CiiiCooler which evenly distribute the air around the nozzle, but have tradeoffs such as visibility and clearance issues.

I’ve found simply printing an adapter shroud for the front slot works fine for my needs.

- Replaced the original 4-point corner bed leveling system with a 3-point bed level (two on the left corners, one on the middle of the right side). This allows for more accurate adjustment, since technically it’s impossible to adjust a flat plane using four points (you end up warping it into a 3-dimensional object).

- Added BLTouch bed leveling. This consists of a probe mounted as close to the nozzle as possible. The probe can sense with a high level of precision when it touches the surface, and reports this data at various parts of the bed to the firmware, which can correct for different heights on the bed’s plane. (It’s still also a good idea to start with a decent attempt at manual leveling.)

- Replaced the BuildTak-like surface with a glass print surface, with a large (but incredibly thin) thermal pad between the heated plate and the glass.

- Added four binder clips to the edges to prevent the glass from separating from the plate.

Not the most exciting mod, but it’s worth pointing out since you need to account for them when doing low-height print head travels. I’ve got some thinner clips ordered, but they haven’t arrived yet.

- Replaced the thin Y carriage with an all-aluminum replacement, allowing for a more stable Y axis.

- Did some of my own firmware mods based on ADVi3++. In particular, the BLTouch sensor’s hardware development is moving fast and the version I received (v3) wasn’t compatible with the support in ADVi3++ (v2), so I backported v3 support from the Marlin development branch.

- Set up a Raspberry Pi with OctoPrint, a USB printer manager. You could just transfer GCODE to an SD card and print it directly from the printer, but OctoPrint gives you more convenience and flexibility. After I slice an object, I can tell Cura to send the GCODE directly to OctoPrint which starts the print. And I’ve got a webcam pointed at the print bed, which OctoPrint shows and lets me monitor the print when I’m away from it, and it also captures a per-layer timelapse of the print.

- The printer’s main board is a variation of a reference Arduino platform, and an annoying side effect is it can be powered from the USB port. I don’t want this, since the USB host is a Raspberry Pi which has its own limited power to deal with, and also means that when I turn off the printer via the back power switch, the main board and LCD remain on (but have no control over the motors, heaters, etc). I solved this by taking a USB cable, stripping off the sheath in the middle and cutting the red wire. This turns it into a “data only” USB cable, so the printer turns off completely when the power switch is turned off. Interestingly, I have yet to find a commercially sold “data only” cable, though obviously the opposite “charging only” is common.

Best Models for 3D Printing Delta・Cults

BERETTA М9А3 SCAN FOR HOLSTER

57,80 €

BERETTA M9A3 + OLIGHT BALDR PRO SCAN FOR HOLSTER

63. 04 €

TAURUS TS9+SUREFIRE X300U SCAN FOR HOLSTER

21.49 €

TAURUS TS9 SCAN FOR HOLSTER

18.06 €

top fan mount with two blowers

free

Drive motor cover

Free

CALIBRATION DISC

Free

DRIVE GEAR BEARING MOUNTING

Free

DELTA BOT FINAL STOP FIX

Free

Lancia Delta 3 exterior door handle detail

6,30 €

Flux 3DP Lights

Free

Lancia Delta Integrale

9.65 €

INERT STORE FOR AREX DELTA NEW FRAME 15RD

7. 22 €

Lancia Delta Integrale Martini 1992 Printing machine by parts

11.26 €

Lancia Delta Integrale Martini 1992 Printed Car body

5.62 €

Lancia Delta Integrale 1992 Printed Car by parts

10.13 €

Lancia Delta Integrale 1992 Printed Car body

5.62 €

Monoprice Mini Delta Glass bumper and screen

Free

Monoprice Mini Delta Riser with switch and SD card adapter Mount

Free

Convair F-106 Delta Dart

3 €

Heating Element and Glass Bed Attachment for Delta Type 9 Printer0003

Free

DELTA Q WALL HOLDER

0,60 €

Convair F-106B Delta Dart

3 €

Caps with nuts for MicroDelta Rework

Free

MicroDelta Rework V3 Pressurized ventilation

Free

20mm aluminum extrusion recirculating bearing bottom bracket

Free

Griffin 3D Printer Vertical 20mm x 40mm Vertex Top/Bottom Frame

Free

X-15 Delta

Free

Delta plate holder for extruded frames

Free

Lancia delta 1987

0. 75 €

3KU Bed Work Lights

Free

Kyes120 - Compact Delta Printer

Free

Anti-vibration delta feet

Free

Delta flyer keychain

Free

RPi camera mount + 12 LED rings

Free

burs

1.87 €

MPMD Bed Clip

Free

New bed test for wide area heightmap.

Free

u joints for Kossel

0.50 €

HEADLIGHT GRILLE LANCIA DELTA INTEGRALE RC 1/10 TAMIYA , TEAM C O KILLER BODY

5 €

Kossel Delta Magnetic Sticks Adhesive Assistant

Free

Kossel top end cap with integrated bolts

Free

BLTouch Adjustable Mount for Anycubic Kossel

Free

Kossel tennis ball feet

Free

Anycubic Kossel Plus Heated Bed Clips

Free

Hang glider Vole libre

3,50 €

Arex Delta Traning

2. 71 €

Delta Ruin #1

4.19 €

Overview of the budget 3D printer Monoprice Select Mini

3DPrintStory Reviews Overview of the budget 3D printer Monoprice Select Mini

Prices for desktop 3D printers continue to fall. There were times when a $600 3D printer was a delight and a desire to order it as soon as possible, but technology does not stand still, and developers and manufacturers are looking for new options to lower the price even lower. This review is dedicated to one of the budget 3D printers costing about $200 - Monoprice Select Mini.

It is worth noting that this inexpensive model breaks established traditions and did not start with Kickstarter, unlike others like M3D Micro, Tiko, OLO / ONO and Trinus, which attracted the attention of consumers and investors thanks to crowdfunding platforms (by the way, this is really an effective development strategy for small startups, but there is often a mismatch between expectations and the final product).

Monoprice is different. This is an American company that did not particularly bother with the development and production of its own 3D printer, but simply imported the Malyan M200 from China, hung its logo on it and put an attractive price of $199. What if you got a defective 3D printer? No problem, send it back and they will replace it for you.

A reasonable question arises: can such a cheap 3D printer compete with Ultimakers or Printrbots? And is it even worth comparing? We will try to answer these and other questions in the review below.

Features Monoprice Select Mini

- Available;

- Robust design;

- Easy to use;

- Predictable 3D printing at low speed;

- Works with any slicing software and standard 3D printing materials;

- Upgradable and upgradeable;

- I think we already mentioned the price?

Disadvantages Monoprice Select Mini

- Difficult to calibrate;

- Prints poorly at high speeds;

- Print table unprotected;

- Faulty power supply;

- WiFi module not active;

- Unstable nozzle temperature;

- Strange quirks.

..

Short Verdict

The Monoprice Select Mini is a great 3D printer for the price. There is a heated table, easy to operate if you do not use high speeds, stable 3D printing quality.

Naturally, there are disadvantages. During operation, the temperature of the nozzle may change, and at high speeds, 3D printing errors occur. The calibration process takes a lot of time and the first time you have to tinker. Well, the most interesting thing is that the power supply burned out after 12 hours. But the latter, incorrect, can be attributed to an accidental marriage.

Despite all the shortcomings, the Monoprice Select Mini is a wonderful little 3D printer with many great features. In general, it performs in accordance with the information in the technical specifications, and the quality of the 3D printing even exceeded our expectations.

If you are not afraid to take it apart / put it back together, then you can do a few upgrades. The first thing to do is to replace the hotend and update the firmware to activate the WiFi module ( be careful! These upgrade options have not been tested as part of this review and may damage your 3D printer! ). You can install the glass on the print table. Even with these upgrades, the price will still remain acceptable.

Would you recommend the Monoprice Select Mini as your first 3D printer? Yes, definitely.

Specifications and features Monoprice Select Mini

Monoprice Select Mini workspace 120 x 120 x 120 mm. The maximum resolution of 3D printing is 100 microns. Heated table. The 3D printing speed is 55 mm/s.

You can upload your 3D model via micro SD card or USB. The manual states that compatible slicing programs are Cura, Repetier-Host, ReplicatorG, and Simplify3D. This means that the Monoprice Select Mini recognizes the standard G-code, and this 3D printer is not tied to any particular software. Cura was used during testing for this review.

Monoprice Select Mini doesn't limit you in the media you use. You can print with any standard 1.75 filament using PLA or ABS thermoplastics. In our case, PLA plastic from ColorFabb was used.

These two points - the freedom to choose software and filament - are very important in this price range, because manufacturers such as M3D Micro and XYZprinting, which are Monoprice's main competitors in this niche, tend to use proprietary software and their own materials for 3D printing .

Unpacking and installation of the Monoprice Select Mini

Installation of the Monoprice Select Mini is quite simple. You can start typing within 20 minutes.

Inside the box you will find a 3D printer, a power supply, an imbus wrench for calibrating the table, a plastic spatula to scrape off the rest of the material from the table after printing, a 256 MB micro SD card and a micro USB cable.

One piece of paper contains basic instructions and a link to a website where you can download the full version.

You will also find a rectangular steel sheet, the purpose of which is not clear at first. It turns out that this is a coil holder that is attached to the side of the main unit.

It is important to note that the Monoprice Select Mini kit does not include media test samples. So stock up on filament with a diameter of 1.75 mm.

You can use the wheel to adjust. The menu is well structured and easy to understand. You can start the calibration process, preheat the extruder and feed the filament.

Calibration can be somewhat difficult. In theory, it should be carried out even before shipment, in production, and you should have a piece of paper between the nozzle and the printing table. If it doesn’t work, then hex keys will come in handy here. It will be necessary to try and tighten the screws at the corners of the table so that the sheet still passes.

At this stage, the first important shortcoming of this model becomes clear. The printing table is made of aluminum and does not have a special protective film or coating on it. So stock up on blue 3D printing tape or install glass right away. Otherwise, the table will wear out very quickly and you will have to change it.

Well, one more bug that got out in our particular case. The power supply burned out after 12 hours of use. Foaming it was not difficult, but it was very unpleasant. You can probably throw it off for marriage, but in any case, be prepared for a similar turn of events.

Design and build quality of the Monoprice Select Mini

Very pleased with the build quality of the Monoprice Select Mini. The construction is strong, reliable, with a steel sheet metal case that hides all the electronics. So don't worry about shipping damage.

This 3D printer uses deposition modeling technology. The classical Cartesian coordinate system is used. The design is similar to Printrbot Simple. One cooler is used to cool the nozzle. It is likely that problems may arise during 3D printing with unusual materials.

The extruder has a diameter of 0.4 mm and can be heated up to 230°C. We have not been able to test how easy it is to change, but in the long run this is an important factor as the nozzle will still need to be changed over time.

Monoprice Select Mini Print Quality

Models will already be preloaded on the micro SD card. They are supposed to be optimized for 3D printing on the Monoprice Select Mini. So before uploading our own models, we printed test ones.

The cat was printed first. The resolution was 200 microns. Everything went well until the last layers. The upper part of the paw and ears could not be printed even once. There were 3 attempts in total.

G-code analysis in Simlify3D showed that the table accelerated up to 55 mm/s during the printing of the last layers. That is why the error was repeated. Quite a strange decision of the company - to provide a test model, which a priori will be printed with errors...

The second model that we printed is a test elephant. The resolution was also 200 microns and 10% infill. There were no problems! The result is excellent and you can see it in the photo below.

Next we moved on to our own models. We used Cura for slicing. This article reveals the excellent Cura settings for 3D printing on the Monoprice Select Mini and we used them.

We printed a classic 3DBenchy and Graphica model: a MEGA Ghost with 200 micron resolution and 10% infill, a V29 whistle with 200 micron resolution and 100% infill, and another 3DBenchy model with 100 micron resolution and 10% infill.

The simple 200 micron models worked well. There are no special problems with small protrusions and holes, although there are sagging. The layers are laid evenly along the X and Y axes.

The V29 whistle sounds as loud as intended, which means the partitions were printed correctly. The Graphica Mega Ghost with its long tongue also printed correctly. The hinge glided smoothly. The

3DBenchy at 100 microns worked well too. When you look at the photo, don't forget that this is a $19 3D printer.9.

We have noticed that most errors in 3D printing occur when the spool of filament clings or there is not enough adhesive coating on the printing table. This cannot be attributed to the shortcomings of the Monoprice Select Mini itself, since this is a global problem for all FFF printers.

During operation, the print table may block access to the control wheel. This point is implemented in the design is not very ergonomic.

Another disadvantage is that the nozzle temperature has an error in the region of 5°C. For example, when the 3D printing temperature is set to 215°C, it jumps between 213°C and 217°C on the control panel.

This does not particularly affect printing with PLA plastics, but may have a negative effect during 3D printing with materials that are more sensitive to temperature changes.

Finally, we printed a Low Poly Moai bust. We scaled the model by 50% and printed with 100 micron settings and 30% infill. It turned out well on the whole, the only small marriage is the influx of material on the chin. By the way, we observed the same effect when printing 3DBenchy with resolution settings of 100 microns.

Life hacks and upgrades Monoprice Select Mini

A few words about upgrading the Monoprice Select Mini 3D printer. There are no official upgrades! But here are a few options that you can try to implement on your own.

In our opinion, it is necessary to deal with the temperature of the extruder, make it more stable. For example, you can implement a PID temperature controller.