Large format dlp 3d printer

Large format resin 3D printer: big volumes from $1,299

A large resin 3D printer is an excellent choice for professionals looking to produce high-quality prototypes and end-use parts. Small build volumes and expensive pricing used to be limiting factors for many, but new technology is presently addressing both of those issues. In this article, we take a look at some of the best large volume resin 3D printers for professionals.

Last update May 31, 2022

We removed discontinued printers from Peopoly and Phrozen, and added the NXE400 from Nexa3D.

Table of contents

Large resin 3D printers: a new trend?

Best large volume resin 3D printers 2022

Phenom L

Phenom XXL

Form 3L

Liquid Crystal Magna

NXE 400

SLA vs FDM vs SLS

Benefits of resin printing

Resin 3D printing drawbacks

3D printing resins: what materials are available?

Resin 3D printing: how fast is it?

FAQ

Large resin 3D printers: a new trend?

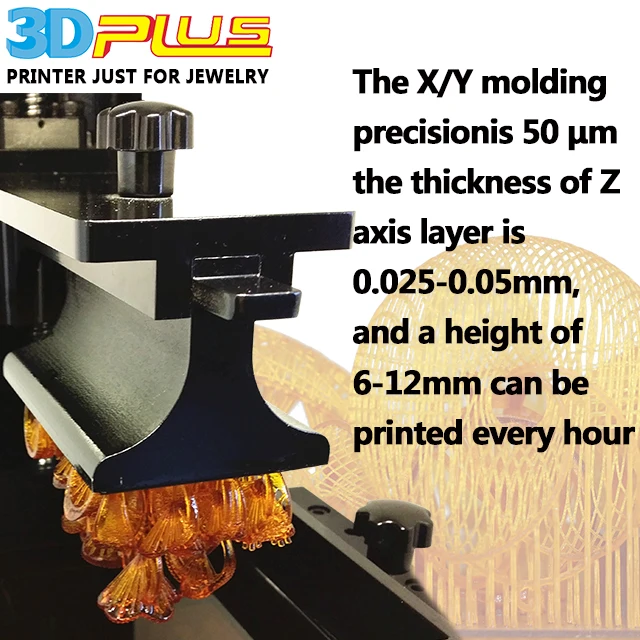

Stereolithography (SLA) has been around for decades, with two main sub-technologies: laser SLA and DLP (Digital Light Processing). These resin 3D printing methods offer highly accurate and smooth results but are generally limited to small build volumes, unless you’re looking at industrial systems worth several hundred thousand dollars.

However, another SLA sub-technology has recently made its way to the market: MSLA (Masked Stereolithography). In short, MSLA 3D printers use LCD screens as light masks over LED lights, simplifying the resin 3D printing process and drastically bringing prices down.

On that account, large volume resin 3D printers are now affordable enough (and actually available on the market) for SMEs and entrepreneurs, whether it’s for prototyping or small production series.

That said, there aren’t many options yet, as you can see in our large format resin 3D printer selection below. This selection is based on large resin printers that are priced under $20,000, hence excluding large industrial SLA printers which we’ll soon cover in another guide.

Our guide also covers the main pros and cons of resin 3D printing, which resin materials are available, and how fast resin printers are.

Best large volume resin 3D printers 2022

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Peopoly | Phenom L | 345 × 194 × 400 mm13.58 × 7.64 × 15.75 in | China | $ 2,7992 799 €2,483 £417,208 ¥ | Quote |

| Peopoly | Phenom XXL | 527 × 296 × 550 mm20.75 × 11.65 × 21.65 in | – | $ 6,9996 999 €6,208 £1,043,243 ¥ | Quote |

| Formlabs | Form 3L | 336 × 200 × 300 mm13.23 × 7.87 × 11.81 in | – | $ 12,00012 000 €10,644 £1,788,672 ¥ | Quote |

| Photocentric | Liquid Crystal Magna | 510 × 280 × 350 mm20. 08 × 11.02 × 13.78 in 08 × 11.02 × 13.78 in | – | $ 19,92017 995 €17,670 £2,969,196 ¥ | Quote |

| Nexa3D | NXE 400 | 270 × 160 × 380 mm10.63 × 6.3 × 14.96 in | United States | upon request | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Build volume | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|

| Peopoly | Phenom L | 345 × 194 × 400 mm13.58 × 7.64 × 15.75 in | 26.77 L | China | $ 2,7992 799 €2,483 £417,208 ¥ | Get a quote |

| Peopoly | Phenom XXL | 527 × 296 × 550 mm20.75 × 11.65 × 21.65 in | 85.8 L | – | $ 6,9996 999 €6,208 £1,043,243 ¥ | Get a quote |

| Formlabs | Form 3L | 336 × 200 × 300 mm13. 23 × 7.87 × 11.81 in 23 × 7.87 × 11.81 in | 20.16 L | – | $ 12,00012 000 €10,644 £1,788,672 ¥ | Get a quote |

| Photocentric | Liquid Crystal Magna | 510 × 280 × 350 mm20.08 × 11.02 × 13.78 in | 49.98 L | – | $ 19,92017 995 €17,670 £2,969,196 ¥ | Get a quote |

| Nexa3D | NXE 400 | 270 × 160 × 380 mm10.63 × 6.3 × 14.96 in | 16.42 L | United States | upon request | Get a quote |

Overview of the best large format resin 3D printers

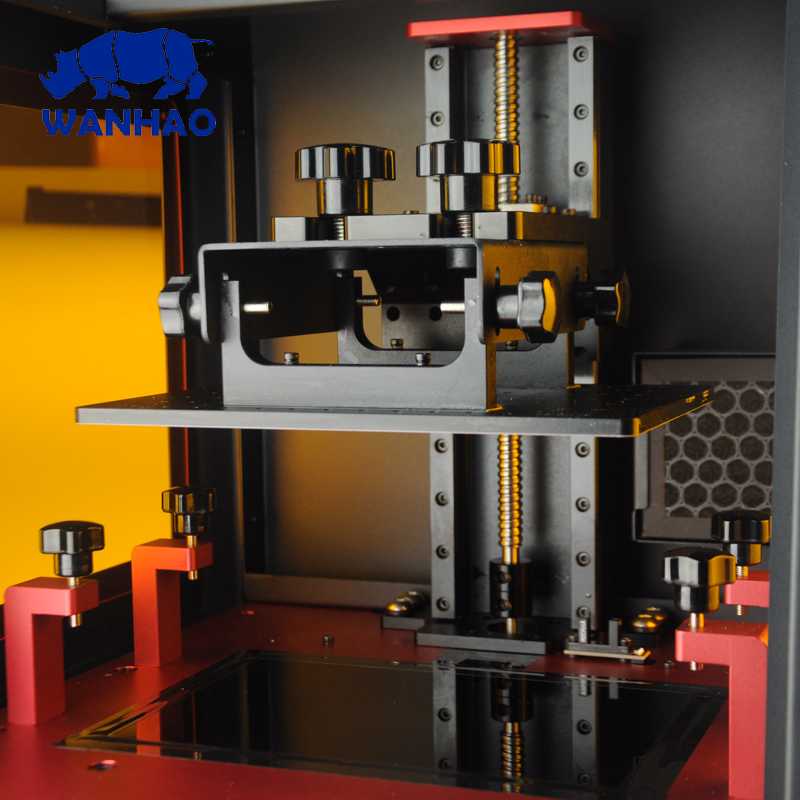

The Phenom L is an enlarged version of the Peopoly Phenom, which is also included in this selection further below. Peopoly’s other resin 3D printers, such as their flagship Moai series, use laser-based SLA. Phenom 3D printers, however, are based on MSLA 3D printing technology with LED lighting and a 4K LCD masking screen.

Its large build volume enables users to print small production series and tall parts (400mm). The Phenom L is one of the largest resin 3D printers available.

The Phenom L is one of the largest resin 3D printers available.

Contact manufacturer Get a quote Add to comparison

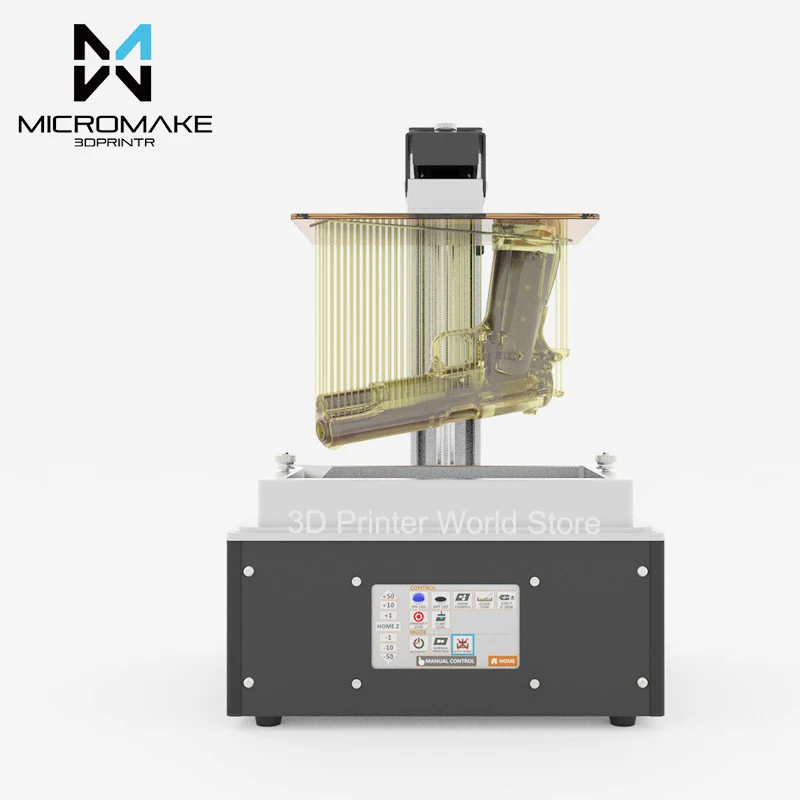

The Peopoly Phenom XXL is a large resin 3D printer that uses MSLA technology. MSLA stands for Masked Stereolithography, which is based on the use of an LCD screen to mask a projector’s light.

Peopoly, a Hong Kong-based 3D printer manufacturer, launched this large resin 3D printer to cater to more advanced users in automobile, entertainment, and medical industries. The Phenom XXL offers a 500% bigger build volume than the standard Peopoly Phenom, and provides over four times more volume than the Formlabs Form 3L.

Contact manufacturer Get a quote Add to comparison

The Form 3L, based on the standard Form 3, is the only large resin 3D printer on this list to use laser-based SLA, providing an excellent 23-micron resolution with two 250mW lasers. It features constant, closed-loop calibration and is able to send user alerts for users to remotely monitor their print progress.

The printer’s interface and cartridge-based workflow are geared towards ease of use, and Formlabs has developed a wide range of proprietary resins over the years to suite numerous applications.

Contact manufacturer Get a quote Add to comparison

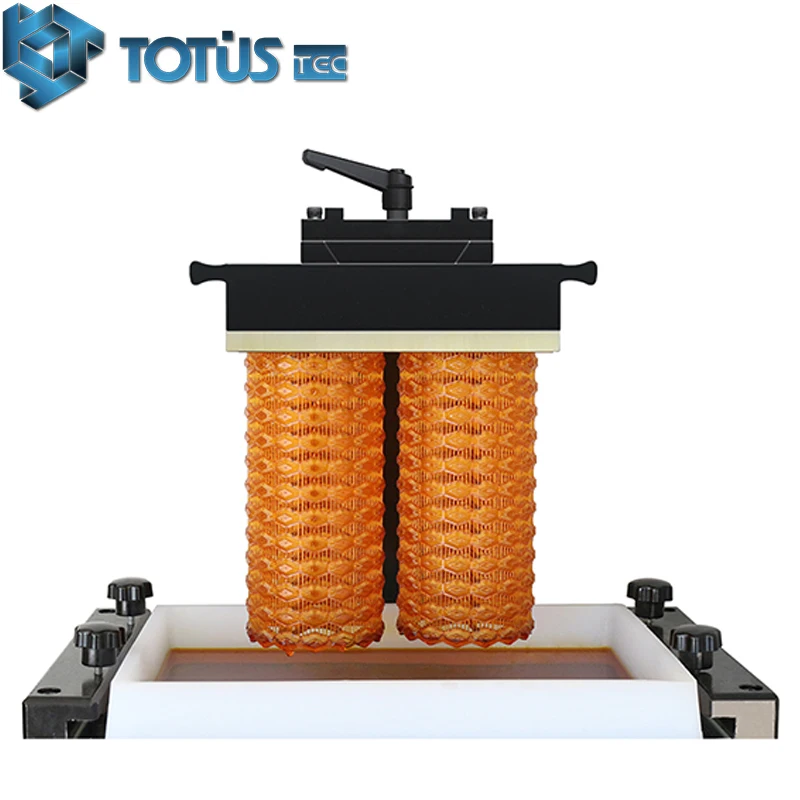

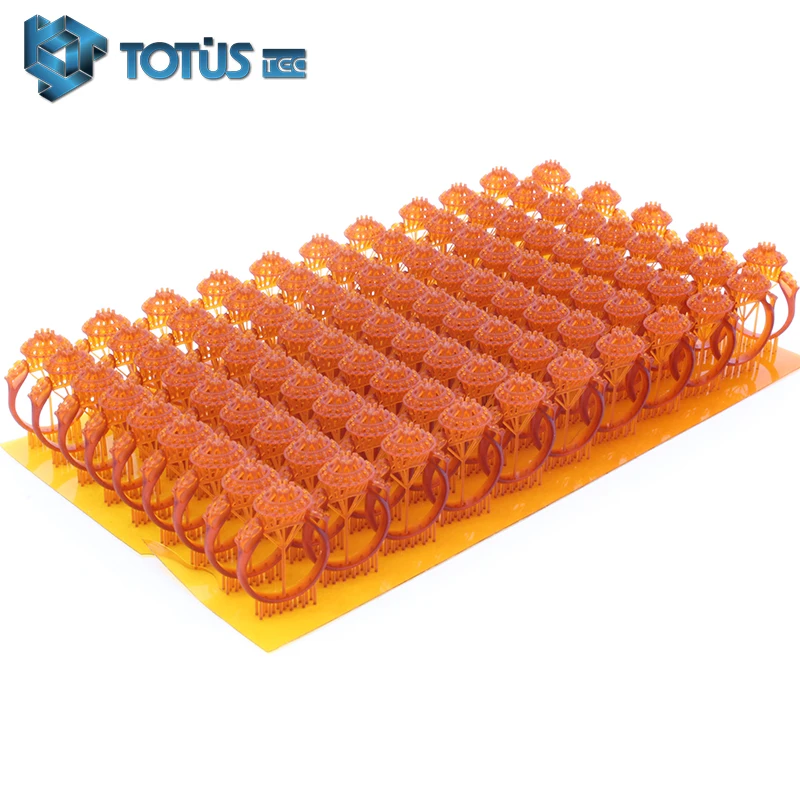

The Liquid Crystal Magna is the largest resin 3D printer in its price range, with a 23.8-inch 4K Ultra HD LCD masking screen. This printer, destined for professional and industrial use, is advertised by Photocentric as “the right tool for custom mass manufacture”.

The LC Magna does sport a pretty fast curing speed of 5 to 8 seconds per layer (13.3mm/hour). Its large build platform enables the production of small, detailed series. For example, as displayed on the Photocentric website, it’s possible to 3D print up to 46 dental arches in 2 hours.

Contact manufacturer Get a quote Add to comparison

The NXE 400 is a professional 3D printer produced by Nexa3D. Nexa3D is a 3D printer manufacturer based in United States. The NXE 400 was released in 2019 and uses resin 3D printing technology.

The NXE 400 was released in 2019 and uses resin 3D printing technology.

Contact manufacturer Get a quote Add to comparison

Resin 3D printing: main takeaways

We highlight a few of the key advantages of using a resin 3D printer while also touching on a few of the cons.

SLA vs FDM vs SLS

While many FDM 3D printers offer bigger build volumes, resin 3D printers provide much smoother results in terms of accuracy and surface quality. In this price range, the only kind of printer that could potentially match resin printing quality would be a desktop SLS 3D printer. There’s a very limited range of available powder types and colors, however.

Benefits of resin printing

These are some of the main, high-level advantages of resin 3D printing.

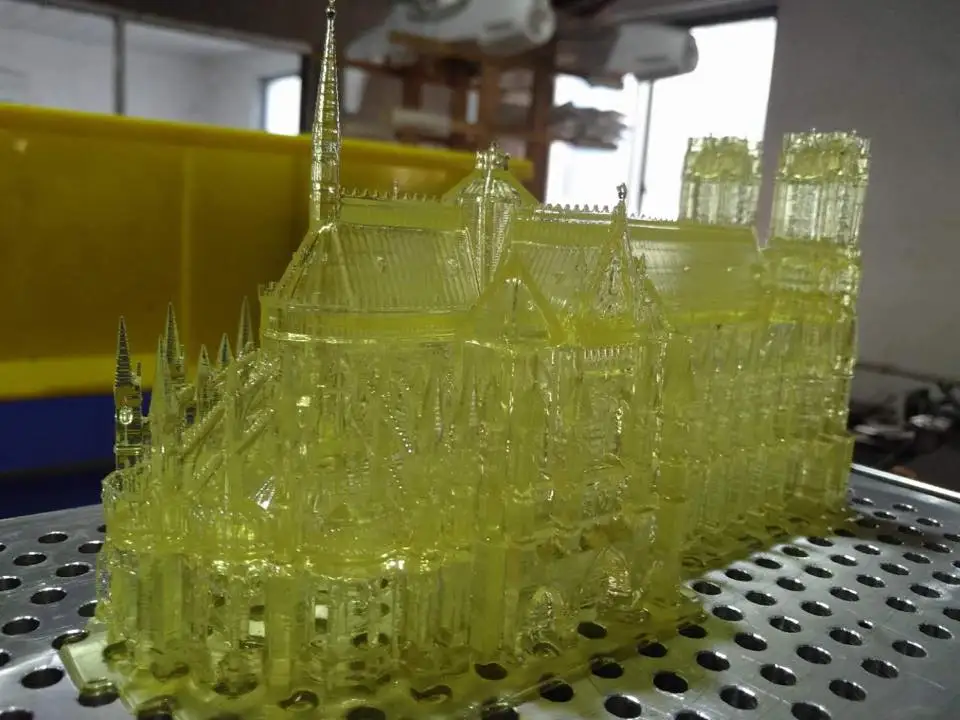

- Smooth surface finishes – Resin printers are able to produce very thin layers that are barely visible to the human eye, if not invisible.

- High level of details – It’s possible to print complex, intricate models with tight tolerances.

- Unique resins – The selection of specialty resins is quite impressive, from colored or transparent resins to strong, rubbery, or castable resins.

- Speed* – Whether you print one small object, several parts, or one large model (all either simple or intricate) of the same height, the overall print time will be the same.

*Does not apply to laser-based SLA 3D printers.

Resin 3D printing drawbacks

While resin 3D printing offers compelling advantages, there are still a few things you may want to keep in mind.

- Material prices – Resin can be expensive, especially if the system you choose doesn’t work with third-party resins.

- Post-processing – Prints must be washed and then cured with UV light or sunlight. Most manufacturers sell separate, dedicated “stations” for these steps to make them less troublesome.

- Toxicity (and smell) – It’s important and necessary to wear gloves, and working in the same room as an active resin 3D printer is highly discouraged.

3D printing resins: what materials are available?

Most manufacturers sell basic or standard resins in several colors, plus specialty resins for different kinds of applications.

Here are some common types of resin:

- Biocompatible

- Castable

- Transparent

- Hard

- High-tensile

- Temperature-resistant

- Flexible

Not all resins are compatible with all resin printers, and some resin printers only tolerate their manufacturer’s proprietary materials (e.g. Formlabs). This is true for other technologies, too, such as FDM/FFF, e.g. Stratasys with proprietary filaments, or SLS, with almost all manufacturers curbing compatibility.

Resins can also be specially formulated for certain types of technologies. For example, MSLA printers won’t be able to cure resins made for laser SLA printers. This is partly because they use a less powerful light source.

For example, MSLA printers won’t be able to cure resins made for laser SLA printers. This is partly because they use a less powerful light source.

Resin 3D printing: how fast is it?

Resin 3D printing speeds are generally listed in one of two ways:

- As a maximum height reached in a certain amount of time (mm/minute, cm/hour)

- As the amount of time it takes to cure one layer (seconds/layer, layers/minute)

It’s a good idea to keep resin 3D printing speeds in mind, even if a variety of factors– namely layer thickness and type of resin– make that number hard to narrow down. For reference, the PartPro 120 xP from XYZprinting is currently one of the fastest 3D printers on the market. It’s capable of printing a 3-cm-tall part in only 10 minutes, while some resin printers would require over an hour.

FAQ

What’s the largest resin 3D printer available?

At the moment, that would be the UnionTech RS Pro 2100, which happens to be an industrial SLA 3D printer. This massive machine has a build area of 2100mm x 700mm x 800mm.

This massive machine has a build area of 2100mm x 700mm x 800mm.

Is 3D printing resin toxic?

Yes, while toxicity levels can vary, resin is something you’ll want to keep off your skin and out of your eyes. Gloves and protective eyewear are necessities when working with any type of resin.

The First Affordable Large SLA 3D Printer

Skip to Main Content

With a large build volume of 33.5 × 20 × 30 cm (13.2 × 7.9 × 11.8 in),

you can print full-scale bulky prototypes or detailed models.

Stop outsourcing large-scale prints.

Work faster with a large format 3D printer that’s versatile enough to bring large scale fabrication in-house.

Life-sized prints for larger-than-life ideas.

The Form 3L is large enough to print human-scale models, like a prototype of a helmet that’s ready to try on.

Perfectionism that scales.

Two precision Light Processing Units inside the printer achieve consistent accuracy and detail across the entire build platform.

Material

Print Time

Print Cost

Part By

Black Diamond Equipment is prototyping climbing helmets at 1:1 scale to test for form and fit, producing several iterations per week in-house and reducing costs. Read more about how Black Diamond uses the Form 3L.

Note: print time and cost will vary based on part geometry, material, layout, and orientation.

Get more done and work more efficiently with an end-to-end 3D printing workflow. From printing, to post-processing, each step of the process was designed with efficiency in mind.

Watch the Webinar

Choose from a wide range of advanced materials, developed specifically for Formlabs printers by in-house materials scientists. With simplified material switching and automatic resin dispensing, the Form 3L allows you to walk away and focus on other work once your print job starts.

Many applications, one printer.

Print in over 15 functional resins to support a wide range of workflows on a single platform.

Switch materials in minutes.

Avoid the hassle and mess of purging materials with our swappable cartridge system, cross-compatible with other Formlabs SLA printers.

Automatic resin dispensing.

Our automated resin system dispenses resin as parts print. The Form 3L holds two cartridges of resin to avoid mid-print interruptions.

Explore All Materials

Available layer thickness settings vary by material. Visit our material settings roadmap for more details.

Formlabs is known for designing end-to-end additive workflows you’ll be excited to use. The Form 3L brings the Formlabs experience to large format 3D printing.

Streamline your 3D printing workflow and consistently produce high-quality parts with our automated large-format post-processing solutions, Form Wash L and Form Cure L.

Learn More

Printer

Form 3

Form 3L

Build Volume (W × D × H)

14. 5 × 14.5 × 18.5 cm

5 × 14.5 × 18.5 cm

5.7 × 5.7 × 7.3 in

33.5 × 20 × 30 cm

13.2 × 7.9 × 11.8 in

33.5 × 20 × 30 cm

13.2 × 7.9 × 11.8 in

XY Resolution

25 microns

25 microns

25 microns

Biocompatible Materials

No

No

Yes

Laser Power

One 250 mW laser

Two 250 mW lasers

Two 250 mW lasers

Weight

17.5 kg

38.5 lb

54.4 kg

120 lb

54.4 kg

120 lb

Printer Dimensions (W × D × H)

40.5 × 37.5 × 53 cm

15.9 × 14.8 × 20.9 in

77 × 52 × 74 cm

30.3 × 20.5 × 29.1 in

77 × 52 × 74 cm

30.3 × 20.5 × 29.1 in

Explore Form 3

Buy Now

Reach new levels of productivity with a fully automated fleet of Form 3+ 3D printers that you can operate from anywhere. Skyrocket your ability to produce high-quality, affordable parts with 24/7 back-to-back production with Formlabs Automation Ecosystem: Form Auto, Fleet Control, and the High Volume Resin System.

Learn More

Buy the Form 3L

Luxury and Budget Printers

Contents

With the range of large format printers available today, deciding which one is right for you can be tricky.

To find the model that will suit your needs, your decision should be based on the following criteria:

- The exact size of the printed layer.

- Whether you need plate heating or not.

- Easily eject the finished print. nine0012

- Assembly required or not.

- Automatic or manual alignment.

- Filament detection.

- Accuracy level.

- Software compatible.

After a thorough review of the most popular large format 3D printers, I would say that the Creality Ender 5 Plus is an excellent choice for home use.

Automatic alignment. Filament detection. Resume feature. Heated bed. Convenient to use and easy to assemble. High precision and extra glass plate. Ideal for a huge number of projects. nine0003

Ideal for a huge number of projects. nine0003

Best Large Format Printer: Creality Ender 5 Plus

- BLTouch Auto Bed Leveling Sensor: It can accurately measure the slope of the hot bed surface and offers Z.

- Equipped with two Z-axis drive screws: the hot bed is held stably on the Z-axis frames, don't worry.

The Creality Ender 5 Plus is a high quality, durable 3D printer that offers great compatibility and speed. nine0003

That's a great price for print results! It is easy to assemble and use immediately.

The texture is quite accurate, with minimal errors and smooth lines and layers.

The print size is 350 x 350 x 400 millimeters (or 13.7 x 13.7 x 15.7 inches) when using the BL Touch Glass bed.

Pros:

- The printer is easy to assemble and takes little time.

- This is a plug and play system that is easy to use after assembly. nine0012

- Online Resources are available at no extra cost and include videos and tutorials to help you every step of the way.

Cons:

- Printer may need to be updated to get better results.

- The motherboard is noisy, which can be fixed with the silent board update v2.2.

- In some cases, it takes several attempts before you see a good result, although most users are satisfied with the result. nine0012

Best Budget Large Format Printer: Open Source Creality 3D Printer

- .

- ❤ Resume Print ❤.

This open source Creality 3D printer features a heated bed with a glass bed. The printer includes a 12" x 12" x 15.5" all-metal frame. nine0003

You will find the body space large and one of the largest available with the ability to print more models than up to 90% of other printers.

The metal frame and flat glass base provide a stable surface to avoid irregular beds and structures. This is the perfect 3D model printer for beginners as it is easy to use.

Pros:

- Inexpensive for the level of quality.

- The detail is impressive and the printer delivers great results with virtually no errors. nine0012

- Printer setup takes less than 30 minutes.

Cons:

- With small movements there is some distortion of the text or a slight ghost, although this is minimal.

- No automatic bed leveling.

Other Best Large Format 3D Printer Options

If none of the above options work for you, check out these other top 3 wide format 3D printer options.

AnyCubic Chiron 3D Printer - Semi Auto Leveling FDM Printer

- Large build volume, the ANYCUBIC Chiron 3D printer comes with one of the largest build volumes of 15.75x.

- Semi-automatic alignment and resuming printing, Equipped with an automatic alignment module that automatically.

This 3D printer is equipped with an ultra-basic heater that works with 1.75mm filament and measures 15.75 x 15.75 x 17.72 inches (or 400 x 400 x 450 millimeters).

The Chiron 3D Printer is fantastic for maximizing creativity and printing a wide range of designs, more than most 3D printers on the market. nine0003

Nozzle provides high precision for high prints.

Pros:

- High print accuracy means precise, sharper results.

- The printer screen is large and the touch screen makes the device very user friendly.

- The ideal printer for large prints and easy to calibrate.

Cons:

- Online customer support could be improved a bit, more advice and help with 3D printer problems could make a difference. nine0012

- Several attempts may be required to obtain the desired result.

LGT Longer LK1 3D Printer Large DIY Kit

- 【LARGE PRINT PLATFORM】The maximum build size for this LK1 3D printer is 300*300*400mm, and it can…

- 【PRINT RECOVERY FUNCTION】LK1 printer can resume printing even after power off.

This fantastic 3D printer has a built-in media feed sensor. The LK1 printer has the ability to resume printing under various conditions, including a power outage. nine0003

The LK1 printer has the ability to resume printing under various conditions, including a power outage. nine0003

This convenient process allows you to continue printing without interruption, saving time and materials.

Price is reasonable for quality and user experience.

Pros:

- After purchase, one year technical assistance service with an option to extend lifetime coverage is included.

- Technical assistance is available 24 hours a day with excellent support and social media forums. The

- 3D printer is stable, quiet and pleasant to use. nine0012

- It is partially assembled and it takes a little time to assemble the parts.

- The interface is easy to use and basic.

Cons:

- This is not an ideal device for use with modified firmware or BL Touch.

- The power switch is poorly located and difficult to reach to turn it on.

Creality CR-10S Pro V2 3D Printer - with BL Touch

- BL Touch Auto Leveling: Matrix auto bed leveling, quality BLTouch auto leveling device.

CR. nine0012

CR. nine0012 - Upgraded silent motherboard: Creality CR 10S Pro V2 adopts V2.4.1 independently developed silent.

This Creality 3D printer features an upgraded BL Touch auto leveling silent motherboard with a 500W Meanwell power supply.

This is a convenient and efficient system that delivers accurate, consistent printing with long lasting quality.

Pros:

- Printing is secure, fast and quiet. nine0012

- Alignment is easy and using the auto alignment feature makes printing accurate and easy with flawless results.

- 3D assembly is considered easy for most users, although some reports indicate some difficulty.

Cons:

- In some cases, parts may be missing or must be ordered separately.

- Assembly may take longer than expected and may require some assistance or customer service. nine0012

Features to look out for in large format printers

Before investing in a large format 3D printer, there are some important features to consider.

You may need certain features if you are planning specific projects or just want a high quality machine for your first purchase.

Price range varies considerably depending on features and upgrades.

The type of 3D printer you are looking for can be an FDM (Fused Deposition Modeling) printer, a digital light processing (DLP) printer, a selective laser sintering (SLS) printer, or a stereolithography (SLA) printer.

Before you complete your large format printing purchase, you may want to review some of the following features.

Safety features

Safety features are often built into the machine, including nozzle cooling after bed heating during printing. nine0003

When you pause a print job, some machines move the nozzle away from the project to prevent damage from overheating and excess filament.

Destination

What do you want to print? Do you have a particular style or project in mind, or are you looking for a basic, easy-to-use machine for beginners?

Resolution

Micron is a unit of measure for the resolution of a 3D printer, and it varies considerably: FDM machines offer resin-based printing at 25 microns, while high-end printers have a resolution of 100 microns. nine0003

nine0003

Customer Support

Find a quality brand with reliable support and customer service. Some brands offer an annual manufacturer plan that includes 24/7 online support.

Evaluate the level of professionalism of the company: is it a general online system or comprehensive individual support?

Options

You will want to consider other factors, including the type of software, future upgrades, and availability of filament and options. nine0003

For example, the price of a printer may seem reasonable at first glance, but once purchased, you may have to spend much more money on upgrades and additional items.

Other higher priced machines may include everything you need to get you up and running right away!

Related questions:

If you are new to the world of 3D printing, you need to carefully consider all options and goals for your project.

You will find many options and types of machines, including dimensions, accuracy and upgrades. nine0003

nine0003

What is the largest 3D printer you can buy?

If you are looking for the largest 3D printer then the biggest option is BLB Industries the Box which offers a build volume of 2000 x 2000 x 1500 millimeters and 6000 liters.

What can you do with a large format printer?

You will find many ideas for your new large format printer.

Basically anything that can be printed on a standard desktop 3D printer is possible; you just have the option to make larger prints. nine0003

Are large format printers suitable for home use?

Large format 3D printers are exceptionally suitable for school projects and hobbyists who enjoy creating 3D models.

Debriefing

So you've seen the best of what's available, and now it's time to make your final decision. If you are still struggling with the choice, I would advise you to choose the Creality Ender 5 Plus.

It has some amazing features, is reasonably priced, and isn't too hard to assemble and figure out how to use. nine0003

nine0003

It may not be the largest model, but it is roomy enough for typical home use and the craftsmanship and precision are hard to beat.

Last Updated 2022-05-17 at 05:18 / Affiliate Links / Images from Amazon Product Advertising API

Comparison of 3D printing technologies: FDM, SLA and SLS expands technological capabilities in product development. 3D printing technologies offer versatile solutions for applications ranging from rapid concept and functional prototypes in the field of prototyping to fixtures and clamps or even final parts in manufacturing. nine0003

Over the past few years, high resolution 3D printers have become more affordable, more reliable and easier to use. As a result, more companies have been able to use 3D printing technology, but choosing between different competing 3D printing solutions can be difficult.

Which technology is right for your needs? What materials are available for her? What equipment and training is needed to get started? What are the costs and payback? nine0003

In this article, we take a closer look at three of today's most well-known plastic 3D printing technologies: Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Choosing between FDM and SLA 3D printer? Check out our detailed comparison of FDM and SLA technologies.

Download this high resolution infographic here.

VIDEO MANUAL

Can't find the 3D printing technology that best suits your needs? In this video tutorial, we compare Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) technologies in terms of the top factors to consider when purchasing. nine0003

Watch Video

Fused Deposition Modeling (FDM), also known as Fused Filament Manufacturing (FFF), is the most widely used form of 3D printing at the consumer level, fueled by the rise of consumer 3D printers. On FDM printers, models are made by melting and extruding a thermoplastic filament, which the printer's nozzle applies layer by layer to the model being built.

The FDM method uses a range of standard plastics such as ABS, PLA and their various blends. It is well suited for making basic experimental models, as well as for quickly and inexpensively prototyping simple parts, such as parts that are usually machined. nine0003

It is well suited for making basic experimental models, as well as for quickly and inexpensively prototyping simple parts, such as parts that are usually machined. nine0003

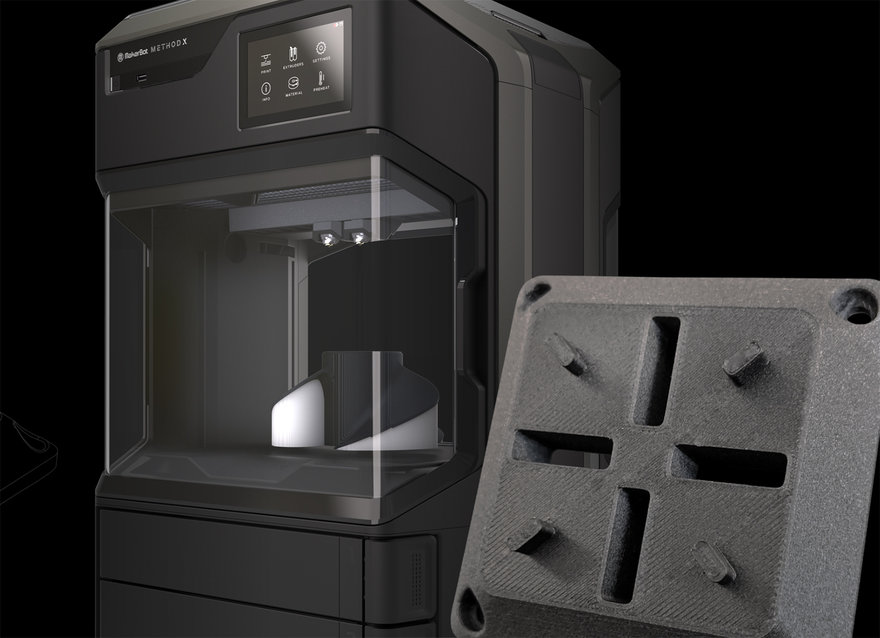

FDM models often show layer lines and may have inaccuracies around complex features. This sample was printed on a Stratasys uPrint FDM industrial 3D printer with soluble support structures (price starting at $15,900).

FDM printers have the lowest resolution and accuracy of SLA or SLS and are not the best option for printing complex designs or parts with complex features. Surface quality can be improved by chemical and mechanical polishing processes. To address these issues, industrial FDM 3D printers use soluble support structures and offer a wider range of engineering thermoplastics, but they are also expensive. nine0003

FDM printers do not handle complex designs or parts with complex features (left) compared to SLA printers (right).

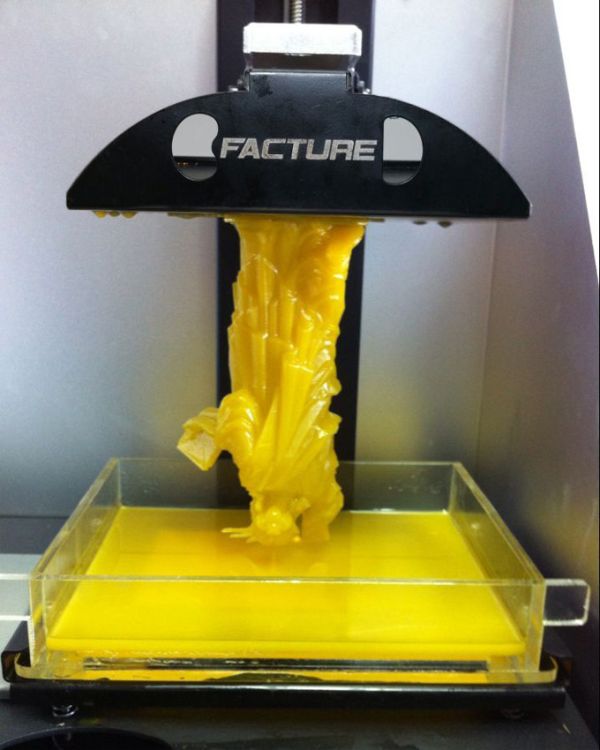

Invented in the 1980s, stereolithography is the world's first 3D printing technology and is still one of the most popular technologies among professionals today. SLA printers use a process called photopolymerization, which is the conversion of liquid polymers into hardened plastic using a laser.

SLA printers use a process called photopolymerization, which is the conversion of liquid polymers into hardened plastic using a laser.

See stereolithography in action.

Models printed on SLA printers have the highest resolution and accuracy, the sharpest detail and the smoothest surface of all plastic 3D printing technologies, but the main advantage of the SLA method is its versatility. Materials manufacturers have developed innovative formulas for SLA polymers with a wide range of optical, mechanical and thermal properties that match those of standard, engineering and industrial thermoplastics. nine0003

Models created using SLA technology have sharp edges, a smooth surface and almost invisible layer lines. This sample was printed on a Formlabs Form 3 Desktop Stereolithographic 3D Printer (price starting at $3499).

SLA is an excellent option for making highly detailed prototypes that require tight tolerances and smooth surfaces such as molds, templates and functional parts. SLA technology is widely used in industries ranging from engineering and design to manufacturing, dentistry, jewelry, modeling, and education. nine0003

SLA technology is widely used in industries ranging from engineering and design to manufacturing, dentistry, jewelry, modeling, and education. nine0003

White Paper

Download our in-depth white paper to learn how SLA printing works, why thousands of professionals use it today, and how this 3D printing technology can be useful in your work.

Download white paper

free sample

Experience Formlabs print quality firsthand. We will send a free 3D printing sample directly to your office.

Request a free sample

Selective laser sintering is the most common additive manufacturing technology used in industry.

Selective Laser Sintering (SLS) 3D printers use a high power laser to sinter fine polymer powder particles. The unsprayed powder supports the model during printing and eliminates the need for special support structures. This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper. Models produced using SLS printing have excellent mechanical characteristics: their strength can be compared with the strength of injection molded parts. nine0003

This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper. Models produced using SLS printing have excellent mechanical characteristics: their strength can be compared with the strength of injection molded parts. nine0003

Models created with SLS technology have a slightly rough surface, but almost no visible layer lines. This sample was printed on the Formlabs Fuse 1 SLS workshop 3D printer (price starting at $18,500).

The most common selective laser sintering material is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon is light, strong and flexible, resistant to impact, heat, chemicals, UV radiation, water and dirt. nine0003

The combination of low part cost, high productivity, and widely used materials makes SLS a popular method for engineering functional prototyping and a cost-effective alternative to injection molding in cases where production runs are limited.

White Paper

Looking for a 3D printer to create durable, functional models? Download our white paper to learn how selective laser sintering (SLS) technology works and why it is popular in 3D printing for functional prototypes and end-use products. nine0379

nine0379

nine0386

nine0386 Either way, you should choose the technology that best suits your business. Prices have dropped significantly in recent years, and today all three technologies are offered in compact and affordable systems.

3D printing costing doesn't end with initial equipment costs. Material and labor costs have a significant impact on the cost of each part, depending on the application and production needs. nine0386

INTERACTIVE MATERIAL

Try our interactive ROI tool to see how much time and money you can save by printing with Formlabs 3D printers.

Calculate savings

FDM, SLA and SLS printed ski goggle frame prototypes (left to right).

We hope this article has helped you narrow down your search for the 3D printing technology best suited to your needs.