Direct drive 3d printer

3D printer with direct-extruder - 3DJake International

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

Filters:

- Direct Drive Extruder

-

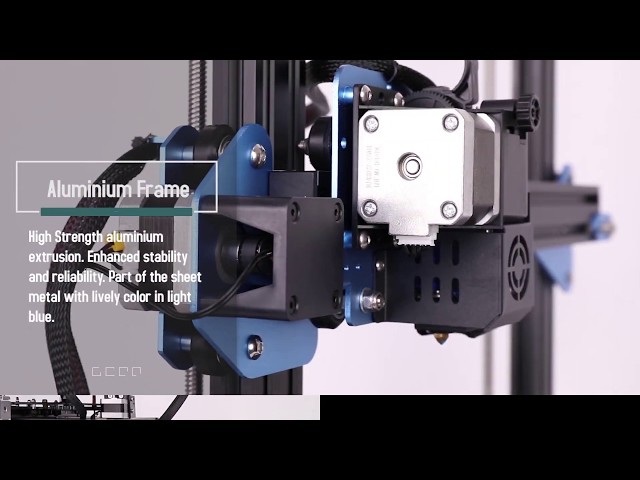

Artillery Sidewinder X2- Very large installation space

- Automatic bed levelling

- Titan extruder

-

FlashForge Creator 3 V2- Independent twin extruder setup

- Flexible building board

- Wireless connection

-

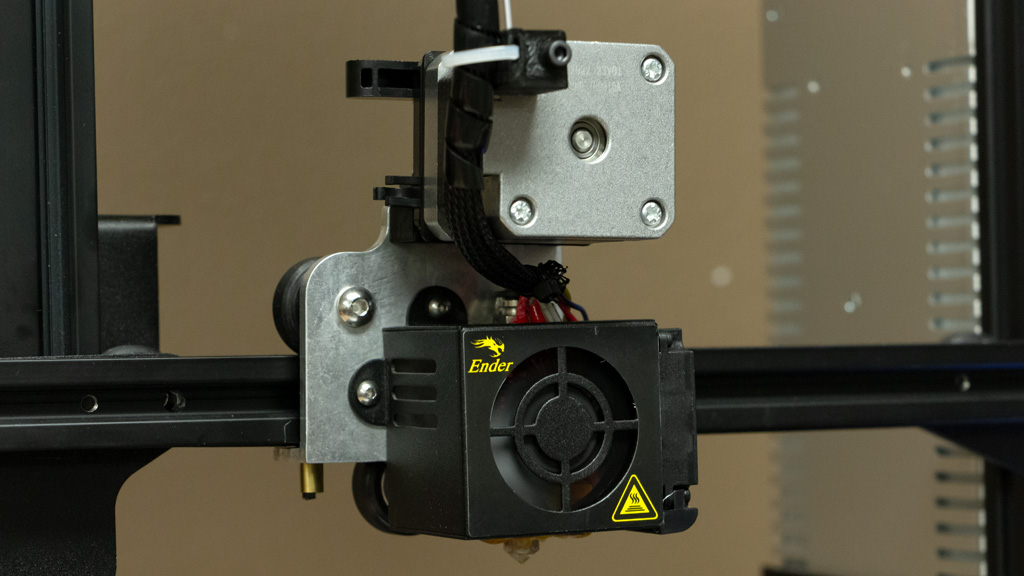

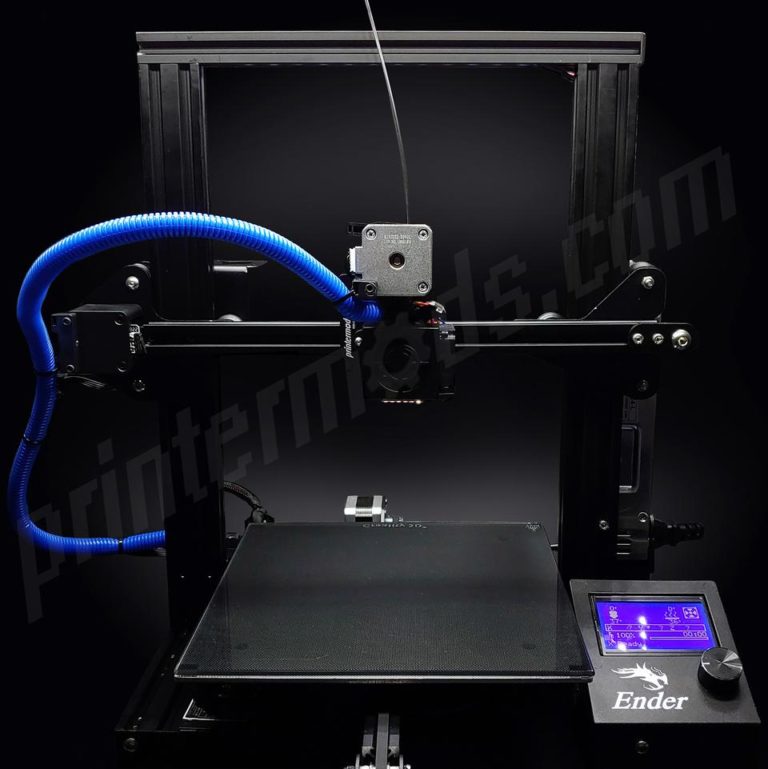

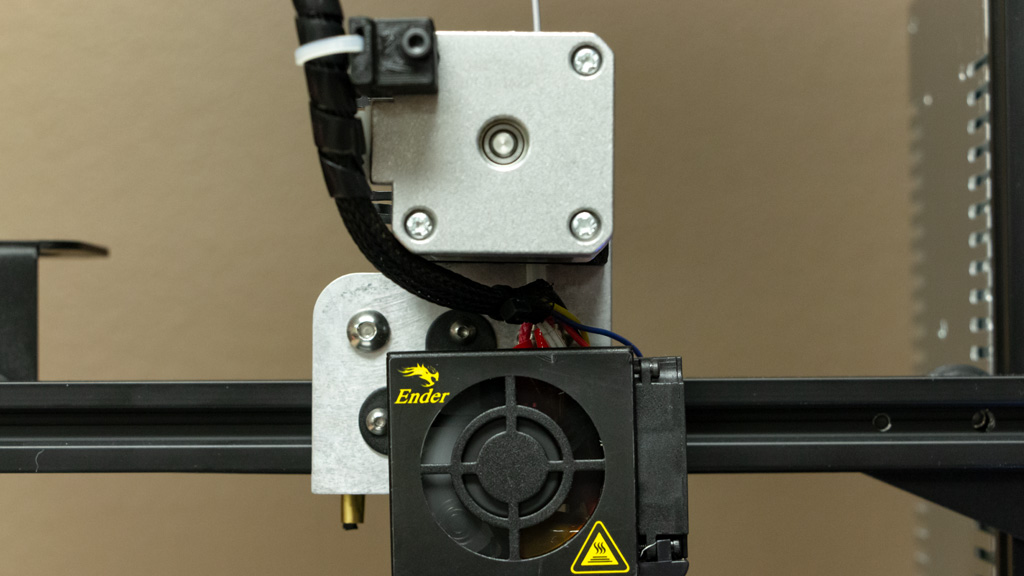

Creality Ender 3 S1- Direct dual gear extruder

- CR-Touch Automatic bed levelling

- 32-bit silent mainboard

-

MINGDA Magician Max- 320 x 320 x 400 mm build volume (L x W x H)

- Direct drive extruder with dual gear drive

- Dual Z-axis with a toothed belt

-

Qidi Tech i-Fast- 2 dual extruders (normal & high temperature up to 350°C)

- High temperature

- Large print size

-

Zortrax M200 Plus- Wi-Fi Module

- Filament Sensor

- Improved Cooling System

-

Zortrax M300 Plus- Large build space

- Filament sensor

- Wi-Fi connection

-

Qidi Tech i-Mate S- No assembly necessary

- Ultra-light

- More precise nozzle

-

Qidi Tech X-Plus- Large enclosed build space

- High precision

- Stable double Z-axis

-

Anycubic Kobra- LeviQ - Automatic Print Bed Leveling

- Direct Drive Extruder

- Modular design

-

FlashForge Creator Pro 2- Independent dual extruder

- Enclosed build space

- Solid metal frame

-

Snapmaker Snapmaker 2.0 Including Enclosure- 3D printing

- Laser engraving

- CNC milling

-

Intamsys Funmat HT Enhanced- Printing with high-performance plastics

- Easy handling

- Constant internal temperature

-

Artillery Genius Pro- 220 x 220 x 250 mm build space

- Titan extruder & modular nozzle set

- 32-bit motherboard upgrade

-

Qidi Tech X-Max- Huge closed space

- High precision

- Stable double Z-axis

-

Elegoo Neptune 3 Pro- Powerful & low-noise

- STM 32-bit motherboard

- Direct dual-gear extruder

-

Creality CR-10 Smart Pro- All-metal direct drive extruder

- Dual-mode levelling

- AI HD camera & intelligent handheld control

-

CraftBot Flow- Large printing area

- Reinforced steel frame

- Metal hotend

-

Creality Ender 3 S1 Plus- 300 x 300 x 300 mm build volume

- Sprite Direct Dual Gear Extruder

- CR-Touch automatic bed levelling

-

MINGDA Magician X- 230 x 230 x 260 mm construction volume (L x W x H)

- Direct drive extruder with dual gear drive

- Dual Z-axis with toothed belt

-

Creality Ender 3 S1 Pro- Sprite Direct Dual Drive Gear Extruder

- Higher nozzle and heated bed temperature (300 °C & 110 °C)

- LED strip

-

FLSUN V400- Ø300x410mm

- Printing speeds up to 400 mm/s

- Printing temperature up to 300 °C

-

FlashForge Creator 3 Pro- Dual extruder

- Large build space

- Optimised extruder structure

-

Anycubic Kobra Neo- Automatic print bed levelling

- Direct drive extruder

- Magnetic PEI spring steel build plate

All prices incl. VAT.

VAT.

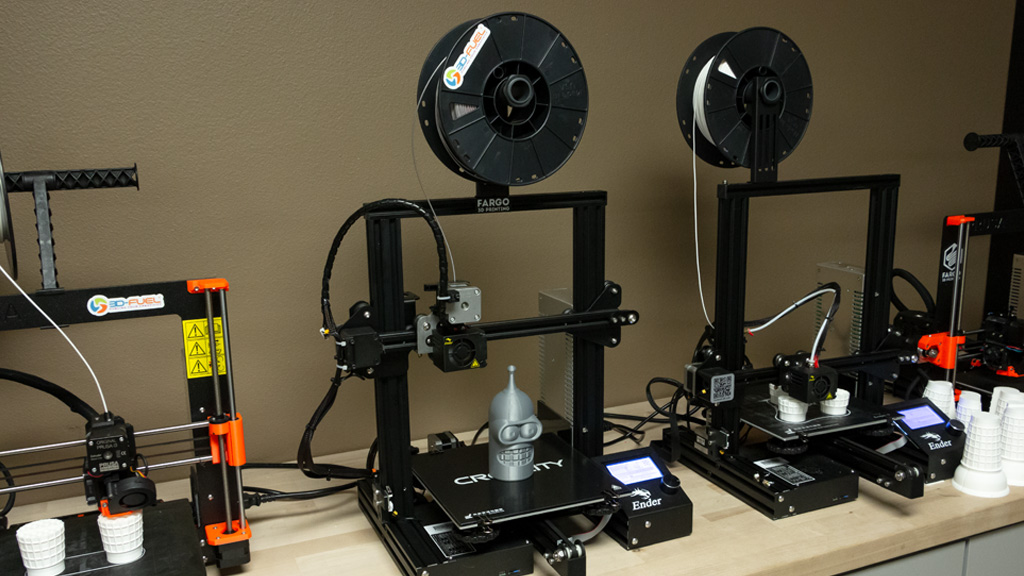

Top 5 Best Direct Drive 3D Printers For All Uses - Ranked

Extruders make or break your 3D printing experience — so picking the best type of extruder is key. Do you want your TPU to print right almost every time, or are you a speed demon looking to print as fast as possible?

If you’re looking for consistent, accurate and reliable 3D printing, look no further than direct drive 3D printers.

What is a direct drive extruder?

Extruders are found on FDM 3D printers. They push plastic filament through to the hot end where it is melted and extruded out through the 3D printer’s nozzle to make your model.

Extruders have a stepper motor, hobbled drive gear, and mounted idler for pushing filament through.

There are two types of extruder however: direct drive extruders and bowden extruders.

In direct drive extruders the extruder is attached to the print head, rather than with bowden extruders where it is on the side of the printer’s frame.

Direct drive extruders push filament directly through to the hot end as they are so close together, while bowden extruders use a PTFE tube to push the filament the longer distance.

Here’s a very quick round-up of the differences, and advantages and disadvantages of these two types.

Direct Drive Extruder 3D printers

Advantages of direct drive extruders

Better retraction controls as the extruder is closer to the hot end.

The shorter distance and quicker command receiving from the hot end improves control over the material, leading to good quality prints – as well as making it easier to print flexibles.

Less force is required to have the same effect on the filament than would be required with a bowden extruder. You can therefore use a smaller stepper motor, and you have less chance of filament slipping.

Limitations

Adds mass to the 3D printer’s extruder and overall gantry system.

This added mass limits print speed as vibrations and wobbles start to creep in, creating imperfections in the print. You’re therefore more restricted with your printer’s top speed with a direct drive extruder.

You’re therefore more restricted with your printer’s top speed with a direct drive extruder.

Bowden Extruders

Pros

- Can 3D print faster as they’re lighter without losing print quality

Cons

- TPU can struggle — needs specially designed hobbled gears for this softer material, and larger retraction settings

The Best Direct Drive 3D Printers

Here are some of the direct drive 3D printers we recommend, broken down into our top picks in each category and for different uses.

Prusa i3 MK3S+ – best 3D printer with a direct drive extruder in its price range

- Price: $749-$999 — Kit available here / Pre-assembled available here

- Build volume: 250 x 210 x 210 mm

The Prusa i3 MK3S+ is the undisputed king of desktop direct drive 3D printers. It’s tough as old boots, indisputably reliable, and always being upgraded and improved by the Prusa Research team.

Newly upgraded, the Prusa i3 MK3S+ is fitted with a superPINDA probe which improves your print’s first layer calibration and adhesion, adding to the huge range of features that come with this FDM kit king: power loss print recovery, a run-out filament sensor, quiet mode for printing at night or when you don’t want to be disturbed, and it’s open source.

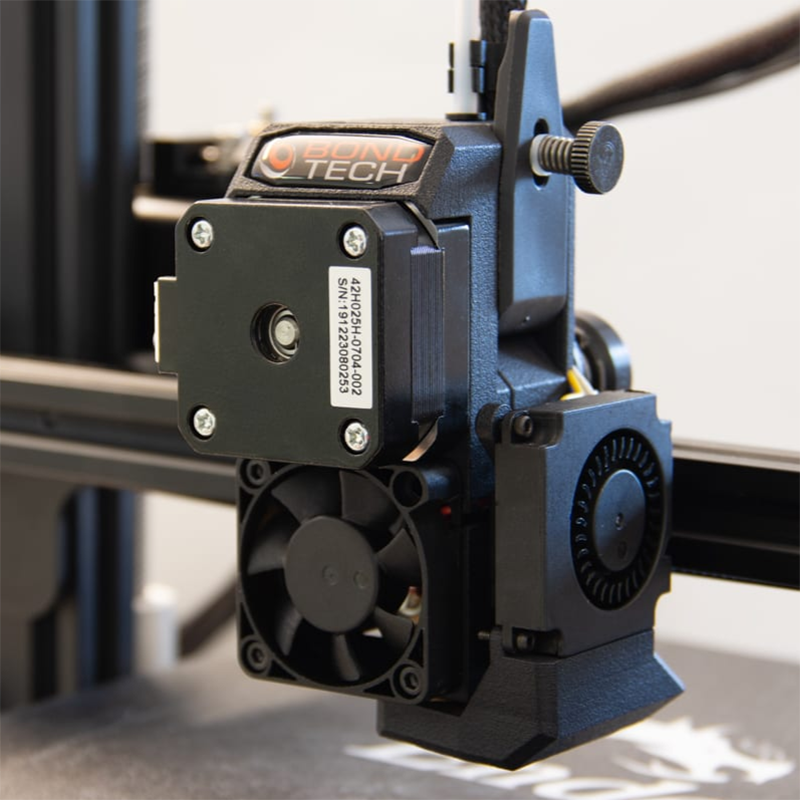

Part of the reason Prusa kit printers are so famed for their durability and reliability is down to the high-quality parts that go into it — the direct drive extruder is developed by Prusa internally, and fitted with an E3D V6 hot end and Bondtech parts.

You can even upgrade your Prusa with the Multi Material Upgrade 2.0 and print up to 5 different filaments and colors simultaneously!

For more information on printing in multiple colors, read our guide to multi color 3D printers

Overall, the Prusa is undoubtedly one of the best direct drive extruder 3D printers around, and is still one of the most popular printers among hobbyists and professionals.

Creality CR-10 V3 — With New E3D Titan Direct Drive Exruder

- Price: $499 — Available on Creality Store here / Available on Amazon here

- Build area: 300 x 300 x 400 mm

Creality make some of the world’s most popular desktop 3D printers including the Ender 3 and Ender 5 range, as well as the highly-rated CR-10 range.

Now onto the third iteration, the CR-10 V3 shifts away from the bowden extruder and implements an E3D Titan direct drive extruder, which Creality say boosts its performance for TPU and ABS 3D printing, as well as improving retraction and avoiding filament stringing and oozing.

Other key changes from the CR-10 V2 to V3 include an upgraded silent motherboard along with improved power supply, supercharging the CR-10 V3 with the power to print more precisely and quietly — a great advantage for those who want to run it all night but don’t want to be woken up by their printer.

The strong z-axis triangular beams improve stability as they are anchored against the axes, and though it doesn’t come with auto-leveling as standard, you can install BLTouch for auto-leveling without much issue. The CR-10 also has dual port fan cooling for more effective part cooling while printing, which Creality estimate improves print precision by 10%, and is 55% better at cooling than previous models.

Qidi Tech X-Plus

- Price: $699 — Available on Amazon here

- Build volume: 270 x 200 x 200 mm

A reasonably priced enclosed 3D printer with a direct drive extruder, the Qidi Tech X-Plus is great for tackling tougher filaments that need carefully maintained temperatures within the build chamber to print well.

The X-Plus ships with two interchangeable nozzles, one standard nozzle for printing filaments like PLA and ABS, and one high-temp premium nozzle for printing PC, Nylon, and carbon fiber. With both the high-temp nozzle and enclosed build chamber, the X-Plus is the ideal low-cost commercial 3D printer for all your printing needs. You can also print flexibles like TPU without much issue with direct drive extrusion.

It’s precise, with a double z-axis system for extra stability and accuracy even across larger prints. It automatically shuts off after printing, a nice touch if you’re printing overnight, and the WiFi connectivity and large touchscreen make it super easy to navigate and work with. Overall, it’s a great direct drive 3D printer and a reliable and durable printer for both fun home use and more commercial prototyping.

Overall, it’s a great direct drive 3D printer and a reliable and durable printer for both fun home use and more commercial prototyping.

Flashforge Creator Pro 2 — best dual extruder direct drive 3D printer

- Price: $649 — Available at Flashforge Official store here / Available on Amazon here

- Build volume: 200 x 148 x 150 mm

The original Flashforge Creator Pro was a big hit, with the upgraded Creator Pro 2 upgrading on areas where the tech had since advanced.

The main selling point is the Creator Pro 2’s upgraded IDEX dual extruder, meaning each extruder moves independently, opening up a range of new possibilities. The printer features four modes for printing:

- Mirror Mode: prints two mirrored designs

- Duplicate Mode: prints two completely identical models, but at twice the speed

- Multi-material Mode: for printing multi-colored parts

- Soluble Support Mode: for printing filaments like HIPS and PVA that can be dissolved to leave blemish-free ABS and PLA parts

This makes the Creator Pro 2 the ideal direct drive 3D printer for soluble filament 3D printing, and it can print filaments like ABS and HIPS, and PVA and PLA, without issue.

The robustly built frame anchors the printer down and prevents any vibrations from affecting print quality, and the intuitive touchscreen is always a nice extra feature to have. It’s enclosed, with the top filtration part, and overall it’s a great dual extruder printer with a direct drive extruder.

Qidi Tech X-Max — Great Enclosed Direct Drive 3D Printer

- Price: $1,099 — Available on Amazon here

- Build volume: 300 x 250 x 300 mm

The bigger and even more high-spec brother of the Qidi Tech X-Plus, the X-Max can print enormous models with it’s large enclosed build area, useful for fun home use 3D printing cosplays and other large projects, as well as for large prototype 3D printing for commercial uses.

The X-Max comes fully assembled so you can get straight to printing, and is easily accessible by WiFi to save you time, though it’s also USB connectable if you prefer this.

It can level quickly, is easy to use with the large 5-inch touchscreen, and features advanced air filtration systems to keep fumes from filaments like ABS away from you.

Like the X-Plus it comes with two sets of direct drive extruders which you can switch out based on what filament you’re printing. For casual use you can use the standard extruder, and for tough filaments like Nylon and PC, switch in the high-temp extruder.

The huge build volume is sure to impress, but the reliability and durability of the X-Max is another major factor in it being one of the best direct drive 3D printers around in its price range.

Extra help with direct drive 3D printing and further resources

This article touches on most aspects of direct drive extruders, but for a deeper understanding we recommend you read our complete 3D printer extruder guide.

Many people also confuse the extruder with the hot end – the part responsible for quickly melting filament so it can be extruded. You can read more about 3D printer hot ends here.

A common debate is whether you can 3D print flexible filaments like TPU well with a bowden extruder, or if you should always use a direct drive extruder for flexibles. We go into more depth in our extruder article, but have some tips in our guides to 3D printing flexible filaments and TPU.

We go into more depth in our extruder article, but have some tips in our guides to 3D printing flexible filaments and TPU.

We also have buyer’s guides for a number of different uses:

- The best 3D printers for cosplays

- The best 3D printers for miniatures

- The best 3D printers for beginners

- The best delta 3D printers

- Ender 3 direct drive upgrades

3D Printer Extruder - Complete Manual Heatle

Learn the basics of direct drive and Bowden extruders, hot and cold ends, nozzle sizes and materials, and find the best 3D printer cartridge for your needs.

The 3D printing process can be briefly described as follows: a filament of plastic material is fed into a heated metal block with a nozzle, where it is melted and extruded in a given form. This path is repeated, gradually building up until a solid three-dimensional object is formed. nine0003

The entire business task of handling the material, melting it and exiting for printing takes place in a block called 3D printer extruder .

In this article, we will look at the main sections of the 3D printer extruder, the options and advantages of different styles of extruders, popular models on the market, as well as cartridge heaters for 3D printers and other items.

What is an extruder

The 3D Printer Extruder is a set of parts that together process and move plastic filament. nine0003

Some consider the extruder to be just the motor and associated parts that push and pull the filament, others the entire assembly including the heated part that melts and deposits the filament.

For simplicity, this article treats the entire assembly as an extruder. To begin with, while explaining the key components of a 3D printer extruder, we will divide it into two elements: a cold zone and a hot zone.

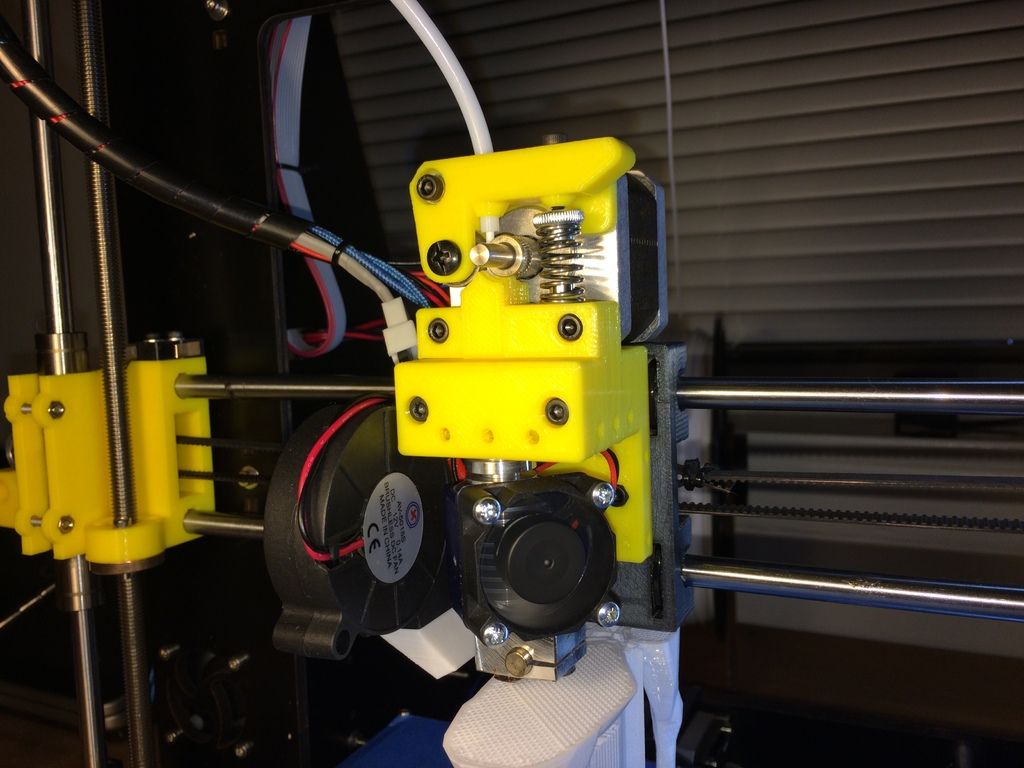

Cold zone

As the name implies, the cold zone is exactly that - cold. It's The top of the 3D printer's extruder system, into which the filament is fed and then passed into the hot zone to be melted and extruded onto the print platform.

The appearance and location of the cold zone on your 3D printer depends on whether it is a direct drive or Bowden drive extruder (both of which are detailed below).

There is no filament heating here. The cold zone consists of the extruder motor and gear train, which are usually mounted either on the printer frame or on the print head itself, depending on the type of extruder, and a PTFE tube to smoothly guide the filament into the hot end. nine0003

What happens in the cold zone?

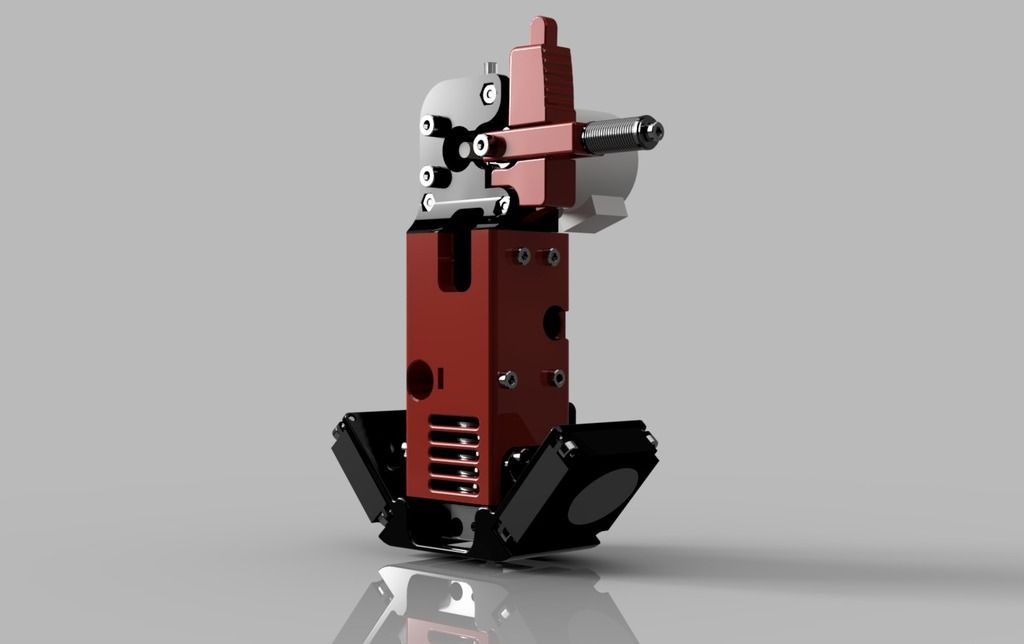

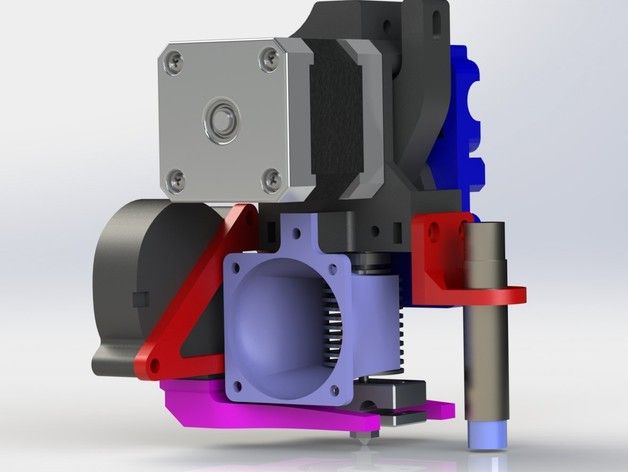

With the heatsink removed on this e3D Titan Aero, we can see the inner workings of the 3D printer's extruder.

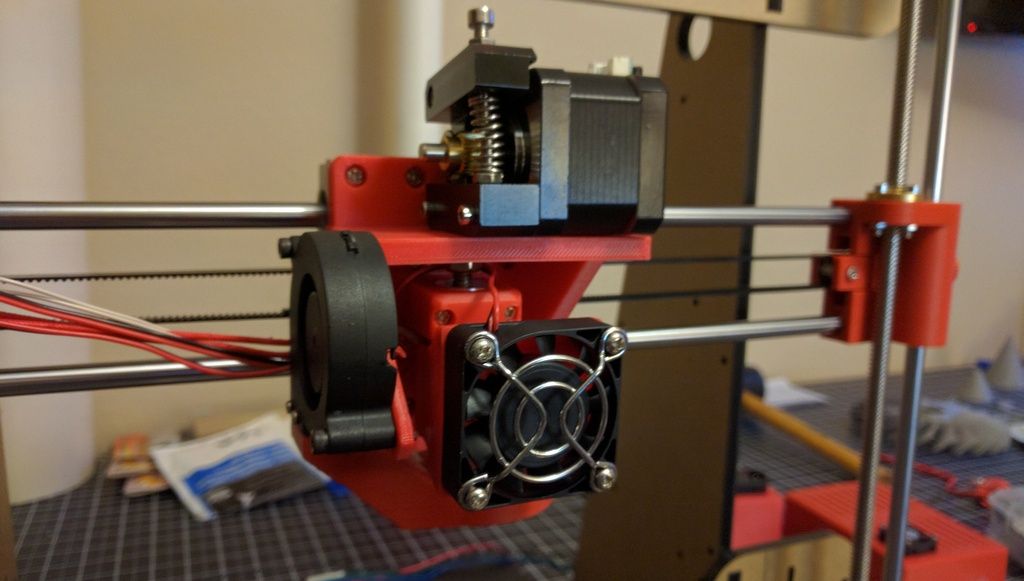

Essentially, the cold zone consists of a stepper motor, some form of gear, a toothed bolt or gear, a spring-loaded idler (usually a bearing of some kind) to hold the filament, and then a PTFE tube to guide the filament.

A humble stepper motor with a metal gear required for a 3D printer's extruder drives the filament extrusion in most if not all modern desktop 3D printers.

However, one stepper motor is not enough to feed the filament to the hot end. The parts attached to and operating the stepper motor drive shaft must physically grab the filament and push it on its way to the hot end.

In this cutaway view of a 3D printer extruder, we see a metal gear and a plastic gear with a toothed shaft. nine0038

This usually uses a combination of toothed gears and toothed bolts or shafts (in the image above we see a metal gear and a plastic gear with a toothed shaft) serving as a pressure wheel along with a bearing or other rigid frictionless material.

Here we see a plastic lever with an integrated bearing, an extension spring and a plastic gear with a toothed shaft. Together they apply pressure to the filament and force it through the extruder. nine0038

Alternatively, there are versions of the cold end of the 3D printer extruder that use a slightly different arrangement of parts to feed the filament. Such deviations are often claimed to provide increased traction and yarn delivery.

Such deviations are often claimed to provide increased traction and yarn delivery.

Here we see both sides of the Prusa i3 Mk3 cold end, including the Bondtech extruder gear train.

As mentioned, there are varieties of 3D printer extruder that use these parts in slightly different layouts. Each has its pros and cons. Next, we will look at what is the difference between a direct drive 3D printer extruder and a Bowden 3D printer. nine0003

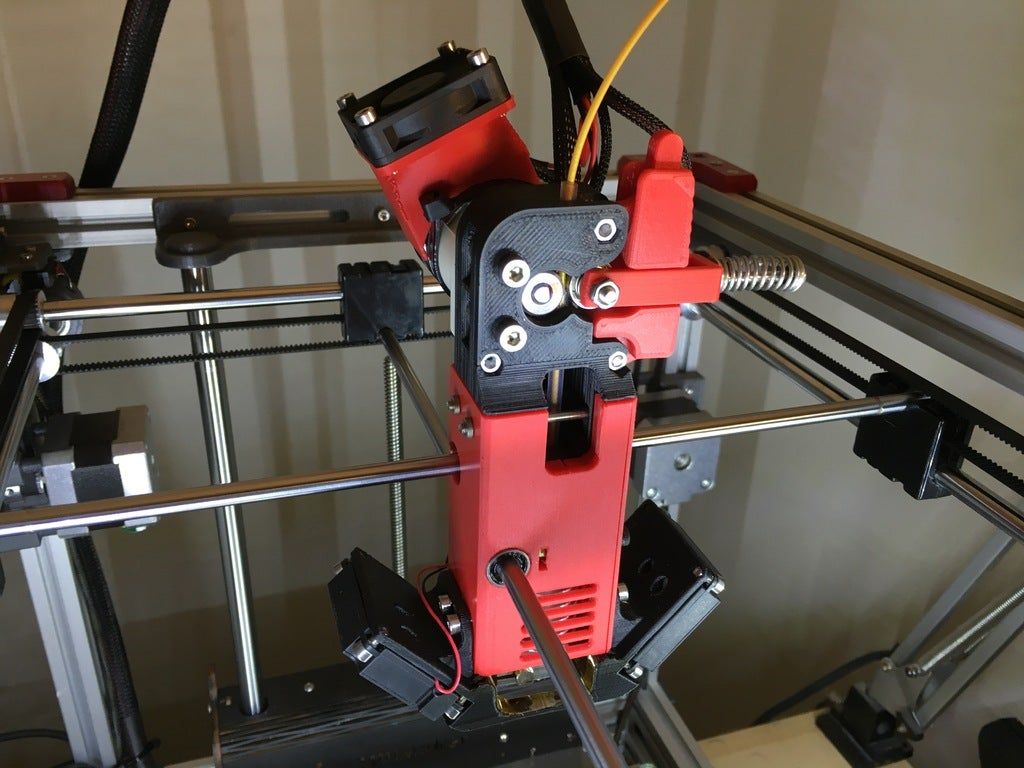

Direct drive extruders

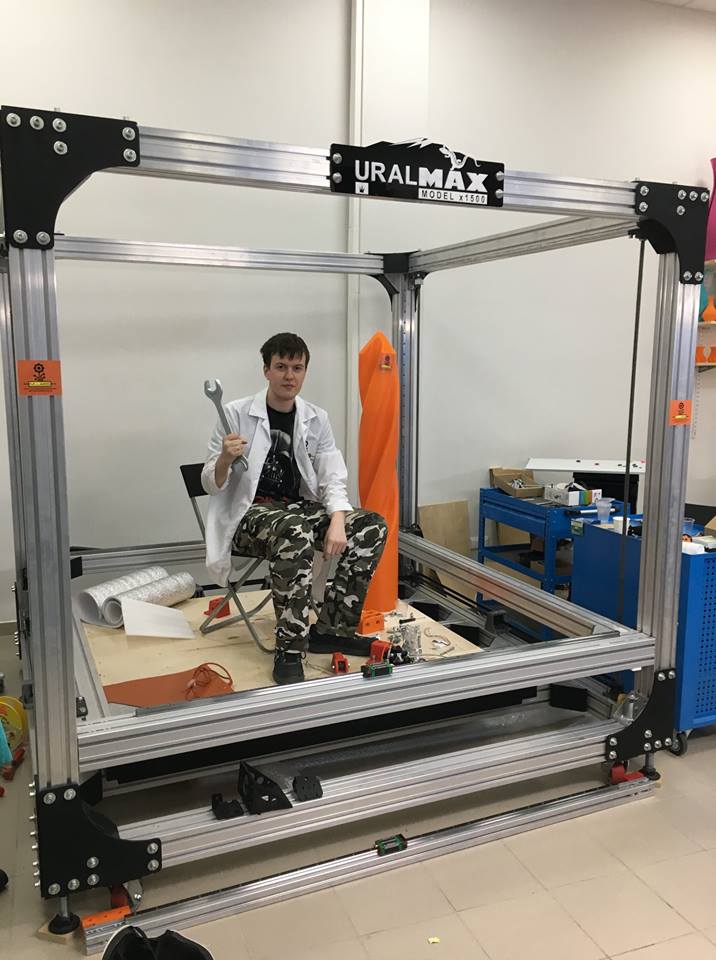

The Direct Drive 3D Printer Extruder is different in that it places the extruder motor directly above the heating unit. This arrangement minimizes the travel distance of the filament to the hot end and can enable more reliable 3D printing of flexible filaments.

The advantage of using direct drive is more precise retraction control. Due to the location directly above the hot end, there is less distance between the clamp and the thread passing through the thermal barrier into the heating block. Consequently, the filament has less room to bend and deform under pressure. nine0003

Consequently, the filament has less room to bend and deform under pressure. nine0003

Bowden extruders

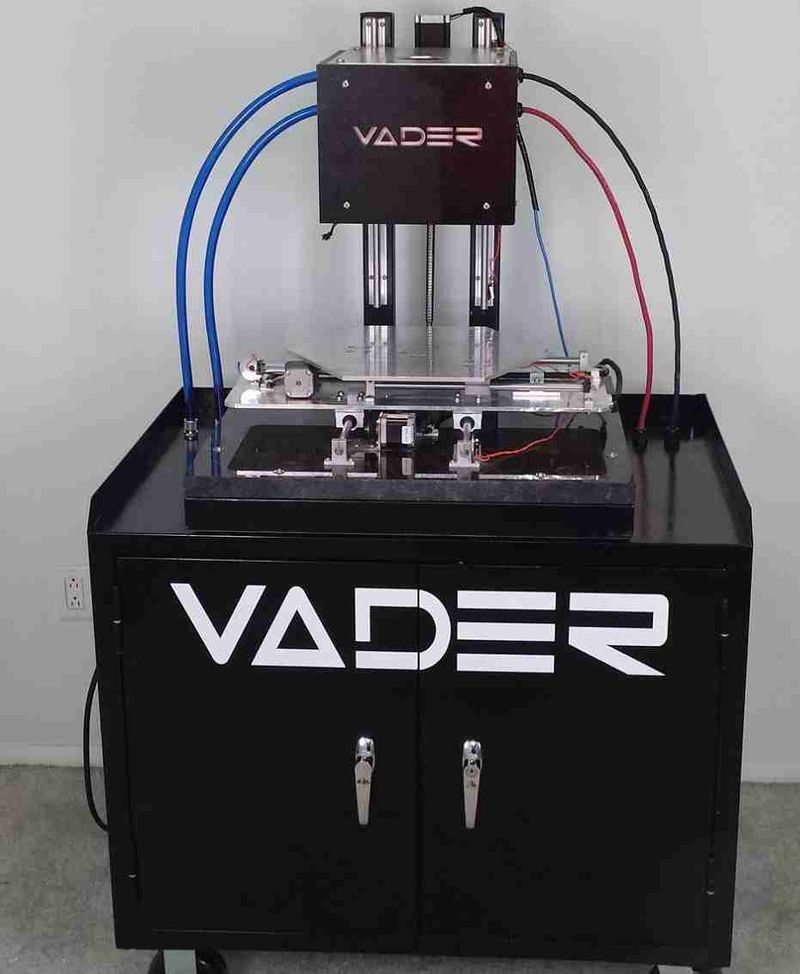

Bowden Style 3D Printer Extruder The does not mount directly on the top of the hot end like a direct drive 3D printer extruder, but the motor and gear assembly mounts on the frame of the printer. This gives this type of extruder an advantage over its head-mounted direct drive brother: speed.

By placing the mass of the 3D printer's extruder on the frame instead, the printhead is freed up to print at higher speeds without sacrificing print quality. nine0003

A side effect of placing the 3D printer's extruder this way is that the filament now has to travel a long way in a tube that's a fraction wider than it is. There should be enough room along the entire length of the tube for a slight bend in the thread. When pulling in the thread between strokes, this slack in the thread shortens the pull-in distance. Without correction (i.e., an increase in retraction), this results in a delay in relieving the pressure exerted on the hot end. In short, you can get confused if you don't change your retract settings. nine0003

In short, you can get confused if you don't change your retract settings. nine0003

Heating block (Hotend)

Inside the knot, known as the hot end, the filament passes into a heated chamber where it changes from solid to liquid. Sounds simple, and mostly it is. Although there is a lot more to make the filament silky extrude onto the build plate.

What happens in the heating zone?

The E3D Titan Aero combines a heating unit and an extruder in one compact unit. The hot end usually only has the central parts of this image: the heatsink (and fan), the heating element (micro cartridge heater), the heater block, the thermistor, and the nozzle. nine0038

A typical 3D printer hot end consists of a specific sequence of parts. There is a slight difference depending on whether you are using PTFE/PEEK or a full metal hot end. Here we explain the all-metal hot block.

First, it is a filament supply tube. In both a Bowden 3D printer extruder and a direct drive extruder, it will just be a PTFE tube coming from your cold filament feeder. nine0003

nine0003

You can sometimes find direct drive 3D printer extruders where the filament runs straight into the print head.

On a Bowden 3D printer's extruder, this feed tube inserts the filament directly into the thermal barrier via a heatsink. The thermal barrier that is screwed into the heatsink is often a threaded stainless steel (or other non-conductive metal such as titanium) tube.

Split in two (note the two separate threads in the image below - longer for the heatsink, shorter for the heater block) and machined on the inside, the thermal break allows the filament to pass freely into the extrusion nozzle. nine0003

Clockwise from bottom left: steel thermal barrier, aluminum heating block and brass nozzle.

But since we're dealing with precision and a material that liquefies for rapid recooling, the 's temperature management is critical. The thermal barrier, in combination with the heat sink, maintains a certain limit at which the filament is exposed to high temperatures. nine0003

nine0003

The top, which is actively cooled by a heatsink and dedicated fan, prevents heat from escaping from the hot end and weakening the filament before it is where it needs to be for extrusion. This unwanted phenomenon is known as thermal creep.

The lower part of the thermal barrier is located inside the heater block together with the cartridge heater, the temperature switch thermistor and the nozzle.

The heater block, usually made of aluminum, ensures a smooth transition of the filament from the open end of the thermal break tube to the nozzle. nine0003

The temperature to melt the filament has to come from somewhere, and this is where the cartridge heater comes into play. Under the action of an electric current, the cartridge heating element heats up, transferring heat to the nozzle through the heater block, in which they are both enclosed.

Clockwise from top left: heating block, thermistor, cartridge heater, nozzle, thermal break.

Power resistors are an alternative means of heating a hot end block, but they are less common these days. nine0003

Also inside the heater block is a thermistor, a small sensor that transmits the temperature of the block to the 3D printer's motherboard, allowing the correct settings to be made.

And on the uneven edge of the entire system is a nozzle. The nozzle itself is a small piece of machined metal, consisting of a chamber containing molten filament that tapers towards the nozzle opening.

Techno Print 3D Company

nine0002 This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→ The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them.