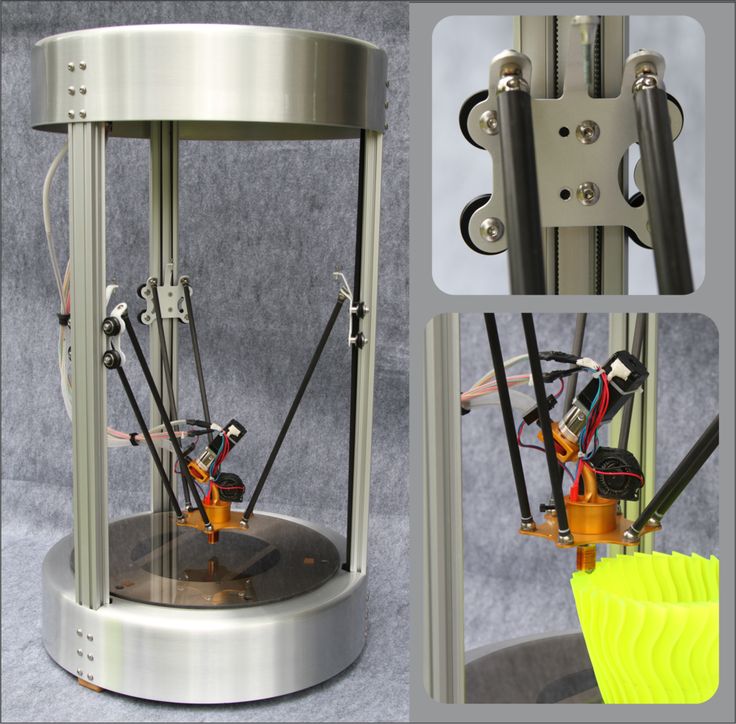

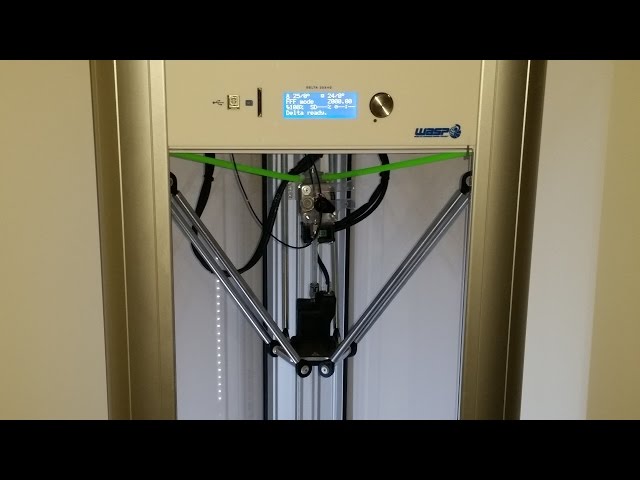

Delta wasp 3d printer

Delta Wasp 2040 Turbo Problems - 3D Printers - Talk Manufacturing

Beostigma

#1

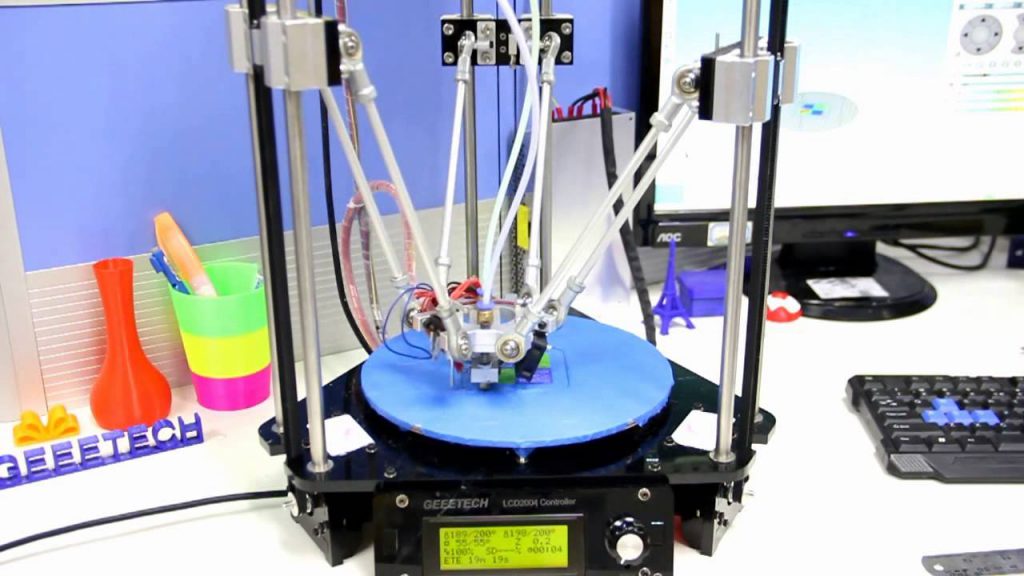

Hey guys first time writing here. I own a Delta Wasp 2040 Turbo and have two issues with it.

The first one is something that started happening recently. When I save gcode from Cura (that is configured for delta) and try to start print on my Delta the head starts lowering towards the build plate and then starts moving right where it stops and the error message shows up on the display bottom saying “Out Of Plate”. I am not sure how to solve this one. The print is normal size and nothing that goes out of the borders.

The second problem is something I had from the beggining with Delta. The print starts and finishes fine but then the head moves to its “Home” and then it just falls on top of my finished print burning the point it touches with the nozzle. It is if the breaks are not working and the head just crashes on the finished print. Same thing happens if I set the head to go to “home” position and then turn the printer off, the head just falls down on the plate.

I hope someone can help me with these problems or provide link to similar posts. Since I couldnt find any.

Thanks in advance

tpalagyi

#2

Hi,

Can you please share your Cura start and end g-code there must be the problem.

Its sounds strange that the head falls down after the motors are powered off (M84 command at your cura end code). Do you have your belts tightened enough. Maybe a video can be useful from this event if you have time for it.

Tamas

Beostigma

#3

.

Beostigma

#4

I solved the first “Out of Plate” error when I switched from Cura to Slic3r since the new cura abviously doesnt support the circular plate. I dont know if anyone found how to solve it, but for now Ill stick with slic3r for my Delta.

Ok I will try to record the event when the head falls. It really is a mess since I have to be around everytime the print will finish, if Im not, the head falls with fully heated nozzle and melts the finished print. The head goes on home position and than it stays there for a while and then starts slowly fallling. It does the same thing with Slic3r softwere.

Thanks

tpalagyi

#5

Hi,

Yes the new Cura is a PITA, still using 15. 04.6 for my Deltas.

04.6 for my Deltas.

Maybe it will be a good a idea to move the head to a different place after print finished.

So as the print completed the printer will perform a home (G28) than move the head to the Z tower where it can freely fall not ruining the print.

You can put this into your end code in your slicer.

Let me know if you need assistance to make this work.

Br.,

T:

PicoTurbine

#6

Hello, make sure you are using Cura 15.05.6 (not the new/Beta 2.0). In Cura go to: Machine>Machine Settings (make sure you have the 2040 selected)> Build Area Shape>Circular.

To prevent the head crashing down, do the following in Cura:

Start/End G-code>end.gcode>Delete line M84 (and close the gap)

G28 X0 Y0 ;move X/Y to min endstops, so the head is out of the way

M84 ;steppers off

G90 ;absolute positioning

G28 X0 Y0 ;move X/Y to min endstops , so the head is out of the way

G90 ;absolute positioning

Beostigma

#7

Sorry for the late respond. This worked. Thanks a lot

This worked. Thanks a lot

1 Like

User_2246

#8

s

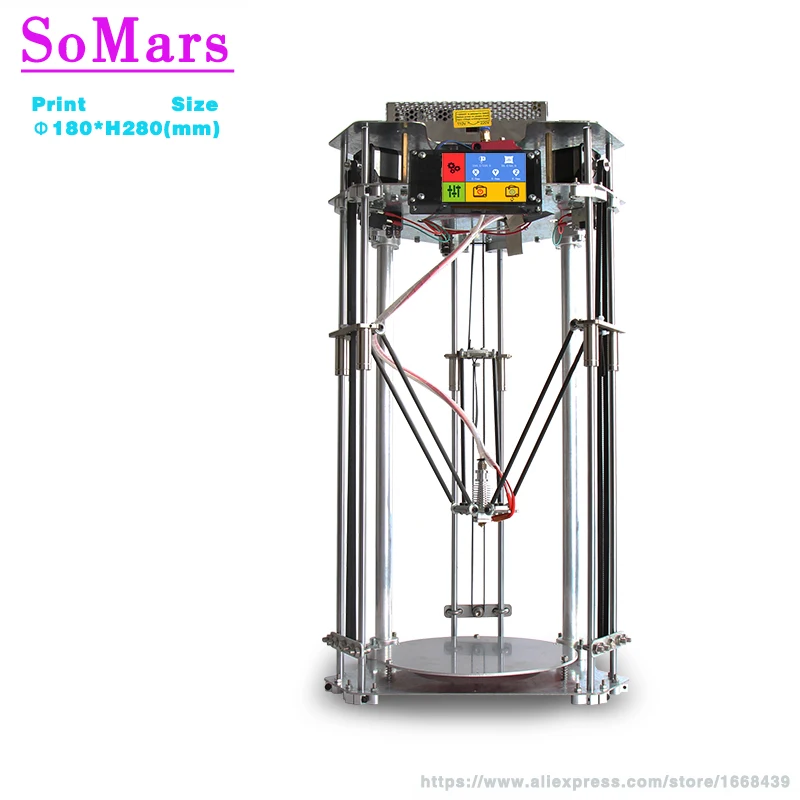

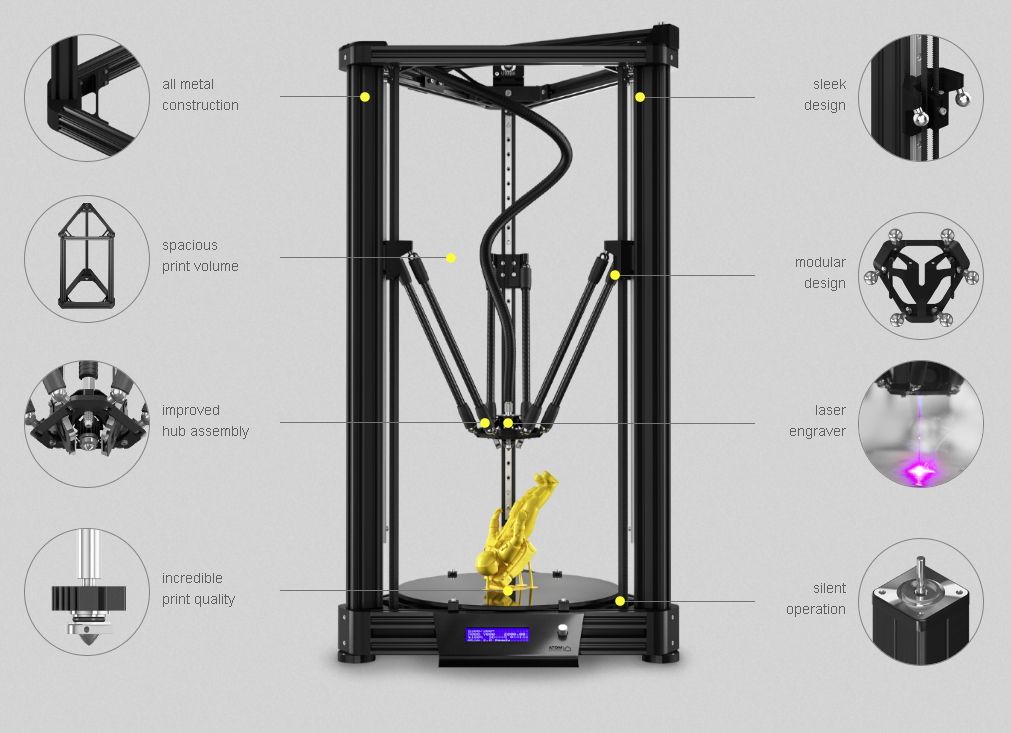

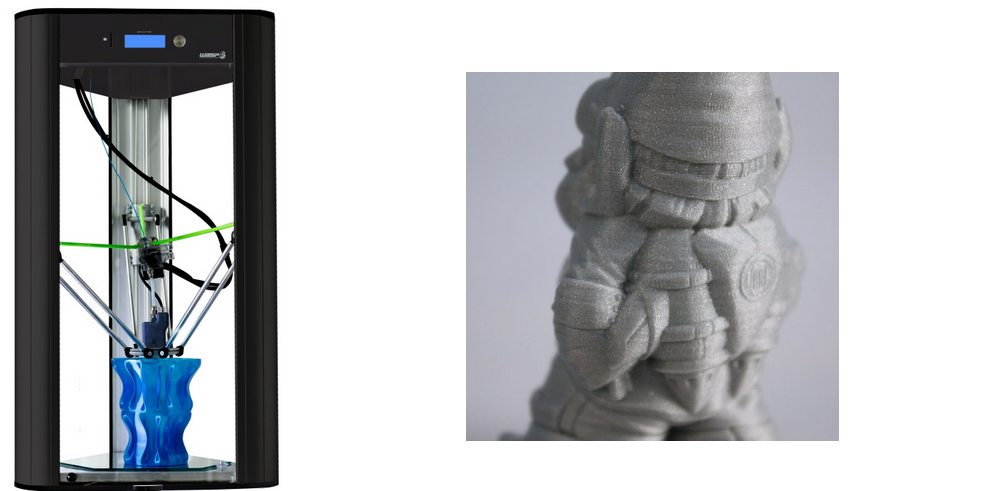

Delta WASP 2040 Hybrid 3D Printer – Oz Robotics

$4,500.00

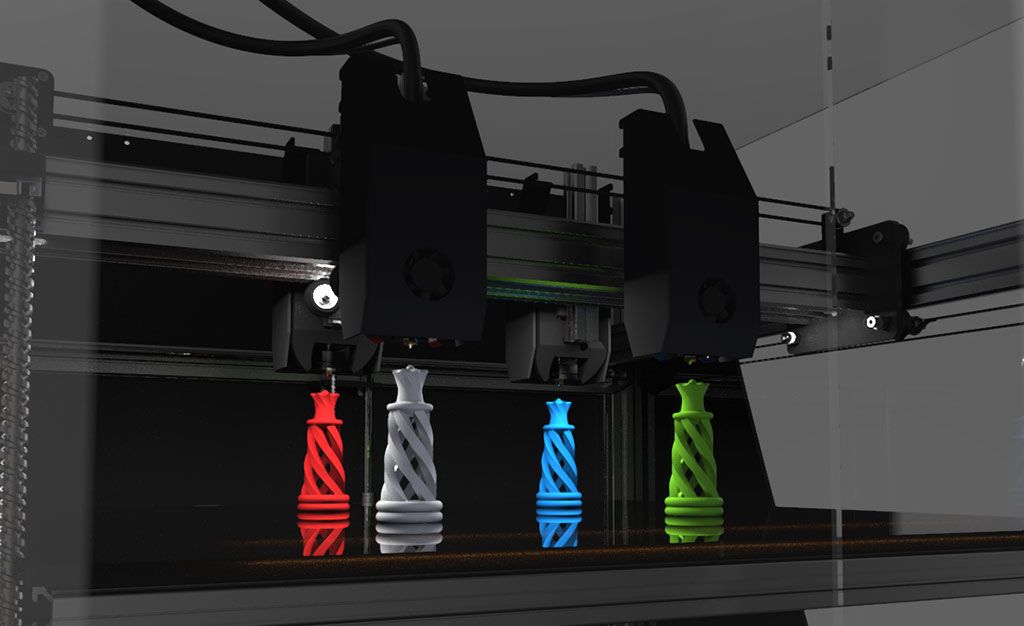

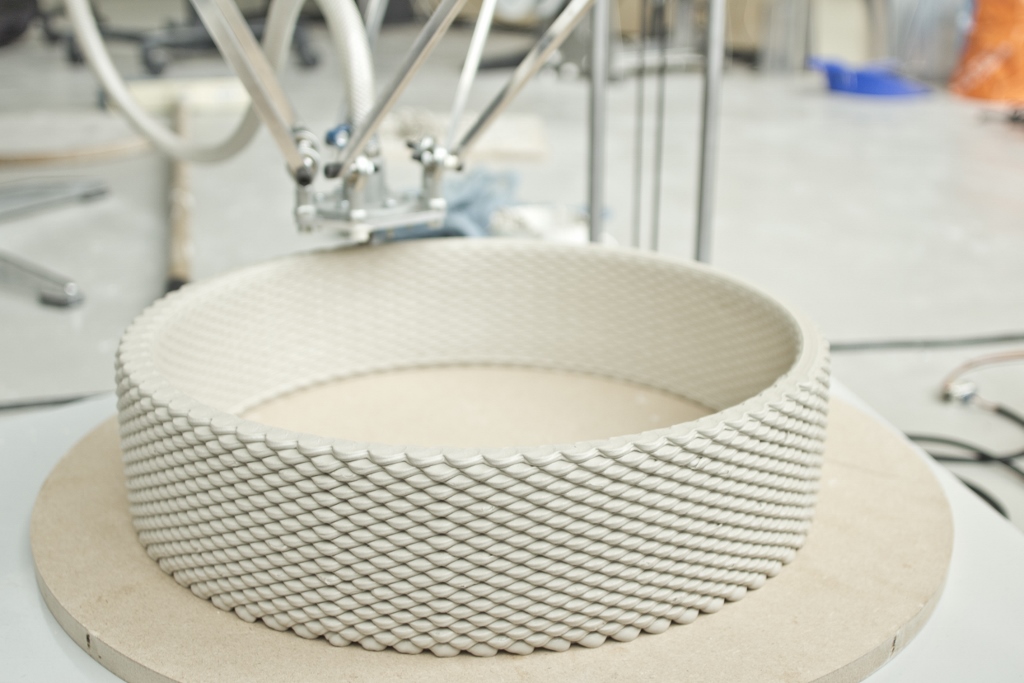

Accurate and reliable with all materials, WASP’s Suspended Bowden driver for Spitfire Extruder makes printing faster and minimizes the weight of the mobile crew. Easily switch to your LDM (liquid deposition modeling) Extruder for printing ceramic materials! Resurrection and Free Zeta System allow you to continue your print from its last location should your printer lose power. Extend your warranty and add a support package for training, design/slicing consultation, and more.

Delta WASP 2040 Hybrid 3D Printer quantity

Add to My Wishlist

Made In: United States (US)

Brand: PicoSolutions SKU: WU-9033-0 Category: 3D Printers Tags: Hybrid 3D Printer, WASP 3d printer More From: PicoSolutions Group

- Description

- Specifications

- Reviews (0)

- Manuals

- Supplier

- Policies

- Shipping

- Ask a Question

- Sell on Oz Robotics

- Become An Affiliate

Delta WASP 2040 Hybrid 3D Printer

Accurate and reliable with all materials, WASP’s Suspended Bowden driver for Spitfire Extruder makes printing faster and minimizes the weight of the mobile crew. Easily switch to your LDM (liquid deposition modeling) Extruder for printing ceramic materials! Resurrection and Free Zeta System allow you to continue your print from its last location should your printer lose power. Extend your warranty and add a support package for training, design/slicing consultation, and more.

Easily switch to your LDM (liquid deposition modeling) Extruder for printing ceramic materials! Resurrection and Free Zeta System allow you to continue your print from its last location should your printer lose power. Extend your warranty and add a support package for training, design/slicing consultation, and more.

Click here to see Delta WASP 2040 Hybrid 3D Printer Features and Technical Content.

Additional information

| Weight | 110 lbs |

|---|---|

| Dimensions | 21 × 23 × 54 in |

Product Manuals

If applicable, the Product Documentation, Brochure, Reference Materials, CAD design(s),.STEP file(s) and other drawing files, Manuals, and Tutorials will be available for download upon purchase. In addition, the order confirmation email will include a downloadable link to the product file(s), which can also be downloaded from the My Account section if needed.

Shipping Policy

WE SHIP WORLDWIDE: We primarily ship via FedEx, UPS, DHL, EMS, TNT, and USPS because they are fast, reliable, and easily trackable. We usually ship within two to three business days after the full payment. Standard delivery generally occurs within 5 to 7 business days after the shipping date. However, sometimes delivery may take about 7 to 10 business days, depending on the shipping destination, logistics mode, weather conditions, product weight, size, or shipping company distribution structures based on re-planning, such as staff shortages caused by COVID.

SHIPPING COSTS:

For some industrial products, e.g., heavy wheels, CNC machines, etc., the shipping cost is calculated based on the product weight, not quantity. To benefit from lower shipping costs for orders with multiple items, don't hesitate to contact us at [email protected]. Our shipping rates are listed very clearly on each product page under the SHIPPING tab. Additionally, to see the shipping cost for your country, add the item to the Shopping Cart; you will see the shipping cost based on your Country and Location.

CUSTOMS and TARIFFS: While not all products require a tariff, some products may require a minimal tariff if applicable in your country for orders of $800.

We usually ship within two to three business days after the full payment. Standard delivery generally occurs within 5 to 7 business days after the shipping date. However, sometimes delivery may take about 7 to 10 business days, depending on the shipping destination, logistics mode, weather conditions, product weight, size, or shipping company distribution structures based on re-planning, such as staff shortages caused by COVID.

SHIPPING COSTS:

For some industrial products, e.g., heavy wheels, CNC machines, etc., the shipping cost is calculated based on the product weight, not quantity. To benefit from lower shipping costs for orders with multiple items, don't hesitate to contact us at [email protected]. Our shipping rates are listed very clearly on each product page under the SHIPPING tab. Additionally, to see the shipping cost for your country, add the item to the Shopping Cart; you will see the shipping cost based on your Country and Location.

CUSTOMS and TARIFFS: While not all products require a tariff, some products may require a minimal tariff if applicable in your country for orders of $800. 00 and above. The total amount for your order does not include a customs fee/tariff. A tariff belongs to the buyer when applicable. Why don't we add tariffs to the product's retail price? - If all countries deducted the same tariff amount, we would have added the tariff amount to the product price. However, we do not do that because each country charges a different amount, while some do not even charge. Therefore we can't add any tariff to the product's retail pricing. Oz Robotics, Manufacturing Partner, or Supplier are not responsible for tariffs. Please check the "Made In" and "Made By" labels on the product page to see the product's origin. The total amount for your order does not include any duties, import taxes, customs fees, and GST/VAT. The buyer must pay all import duties. Please click here to see more on Tariffs.

00 and above. The total amount for your order does not include a customs fee/tariff. A tariff belongs to the buyer when applicable. Why don't we add tariffs to the product's retail price? - If all countries deducted the same tariff amount, we would have added the tariff amount to the product price. However, we do not do that because each country charges a different amount, while some do not even charge. Therefore we can't add any tariff to the product's retail pricing. Oz Robotics, Manufacturing Partner, or Supplier are not responsible for tariffs. Please check the "Made In" and "Made By" labels on the product page to see the product's origin. The total amount for your order does not include any duties, import taxes, customs fees, and GST/VAT. The buyer must pay all import duties. Please click here to see more on Tariffs.

Return Policy

COVID: We are suspending product returns due to the current COVID-19 pandemic unless there is a manufacturing defect. Please study the product and ask us questions before you buy. Thank you.

ORDER CANCELLATION: After you place an order, you have 5 hours to request an order cancellation. After 5 hours, your item(s) have either already been shipped, prepared to ship, or are currently being custom-made. It means we will not process your cancellation request after this period has passed. By placing your order, you signify that you agree to be bound by our Order Cancellation Policy.

PAYPAL and STRIPE SERVICE FEES: Please note both PayPal and Stripe do not offer a refund for the service fees they charge when you purchase a product. Therefore, after placing an order, if you change your mind and ask for a refund, we will deduct the service fee for PayPal or Stripe, whichever one you used to purchase. If you have any questions about this, please contact PayPal or Stripe.

EXCHANGE POLICY: Oz Robotics wants you to be happy with your new purchase. However, we abide by the exchange policy of our suppliers because we do not manufacture these products; our suppliers do.

Thank you.

ORDER CANCELLATION: After you place an order, you have 5 hours to request an order cancellation. After 5 hours, your item(s) have either already been shipped, prepared to ship, or are currently being custom-made. It means we will not process your cancellation request after this period has passed. By placing your order, you signify that you agree to be bound by our Order Cancellation Policy.

PAYPAL and STRIPE SERVICE FEES: Please note both PayPal and Stripe do not offer a refund for the service fees they charge when you purchase a product. Therefore, after placing an order, if you change your mind and ask for a refund, we will deduct the service fee for PayPal or Stripe, whichever one you used to purchase. If you have any questions about this, please contact PayPal or Stripe.

EXCHANGE POLICY: Oz Robotics wants you to be happy with your new purchase. However, we abide by the exchange policy of our suppliers because we do not manufacture these products; our suppliers do. Once you used the product, our supplier(s) and we have the right not to issue a refund. Still, we will offer an exchange for the wrongly purchased items or products with serious and irreversible defects or technical problem(s). The buyer will pay the shipping fee for wrongly purchased products or any other similar issues. If the product you purchased is defective, please email us at [email protected] with some photos or a video of the defective parts to evaluate before you send it. Click HERE for more on Refund and Replacement Policy

REFUND POLICY: Oz Robotics accepts refunds on a minimal basis unless there is a manufacturing defect. For any electronic items, returns are only accepted on devices with serious and irreversible problems; meanwhile, the customer must apply for the returns within seven days from the delivery date. Before a refund acceptance, please include images or a video and any other material proof of the defect. However, we abide by the exchange policy of our suppliers because we do not manufacture these products; our suppliers do.

Once you used the product, our supplier(s) and we have the right not to issue a refund. Still, we will offer an exchange for the wrongly purchased items or products with serious and irreversible defects or technical problem(s). The buyer will pay the shipping fee for wrongly purchased products or any other similar issues. If the product you purchased is defective, please email us at [email protected] with some photos or a video of the defective parts to evaluate before you send it. Click HERE for more on Refund and Replacement Policy

REFUND POLICY: Oz Robotics accepts refunds on a minimal basis unless there is a manufacturing defect. For any electronic items, returns are only accepted on devices with serious and irreversible problems; meanwhile, the customer must apply for the returns within seven days from the delivery date. Before a refund acceptance, please include images or a video and any other material proof of the defect. However, we abide by the exchange policy of our suppliers because we do not manufacture these products; our suppliers do. For more info on Refund and Replacement Policy please visit Refund and Replacement Policy.

Other than our supplier’s default policy, once a return is agreed upon, you can ship your defective item to the provided return address that you should receive from us first. Please ship the order in original packaging with all the accessories and additional parts. If the Required Parts are not sent back, they will be billed for or expected to be shipped at a later stage. And only once all items have arrived will our staff check the returned product for testing. Include in your package a signed letter stating the reason for your return and the original receipt as well as any mentioned proof of defect, images, or a video, etc. It will help us to speed up the process on your behalf.

The purchaser (customer/buyer) is responsible for all shipping costs when returning an item. However, upon receiving the returned order, we will assess the product. If it is determined that there is, in fact, a manufacturing defect, then we will refund the shipping costs as well as repair or replace or refund the full amount to the purchaser if the product is not fixable.

For more info on Refund and Replacement Policy please visit Refund and Replacement Policy.

Other than our supplier’s default policy, once a return is agreed upon, you can ship your defective item to the provided return address that you should receive from us first. Please ship the order in original packaging with all the accessories and additional parts. If the Required Parts are not sent back, they will be billed for or expected to be shipped at a later stage. And only once all items have arrived will our staff check the returned product for testing. Include in your package a signed letter stating the reason for your return and the original receipt as well as any mentioned proof of defect, images, or a video, etc. It will help us to speed up the process on your behalf.

The purchaser (customer/buyer) is responsible for all shipping costs when returning an item. However, upon receiving the returned order, we will assess the product. If it is determined that there is, in fact, a manufacturing defect, then we will refund the shipping costs as well as repair or replace or refund the full amount to the purchaser if the product is not fixable. If you wish to return an unused product, please do so within seven days from the ship date for a refund on the purchase price, minus shipping, handling. Refunds will be credited to the original credit card used for payment in 24-48 HOURS after receiving the product back. We will charge 50% restocking fee.

Once your return is received and inspected, and if agreed for a refund, refunds will be credited to the original credit card used for payment in 24-48 hours. Please note that we will charge a 50% restocking fee once you return a product without any defect.

Once your refund is processed, PayPal will return the money to the card used. It may take at least five business days (depending on the bank and credit company) before your refund is posted in your bank account and statements. Contact Us if you still have not received your refund after 5 business days.

Do not return your product to our New York office. For any exchange or refunds, please email us first at support@ozrobotics.

If you wish to return an unused product, please do so within seven days from the ship date for a refund on the purchase price, minus shipping, handling. Refunds will be credited to the original credit card used for payment in 24-48 HOURS after receiving the product back. We will charge 50% restocking fee.

Once your return is received and inspected, and if agreed for a refund, refunds will be credited to the original credit card used for payment in 24-48 hours. Please note that we will charge a 50% restocking fee once you return a product without any defect.

Once your refund is processed, PayPal will return the money to the card used. It may take at least five business days (depending on the bank and credit company) before your refund is posted in your bank account and statements. Contact Us if you still have not received your refund after 5 business days.

Do not return your product to our New York office. For any exchange or refunds, please email us first at support@ozrobotics. com for us to provide you with the steps that need to be followed. Any product you return must be in the same condition you received and returned in the original packaging without being used. Please keep the original receipt.

More on Refund and Replacement Policy.

com for us to provide you with the steps that need to be followed. Any product you return must be in the same condition you received and returned in the original packaging without being used. Please keep the original receipt.

More on Refund and Replacement Policy.

Shipping costs

| Shipping from | United States (US) |

| Within United States (US) | $229.00 |

National Shipping Details

| Minimum shipping charge per order | $4.00 |

Shipping Details

| Product handling fee | $6.00 |

Upon submitting your question, your email will include the product link automatically.

There are no questions yet. Be the first to ask a question about this product.

Start Selling on Oz Robotics

Got a similar product, or working on another fantastic innovation? Let us help you spread the word and sell your Hardware, Software, Books, Subscription-Based Apps, SaaS, and even Technology related Freelance Services. Reach out to millions of new customers looking for great Products and Services like yours. Start Selling

Become an Affiliate and Earn Extra Income!

You’re already spending so much of your valuable time and sharing many things online without making any money! So why not share our products and earn an extra income when visitors buy? See Details

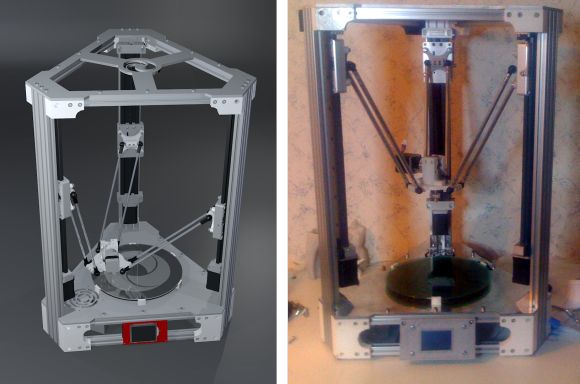

About useful modifications for the Delta 3D Printer.

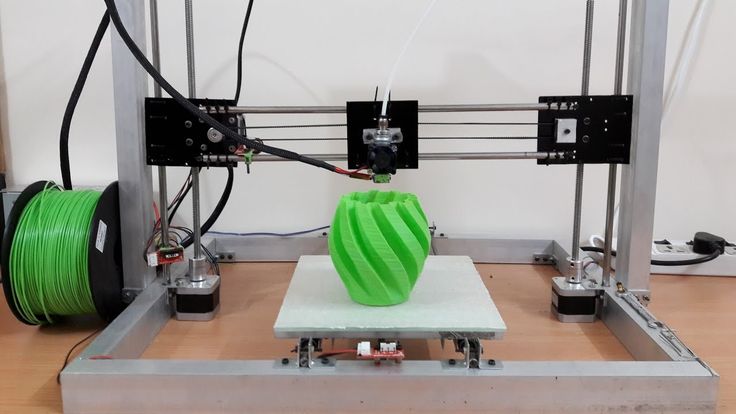

When building a 3D Printer, my choice fell on Delta. I was attracted by the fact that it does not look like any of the existing 3D printers. It has an unusual design, unusual technical solutions and high printing speed.

Very often, those who want to build their own Delta consult and ask what parts are best to use for assembly!? And how to improve the print quality of an already assembled printer!?

In this article I will try to explain

which is better to use when creating a Delta using the U3D Delta II 3D Printer as an example.

1. An important role in the Delta printer is played by the quality of the movement of the carriages along the vertical racks.

When printing, the carriages move at different amplitudes and speeds. Sometimes the speed is very high, and the amplitude of movement is very small.

Commonly used options:

- Linear Cylindrical Guides with bearings. They are inexpensive and there are a wide range of manufacturers. Linear Cylindrical Guides are used in many 3D Printers and perform their role very successfully. And they can also be used in a Delta printer with a small print field. nine0002 But the disadvantage of is to use them in a Delta printer with a print height of more than 150 mm.

is that due to the high speed and small amplitude of movement of the carriage, the linear guides begin to oscillate and resonate. Printed products are obtained with irregularities and waves. We have to reduce the print speed and thereby reduce the fluctuations.

is that due to the high speed and small amplitude of movement of the carriage, the linear guides begin to oscillate and resonate. Printed products are obtained with irregularities and waves. We have to reduce the print speed and thereby reduce the fluctuations. .

- The second option is carriages with bearings and PTFE rings.

The bearing rings are made of durable polymer. The bearings, like rollers, roll along a T-profile in an aluminum guide. It is also a common and inexpensive solution. nine0003 You only need to buy bearings and polymer rings on them.

The advantage of using this option is that the T-profile is stronger than the linear cylindrical guides and there is no vibration when the carriages move. You can not slow down the print speed.

The disadvantage of is that the rings on the bearings wear out quickly despite the tough polymer. As a result, a gap gradually appears between the roller and the T-profile. If you do not notice this defect in time, then you may not even understand why the products are getting worse and worse in quality. Products are obtained with deviations in size and wavy walls. nine0003

If you do not notice this defect in time, then you may not even understand why the products are getting worse and worse in quality. Products are obtained with deviations in size and wavy walls. nine0003

In the U3D Delta II 3D Printer, it was decided to use profile rail guides with carriages, which are used in the CNC machine.

This made it possible to improve the quality of printing, to increase the accuracy of the positioning of the printing nozzle above the table.

Profile rails and carriages have a high accuracy class, so that movements occur without jerking and sticking. And there is no vibration on the guides, they are tightly fixed to the T-shaped profile with bolts.

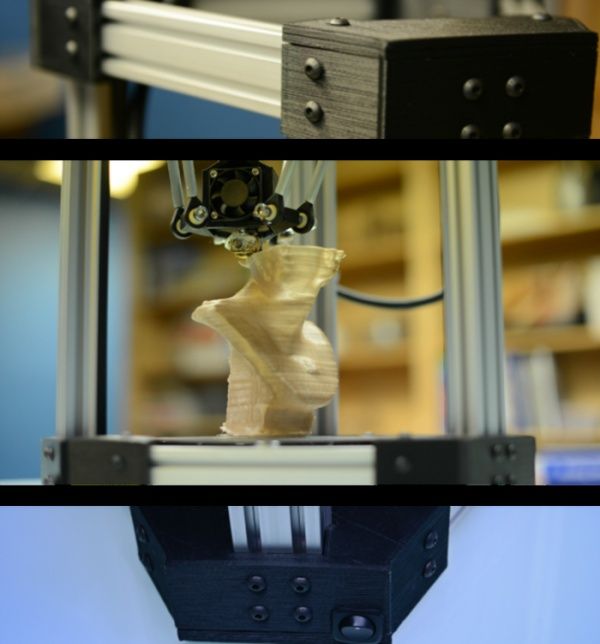

2. The following modification affecting the print quality:

The articulated joint is mainly used to fix the platform and move it in several planes.

These can be bought from a model shop

Or print bushings and insert a metal rod.

The disadvantage of is that they sometimes stick or there is play in the ball joints. At best, this can be the cause of poor print quality, size deviation, and wavy walls on the product. In the worst case, the connection may jam and the 3D printer will be damaged. nine0003

The U3D Delta II 3D Printer uses magnetic ball joints and carbon rails.

This joint design helped to reduce friction, play and jams. The movements are fast and precise. In addition, it is a very durable solution.

Magnetic connection allows you to quickly remove the hot end platform to clean it and reattach it just as quickly.

3. Modification for belt tension

It is very important to watch the belt that moves the carriages. All belts must be equally tight. Excessive belt tension will place undue stress on the stepper motors. This will cause overheating, uneven operation, and damage to the stepper motor.

This will cause overheating, uneven operation, and damage to the stepper motor.

Insufficient tension will cause belt slippage and printing failure.

Nylon tie is sometimes used for tensioning.

Or another clothespin spring

These options do not give much accuracy, it is not possible to understand how tightly and evenly the belts are tensioned.

It is better to use a ratchet - a gear mechanism with intermittent movement. Ratchet

This ratchet made it easy to fix and adjust the belt tension in the U3D Delta II.

The belt is simply inserted into the hole and even tension is adjusted by the number of wheel clicks.

4. A modification that will be useful to many. nine0017

A large number of wires are routed to the hot end. (Cooling, lighting, sensor wires and hot end power)

Previously, these wires were constantly dangling and clinging to everything. It was necessary to constantly monitor that they did not interfere with the printing process. This problem was solved by using a self-tensioning clip roller.

It was necessary to constantly monitor that they did not interfere with the printing process. This problem was solved by using a self-tensioning clip roller.

This roller hangs from the top of the printer and the cord attaches to the wires to eliminate excess slack.

5. Modification is Sitall glass U3D

Many people have probably heard about U3D glass-ceramic glass, others already print on it both in Russia and in other countries.

The benefits of U3D Sitall Glass and how it differs from other options for HeatBed coatings, I will soon tell in my new article.

Everything written in this article is based on my own experience and testing.

Yuri Lvov.

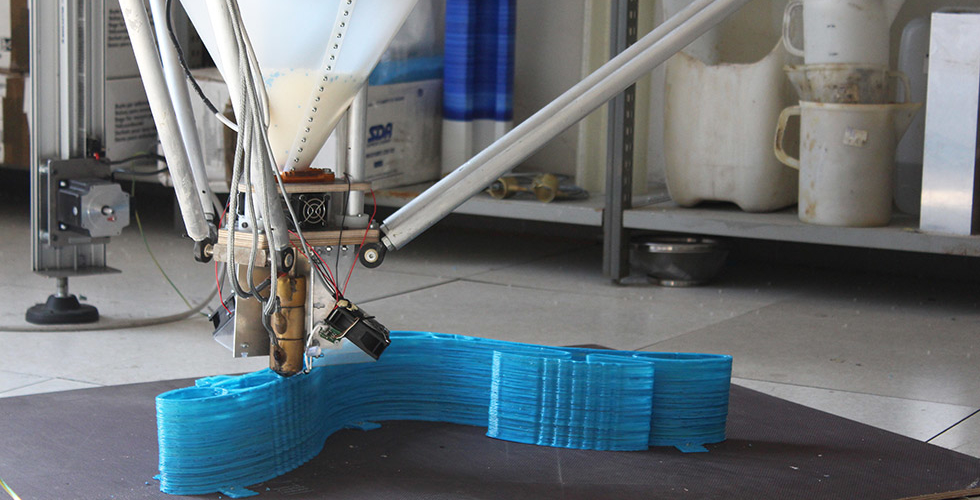

3D printer for building a house

3D printers today can print both residential and non-residential buildings. We are talking not only about miniature summer houses, but also about multi-storey structures suitable for year-round use. They are made on the basis of concrete, therefore, in terms of their technical characteristics, they are almost identical to standard housing. With the help of 3D, you can create buildings of unusual shape and configuration, bring to life the most avant-garde design solutions. It is much easier and cheaper than trying to implement the same idea using traditional building technology. nine0003

They are made on the basis of concrete, therefore, in terms of their technical characteristics, they are almost identical to standard housing. With the help of 3D, you can create buildings of unusual shape and configuration, bring to life the most avant-garde design solutions. It is much easier and cheaper than trying to implement the same idea using traditional building technology. nine0003

The main prospects for 3D printing in construction are twofold. The first is the economically rational creation of unique buildings according to author's projects. The second is to provide the poor with durable, environmentally friendly, comfortable housing with minimal financial investment. Unfortunately, the development of both of these areas today is hindered by the lack of a legislative framework for 3D construction. In the absence of uniform standards and regulations for the entire industry, this technology cannot become truly mass-produced. This article will give an overview of already implemented 3D construction projects, describe the nuances of building mixtures and printers, and list the objective pros and cons of this technology. nine0003

nine0003

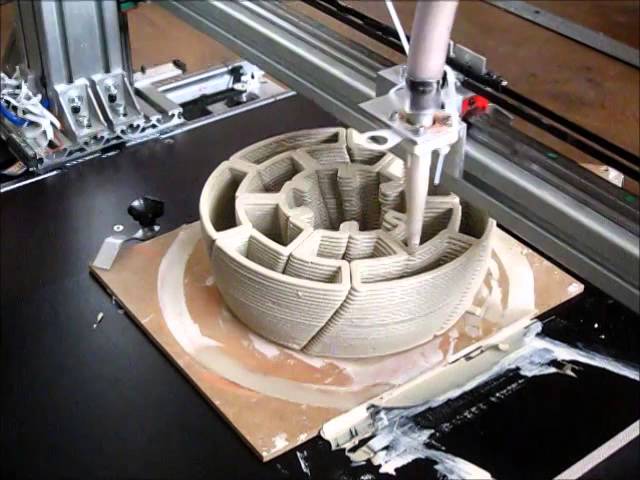

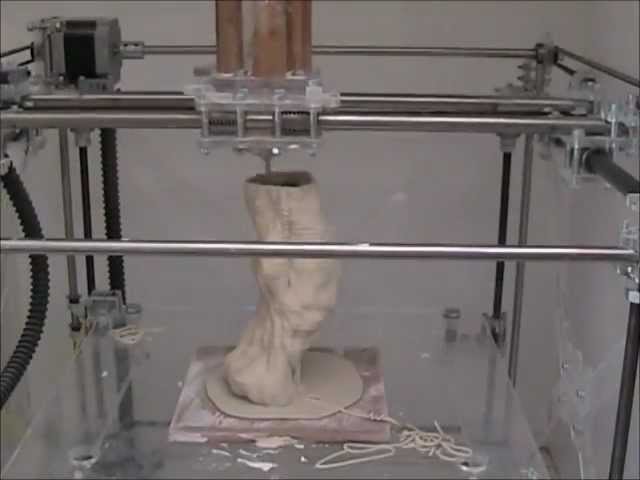

Construction 3D printer technologies

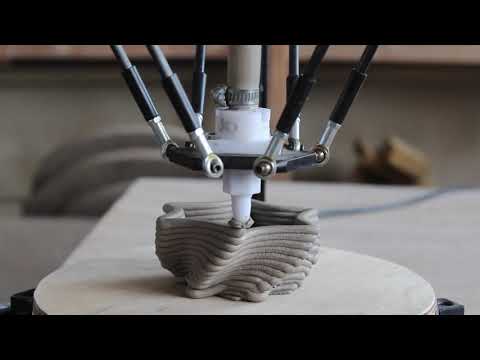

Construction 3D printers are equipped with extruders, from which concrete is extruded and laid in layers, forming the outer and inner walls of the future building. The drawing of the building is preliminarily developed as a three-dimensional model in a CAD computer program. To give concrete the necessary liquid consistency, it is mixed with water and additives. The resulting mixture is fed under pressure into a hose connected to the printer head. From the head, the material flows to the previous printed layers or directly to the construction site. nine0003

When compared with ordinary building concrete, the material for 3D construction will most closely resemble the M50 grade in terms of its characteristics. To give it additional strength, the walls of the building are reinforced. For this purpose, fiber is added to the solution or fiberglass reinforcement is laid in the walls.

WARNING : Finished building walls will not be perfectly smooth.

Living builders will have to level them, plaster, and perform cladding.

3D printing is not very suitable for creating long structures. In the absence of legislation that would regulate its use for continuous development, this technology will be used primarily to create:

- gazebos;

- landscape buildings;

- flowerbeds and benches;

- small bridges;

- country houses;

- children's towns;

- garages;

- buildings for economic purposes. nine0032

This level of medium and small 3D businesses, but not large urban developers.

CAUTION : The 3D building site must be perfectly level. This is required both for laying the guide rails and for ensuring their subsequent parallelism.

Types of 3D construction printers

XYZ printers

Such devices are also known as portal devices. These are frames in which the print head moves along the XY axes. To hang the head from the frame, portals are used (usually there are three of them). High-precision stepper motors are used to move portals. nine0003

To hang the head from the frame, portals are used (usually there are three of them). High-precision stepper motors are used to move portals. nine0003

Use XYZ printers in three ways:

- If the building is compact, it can be printed entirely.

- If the building is large, the printer will be placed in the workshop and will print the components of the building individually.

- If you place the printer inside a building you are building, it will be able to print the interior walls for it.

Delta

Delta printers can create more sophisticated objects than XYZ devices. They are not tied to 3D guides. Their printheads hang on thin arms attached to vertical rails. nine0003

Robots

Printers of this variety are industrial type robotic arms. They are equipped with extruders, controlled by a computer.

D-Shape

D-Shape devices are separated into a separate category for an objective reason: their filament is not a solution, but a dry powder material. The filament is laid in layers with the desired thickness and compacted, then it is impregnated with a binder substance from the printer nozzle. Then, excess raw materials are removed from the finished element. nine0003

The filament is laid in layers with the desired thickness and compacted, then it is impregnated with a binder substance from the printer nozzle. Then, excess raw materials are removed from the finished element. nine0003

Building mixtures

3D printing in construction is based on concrete. Difficulties can arise when the material passes through the extruder, so the consistency of the concrete must be such that it does not spread and lays down in uniform layers. The material must set quickly in order to retain its shape - however, if the process is carried out at too high a speed, the superimposed layers will lose their chemical activity and will not form a single structure at the point of contact. Also, if the concrete sets too quickly, it will clog the nozzle and damage the printer. The strength of concrete is increased by adding plasticizers. Thanks to them, the mixture becomes more mobile, the water-cement ratio decreases. nine0003

WARNING : The concrete used for 3D printing is not the same as for traditional construction.

In 3D, fine-grained mixtures are needed, which each company produces according to its own recipe. When compiling the recipe, the specifics of the target objects are taken into account, as well as the nuances of the design of the printer and its nozzle.

Examples of houses printed on a 3D construction printer

Houses printed using 3D technology have already been built in many countries of the world: Russia, China, USA, UAE. Here are some of the most striking examples of this. nine0003

AMT "Spetsavia"

This Yaroslavl enterprise first specialized in the production of CNC machines, and now has shifted to the development of construction 3D printers. The hallmark of this company was the building for the guards of the Yekaterinburg cement plant, stylized as the Winterfell castle from the Game of Thrones. The first property with an area of 165 sq. m AMT was printed in 2015: part of the structure was created on the site, and part was delivered from the factory in a disassembled state. nine0003

nine0003

Apis Cor

The Irkutsk company Apis Cor uses a curious technology: the print head is placed on a telescopic rod, which is adjustable in height and placed on a turntable. Such an installation prints walls around itself from a gypsum mixture. Once completed, the printer can easily be transported to a new construction site using a conventional crane. In 2019, the company built a 640 sq. m, which required 500 hours of printer operation. In Stupino, a similar building was erected for demonstration purposes, not for living. nine0003

Winsun

Winsun has been on the market since 2003 and has registered 225 national patents. Its pragmatic goal is to provide affordable housing for the poor, cut construction costs in half, and use sustainable materials to ensure that Chinese cities do not have a haze of smog.

In 2014, Winsun made an ambitious announcement that they were ready to print 10 residential buildings in 10 days. As a result, they really built 10 houses with an area of 200 square meters. m and costing only $4,800 each. The configuration of the houses was the most primitive, but they could be inhabited. nine0003

As a result, they really built 10 houses with an area of 200 square meters. m and costing only $4,800 each. The configuration of the houses was the most primitive, but they could be inhabited. nine0003

In 2015, Winsun Suzhou Industrial Park realized more complex 3D projects: a cozy mansion with an area of 1,100 square meters. m and a five-story residential building. The dimensions of the printer used for these works were 6 × 10 × 40 m. The blocks were printed separately and then assembled into a single structure. For the production of the building mixture, construction and industrial waste, fiberglass, sand, cement and a specialized hardener were used. Both building materials and time were required 3 times less than for the construction of buildings using traditional technology, and the composition of the construction team decreased by 5 times. nine0003

CyBe Construction

In 2019, this Dutch company was approached by clients from the UAE. They would like 25% of all new buildings in Dubai to be 3D by 2025. The world's first 3D office building is located in Dubai. CyBe Construction was invited to showcase its capabilities at SRTI Park, a research center specializing in water technology, renewable energy, environmental technology, digitalization, industrial design 4.0, mobility and smart cities. The CyBe Construction 3D Printer runs at speeds up to 600mm/s and creates all the supporting structures for a building in less than an hour. It can perform formwork, walls, sewer pits, floors. nine0003

They would like 25% of all new buildings in Dubai to be 3D by 2025. The world's first 3D office building is located in Dubai. CyBe Construction was invited to showcase its capabilities at SRTI Park, a research center specializing in water technology, renewable energy, environmental technology, digitalization, industrial design 4.0, mobility and smart cities. The CyBe Construction 3D Printer runs at speeds up to 600mm/s and creates all the supporting structures for a building in less than an hour. It can perform formwork, walls, sewer pits, floors. nine0003

D-Shape

As mentioned above, D-Shape printing technology is somewhat different from the rest. It uses the stereolithography method, and sand with an inorganic binder composition acts as a filament. In its appearance, such a material resembles marble, and in terms of strength and durability it surpasses both reinforced concrete and masonry. It only takes 24 hours for the mixture to dry completely. Already in 2012, the company announced its readiness to print two-story buildings with interior walls, stairs, pipelines, vaulted roofs, columns and other elements. The development priority of D-Shape is the creation of custom-shaped houses that are not afraid of hurricanes, earthquakes and other natural disasters. nine0003

Already in 2012, the company announced its readiness to print two-story buildings with interior walls, stairs, pipelines, vaulted roofs, columns and other elements. The development priority of D-Shape is the creation of custom-shaped houses that are not afraid of hurricanes, earthquakes and other natural disasters. nine0003

BatiPrint

At the 2017 Design Week in Nantes (France), BatiPrint printed a residential building called Yhnova House. This social project was developed by scientists from the University of Nantes. First, it was opened for viewing and visits, and then people settled in the house. The area of Yhnova House is 95 sq. m, it has 5 rooms. The building is energy efficient, so the bills for housing and communal services for its inhabitants are lower than for residents of ordinary houses. BatiPrint used a laser-guided robot arm to print. The construction process did not depend on the vagaries of the weather, for the construction it was not necessary to erect scaffolding. The creators of the project especially focused on the fact that there was much less waste and environmental damage from it than with traditional construction. nine0003

The creators of the project especially focused on the fact that there was much less waste and environmental damage from it than with traditional construction. nine0003

WASP

The Italians WASP, in collaboration with architects from Mario Cucinella Architects, have built unusual residential buildings in Bologna with an easily recognizable rounded shape. This project was named Tecla. For the construction of houses, they used recycled materials and an XYZ printer called Crane. Previously, the company printed a GAIA house, literally created from damp earth. Builders are guided by the principle of "zero kilometer" - it is important for them that building materials are of local origin, and they would not have to be transported from other regions or countries. nine0003

The very name of the WASP brand is translated as "wasp". His team draws inspiration from nature and strives primarily for sustainability and energy efficiency. The company sets as its task the construction of not individual buildings, but ecovillages designed to solve the problem of overpopulation of the planet and the shortage of traditional resources. The layout of such settlements is based on honeycombs. Despite the fact that the buildings from WASP look like summer houses, they are designed for year-round operation. nine0003

The layout of such settlements is based on honeycombs. Despite the fact that the buildings from WASP look like summer houses, they are designed for year-round operation. nine0003

Contour Crafting

The American company Contour Crafting holds over 100 patents and considers construction speed a top priority. She plans to spend less than a week building one house, and people can move in 2-5 days after construction is completed. The 3D printer from Contour Crafting weighs only 360kg and has a standard reach of 12m and is expandable. According to company representatives, their technology is more promising than that used in Winsun. The Chinese combine 3D technologies with a traditional approach, and Contour Crafting seeks to fully automate the process, thereby speeding up and reducing the cost as much as possible. The house does not have to be assembled in parts: the printer will build it in layers from cement right on the construction site. nine0003

Pros and cons

The pace of development of 3D technologies suggests that the shortcomings that builders have to put up with so far will be overcome in the very near future.

Pros

- Building with an original design is much easier and cheaper to print in 3D than to build using traditional technologies.

- 3D printing makes it possible to realize almost any fantasy of architects and designers.

- The printing process is fast and precise. The printer unmistakably transfers all the details of the project into material reality. If something went wrong, it means that there was an error in the project or a low-quality filament was caught. nine0032

- The need for human labor is practically eliminated.

- Less debris and waste from construction. All components are printed exactly in the right quantity for a specific project. If some components for unforeseen reasons remain unused, they can be disposed of (that is, a new filament can be made from them).

- The construction process creates significantly fewer risks and threats for both people and the environment.

Cons

- Living builders, manufacturers of traditional building materials, construction equipment rental companies are out of work.

- Those living workers who will nevertheless be involved in the process will have to urgently acquire new skills and improve their qualifications.

- Many printers today can only print on one type of filament.

- The choice of building filaments is limited.

- Printers can be difficult to store and transport from one job site to another. nine0032

- The development of models for printing buildings can only be trusted by experts, who are still very few. Lack of knowledge or experience can lead to the collapse of the structure and other unpleasant consequences.

- Assembly of prefabricated components on site can in some cases be as time consuming as conventional construction.

- Modern legislation is not perfect enough to put 3D construction on stream.

3D technologies are already making it possible to build comfortable residential buildings for year-round use. These can be both compact houses with a minimum area and cost, as well as spacious mansions and five-story apartment buildings.