Eos 3d printer metal

DMLS Technology for 3D Printing

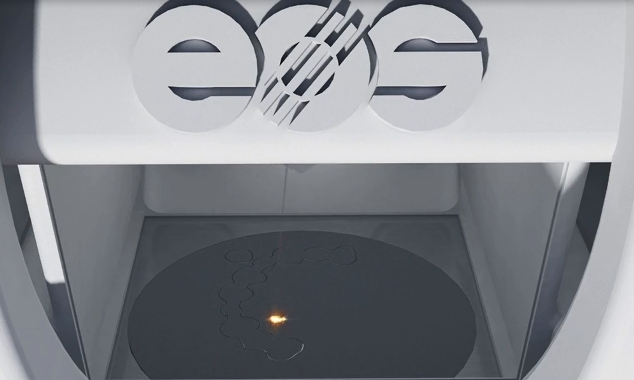

DMLS: Laser Powder Bed Fusion of metal powder in a 3D printer

With DMLS it is possible to create 3D printed metal parts directly from a computer model. The main ingredient to create such a part is a powder of a metal alloy. The technology is used for industrial 3D printing.

In the metal 3D printer, an ultra-fine layer of the metal powder is spread across the building platform. Then, a powerful laser in the 3D printer melts the powder exactly at the points defined by the CAD model. In this way, one layer of the 3D printed part is completed. This procedure repeats until the part is completed:

Three steps of the DMLS technology

- The 3D printer continues to spread layer by layer of the metal material

- The laser precisely melts the desired shape in each layer

- The 3D printed part grows layer by layer.

The DMLS technology, as used by EOS metal 3D printers, follows the principle of - in German - "Direkt Metall Laser Schmelzen" (DMLS, Englisch translation Direct Metal Laser Melting). It is a Laser Powder Bed Fusion, or short LPBF technology, and stands for one of the world's most advanced and reliable technologies in metal additive manufacturing. This high-end 3D printing technology is used for serial manufacturing of (industrial) 3D printed metal parts for a wide range of industries. The main applications are aerospace, automotive, medical, tool and turbomachinery. EOS is the leading global provider for industrial metal 3D printer and has been using the DMLS technology for almost three decades.

Freedom of Design

06_design_freedomComplex Structures

10_filigreeIncreased Productivity

05_incr_productivityTailored Solutions

53_individual_productionWorldwide

in Different Industries

Experience

Benchmark for Serial Production

For our DMLS

Metal 3D Printers

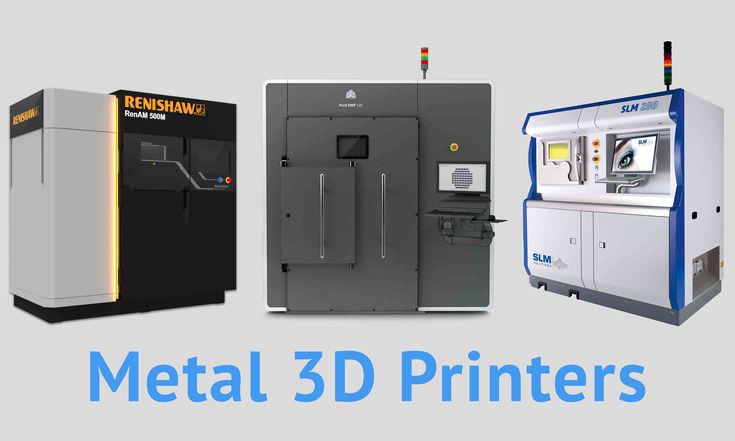

EOS offers metal 3D printing systems for every need

Reliable production for many customers around the world: Are you looking for the right metal 3D printer for your parts production? EOS offers additive manufacturing machines with proven DMLS quality – perfectly suited to your individual manufacturing requirements.

The workhorse in metal additive manufacturing, the mid-sized 3D printer EOS M 290 with the widest range of metal materials offers you the perfect package for high-quality parts.

To manufacture delicate metal components e.g. for medical applications our EOS M 290 is the 3D printer of choice.

For serial production of additive manufactured metal parts, we offer flexible and highly productive 3d printing solutions: powerful big volume metal 3D printer for large metal parts and ultra-fast four-laser systems for an efficient production of high-quality serial parts.

Find the perfect Metal 3D Printer for your need

To ensure a high quality of your part, it is important to use a high-end material for the metal 3D printer. EOS offers a wide range of high tech materials designed specifically for metal 3D printing using our DMLS technology. Depending on the need of your individual production you can choose an alloy from our DMLS material portfolio. That could be aluminium, cobalt- chrome, nickel-based, refractive metal, stainless steels, tool steels, case-hardening steels, copper, and titanium alloys as well as precious metals like gold.

That could be aluminium, cobalt- chrome, nickel-based, refractive metal, stainless steels, tool steels, case-hardening steels, copper, and titanium alloys as well as precious metals like gold.

Find the perfect metal 3D printing material for your need

The use of titanium as the material for the retaining brackets of our satellites has proven highly effective. The main weakness, however, was the connection of the brackets with the carbon panel of feed and reflector assembly because here the thermal stress was a negative factor. Thanks to Additive Manufacturing, we were able to redesign the bracket and eliminate this vulnerability. There were other benefits, too, such as shorter, more cost-effective and more lightweight production.

Otilia Castro Matias | COC Antennae | Airbus Defence and Space

Our DMLS technology is being used for wide range of industries such as aerospace, automotive, medical, tool and turbomachinery. See some of our references.

See some of our references.

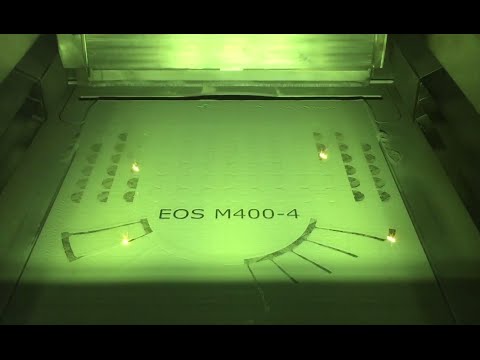

Large and ultra-fast 3D Printer with 4 laser

05_incr_productivityUp to 4x more productivity

12_laserFour precise 400-watt fiber lasers

52_construction_spaceBuild volume of

400 x 400 x 400 mm

With a build volume of 400 x 400 x 400 mm and four lasers, the EOS M 400-4 platform achieves up to four-times higher productivity, making it perfect for industrial applications. Four precise 400-watt fiber lasers work over an area of 250 x 250 mm each, with 50 mm overlap.

With its intuitive user interface, flexible software tools and diverse accessories, the system meets every usage requirement of an industrial production environment. Highly automated procedures and processes guarantee ease of operation.

Highly automated procedures and processes guarantee ease of operation.

A broad portfolio of materials is available, from light metals to stainless steel, tool steels and super alloys. Any process from the EOS M 290 can be transferred to the EOS M 400-4 to achieve equivalent part properties.

| Construction Volume | 400 x 400 x 400 mm (15.8 x 15.8 x 15.8 in) (height incl. build plate) | |

| Laser Type | Yb-fiber laser; 4 x 400 W | |

| Precision Optics | 4 F-theta-lenses; 4 high-speed scanners | |

| Scan Speed | up to 7.:quality(80)/images.vogel.de/vogelonline/bdb/410900/410995/original.jpg) 0 m/s (23 ft/s) 0 m/s (23 ft/s) | |

| Focus Diameter | approx. 100 µm (0.004 in) | |

| Power Supply | 3 x 50 A | |

| Power Consumption | max. 45 kW / typical 22 kW | |

| compressed air supply | 7,000 hPa; 20 m³/h (102 psi; 706 ft³/h)" | |

| Machine Dimensions (W x D x H) | 4,181 x 1,613 x 2,355 mm (164.6 x 63.5 x 92.7 in) | |

| Recommended Installation Space | min. 6.500 x 6.000 x 3.300 mm (256 x 236 x 130 in) | |

| Weight | approx. 4,835 kg (10,659 lb) 4,835 kg (10,659 lb) | |

| Software | EOSPRINT 2, EOSTATE PowderBed, EOSCONNECT Core, EOSCONNECT MachinePark, Materialise Magics Metal Package and modules |

Source: Václav Jirásek

3D lattice palms ready for microwelding

Challenge:

Bring a goldsmith’s creation to life by printing an intricate and luxurious life-size 3D lattice face mask and palms, to which jewels could be micro welded.

Source: One3D

One3D facility in Mohelnice with EOS M 400-4

Solution:

- One3D AM Engineers

- EOS M 400-4

- EOS StainlessSteel 316L

Source: Václav Jirásek

Post-processed 3D lattice palms

Results:

- Design, print and post-processing of complex parts in just 5 days

- Complete design freedom for artist and One3D engineers

- Rapid printing of 207 cm3 build volume enabled highly detailed and considered 3D lattice palms ready for post-processing

53_individual_production Metal Materials for the EOS M 400-4

EOS Aluminum AlSi10Mg

Parts printed using EOS Aluminum AlSi10Mg offer strength, hardness and dynamic properties as well as excellent thermal properties and low weight.

EOS NickelAlloy IN718

Parts show excellent tensile, fatigue, creep and rupture strength at temperatures up to 700°C, making it ideal for many high temperature applications.

EOS NickelAlloy HX

Parts show high strength and oxidation resistance also at elevated temperatures up to 1200°C making it ideal for applications in aerospace, gas turbines, etc.

EOS NickelAlloy HAYNES® 282®

This material is a precipitation strengthened nickel-base superalloy with a unique combination of high temperature strength, thermal stability, and fabricability. The alloy was developed for high temperature structural applications.

EOS Maraging Steel MS1

Parts have excellent mechanical properties and are heat-treatable using a simple thermal age-hardening process to obtain superior hardness and strength.

EOS StainlessSteel 316L

Parts show a high level of corrosion resistance, toughness and ductility as well as a high resistance to acids.

EOS Titanium Ti64

Titanium’s material characteristics make it ideal for many high-performance applications in aerospace, automotive & medical.

EOS Titanium TiCP grade 2

Titanium’s material characteristics make it ideal for many high-performance applications in aerospace, automotive & medical.

11_modularity Material Management Metal Materials

IPM M Powder Station L

The IPM M Powder Station L is the fully-automatic and intelligent material management solution that offers a closed powder cycle in a protective gas atmosphere in just one module.

13_automation Software

EOSPRINT 2

EOSPRINT is an intuitive, open and productive CAM tool for EOS systems that enables the assignment and optimization of build parameters for your CAD data. Together with data preparation software like SIEMENS NX or Magics, it offers an extensive additive manufacturing CAM environment for a smooth 3D printing process.

Together with data preparation software like SIEMENS NX or Magics, it offers an extensive additive manufacturing CAM environment for a smooth 3D printing process.

EOSTATE Monitoring

EOSTATE is the modular solution for seamless monitoring of all production and quality-relevant data in industrial 3D printing. EOSTATE comprises 4 modules that can be used individually or in combination.

EOSCONNECT Core

EOSCONNECT Core is the connectivity solution for monitoring production. EOS systems are IIoT-capable and can be integrated into existing IT infrastructures via EOSCONNECT Core. EOS offers an open interface for this.

EOS systems are IIoT-capable and can be integrated into existing IT infrastructures via EOSCONNECT Core. EOS offers an open interface for this.

EOSCONNECT MachinePark

Expand the capabilities of your EOS system. Increase your productivity with EOS Web Apps and monitor your entire EOS machine park from anywhere in an intuitive dashboard. Receive automatic notifications on machine status and print jobs.

3D printers EOS (Electro Optical Systems). Industrial printers

Electro Optical Systems (EOS) is a German company considered one of the pioneers in the development of 3D technologies in general and additive manufacturing in particular. The brand was founded in 1989 and over almost 20 years of activity, the company has become a world leader in the production of SLS systems - selective laser sintering of metal powders used as a printing material on industrial EOS plants.

The brand was founded in 1989 and over almost 20 years of activity, the company has become a world leader in the production of SLS systems - selective laser sintering of metal powders used as a printing material on industrial EOS plants.

The SLS technology developed by the specialists of this brand is based on the use of a laser platform and a high power beam - today there are full-featured sintering systems for both powder metal alloy and plastic and even sand, which significantly expanded the range of applications for Electro Optical Systems printing machines.

The brand's industrial printers can solve various problems in such areas as the production of full-featured plastic parts for completing various products, the production of spare parts from thermoplastic materials, the sintering of polyamide materials, the production of parts and mold inserts from metal using tool and non-tool production methods.

The German company EOS (EOS) is considered the world leader in the field of 3D printing based on metal powder and plastic. By successfully applying the technology of laser sintering (SLS), using the equipment of this manufacturer, it is possible to obtain durable products that fully comply with the specified parameters. To guarantee high quality, the company supplies not only industrial 3D printers, but also all the necessary related materials for additive manufacturing.

By successfully applying the technology of laser sintering (SLS), using the equipment of this manufacturer, it is possible to obtain durable products that fully comply with the specified parameters. To guarantee high quality, the company supplies not only industrial 3D printers, but also all the necessary related materials for additive manufacturing.

Where and why you can use EOS 9 products0013

- To create a small-scale or piece object of complex geometric shape. Using 3D scanning, you can set the parameters of the future product.

- For the production of a prototype in the shortest possible time.

- For the production of parts by laser melting of metal powders. The result is solid and smooth 3D objects that do not need further processing.

All EOS equipment is professional, and finds its customers among the research centers of industrial organizations working in the field of aviation and space, mechanical engineering, medicine, dentistry and jewelry.

3DMALL offers EOS metal powder based 3D printers: PRECIOUS M 080, EOS M 100, EOS M 290, EOS M 400. The numbers in the model name indicate the printing area.

The largest machine in this series is the EOS M 400. In just a few hours, it can create a large 3D model. The high speed of the press allows to use this device for mass production. Modular design allows you to improve the printer with the integration of new developments. To get a modern model for 3D modeling, you do not need to completely change the apparatus.

EOS PRECIOUS M 080 is designed for precious materials. It is very easy to make 3D prototyping with this model, because the machine works with a wide range of precious metals, is of high productivity and quality.

Any of the above EOS models can be ordered with delivery in Moscow and Russia. In stock and on order there are professional models and products for beginners from the world's leading manufacturers TEVO, Imprinta, Concept Laser, BQ, Mass Portal and many others. All of them work on modern technologies FDM, FFF, SLA, DLP, PolyJet. Delivery within Moscow time is free, within the Russian Federation it depends on the total amount of the order.

All of them work on modern technologies FDM, FFF, SLA, DLP, PolyJet. Delivery within Moscow time is free, within the Russian Federation it depends on the total amount of the order.

EOS M 100 3D Printer - Scientific Equipment

The EOS M 100 is a professional machine specially designed for powder raw materials. The technology of directed, direct laser sintering of metal melting within a hermetically sealed chamber guarantees minimization of base material waste, which significantly affects the cost of products.

The high-power laser that comes with this device guarantees the best quality of detail, which is of great importance for the additive manufacturing of high-precision products for various purposes. The stability of production quality is guaranteed throughout the entire printing cycle, and the economic efficiency of industrial production of metal products is ideal for serial replication of highly complex elements.

Features:

- Best detail settings.

- High quality resolution.

- Efficiency.

- Economy.

- Easy to use.

Media Types:

The EOS M 100 industrial machine is considered to be a multi-purpose machine, as it works with almost all the most popular types of powder metals, which allows it to be used in various industries, including science and research.

EOS Cobalt-Chrome SP2 is a finely dispersed biocompatible powder alloy that guarantees the creation of the most durable and reliable parts of various configurations, including those with complex geometries. Applicable in dental medicine.

EOS 316L stainless steel is a high strength and corrosion resistant alloy used in a variety of industries such as jewelry, watch parts, medical and surgical instruments, prototyping and modeling in the aerospace and automotive industries.

EOS titanium Ti64 (currently under development, research stage) is a biologically compatible alloy with high strength, anti-corrosion properties and low density, used for the production of implants, as well as parts, spare parts and components for various equipment, requirements for the mechanical stability of which are elevated.

Applications EOS M 100:

The EOS M 100 works in direct powder metal sintering technology, which guarantees high performance and economical consumption of base materials.

Medicine - production of high quality biocompatible implants, surgical instruments, templates.

Industry - production of high-quality, high mechanical strength parts with complex geometry.

Manufacture of clocks, decorations, jewelery - the cultivation technology based on metal sintering guarantees high precision in the reproduction of the smallest details.

Interface/Software options:

The machine comes with original software EOS RP Tools/EOSPRINT, designed specifically to improve the parameters of work with powdered metal alloys. The system is equipped with a large number of pre-installed protocols and allows the user to adjust the previously set parameters during the production process, which is very convenient for both beginners and professionals. The platform allows you to use different strategies for processing metals, depending on their class, physical and chemical properties. The user-friendly, practical and intuitive Ethernet system is used as the connection interface.

The platform allows you to use different strategies for processing metals, depending on their class, physical and chemical properties. The user-friendly, practical and intuitive Ethernet system is used as the connection interface.

| CHARACTERISTICS | VALUE |

|---|---|

| Print Technology | DMLS |

| Media | Metal powder |

| Print area, mm | 100×95 |

| Layer thickness, mm | 0.04 |

| Laser power, W | 200 |

| Laser type | Yb-fiber laser |

| Construction, µm | x=100, y=95 |

| Operating systems | Windows |

| Supported file formats | STL |

| Display | Touch |

| Connection interface | Ethernet |

| Software | EOSPRINT/EOS RP Tools, CAMbridge, Magics RP |

| Body material | Plastic, metal |

| Power supply, V | 200-240 V, up to 1. |