3D printing systems scanner

How to Choose the Best 3D Scanner to Use With Your 3D Printer

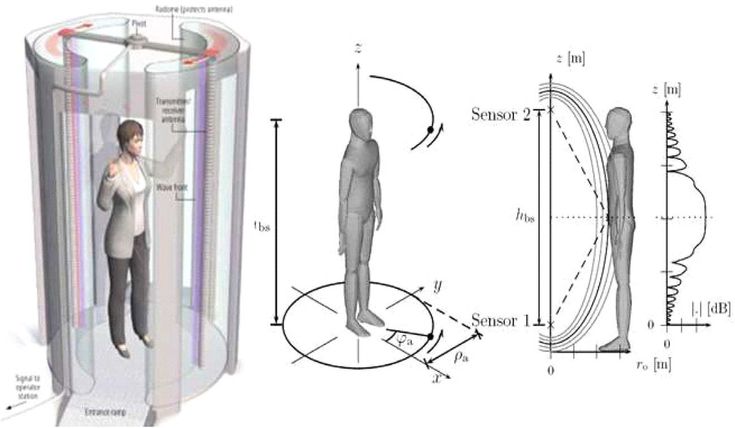

3D scanning has an important place at the beginning and end of 3D fabrication workflows. Engineers, product designers, and researchers use 3D scanners as a faster and more efficient way to start constructing digital models, whether by incorporating existing designs via reverse engineering, digitizing hand-sculpted clay designs, or referencing the exact shape of the human body.

After fabrication, 3D scanning can support quality control and help to verify the accuracy of a 3D printed part, or, after the part has been used, a scanner can reveal how it’s performed—a scan of a deformed part can show you where to reinforce the design in the next revision.

With such a wide range of product options from handheld 3D scanners to desktop 3D scanners, it can be difficult to choose the best 3D scanning system that’s right for your application and budget. In this post, we explore the most important factors to consider when purchasing a 3D scanner and showcase some of the key applications that are empowered by combining 3D scanning and 3D printing.

White Paper

3D scanning and 3D printing workflows can be applied to replication and restoration, reverse engineering, metrology, and more. Download our white paper to explore these applications and learn how to get started.

Download the White Paper

There are multiple scanning technologies currently on the market, all offering their own advantages and weaknesses.

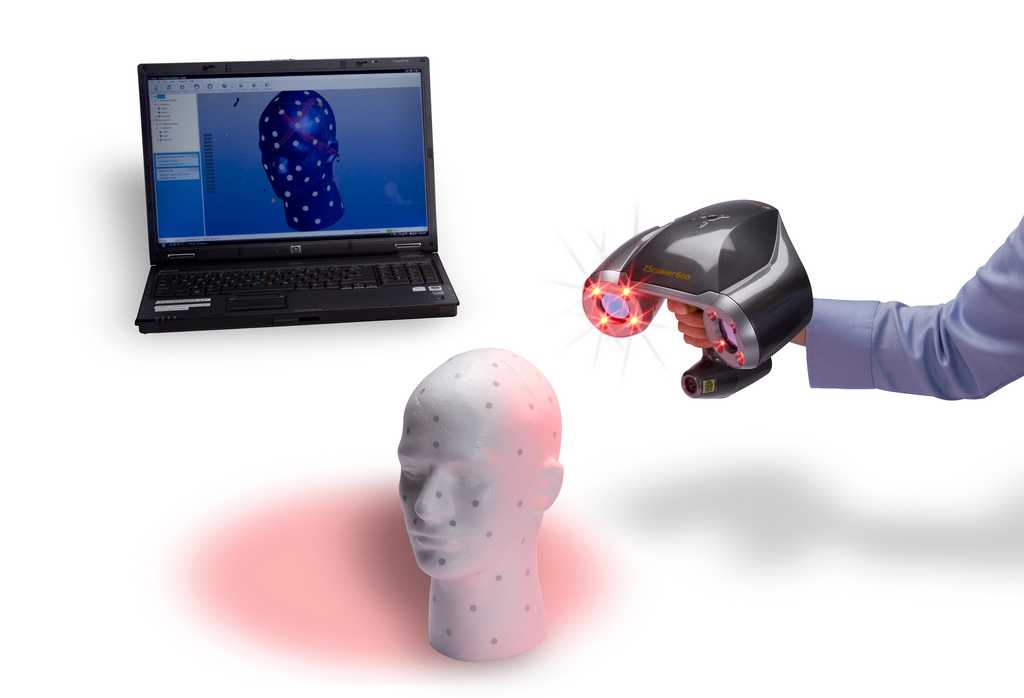

Laser triangulation uses light projected onto the object to take up to millions of measurements (dots) per second. The light reflected from the dots back into the scanner’s sensor to help it capture the geometry of the object. These types of scanners are often the most accurate, and are great for highly detailed parts that have opaque surfaces.

Laser triangulation scanners do have limitations. For example, this technology is not used in most portable scanners because the laser dots need to project from a stable source, and the source has to be kept a close distance from the scanned object. Laser triangulation scanners don’t always work on transparent or shiny surfaces either. Typically, they require reflective markers to be applied onto the object, which need to be removed after use and can be an obstacle depending on the object being scanned.

Laser triangulation scanners don’t always work on transparent or shiny surfaces either. Typically, they require reflective markers to be applied onto the object, which need to be removed after use and can be an obstacle depending on the object being scanned.

Finally, the laser dots can be harmful to human eyes, so it is important to use extra safety precautions when scanning body parts with a laser triangulation system, or to check with your scanner manufacturer to make sure the device is eye-safe.

Structured light scanners (also known as white light scanners or blue light scanners) generally use a projector with two cameras at angles on either side. A pattern of light is projected and laid over the component being scanned, the cameras capture the ways in which the object deforms the light pattern, and then multiple images are integrated into a single 3D snapshot.

Structured light scanners are available in both stationary and portable format—the technology is the most commonly used process for handheld 3D scanners. Structured light scanners are far more common in medical applications, since it is safe to use on both humans and animals and excels when an object is not perfectly still. Traditional white light scanners have been slower to scan than laser triangulation scanners.

Structured light scanners are far more common in medical applications, since it is safe to use on both humans and animals and excels when an object is not perfectly still. Traditional white light scanners have been slower to scan than laser triangulation scanners.

Structured light scanning is the most commonly used technology in handheld 3D scanners.

Depth-sensing cameras project a field of dots in infrared (IR) to sample a 3D scene. Depth-sensing cameras are simple to use and are the least expensive scanning option, but their accuracy and resolution are low, and fine details are sometimes lost. Large objects may be captured with depth-sensing cameras, but accuracy declines with increased distance from the subject and at steeper angles to the camera.

Photogrammetry means the act of deriving precise measurements from photographs. It involves taking a set of overlapping photos of an object, building, person, or environment, and converting them into a 3D model using a number of computer algorithms. This is the most commonly used method when creating a 3D scan with a smartphone, since modern phone cameras are capable of capturing and combining a large numbers of photos. Photogrammetry should be considered the least expensive and least accurate method for creating 3D prints, and is not suitable for serious business applications.

This is the most commonly used method when creating a 3D scan with a smartphone, since modern phone cameras are capable of capturing and combining a large numbers of photos. Photogrammetry should be considered the least expensive and least accurate method for creating 3D prints, and is not suitable for serious business applications.

LiDAR (light detection and ranging) sensors can be found on some higher-end smartphones and tablets, such as the latest versions of the iPhone Pro and the iPad Pro. This has made the iPhone and iPad viable scanners for those with only occasional scanning needs, offering performance a step above devices that only have access to photogrammetry. Applications that generate 3D mesh files via your smartphone’s or tablet's camera should be seen as the floor for entry-level scanning; users should expect additional work in their CAD software to remove gaps in meshes and improve the 3D model for applications like sending it to a 3D printer. Smartphones use fewer light points when scanning objects, resulting in less detail than a true, stand-alone scanner. iPhones are good substitutes for scanners if you have significant CAD design ability or need to transfer basic models into a digital space.

iPhones are good substitutes for scanners if you have significant CAD design ability or need to transfer basic models into a digital space.

WEBINAR

Watch this webinar with Peel 3D to explore how to integrate 3D scanners into your 3D printing workflow to elevate your product development process.

Watch the Webinar Now

Scan accuracy varies considerably between scanner technologies, and higher accuracy generally comes at a higher cost. The required tolerances of your final part can be a helpful guide for determining your accuracy requirements for a 3D scanner.

| High Price, Highest Accuracy ($15,000 and more) | More Affordable, High Accuracy ($12,000 and under) | Low price, Low Accuracy |

|---|---|---|

| Zeiss T-Scan Hawk Scantech Simscan EviXscan Optima+ M Creaform HandyScan 307 Silver Series | peel 3d peel 1, peel 2 & peel 2-S FARO Freestyle 2 Polyga Compact S1 | iPhone Pro and iPad Pro Structure Sensor Matter and Form 3D Scanner V2 Revopoint POP |

With accuracy in the range of 0. 1 mm or better, laser and structured light scanners are a good fit for professional applications and alongside high-resolution 3D printers. Formlabs stereolithography (SLA) 3D printers (such as the Form 3+) produce parts at a similar accuracy, and with a similar printable area, to the scan volume of many desktop 3D scanners.

1 mm or better, laser and structured light scanners are a good fit for professional applications and alongside high-resolution 3D printers. Formlabs stereolithography (SLA) 3D printers (such as the Form 3+) produce parts at a similar accuracy, and with a similar printable area, to the scan volume of many desktop 3D scanners.

Besides the accuracy between measured points and their actual location, scanners also vary in terms of resolution, which is the distance between captured points at a given scan distance. This means that details on the scanned object that are smaller than the scanner’s resolution won’t be captured. For example, a highly accurate 3D scanner with a lower resolution might detect the general shape of jewelry on a statue, but not clearly show individual details on a ring or necklace. Depending on your project requirements, this may or may not be a dealbreaker.

An easy way to remember these metrics is: accuracy is the measurement error between the part and digital value. Resolution refers to the density of measurements.

Resolution refers to the density of measurements.

Accuracy can mean slightly different things depending on the manufacturer and 3D scanning technology. For example, the accuracy of handheld scanners depends on the distance to the subject and the quality of scan reconstruction, while desktop scanners have consistent accuracy within the constrained scan volume. If you are considering buying a 3D scanner for precise measurement, make sure to compare like to like.

In general, structured light scanning provides the best resolution and accuracy when compared to laser scanning. For some artistic use-cases for 3D scanning you may need a lot of detail, while overall accuracy is less important—especially if you don’t require your part to fit precisely with other parts in an assembly. In these cases, photogrammetry is an excellent low-cost option to explore.

Both depth-sensing cameras and photogrammetry are a good solution for scanning large objects in order to create 3D printed scale models and also offer enough accuracy for capturing the shape of the human body.

Several entry-level laser scanners are available using technology similar to higher-end systems. These scanners are a great way to start replicating small objects at 1:1 scale. As one would expect, the accuracy of entry-level laser 3D scanners is lower than a high-end scanner, but they can easily provide enough detail to replicate small decorative objects and figures where accuracy is not critical.

If you only have occasional 3D scanning needs, digitization services can scan your object, as well as perform CAD translation and accuracy inspection.

The area that a 3D scanner can capture varies significantly between scanners. Find a scanner that fits your size and resolution requirements without too much overhead, as cost typically increases with scan volume.

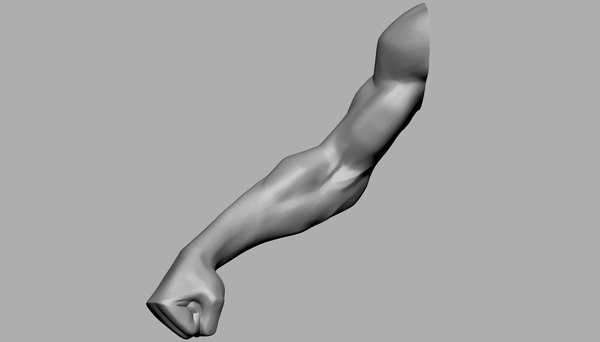

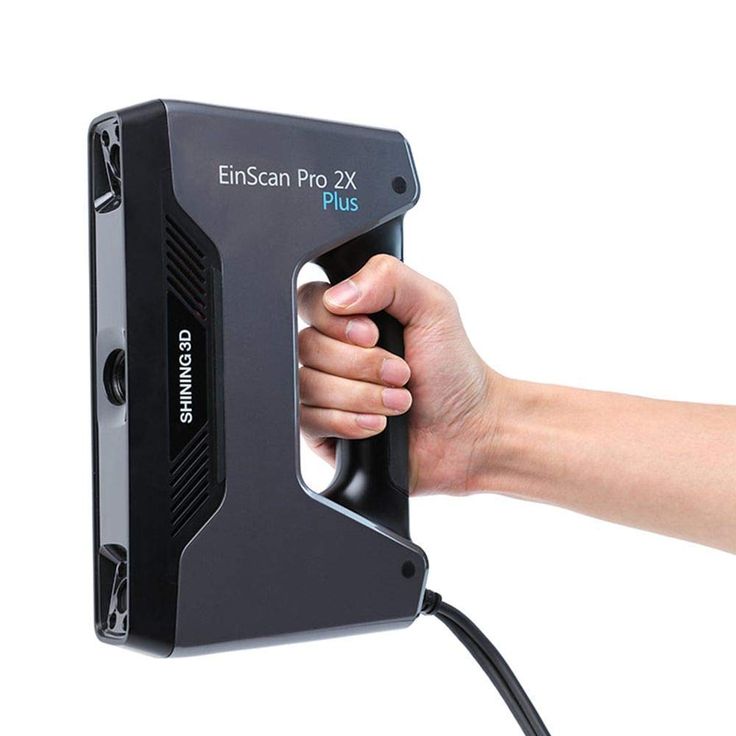

Handheld scanners can be manually moved around the object and have fewer size constraints than desktop models. Most inexpensive handheld scanners can capture objects from the size of a basketball to an entire room. High-end handheld scanners have an even wider range, and fill the niche for all objects that require precise measurements, but cannot fit in a desktop scanner. Handheld scanners are also able to capture objects nearly instantaneously, which makes them well-suited for taking human measurements (where the subject is not perfectly still) for ergonomics and medical applications.

High-end handheld scanners have an even wider range, and fill the niche for all objects that require precise measurements, but cannot fit in a desktop scanner. Handheld scanners are also able to capture objects nearly instantaneously, which makes them well-suited for taking human measurements (where the subject is not perfectly still) for ergonomics and medical applications.

If the area of the model can’t be seen by the scanner, it will cause a gap in the model. You can automatically repair small missing sections with most scan software programs to create a 3D printable model. However, repaired holes are rarely accurate to the original object. For parts that demand close to perfect accuracy, auto-repair of gaps or holes will not be sufficient. Read our MeshMixer tutorial for advanced tips to edit and repair 3D files for 3D printing.

Many scanners use turntables to increase what the scanner can see. The sophistication of a scanner’s turntable affects how easily and completely the object is captured: some scanners have the ability to move the object around multiple axes, imaging the object from more angles. This feature is important when reverse engineering plastic parts with deep recesses and ribs, which are impossible to capture from a single angle.

This feature is important when reverse engineering plastic parts with deep recesses and ribs, which are impossible to capture from a single angle.

Scanners may rotate the object to capture occluded areas. Red regions are occluded and will be missing in the scan. Areas with deep relief are difficult for a single axis turntable to fully capture due to occlusion.

Cost concerns are straightforward; how much you are willing to spend on a scanner will reflect your business’s budget and how often the scanner is going to be used. Higher cost scanners will be able to capture small objects and create highly-detailed meshes that don’t require significant touch-ups in CAD software. Handheld scanners are also often on the higher end of the price range, due to their portable nature. The low-cost scanning market offers a wide range of options, but you have to know what to look for.

Use this flowchart to determine what scanner you need based on accuracy, scan volume, and budget.

Download the high-resolution version of this infographic here.

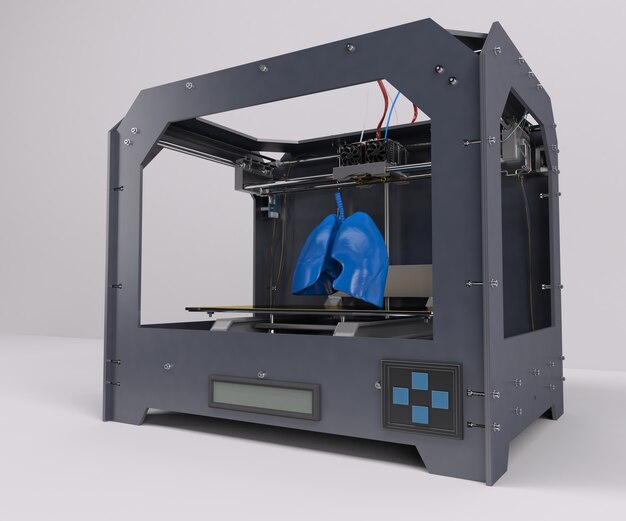

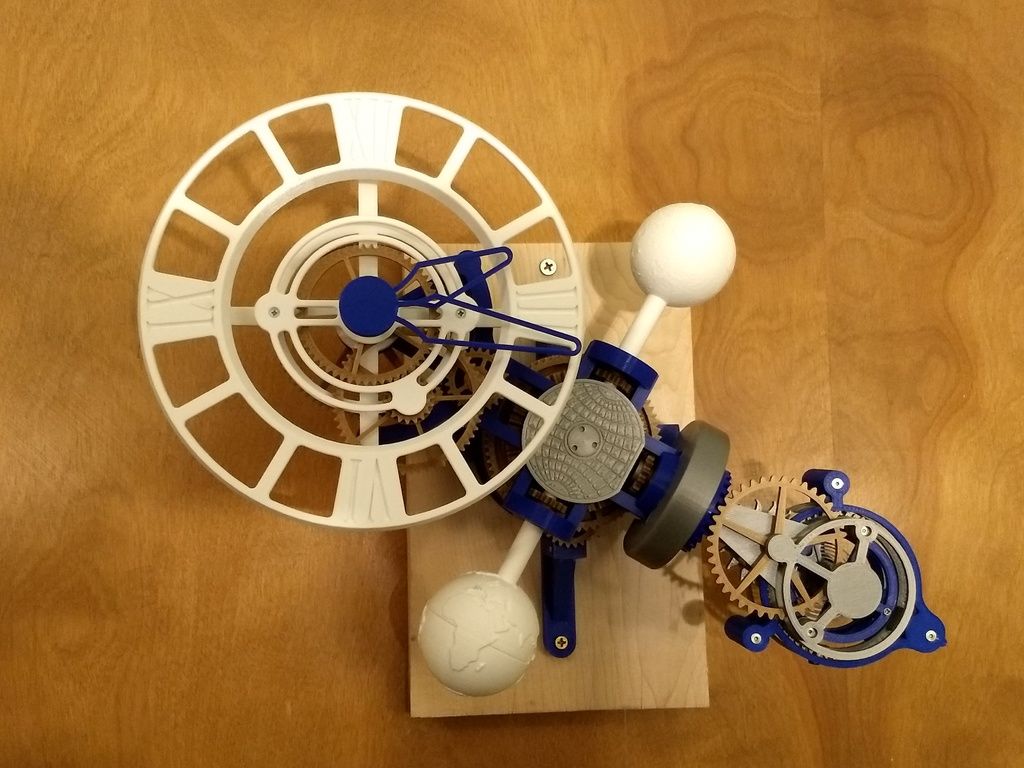

A 3D scanner expands the capabilities of a 3D printer, allowing you to replicate the shape of almost any object. Together, the two technologies create a powerful, digital workflow that can simplify and sophisticate processes in a range of industries.

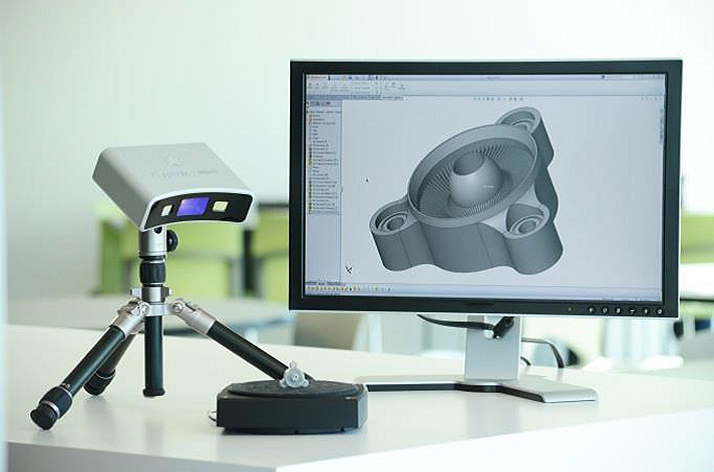

The output from a 3D scanner is a mesh of triangles representing the surface of an object at a real-world scale. In some cases, the scan can be used directly to replicate objects without any CAD work. A hybrid workflow can also be powerful, where solid CAD models are combined with scanned 3D models. For example, customized ergonomics capture a physical imprint of a part of the human body, and integrate them with a mechanical design.

3D scanners are also valuable tools for measuring the accuracy of manufactured objects. Many factors affect 3D print accuracy, and metrology-grade 3D scanners provide a clear picture of how a material performs for demanding applications.

A variety of powerful workflows are enabled by combining a 3D printer and a 3D scanner:

- Reverse engineering to create replacement parts, products with custom ergonomics, and more.

- Replication and restoration of parts, especially in art and jewelry.

- Consumer audio for creating custom earpieces.

- Dental and medical applications, and how 3D scanning is enabling patient-specific workflows.

- Metrology to validate and measure the accuracy of manufactured objects.

Webinar

Watch this webinar for a detailed look at how to start using 3D scanning to improve part design and production when paired with reverse engineering CAD and 3D printing.

Watch the Webinar Now

3D scanners and 3D printers are essential parts of digital workflows across industries. Download our white paper or watch our webinar to get a detailed look into how to start using 3D scanning to improve part design and production and learn how to pair 3D printing and 3D scanning to empower a variety of workflows in engineering, product design, and more.

Learn more about the 3D printer side of the equation: get to know stereolithography (SLA) and selective laser sintering (SLS) 3D printing technologies and see Formlabs advanced 3D printing materials for yourself with a free sample 3D printed part.

Explore Formlabs 3D PrintersRequest a Free Sample Part

3D Printing | 3D Scanner for 3D Printer

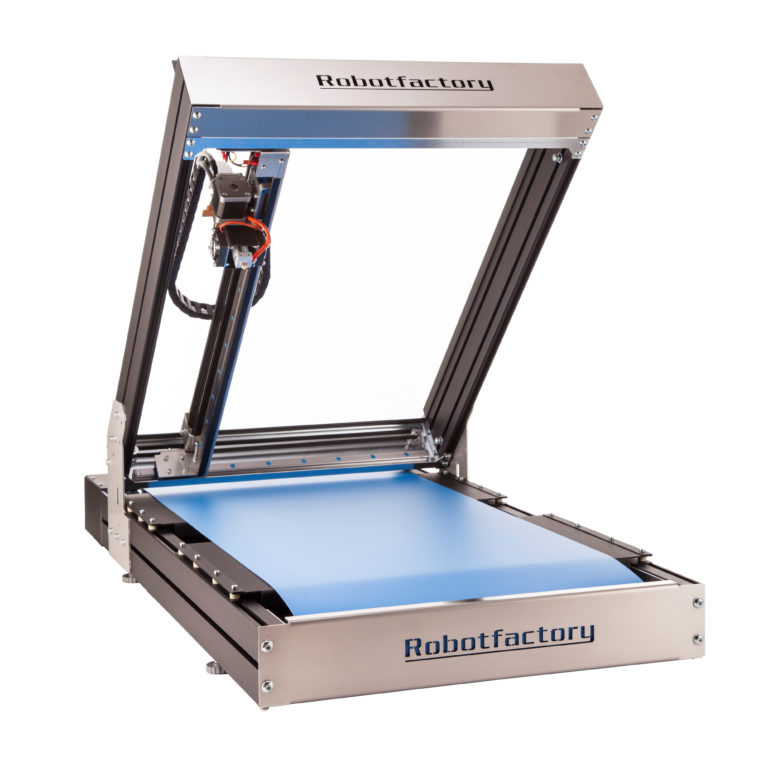

Trusted 3D Solutions Accelerate 3D Printing

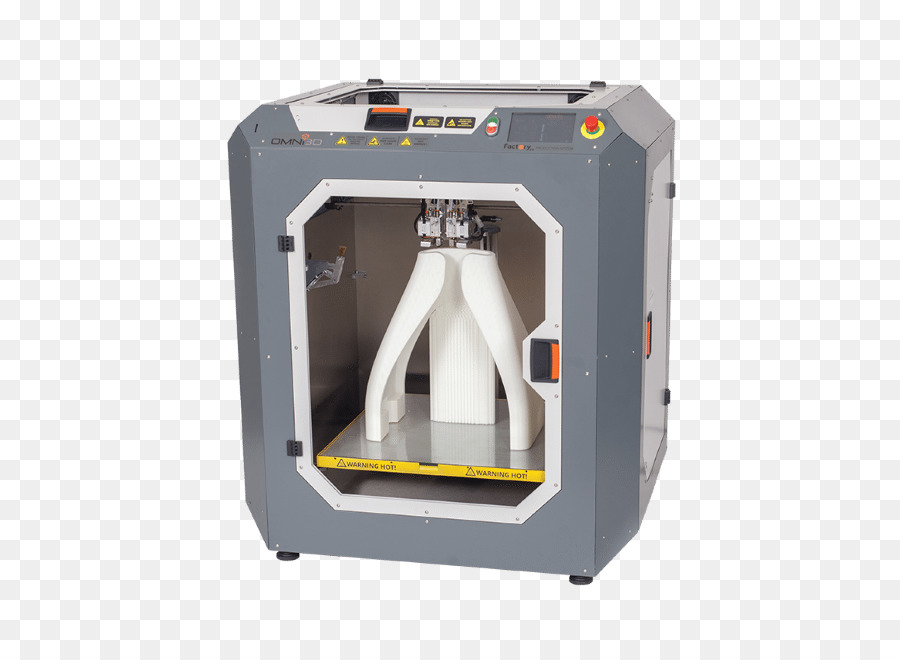

3D printing allows you to replicate any objects in front of you. It creates objects that range in size, shape, and color through a layering method. By adding materials such as plastic and metals layer by layer, users can create complex objects at low costs and high efficiency. As one of the latest technologies in the world, it is expected to bring a new revolution to various industries, including machinery manufacturing. Typically, 3D modeling software such as UG, Solidworks, and 3Dmax is used for creating 3D models for printing. It requires professional 3D modelers to conduct time-consuming and expensive tasks.

How to Use a Handheld 3D Scanner for Efficient Inspection?

3D Scan Objects

Fast 3D scanning and precise digital replicas of objects

Output 3D Data

Various output formats such as obj., stl., and ply.

Slice the Data

Seamless integration with slicing software

3D Print Objects

Accurate 3D data ready for 3D printing

Benefits

Accurate and fast 3D scanners to capture 3D data and create 3D models ready for 3D printing to reduce costs and increase efficiency.

0.00 mm

Max Accuracy

Our 3D scanners can capture accurate 3D data with an accuracy of up to 0.02 mm due to their sophisticated algorithm. It helps users to create high-quality digital replicas of objects ready for 3D printing instead of starting from scratch. Paired with our software ScanViewer, these portable 3D scanners allow users to convert point clouds into 3D models compatible with 3D printers for further use.

0 min

Fast Data Capturing

By using laser 3D scanners, which measure parts millions of times per second, you can capture 3D data of small objects in around half an hour. Highly precise measurement results and fast processing times will benefit your business.

0% ↑

Costs Efficiency

Scantech 3D scanners are more flexible in performing various inspection tasks than traditional methods. Customers can use these cost-effective 3D scanners to capture data of objects anytime and anywhere. It is fast and easy to obtain point clouds of objects while ensuring high accuracy. It reduces expensive man-hours and saves a significant amount of time.

Applications

Automotive

From a simple interior element to a dashboard, automakers can quickly create prototypes of these physical parts with 3D printing, which enable companies to verify the feasibility of design concept and ideas. It is common for designers to rework 3D printed parts to make them function better and connect with other components better. High-tech 3D scanners can help record modifications of printed parts, which can shed light on improving existing design.

It is common for designers to rework 3D printed parts to make them function better and connect with other components better. High-tech 3D scanners can help record modifications of printed parts, which can shed light on improving existing design.

Learn more >

Rail Transport and Shipbuilding

Manufacturers in shipbuilding and rail transport industry use 3D printing to create parts with complex structures to reduce weight and increase strength. High-tech 3D scanners can help to determine the material properties in deformation tests by fast scanning and inspection. In this way, manufacturers can choose materials perfectly suit for 3D printing.

Learn more >

Energy & Heavy Industry

The use of 3D printing in power generation and heavy industry is constantly increasing. Professionals and engineers are embracing the opportunities and benefits of 3D printing to increase efficiency and reduce costs. Our 3D scanners can measure 3D printed parts and generate inspection reports to analyze surface defects, deviations and alignment of the components.

Our 3D scanners can measure 3D printed parts and generate inspection reports to analyze surface defects, deviations and alignment of the components.

Learn more >

Mold

It is possible for mold makers to create 3D printed molds with affordable 3D printers and temperature resistant 3D printing materials. High-precision can help to capture detailed 3D data of molds and compare them with CAD models. Therefore, manufacturers can quickly identify hidden problems and correct defective areas to ensure high-quality parts.

Learn more >

Medical

3D printing, a technique to produce 3D solid objects from a digital file, has showed huge potential for the medical filed. It supports the creation of 3D printed medical products based on the precise 3D data of patients. These medical devices include anatomical models, orthopedic equipment, and prosthetics. Our 3D scanners can capture accurate 3D data of patients and serve as guidance for 3D printing customized medical products.

Learn more >

Scantech Solutions

Scantech helps designers and engineers to scan objects on both small and large scales to create precise and printable 3D models.

Thanks to the sophisticated algorithm and powerful data processing, our handheld 3D scanners are efficient to capture geometric features of objects with intricate details easily and quickly. In this way, professionals can streamline their workflows as they do not have to start from scratch. These 3D data are compatible with slicing software so that users can slice the data for easy 3D printing.

Read more

Product Recommendation

Get the 3D scanner and automated 3D inspection system you need for 3D printing.

KSCAN-Magic Series 3D Laser Scanner

Flexible and composite 3D scanner KSCAN features a wide-range 3D scanning mode with a scanning area up to 1440 mm*860 mm. It is also good at capturing details. KSCAN is the ideal choice to capture 3D data for small-to-large-scale objects.

Learn more

Software

ScanViewer

SIMSCAN 3D Scanner

SIMSCAN is specially designed for scanning parts with narrow spaces or hard-to-reach areas. Due to its compact size and steep view angle, it performs well in 3D scanning deep holes, grooves, and complex details. It has won the German Red Dot Award and China Design Silver Award thanks to its simplicity, aesthetics, and usefulness.

Learn more

Software

ScanViewer

AXE-B17 3D Scanner

Users can use AXE global 3D scanner to scan large-scale objects ranging from subways, and airplanes to bridges. With a scanning rate of 2 million measurement/s and built-in photogrammetry, AXE stands out of its competitors with robust performance. It also boasts high-speed and deep-hole scanning to flexibly cater to different needs.

Learn more

Software

ScanViewer

TrackScan-P42 3D System

Thanks to its intelligent optical tracking measurement technology, plug-and-play TrackScam supports efficient 3D scanning without sticking targets. Besides, it causes no harm to the object to be scanned due to its non-destructive measurement. By freely switching between multiple working modes, it can quickly capture accurate 3D data of large-scale objects.

Besides, it causes no harm to the object to be scanned due to its non-destructive measurement. By freely switching between multiple working modes, it can quickly capture accurate 3D data of large-scale objects.

Learn more

Software

ScanViewer

AM-DESK

AM-DESK, AutoScan-T42, AutoScan-K are designed for intelligent automated measurements of parts in a large volume. They can conduct 3D measurements right on the shop floor regardless of environmental conditions. It can be integrated into the production line and greatly increase manufacturing efficiency.

Learn more

Software

ScanViewer

Top Ten 3D Scanners from $100 to $100,000 / Sudo Null IT News There are several ways for you: you can of course create your 3D model from scratch in a 3D modeling program or find a suitable one on the Internet, but you can also scan an existing object! The purpose of this review is to help you understand the variety of 3D scanners available and offer the best in every price segment from a photogrammetric smartphone app to professional 3D scanners.

Scanners are listed in ascending price order so you can choose the one that suits your budget and use the resulting 3D models for both 3D printing and animation.

If you are not satisfied with the proposed solutions, there is an extended overview at this link.

3D scanner in hand:

1. Best smartphone app: Autodesk 123D Catch (free)

Autodesk 123D Catch is a free photogrammetric application. It allows you to create a 3D model from photographs of an object taken from different angles. You can use it to scan objects, people, and even the landscape. For some applications, if you don't need perfect accuracy, you don't need special equipment. This application actually provides quite good detail and is easy to use. However, it will take you at least 30 minutes for the app to process your photos as the processing takes place on the server and it takes time to send them.

2. Best DIY 3D Scanner: Kinect ($99.99)

The Xbox Kinect is designed to expand your gaming experience. It is not designed for 3D scanning, but you can easily find manuals and third party software (like ReconstructMe) to turn it into a 3D scanner. If your arms are growing out of your shoulders, this is an interesting and inexpensive solution for 3D scanning.

It is not designed for 3D scanning, but you can easily find manuals and third party software (like ReconstructMe) to turn it into a 3D scanner. If your arms are growing out of your shoulders, this is an interesting and inexpensive solution for 3D scanning.

Price: $99.99

Resolution: 0.051mm

)

This scanner can be attached to your tablet or phone (generally designed for iPad, but can be adapted to other devices). Lightweight and easy to use, with a very good resolution. Suitable for large items (can scan a full-length person) and outdoor scanning. You will be able to use it with software running on Occipital's SDK. This will increase the resolution and give you access to special features like room scanning. It probably won't be something you'll use for 3D printing, but it's interesting for game development, for example.

Price: $ 379

Resolution up to: 0. 5 mm

5 mm

accuracy to: 4 mm

4. The best of cheap manual 3D scanners: Cubife ($ 399)

3D scanners can be quite affordable and easy to use if you choose from inexpensive portable models. Cubify fits these criteria very well and has a relatively good resolution. But still, its capabilities are not enough for texture scanning and it is better to use it for subsequent 3D printing of one-color models.

Price: $ 399

Resolution: 0.9 mm

Deep permit at a distance of 0.5 m: 1 mm

3D scanner on the table:

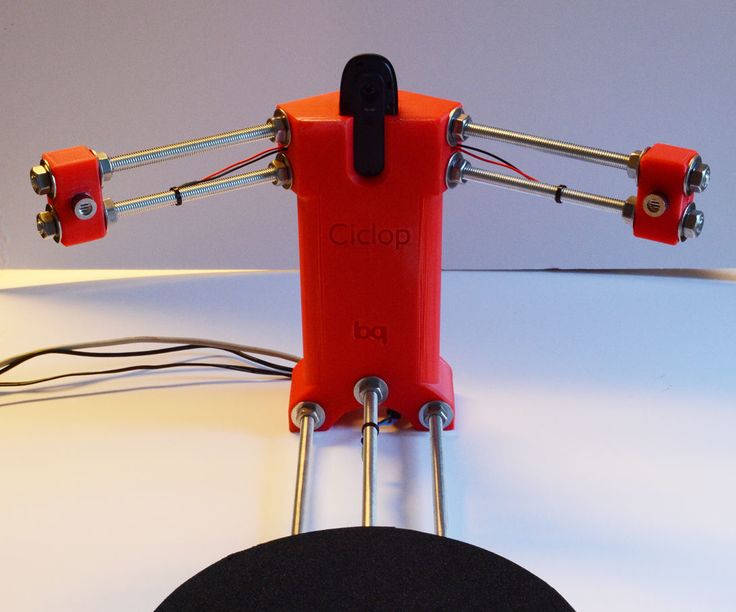

5. Best and cheapest table 3D 3D 3D 3D 3D 3D 3D 3D 3D 3D 3D 3D 3D- Scanner: Matter and Form ($519)

If you're looking to take your quality to the next level, you can purchase a desktop 3D scanner. This model is compact, easy to use, and delivers good resolution, especially considering the price (not your go-to option if you're looking for perfection, but great for educational and demo purposes). The scanning process takes place with the help of a laser and a rotating platform. The scan takes about five minutes and simultaneously reads the texture of the object.

The scanning process takes place with the help of a laser and a rotating platform. The scan takes about five minutes and simultaneously reads the texture of the object.

Price: $ 519

Resolution: 0.43 mm

accuracy: ± 0.25 mm

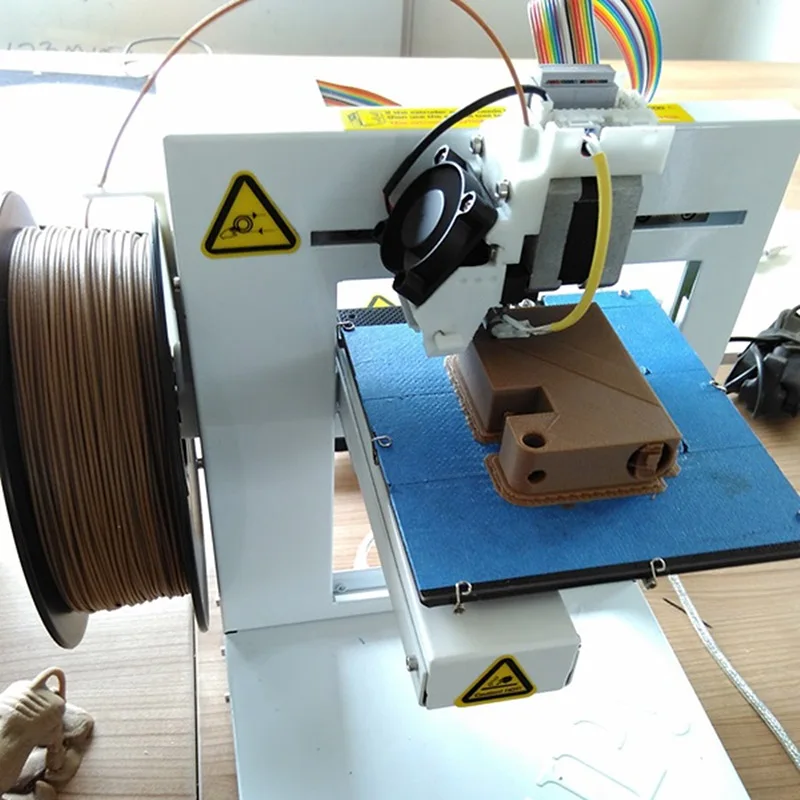

6. The best device "two in one": XYZPRINTING DA VINCI 1.0 ($ 600)

is inexpensive combines a 3D scanner and a 3D printer. The quality of the models is not too high, but the price is very low for such a combined device. This makes the XYZprinting Da Vinci the easiest solution for beginners who want to get into the world of 3D scanning-printing.

Professional 3D scanners:

7. Best value for money portable 3D scanner: Fuel3D Scanify ($1490)

Very easy to use, intuitive, and feels good in the hand, this scanner delivers good accuracy and texture quality. The only limitation is that the size of the scanned area is limited, which is great for small objects, but for scanning a full-length person, for example, it will not work.

Price: $ 1490

Resolution: 0.35 mm

accuracy: to 0.3 mm

8. Best price The scanner uses a different scanning technology than others. Instead of a dual laser scanning system, it uses a structured light source and cameras for fast scanning with very fine detail down to 0.06mm! The scanner comes with DAVID Pro Edition 3 software that works with OBJ, STL and PLY 3D file formats that can be exported to other programs for further editing.

Price: $ 3995

Resolution: 0.06 mm

accuracy: 0.5% of the size of the object

9. The best table professional 3D scanner: SolutionIX Rexcan 4 ($ 79 900)

The 3D scanner and its price provides much better scanning quality. Solutionix Rexcan is equipped with two cameras for greater accuracy. It uses optical phase shift triangulation technology and two high-resolution CCD cameras to provide high-precision data. The scanner can be used to scan larger objects by increasing productivity with a photogrammetric system. As an option, it can be equipped with an automatically rotating platform capable of supporting up to 50 kg of weight.

The scanner can be used to scan larger objects by increasing productivity with a photogrammetric system. As an option, it can be equipped with an automatically rotating platform capable of supporting up to 50 kg of weight.

Price: $ 79 900

accuracy: from 0.03 to 0.71 mm

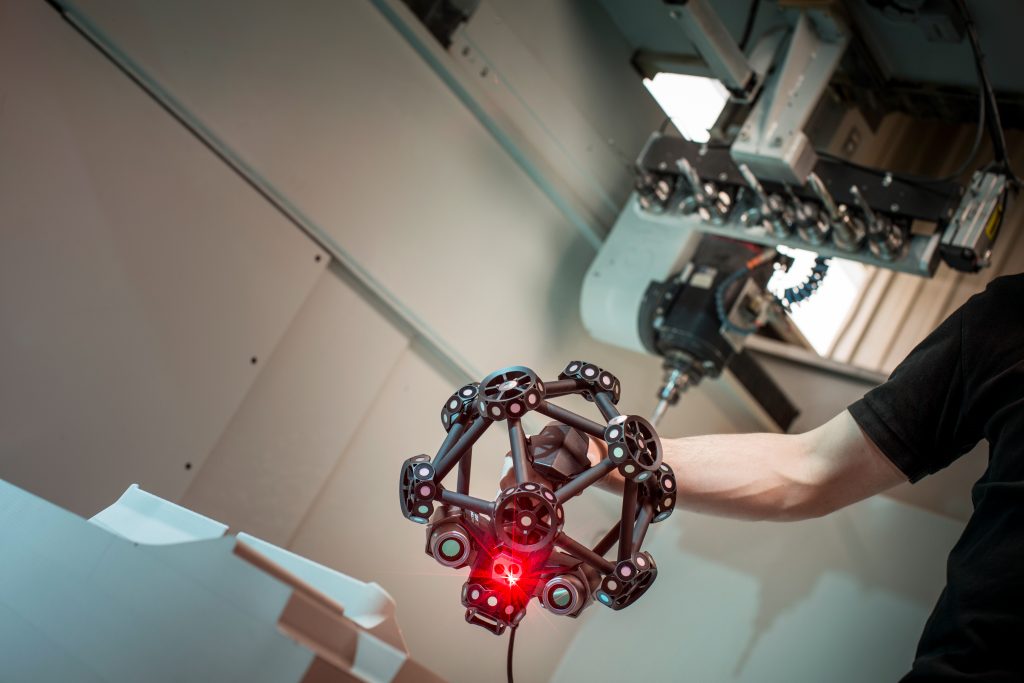

10. Best professional manual 3D scanner: Metrascan 750 ($ 50,000 - $ 100,000) 9001 CreaForm Metrascan 750 is a complete professional, production solution for accurate 3D scanning. It is light, accurate, fast, and scans objects of any surface quality, with any texture with excellent accuracy. Price: $79900 We hope this was a useful read and you found a 3D scanning solution suitable for your needs and your budget! If you want to learn more about photogrammetry, you can read this article. Good luck with your 3D scanning! Reverse engineering is a way of creating digital models from physical ones. 3D scanner able to quickly read the size and shape of complex models. Due to the presence of physical objects, it can help to significantly speed up the design. The ability to copy and reshape models allows you to print parts for all kinds of existing equipment. For example, printed fixtures can be used to secure a drill or saw, as well as to ensure precise assembly of parts. Create tight-fitting, reusable masks for sandblasting, painting or engraving. In this article, we will talk about reverse engineering a vent and explain how to scan a model for 3D printing. You'll also find tips for using reverse engineering tools here, from CAD software to 3D scanners and 3D printers. To learn more about 3D scanning processes and technologies, download our white paper. Download technical report Looking for a 3D scanner for your 3D printer? Check out our guide to choosing the right 3D scanner for your 3D printer. One of the main challenges of converting physical objects to digital ones is the incompatibility between two different types of 3D models: polygonal and solid . The 3D scanner generates a polygon mesh rather than a structural solid model. To modify a polygon model, you must convert it to a solid model. At the output of the 3D scanner, you will get polygon model in STL format, which is supported by most 3D printers. A polygon mesh is a collection of vertices and faces that define the shape of an object. It contains almost no information about the object, except for data on the position of the edges that determine the shape. Engineers typically work with solid models that contain encoded information about the design of an object. With CAD, you can resize one element and update the rest of the model to reflect those changes. Meshes do not contain information about the structure of the object, so CAD programs such as Solidworks and Onshape do not allow you to modify them directly.

Resolution: 0.050 mm

Accuracy: Up to 0.03 mm Using 3D scanning and 3D printing in reverse engineering

Together with 3D scanning and 3D printing, it is an effective tool for prototyping.

Together with 3D scanning and 3D printing, it is an effective tool for prototyping.

To make changes to the basic design of a scanned model, the mesh must be converted to a CAD drawing. It is this process that is called0012 reverse engineering

To make changes to the basic design of a scanned model, the mesh must be converted to a CAD drawing. It is this process that is called0012 reverse engineering

Reverse engineering is used to create new models based on existing ones when the original CAD design is not available.

For example, you can create replicas of damaged parts or use the complex surfaces of existing objects to create printed fixtures for customizing mass-produced and handmade items.

Let's walk through the process of building a prefabricated jig for the Volkswagen Golf vent.

Spray an anti-reflective spray on the object to improve scanning accuracy. Even a slight sheen can degrade the quality of the scan. Be sure to treat reflective and transparent surfaces with matte finish.

Use anti-reflective spray to improve scan quality.

Use a high precision 3D scanner to capture all important parts of the model. Desktop light and laser scanners produce results with an accuracy of ±100 or better.

Find out how to choose a 3D scanner for your application in our white paper on 3D scanning:

Note : An object that has dimples sometimes needs to be rotated and scanned multiple times.

Some scanners generate mesh files that are too large to work with.

The scanner software allows you to correct small imperfections and make the image easier to edit in CAD. Try to reduce the model as much as possible, keeping all the important details.

Tip : Use the Meshmixer to edit the mesh.

Import the mesh into CAD software to access reverse design tools. Use Geomagic for Solidworks for complex organic shapes.

Xtract3D is a more economical and lightweight alternative for simple flat surfaces.

Move and rotate the mesh to align it with the current structure elements.

Tip : Make your drawings easier by rotating the scanned model and aligning it with the orthographic projection directions.

Three methods of mold extraction are available in CAD to create a solid model: semi-automatic surfacing, automatic surfacing, and manual copying.

Semi-automatic surface creation

Complex curved surfaces are difficult to create manually. To do this, you can use the semi-automatic creation function, which generates surfaces based on areas obtained by scanning. In this case, the accuracy of the digitized surface depends on the sensitivity settings of the scanner.

Tip : Geomagic for Solidworks copies the surface using 3D model curves. Use the "brush" to manually add or remove areas on the image.

You may need to repeat this process several times with different sensitivity settings to capture all surfaces. They can then be cut and joined to create an editable solid model.

Use semi-automatic surfacing to create curved shapes if you need maximum editability and edge precision later on.

Formed surface after cutting.

Automatic generation generates a solid model from any closed mesh. This feature allows you to remove and add regions to the generated surface using standard CAD tools, but makes it difficult to move the main elements on the body itself.

This method is fine if you don't need to place the edges manually. So, when scanning a part of the human body to create non-standard ergonomically shaped products or making fixtures for repeatedly modifying a handmade object, automatic surface creation will reduce modeling time.

Note : Compare the results of automatic and semi-automatic surface generation. Some precision is lost, especially around sharp edges.

Simple features such as tabs, holes and pockets are usually easier to redraw using the scanned model as an example. Reverse design software allows to create sketch planes aligned with flat surfaces and extract mesh cross sections to copy the shape of the original object.