Mass production with 3d printing

The Advantages of 3D Printing Production

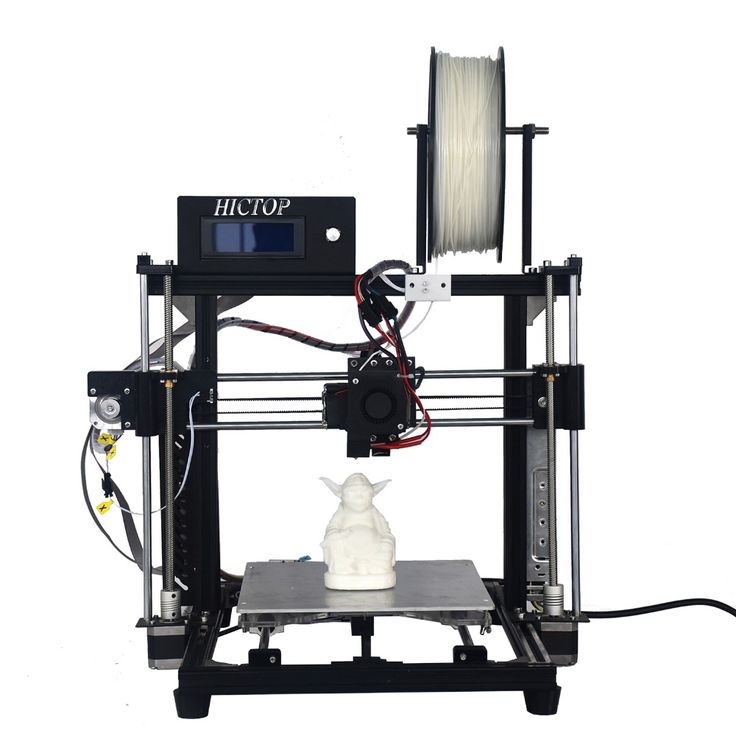

3D printing is an excellent process for making prototypes and real-life products and has formed the basic call-up methods for efficiency and efficacy in production. And 3D printing is positively impacting the world that has been tending towards using rapid prototyping processes in mass production.

Therefore, it is important to know about applying 3D printing mass production, its advantages, and its various applications. This article will introduce everything you need to know about mass production using 3D printing.

The Advantages of Using 3D Printing for Mass Production3D printing is a great technique used in mass production which comes to knowing the advantages of the method. Below are the reasons that make 3D printing a better choice.

· Faster Time to Market by Rapid ToolingThe manufacturing world is highly competitive, and the time taken to reach the market can be a huge deciding factor in the success of a business. This means that the chosen manufacturing process must be able to deliver a large number of products within a short period of time. An increase in production time and delivery will improve the availability of the business’s product in the market and give them an edge competition-wise.

Among the manufacturing process used in rapid prototyping, 3D printing is able to produce the necessary prototypes to check for flaws and deliver in terms of the real product. 3D printing mass production is not only in making products itself but also in making entities that can help in other manufacturing processes. For example, manufacturers can use the process to make 3D printed injection molds, which helps mass production injection molding.

· Flexibility to Quickly Change What You Are MakingIn production 3D printing, manufacturers can easily change whatever they are making when there is an error or a need for a change. This trait is important in 3D printing batch production as it allows manufacturers to make prototypes by which they can check for flaws, analyze the functions of the parts, and do other things depending on the type of prototype they are working with. Consequently, it is easy for the designer to change things when they detect an error.

Consequently, it is easy for the designer to change things when they detect an error.

Performance and aesthetics are basic requirements of any growing business. Performance is in terms of product quality, while aesthetics is to attract customers. Both performance and aesthetics depend on the customization of products. Out of the different rapid prototyping processes used recently, production 3D printing is the most suitable for customization.

Depending on orders, you can delay or increase production. You can also demand a shift in 3D printing production parts’ design if there is a demand for a new type of product. Different types of materials available for 3D printing also make customization very easy.

3D Printing Materials For Mass Production PartsThere are three categories of materials in 3D printing. Each category comprises different materials with unique features and properties suitable for different products. Below are the common materials you could use.

Each category comprises different materials with unique features and properties suitable for different products. Below are the common materials you could use.

Plastics are the most common materials used in volume 3D printing. With it, it is possible to make products such as 3D-printed toys, household fixtures, desk utensils, vases, etc. Plastic materials’ popularity is due to features such as firmness, flexibility, smoothness, and color option, further improving their use in 3D production parts. We have a list of the common types of plastic polymers you can use.

· Polylactic Acid (PLA)Polylactic acid/PLA is an eco-friendly plastic made from natural products and known for its biodegradability. It occurs in two forms: soft and hard, which shows their strength. Hard PLA is the more common type in mass production due to its hardness, strength, and durability.

· Acrylonitrile Butadiene Styrene (ABS)ABS material or LEGO plastic is a plastic polymer known for its strength, firmness, and flexibility. ABS has many colors making it a common production 3D printing material for making tickers and toys, jewelry, and vases.

ABS has many colors making it a common production 3D printing material for making tickers and toys, jewelry, and vases.

If you need a 3D printed filament and bother with choosing the materials between PLA vs ABS, check out the article on our website.

· Polycarbonate (PC)Polycarbonate/PC is a suitable plastic polymer for 3D printers with nozzle design at high temperatures. It is common in mass production as a result of its high strength, toughness, insulation properties, and heat and impact resistance. The material is suitable for making electrical and telecommunication products.

· Polyamide (Nylon)Polyamide or Nylon is a popular volume 3D printing material because of its strength, flexibility, and how it allows a high level of detail in printed products. The material is commonly used for printing products such as fasteners, toy cars, and figures.

ResinsResins are less common 3D printing materials due to their limited flexibility and strength. They reach their end state when exposed to UV light and have different color options. Below are the three categories of resin materials you could use:

They reach their end state when exposed to UV light and have different color options. Below are the three categories of resin materials you could use:

This type of resin has a smooth surface and provides intricate details on small models. They are the perfect materials for testing designs.

· Paintable ResinThese types of resin have aesthetic appeals making them suitable for making products with rendered facial details.

· Transparent ResinIt is the strongest of the three and suitable for many products. It is suitable for models that must have a smooth surface and transparent appearance.

MetalsThese are the second most popular 3D Printing materials. They are used through direct metal laser sintering (DMLS) or Selective Laser Melting (SLM). In 3D printing, metals are used in dust form. The dust is first heated to hardness in order to avoid casting. Consequently, it is possible to make direct use of the dust. Surface finishing process can then be undergone. Metals are common 3D Printing mass production materials due to their strength and durability, and common ones include:

The dust is first heated to hardness in order to avoid casting. Consequently, it is possible to make direct use of the dust. Surface finishing process can then be undergone. Metals are common 3D Printing mass production materials due to their strength and durability, and common ones include:

- Stainless steel: For a product that comes in contact with water.

- Bronze: For vases and other fixtures.

- Gold: 3D printed rings, bracelets, and other forms of jewelry

- Nickel: Coins.

- Aluminum: For thin 3D printed metals

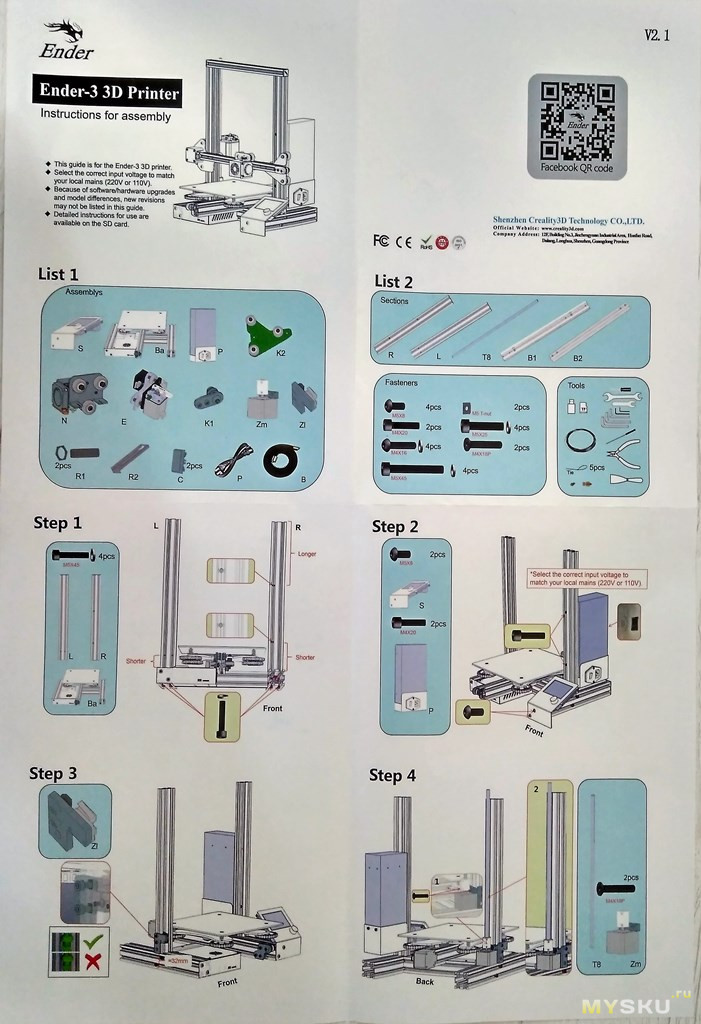

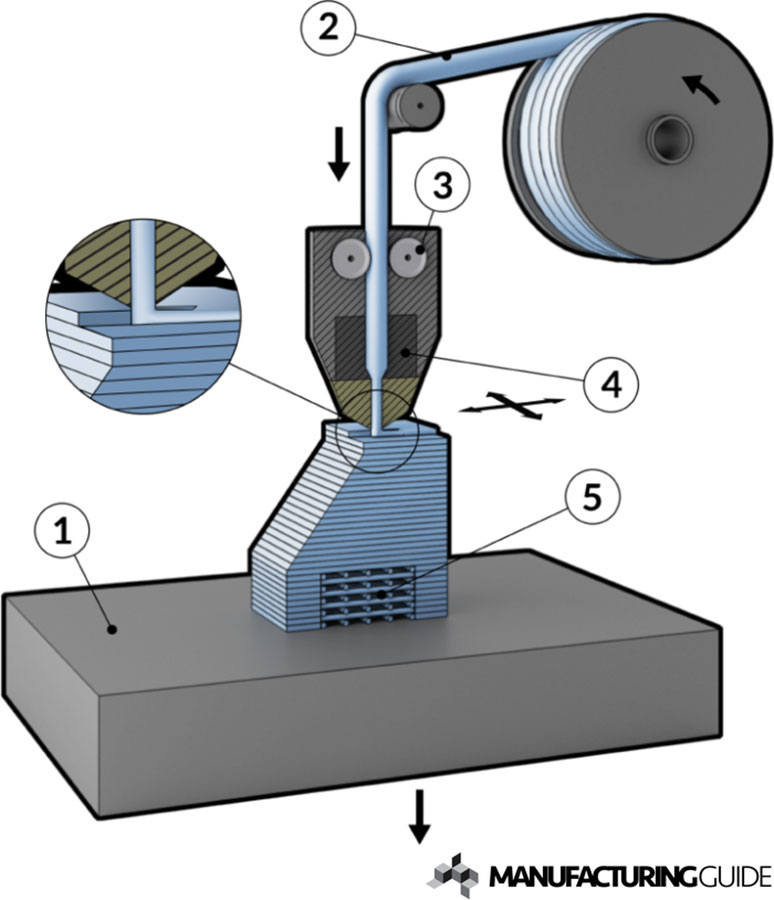

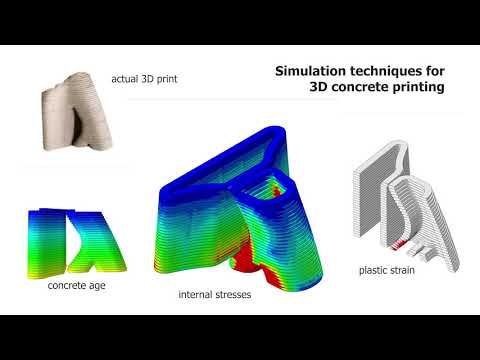

Additive manufacturing is the industrial production name for 3D printing, which allows the creation of an object of varying complexity by making layers of the materials. In contrast to traditional manufacturing, they are efficient, effective, and reliable. Below are some additive manufacturing processes:

· Binder JettingBinder Jetting process uses a powdered material and a binder that acts as an adhesive to deposit a liquid binding agent onto powder particles, layer by layer. The additive manufacturing process has many industrial applications, such as aerospace parts, medical devices, automotive components, and more.

The additive manufacturing process has many industrial applications, such as aerospace parts, medical devices, automotive components, and more.

Direct energy deposition is compatible with many materials such as ceramics, metals, and polymers. The process involves melting materials and fusing them as it deposits. The mechanism is more common in repairing and rebuilding.

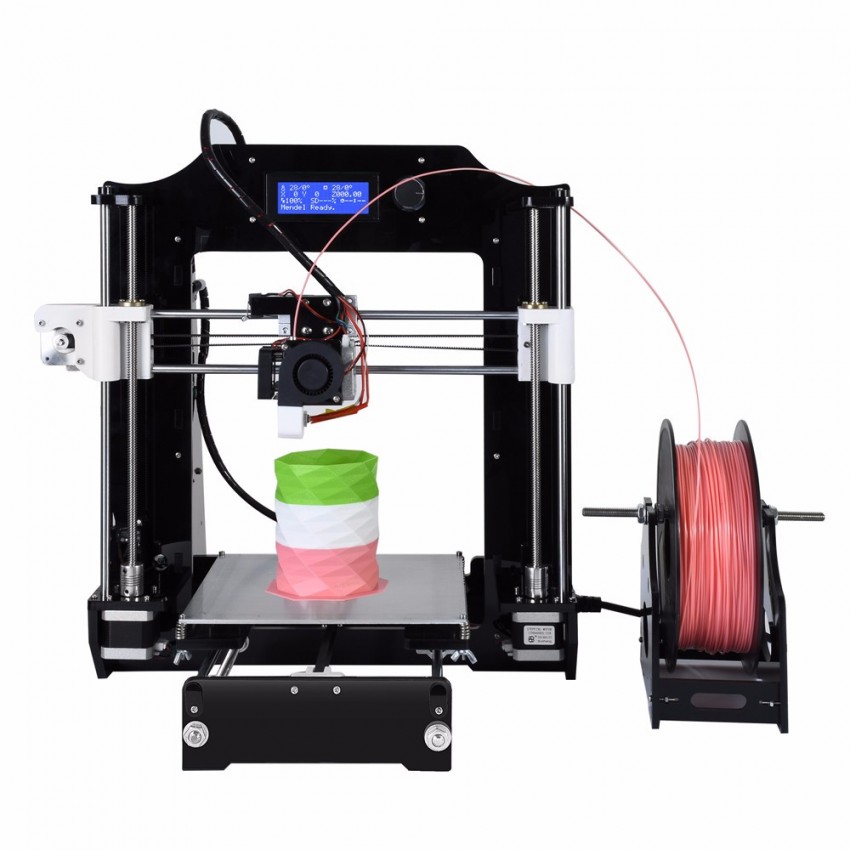

· Material ExtrusionIt is a common additive manufacturing process by which a heated nozzle extrudes the necessary materials. The bed moves vertically while the nozzle moves horizontally. Bonding agents or temperature control mechanisms can adhere to the layers formed to each other.

· Powder Bed Fusion (PBF)This is a metal additive manufacturing process. It takes advantage of either laser, heat or electron beam to melt or fuse powder materials together to form a solid three-dimensional part.

It comprises two methods. On the one hand, Laminated object manufacturing (LOM) is suitable for making products with alternate paper and adhesive having visual appeals. On the other hand, ultrasonic additive manufacturing (UAM) can join metals such as aluminum, stainless steel, and titanium using ultrasonic welding.

· Vat PolymerizationIt involves using a vat of liquid resin photopolymer to create an object layer by layer. Mirrors are then used to cure successive layers of resin through photopolymerization.

· Wire Arc Additive ManufacturingThis additive manufacturing process builds products using arc welding power sources and manipulators. The process is formally known as arc deposition, and it majorly uses wire as a material source.

Try RapidDirect Now!

All information and uploads are secure and confidential.

3D Printing for the masses is becoming a common term due to the advantages to businesses and consumers at large. Currently, there are many applications of the process. Below are a few you could gain insight from.

·

Adidas and Carbon: Mass Producing SneakersAdidas are using Carbon’s Digital Light Synthesis (DSL) technology to print lattice-like sole in about 20 minutes. DSL is ideal for making the lattice structure in the soles, which makes the sole comfortable, lightweight, and flexible. The structure also makes the shoe respond better to an athlete’s leg movement, thereby generating a better cushioning effect and stability.

·

Align Technology: Mass Production, 3D Printing, and PersonalizationAlign Technology has been able to combine personalization, mass production, and 3D Printing in making Invisalign made-to-measure aligners. The company uses SLA machines from 3D Systems to design the mold of the tray, which is completely tailor-made before being thermoformed.

·

Chanel: 3D Printing High-Tech Mascara BrushesIn 2018, Chanel, in collaboration with Erpro 3D Factory, made the Volume Révolution mascara brush. The product has been made on an industrial scale, with Erpro 3D Factory saying it has 3D printed 17 million parts since 2017 with 15 machines that work daily. Additive manufacturing was later introduced to reduce time consumption and cost, which improved the speed of production and the brush design.

·

Formlabs: 3D Printed COVID-19 test swabsAt the start of the Coronavirus pandemic, Formlabs made use of 3D Printing to make an autoclavable and biocompatible nasal swab. With 3D printing, they were able to produce at a rate that meets the country’s needs.

·

Photocentric: 3D Printing Valves to Fight the PandemicPhotocentric during the onset of the coronavirus pandemic also made use of 3D Printing in the mass production of valves compatible with breathing apparatus. They made use of three 3D resin printers, which were able to print more than 600 valves in one night and 40,000 per week. This shows the ability of 3D printers to perform in terms of urgency.

They made use of three 3D resin printers, which were able to print more than 600 valves in one night and 40,000 per week. This shows the ability of 3D printers to perform in terms of urgency.

3D Printing is a rapid prototyping process known for its accuracy, ease of use, and ability to make complex products. 3D Printing uses mass production has reached the limelight with companies such as Adidas, Formlabs, and Chanel, etc., employing the process in their business to boost sales and reach a wider customer. From here, you will know the advantages of 3D Printing mass production in the modern world and how you can think like companies applying the principle in their business.

RapidDirect Custom 3D Printing Services3D Printing a product comes with knowledge of the process, and when you are looking for the best service, you can get the best at RapidDirect. It does not matter whether it is mass production or singular prototypes. At RapidDirect, you have access to the best custom online prototype manufacturing services at a competitive price. Our team has a wide knowledge of 3D Printing and other rapid prototyping processes. Get an instant quote by uploading the files.

It does not matter whether it is mass production or singular prototypes. At RapidDirect, you have access to the best custom online prototype manufacturing services at a competitive price. Our team has a wide knowledge of 3D Printing and other rapid prototyping processes. Get an instant quote by uploading the files.

Get an instant quote

FAQIs 3D Printing expensive for mass production?

Unlike other methods, 3D Printing is more affordable for low volume production. It is also cheaper for high-volume production. Also, it does not require a start-up cost, unlike injection molding.

Is 3D Printing faster than manufacturing?

Yes, 3D Printing is faster than most traditional and rapid prototyping processes. For example, when compared to injection molding, there is no need to create injection molds which are important for the molding process.

Can 3D Printing be Used for Mass Production?

Yes, 3D printing is a suitable method for making products in mass. Its use can be based on its methods or based on helping designers use another rapid prototyping process effortlessly and less costly (e.g., it is suitable for making injection molds used in injection molding). 3D Printing mass production is now common in companies such as Adidas, Chanel, etc.

Large Scale 3D Printing For Mass Production

There are several ways 3D printing can speed up the process of getting products to market. Whether it be with the seamless creation of prototypes, or the full-scale manufacturing of end-user products, 3D printing alleviates key pain points in the supply chain.

Contact a Carbon Expert

3D Printing In Mass Production Explained

Different Types of Additive Manufacturing

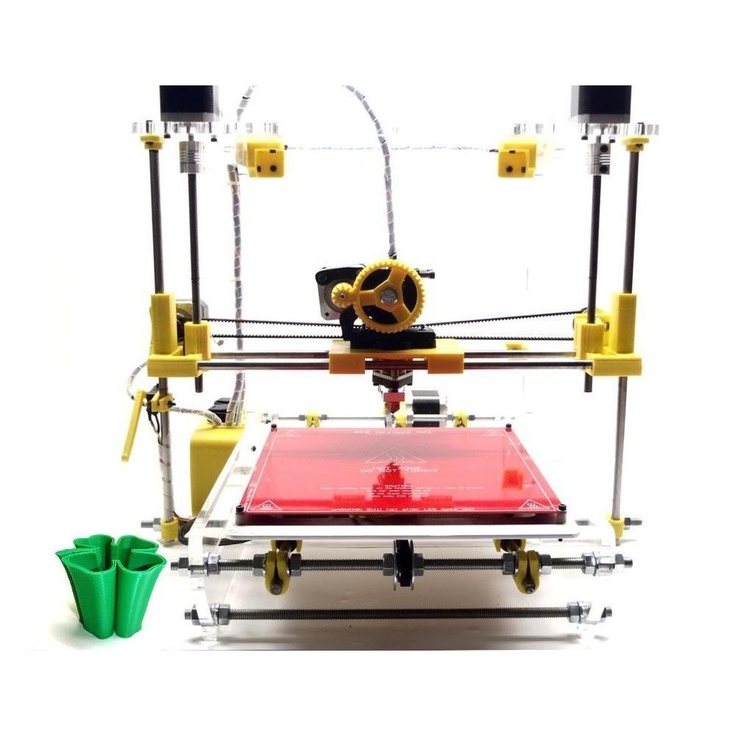

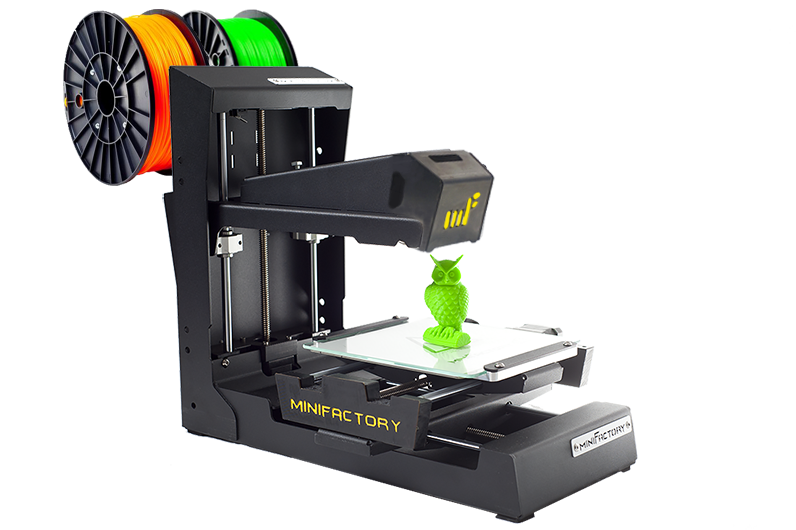

With so many types of additive manufacturing, a.k.a. 3D printing, on the market today, businesses have a plethora of options for streamlining mass production.

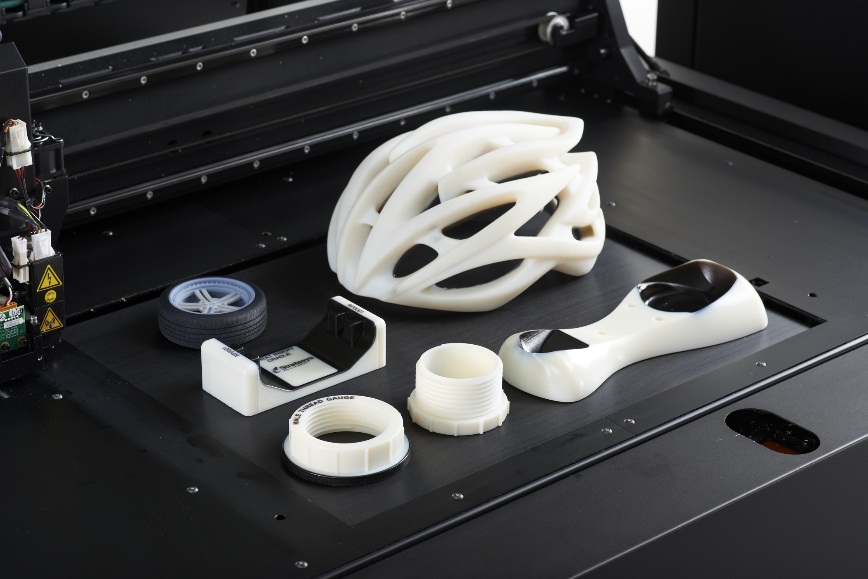

More often than not, the type of component you need to make will dictate your choice of 3D printing technology. For example, Fused Filament Fabrication (FFF) is a great choice for low-volume prototypes, while Stereolithography (SLA) is a better option for end-use parts.

Rapid Prototyping to Accelerate Production Processes

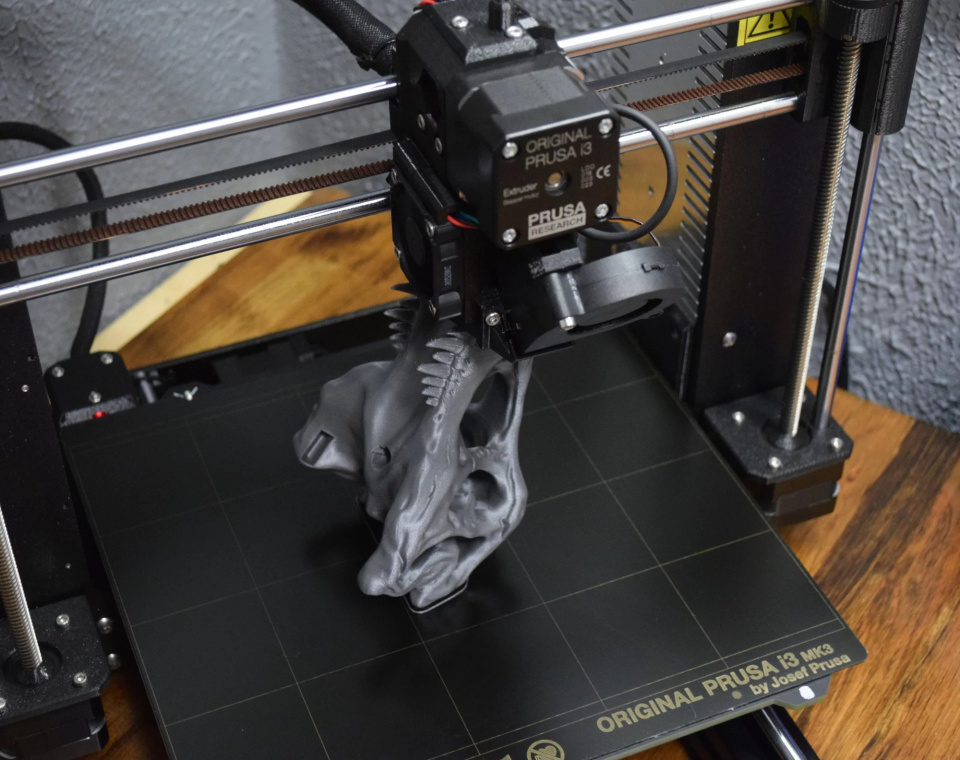

Rapid prototyping greatly accelerates mass manufacturing, making it an extremely popular use for 3D printers.

While functional prototypes are critical during the early design phases of new parts, it can take a very long time to outsource prototype manufacturing. With in-house rapid prototyping, engineers can quickly produce physical models to inspect for functionality and design flaws.

Allows for High Volume of Products

Because additive manufacturing technologies like Digital Light Synthesis (DLS) have progressed so much in the last few years, they can now be used to mass-produce high-quality, end-user products. In fact, the Carbon Digital Light Synthesis process was used to print soles for over 100,000 pairs of Adidas shoes in a single year.

Where 3D Printing is Winning in High-Volume Production

Faster Production Processes

Once you have established a working prototype, there are several ways that additive manufacturing can increase your manufacturing volume:

- Flexibility in production

- High customization

- Increased affordability

- Rapid tooling

Whether it be printing forms to be used for injection molding or printing custom soles for sneakers, additive manufacturing gets your products to market quicker.

Adaptive to New Technologies

Because 3D printing is extremely customizable, it is also extremely adaptive to new technologies. From manufacturing novel components to integrating software with artificial intelligence (AI), the sky is the limit for 3D printing processes.

High Volume with High Quality

Until recently, 3D printing hasn’t been applicable for mass production.

Traditionally, additive manufacturing processes like FFF printing haven’t been able to produce parts of high enough quality for end-user products. This is where more sophisticated processes, like DLS, come in to reshape mass production as a whole.

This is where more sophisticated processes, like DLS, come in to reshape mass production as a whole.

As the 3D printing landscape continues to evolve, novel technologies create new opportunities for high-volume production.

The Benefits of 3D Printing For Mass Production with Carbon

From first-rate manufacturing techniques to top-quality composites, Carbon is the top 3D printing company in the industry.

High-speed Manufacturing Process

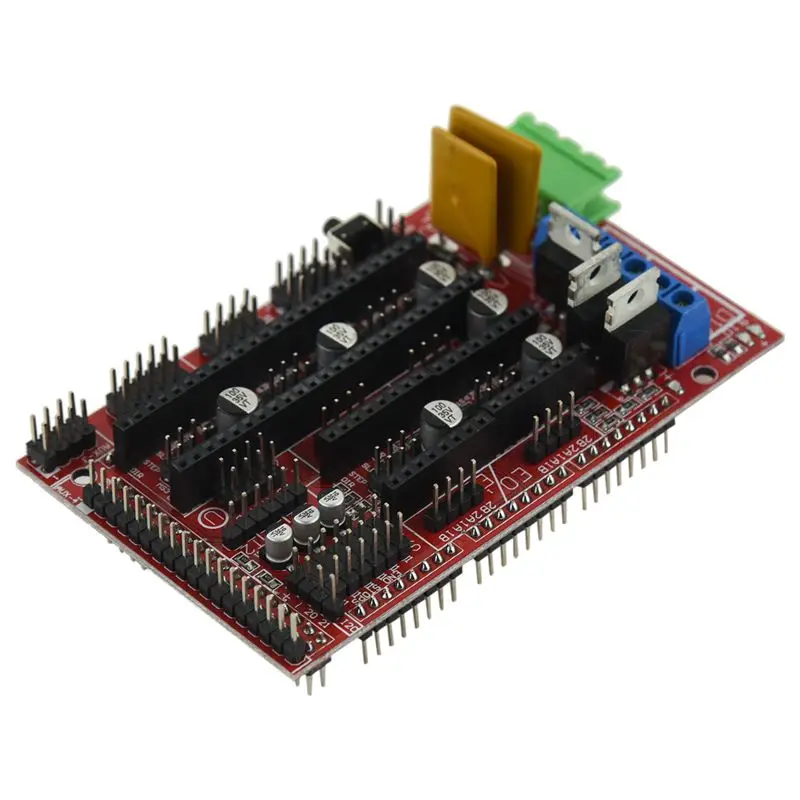

Carbon has developed a full suite of technologies, materials, and processes to streamline the manufacturing process:

- Carbon Digital Light Synthesis 3D printers

- Carbon Engine Design software

- Carbon Production Network

- Carbon 3D printing materials

By working within the carbon network, you have all the tools needed to incorporate additive manufacturing into your business model.

Superior 3D Printing Technology

Carbon DLS technology utilizes photopolymer resins and UV light to print extremely complex geometries and shapes. With Carbon DLS, UV images are cast into a photopolymer, where they then harden into printed parts.

With Carbon DLS, UV images are cast into a photopolymer, where they then harden into printed parts.

Carbon has a variety of DLS 3D printers available that produce components with unmatched performance, high resolution, and exceptional surface quality.

High-Quality End Products on Any Budget

Because Carbon hardware, software, and services are built with scalability in mind, we are able to offer cutting-edge 3D printing at affordable prices.

Carbon has developed different product offerings to ensure that no matter what your budget, you have access to the world’s top 3D printing technology:

- Carbon 3D printer leasing program

- Carbon Production Network

If you aren’t exactly sure about your 3D printing needs, start by outsourcing parts from a Carbon Production Partner.

Rapid Prototype Functional Parts

Carbon 3D printers are capable of producing both rapid prototypes and functional parts. No matter what your additive manufacturing needs, Carbon will ensure you produce a greater number of parts in a shorter time.

On-demand Support Whenever You Need It

As part of the Carbon subscription model, we take care of routine maintenance, software upgrades, and system troubleshooting. Even better, if you have questions about operating a Carbon 3D printer, we provide real-time customer support.

Industry Leaders Trust Carbon With Their Mass Production

Whether it be rapid prototyping or mass production, 3D printing reduces the time it takes to get products to market. With the Carbon platform, we’ve taken the best elements of additive manufacturing and built them into an ecosystem that simplifies the production line.

With cutting-edge hardware, software, processes, and composites, industry leaders from across the globe trust Carbon with their 3D printing needs.

Handle Your 3D Printing For Mass Production With Carbon

With Carbon, you can rapidly design, develop, and scale production for better products in less time. Contact Us to discuss streamlining your business with 3D printing for mass production.

3D as It’s Meant to Be

Interested in utilizing Carbon to accelerate product development? Reach out to us at [email protected] to learn more!

Why mass 3D printing is still not a trend

Photo: asharkyu / Shutterstock, Chris McGrath / Getty Images

The production of goods with individual characteristics is one of the trends in the consumer market. However, personification has not yet become a popular phenomenon. Is this idea promising for business development?

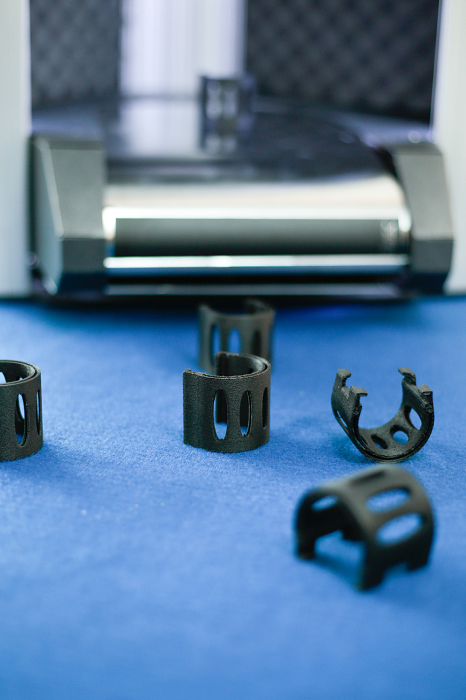

When the problem of shortage of personal protective equipment (PPE) for doctors became acute, the owners of 3D printers united in the volunteer movement #3Dfor doctors. They began to print adapters, which made it possible to connect diving masks with virus-bacterial filters. Manufacturers were able to quickly develop and release adapters in various configurations for popular types of masks found in stores, quickly covered burning needs and saved many lives - and then began to make full-fledged protective masks and shields.

Adapters for masks - example of a customized product (made to order. - RBC Trends ), that is, adapted to different types of masks. How quickly manufacturers were able to design and release a new product with unique characteristics demonstrates the main advantages of 3D printing.

3D printing allows you to create products based on the preferences or personal characteristics of the buyer - personalized goods. This idea arose in the early 2000s, but so far, contrary to forecasts and the rapid development of additive technologies, has not become a mass phenomenon.

Personalization Challenges

Nike and Adidas have been experimenting with 3D printing for sneakers since 2012. The goal is to create sports shoes in the presence of the buyer according to the individual characteristics of his foot. For example, Adidas announced in 2015 that a consumer could walk into a store, spend a couple of minutes on the treadmill, and immediately receive a printed pair of running shoes that take into account the contours of the foot and pressure points while running. At the same time, Nike announced the possibility of printing shoes directly at the customer's home. To do this, you just need to download the file with the parameters of the sneakers and the characteristics of the foot from the corporation's website to your home 3D printer.

At the same time, Nike announced the possibility of printing shoes directly at the customer's home. To do this, you just need to download the file with the parameters of the sneakers and the characteristics of the foot from the corporation's website to your home 3D printer.

However, by 2020 these opportunities remained unrealized. In practice, everything turned out to be more difficult.

The point is the high cost of such products: the consumer is not ready to pay for customized sneakers many times more expensive when you can choose the right model from thousands of more affordable options.

Customization does not take root among automakers either. For example, in 2017, BMW launched the MINI Yours Customized service, which allows you to customize a new or previously purchased MINI car using decorative elements printed on a 3D printer. For example, it was possible to order individual side body inserts, trim parts, LED door sills and LED door projectors. However, the service is currently unavailable.

However, the service is currently unavailable.

Where personification has taken root

So far, 3D printing is most actively used in medicine, where it is vital to take into account the individual characteristics of a person. First of all, the technology is useful in orthopedics and dentistry for the manufacture of prostheses and implants. Customization is especially in demand in the production of prosthetic limbs. With the help of 3D scanning, the parameters of the patient are determined, a digital model of the prosthesis is created, which is printed on a 3D printer. In this case, you can create a unique design of the artificial limb. For example, they produce children's prostheses stylized as favorite movie characters.

Another area where 3D printing is being used to customize products is in the jewelry and fashion jewelry industry. There are enterprises that produce mass products using 3D printing, for example, the American brands LACE, Nervous System and others. Customization is carried out, first of all, by small studios and workshops offering exclusive jewelry. They print digital models created according to customer sketches or cast them from precious materials using 3D printed molds.

Customization is carried out, first of all, by small studios and workshops offering exclusive jewelry. They print digital models created according to customer sketches or cast them from precious materials using 3D printed molds.

Economics of innovation Living hand: who creates bionic prostheses in Russia

As for the majority of goods, the price works here in 99% of cases. Especially when the share of online sales is growing. You type in Google "buy a fountain pen is the cheapest" - and no matter where you are, you buy this fountain pen cheaper. This is where mass production wins.

You can think of many products that could be customized. But you need to be clear about who you will sell them to. Are there enough people willing to overpay for customization to keep your business alive? “In your calculations, you need to take into account real consumer demand, and not the desire to make money on hype,” says Vlasov. “The conclusion is simple: personalized production is possible when it will give approximately the same price as mass production. ”

Denis Alekseev, Head of R&D and Production at JSC ROBBO (educational robotics, Skolkovo resident), is confident that personalized production will become a popular trend of the future. But in order to attract the mass consumer to this segment, it is necessary to overcome a number of technical and organizational issues. For the end user, the process of ordering a customized product should be as simple as possible: with a few steps, order what he wants, while receiving the finished product quickly and conveniently. The cost of individual products may be higher, but this increase must be of value to the customer.

Main disadvantages of 3D printing:

-

low production speed;

-

often low quality products;

-

high cost of the product when trying to mass production.

How to reduce the cost of a customized product?

The cost of the finished product primarily depends on the materials for 3D printing. One way to cut costs is to produce consumables yourself.

Another option to reduce the cost of consumables is possible with the development of additive technologies and the development of new printing materials.

The main question is: who will buy it?

Entrepreneurs will be able to develop the production of personalized goods if they find the answer to the question: who will buy them? Businesses that already operate in a particular market and feel the needs of their audience can feel the demand. It is almost impossible to guess - you need to be sure of the demand.

Artur Gerasimov notes that small-scale production is promising for business development using additive technologies. One of the areas of work of his company Innovax is the production of parts and mechanisms by order of industrial enterprises from the automotive industry, instrument making, and the aerospace industry.

A customization boom will occur when a customer can get a personalized product at the same price and as quickly as a mass product. Therefore, it is up to the development of technologies and services.

Subscribe to the RBC Trends Telegram channel and stay up to date with current trends and forecasts about the future of technology, economics, education and innovation.

Why mass 3D printing has not yet become a trend

The production of goods with individual characteristics is one of the trends in the consumer market. However, personification has not yet become a popular phenomenon. Is this idea promising for business development?

When the problem of shortage of personal protective equipment (PPE) for doctors became acute, the owners of 3D printers united in the volunteer movement #3Dfor doctors. They began to print adapters, which made it possible to connect diving masks with virus-bacterial filters. Manufacturers were able to quickly develop and release adapters in various configurations for popular types of masks found in stores, quickly covered burning needs and saved many lives - and then began to make full-fledged protective masks and shields.

Photo: Sk.ru.

Adapters for masks - an example of a customized product (made to order. - RBC Trends), that is, adapted to different types of masks. How quickly manufacturers were able to design and release a new product with unique characteristics demonstrates the main advantages of 3D printing.

3D printing allows you to create products based on the preferences or personal characteristics of the buyer - personalized goods. This idea arose in the early 2000s, but so far, contrary to forecasts and the rapid development of additive technologies, has not become a mass phenomenon.

Personalization Challenges

Nike and Adidas have been experimenting with 3D printing for sneakers since 2012. The goal is to create sports shoes in the presence of the buyer according to the individual characteristics of his foot. For example, Adidas announced in 2015 that a consumer could walk into a store, spend a couple of minutes on the treadmill, and immediately receive a printed pair of running shoes that take into account the contours of the foot and pressure points while running. At the same time, Nike announced the possibility of printing shoes directly at the customer's home. To do this, you just need to download the file with the parameters of the sneakers and the characteristics of the foot from the corporation's website to your home 3D printer.

However, by 2020 these opportunities remained unrealized. In practice, everything turned out to be more difficult.

The point is the high cost of such products: the consumer is not ready to pay many times more for customized sneakers when you can choose the right model from thousands of more affordable options.

Customization does not take root among automakers either. For example, in 2017, BMW launched the MINI Yours Customized service, which allows you to customize a new or previously purchased MINI car using decorative elements printed on a 3D printer. For example, it was possible to order individual side body inserts, trim parts, LED door sills and LED door projectors. However, the service is currently unavailable.

Where personification has taken root

So far, 3D printing is most actively used in medicine, where it is vital to take into account the individual characteristics of a person. First of all, the technology is useful in orthopedics and dentistry for the manufacture of prostheses and implants. Customization is especially in demand in the production of prosthetic limbs. With the help of 3D scanning, the parameters of the patient are determined, a digital model of the prosthesis is created, which is printed on a 3D printer. In this case, you can create a unique design of the artificial limb. For example, they produce children's prostheses stylized as favorite movie characters.

Another area where 3D printing is being used to customize products is in the jewelry and fashion jewelry industry. There are enterprises that produce mass products using 3D printing, for example, the American brands LACE, Nervous System and others. Customization is carried out, first of all, by small studios and workshops offering exclusive jewelry. They print digital models created according to customer sketches or cast them from precious materials using 3D printed molds.

Living hand: who creates bionic prostheses in Russia

“The prospects for personalized production depend on the specific market,” says Denis Vlasov, founder of 3DSLA – Russian 3D Printers. — Why did 3D technologies take root among dentists and jewelers? These are businesses that work with a unique client. In addition, dental clinics or jewelry workshops are geo-referenced and serve a specific area. Therefore, they can vary the price without much risk that all customers will run away to the neighboring area.

![]()

As for the majority of goods, the price works here in 99% of cases. Especially when the share of online sales is growing. You type in Google "buy a fountain pen is the cheapest" - and no matter where you are, you buy this fountain pen cheaper. This is where mass production wins.

You can think of many products that could be customized. But you need to be clear about who you will sell them to. Are there enough people willing to overpay for customization to keep your business alive? “In your calculations, you need to take into account real consumer demand, and not the desire to make money on hype,” says Vlasov. “The conclusion is simple: personalized production is possible when it will give approximately the same price as mass production.”

Denis Alekseev, Head of R&D and Production at JSC ROBBO (educational robotics, Skolkovo resident), is sure that personalized production will become a popular trend of the future. But in order to attract the mass consumer to this segment, it is necessary to overcome a number of technical and organizational issues. For the end user, the process of ordering a customized product should be as simple as possible: with a few steps, order what he wants, while receiving the finished product quickly and conveniently. The cost of individual products may be higher, but this increase must be of value to the customer.

Main disadvantages of 3D printing:

- low production speed;

- often low quality products;

- high cost of the product when trying to mass production.

“As 3D printing develops and the fleet of 3D printers increases, the possibilities of additive manufacturing will grow,” says Alekseev. - Probably, in the future, a distributed network of 3D printers will be able to compete with traditional mass production, localized at one enterprise. In any case, the issues of quality and cost of products produced on 3D printers must be resolved.”

How to reduce the cost of a customized product?

The cost of the finished product primarily depends on the materials for 3D printing. One way to cut costs is to produce consumables yourself.

“If I created the production of personalized products, I would solve the issue of creating consumables at the point of consumption,” explains Denis Vlasov. — That is, if I planned to produce shoes with custom soles, then I would start producing polymers for them. If you control the cost of consumables, you can get a very good selling price for the finished product.”

Another option to reduce the cost of consumables is possible with the development of additive technologies and the development of new printing materials.

“Russia produces enough materials for 3D printing of acceptable quality. We will definitely not produce materials ourselves, because this is a separate business that requires different competencies,” says Artur Gerasimov, CEO of Innovax (Skolkovo resident). “But what could reduce the cost of 3D production in principle is the emergence of direct-to-raw printing technology.

Currently, materials in the form of powder or filaments are used for printing. If we exclude the intermediate stage of processing raw materials and create equipment that will work on the source material - granules, without an additional stage of processing it into powder or thread, this will reduce the cost of materials by 5-10 times. Such developments are currently underway.

The main question is: who will buy it?

Entrepreneurs will be able to develop the production of personalized goods if they find the answer to the question: who will buy them? Businesses that already operate in a particular market and feel the needs of their audience can feel the demand. It is almost impossible to guess - you need to be sure of the demand.

“Now we are the only ones in Russia who simultaneously produce printing consumables, 3D printers, software, and a hardware platform,” says Denis Vlasov. “With this model, we could create good conditions for the production of customized products.

But we cannot burst into thousands of applications of our technologies. We are not interested in building small businesses ourselves. We create a system - the root and trunk of the tree. And branches and leaves, small markets and businesses, should be grown by those who understand their needs and rules of the game well. And we are ready for such cooperation.”

Artur Gerasimov notes that small-scale production is promising for business development using additive technologies. One of the areas of work of his company Innovax is the production of parts and mechanisms by order of industrial enterprises from the automotive industry, instrument making, and the aerospace industry.

“The pursuit of individuality, conscious consumption are global trends, they will also have an impact on consumer demand,” says Zhamilya Kameneva, Business Development Director of I-Teco Innovation Center LLC. — Despite the difficult economic situation, the production of personalized goods remains a promising niche for start-ups and a good idea to launch new business lines at existing production facilities.

![]()

Learn more