3D printer plastic surgery

3D Printing Is Ready To Tackle Plastic Body Implants

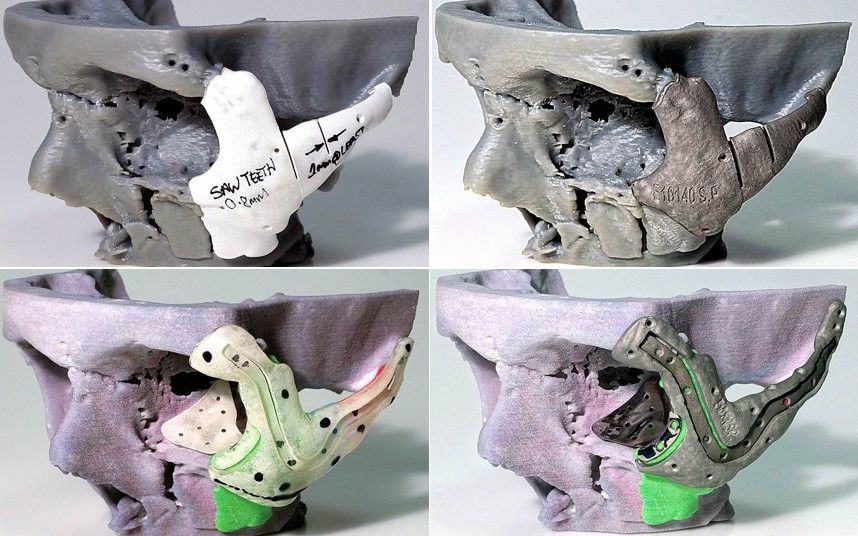

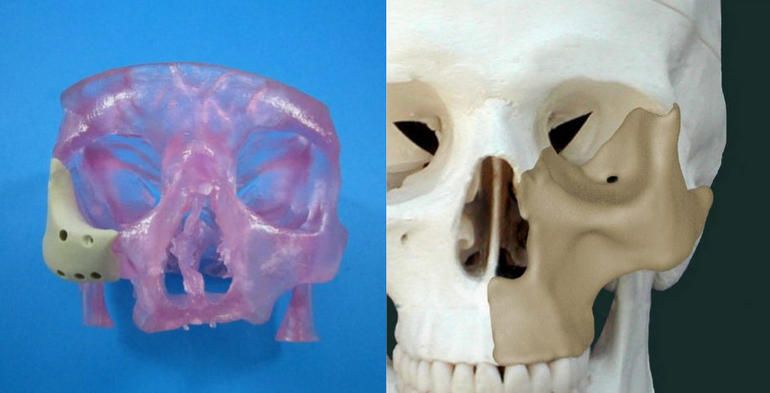

3D-printed skull implant by German MedTech start-up Kumovis.

KumovisAfter an accident left a 40-year-old woman in Sweden with a massive head injury late last year, she received a 3D-printed implant made from a plastic called PEEK to repair her skull.

It was the first time a hospital had designed and 3D printed an implant of this kind on-site, and it could prove a turning point for 3D printing in medical care.

“As far as we know, we are the world’s first to make 3D implants entirely in a hospital, which means that the implants will be better adapted to the patients, right from the start," says Einar Heiberg Brandt, medical engineer in Clinical Physiology at Skåne University Hospital, Sweden. "This will lead to faster surgeries and fewer complications."

In-hospital 3D printing is still in the early stages, but shows great promise, industry experts agree. Although 3D printing has been used in healthcare for more than a decade to manufacture titanium and stainless steel implants, PEEK plastic expands opportunities for the technology to move off the shop floors of medical device manufacturers and into labs at hospitals and clinics worldwide.

In fact, medical facilities represent a vast new market for 3D printing. The healthcare segment of the 3D printing industry, which includes dental and 3D-printed pharmaceuticals, currently is valued at nearly $3 billion.

3D Printing at Hospitals

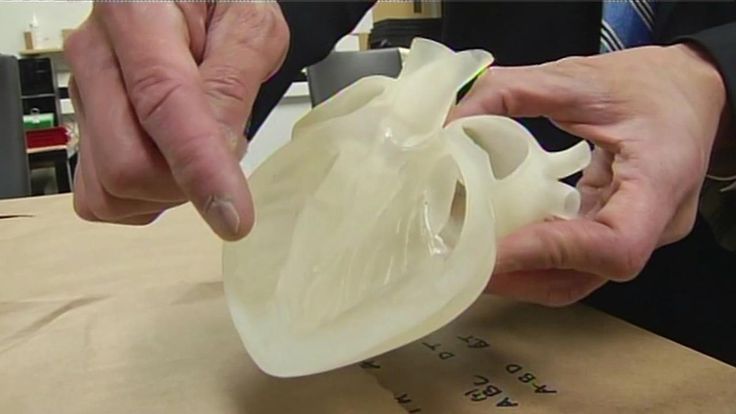

Institutions, such as the Mayo Clinic in Minn. and VA hospitals nationwide, have extensive 3D printing labs. The work there is mostly patient-specific 3D-printed medical models, surgical training tools, and orthopedic braces. However, in the not too distant future, these hospitals may be 3D printing patient-specific implants in PEEK for all types of surgeries.

MORE FROMFORBES ADVISOR

Kumovis offers a workflow, hardware, and materials for in-hospital manufacturing of PEEK medical ... [+] implants.

KumovisUsing a 3D printer and PEEK filament brings a long list of benefits to hospitals, while still having substantial hurdles. The method, when compared to traditional ways medical devices are made, namely machining and injection molding, can be done on-site at the point of care. This means faster implants, lower costs, and closer coordination between the surgeon and the technicians producing the implant.

This means faster implants, lower costs, and closer coordination between the surgeon and the technicians producing the implant.

By using the patient's data from scans and X-rays, hospitals can 3D print a custom implant that fits precisely into the defect space.

Studies show that patient-specific implants shorten surgery time, lower risks of infection, result in better outcomes, and dramatically reduce the length of a hospital stay. 3D printing the implants as needed also relieves the hospital from having to keep an inventory of expensive implants on hand.

Although, as of today, there are no 3D-printed PEEK implants manufactured at hospitals approved by the FDA, that may soon change.

A German start-up specializing in 3D-printed PEEK skull implants, Kumovis, says it’s completing the final hurdles in the FDA approval process.

"There's a lot of excitement around 3D printing on-site at hospitals and the projects that are driving manufacturing at the point of care and showing what is possible," says Miriam Haerst, co-founder and co-CEO of Kumovis.

South Carolina-based 3D Systems, one of the oldest and largest 3D printer manufacturers in the world, recently announced its plans to acquire Kumovis in order to expand from metal implants to PEEK implants at the point of care.

“As [3D printing] technology becomes more user-friendly for medical professionals, more hospitals will be able to implement end-to-end solutions for personalized surgery,” says Gautam Gupta, vice president and general manager of 3D Systems medical devices practice. “This will disrupt existing healthcare models, improve the quality of care, and crucially, save more lives.”

The Kumovis acquisition fits nicely into 3D Systems' established healthcare business and adds a new focus on decentralizing the production of medical implants.

“Shifting the manufacturing to the hospitals will be a game-changer when it comes to the availability of implants,” says Haerst.

For hospitals to become manufacturers, however, requires technical and engineering staff, regulatory processes, along with equipment. This could be managed on-site in a cooperative agreement by current medical device manufacturers, Haerst says.

This could be managed on-site in a cooperative agreement by current medical device manufacturers, Haerst says.

PEEK Plastic vs. Titanium for Implants

PEEK has had FDA approval as an implant material for years when machined, but not yet when 3D printed. Although PEEK is used in numerous implants on the market today from spinal cages to ankle joints, 3D-printed PEEK still has to prove it has the same weight bearing and wear attributes as milled or molded PEEK.

German materials manufacturer Evonik produces an implant grade, 3D printing filament, VESTAKEEP i4 ... [+]4 G, that can be used in permanent medical implants.

EvonikOverall, this bio-compatible material has several perceived advantages over stainless steel and titanium: it's lightweight, permeable to ultrasound, and practically invisible to CT and MRI scans enabling better post-op monitoring.

Over the years 3D-printed titanium gained a reputation for better bone integration and thousands of joint and spine implants are 3D printed every year by major manufacturers, such as Stryker. But PEEK has changed, says Marc Knebel, head of medical systems at Evonik, which manufactures PEEK for 3D printing as well as injection molding and milling.

But PEEK has changed, says Marc Knebel, head of medical systems at Evonik, which manufactures PEEK for 3D printing as well as injection molding and milling.

"Today, PEEK can be designed with additives to gain new features, such as better osteointegration," says Knebel. "We are working with a couple of hospitals on [3D-printed implants] already. The first ones will be active within the next five years."

A 3D printing lab situated next to the operating room ready to churn out individualized implants designed from patient data at a moment’s notice is still a long way off. Regulatory hurdles remain, clinical studies are still in progress, and building buy-in from hospitals will take time. What we’re seeing today, however, are the innovators taking the first steps.

How 3D printing is set to revolutionise reconstructive surgery

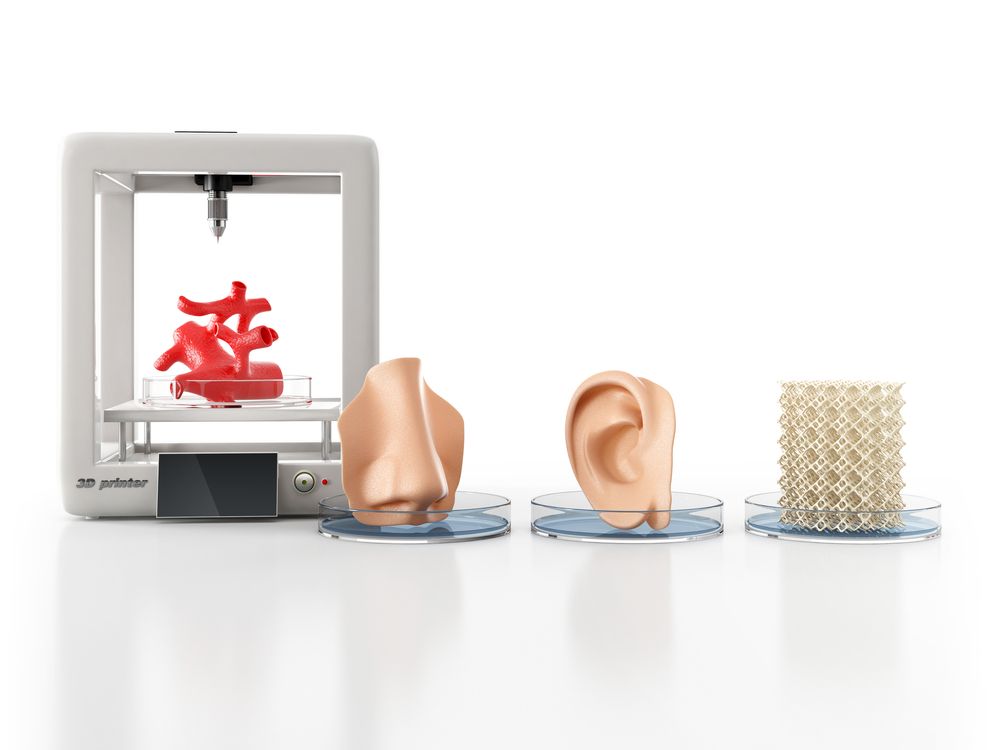

A decade ago, the idea of 3D printing body parts to seamlessly replace damaged or disfigured limbs, joints and features may have seemed like science fiction.

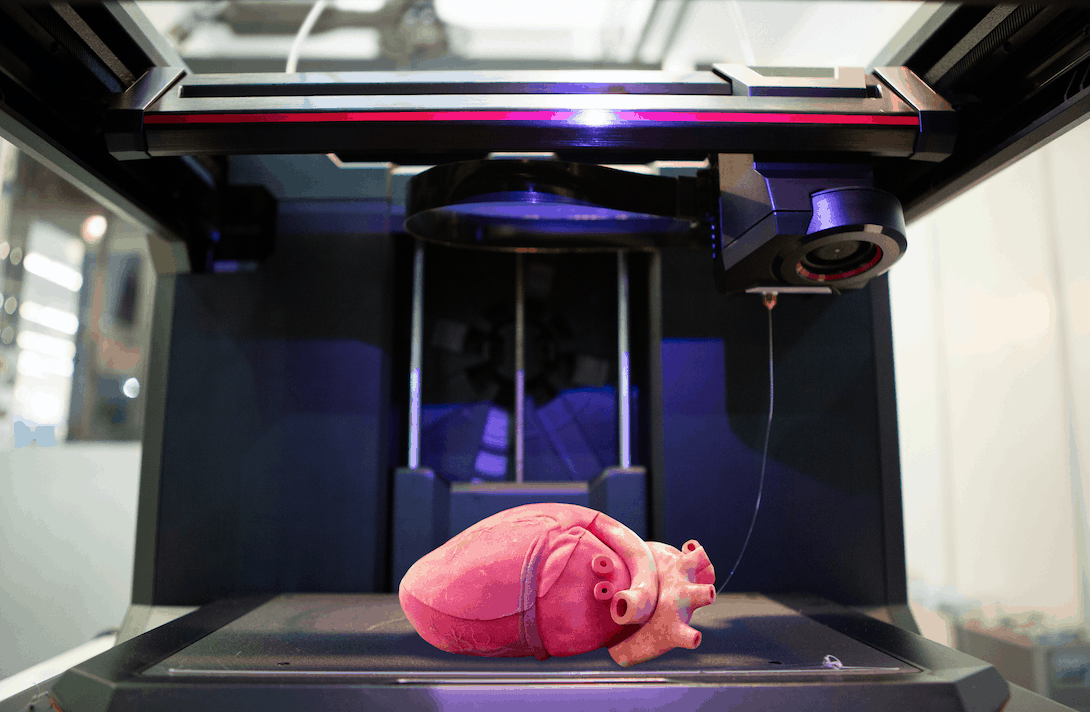

Now, as 3D printing technology stands on the cusp of a new era of combining biosynthetic products with our natural flesh and bone, the way surgeons treat their patients is changing forever.

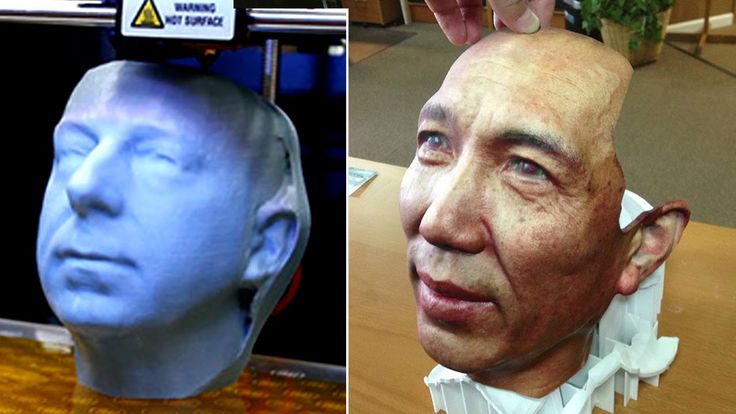

In 2015, American schoolboy Dallan Jannet was the first to receive a 3D-printed nose, at the age of 14, after falling face first on to live electrical cables.

Reconstructive surgeons restored his taste and smell with a functional, 3D-printed nose that even matched his pores, skin tone and wrinkles for a more organic feel.

Once considered groundbreaking, these techniques first explored by pioneering surgeons have advanced to a degree where patients can now receive perfectly matched custom-fitted prosthetics to replace body parts.

We are on the cusp of a new era of tissue engineering

Dr Demetrius Evriviades, King's College Hospital London Dubai

Julian Callanan, managing director of Sinterex, established his 3D printing company in 2016 during the embryonic era of the technology in the UAE.

A pilot project to work alongside surgeons at the Dubai Health Authority’s Rashid Hospital ended this year and explored new areas of printing prosthetics, tools and surgical guides required for the operating table.

Today, the company remains part of the emirate's 3D Printing Strategic Alliance, a platform under the Dubai Future Foundation that pulls together government entities and private companies to accelerate the use of 3D printing across a variety of sectors.

Sinterex also now prints 3D prosthetics for Mediclinic hospitals and Cleveland Clinic Abu Dhabi.

“The way to think about 3D printing in medicine is that each person is different and this enables mass-customised manufacturing,” said Mr Callanan.

“We can make things at scale, which are completely individual and different.

“If you are having a knee replacement, the regular artificial joint comes in only four sizes.

“So, the patient is fitted to the implant, rather than fitting the implant to the patient — as you can do if it is 3D printed. ”

”

Custom-fitted joints and templates for surgery allow doctors to take less time to perform complex procedures, and speed up patient recovery.

On average, surgeons reported 25 per cent less time spent in the operating theatre, due to the pre-planning allowed by using 3D printed models.

It allows for huge savings, about $3,000 to $4,000 in costs per operation.

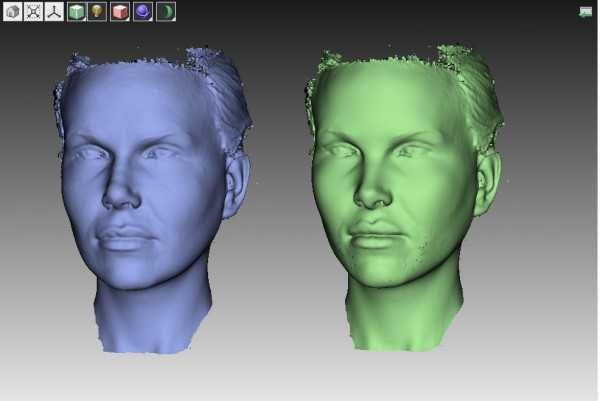

Printing replacement body parts such as ears, lips or a nose involves photogrammetry, a technique that takes several images from a patient to overlay on to an editable model.

The files are then checked alongside MRI data and CT scans of a patient to create a perfect fit.

Digital sculptures then use that data to replicate the damaged body tissue so it can be printed and perfectly fitted to the surviving tissue.

“[The] benefits of 3D printing custom-made joints for patients are they are generally more suitable, so can be fitted faster, last longer and are generally slightly cheaper as the surgery is shorter,” said Mr Callanan.

“Rather than surgeons having to manipulate a joint to fit during surgery, as it is custom built, they know it already perfectly fits.

“In one kidney transplant case, the surgeon said after he had reviewed the surgical 3D model, he changed his approach to go into the patient via their back with keyhole surgery, rather than the stomach with a large incision.

“There was less damage to stomach tissue so it was better for the patient.”

Dental, maxillofacial and orthopaedics are key areas of health care where 3D printing is now used, and can replace bone and teeth using titanium or cobalt materials.

They are proven to be biocompatible over a long period of time and do not leech to pollute the body.

Titanium is also slightly porous, which allows for oscillo-integration, where natural bone can grow into and through the titanium so it is absorbed into the body.

One of those to recently benefit from a new 3D printed knee joint is Mohammad Shafiq, 69, an American in Dubai who had lived with a deformity in his right knee.

Mr Shafiq travelled regularly and endured daily pain while walking until doctors at Burjeel Hospital for Advanced Surgery in Dubai created a replacement knee joint that has transformed his life.

An X-ray of Mr Shafiq’s knee showed an unusually large bone that would make it difficult to fit a standard prosthetic, so a custom knee joint was printed instead.

A CT scan provided the exact dimensions required by the manufacturer in Switzerland, who then created a virtual model and then a titanium implant. Photo: Burjeel

A CT scan provided the exact dimensions required for the manufacturer in Switzerland, who then created a virtual model and then an implant base. It took three to four weeks for the company to finish the product.

“The custom-made implant made it possible to perform a cruciate-retaining surgery,” said Dr Samih Tarabichi, who performed the operation that allowed them to retain more of the patient's ligaments.

“We did not have to resect the posterior cruciate ligament during surgery, thereby maintaining the normal structure of the knee.

“An implant is like wearing a shirt. If it is not of the proper size, you won’t be comfortable wearing it.”

3D-printed knee a perfect fitAfter the complete knee replacement surgery, Mr Shafiq was able to walk about an hour later.

Burjeel currently outsources its 3D printing implant operations to Symbios in Switzerland and the UK.

Currently, only about 3 per cent of custom implants are 3D printed at the hospital, but that is expected to increase significantly.

The hospital aims to have its own 3D printing centre on site within six months, to reduce reliance on overseas printers, which delays patient recovery, said Dr Tarabichi.

“It will be a breakthrough for the region,” he said.

“When we do this in-house, design and printing, we can be the source for 3D printing in the GCC.

“It will save time, from three months down to just a week, and we can ship it to anywhere in the Middle East.

“To build this infrastructure with computer ability and engineers in Dubai is doable and really exciting for us. ”

”

Reconstructive surgery is another area of specialist care set to greatly benefit from new developments in 3D printing in the years to come.

From titanium implants that fit seamlessly into bone, to biomaterials used alongside a patient’s body tissue to reconstruct damage, 3D printing has an important role to play.

Facial features rebuilt thanks to new technologyDr Demetrius Evriviades, a plastic surgeon at King's College Hospital London Dubai, operated on Pakistani activist Malala Yousafzai to rebuild her face after an assassination attempt by the Taliban on a school bus in the Swat Valley in 2012.

Dr Evriviades was one of two reconstructive surgeons who helped wounded soldiers during the worst years of the Taliban insurgency in Afghanistan, rebuilding genitalia damaged by roadside bombs.

Now working in the UAE, he is excited about the future potential of 3D printing in his field.

Dr Demetrius Evriviades, a combat trauma surgeon, speaks about how 3D printing is revolutionising the way people are being put back together after suffering severe injuries. Victor Besa / The National

Victor Besa / The National

“This technology is hugely beneficial in our pre-surgical planning and has become routine in head and neck reconstruction surgeries,” said Dr Evriviades.

“We can now print a perfect titanium implant which goes into the bone for amputees. It is completely anchored into the femur of the amputee, so they can then click on a prosthetic limb, terminator style.

“That conveys huge functional improvements for an amputee as they no longer have to wear a socket, which causes a lot of problems and discomfort.

“We can print a bespoke implant, designed specifically for that patient, based on results from a 3D CT scan. It is like buying a suit off the peg, compared with one that is tailor made.”

In patients born without an ear, or who lose one through misfortune, reconstruction is challenging.

Now, biological scaffolds can be printed for ear reconstructions to be implanted.

It involves harvesting rib cartilage and spending hours carving a scaffold for an ear, securing it with wires, implanting it in the head and then covering it with biological tissue and skin.

“We are on the cusp of a new era of tissue engineering,” said Dr Evriviades.

“By printing a biological scaffold, you can create a perfect replica of someone’s ear can then be implanted and transferred. It is an exciting development.”

Tissue manufacturing is already in place, where bovine collagen and shark fin cartilage are used to generate a new human skin with a silicon layer on top, called Integra.

It can be used to make the dermis, the inner layer of the skin beneath the epidermis. The body grows into it, it is vascularised and eventually replaces the bovine collagen and shark collagen with the patient’s own new dermis.

It takes a few weeks but it is a way to create new skin, minus the nerve endings and hair follicles.

“In reconstruction, if you can take something from elsewhere in the body, it is less likely to be rejected by the body,” said Dr Evriviades.

“But that has a cost to the patient, with extra surgery, scarring, pain and morbidity. If we can take a patient’s cells and grow them into more cells to populate them into a structure, that is the holy grail.”

If we can take a patient’s cells and grow them into more cells to populate them into a structure, that is the holy grail.”

Updated: October 07, 2022, 6:00 PM

Aesthetics of the body or how 3D printing is used in plastic surgery

Application

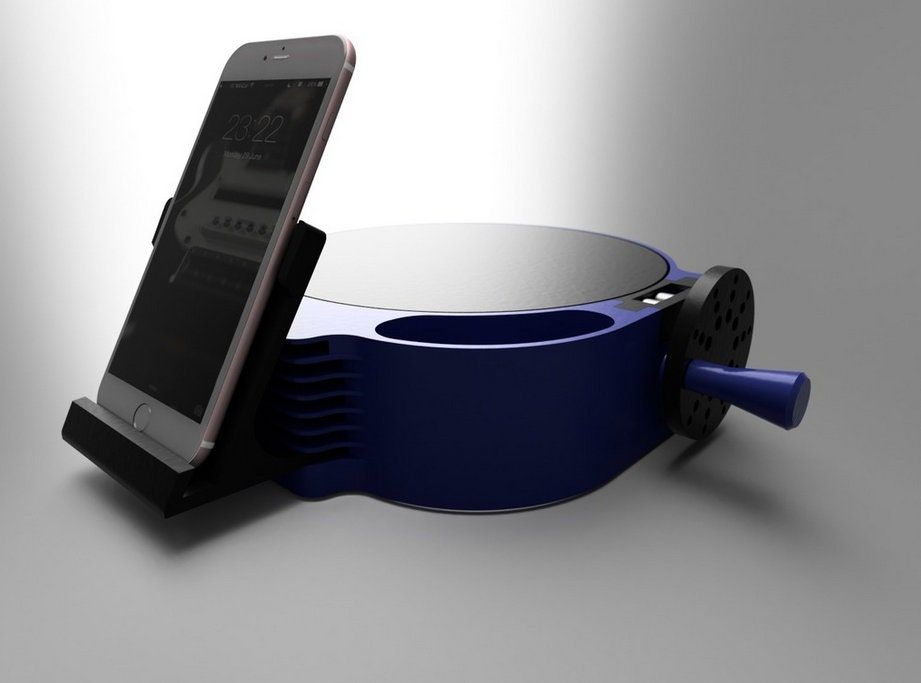

Formlabs Form 2

It's no secret that 3D printing is widely used in various fields, including medicine. Plastic surgery has become one of the areas using the possibilities of 3D printing. To model a new appearance, silicone implants are used, which are placed under the skin. Using standard templates can create an unnatural look, so there was a need for an individual approach. One of the first to use a 3D printer to solve these problems was the VIPstudio clinic of Dr. Guryanov, whose specialists use the Formlabs Form 2 3D printer to create prostheses. Many aesthetic and restorative surgeries have already been successfully carried out.

Watch a video on the use of 3D printing in plastic surgery created by VIPstudio in collaboration with iGo3D

Form 2 is a new high-precision printer for jewelry and dentistry, as well as high-resolution modeling of small objects, printing with SLA technology ( stereolithography). Formlabs has given a global upgrade to the successful Formlabs Form 1 Plus. The new model uses a more powerful laser with a power of 250mW, and the monochrome display has been replaced with a user-friendly touchscreen. Also, the print area has been increased, a Wi-Fi module has been added, an automated system for leveling and cleaning photopolymer resin has been added.

iGo3D is an official partner of FormLabs, as well as the only distributor in the Russian Federation, the Republic of Belarus and Kazakhstan. Want to get the best value for your Formlabs Form 2 3D Printer and enjoy superior technical support? Do it right now on the iGo3D website! Best price guarantee!

Our groups in social networks:

YouTube

VKontakte

Your iGo3D team

Subscribe to the author

Subscribe

Don't want

5

Article comments

More interesting articles

arelav

Loading

02/10/2023

5164

53

Follow author

Follow

Don't want to

I noticed this tool a long time ago. But before buying I wanted to try if it is comfortable to use...&...

But before buying I wanted to try if it is comfortable to use...&...

Read more

17

Subscribe to the author

Subscribe

Don't want

I think many pet owners are familiar with these rollers to remove pet hair from o...

Read more

155

Follow author

Follow

Don't want

Good day, dear colleagues!

In this post I would like to tell you about such...

Read more

Read blogs

» 3D MODELING IN PLASTIC SURGERY

DO YOU THINK ABOUT WHAT YOU WILL LOOK AFTER PLASTIC SURGERY? THE ANSWER TO THIS QUESTION WILL BE THE METHOD OF 3D MODELING IN FACE PLASTIC SURGERY.

The 3D modeling method, which facilitates the work of plastic surgeons, allowed patients to get an idea of the final results of the operation. Prof. Khalil Ibrahim Janter, Aesthetic, Reconstructive and Plastic Surgeon at Acıbadem Bakırköy Clinic, shared with us details about 3D facial imaging, a technique that has many advantages when it comes to achieving the desired result.

Prof. Khalil Ibrahim Janter, Aesthetic, Reconstructive and Plastic Surgeon at Acıbadem Bakırköy Clinic, shared with us details about 3D facial imaging, a technique that has many advantages when it comes to achieving the desired result.

What is the 3D method modeling ?

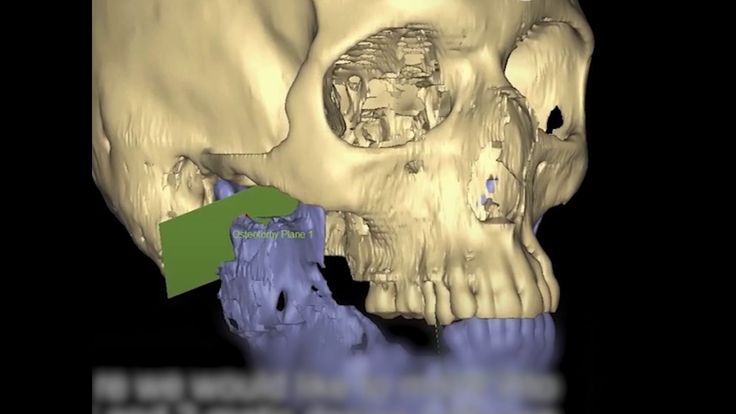

Human faces have a very complex structure. When planning a surgical procedure based on the perception obtained from the evaluation of a single photograph or physical examination, there is always a risk of error. Moreover, it is of utmost importance to us that patients can recover and return to their previous condition, as well as to monitor the changes that occur during procedures for patients who are treated solely for cosmetic reasons, and to revise procedures in accordance with the progress of the operation and the condition of the patient. . Therefore, the original documentation is vital. Thanks to the use of advanced technologies, we can now acquire images by combining images of soft tissue and bone contours obtained using 3D computed tomography and 3D cameras. We use image data for both planning and procedures.

We use image data for both planning and procedures.

| WHEN DID THIS TECHNOLOGY START? 3D CT technology has been around for many years, but its capabilities are constantly changing. I started using a system using this technology back in 2005. At that time I was using the seventh version of this system, currently - the sixteenth. The capabilities of the technology are based on solid scientific evidence, and they continue to strengthen its power. Therefore, our confidence in 3D CT is growing stronger every day. |

What are the advantages of technology?

3D visualization in facial plastic surgery is used for more than just documentation. It is now also possible to plan operations in a more efficient way using the mentioned 3D digital images and various program interfaces. Recent developments have also given rise to 3D printers. Titanium 3D printers allow us to create solid models of patient tissues and make incisions on these models that are supposed to be performed during the operation. The printers also allow surgeons to create 3D fixation plates and 3D cutting molds used to hold patients' bones in place during surgery and to simulate bone incisions that must be made prior to surgery. Bone implants intended to provide an external contour for cosmetic purposes can also be planned and produced in advance. In other words, these technologies ensure that nothing happens by chance. Thus, surgeons apply accurate mathematical measurements during preoperative planning and perform operations according to the plan.

Titanium 3D printers allow us to create solid models of patient tissues and make incisions on these models that are supposed to be performed during the operation. The printers also allow surgeons to create 3D fixation plates and 3D cutting molds used to hold patients' bones in place during surgery and to simulate bone incisions that must be made prior to surgery. Bone implants intended to provide an external contour for cosmetic purposes can also be planned and produced in advance. In other words, these technologies ensure that nothing happens by chance. Thus, surgeons apply accurate mathematical measurements during preoperative planning and perform operations according to the plan.

“Because 3D modeling makes it possible to successfully perform procedures that were considered “impossible” or “ineffective”, it plays an important role in cosmetic and reconstructive surgeries. This method has become an indispensable element in facial plastic surgery.”

What is the preoperative course of the procedure performed using 3D modeling ?

The first thing to decide is whether the procedure will involve both soft tissue and bone structures. If it is limited to soft tissues, then CT is not necessary, as its use exposes the patient to unnecessary radiation. It is possible to use 3D CT for medical purposes, however, the same surface images can be obtained using 3D cameras. Once acquired, these images can be used in rhinoplasty, measurement of certain aesthetic surgery points, and volume calculations. On the other hand, CT scanning is necessary for procedures related to bone structures.

If it is limited to soft tissues, then CT is not necessary, as its use exposes the patient to unnecessary radiation. It is possible to use 3D CT for medical purposes, however, the same surface images can be obtained using 3D cameras. Once acquired, these images can be used in rhinoplasty, measurement of certain aesthetic surgery points, and volume calculations. On the other hand, CT scanning is necessary for procedures related to bone structures.

In which areas is the technology applied ?

It is often used for mandibular and maxillary reconstruction and eyelid surgery. This technology is also being used to document the results of reconstructive surgeries in patients with cleft lip and palate, as well as missing ears or protruding ears. Another important area of application is the cosmetic operations of the nose and face with the help of fillers.

Do you consult with a patient who will undergo surgery ?

When I share my images, I still remain reticent about showing them the simulation results. When you show patients an electronic simulation on a computer, it is taken as a promise about the end result, and it is assumed that you just need to do the same. However, due to the possibility of complications during the operation, I do not believe that the surgeon should make such promises, especially when it comes to complex operations. On the other hand, I put such images into practice when planning an operation and inform patients that the images will be used for this purpose. If there is a desire, I can also provide them with images, but only after the operation. There are times when I prefer not to share intermediate planning steps. But sometimes I show patients, especially those who will be undergoing reconstructive surgery, simulations to help them understand what will happen in the intermediate stages. This gives patients a better understanding of the procedure, as well as information about the postoperative recovery period.

When you show patients an electronic simulation on a computer, it is taken as a promise about the end result, and it is assumed that you just need to do the same. However, due to the possibility of complications during the operation, I do not believe that the surgeon should make such promises, especially when it comes to complex operations. On the other hand, I put such images into practice when planning an operation and inform patients that the images will be used for this purpose. If there is a desire, I can also provide them with images, but only after the operation. There are times when I prefer not to share intermediate planning steps. But sometimes I show patients, especially those who will be undergoing reconstructive surgery, simulations to help them understand what will happen in the intermediate stages. This gives patients a better understanding of the procedure, as well as information about the postoperative recovery period.

Motivation of the patient prior to plastic surgery affects the success rate of the procedure to a large extent.

What are the technical differences between 3D modeling and CT?

In ordinary life we need both eyes for depth perception. Likewise, we will not be able to obtain a 3D image if two optical glasses are not used at the same time. Images taken with a single optical glass must be two-dimensional. Accuracy can only be increased by increasing the number of glasses. The 3D modeling system we use provides simultaneous acquisition of images from different angles thanks to six cameras. The computer software, running in the background, combines all the images and turns them into three-dimensional surfaces. CT is slightly different. X-rays provide a cross section of the images as they pass through. When all the images are stacked on top of each other, a large number is obtained, like a deck of cards. CT works in a similar way. However, the CT image is converted into digital information that can be used everywhere. You can use this data to overlay 3D CT images with 3D photographs, or get an idea of how changes affect each other.