Linear rail 3d printer

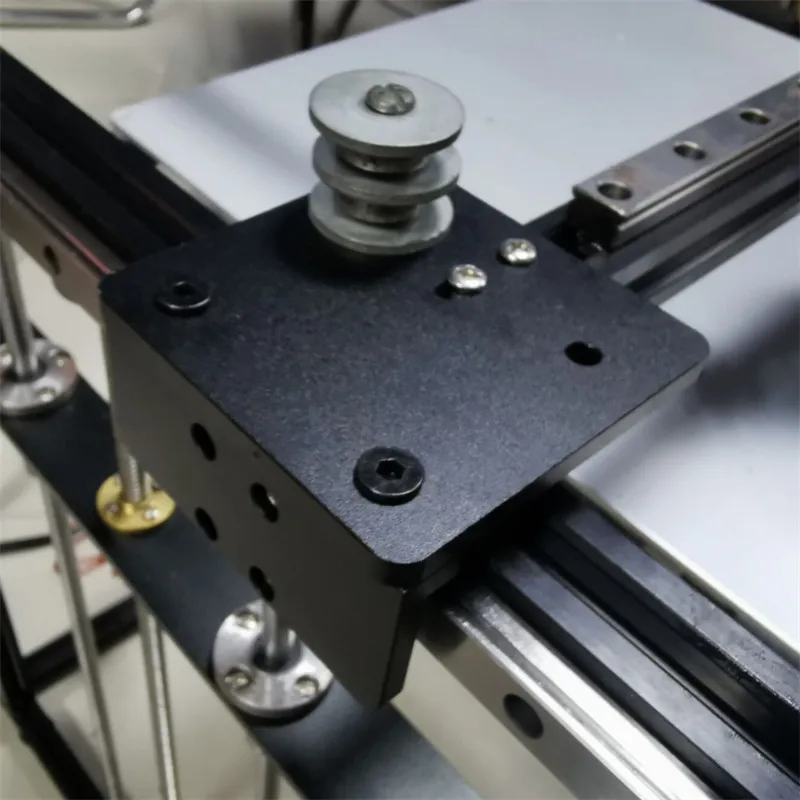

Linear Rails - 3D Distributed

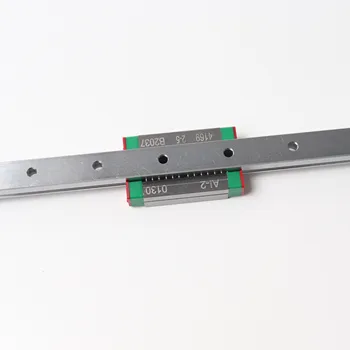

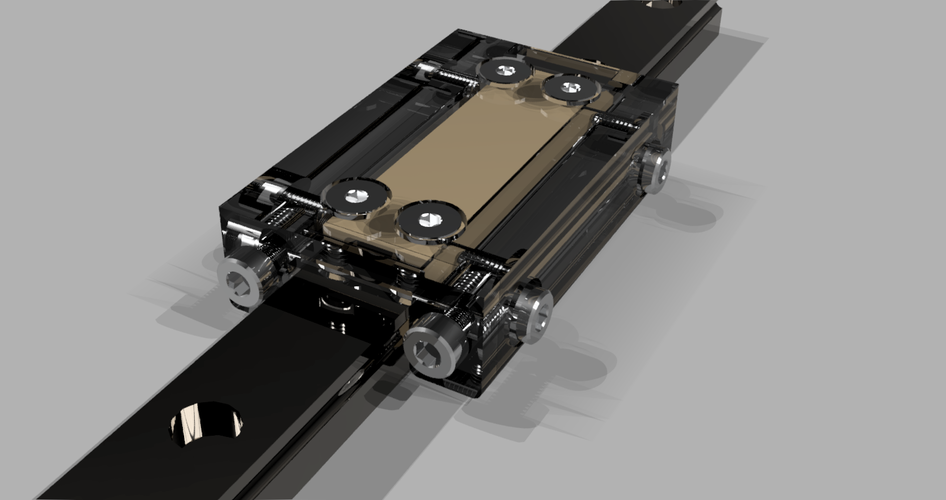

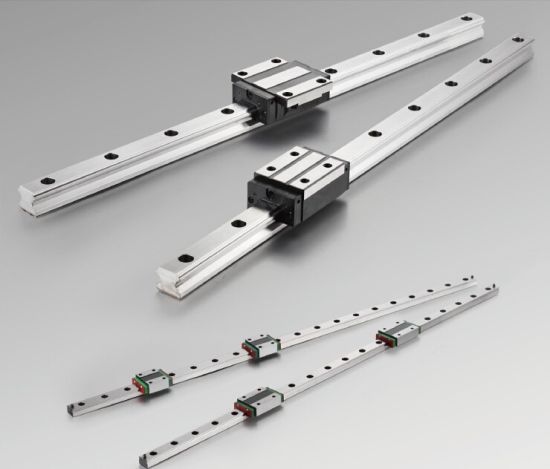

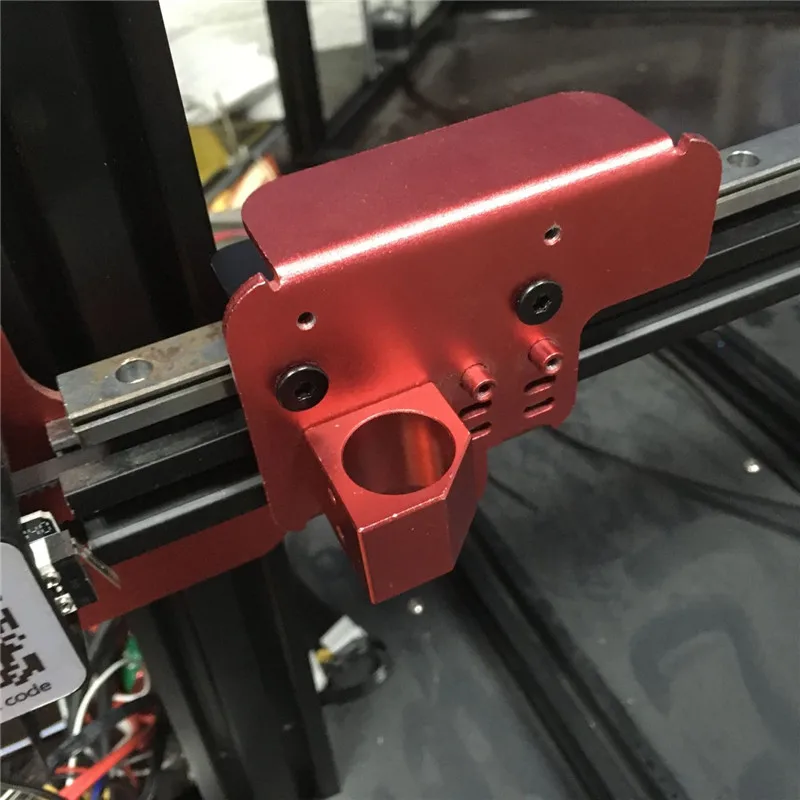

MGN12-H Linear RailAre linear rails better?Linear rails produce a high degree of accuracy and stability compared to round rods with linear bearings. They have better mounting, and smoother motion which improves print quality and machine reliability.

What are linear rails used for?Linear rails are used in different applications in industrial machine and motion system design. Linear Rails are designed to support the movement and load of a mechanical motion system.

Linear rails are used in different applications. Different levels of stiffness in different directions can have stresses on a given plane, or in some cases you may want the rail to slightly flex in one plane opposed to the other.

- Placing the surfaces for the rollers strategically, for example in a location that is unlikely to get contaminated, or where the maximum force will be applied.

- Curved paths, so that the carriage can move along a line that is not straight.

Accuracy of Linear Rails

Linear rails provide a high level of accuracy and stability compared to round rods with linear bearings or other methods.

Linear Rail Applications

Linear rails are used in different applications.

Different levels of stiffness in different directions can have stresses on a given plane, or in some cases you may want the rail to slightly flex in one plane opposed to the other.

Curved paths, so that the carriage can move along a line that is not straight.

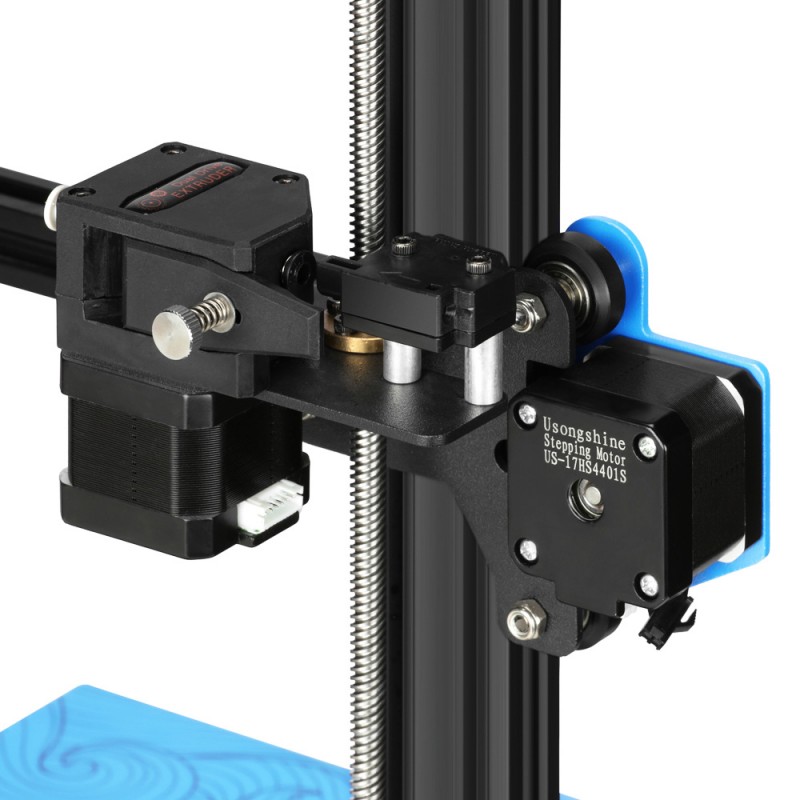

Linear Rail Alignment

Linear Rail Alignment- Make sure the linear rails are parallel to each other to prevent binding.

- Check for flatness and alignment of the paired sets of rails.

- Check the perpendicularity to the mid-plane between the two rails.

- Make sure the linear rails are parallel to each other to prevent binding. Check for flatness and alignment of the paired sets of rails.

- Check that the gantry is perpendicular to the mid-plane between the two rails. If the gantry becomes over constrained it will cause the stepper motor to skip steps.

- Check the Z-axis lead screws aligned and concentric to the stepper motor shafts. If not, mechanical binding may occur. The gantry can’t really tilt, so the linear rails could be damaged over time. It’s important to not over constrain the z-axis, because it can cause z banding.

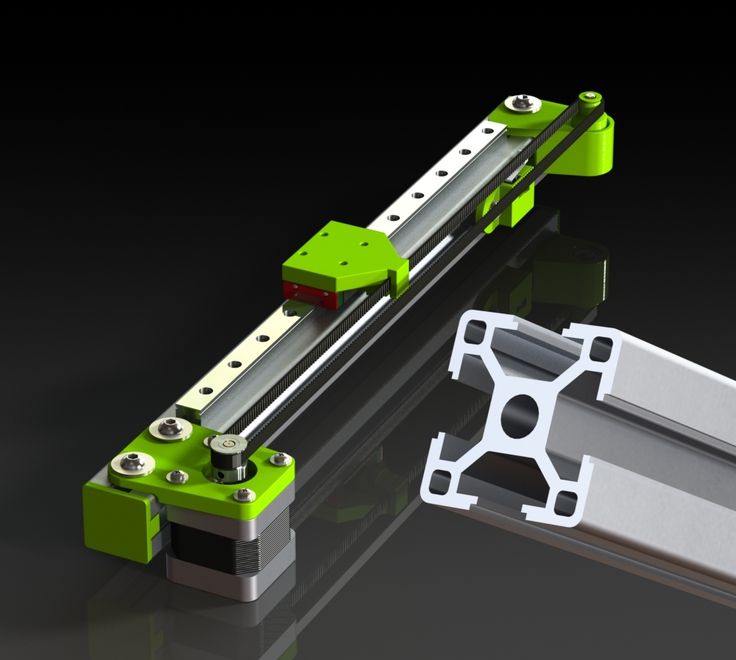

Mounting Linear Rails

Linear Rail AlignmentLinear rails can be mounted along the full length of the rail, rather than the specific area of motion, thus increasing the accuracy of their positioning and rigidity. The contact surface between the rollers and the bearings is flat, cylinders can be used instead of spheres. This minimizes mechanical stresses, and the amount of play within the system. This increases mechanical longevity and allows for increased bearing load. The bearings only allow for one degree of movement.

The contact surface between the rollers and the bearings is flat, cylinders can be used instead of spheres. This minimizes mechanical stresses, and the amount of play within the system. This increases mechanical longevity and allows for increased bearing load. The bearings only allow for one degree of movement.

The contact surface between the rollers and the bearings is flat, cylinders can be used instead of spheres. This in turns diminishes the mechanical stresses, and the amount of play, increases longevity and allows for more bearing capacity, among others. Linear rails can be anchored along their full length to aluminum extrusion profiles, thus increasing the accuracy of their positioning, stiffness and their bearing capacity.

Rail Parallelism

The parallelism of the linear rails or linear guide system is key for proper movement of a motion system. As the number of rails and carriage blocks used within a system increases the more important it is to ensure the rails used are parallel. Unnecessary load can result if the the linear rails or linear guide are not parallel within a manufacturer’s specified parallelism tolerance.

Unnecessary load can result if the the linear rails or linear guide are not parallel within a manufacturer’s specified parallelism tolerance.

The bearings on a linear rail provide proper constraint of movement. There must be two rods with linear bearings to provide the same results of linear rails.

Light Weight Linear Rails

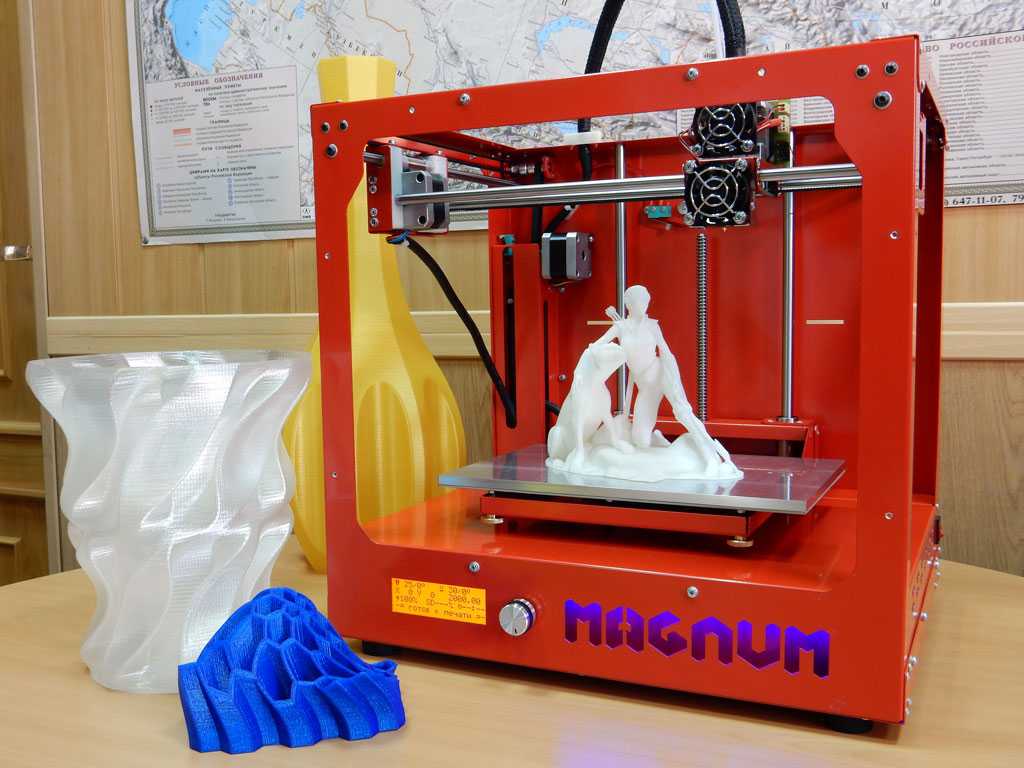

Light Weight Linear RailsLinear Rails BearingsWhen it comes to applications of consumer-grade FDM 3D printers the advantage of 3d printers with linear rails is print quality and reliability.

- The mechanical stresses involved in 3D printing are reduced.

- The movement is constrained along a straight path.

While 3d printer designs with rods + linear bearings are cheap, effective, simpler and lightweight, all characteristics that are highly desirable in a 3D printer. In general, linear rails are preferred over rods because they offer greater precision and smoother motion which can improve print quality and reliability. Specific machine designs benefit from use of linear rails.Depending on the mechanical arrangement of the linear guide system, movement will require rigidity and support from load or gravity.

Linear Rails vs Rods

In most applications, linear rails are prefered over rods. Although, there are specific designs that may benefit from rods. For example, a cantilever arrangement may be better due to linear rails constrain movement in all but one direction, and the orientation offers maximum rigidity against gravity.

While 3d printer designs use rods with linear bearings are cheap, effective, simpler and lightweight, all characteristics that are highly desirable in a 3D printer.

Many of the earlier 3d printers were designed around cheaper mechanical parts such as carbon rods or stainless steel smooth rods which were once commonly used and recommended. As the cost of linear rails become cheaper and cheaper due to the economy of scale and increasing number of buyers and large volume production of manufactures and suppliers. 8mm steel rods and linear bearings are slowly being somewhat phased out but still used on cheap kits found on Aliexpress.

What are linear rails made of?Most linear rails are manufactured from hardened steel and are corrosion-resistant. Hard strength steel or stainless steel is a cold-drawn and ground down to the profile shape and assembled to a linear rail carriage block.

How do you use a linear guide rail?Align and ensure parallelism of the linear guide for proper accuracy.

Are linear rails worth it?Upgrading your 3d printer to linear rails will increase the smoothness of the motion and movements along the axis mounted. Linear rails can improve print quality through smoothness and precision which will decrease artifacts found on 3d pints.

Linear rails can improve print quality through smoothness and precision which will decrease artifacts found on 3d pints.

Here’s the methods to repair linear rails.

- Clean remove the dirt and grease from the rail and carriage block.

- Lubricating light machine oil.

- Run in the carriage along the rail.

- Replace the stainless steel bearing balls if needed.

- Clean and polish the rail channels.

What is a linear rail carriage block?

The linear rail carriage block moves along the rail track groove and constrains the components of the linear slide and provides motion with the direction of a specific axis.

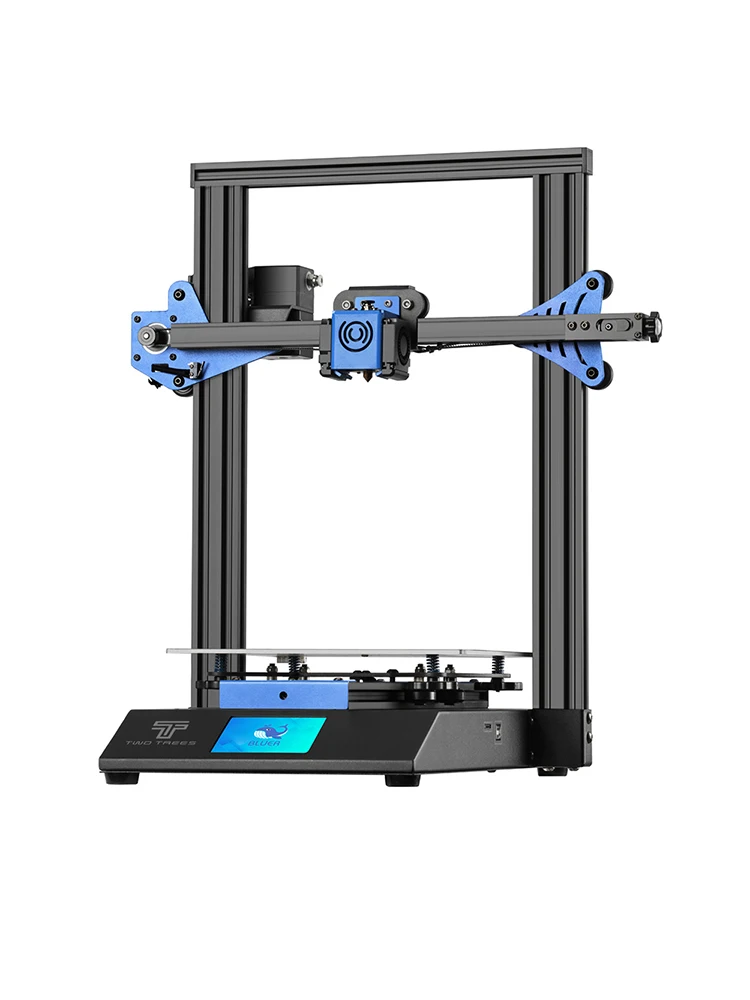

3D Printers With Linear Rails

- Workhorse 3D Printer

- Solidcore CoreXY

Buy Linear Rail Products

Buy 3D Printer Kit

Buy Linear Rails

Linear Rail Stop 2020

$10.00

Linear Stops & End Stop Mounts

Machined Hardware Parts List Machined Hardware Parts 3D Distributed Price Quantity Source Documentation Gantry Plates 2pcs w/bearings $ 80. 00 2pcs. 3D Distributed Folder X- Axis Carriages 2pcs $ 49.50 2pcs. 3D Distributed Folder Y-Axis Carriage 1pc $ 24.50 1pcs. 3D Distributed Folder Y-Axis Motor Mount 1pc $ 22.50 1pc. 3D Distributed Folder Y-Axis Idler Mount

00 2pcs. 3D Distributed Folder X- Axis Carriages 2pcs $ 49.50 2pcs. 3D Distributed Folder Y-Axis Carriage 1pc $ 24.50 1pcs. 3D Distributed Folder Y-Axis Motor Mount 1pc $ 22.50 1pc. 3D Distributed Folder Y-Axis Idler Mount

by Shane Hooper

SolidCore 350mm x 350mm BOM 350mm x 350mm x350mm Quantity Description Source $ Each $ Total Documentation Frame Extrusions 2020 T-Slot ZylTech Frame Size List 570mm Long 6 Vertical (Tall) ZylTech Frame Size List 430mm Long 3 Vertical (Z-Axis Rail) ZylTech Frame Size List 660mm Long 4 Length (Long) ZylTech Frame Size List 500mm Long

by Shane Hooper

SLM – Selective Manufacturing

by Shane Hooper

Like this:

Like Loading. ..

..

V Slot Wheels VS Linear Rails – Kywoo3d

I guess most people especially beginners don’t have a clue about what is the differences between the 3d printer v-slot wheel and linear guide, which one would be perform better on 3d printer? And what about the model precision. Today let’s figure it out more deeply.

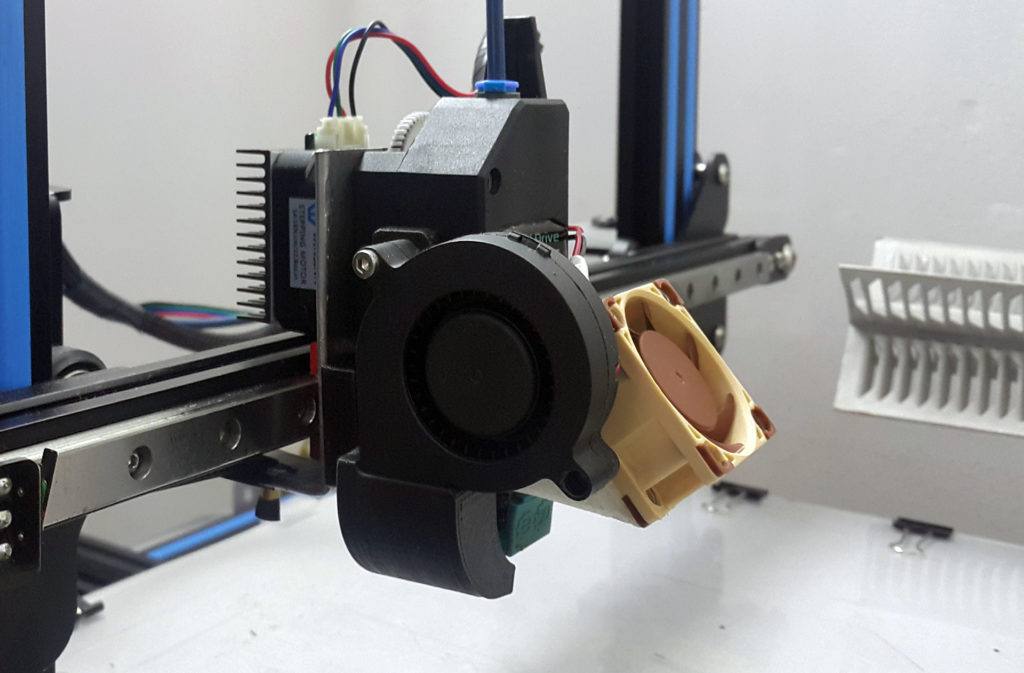

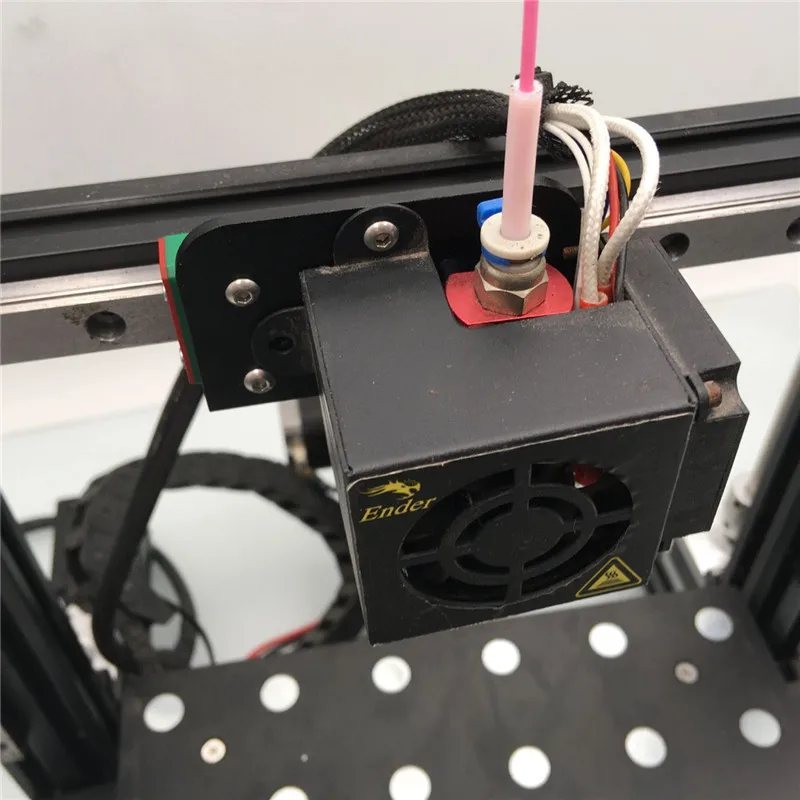

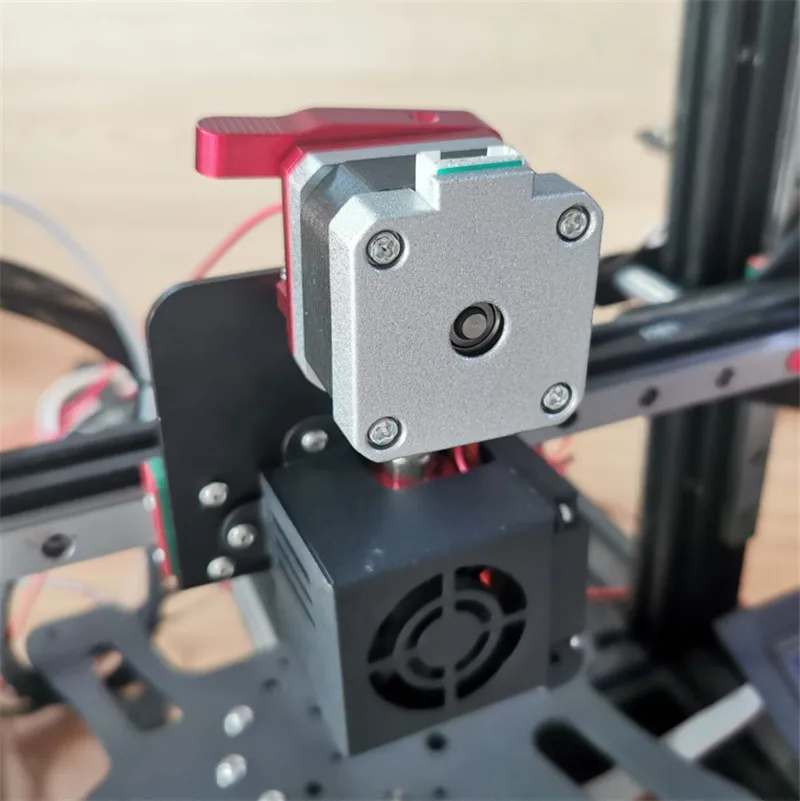

Before you select a FDM 3d printer, what you must do is to learn what are the components included on a 3d printer, which including the mainboard, power supply, extruder( Bowden extruder kit or direct extruder kit), printer display, hot end, cool fan, and printing bed. But the most important part is about the x-axis moving system, which can be the one with a V slot or linear rail guide. This can partially tell whether the movement track is smooth enough to make sure the model comes out perfect with the series layer.

Most people might be more familiar with the V slot wheel 3D printer motion mode, General 3D printing can ensure the basic printing quality with this kind of structure.

Most of the 3d printers in the market currently are come with this V-wheel, Saying that the V-wheels system vibrates more than linear rails, takes more play, and as changes in geometry in time, that it needs to be verified and tightened more often.

The traditional V-slot is fine for the x/y axis on just about any FDM printer with a practical XY build location. The issue (especially with the d-bot/c-bot variations) is its usage for the cantilevered z-axis. There is just excessive play in between the wheels, plates, and also extrusion to utilize v-slot on large/heavy cantilevered setup. Also, a lot of the time the wheel will get used after use for a long time.

Linear rails, likewise referred to as straight movement overviews and linear slides, are common motion elements used to attain smooth gliding movements. They can be found in 3D printers, CNC mills, waterjet cutters, and the like. ... This allows a smooth moving movement as the balls roll between the surface areas.

Linear rails can be secured along with their complete size, as opposed to at their extremes, hence increasing the precision of their positioning, their rigidity, and also their bearing capacity.

Linear rails can be machined while pre-loaded, thus achieving optimum accuracy when in use, as opposed to when coming out of the factory.

The bearings on Linear rails just enable one level of motion. There need to be two poles with linear bearings/bushes to achieve the very same result.

I’d said when it comes to the details application of consumer-grade FDM 3D printers, it appears that none of the above is very appropriate, nor provides any kind of actual advantage to the printer in regards to the top quality of the last print:

- the mechanical stress and anxieties associated with 3D printing are extremely tiny,

- the movements all occur along straight lines,

the majority of the axis can not be anchored to a big, inflexible body

On the other hand, the style with poles + direct-bearings is cheap, reliable, less complex, and lightweight, all characteristics that are very desirable in a 3D printer.

Do we need higher precision in the 3D printer axis? Sure we can have quality assurance boards that make up to some extent nevertheless the technicians of the maker are of utmost vital before you select the high quality of board and software. Why set up a $300 motion control on a low-cost linear rod printer if you're not visiting the full benefits?

So sure, your rod directed printer jobs. Nevertheless, it will certainly never work in addition to my linear rail directed printer with ballscrews as well as servos. You can have your layered unclear prints. I will maintain my smooth completed injection molded-looking components that are made from materials a typical desktop can not also print. So to suggest it's not needed is suggesting that top quality isn't accepted in a reduced rate point market.

Which Kind of movement system is best for you?However, people might back off after seeing the prices when they are considering trying the linear rail guide, any decent linear rail will easily cost several times more than a comparable combination of linear rod and bearing. The premium precision, stiffness, and smooth motion come at an equally premium price.

The premium precision, stiffness, and smooth motion come at an equally premium price.

Now in the market, the linear rail 3d printer cost around $1000 even more as it comes with industry printing precision. if you don't have enough budget for it, you can actually try the V-slot wheel.

I checked on reddit forums saying mostly are linear rail works perfectly than the V-slot wheel because the traditional V-slot wheel was easier to get wear and need to be replaced very frequently.

There’s a review on Reddit from troy_proffitt says that he finds out that linear rail is absolutely smoother than V-wheels and after running his printer for 2 years using Delrin wheels, they started to fall apart. Hope that it won’t happen with the linear rail.

As the price so height, we find that most of the linear rail 3d printers are quite high, and some people can not even get a choice to try them. there comes Kywoo Tycoon, a linear rail 3d printer with a direct drive that can better print with PLA/PETG/TPU filament, it’s the price is about $400-$600, most customer especially the beginners can get a better option than the V-slot version.

In a word the V-slot wheel 3d printer is a kind of traditional design for most FDM 3d printer in the market, will Linear rail be the next stream in 3d printing market as the higher printing precision, we will see that.

Share:

linear guides - 3DPrinter

Showing all 7 items

Initial SortBy PopularityBy RatingSort by Latest Price: Ascending Price: DescendingAdd to Cart

Carriage MGN15C for linear rail guide

399 UAHRail Carriage - The best linear guide on the market for 3D printers.

The accuracy and payload of the rail allows it to be paired with a 3D printer printhead, laser or even a milling head.

Installing the rail will greatly improve the 3D printing quality of your 3D printer.

Attention: the price is for MGN15C bottom bracket.

The rail can be purchased here.

*Bracket type: MGN15C

Carriage and rail guide MGN12H - set

720 UAH – 800 UAHRail is the best existing linear guide on the market for 3D printers.

The accuracy and payload of the rail allows it to be paired with a 3D printer printhead, laser or even a milling head.

Installing the rail will greatly improve the 3D printing quality of your 3D printer.

Add to cart

Rail linear guide MGN15 - 100 cm

1200 UAHRail is the best existing linear guide on the market for 3D printers.

The accuracy and payload of the rail allows it to be paired with a 3D printer printhead, laser or even a milling head.

Installing the rail will greatly improve the 3D print quality of your 3D printer.

Country of origin: China

Please note! The rail in this lot is sold WITHOUT the carriage. You can buy the MGN15C bottom bracket at this link.

Rail length - 100 cm.

Round Smooth Hardened Shaft for 3D Printer

250 UAH – 315 UAH3D Printer Shaft is an excellent and inexpensive solution for organizing the linear movement of the print head and platform.

Shaft diameter 8mm, 12mm

Buying a new roller can be justified both when building a new 3D printer, and when repairing an old one to replace a damaged or worn roller.

Price per 1 m

Add to cart

Shaft support SK8

31 UAHShaft mount - allows you to conveniently and securely fix the guide shaft in the 3D printer housing.

SK8 is a mount designed for 8mm shaft, the most commonly used shaft in desktop 3D printers.

Scope of supply: 1 pc.

Shaft holder SHF for 3D printer

35 UAH – 79 UAHShaft retainer - designed for fastening linear guides (shaft) on the 3D printer body.

SHF8 or SHF12 - retainer for 8/12mm shaft. The hardened round shaft is a simple and inexpensive solution for linear movement of moving parts in desktop 3D printers.

Scope of supply: retainer 1 pc.

90,000 guides rail in the category "Industrial Equipment and machines"

Profile rail guide MGN12 30cm with carriage 3D Printer EP

Delivery in Ukraine

1 846. 94 UAH

94 UAH

923.47 UAH

Ephir.com.ua 9000 9000 9000 9000 9000 9000 9000 rail guide MGN12 30cm with carriage 3D printer ps

Delivery across Ukraine

0002 Online store PRICESS

Ballistic Visor for Fast Fight helmets with rail guides

in warehouse

Delivery in Ukraine

14 200 UAH

Bronegilet.com

Profile rail guide mgn12 30 ° C

In stock

Delivery across Ukraine

745 — 812 UAH

from 6 sellers

745 UAH

Buy

AltMarket - online store 9Ol000 rail guide Hiwin HGR20H, linear rail

in a warehouse in the city of Rivne

Delivery in Ukraine

9000 3 484 UAH/pog.m2 369 UAH/pog.m

Buy

CNCPROM

Profile rail guide Hiwin Hiwin Hiwin HGR25H Linear Rail

In a warehouse in the city of Rivne

Delivery in Ukraine

4 141 UAH/Pog. m

m

2 778 UAH/Pog.m

Buy

CNCPROM

Profile rail guide HIWIN HGR30H, Linear rail

on warehouse in the city of Rivne

Delivery in Ukraine

4 692 UAH/Pog.m

3 363 UAH/Pog.m

Buy

CNCPROM

Profile rail guide HIWIN HGR35H, linear rail

in a warehouse in the g. Exactly

Delivery in Ukraine

3 948 UAH/m

Buy

CNCPROM

Delice for rail guides, C6 D2, HIWIN

in Kyiv

Delivery

1.98 GRN

Buy

TOV "Kyugel Ukraine"

Plugs for rail guides, C5, HIWIN

In stock in Kyiv

Delivery across Ukraine

1.98 UAH

Buy

TOV "Kyugel Ukraine"0003

Pelshii for rail guides, C4, Hiwin

in a warehouse in Kyiv

Delivery in Ukraine

0. 79 UAH

79 UAH

Buy

COUGEL Ukraine CUGEL

Puppies for rail, C8, Hiwin

on warehouse in Kyiv

Delivery across Ukraine

1.98 UAH

Buy

TOV "Kyugel Ukraine"

Rail linear guide HIWIN HGR15 1mm HIWIN analog

Delivery across Ukraine

1 150 UAH

Buy

CNC and components

RIKOVAICHICHICH HGR15 500mm

In warehouse

Delivery in Ukraine

457 UAH

INNERTERNENCE-store MIKRAAPEPERS also

guide MGN12 500mm

In stock

Delivery across Ukraine

658 UAH

Buy

Online store "Mikroamper"

Rail guide HGR15 300mm 9Ol000 store "Mikroamper"

Rail guide MGN12 600mm

In stock

Delivery across Ukraine

788 UAH

Buy

Internet store "Mikroamper"

Delices for rail guides - 15mm

Delivery from Ostrog

45.