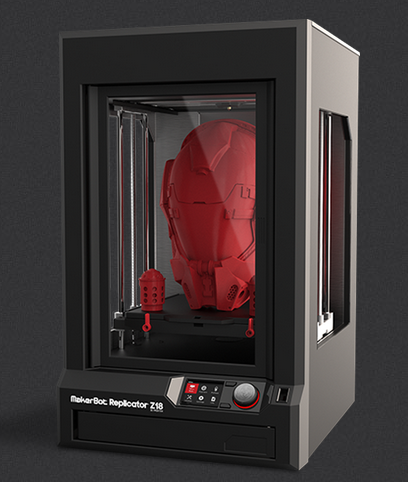

Makerbot z18 3d printer

MakerBot Replicator Z18 Review 2022

4.2

See Price

| Printing Area | 300 mm x 305 mm x 457 |

| Layer Resolution | 100 microns |

| Supported Filament | PLA |

| Filament Diameter | 1.75mm |

| Extruders | 1 |

| Extruders Diameter | 0.4 mm |

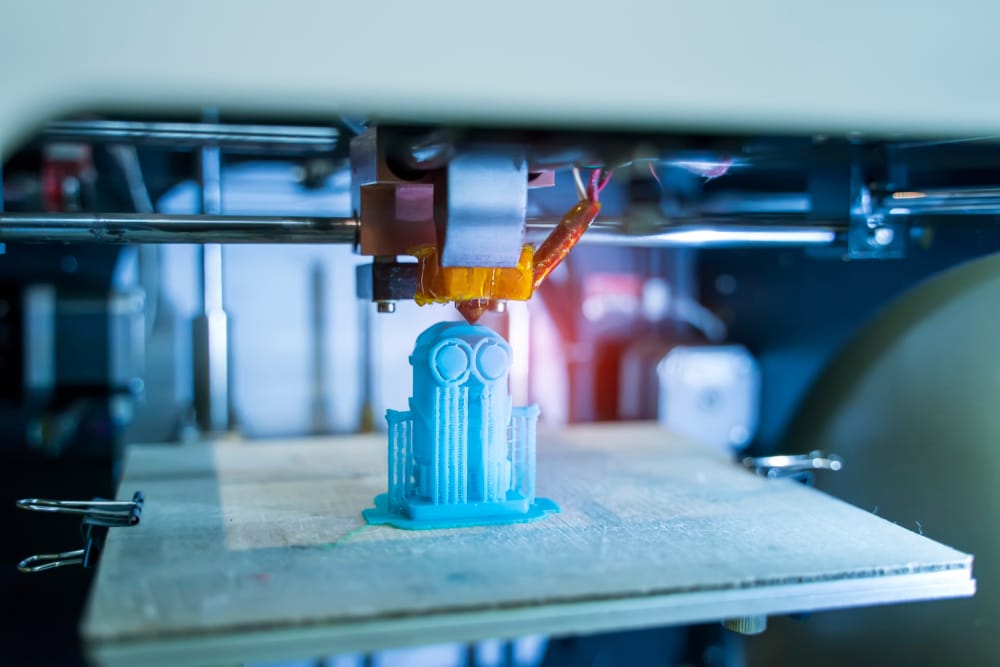

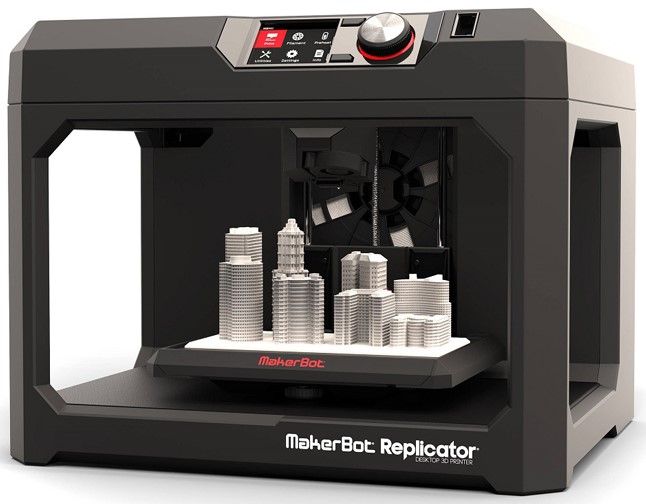

With the Replicator Z18, MakerBot strives for professional grade quality and build volume while keeping a desktop form factor, and on the surface, this 3D printer does just that doing away with the cumbrous size of standalone pro models that cost remarkably more. Think large scale industrial prototypes not produced by the industrial-like mega printers that inhabit the dark recesses of workshops across the world.

Does it stand up to these grandiose aspirations and what exactly does the MakerBot Replicator Z18 sport under the hood? Here’s our take on the Replicator Z18.

Table of ContentsShow

Design and Features

From the onset, the Replicator Z18 emits an air of refined construction with stunning sheer right angles that define it’s all black powder-coated casing and towering cabinet allure. Acrylic panels provide front and side windows onto the build area, while the back panel is filled in.

The front window swivels open with a simple press of the locking mechanism to access the build plate, and once shut provides a fully enclosed heated chamber that controls the ambient temperature to ward off warping caused by thermal fluctuations.

As for the construction, the frame and mechanical parts are made of powder-coated steel with PC-ABS and aluminum composite material weighing in at a total of 90lbs. In keeping with the Cartesian FDM design, the Replicator utilizes the common Z18 1.8° step angle with 1/16 micro-stepping motor configuration printing at a set layer resolution of 100 microns with a standard 0.4 mm nozzle. Nothing fancy here, but well within the realm of acceptability.

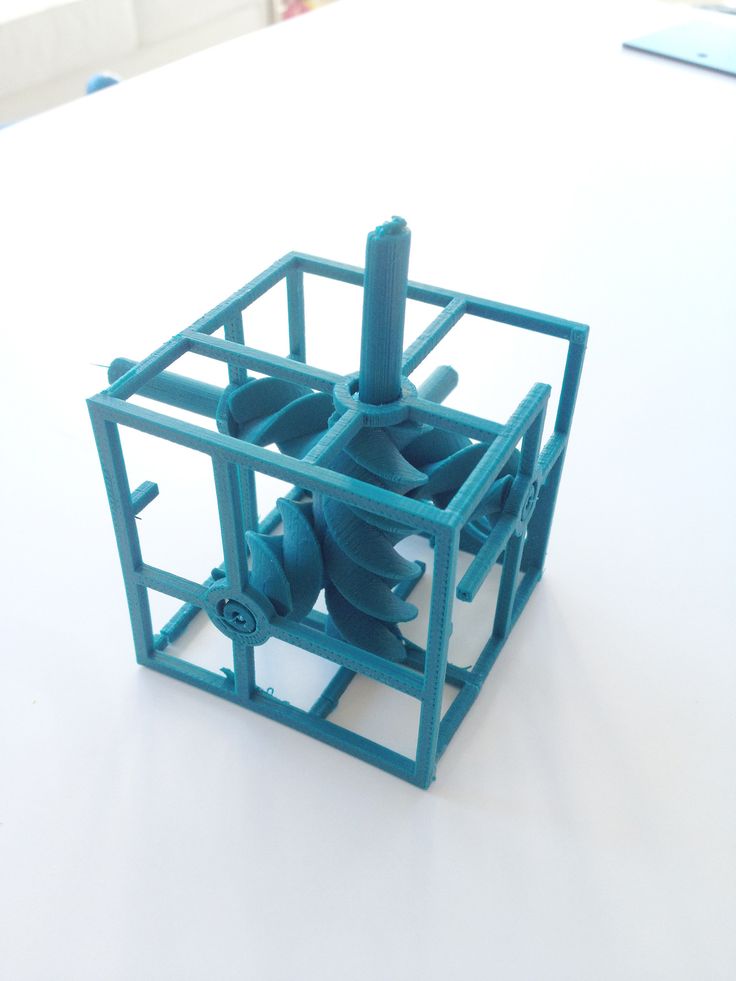

The build area measures in at a massive 300 mm x 305 mm x 457 mm with an emphasis on verticality, but truth be told all three axes are covered with over 2500 cubic inches of build space and enough room to print even the most ambitiously sized prototypes and parts. The build plate itself is formed of injection molded PC-ABS and sits atop the plate support bracket via a set of clips for easy removal once a print is finished.

The Replicator Z18 on sale today is a little different to the original model launched back in 2014 alongside the much-maligned fifth generation of Replicator 3D printers. The most significant upgrade is swapping out the notoriously error-prone extruder for the significantly improved MakerBot Smart Extruder +. The modular design means you can swap it out for a replacement with ease and an inbuilt feature detects filament levels and ferries progress information across to the software for monitoring.

As far as filament support, the Replicator Z18 is limited to 1. 75 mm diameter PLA. Although MakerBot recommends its own proprietary PLA in large 2 lbs spools and says the Z18 is optimized for it, the printer can accommodate third-party filament without any problems.

75 mm diameter PLA. Although MakerBot recommends its own proprietary PLA in large 2 lbs spools and says the Z18 is optimized for it, the printer can accommodate third-party filament without any problems.

MakerBot flogs its filament as durable, resistant to impacts and subject to over 160,000 hours of testing or so goes the marketing spiel, but we found it to be overpriced for little improvement on standard fare PLA and it performed worse than lower-priced alternatives.

In other features, the Replicator Z18 includes a 320 X 240 resolution onboard camera that takes reference pictures every few seconds for monitoring through the MakerBot app and to share on Makerbot Thingiverse and social media if you are that way inclined. It also has a bellow that guides with the extruder to prevent heat from escaping, a nozzle brush, and filament collection waste bin.

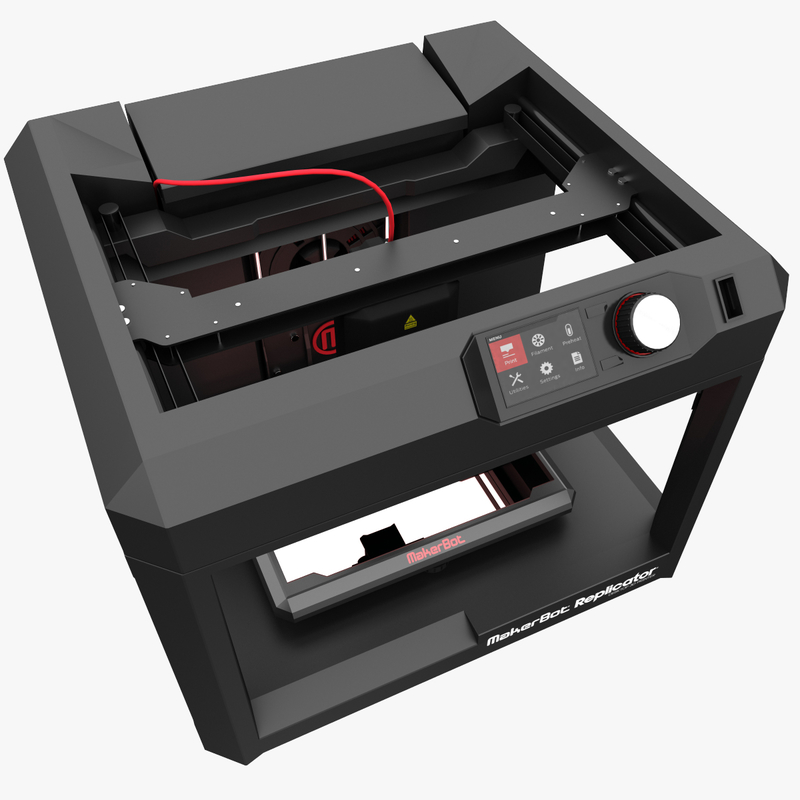

The Replicator has a 3.5 inch full-color LCD with a turn dial to navigate the menus allowing you to peruse your library of models, calibrate the printer, lower the build plate, load filament, monitor chamber/print head temperature, preheat the printer, swap out the extruder, update the firmware and so on. We found it has a degree of depth without being overly complex and remaining intuitive to use. It works as a great hands-on addition to software.

We found it has a degree of depth without being overly complex and remaining intuitive to use. It works as a great hands-on addition to software.

Speaking of software, you can connect to the Replicator Z18 via WiFi, USB-to-PC, and Ethernet using MakerBot’s slicing desktop software and mobile app, MakerBot Print and MakerBot Mobile respectively. The software supports STL, OBJ, THING, MakerBot file types. Both applications are compatible with Windows 7/10, Linux, and Mac OS X and benefit from regular updates to improve functionality and performance. It links up with Thingiverse offering an amazing archive of models to print.

Cloud-based MakerBot Print does the majority of the work behind the scenes with tinkering options for the user to mess around with from print mode, to scaling, adding supports, rafts, and creating print profiles. It won’t wow enthusiasts, but is more than able to process and send files for printing without issues. The mobile app is a skeleton version of the desktop software and allows you to monitor prints, receive notifications, pause and cancel prints on the go.

Assembly

The MakerBot Replicator Z18 ships in a package mounted on a wooden crate befitting its large size. The protective packaging matches the price tag, and MakerBot has gone to length to protect the printer. The small touches like a piece of foam preventing the door from smashing open and closed are a welcome touch. The biggest issue was getting it off the crate and onto a table, which turned out to be a three-person job due to the large profile and weight of the Replicator Z18.

The package includes the printer itself, a quick start unpacking guide, PLA filament spool, Smart Extruder +, build plate tape, power cord, USB cable, and 5 mm hex wrench.

There’s a 16 step installation process before you can start using the printer, which should take no more than 15 minutes. It involves removing the protective tape, clips, and film first, then adjusting the rubberized feet to the surface. Next comes fitting the extruder (very straightforward – just push it into the carriage and magnets secure it), loading the filament spool into the holding bay that sits on the bottom of the printer below the LCD, feeding filament into the tubing, applying tape to the build plate, plugging in the power cord, and following the onscreen instructions.

Once powered up, we had to feed the filament from the tubing into the extruder which involved heating the extruder, feeding the end until it latched onto the gears, then fitting the feeder tube over the top of the extruder. It couldn’t be simpler, and the LCD provides detailed information throughout the process.

The Z18 comes pre-leveled although the assisted build plate feature is easy to use and guides the user through each step of the process instructing the user to tighten screws based on blinking LEDs. Plugging in the USB cable and firing up MakerBot Print also triggered a firmware update, which is a good sign of constant support.

Printing

At first, the print quality of the Replicator Z18 was nothing short of disappointing with successive botched prints. Eager to get the most out of the printer, we contacted MakerBot support who walked us through leveling the bed assisted by the LCD instructions. A few twists of screws later and we were back in business. It had dislodged in transit.

From here onward, the print quality was nothing short of astonishing. Regardless of the size of the print, the Z18 produced blemish-free, smooth prints with details worthy of its marketing as a professional grade printer. The Smart Extruder + makes all the difference and gone are the days of joyless troubleshooting that defined earlier models of the Z18.

The quality of the prints mean they can compete with the highly accurate demands of an engineering context where parts, models, and prototypes are used to run stress tests before full-blown manufacturing commences.

Where the Z18 loses points is when we consider its speed: it’s a slow printer, and although faster than previous iterations, it is still way behind similarly priced printers. Equally, it takes a while to warm up and get printing. We understand that upcoming firmware updates will attempt to increase the speed, so MakerBot is aware of the issue and is working towards a solution.

Support

From our experience, the support from MakerBot is of the highest caliber and the people we spoke to were not only friendly and knowledgeable but eager to help us get the most out of the Replicator Z18.

MakerBot offers an extensive library of troubleshooting guides, educational articles, phone/live chat/email contacts, part replacement service, and up to three years of warranty coverage if you opt for the MakerCare Platinum package (plus priority response, wear and tear coverage, etc.). The standard warranty is a respectable one-year.

Verdict

MakerBot lives up to its ambitions of providing a desktop-friendly professional grade printer with a massive build volume and overall ease of use. It’s miles away from the first versions of the Z18 plagued with numerous issues and the fruit of MakerBot listening to builders to finally ship the printer it was supposed to be when it first launched.

The print quality is of the highest level and should suit most professional environments down to a tee; however, we see the Z18 as the perfect prosumer 3D printer for hobbyists that have the budget and drive to create sizeable, complicated prints on a reliable, stylish, and well-designed printer.

The slow speed, cumbersome profile and software limitations don’t weigh in enough to sway us away from recommending the MakerBot Replicator Z18.

MakerBot Replicator Z18 3D Printer

MAKERBOT

The Best Price to Performance Ratio in the Extra-Large, Professional 3D Printer Category

The MakerBot Replicator Z18 combines an extra-large build volume with ease-of-use and connectivity features so you can go from 3D model to 3D print efficiently and easily. Optimized for MakerBot PLA filament, the Replicator Z18 can create extra-large, ultra-tall industrial prototypes, models, and products.

View Video Brochure Request Demo

- Overview

- Key Features

- Advantages

- Materials

- Specifications

- Request a Quote

Massive Build Volume for the Professional Innovator

Minimize downtime and keep on 3D printing with a swappable, easy-to-use Smart Extruder. You can also upgrade to the Smart Extruder+. The 3D printer’s three connectivity options —USB, Wi-Fi, and Ethernet— allow for a seamless workflow. Cloud and app-enabled, the MakerBot Replicator Z18 connects to MakerBot’s software and wider resources to provide you with a refined, streamlined 3D printing experience so you can focus on making things bigger and better.

You can also upgrade to the Smart Extruder+. The 3D printer’s three connectivity options —USB, Wi-Fi, and Ethernet— allow for a seamless workflow. Cloud and app-enabled, the MakerBot Replicator Z18 connects to MakerBot’s software and wider resources to provide you with a refined, streamlined 3D printing experience so you can focus on making things bigger and better.

Build Volume

At 2,592 cubic inches, make extra-large and ultra-tall industrial concept models and prototypes. Think and build bigger than ever.

Cost Efficiency

With the massive build volume of the Z18, you can print prototypes and parts at a vastly lower cost than industrial 3D printers.

Connectivity

Send print files to your 3D printer via Wi-Fi, USB, Ethernet or with a USB drive. Control your printer via MakerBot Print or remotely with MakerBot Mobile.

Optimized Filament

Safe for the office or classroom, this filament is non-toxic and easy-to-print with minimal warping or curling. It’s also optimized to give you the best results and highest quality for the MakerBot Replicator Z18 Printer.

Create professional, high-resolution prototypes and complex models that are great for displays, demonstrations and presentations. Print with MakerBot PLA Filament, tested in-house to ensure highest quality standards. Models can be printed to be smooth-to-the-touch without the need for sanding or finishing.

SHOP MAKERBOT PLA FILAMENT

Massive Build Volume

The Replicator Z18 3D Printer from MakerBot allows you to print large, detailed objects up to 12″ in width and depth, and up to 18″ in height. To ensure accurate printing and to minimize warping even throughout lengthy print jobs, the Z18 features a heated build chamber to maintain a consistent temperature, and a polycarbonate ABS build plate that is resistant to temperature extremes.

2,592 Cubic Inches

30.0 L X 30.5 W X 45.7 H centimeters

11.8 L x 12.0 W x 18.0 H inches

Optimized for MakerBot PLA Filament

Safe for the office or classroom, this filament is non-toxic and easy-to-print with minimal warping or curling. It’s also optimized to give you the best results and highest quality for the MakerBot Replicator Z18 Printer.

Use MakerBot Tough PLA to print durable, high-impact strength prototypes and fixtures. This filament has been tested and optimized to deliver repeatable results with the Tough PLA Smart Extruder+

Full-Featured Software

Store, organize and access all your 3D designs in the cloud-enabled library in MakerBot Print.

For on-board control of your printer, the Z18 features a 3.5″ full-color LCD display and intuitive dial. Access your object library, see previews of your 3D model files, and employ utilities to set up and maintain your 3D printer.

LEARN MORE

BioLite

Consumer Products

View Case Study

Canary

Consumer Products

View Case Study

Lockheed Martin

Aerospace

View Case Study View Video

Peloton

Consumer Products

View Case Study

Perkins+Will

Manufacturing

View Case Study View Video

Lockheed Martin

Perkins+Will

True Colour PLA Filament

Print amazing, large pieces in many vibrant colours.

LEARN MORE

Tough PLA

For large prints that require tensile strength for testing.

LEARN MORE

Print Technology |

Print TechnologyFused Deposition Modeling (FDM) |

Build Volume |

Build Volume30.0 x 30.5 x 45.7 cm (11.8 x 12.0 x 18.0 in) |

Layer Resolution |

Layer Resolution100 microns [0.0039 in] |

Build Surface |

Build SurfaceInjection Molded PC-ABS |

Filament Diameter |

Filament Diameter0. 069 in [1.75 mm] 069 in [1.75 mm] |

Extruder Compatibility |

Extruder CompatibilitySmart Extruder+, Tough PLA Smart Extruder + |

Filament Compatibility |

Filament CompatibilityMakerBot PLA Filament Large Spool 0.9 kg [2.0 lb], MakerBot Tough PLA Filament Large Spool 0.9 kg [2.0 lb] |

Camera Resolution |

Camera Resolution320 x 240 |

Software Bundle |

Software BundleMakerBot Print Software |

Supported OS for MakerBot Print |

Supported OS for MakerBot PrintWindows 7 & 10, Mac OS X (10. 9+), No Linux Support 9+), No Linux Support |

Connectivity |

ConnectivityWi-Fi, Ethernet, USB |

Product Dimensions |

Product Dimensions19.4 x 22.2 x 33.9 in [49.3 x 56.5 x 86.1 cm] |

Product Weight |

Product Weight90 lbs [41 kg] |

Make sure your prints print larger with the best consistency by using MakerBot certified materials & accessories

SHOP NOW

MakerBot Replicator Z18 3D Printerfrom MakerBot Industries, LLC The MakerBot Replicator Z18 is MakerBot's large-scale 3D printer.

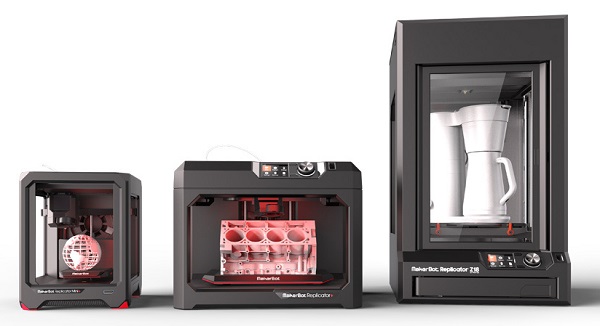

The name speaks for itself. "Z18" stands for "18" vertical, which gives a good idea of the true dimensions of the new printer's chamber. In the horizontal plane, the dimensions are somewhat more modest, but still impressive: 12 inches along the X and Y axes. In metric terms, it comes out 305x305x457mm, which is an order of magnitude higher than 252x199x150mm for the flagship.

The name speaks for itself. "Z18" stands for "18" vertical, which gives a good idea of the true dimensions of the new printer's chamber. In the horizontal plane, the dimensions are somewhat more modest, but still impressive: 12 inches along the X and Y axes. In metric terms, it comes out 305x305x457mm, which is an order of magnitude higher than 252x199x150mm for the flagship. About the MakerBot Replicator Z18

One of the biggest complaints about MakerBot Replicator 3D printers has always been a relatively small build area. The company itself has always parried such attacks, pointing out the possibility of printing large parts in parts, followed by gluing. And yet, this approach is more pragmatic when printing with ABS plastic, which can be easily glued (in fact, fused) with acetone. "Replicators" are traditionally created to work with polylactide (aka PLA plastic). But as it turns out, the creation of a professional and even industrial-level printer with a large working area has long been part of the company's plans. And so, it happened. The fifth generation of MakerBot Replicator printers includes three models at once: the basic, flagship Replicator, the compact and affordable Replicator Mini, and the professional printer for large-scale printing, called the Replicator Z18. nine0003

And so, it happened. The fifth generation of MakerBot Replicator printers includes three models at once: the basic, flagship Replicator, the compact and affordable Replicator Mini, and the professional printer for large-scale printing, called the Replicator Z18. nine0003

Design

The Replicator Z18 is MakerBot's first large-scale target 3D printer

due to a high-tech gadget. It seems that the company is trying to erase the last traces of its humble beginnings in the ranks of RepRap enthusiasts.

As with the Mini, the openings in the Z18 are covered with transparent panels. In general, this is not the best option for PLA printers, as polylactide takes a long time to vitrify. As a rule, in such cases, open cases are used to speed up the cooling process. Until now, the MakerBot team has adhered to this unspoken rule, and still adheres to it - the flagship has an open case. The developers explained the closed case of the Replicator Mini with the need to increase user safety, because this printer is intended for use in everyday life and educational institutions, and curious kids can easily get burned on a hot extruder. But the choice of a closed case for the professional Z18 is not entirely clear. We can only hope that the problem of ventilation and cooling has been properly addressed by the designers - judging by the quality of the models shown, it is. nine0003

But the choice of a closed case for the professional Z18 is not entirely clear. We can only hope that the problem of ventilation and cooling has been properly addressed by the designers - judging by the quality of the models shown, it is. nine0003

New extruder for MakerBot fifth generation printers

Like the rest of its peers, the Z18 is equipped with a new "smart" extruder. This printhead is equipped with a special sensor that can alert the user when a supply has stopped feeding. Printing automatically pauses while waiting for the spool to be replaced. The importance of this feature cannot be overestimated, especially given the size of the parts produced by the Z18 - it would be a shame to lose a model just because the plastic ran out in the middle of the printing process, and neither the printer nor the user noticed the impending disaster. In addition, the extruder is equipped with Hall sensors that allow precise platform calibration. nine0003

True, there is a fly in the ointment in a barrel of honey. The extruder used is universal and can be used on both the Z18 and the Mini and the flagship. And if there are no reports on the reliability of the large and small versions of the “replicator” yet (so far only pre-orders are being processed), then the flagship has already been tested with not entirely comforting results. Some users complain about the weak pulling mechanism of the extruder and clogging thereof. This problem can be exacerbated when using third-party supplies, which often fall short of the high standards of MakerBot supplies. An oval cross-section of the thread or dusting can easily lead to the failure of the extruder, and repairing it at home will not be an easy task. There is, however, an unusual plus: the extruder is mounted only on strong magnets. If desired, the entire assembly can be “teared off” and a new one inserted in its place, and the failed one can be sent to a service center. nine0003

The extruder used is universal and can be used on both the Z18 and the Mini and the flagship. And if there are no reports on the reliability of the large and small versions of the “replicator” yet (so far only pre-orders are being processed), then the flagship has already been tested with not entirely comforting results. Some users complain about the weak pulling mechanism of the extruder and clogging thereof. This problem can be exacerbated when using third-party supplies, which often fall short of the high standards of MakerBot supplies. An oval cross-section of the thread or dusting can easily lead to the failure of the extruder, and repairing it at home will not be an easy task. There is, however, an unusual plus: the extruder is mounted only on strong magnets. If desired, the entire assembly can be “teared off” and a new one inserted in its place, and the failed one can be sent to a service center. nine0003

The Replicator Z18 comes with a built-in camera to monitor the print process

There's also a built-in camera that allows you to monitor the print process remotely. Moreover, MakerBot is actively developing cloud support - as the head of the company, Bree Pettis, says, now you can start printing and go to a cafe for a cup of tea, but at the same time watch the process using your smartphone.

Moreover, MakerBot is actively developing cloud support - as the head of the company, Bree Pettis, says, now you can start printing and go to a cafe for a cup of tea, but at the same time watch the process using your smartphone.

The Z18 work table is made from a mixture of polycarbonate and ABS plastic. For a better setting of the first layer, it is recommended to use a regular wax impregnated masking tape. This method is well known and popular among DIY enthusiasts. You can buy the tape yourself, or you can purchase ready-to-size coatings from MakerBot. Of course, the use of a plastic table means that the platform is not heated. In principle, it is not needed, since PLA plastic has a very low degree of shrinkage, and the probability of twisting the first layers is minimal. In addition, the same closed case can contribute to uniform cooling and prevent deformation. nine0003

Mobile stand for Replicator Z18

The considerable size (493x565x854mm) and weight (41kg) of the printer prompted the developers to create a special cabinet on casters. Whether such a stand is worth the declared $1,250 is a big question. It may be easier to find a permanent installation site.

Whether such a stand is worth the declared $1,250 is a big question. It may be easier to find a permanent installation site.

Replicators have always been renowned for their high resolution and print accuracy. The designers of this company never promise anything fantastic, but keep their word. The Z18 is designed to print with a minimum layer thickness of 100 microns, which is excellent, and often overkill. The positioning accuracy of the print head is also on top, reaching 11 microns along the X and Y axes, and 2.5 microns along the Z axis. And do not forget about the volume of the working area, which allows you to create such masterpieces in their entirety:

MakerBot CEO Bree Pettis before and after "plastic surgery"

Special consumable reels are an interesting innovation. If standard reels reach 1kg in material weight, then special spools for Z18 weigh all 4.5kg. It is understandable - large models require a large consumption of materials. In addition, it is possible to use branded coils of less weight. The latter are loaded into a sliding compartment built into the bottom of the device. The giant 4.5 kg spools come in their own case for external installation. nine0003

In addition, it is possible to use branded coils of less weight. The latter are loaded into a sliding compartment built into the bottom of the device. The giant 4.5 kg spools come in their own case for external installation. nine0003

Special 4.5kg consumable spools

Fortunately, the creators have left the possibility of using third-party consumables. There are no tricks to prevent their use, unlike rival 3D Systems printers. The only obstacle will be the non-standard size of branded coils for the fifth generation, for which the internal compartments of printers are designed. However, non-branded coils can be installed outside. nine0003

Software

Like the rest of the fifth generation replicators, the Z18 uses the MakerBot Desktop software suite, which includes MakerWare's digital model processing and slicing software, plus integration with Thingiverse's proprietary website and cloud support.

MakerBot Desktop software combines editor, slicer and browser functions

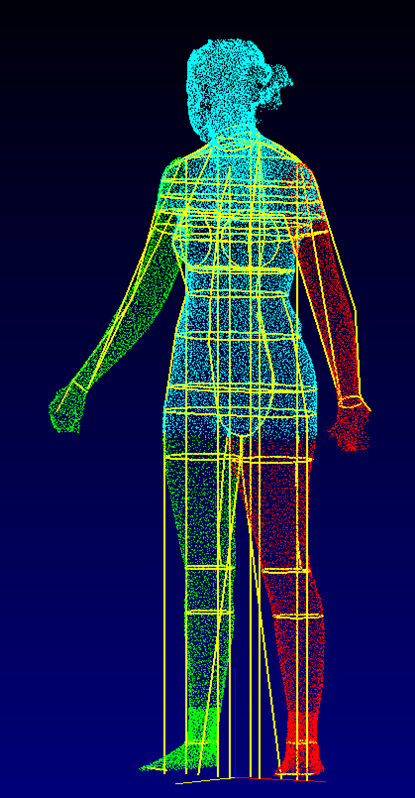

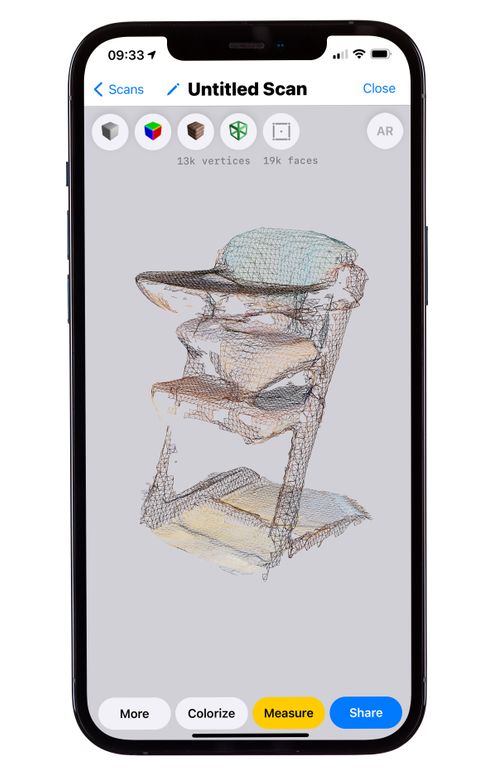

Create your own models using common CAD software. Those who wish can also use the MakerBot Digitizer proprietary 3D scanner to clone existing physical models. nine0003

Those who wish can also use the MakerBot Digitizer proprietary 3D scanner to clone existing physical models. nine0003

For data exchange, the Z18 is equipped with an Ethernet interface and a USB connection. Developers abandoned SD cards in favor of supporting USB drives - offline printing is still possible. The Z18 has a control module, similar to the module on the flagship. There is a large LCD screen and a convenient rotary knob, “like on expensive stereo systems”. Designers have decided not to mess with touch displays yet.

Summary

The Replicator Z18 is the lifelong dream of company founder Bree Pettis. Bree does not hide the fact that this device is intended not just for professional, but for industrial use. According to him, the Z18 will be actively used for prototyping and small-scale production by MakerBot itself. With all this, the Z18 is no more difficult to handle than the flagship Replicator, being quite within the power of the average user - an optimized design and software guarantee this. nine0003

nine0003

Some dampness of the new extruder and minor issues with the printer firmware will no doubt be resolved in time. MakerBot has always taken the quality of its devices and user support seriously. There is only one serious drawback - a very high cost. With a listing price of $6,499, this formidable 3D printer will only be affordable for well-to-do professionals.

Advantages

- Large build area

- High print quality

- Easy to use

Shortcomings

- Shortcomings in the design of the extruder and firmware

- High price

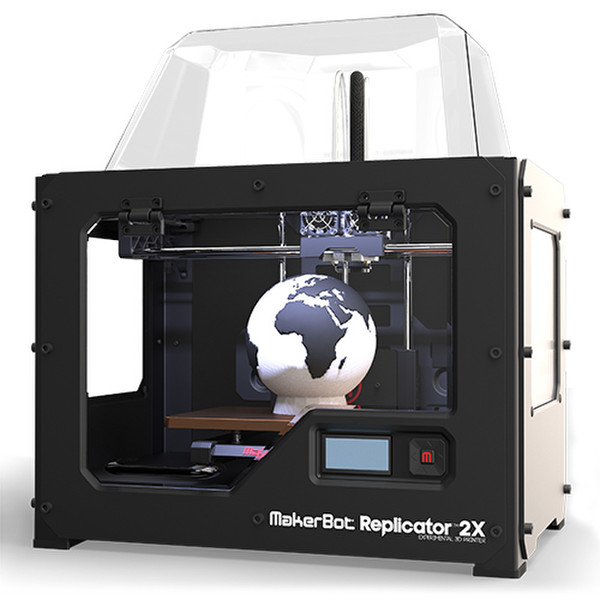

MAKERBOT REPLICATOR 2 3D printer

MakerBot introduced one of the best home 3D printers - Replicator 2.

Now even larger print area: 28.44 x 15.49x 15.24 cm. The case is made of durable steel, thanks to which the equipment is rightfully considered reliable. When printing, the MAKERBOT REPLICATOR 2 uses environmentally friendly PLA plastic, which has excellent adhesion to the materials used. It allows you to print even on fairly flexible products.

It allows you to print even on fairly flexible products.

The MAKERBOT REPLICATOR 2 3D printer allows you to achieve the highest quality product. In a technique designed for printing three-dimensional objects, the quality and accuracy is determined by the thickness of the coating layer. More specifically, the thinner the layer, the better the result. This is due to the high resolution used for the best print quality. The following modes are defined for the MAKERBOT REPLICATOR 2: 340 microns - fast printing, 270 microns - normal, 100 microns - fine. In the latter case, the thickness of the plastic applied to the product is comparable to the thickness of a standard sheet of paper. Environmentally friendly PLA plastic perfectly fits on a perfectly smooth surface, while there is no need for its processing. The products that are obtained at the output have a realistic bright appearance and are quite pleasant to the touch. Thanks to the use of high technology, the printer is able to work even incredibly small parts, while achieving the highest quality of the finished product. nine0003

nine0003

In order to know how high quality product you get, you need to understand what PLA plastic is. This material is widely used due to its physical and chemical properties. Plastic is applied to the product in a heated molten state. Firstly, it absolutely does not emit any odor or fumes - it is harmless to health and the environment. Thanks to this, MAKERBOT REPLICATOR 2 can be used in any room, even at home. Secondly, PLA plastic is economical in processing and has perfect adhesion to the material being processed. When compared to ABS plastic, energy costs are reduced by 32%. This is a significant indicator for maximizing profits. Thirdly, the finished product is perfectly smooth and pleasant to the touch, and the range of plastic colors is constantly expanding. nine0003

The MAKERBOT REPLICATOR 2 has significantly increased the volume of the working chamber. Compared to its predecessor, by 37%. The camera is now 410 cubic inches in size, which allows you to work with objects up to 28. 44 x 15.49 x 15.24 cm. With this improvement, the 3D printer is able to create quite large objects, as well as process many small objects in one pass. By doing this, you can save time that was used to perform tasks one by one.

44 x 15.49 x 15.24 cm. With this improvement, the 3D printer is able to create quite large objects, as well as process many small objects in one pass. By doing this, you can save time that was used to perform tasks one by one.

The printer is controlled by MakerWare's proprietary software. Thanks to a simple and understandable program shell, everyone can work with the device - you do not need additional training. The developers managed to reduce the printing time by software optimization of the process. Using this software, you will speed up your work by 30%. The program can run on various operating systems such as Linux, Windows and Mac. Object details are considered in the most common formats - .stl and .obj. nine0003

| Specifications: | |

| Interaction interface | SD card or USB cable |

| Printable area dimensions | 28. |

| Platform | acrylic |

| Dimensions | |

| Printer dimensions (dimensions) | 19.1 x 12.8 x 14.7 in [49 x 32 x 38 cm] |

| Package dimensions (dimensions) | 23 x 21.5 x 17 in [59 x 55 x 43 cm] |

| Printing Plastic | PLA |

| Plastic diameter | 1.75 mm | nine0128

| Material tolerances | 1.75+-0.1 mm |

| Temperature sensors | thermocouples |

| Characteristics of the print object | |

| Positioning accuracy | 0. |

| Layer height | 0.1 mm - 0.4 mm | nine0128

| Vertical print speed | increased |

| Object dimensions | 28.44 x 15.49 x 15.24 cm |

| Display type | LCD with backlight |

| 3D plastic | |

| Media | PLA |

| Plastic color | Unlimited plastic colors |

| Plastic diameter | 1. |

| Weight per reel of plastic | 1 kg |

| Component Specifications | |

| MK8+ Dual Extruder | 1 extruder |

| Maximum temperature | 260°C (500°F) |

| Printer weight | 11.5 kg |

| Power supply | 220V / 110V (universal power supply) |

| Power | 300W |

| Print model format nine0126 | STL, G code |

| Supported OS | Windows, Linux, Mac |

| Printing without a computer | Via SD card, X3G format |

| Software | Replicator G, MakerWare |

Only registered customers who bought this product can post reviews.

44 x 15.49 x 15.24 cm

44 x 15.49 x 15.24 cm  1 mm

1 mm  75 mm

75 mm