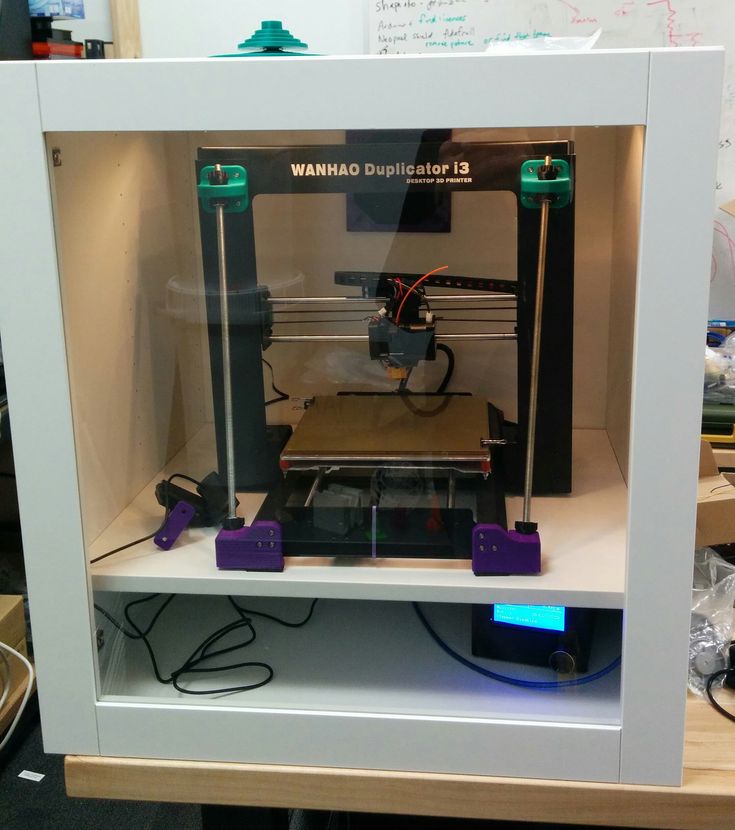

Foam board 3d printer enclosure

▷ foam printer enclosure clips 3d models 【 STLFinder 】

foam printer enclosure clips

thingiverse

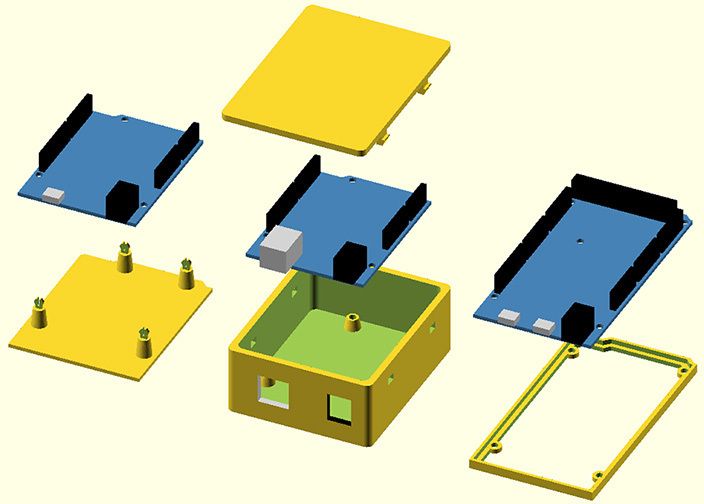

Please let me know if anyone has any suggestions.** This is a set of clips I made up to make a 1" foam enclosure for my printer. I was having problems printing ABS and need to raise the ambient temp. After a quickly cobbeled together box worked I...

Insulated Foam Board 3D Printer Enclosure

thingiverse

A mount to fit 50mm Reticel foam board around your printer. ... It keeps the heat in, allowing better printing of materials like ABS and reducing running costs.

My Customized rotating ajustable vent for foam insulated printer enclosure

thingiverse

foam in a 4ft. x 8ft. sheet to build an enclosure for my HICTOP 3DP-11 it worked well except the fact that the parts were printed form PLA and not ABS like I originally thought. What happened is some of the parts warped from the extra heat. I took...

Foam Mat Clips

thingiverse

Made some clips to hold together some eva foam mat. I got mine from [harbor freight](https://www.harborfreight.com/4-piece-anti-fatigue-foam-mat-set-94635.html). ...This works well for reducing printer noise.

Foam Sound Absorber clips

thingiverse

Foam Sound Absorber clips

Foam Mat Clips

cults3d

Made some clips to hold together some eva foam mat. I got mine from harbor freight. ...This works well for reducing printer noise.

More Foam Board Clips

thingiverse

I'd been looking for ways to make an enclosure for my 3D printers using my 3/16" (4.8mm) foam boards and came across clips by Mastermortis (https://www. thingiverse.com/thing:3401773). These worked very well, but my foam boards were tnot big enough...

thingiverse.com/thing:3401773). These worked very well, but my foam boards were tnot big enough...

Foam Board Clips

thingiverse

Three types of clips to hold 4.8 mm Foam board well gluing.

Foam Core Board Clips

thingiverse

One the clips are attached to the wall or other substrate you just slide the foam core board into the clips. I suggest one for each side and one for the bottom as well (total of three) when hanging something on the wall. ...Print Settings Rafts: ...

3D printer foam golfball feet

thingiverse

These feet use golf balls made of foam (like a stress ball) to reduce noise transfer from the printer to the desk. These practice golf balls are readily abatable on amazon and come in several colors.

...

These practice golf balls are readily abatable on amazon and come in several colors.

...

Clips for Mounting 3mm Enclosure onto Lulzbot Mini 3D Printer

thingiverse

Top and side panels for Lulzbot Mini 3D printer and printable clips used to attach them to the Lulzbot Mini or Mini2 3D printer. Print them and used the panel profiles to cut out side panels for you 3D printer. Thanks, Enjoy! ...

Robo3D Foam Enclosure & Mounts

thingiverse

https://printedsolid.com/collections/accessories-and-upgrades/products/robo-3d-safety-enclosure-kit If you cant work with acrylic then this foam enclosure may be a good option for you. The Case clip is designed to press up on the Robo3D cover. It...

The Case clip is designed to press up on the Robo3D cover. It...

TimSav Foam Board Holddown Clips

thingiverse

Clips for locating, and holding down foam board.

Foam Cutter holder for 3Drag printer

thingiverse

... cutter so it can be used as a plotter for fast modeling. ...You can make any shape you want! 3Drag site: http://www.open-electronics.org/3drag-3d-printer/ Instructions Insert 2pcs M5 bolt in the bracket and use 2pcs M5x20 screw for fix the foam cutter.

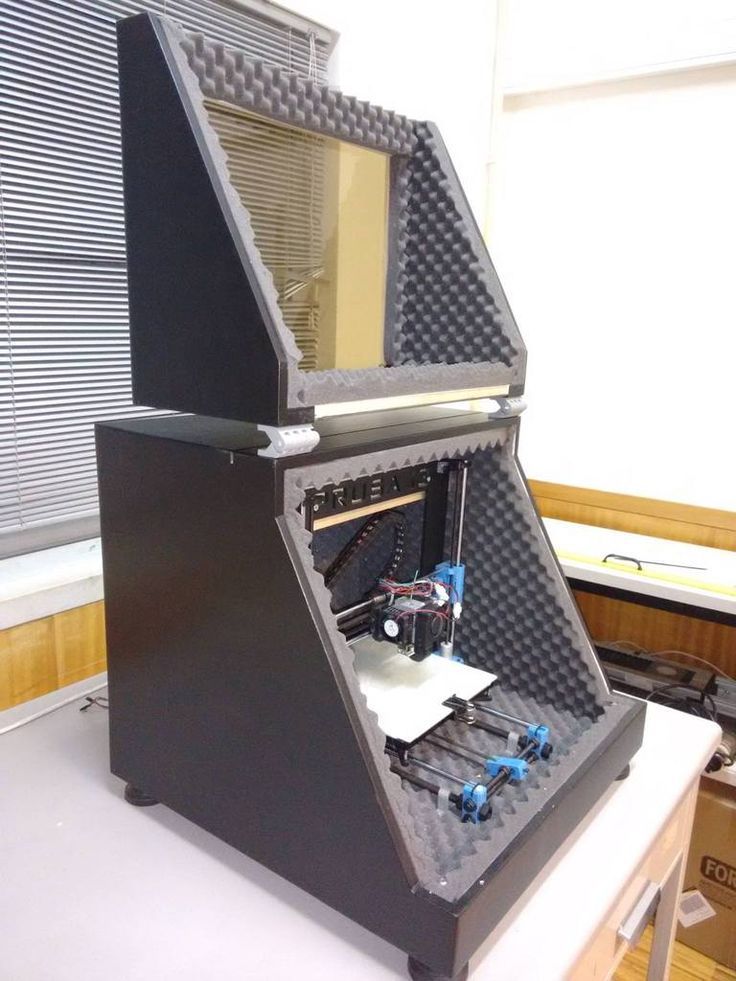

PRUSA i3 FOAM BOARD enclosure

thingiverse

PRUSA i3 FOAM BOARD enclosure

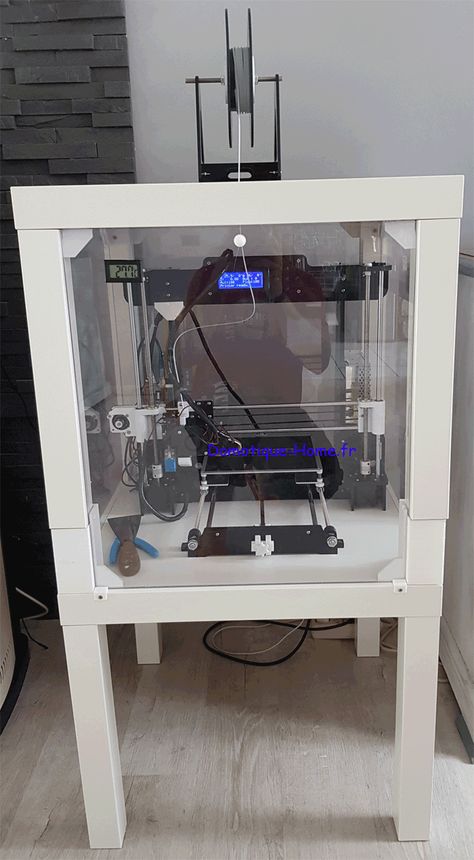

Foam Board IKEA LACK Enclosure

thingiverse

This thing consists of files to construct the legs and supports for creating an IKEA 3D Printer enclosure with foam board walls. Remix of: Tinker-Friendly LACK Enclosure by zuspiel

Fins to, increased the size of, the feet for the IKEA Lack...

Remix of: Tinker-Friendly LACK Enclosure by zuspiel

Fins to, increased the size of, the feet for the IKEA Lack...

Printer Enclosure

thingiverse

3D Printer enclosure ================ This is a universal 3d printer enclosure build from two IKEA Lack table. In the under table there are a filament storage for ten 1kg filament spools. In the upper table there are the 3d Printer. The filament...

Printer Enclosure

prusaprinters

3D Printer enclosure This is a universal 3d printer enclosure build from two IKEA Lack table. In the under table there are a filament storage for ten 1kg filament spools. In the upper table there are the 3d Printer. The filament run trougt the table...

In the upper table there are the 3d Printer. The filament run trougt the table...

Printer enclosure

thingiverse

... prochaine étape. Pour avoir une dépression assez forte avec les filtre j'ai installer les deux ventilateurs en extraction Prochaine étape filtres HEPA Print Settings Printer Brand: RepRap Printer: PRUSA I3 Rafts: No Supports: Yes Resolution: 0,3 mm

Printer enclosure

thingiverse

Edit it online https://www.tinkercad.com/things/gwAmGtOSeQM I used a 23,5mm diameter pvc frame for my printer enclosure. This part is the corner element for the frame. ...See https://www.thingiverse.com/thing:2919027 for base elements to screw the frame. ..

..

Printer enclosure

thingiverse

... to change. The current design is a mix of a thingy that I found and my own design. The deign I used is quite large but this allows for upgrading your printer to a bigger system without the need to rebuild an enclosure or enlarge the current one.

Printer Enclosure

thingiverse

This is a collection of stuff I designed for my 3D printer enclosure: - Obviously a filament roller support - a small pipe to allow the filament to go through the table (top) - A "Nuclear like" chimney use with a 120mm PC fan as an air extractor to...

Printer Enclosure

prusaprinters

This is a series of printed (PETG) parts that turn 4mm Marlon Corotherm (multi-wall polycarbonate - intended for clear insulated roofing and horticultural construction) into a 600x600x600 (internal) printer enclosure. Before you say it, I know, Prusa...

Before you say it, I know, Prusa...

Printer Enclosure

thingiverse

This is an idea i had for a cheap 3D printer enclosure an absolute necessity for printing ABS and prevent curling of PLA in winter. A 2 tier greenhouse. The top is not designed to be a shelf but as the side fittings are the same, can be used as a...

Printer Enclosure

prusaprinters

Enclosure BOM 4 MakerBeam XL 750mm https://www.amazon.com/gp/product/B06XJ3Q968/ref=oh\_aui\_search\_detailpage?ie=UTF8&psc=1 4 MakerBeam XL 500mm https://www.amazon.com/gp/product/B06XHQMM61/ref=oh\_aui\_search\_detailpage?ie=UTF8&psc=1 50...

Printer Enclosure

thingiverse

As a side benefit, the enclosure helps the printer maintain a more stable ambient temperature, and keeps dust off the printer. This design is a remix of DrewPetitclerc's terrific 3D printer enclosure. There are a few notable changes: Designed for...

This design is a remix of DrewPetitclerc's terrific 3D printer enclosure. There are a few notable changes: Designed for...

Foam Board Enclosure 5mm thick

thingiverse

... and dollar tree but im sure they can be purchased alot of other places. they are cheap at a dollar a sheet an once put together with the brackets if u use screws through the brackets to hold the foam they are alot stronger than i had expected.

Enclosure joint for foam board enclosure

thingiverse

As I am 13, I didn't have much to play around with so I went to Walmart and bought some foam boards because I figured if foam is used for insulation, wouldn't it be good enclosure material?(plus they were only like 3 bucks each) This joint will. ..

..

Runner holder clips for foam board

thingiverse

Made this to hold foam boards together to make a sprue/ runner holder

Foam Core Clips (5mm Poster Board)

prusaprinters

Attach 5mm foam core with these clips. ...We used them to create a large popcorn box that we can disassemble when we are done. Printed in eSUN PLA+ White.Layer Height: 0.2Infill: 40%Inspired by...

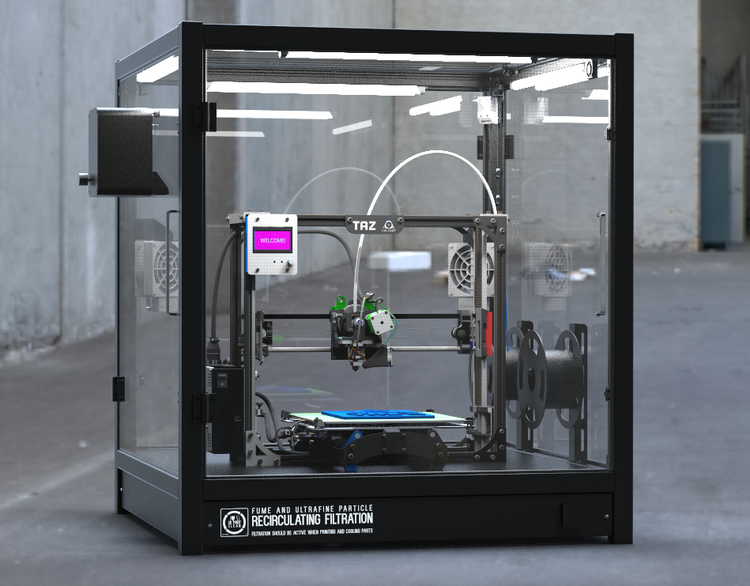

3D Printering: Why Aren’t Enclosures Easier?

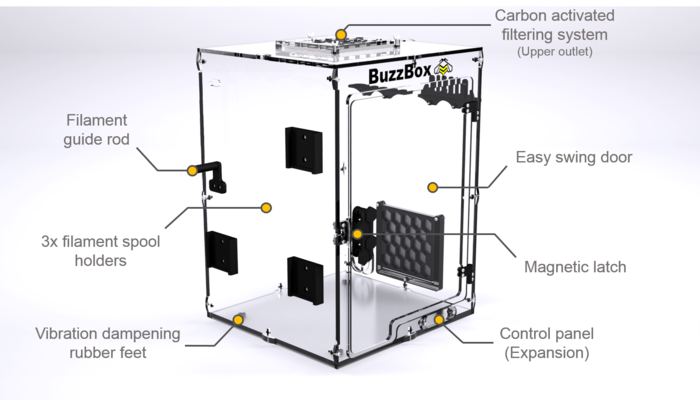

For 3D printers that aren’t already enclosed, why is easily adding a cheap and effective enclosure still not a completely solved problem? The reason is simple: unless one’s needs are very basic, enclosures are more than just boxes.

Different people need different features, printers come in different shapes and sizes, and creating something that can be both manufactured and shipped cheaply is a challenge in itself. In this article I’ll explain how those things make boxing up your printer a tougher nut to crack then may seem at first glance.

Enclosures Have Different Jobs

People have different expectations of what an enclosure’s job should be, and that determines which features are important to them and which are not. Here is a list of meaningful features for 3D printer enclosures; not everything on this list is important to everyone, but everything on this list is important to someone.

Improving Print Quality

An enclosure can provide a better printing environment by protecting against drafts and partially retaining heat, creating an environment with a temperature that is more stable than the room it occupies. While retaining too much heat can lead to its own issues, a stable and draft-free environment is a plus.

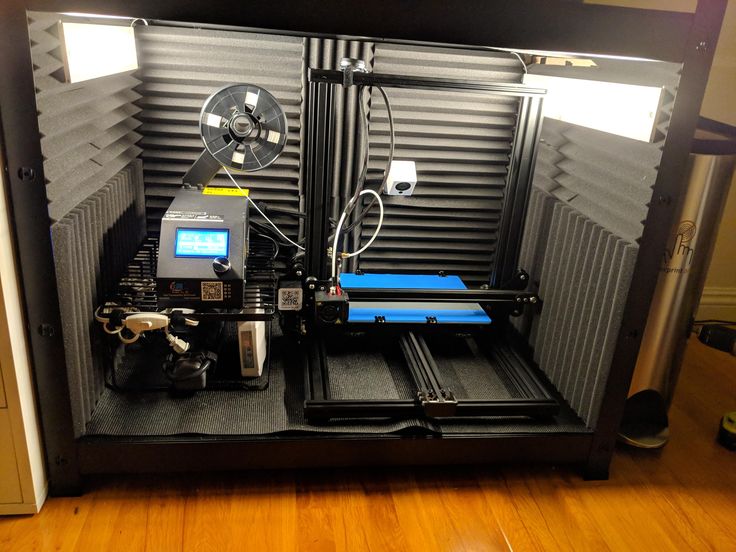

Reduction of Noise

Some printers are noisier than others, and not every printer has the luxury of chattering happily away on a workbench without disturbing anyone. Though it’s rarely the sole factor in noise control, an enclosure can help reduce noise in environments where it is an issue.

Protecting Moving Parts

In some environments, loose objects or curious fingers (or paws) are more common than others. An enclosure helps keep the moving parts of a printer safely away from anything that might interfere with, or damage, them.

Staying Clean

Enclosures help keep dust away, but can also perform functions like air filtering and can help with humidity control.

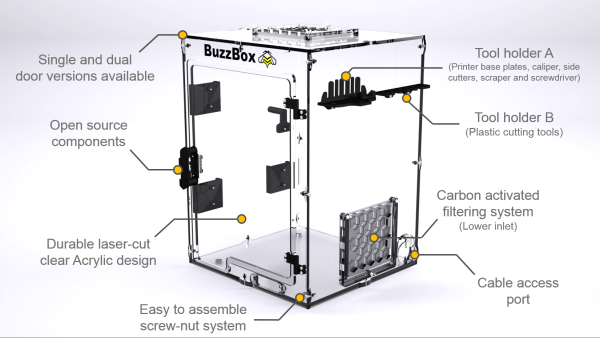

Device Mounting and Cable Management

Mounting and wiring for devices like a webcam, LED lighting, or a Raspberry Pi running OctoPrint becomes much easier and tidier with an appropriate enclosure.

Improved Storage

An enclosure that allows the machine to be more easily moved, or even stacked, can have a lot of value in a workshop where bench space is limited, or printing is only done occasionally. I’ve personally always aimed to have my printers enclosed, at a comfortable working height, and on wheeled bases so that they can be moved as needed.

I’ve personally always aimed to have my printers enclosed, at a comfortable working height, and on wheeled bases so that they can be moved as needed.

It is impractical to have an enclosure attempt to do everything, which means that features need to be chosen carefully to match needs. This is especially true if costs are to be kept to a minimum. However, a number of factors complicate this.

Complications Abound

Anyone can make a great enclosure if money and materials aren’t a factor. But if the goal is to implement a design both cheaply and effectively, the issues below make that more of a challenge.

- Fire resistance will rule out some materials, increasing costs. For example, if fire resistance is a priority then designs built around wood or cardboard cease to be an option.

- Durability usually comes with expense, either because durable materials cost more, or because durable materials are simply more difficult to work with.

Both increase production costs.

- Costs rapidly add up for common materials like aluminum extrusions and acrylic sheets, when used in quantities necessary to enclose a printer. The size and weight of these components also makes them more expensive to ship.

- Enclosures need windows and doors of some kind so one can see what’s going on, as well as have easy access for print removal, filament loading and unloading, and maintenance. Adding windows and doors always complicates a design.

- One size absolutely does not fit all. Printer size and shape — as well as related issues like filament feed location and direction — are not standardized, but have a big impact on enclosure design.

Doing

Everything Isn’t PracticalCreality’s soft-shell enclosure hits an attractive price point, but only serves some needs.Accommodating every need while still being both economical and effective is impractical, and also probably impossible. Therefore, enclosure designs need to pick and choose their features, with the result being that not everything works for everyone. This goes a long way toward explaining the seemingly endless variety of design solutions that greet people who look online for printer enclosures.

Therefore, enclosure designs need to pick and choose their features, with the result being that not everything works for everyone. This goes a long way toward explaining the seemingly endless variety of design solutions that greet people who look online for printer enclosures.

Aside from DIY solutions, there have been efforts to create enclosures that can be offered as products. Here are a few of the very different approaches organizations have taken to try to make enclosures easier:

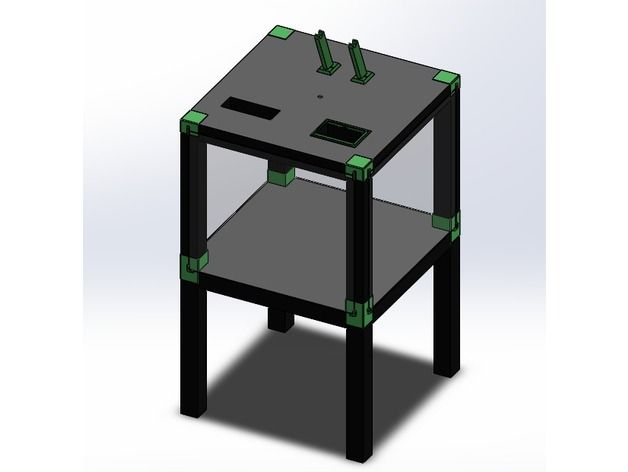

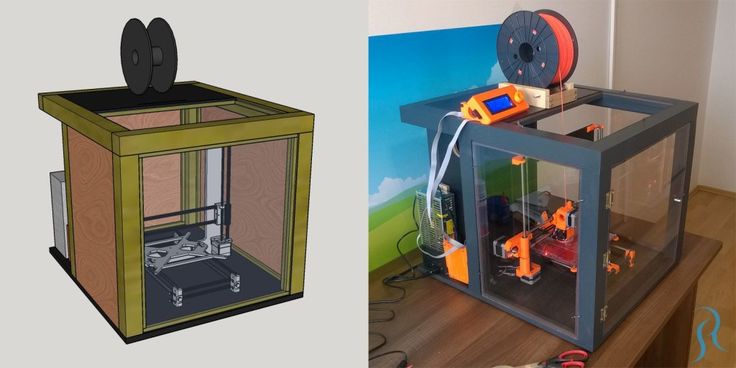

- Prusa Research has a DIY option with a few variations. In this blog post discussing their first version, Prusa revealed that they had designed an enclosure, but couldn’t get the price low enough after considering cost of materials, shipping, and packing. They instead opted to release a DIY design that relies on people using locally-sourced materials, based mainly around the IKEA LACK table, acrylic panels, and 3D-printed parts.

- Creality is offering a “soft” enclosure option that is sized for specific printer models.

They look similar to grow tents for plants, providing some useful features at a sub-$100 price point.

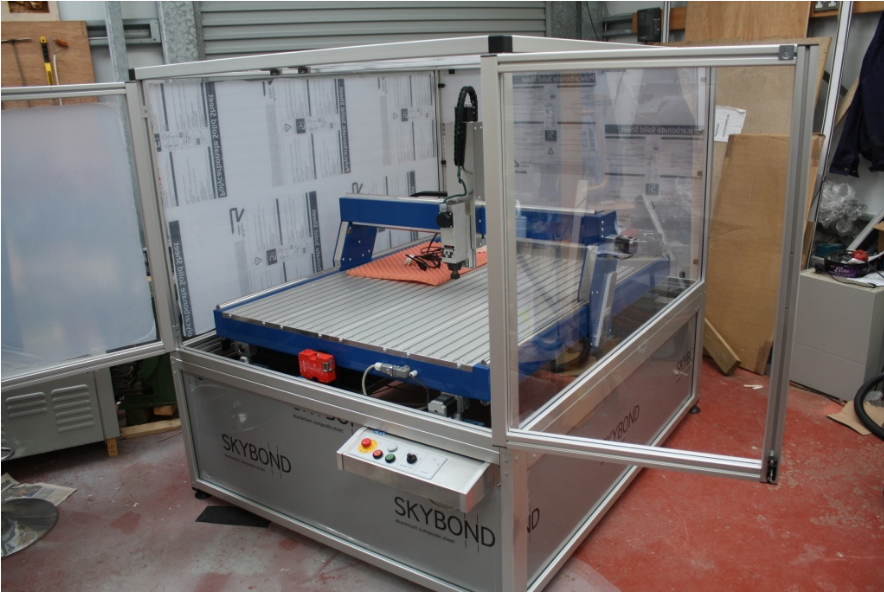

They look similar to grow tents for plants, providing some useful features at a sub-$100 price point. - OpenBuilds offers a modular enclosure system which is solid, durable, and configurable. It comes at a price, however, and panels are not included.

Even DIY Enclosures Can Get Expensive Easily

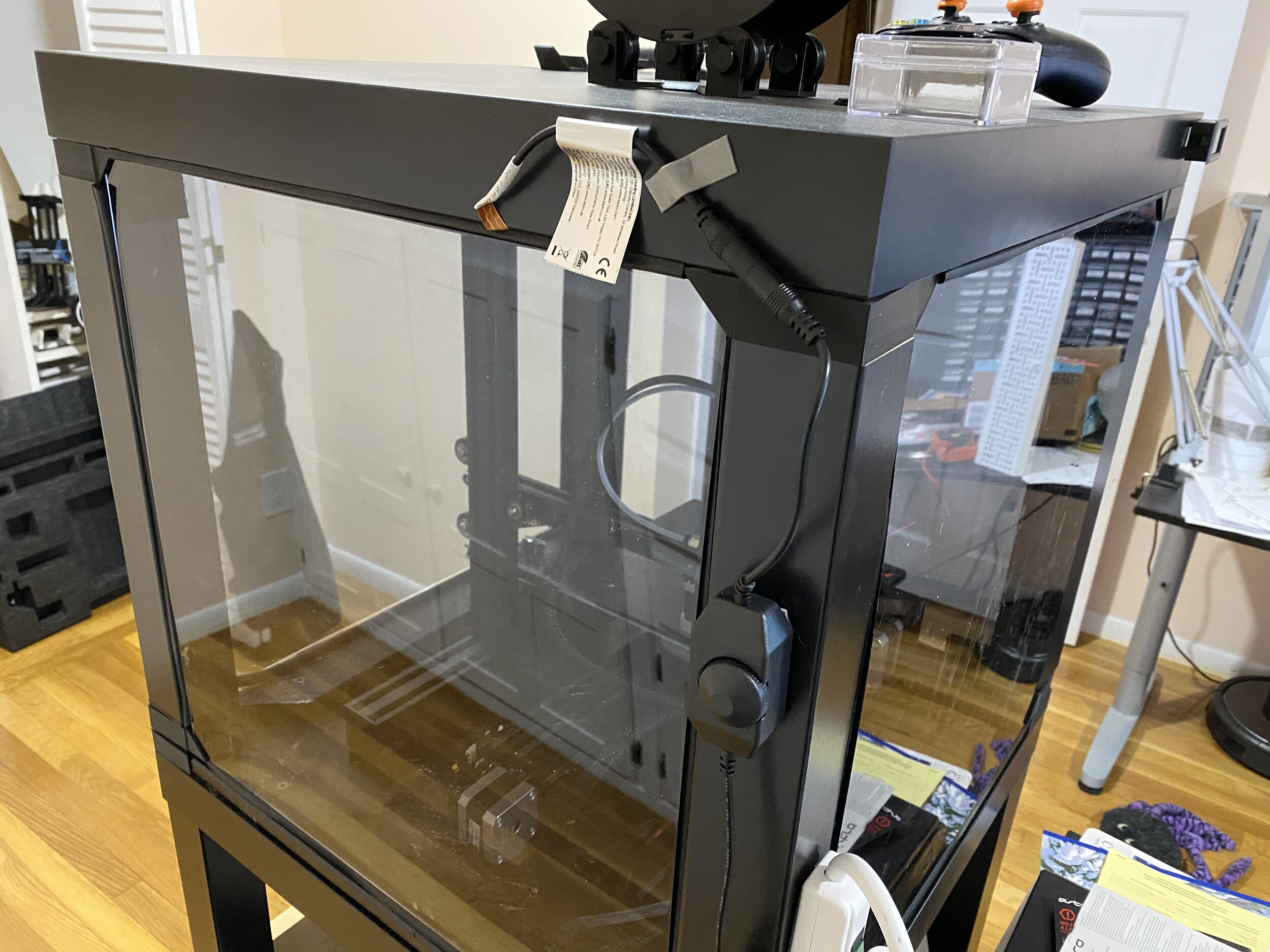

The Prusa Printer Enclosure V2 uses readily-available materials.I want to share a quick word on costs. I discovered first hand how quickly and easily enclosures can get expensive when I built my own Prusa Printer Enclosure V2.

I used locally-sourced materials whenever possible, but it was surprisingly expensive by the time I was finished. I needed two LACK tables, three spools of PETG filament (for over 2 kg worth of printed parts), an acrylic sheet from a local supplier (which they cut into the panels needed at a reasonable price), plus the cost of other hardware like magnets and screws.

According to my spreadsheet, I easily spent over $200 USD on materials alone, and that amount doesn’t even include additional parts I added like fire alarm, caster wheels, and LED lighting. It would have been even more expensive if had I needed to pay shipping on parts instead of picking them up locally.

It would have been even more expensive if had I needed to pay shipping on parts instead of picking them up locally.

Designs Must Pick and Choose

A collapsible photo tent can cheaply meet some basic needs. (Photo: Prusa Research)Unless using a pop-up photo tent as an enclosure will satisfy all of one’s needs, an effective solution that can be manufactured and shipped cheaply remains a considerable challenge. Enclosures aren’t just boxes, and different people have different needs.

Until someone comes up with something very clever, a cheap and effective drop-in solution will remain something plenty of people search for, but few find a satisfying solution to. Still, hackers being hackers, there is no lack of solving one’s own problems when it comes to printer enclosures.

Do you have a favorite solution, or clever idea that would make enclosures easier? We’re sure you do, so let us hear all about it in the comments.

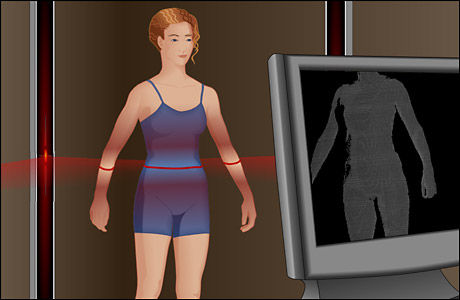

High-quality foam and plastic figures in Sprint 3D!

We live in a time when advertising drives progress, the economy and even the social sphere. The number of various advertising media is simply huge. Some of them are more effective, others are less. We want to draw your attention to one of the types of advertising (and not only). Our theme is figures made of foam and plastic.

plastic and polystyrene life figures can serve as both advertising and decoration. They can be used almost everywhere: on the street, in shopping and entertainment centers, exhibition areas, cafes and restaurants, in landscape gardening areas, etc. Even in office or residential premises, they will find a place as part of the interior. nine0005

In our company you can order turnkey production of life figures - from the development of a three-dimensional model to the actual production. We offer a look at what it is, what is the difference between plastic and foam figures, and why their use is relevant right now.

3D body figures in Sprint 3D

Our figures are more durable than concrete figures and withstand extreme temperatures

Any sizes of figures

Coordination of 3D-model before execution

Execution of realistic figures of any complexity

Professional painting (full color, monochrome, metal effect)

High speed of execution throughout Russia and

CIS countries

Styrofoam figures: light, durable and inexpensive

Styrofoam has been used for more than a decade to create various decorative elements and original advertising. Light weight, ease of shaping the desired shape by milling, low cost - only a small part of the advantages of foam as a production material. nine0005

Styrofoam can be used to produce products of almost any shape and size. And thanks to the metal frame and a special anti-vandal fiberglass coating, they are characterized by very high strength with low weight.

We can make almost anything for you:

- figures of people, animals, game characters, movie and cartoon characters in almost photographic quality;

- whole compositions of figures and elements of any complexity and size; nine0058

- other items and objects having an advertising or decorative function.

Just contact us and let us know which shapes you need. We will develop a unique 3D model for you, approve it together with you, after which we will make a figure based on it by milling. We paint and process all products ourselves so that they get a complete look.

Right now, custom-made foam plastic figures made by us are used in the promotion of goods and services, as decoration, as unusual elements of photo zones, etc.

Plastic figures: maximum strength and durability

If you plan to actively use advertising figures, transport them regularly or place them for a long time in areas where they will be exposed to aggressive external influences, your choice is plastic. Yes, these pieces will be heavier than foam pieces , but they are even more durable. Sun, rain, cold, sun - they don't care. Although we emphasize that thanks to the anti-vandal coating, our foam figures are almost in no way inferior to plastic ones.

One of the main differences between foam and plastic figures is in the production method. The process is almost identical except for the manufacturing method itself:

- Preparing a 3D model.

- 3D printed product.

- Processing and painting, giving the figure a complete look.

- Vandal-resistant coating of the entire product for increased durability. nine0058

As in the case of foam plastic, thanks to 3D printing technology, plastic opens up the widest possibilities for creating unique shapes: people, animals, geometric elements of any complexity, product layouts and much more. There are practically no restrictions.

There are practically no restrictions.

Buy life figures in our company and get maximum benefits

Our main advantages are price and quality. Thanks to the full production cycle, we provide customers with a truly individual approach, standardized quality of all products and fair prices without markups. nine0005

Working with us, you get:

- unique products that fully meet your wishes;

- the ability to use your own layouts, sketches and other developments;

- clear pricing without involving third parties in the production process;

- quick calculation of the cost without its subsequent unforeseen increase;

- strict adherence to the deadlines for the manufacture of plastic and foam figures without "force majeure". nine0058

Our offer will interest everyone who works in advertising, product and brand promotion, decoration, landscape design and so on. Even if you just decide to decorate your own house, cottage or garden with original products that will last more than 20 years and will please the eye, please contact us. Let's discuss all the details and start manufacturing.

Let's discuss all the details and start manufacturing.

If you still have questions, you do not know what to choose - plastic or foam, or just want to get a preliminary consultation from a specialist, please contact us during business hours in any way convenient for you. nine0005

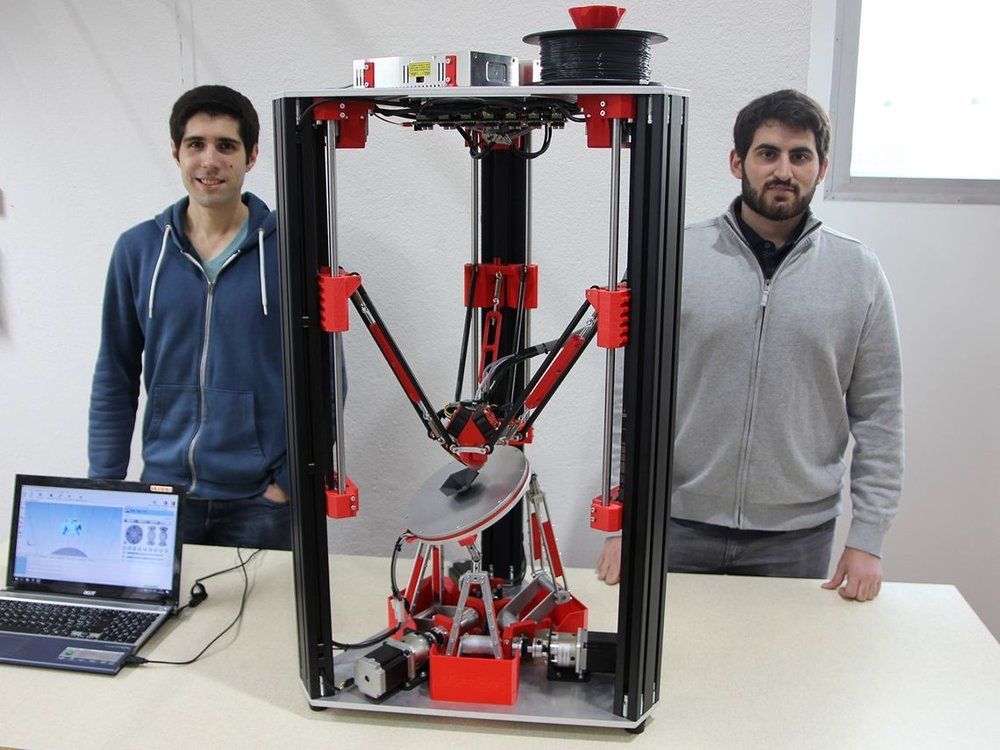

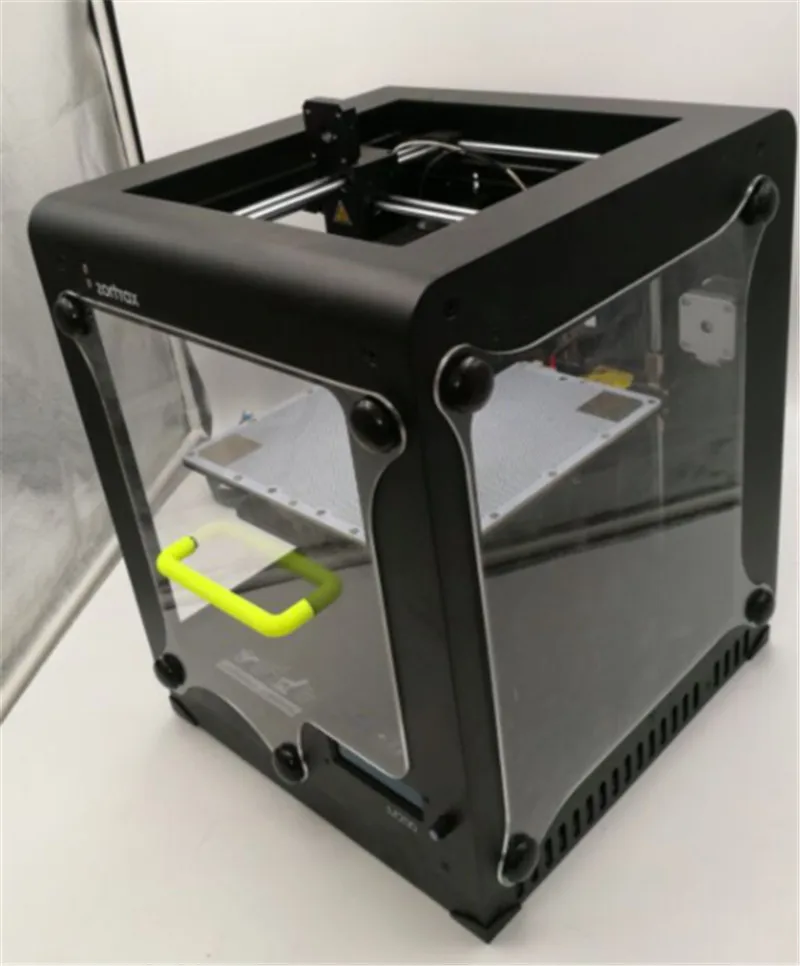

Raise3D N1 Dual 3D printer review by REC

Hello everyone! Meet the review of the Raise 3D N1 Dual 3D printer.

This is an amazing dual extruder 3D printer from China.

General information

Packaging and contents

The printer is packed really well. Large pieces of foam that securely protect the printer. nine0139 The package includes an excellent instruction, two branded holders for coils, a power cable, a USB flash drive, two plastic coils, a set of hexagons, and a couple of pleasant little things.

Appearance and technical details

The printer has a very aesthetic, durable and rigid body.

The dashboard and connectors are conveniently located for the user.

Touch display with a clear and stylish design. For beginners in 3D printing, this solution will be extremely convenient. nine0005

It displays the process and print settings, impressive.

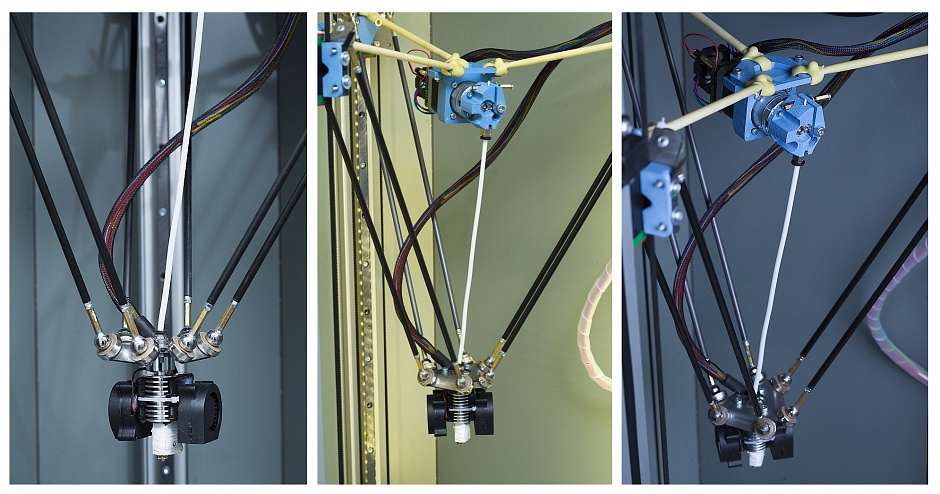

Two parallel extruders - many people say this scheme is “dead” and, as a rule, does not work. Let's check.

Let's check.

The print head is somewhat similar to the Ultimaker head, with one exception, the push mechanism is on it, in addition, it has a “straightener” for the bar. This creates a more confident and accurate feed of the bar into the hot end by reducing the stress on the filament due to bending. nine0139 The first impression of the motors heaped on the head is not a good idea.

As for the kinematics, this Cartesian scheme is well done and again copies Ultimaker. A lot of good components and custom parts made of metal and molded plastic.

As for the table itself, it is located on shafts and ball screws of sufficient thickness. Doesn't wobble or bend.

The table is adjustable with four bolts - not very cool, but a classic. nine0005

Software

The program is called IdeaMaker - it comes with the printer or is downloaded from the manufacturer's website.

It's a bit more complex than Cura in terms of interface, but it's easy to understand.

Very pleased with the ability to quickly and conveniently visualize the printing process.

If necessary, you can use another slicer and fill in the g-code in the ideal maker, but we have not tested this functionality.

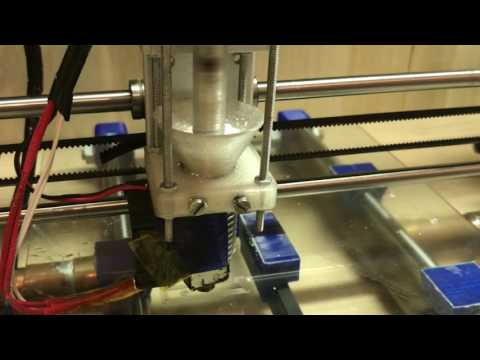

REC ABS and RELAX

This is the very first attempts to print on this device

layer 0.15 mm

REP PLA

OPA

REC ABS and Rec PLA

REC FLEX

Exceeded expectations with Flexom, layer height 0.15 mm

REC ABS + REC HIPS

Print time 16 hours. layer 0.15 mm.

layer 0.15 mm.

As you can see from the photos, the printer prints very confidently and with high quality with a large amount of materials. Unfortunately, REC RUBBER is not one of them - for this extruder, the rod turns out to be too soft and we did not succeed in correctly setting up the print to obtain a stable result.

As for the calibration of the nozzles - on this printer it is quite simple (for this there is only one bolt that corresponds to the height of each nozzle from each other) compared to other printers with a similar layout of extruders. nine0139 Just park the printer to zero, unscrew the screw holding the right nozzle, and when it comes out and touches the table, we twist it back.

We have identified one printing issue, which we will discuss below.

Pros

- Two extruders with filament guide, can print many different filaments

- Large table with good Z-axis

- Stylish Rigid Chassis

- Incredibly cool progress display

- Lots of usb connectors

- Good and convenient software

- Very noob friendly printer

- Reliable packaging, kit and instructions

- Built-in battery and memory, when the power is turned off, the printer will remember where it finished printing.

When the power comes back on, the device will continue to print as if there was no interruption.

When the power comes back on, the device will continue to print as if there was no interruption. - The printer is quite quiet, as it is assembled on meringue good components. nine0058

- It is possible to connect via the Internet and search for models

Cons

- The printer is a little less stable in its result than we would like, quite often when printing, the extruder motors on the print head heat up so much that they soften the bar. Thus, it ceases to be pushed into the hotend and the printing process ceases to be carried out correctly. This happens more often with PLA plastic than with ABS and PET-g, but it happens with them too. Additional cooling of the extruder motors is necessary, as they heat up to 60-70 degrees, and sometimes more. nine0058

- Flash drives stick out very strongly, it is easy to hurt - break the port and break the seal

- There is a small bug with displaying the printing process on the monitor, if there is a column for cleaning nozzles, the model progress is not shown or very late, the failure does not always occur and it has not been proven that this is not a problem of our instance.

- Comparably slow print speed due to a heavy print head, although the printer is not slow. nine0056 Poor airflow for the part, with PLA plastic, when printing small models at low speed, the PLA flows around.

- The power wires to the extruder itself fly out of the fasteners despite the nice corrugation, not critical but unpleasant.

- The unevenness of the magnetic pressure on the print chamber door is a little annoying, of course, this is nit-picking, but considering how often you have to deal with the door, you pay attention to it.

Conclusion

China's Raise 3D N1 Dual can be called a new generation 3D printer because it sets the bar: “high-quality touch display, closed housing, two extruders, print auto-restart, user-friendly software.” At the same time, technically, the printer is a set of well-executed and well-proven technical solutions - the simplest system of two nozzles, a kind of bowden and direct extruder synthesis, kinematics from Ultimaker.