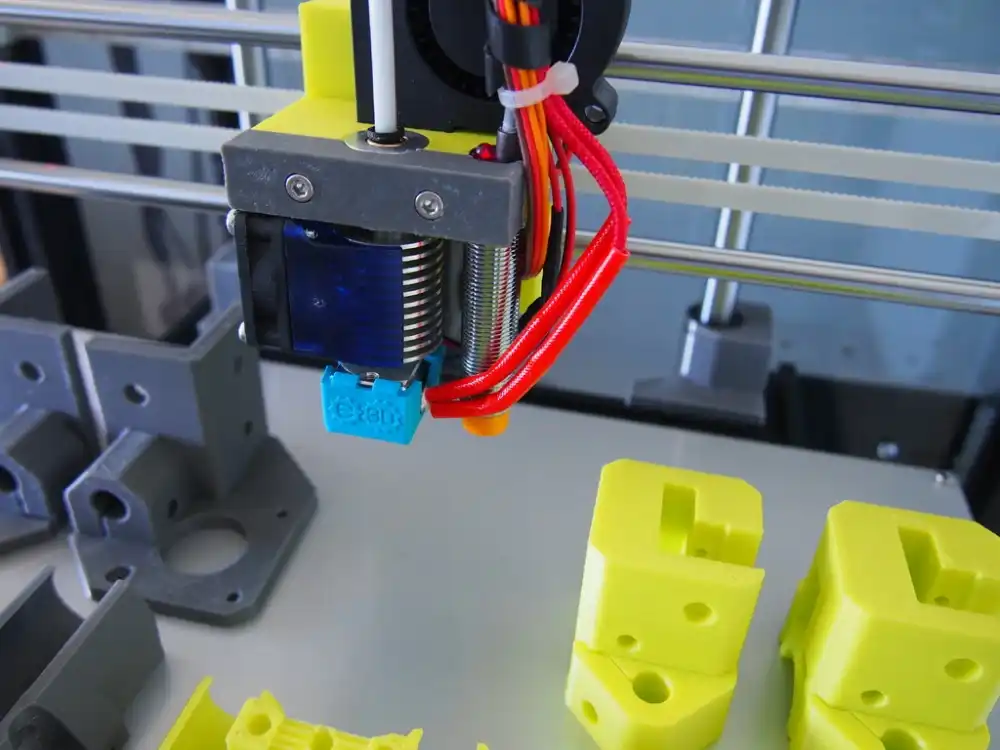

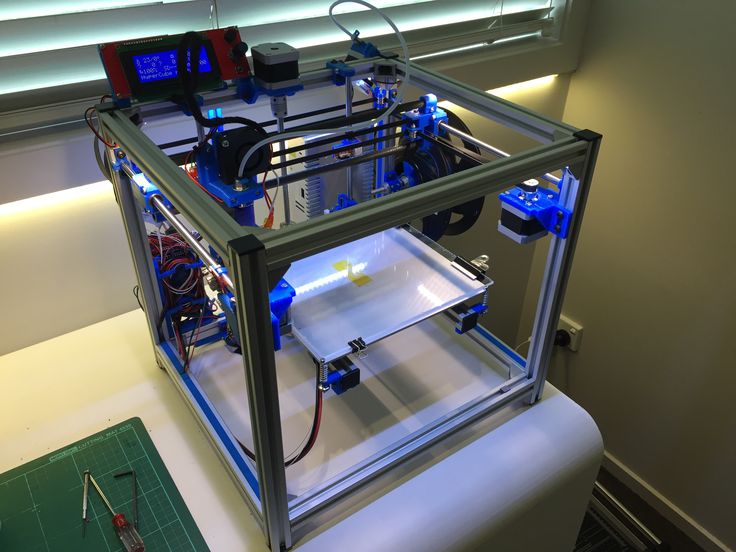

Evo 3d printer

Training

Training

Just embarking on your 3D Printing Journey or seasoned

professional? Take your skills to the next level with our onsite training

partner 3D 360.

who are 3d 360?

“Breaking the Mould”

3D 360 is born out of industry and the realisation that 3D printing is the future of manufacturing and is changing the way things are made today.

3D 360 is owned and run by two vastly experienced engineers from the Nuclear, automotive, and commercial design sectors. Both have many years’ experience providing consultancy services to the engineering and manufacturing sectors and in utilising 3D printing within industry for prototyping and production applications.

The 3D 360 support ethos comes from our extensive experience within industry in supporting equipment through its entire product life cycle, and not just stopping at selling you a printer.

Our aim is to support you and your equipment through its life, offering ongoing advice on how to achieve the best results from your printer.

Learn more

3D 360 were advisors to the High value manufacturing catapult for the government commissioned Emerging skills Project for AM and are the only UK training provider to deliver the entire pilot training programme.

The UK Government commissioned the programme to identify key digital skills gaps and produce short and effective training programmes to rapidly upskill the UK workforce.

We are also working with Pearson’s to write the 2023, level 4 & 5 (HNC & HND) further education curriculum for AM.

1-day onsite training including the commission of your new machine and introduction to Additive manufacturing.

Once your machine is fully working out skilled trainer technician will demonstrate to your team how to operate your new piece of equipment covering the following areas

Slicing software functionality.

(Temperature, material, infill selection, layer height, adhesion and support options)

Remote printing and monitoring

Printer calibration

Build plate levelling or auto levelling sequence

Printer set up to a ready to print condition

Filament loading and unloading

Perform sample calibration or manufacturers’ recommended print

Nozzle change / replacement

Maintenance schedules

Routine Maintenance

Recommended service schedules and location of components

Scheduled Maintenance

Consumables

Two-day extended course

The additional day allows our trainer to recap and go into greater detail on the previous day’s subjects. Additional areas would be:

Additional areas would be:

Advanced slicing setting

Multi filament / Resin set up and change over procedures

System integration

Practical demonstration on how to replace serviceable components

Specialist Bespoke training packages tailored to your requirements.

3D 360 was born out of industry and our team have the

experience and expertise to support you through your Additive and digital manufacturing journey.

With the support of our friends at EVO 3D, our combined technical teams can produce and deliver bespoke training designed to address your current and future production needs.

Some examples of training courses we have delivered to industry and education.

• Advanced technician training for in house servicing, upgrades and repairs

• Multi-printer type and manufacturing process integration for hybrid production

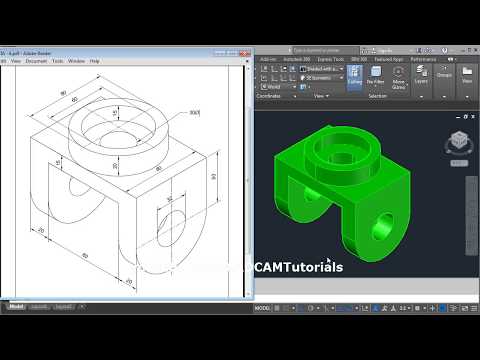

• Design for AM (Products, checking fixtures, test rigs, customer engagement)

• Advanced introduction to AM covering the 7 major AM processes and applications

• Volume production using AM – Printer farms, JIT cells & rolling maintenance support

• Additive Manufacturing integration for production parts

• Introduction to Digital manufacturing / industry 4. 0

0

• Advantages of using AM – Cost savings, carbon footprint, energy savings, flexibility

• Using 3D printers to produce obsolete parts for production lines, equipment

Contact us

TESTIMONIALS

“The infectious and knowledgeable enthusiasm of 3D 360 has been FANTASTIC, giving us the confidence to invest in the appropriate 3D systems to meet our operational aspirations. In 3D 360 we have found a GREAT solutions provider and most welcome partner, creating the foundations for a productive, innovative future.”

Peachy Keen

3d 360 clients

Free advice

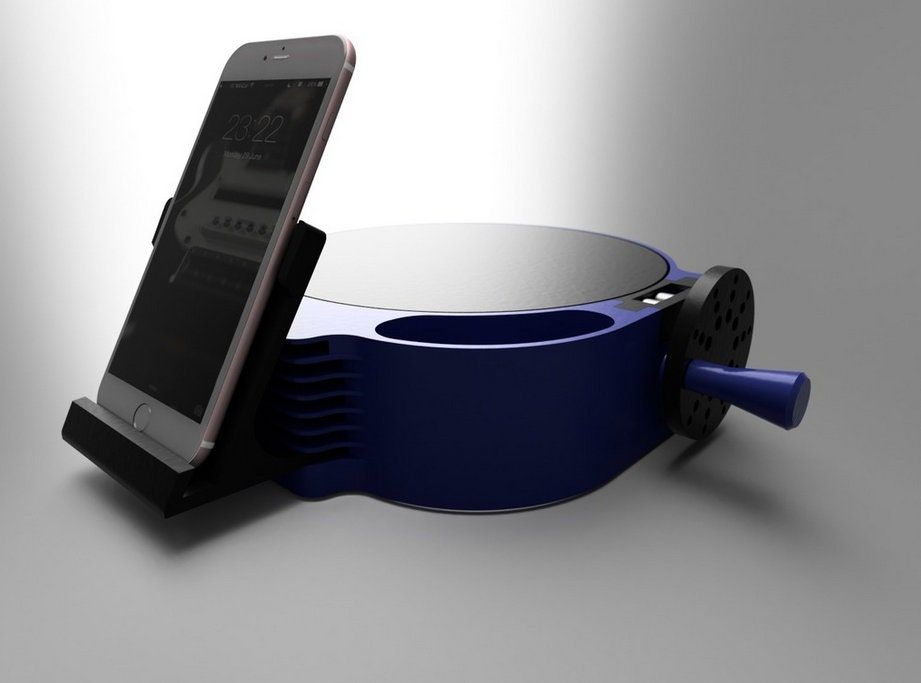

Need advice? EVO3D will support your business to help you embark on a complete 3D solution.

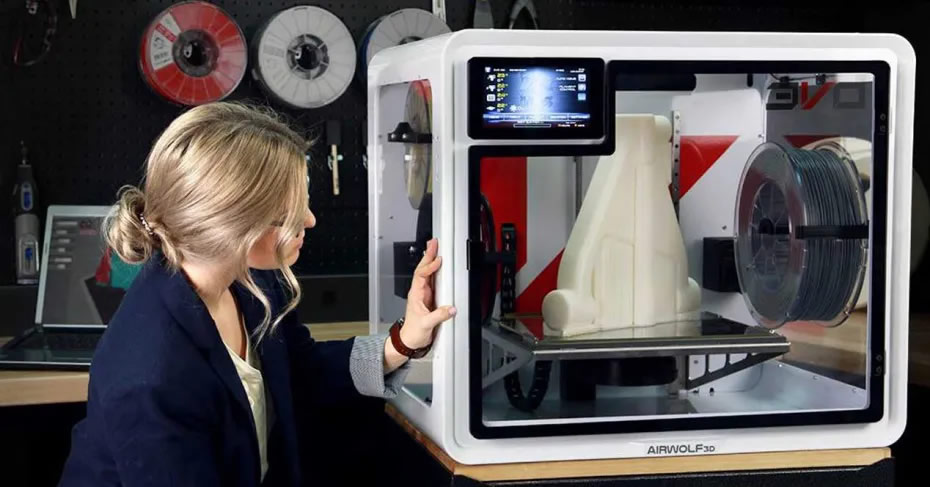

Airwolf 3D EVO - World's Most Efficient and Advanced 3D Printer

Easily manufacture large functional prototypes and production parts at top speeds with Airwolf 3D EVO, the world’s most advanced desktop Additive Manufacturing Center (3D Printer).

Oversized Build Environment

Manufacture large size, end-use parts within the EVO’s huge build volume in over 40 different materials. Optimized for production, the 12 x 12 x 11-inch enclosed build volume is configured for producing large, strong parts.

TRI-HEAT™ TECHNOLOGY

Manufacture the highest quality parts possible on an industrial 3D printer, thanks to proprietary Tri-Heat™ technology that warms the chamber and dries the filament within.

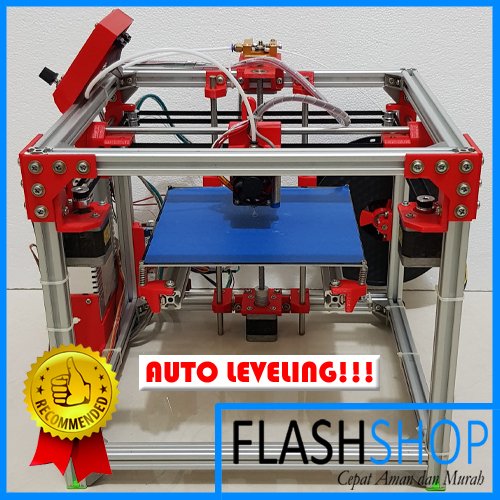

AUTO-LEVELING & CALIBRATION

Enjoy Airwolf 3D’s proprietary auto-leveling technology along with AutoPrime, and Sweep. Ultra-durable Extended-Life nozzles save time and money while providing higher precision, speed and efficiency on 3D printing.

AIR CLEANSING SYSTEM

EVO features an oversized air purifying system for active containment of UFP and VOC emissions, providing an extra layer of protection and peace of mind when 3D printing in schools or smaller spaces.

PARTSAVE™

Avoid part failure due to power outage, an accidentally unplugged machine, or other unexpected interruptions. As soon as power of the 3D printer is restored, PartSave™ empowers you to resume production right where it left off.

FAILSAFE™

Whether you run out of filament or experience a jam, FailSafe™ has you covered. Just place the print head where you left off, and FailSafe™ will do the rest, restoring your print and completing the 3D print with time to spare.

WHAT COMES WITH YOUR Airwolf 3D EVO ADDITIVE MANUFACTURING CENTER (3D PRINTER)?

- (1) Extra 0.50 Extended-Life Nozzle

- (1) Double-Sided Flex-Resistant Glass

- (1) 2oz Bottle of Wolfbite Premium Adhesive Solution

- (1) 2-Pound Spool of ABS Filament (2.85mm)

- (1) USB Drive

- (1) Nozzle-Cleaning Tool

- (1) APEX Software

- One-Year Parts and Labor Warranty

- 2 Service Maintenances included in first year

For the first time in history, you can start, stop, and resume the 3D manufacturing process at any time, thanks to EVO’s industry-first PartSave™ technology. Gone are the days of losing prints due to machine failure, power failure, or accidental shutdown.Whether you need to pause part production for one minute or one hundred years, PartSave™ ensures the 3D printing process will be ready to continue as soon as you are.

Gone are the days of losing prints due to machine failure, power failure, or accidental shutdown.Whether you need to pause part production for one minute or one hundred years, PartSave™ ensures the 3D printing process will be ready to continue as soon as you are.

Both the brain and heart of the Airwolf 3D EVO 3D Printer, Airwolf 3D’s proprietary GENESIS Microcontroller drives the leaps and bounds that EVO has made in desktop additive manufacturing technology.

Fully proprietary and engineered from the ground up to support high-performance industrial manufacturing, the GENESIS board is an automotive-grade 32-bit redundant embedded controller that delivers 2-3 times higher speeds, more precision, and greater control at ultra-high temperatures than any other desktop 3D manufacturing system on the market.

MATRIX TOUCHSCREEN CONTROLControl Airwolf 3D EVO with a single touch. A spacious 7″ full-color touch display makes it easy to control everything from PartSave™, material selection, internal ambient temperature, and expert settings to an on-screen keyboard for writing and executing g-Code on the fly.

Manufacture the highest quality parts possible on a desktop additive manufacturing system, thanks to the EVO’s proprietary Tri-Heat™ technology. Two internal heaters and a high-temperature bed maintain precise temperature control and heated airflow for optimum manufacturing of stronger, smoother, higher-quality engineering-grade parts from materials including ABS, nylon, and polycarbonate.

The Integrated Filament Drying System further facilitates optimal printing conditions, drying up to 10 pounds of material at a time for immediate extrusion or long-term storage.

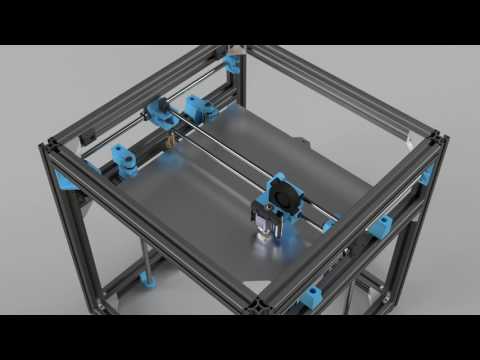

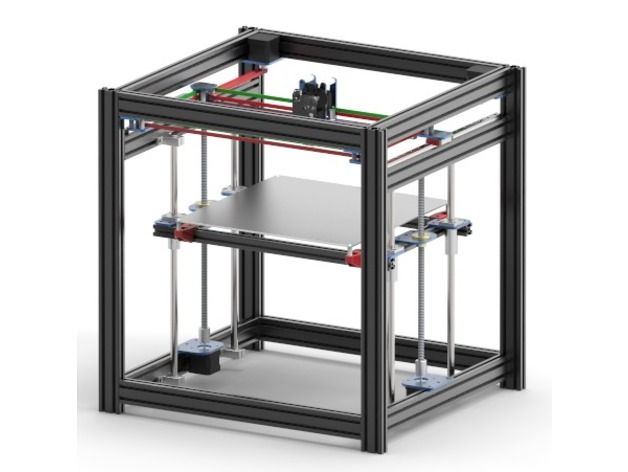

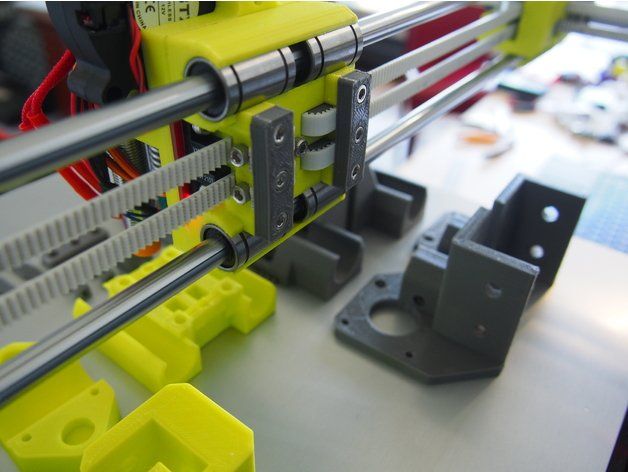

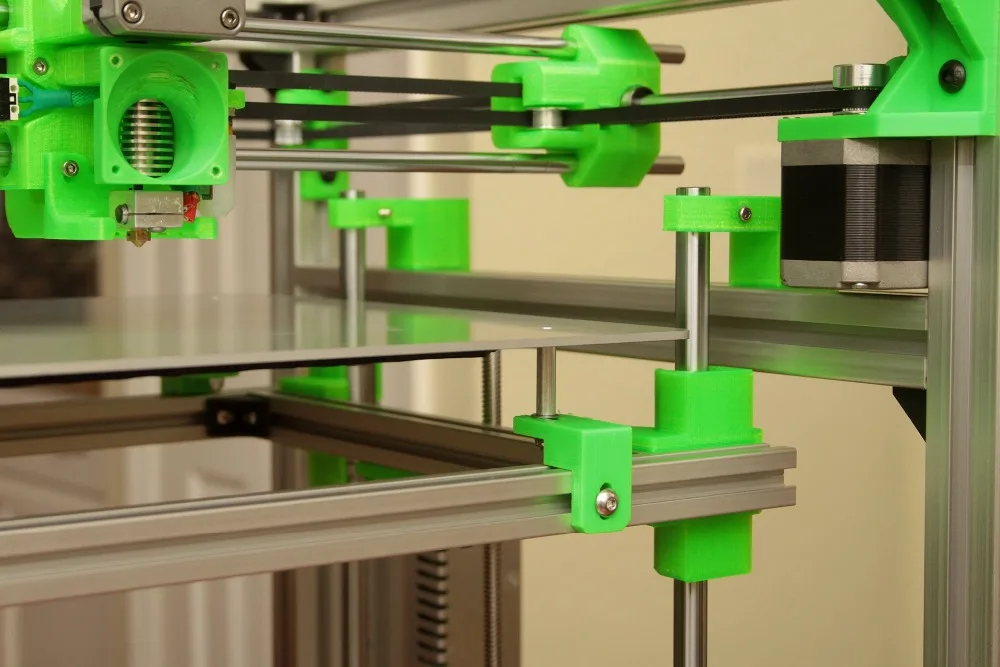

MAINTENANCE-FREE PRECISIONThe CoreXY Motion System receives a leading-edge update thanks to CNC-style linear precision guides. Up until now, the successful integration of a heavy-duty linear-guide-based motion control system was available only in high-end 3D printing systems at over five times the price of the Airwolf 3D EVO 3D printer. One of the most future-proof design elements of the EVO AMC, the linear-guide-based CoreXY Motion System provides unparalleled manufacturing precision with zero maintenance.

One of the most future-proof design elements of the EVO AMC, the linear-guide-based CoreXY Motion System provides unparalleled manufacturing precision with zero maintenance.

Manufacture large parts quickly with the Airwolf 3D EVO’s industry-leading 0.4lb/hour maximum material deposition rate. A cartridge-style planetary extruder assembly achieves increased torque capacity for faster extrusion speeds while an unbreakable three-bolt-reinforced hot end precisely distributes over 40 materials ranging from PLA and ABS to exotic materials including carbon-fiber-reinforced nylon and PC as well as HydroFill, Airwolf 3D’s proprietary water-soluble support.Performance is further optimized by extended-life replaceable nozzles that help minimize part distortion.

BALL SCREW Z STAGEThe EVO’s bulletproof z stage comprises a proprietary coupling linking a ball screw with a stepper motor and is powerful enough to support up to 50 pounds and provides precision of nearly one thousandth of an inch over its 11-inch build height, providing incredible accuracy. Approximately the size of a human hair, the precision movement is barely discernible by the human eye.

Approximately the size of a human hair, the precision movement is barely discernible by the human eye.

The strongest 3D printer on the market, the Airwolf 3D EVO has a 100% aluminum unitized frame constructed in a rigid monocoque to maximize structural integrity while minimizing bulk and weight. The unitized build platform supports up to 50 pounds and also employs one-piece construction to save weight and space in order to maximize strength while minimizing part distortion.With an oversized 1000-watt power supply, the EVO has power in reserves, easily adapting to ultra-demanding applications in even the harshest environments. An automatic circuit breaker provides a safer, more reliable, and more serviceable system than conventional fuse replacement.Though rugged and unbreakable, the Airwolf 3D EVO is light enough to transport easily and can be stacked up to four units high for multiplied part production.

OVER 40 MATERIALS, INCLUDING METAL

Manufacture in over 40 materials ranging from PLA and ABS to exotic materials like metal, carbon fiber-reinforced nylon, polycarbonate, and HydroFill Water-Soluble Support. Produce larger, more complex parts than ever before, thanks to the carefully controlled thermal environment offered by Airwolf 3D EVO’s Tri-Heat™ Enclosed Build Chamber and Integrated Filament Drying System.

Produce larger, more complex parts than ever before, thanks to the carefully controlled thermal environment offered by Airwolf 3D EVO’s Tri-Heat™ Enclosed Build Chamber and Integrated Filament Drying System.

Airwolf 3D EVO Official product page

https://airwolf3d.com/shop/industrial-3d-printer/

Contact our sales for more details.

Brand

Airwolf 3D

Southern California-based Airwolf 3D was built on a simple premise: Create a superior desktop 3D printer that empowers users of all ages to create and print objects thought impossible until now. They have built FDA approved 3D printer which is good for medical use. Addify was appointed as their exclusive reseller in Hong Kong.

They have built FDA approved 3D printer which is good for medical use. Addify was appointed as their exclusive reseller in Hong Kong.

Tech Spec

Printing Performance | |

| EXTRUDER CONFIGURATION | Planetary Direct Drive |

|---|---|

| BUILD VOLUME | 12″ x 12″ x 11″, 305 mm x 305 mm x 280 mm |

| RECOMMENDED MAX PRINT SPEED* | 100-150 mm/sec |

| TRAVEL SPEED | 125+mm/sec MAX |

| MAX EXTRUDER TEMP | 315°C |

| MAX BED TEMP | 160°C |

| MINIMUM LAYER HEIGHT | 0.04mm |

| RECOMMENDED LAYER HEIGHT | 0.2mm |

| CALIBRATION | Auto-Leveling |

| UPGRADEABLE | Yes |

Filament Compatibility | |

| MATERIALS | Metal, Over 40, incl ABS, PC, PP, Nylons, TPE, TPU |

| FILAMENT SIZE | 2. 85mm +/-0.10 85mm +/-0.10 |

Printer Design | |

| WEIGHT (LBS) | 60 lbs |

| HEIGHT (IN) | 24″ |

| WIDTH (IN) | 28″ |

| DEPTH (IN) | 24.5″ |

| FRAME CONSTRUCTION | One-piece aluminum main frame, polycarbonate |

| MOTION SYSTEM | CoreXY |

| ENCLOSED PRINT CHAMBER | Yes |

| HEATED BED | Yes |

| PRINT PLATE MATERIAL | Borosilicate Glass |

| DISPLAY | MATRIX TOUCHSCREEN CONTROL |

| INTERCHANGABLE NOZZLES | Yes |

Connectivity & Accessories | |

| PROVIDED SOFTWARE | APEX, APEX PRO |

| CONNECTIVITY | Ethernet, USB Drive, USB Cable |

| PRINT VIA REMOVABLE DEVICE | USB Drive |

| MAINTENANCE TOOLS INCLUDED | Allen Wrenches, Micro Drill Bit Set |

| FILAMENT INCLUDED | Yes |

Help & Support | |

| WARRANTY | 12 Month, by Manufacturer |

| EMAIL SUPPORT | [email protected] [email protected] (Reseller in HK) |

| PHONE SUPPORT | Airwolf Hotline: +1 (949)478-2933 or calling Addify3D: +852 64811751 |

| TUTORIALS | www. youtube.com/airwolf3d youtube.com/airwolf3d |

Software

SLICERS

Ultimaker Cura

https://ultimaker.com/software/ultimaker-cura

APEX 3D Printing Software

https://airwolf3d.com/3d-printing-software/

APEX is 3D-printing software developed exclusively for Airwolf 3D printers and designed to make 3D printing a more simple, intuitive process. Built on top of Cura’s open source slicing engine, APEX comes preconfigured with print profiles for major materials, such as ABS, PLA, TPE, TPU, and polycarbonate. Plus, the material profiles are fully optimized for all models of Airwolf 3D machines. Best of all, APEX is free and we recommend that all Airwolf 3D customers begin using the software. Learn more about APEX. Spend less time worrying about software settings and more time creating beautiful 3D prints.

Frequently Asked Questions About EVO

What is the build volume of the EVO?

The build volume of the EVO Additive Manufacturing System is: 12 x 12 x 11 in.

What is EVO’s resolution/minimum layer height?

The EVO’s minimum layer height is 40 microns. However, 200 or above is recommended.

What materials can the EVO print in?

The EVO’s proprietary high-temperature, jam-resistant dual AX2 hot end prints in all materials with print temperatures up to 320 degrees, including metal filament. Thanks to the Tri-Heat™ Enclosed Build Environment’s superior thermal management, you can print even large parts out of high-temperature materials like ABS, polycarbonate and polypropylene.

For best results, always choose high-performance, engineering-grade materials like the filament tested and certified by Airwolf 3D.

What Metal Material Can Be Used With the EVO?

The current material tested with the EVO is Ultrafuse 316LX by BASF. The filament is a 90% 316 stainless steel and is designed for use with the same debinding and sintering processes used in traditional metal injection molding.

What Level of Precision Can You Get With the Material?

Precision of your end parts is determined by your printer settings and the shrinkage factor of the metal once all of the binder is removed. Based on the Catamold data from BASF and test printing, you can expect approximately 20% shrinkage.

How Strong are the Metal Parts?

Strength of the 3D-printed parts is similar to the strength of metal-injection-molded and forged parts. We are working on releasing data comparing the strength of parts created using these production methods.

Where can I find the EVO User Manual?

The user manual is located here: EVO User Manual

For a QuickStart Guide, please refer to: Get Started: EVO Unboxing and Set Up

What is the EVO Owners Program?

The EVO Owners Program is designed to give you the unparalled service you expect when purchasing a best-in-class machine. VIP benefits of EVO ownership include White Glove Service, access to key firmware updates, prioritized feature requests, and early access to hardware upgrades and beta products.

To ensure that you receive all the benefits that come with EVO ownership, please be sure to register your machine.

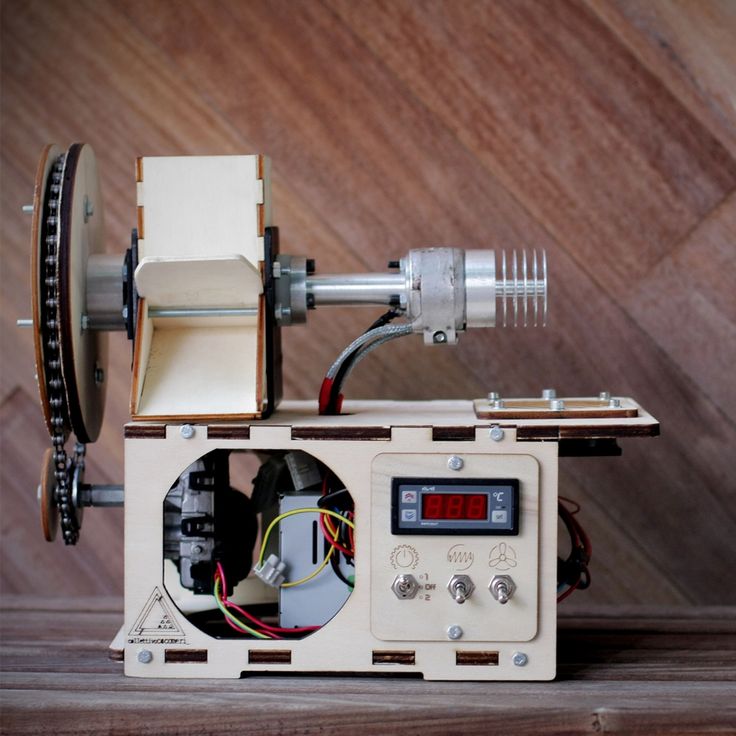

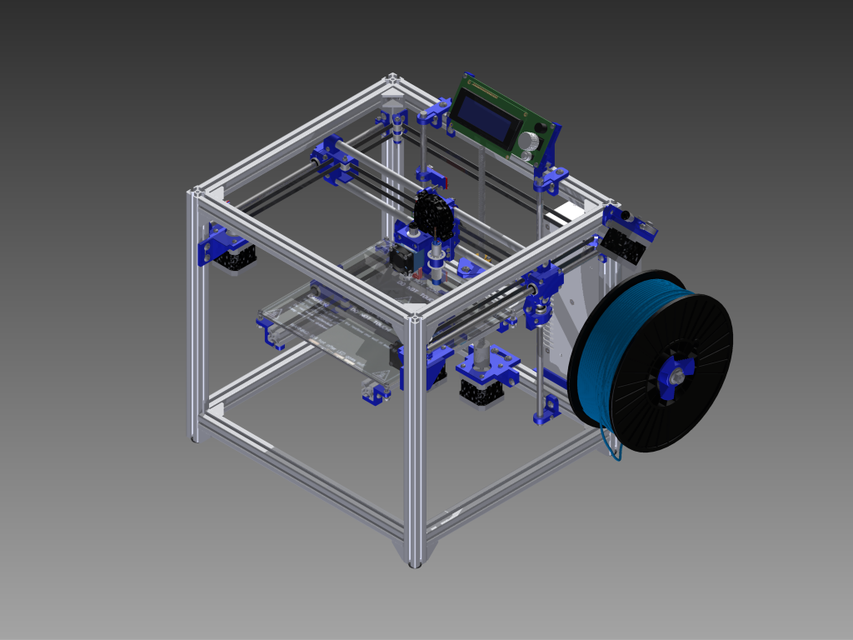

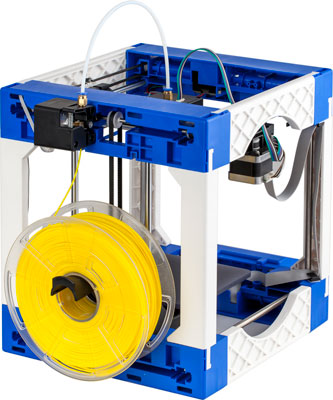

3D printer Funtastique EVO v1.0: first acquaintance / Sudo Null IT News For me, it has always been something complicated and incomprehensible, something that can only be collected in laboratories. But the year 2017 has come, and the printer can be assembled at home. Just read the instructions. Modular 3D printer Funtastique EVO v1.0 is suitable for the role of the first home printer when special knowledge in 3D printing is not required. It is assembled simply, like a children's designer, you do not need to solder or program anything. Everything has already been set up for us.

Packaging

The box is impressive. What's inside?

What's inside

Packing List.

Packing List

Specifications Print layer height: from 0.05 mm

Nozzle diameter: 0.40 mm

Software: CURA RepetierHost

Consumable types: PLA, PVC, PETG, PP, Wood

Weight: 5. 0 kg

0 kg

Parts lie tightly in foam

Modularity

The printer consists of modules. The manufacturer offers the printer in finished form and in the form of a designer. I received the printer in a blue DIY kit. As far as I know, Dajet also has orange.

Opening

Assembly

It is easy to assemble and disassemble. All parts are fastened with clamps. Lightweight frame is made from ABS plastic.

Assembling

If placed in a room or office, it will not spoil the look of the interior at all. All thanks to the stylish design. Assembling and setting up the printer took me half an hour. Fastening all the details with clamps is a pleasure.

Table setting

Magnetic work table. The manufacturer says that you can do without adhesive tape. Partly it is. But if the part is high, then without a tape, further work will be impossible.

Table view

The table is easy to put on and take off. We collect.

We collect.

Assembly

We fasten special guides.

Fastening the rails

Clip the modules into the slots.

Nozzle

We put the block with the nozzle.

Almost done

The outside already looks like a device.

Latches

The latches can be conveniently brought into place with a rubber mallet.

What is a hammer and what can it do

When all the parts are installed, we connect the drive belts.

Belt

In the instructions, we carefully follow the numbers of the parts to be mounted.

Tube

We connect the plastic guide tube.

Control box

Insert the control box.

Connect

And connect all the wires.

Starting up

Starting the printer

The printer blinked and happily announced that it was ready to go.

Head

The peculiarity of this printer is that it can work offline. It is enough to throw the model in gcode format on a flash drive and upload it for printing.

Software

The printer is easy to manage with the included Cura software.

Cura is included in the kit

Cura is completely in Russian, it is a pleasure to work with it, at least for me, a complete loser in this new business for me.

Test print

Test print

Trying a test print.

Be sure to put the gasket

Indispensable without lining. Even better is to purchase a special adhesive tape. Below I will show why. Then the part will sit securely on the table.

Monitor

The printing process took about 5 minutes.

Plastic feed

Plastic is fed through the plastic feed unit.

Coil holder

The coil is located below.

Printing process

Printing without any errors.

Printed

The output is a finished geometric object.

Printing without sticky paper results in a crooked bottom instead of a bottom

If you try to print a model without sticky tape or paper, the model may come out slightly crooked. In general, the main reliable bottom.

The first pancake is lumpy

Marriage as a reason for printing without a special tape

One-sided tape failed at the very end when the robot needed eyes. The model shook and the robot was left without eyes. Therefore, it is important to install a special ribbon for printing.

Correct printing

After calibration, the figures are clear. I liked the printer. If everything is done according to the instructions, namely: put a lining under the table, use adhesive tape, calibrate, then there are no problems. I recommend this model as the first 3D printer for learning software, printing the details you need for your home. In the future, I want to print 3D parts for my car. The car is old, parts are not easy to get and not cheap. And you can find software on the Internet. Something like this. Thank you!

In the future, I want to print 3D parts for my car. The car is old, parts are not easy to get and not cheap. And you can find software on the Internet. Something like this. Thank you!

For those who are interested in Funtastique EVO v1.0 3D printer and want to save 10% on its purchase, please use promo code GT-3D , which is valid for 14 days.

Author: Dmitry (KOT-DE-AZUR), Essentuki

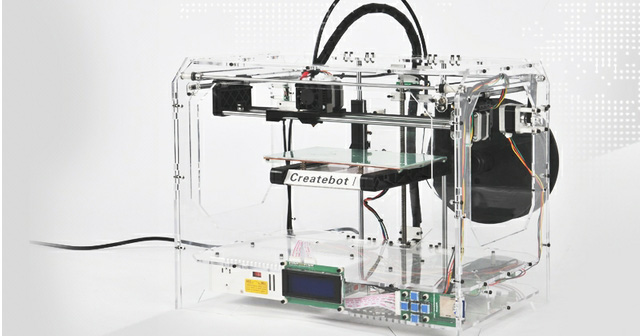

3D printer XYZPRINTING DA Vinci Pro Evo-3D printer FDM Premium

XYZPRINTING, founded for the first making a name for itself in the world of FFF 3D printing with a range of extrusion machines that make this technology accessible to a much wider range of people. The latest addition to the XYZprinting portfolio is the da Vinci Pro EVO. Conceived as the successor to the previously released da Vinci 1.0 Pro system, the single extruder FDM system comes with several feature upgrades that make this system worth considering.

XYZprinting's Pro Series is a versatile line offering everything from cost-effective entry-level systems to professional-level printers. With increased build volume and automated platform leveling for a better user experience, the da Vinci Pro EVO offers more features than ever in a neat desktop configuration.

The 3D printer is aimed at a wide range of potential users. The 3D printer comes with everything you need to start printing, including a 600g PLA-CF spool, an 8GB USB flash drive, a Wi-Fi dongle, and some tools to keep your printer in good condition.

Like its predecessors, the 3D printer also works in Cartesian configuration, a method known to be more rigid and precise, but slower than the delta or CoreXY system. The print head moves along the X and Y axes, and the platform moves along the Z axis. The printer has a fully enclosed print volume of 220x200x200mm, which allows users to print complex filaments without delamination and deformation problems. The detachable print bed is covered with PEI sheet and is magnetic and flexible, making it easy to remove parts after printing. For the extrusion module, XYZprinting increases the temperature by 20°C compared to the da Vinci 1.0 Pro to 260°C. A higher nozzle temperature provides even greater material compatibility.

The detachable print bed is covered with PEI sheet and is magnetic and flexible, making it easy to remove parts after printing. For the extrusion module, XYZprinting increases the temperature by 20°C compared to the da Vinci 1.0 Pro to 260°C. A higher nozzle temperature provides even greater material compatibility.

On the electronics side, connectivity options include Wi-Fi, USB cable, and USB stick. Wi-Fi works great and file transfers are very fast. Users have a 5" color touch screen on the front that allows them to calibrate the bed, load filament and start printing. The user interface is intuitive and easy to use. The only thing that could be improved is the access to the parameters during the printing process (temperature, Z-shift or print speed control). To do this, you first need to return to the main screen and then access the settings.

One of the most innovative features is a pair of motors under the work platform. Calibration is done in 2 steps: First, the sensor examines the bed at three points to determine its plane to make it parallel to the plane of the X and Y axes. Then, the sensor will create a grid to correct the flatness of the platform in real time during printing, examining the 11×11 matrix , or 121 points.

Calibration is done in 2 steps: First, the sensor examines the bed at three points to determine its plane to make it parallel to the plane of the X and Y axes. Then, the sensor will create a grid to correct the flatness of the platform in real time during printing, examining the 11×11 matrix , or 121 points.

The user must first download and install the XYZmaker Suite software in order to finally have the choice between three different slicers depending on the machine being used. Once the model is imported into the virtual assembly space, users can navigate through various options.

XYZ even provided a "Basic" mode for beginners so you don't get lost in the various settings. However, for more advanced users, XYZ offers an "Advanced" mode that allows you to change all print settings. This includes cooling profiles, temperatures, speeds, filling and even retraction.

The XYZ print showed above average repeatability, with an average offset of 0. 1216 mm in the X axis and 0.0767 mm in the Y axis, resulting in an average of 0.0991 mm in all axes. It should be noted that the Y-axis is much more accurate than the X-axis. Therefore, it is recommended to print along the Y-axis to produce parts with tight tolerances. The average standard deviation is also 0.046 mm, which is ideal for a printer in this price range. It should be noted that this printer has an E-step adjustment function to improve the accuracy of the printer. E-steps are parameters that tell the printer how many steps the stepper motor must take to advance one millimeter.

1216 mm in the X axis and 0.0767 mm in the Y axis, resulting in an average of 0.0991 mm in all axes. It should be noted that the Y-axis is much more accurate than the X-axis. Therefore, it is recommended to print along the Y-axis to produce parts with tight tolerances. The average standard deviation is also 0.046 mm, which is ideal for a printer in this price range. It should be noted that this printer has an E-step adjustment function to improve the accuracy of the printer. E-steps are parameters that tell the printer how many steps the stepper motor must take to advance one millimeter.

Technical characteristics

Assembly volume 220x200x200 mm

Dimensions 485x532x572 mm

Weight 24 kg

Printing heads: 1,

COMPITION OF POTITIONS XY XI X/Y: 0.0125 mm maximum maximum

Maximum nozzle temperature 260°C

Connectivity Wi-Fi, USB stick, USB cable

Nozzle diameter 0.