3D printer multiple materials

The Best Picks for 3D Printing with Multiple Materials

Category Engineering

In this article we’ll assess the most hip and interesting options available in the market right now. So, if you are interested in multi-color or full multi-material 3D Printing quote, this is your one stop shop!

Trailblazing!

Printing objects using diverse materials at the same time is said to be the vital capability of additive manufacturing, that could influence its potential well and truly beyond that of other contemporary manufacturing methods. Some of the ways it can change it for the better are as follows :

- It can eliminate the need for post processing assembly.

- It can reduce the requirement for post-processing stages such as coloring etc.

- It helps in promoting the methodical design of multi-functional objects.

- You will also be able to have a lot of savings in both manufacturing time and costs.

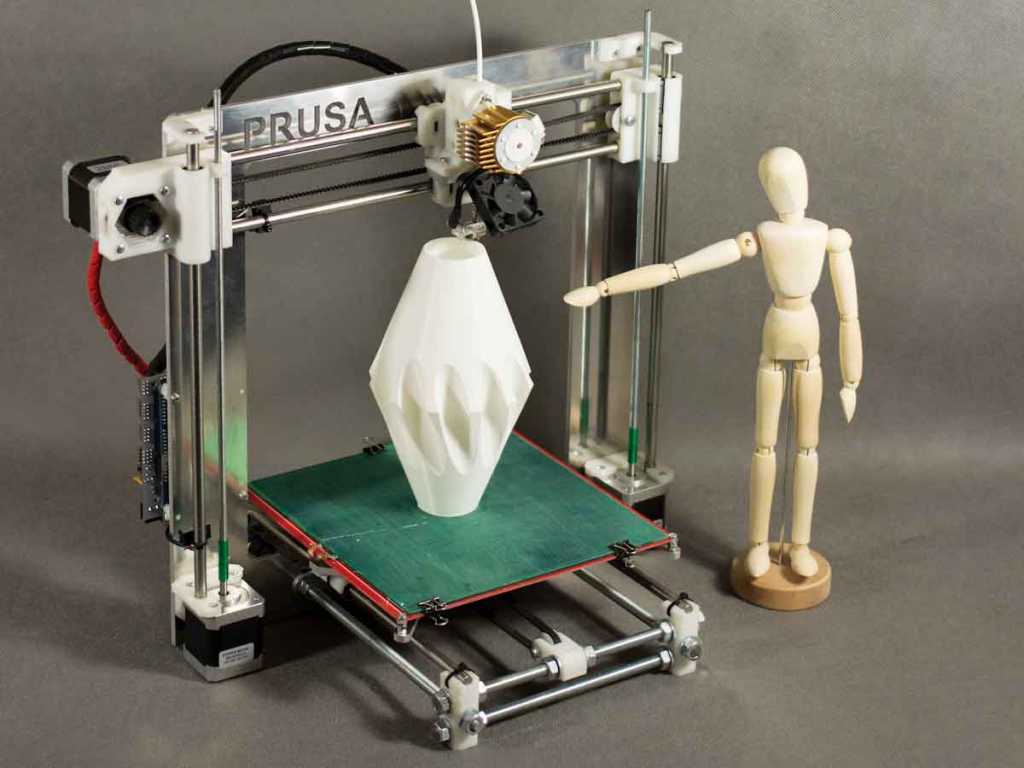

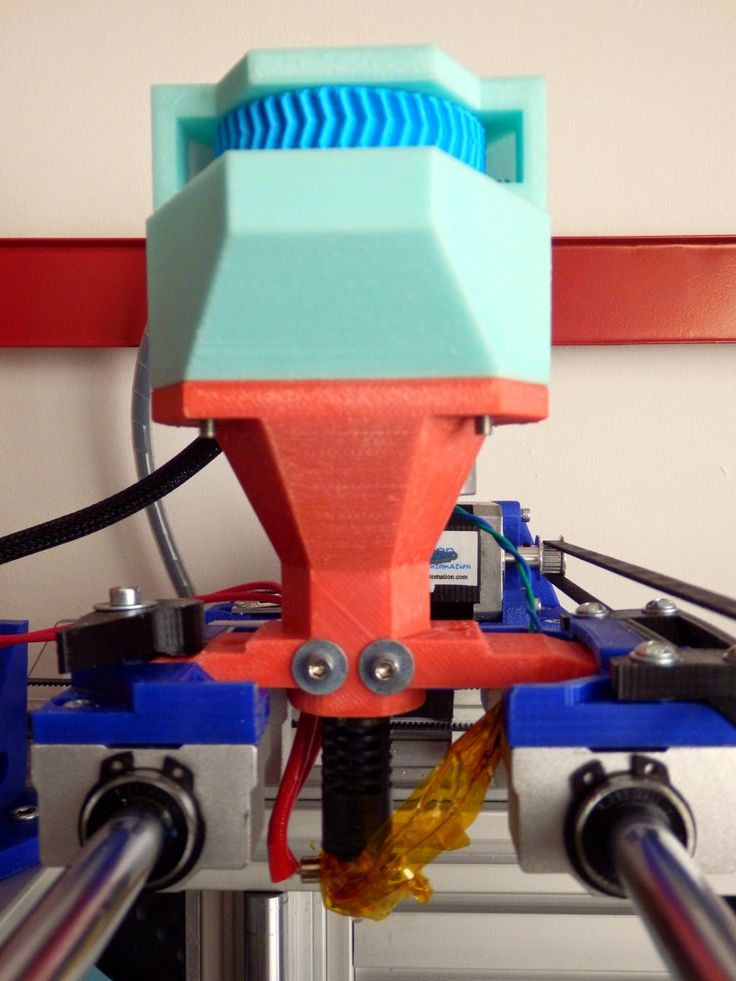

Fused deposition modeling or FDM 3D Printing in India governs the realm of the development of multi-material 3D printers, almost exclusively at the consumer level. But, since your typical desktop FDM 3D printers are equipped with a single-nozzle, single-extruder setup, it creates a lot of problems that are a bit tricky to overcome. Thanks to the ever-advancing technology and human ingenuity there are some savvy solutions, which we’re happy to share with you here.

The Manual Way

Ah the good old manual labor, you can almost always trust your own hands to do a job. This the most rudimentary method. You won’t be requiring any kind of special multi-material 3D printer. You can use any general FDM printer given, you can pause the printing process and switch the filament at any point during the printing procedure.

The trick behind the multi-color 3D printing in India is simply lying to your 3D printing slicer software. While using a slicing software such as Slic3r that supports multiple extrusion, such as, simply go to the “Extruders settings” option and falsely select the option of having more than one hot end. After that, you’ll also need to make the same firmware changes in Repetier Host’s printer settings. Also don’t forget to add a piece of code to the G-Code setting for a change of tool.

After that, you’ll also need to make the same firmware changes in Repetier Host’s printer settings. Also don’t forget to add a piece of code to the G-Code setting for a change of tool.

There are certain limitations though:

- An obvious one is, in hacking your printing in this way you’re going to have a lot of trouble in placing the material in specific regions of an XY layer.

- Lack of control is another limitation of this approach; you can somewhat mitigate this by editing the G-code itself. This can further be simplified by writing a script, in your slicer program. Such that it will pause the printing process, according to your needs. So, you can change the filament at locations.

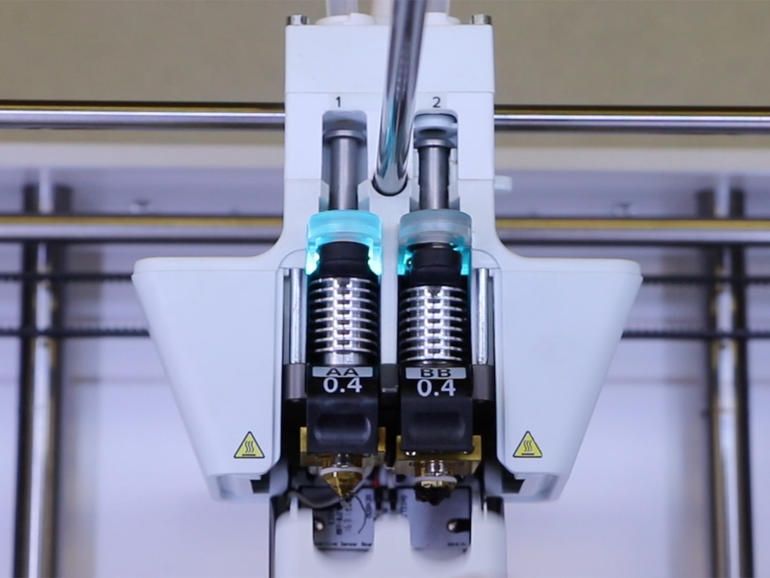

Dual Extrusion

To have cruise control over the material along the X, Y and Z axes, your second-best option is to have a standard printer fitted with two extruders in place of one.

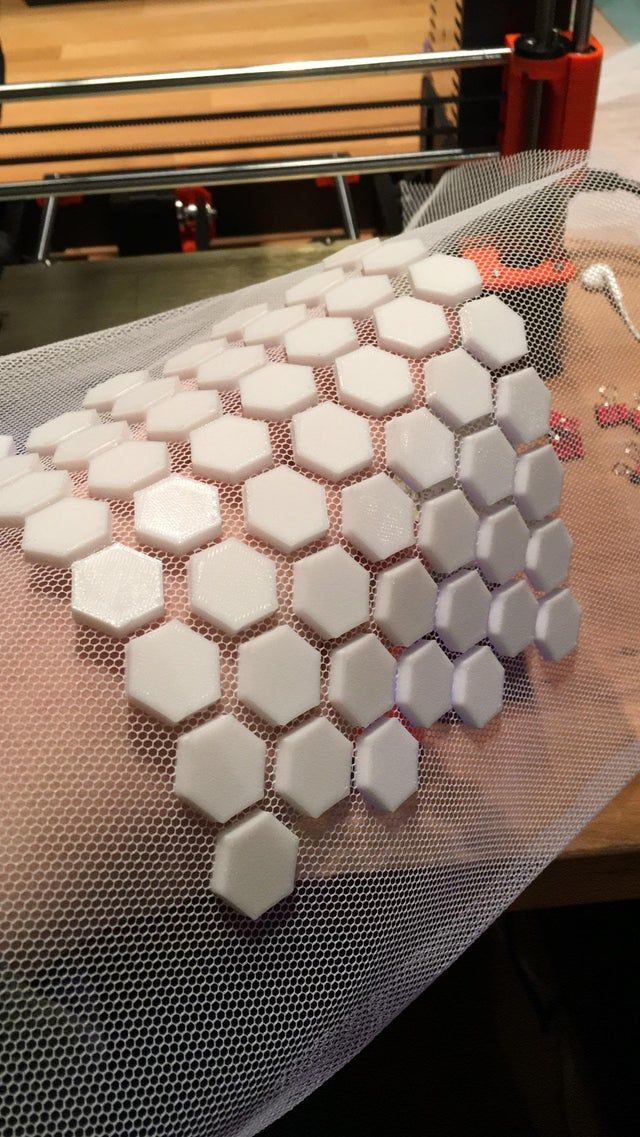

People often prefer using one extruder to print dissolvable supports that can be removed from the print, during post processing. But you may also use them to print in two colors or materials that will be present in the final model.

But you may also use them to print in two colors or materials that will be present in the final model.

Following are a few limitations of the dual extruder printers:

- The presence of a second extruder will reduce the area available for printing with a single extruder.

- There are greater chances of oozing and stringing.

- If by chance one of the extruders causes material deposited by the other to warp, you might see some layer-shifting defects.

Mosaic Palette 2

This is another option; this includes turning your standard FDM printer into a multi-material 3D printer with certain accessory apparatus. There are certain devices available that manage filament switching operations while simultaneously delivering your print through a single extruder.

One of the most appealing options available is the one devised by Mosaic Manufacturing, which introduced the Palette multi-material device, in 2016. Recently the Palette 2 and Palette 2 Pro were also introduced by the company to supersede this.

Recently the Palette 2 and Palette 2 Pro were also introduced by the company to supersede this.

Its ability to splice and fuse sections of different filaments is what sets it apart. Such that by the time they arrive at the nozzle, the right type of filament is being fused and deposited at its proper place. It’s possible to combine up to four different filaments. There seems to be no substantial restrictions regarding the combination of filaments made of the different materials. While printing a multi-material object, you’ll have a “purge block” in your arsenal which is used to switch between the two different materials smoothly.

Various manufacturers of 3D Printing companies have collaborated with Mosaic Manufacturing. Making seamless integration with your FDM printer possible in principle.

Prusa Multi Material Upgrade 2S (MMU2S)

This is basically an upgraded reintroduction of Prusa’s II-gen multi-material add-on. With this the users of Prusa’s i3 MK2.5, MK2.5S, MK3, and MK3S 3D printers can print in up to five different materials or colors.

With this the users of Prusa’s i3 MK2.5, MK2.5S, MK3, and MK3S 3D printers can print in up to five different materials or colors.

The novel MMU2S unit sits upstream in relation to the printer’s extruder, which makes simultaneous collection of all five filaments and feeding the correct filament possible. Prusa has put out some massive overhauls by testing and revision in the MMU2S, this results in a much more reliable design compared to MMU2 model.

In addition to all that, the new Prusa MMU2S includes a revamped body, upgraded filament loading mechanism, and a filament buffer. Additionally, the F.I.N.D.A. filament sensor continuously detects feed of filament, assisting in avoiding any print issues from blockages further up the chain.

Contrary to the first MMU’s four, the MMU2S needs only a single extruder motor to pull the filament. It is compatible with PLA, ABS, PETG, and soluble materials.

What Features Are Most Important to You?After you decide what you’re going to do with your multicolor 3D printer, you’ll want to determine which features are a priority. Different products offer different features with different qualities under a different 3D Printing quote.

Different products offer different features with different qualities under a different 3D Printing quote.

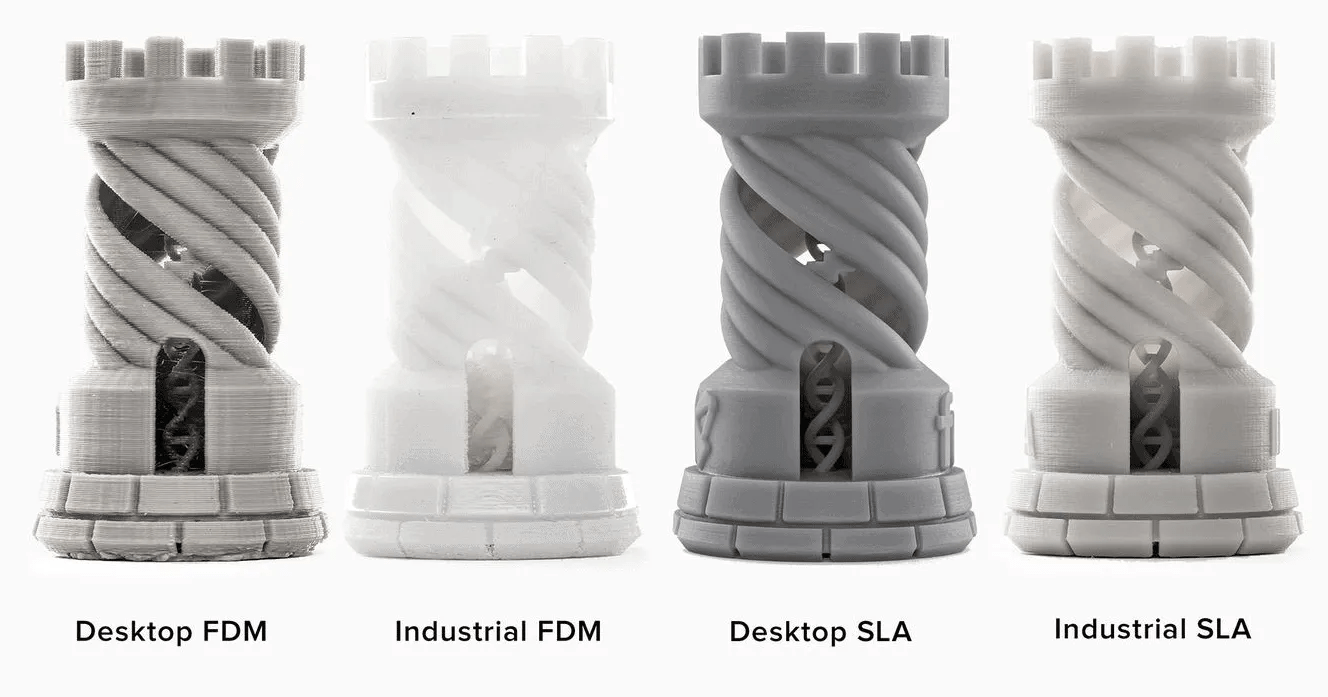

Each 3D printer is going to provide a different level of surface finish, resolution, and accuracy. Which of these features are most important to you? Determine that and you’ll have a solid idea of which 3D printer fits your needs for affordable 3D Printing services.

Color 3D Printing Surface Finish

Surface finish is important for a few pieces. Keep in mind that you can smooth the surface of your item after it's done 3D printing, however, it’s usually best to choose a 3D printer that does this for you.

There are a few reasons you want to select a printer with this feature. First, it reduces the total amount of time it takes to produce an item with 3D Printing service since nothing needs to be done post-processing. Plus, if the smoothing process isn’t done properly there could wind up being problems.

Color 3D Printing Resolution

Next up on the list of features to consider is the printer’s resolution capabilities. Some 3D printers only print with the minimum resolution possible. However, there are also options on the market for online 3D Printing services that offer excellent resolution, so determine how important this feature is to you.

Some 3D printers only print with the minimum resolution possible. However, there are also options on the market for online 3D Printing services that offer excellent resolution, so determine how important this feature is to you.

Remember that the layer height (layer thickness) is what tells your 3D printer what resolution to print. The lower the designated layer height, the higher the resolution you’ll get on your printed item.

Color 3D Printing Accuracy

Last, but definitely not list, is the accuracy of your multicolor 3D printer. You want complex pieces and geometrical parts to print just the way you expect them to, so you want to be sure you’re getting a 3D printer that can handle it.

Additionally, if you plan on 3D printing pieces that will need to be put together later, accuracy is of the utmost importance. Accuracy is definitely something to keep in mind as you decide which 3D multicolor printer makes the most sense for your 3D Printing service in India.

3D Printing Speed

If you’re unfamiliar with 3D printing speed, it’s measured by inches printed each hour. Of course, the amount of time it takes to print your item depends a lot on the size and complexity of its design.

Oftentimes, speed will also depend on the type of different material you’re printing with. Take all these factors into account before you settle on a multi-color 3D printer for online 3D Printing India. Sometimes the ones that brag about their speed aren’t the ones that can handle heavy workloads.

Also, remember that just because you’re getting higher speeds doesn’t mean you’re getting precision. Some 3D multi-color printers sacrifice on accuracy in favor of higher speeds. So, if you’re planning on printing parts that require extreme accuracy, a high-speed printer may not make sense for you.

3D Printer Build Size

When it comes to the size of your printer, you’ll want to primarily think about how much room you have and what you plan on printing with your online 3D Printing services. That’s because you can find multi-color 3D printers that are big enough to fill a closet while others are small enough to sit on a desk.

That’s because you can find multi-color 3D printers that are big enough to fill a closet while others are small enough to sit on a desk.

Most 3D printers specify their build size, so you shouldn’t have any trouble finding the right one. Just be sure you don’t ignore the printer’s build size. If you wind up printing items that are bigger than your 3D printer build size, you’ll wind up with a useless printer.

Multi Color 3D Printer Material

Next, let’s take a look at what type of material you plan on using with your multi-color 3D printer. Were you aware that today, there are a wide variety of materials available to choose from? And the list keeps growing!

When 3D printers launched, the only option was photosensitive resin. But as 3D printing service in India has progressed, multiple materials and options have come into the picture.

Of course, selecting the materials for your 3D printer may depend entirely on what you plan on printing. So, for instance, if you need to print items that need to be durable or flexible, you want to be sure you choose a material that allows for those capabilities.

In today’s market of 3D printing online, there are a wide variety of materials available. There’s even a good possibility you’ll find varying degrees of print quality with the type of material you select. That’s why it’s critical that you know exactly what you’re printing and what type of material you’ll need.

For example, if you plan to print using PLA filament (vs PETG filament, ABS filament, or a different filament), then your 3D multi-color printer will have to work with that type of material. Chances are you’ll want to use various types of materials for color 3D Printing service, so try to find a printer that will accept different color and material options.

FAQs About 3D PrintersQuestion: Can my 3D printed items be sanded?

Answer: Plastic parts made from FDM (FDM 3D printer vs SLA printer) are capable of being sanded with belt sanders or by hand. Think of it as sanding down an automotive part of a piece of wood. The nice thing about sanding is that it doesn’t cost a lot and is an effective method for getting a smooth finish on your print.

Think of it as sanding down an automotive part of a piece of wood. The nice thing about sanding is that it doesn’t cost a lot and is an effective method for getting a smooth finish on your print.

Sanding is one of the most used techniques for finishing a 3D-printed part. You can sand and smooth nearly all your pieces except for a few tiny parts.

Question: What is the life expectancy of a PLA print?

Answer: A decent 3D printed piece will roughly take 6 months to start showing signs of stress and decay. This will show up in the form of cracks and lines in your piece. Of course, the length of time it takes depends largely on the conditions in which the piece resides.

While you may notice that the piece isn’t as perfect as it once was, in the right conditions, your printed project may last up to a decade and a half.

Question: Are the parts I printed on my 3D printer airtight?

Answer: With a high-quality 3D printer, you can now print watertight printed objects such as canisters, cups, and containers. This type of technology makes it possible to create 3D prints that will float or even hold water.

This type of technology makes it possible to create 3D prints that will float or even hold water.

So, what are you waiting for? Go print that 3D boat you’ve always wanted and give it a take on the swim!

Question: Can I make money using my 3D printer?

Answer: Sure, you can! One of the simplest ways to earn a little extra money is by using your multi-color 3D printer to create items and 3D object models and sell them with a good 3D Printing quote. There are sites available online through which you can sell your goods, or you can always create your own.

List your multi-color 3D printer as a service available to others and have them pay you for any items or pieces that you print.

ConclusionWe think that if you need a specific object, buying a whole multi-material 3D printer or an upgrading kit might feel too much like a bother. Fortunately, there are several online 3D Printing services where you can upload your files and have them printed.

Also Read : A Step by Step guide to 3D printing Threads and Screws

The 9 Best Dual Extruder 3D Printers for Multi Material Printing – Clever Creations

Dual-extruder 3D printers are an excellent solution for multi-color and multi-material 3D printing. You don’t need to swap out filaments for a color change or limit yourself to printing with only a single material at a time. In a dual extrusion printing process, you get two entirely separate extruders for printing with multiple filaments.

If you decide to buy a dual extruder 3D printer, you’ll encounter terms like IDEX system, dual print-head system, and more. It can get quickly confusing to select the right printer for your needs, and you might end up getting one that is not the best fit for you.

In this article, we’ve created a list of the best dual extruder 3D printers that are available for you to buy right now and sorted them into different categories to make your buying decision a little bit easier.

Read on to understand more about these machines and how to choose the best dual extruder 3D printer for your needs.

| Dual Extruder 3D Printer | Category | Type | Price (~) | Best Offer |

|---|---|---|---|---|

| Sovol SV02 | Best under $500 | Single hot end | $359 | Sovol3D |

| Flashforge Dreamer | Best under $500 | Dual hot end | $449 | Flashforge |

| TENLOG TL-D3 Pro | Best under $1000 | IDEX | $699 | Amazon |

| Flashforge Creator Pro 2 | Best under $1000 | IDEX | $649 | Flashforge |

| QIDI Tech i-Fast | Best prosumer | Dual hot end | $2299 | Amazon |

| Ultimaker S3 | Best prosumer | Dual hot end | $4725 | MatterHackers |

| BCN3D Sigma D25 | Best professional | IDEX | $3995 | MatterHackers |

| Raise3D Pro 3 | Best professional | Dual hot end | $5249 | MatterHackers |

| Ultimaker S5 | Best professional | Dual hot end | $6355 | MatterHackers |

What is a Dual Extruder 3D Printer?

A dual extruder 3D printer is a machine that has two extruders, as the name suggests. These extruders can be used to print with different colors or different materials simultaneously. This way, you don’t have to swap out filaments every time you want to change the color of your print.

These extruders can be used to print with different colors or different materials simultaneously. This way, you don’t have to swap out filaments every time you want to change the color of your print.

You can also use dual extruders to print with multiple materials at the same time, for example, printing with both ABS and TPU filaments in a single 3D print. This opens up a lot of possibilities for interesting prints that wouldn’t be possible with a single extruder printer.

In this article, we’ve covered three types of different dual extrusion 3D printers: Single hot end setup, Dual hot end extrusion, and Independent Dual Extruder system (IDEX).

The single hot end setup is the least complex. It gives you the benefits of dual extrusion 3D printers without actually having a second print head or a complex motion system.

The dual hot end setup incorporates a second print head next to your primary hot end, and both hot ends move together. You can assign different materials for each hot end, effectively giving you the capabilities of printing with two 3D printers, albeit on a single print bed.

You can assign different materials for each hot end, effectively giving you the capabilities of printing with two 3D printers, albeit on a single print bed.

One of the best and the most practical applications of dual extruders is the IDEX style of 3D printer. These printers have two independent print heads that can be controlled and moved separately. This gives you a lot of control over the printing process and opens up a lot of possibilities for complex prints.

What is the Benefit of a Dual Extruder 3D Printer?

A dual extruder 3D printer triumphs over the regular single extruder 3D printer in many ways. You do not need to swap out any filaments mid-print for any color changes, leading to a faster print speed.

You can print with multiple materials simultaneously with a dual extruder printer. You can use one print head to print the outer shell of the model, while the secondary hot end will print the infill with a more robust material. Similarly, you can use filaments with different colors to print a colorful model.

IDEX printers give you the added benefits of printing modes. You can print multiple objects simultaneously with the duplication mode and print a mirrored version of your design with the mirror print mode. It leads to increased productivity and is useful for 3D printing larger batches of objects.

The last and probably one of the most popular benefits of dual extruder 3D printers is their ability to print soluble supports. You can use PVA or HIPS filament in your secondary extruder to print water dissolvable supports. It gives you the freedom to print complex objects and significantly saves post-processing time, as it takes away the need to remove supports manually.

The Best Dual Extruder 3D Printers

Sovol SV02

Best under $500

Check Price

AmazonSovol3D

The Sovol SV02 is an excellent budget dual extruder 3D printer. It features a Y-shaped, two-in, one-out single print head. It is a clever way to carry out multi-filament printing without adding too many extra 3D printer costs.

The SV02 has a decent printing volume and a dual Z-axis design for better printing accuracy. Its textured glass bed helps with first-layer adhesion and makes the removal of prints easier.

Its mainboard features TMC 2208 stepper drivers for a silent 3D printing process. You also have the option to install a BLTouch auto-leveling sensor as an upgrade, taking away the need for manual bed leveling.

Additionally, you can buy a mixing hot end that lets you mix two different colors simultaneously. This feature gives a lot of room for fun experimentation and creative 3D prints.

The SV02 is an excellent fit for schools to print colorful educational models and for beginners and amateurs users who want to experiment with dual extruder 3D printing without breaking the bank.

Standout Features

- 2-in-1-out hot end

- Optional color mixing

- Dual Z-axis

Technical Details | |

|---|---|

| Build volume | 280 x 240 x 300 mm |

| Dual extrusion setup | Single hot end |

| Max hot end temperature | 260°C |

| Bed leveling | Manual |

| Connectivity | SD Card or Data Cable |

| Compatible materials | PLA, TPU, HIPS, ABS, PETG, WOOD |

What We Like

- Lightweight hot end

- Silent 3D printing

- Can mix two colors

Could Be Better

- Inconsistent print quality

- Occasional filament jams

Find Sovol SV02 at

AmazonSovol3D

Flashforge Dreamer

Best under $500

Check Price

AmazonFlashforgeMatterHackers

The Flashforge Dreamer is one of the most popular dual extruder 3D printers in the market that comes with some elegant features for easy multi-material 3D printing. It comes fully assembled, and you can get started with 3D printing on it within 30 minutes of unboxing the printer.

It comes fully assembled, and you can get started with 3D printing on it within 30 minutes of unboxing the printer.

With the Dreamer, you get two print heads with a direct-drive setup that can help you print a wide variety of materials with ease. The fully enclosed design prevents any harmful 3D printer fumes from leaving the printer and aids considerably with printing ABS. It includes an aluminum heated print bed for a more even heat distribution on the print surface.

The dual extruder design does result in a slight reduction in the build volume of the 3D printer, however, and you get a relatively small print area for the price. Some users also find the bundled FlashPrint slicing software limiting in terms of features.

Nonetheless, considering that the Dreamer is primarily aimed towards beginners, it does an excellent job in the user convenience and accessibility department. It is a good choice for educational institutes and amateur 3D printer users who want a plug-n-play solution for their multi-color and multi-material printing needs.

Standout Features

- Fully enclosed print chamber

- Aluminum build plate

- Wi-Fi connectivity

Technical Details | |

|---|---|

| Build volume | 230 x 150 x 140 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 240°C |

| Bed leveling | Assisted Manual |

| Connectivity | USB cable, SD card, Wi-Fi |

| Compatible materials | PLA, TPU 95A, ABS, PETG |

What We Like

- Stable printing area

- Beginner-friendly

- Plug-n-play functionality

Could Be Better

- Small build volume

Find Flashforge Dreamer at

AmazonFlashforgeMatterHackers

TENLOG TL-D3 Pro

Best under $1000

Check Price

Amazon

The Tenlog TL-D3 Pro is a rare dual extruder 3D printer to feature an IDEX system under $1000. It has two independent extrusion systems that move independently and let you print in mirroring print modes and duplicating modes.

It has two independent extrusion systems that move independently and let you print in mirroring print modes and duplicating modes.

You get a linear rail precision guide on the X-axis to support the IDEX system and a sturdy metal frame to deliver accurate printing quality. The tempered glass heated print bed gives excellent bed adhesion, and the silent motherboard with TMC 2208 and TMC 2225 stepper drivers delivers a quiet 3D printing experience.

The Tenlog TL-D3 Pro is a great dual extruder 3D printer that provides a unique mix of features at an affordable price. If you’re someone who has the need for batch 3D printing in a semi-professional setup, or you want an IDEX 3D printer on a budget, the TL-D3 Pro is a solid option.

Standout Features

- Multiple printing modes

- X-axis linear rail

- IDEX system

Technical Details | |

|---|---|

| Build volume | 300 x 300 x 350 mm |

| Dual extrusion setup | IDEX |

| Max hot end temperature | 300°C |

| Bed leveling | Manual |

| Connectivity | SD card, USB 2. 0 0 |

| Compatible materials | TPU, PVA, PLA, ABS, HIPS, WOOD, PETG, FLEXIBLE |

What We Like

- Easy to assemble

- Silent 3D printing

- Wide material compatibility

Could Be Better

- Open-frame design

Find TENLOG TL-D3 Pro at

Amazon

Flashforge Creator Pro 2

Best under $1000

Check Price

AmazonFlashforgeGeekbuyingAliExpress

While the aforementioned Flashforge Dreamer is suited for beginners and amateur users, the Flashforge Creator Pro 2 is aimed more towards the professional user base. The Creator Pro 2 is a fully enclosed 3D printer with a similar level of user convenience, but now with an upgraded independent dual extruder (IDEX) system.

The Flashforge Creator Pro 2 has multiple printing modes that let you print mirrored designs, duplicate your models for faster 3D printing, and even print with soluble support materials for complex and intricate 3D designs. The heated print bed and the enclosed design further expand the material compatibility of the printer, letting you print with PLA, ABS, HIPS, and PVA.

The heated print bed and the enclosed design further expand the material compatibility of the printer, letting you print with PLA, ABS, HIPS, and PVA.

The Flashforge Creator Pro 2 is a superb dual extruder 3D printer for industry professionals and hobbyists alike. You get a robust build quality, an IDEX system, ease of use, and excellent printing, all for a relatively low cost. In our book, it’s the best dual extruder 3D printer under $1000

Standout Features

- Fully enclosed design

- Residue scraping

- Easy to use touchscreen

Technical Details | |

|---|---|

| Build volume | 200 x 148 x 150 mm |

| Dual extrusion setup | IDEX |

| Max hot end temperature | 240°C |

| Bed leveling | Manual |

| Connectivity | SD Card |

| Compatible materials | PLA, ABS, PVA, PETG |

What We Like

- Affordable IDEX printer

- Excellent print quality

- Great support team

Could Be Better

- Small printing volume

- Lacks air filters

Find Flashforge Creator Pro 2 at

AmazonFlashforgeGeekbuyingAliExpress

QIDI Tech i-Fast

Best prosumer

Check Price

AmazonGeekbuying

The QIDI Tech i-Fast is not for the masses and is instead more positioned as a premium 3D printer for prosumers. For almost $2300, you get a printer that comes with many high-end features and a large build volume (uncommon in dual-extruder 3d printers) to accommodate a wide variety of 3D designs.

For almost $2300, you get a printer that comes with many high-end features and a large build volume (uncommon in dual-extruder 3d printers) to accommodate a wide variety of 3D designs.

Its heated print chamber measures 330 x 250 x 320 mm and is fully enclosed. For better printing with high-end materials like Nylon, Polycarbonate, and PolyPropylene, it can be heated up to 60°C. The motion system is fully supported with high-quality precision linear rails, and it has a dual Z-axis setup for increased accuracy.

The QIDI Tech i-Fast is a feature-packed dual extruder 3D printer for professional use case scenarios and printing high-end prototypes. Despite its high price, it still offers excellent value compared to similar printers in this price range. If you’re planning on adding an industrial machine to your workflow, the i-Fast is likely to be a perfect choice for your prototyping needs.

Standout Features

- Heated build chamber

- Extra all metal print-heads

- Large build volume

Technical Details | |

|---|---|

| Build volume | 330 x 250 x 320 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 300 °C |

| Bed leveling | Manual |

| Connectivity | Wi-Fi, USB and SD Card |

| Compatible materials | PLA, Nylon, TPU, PETG, ABS, PC, Wood, CF |

What We Like

- Quiet 3D printing

- Prints ABS very well

- Retractable hot ends

Could Be Better

- Manual bed leveling

- Limited firmware support

Find QIDI Tech i-Fast at

AmazonGeekbuying

Ultimaker S3

Best prosumer

Check Price

MatterHackers

The Ultimaker S3 is feature-packed and one of the best dual extruder 3D printers by Ultimaker. It is for professional users who want a high-quality, compact printer that consistently delivers excellent print quality.

It is for professional users who want a high-quality, compact printer that consistently delivers excellent print quality.

With the Ultimaker S3, you get a modest build volume of 230 x 190 x 200 mm. This is enough for most typical 3D prints but can be a limitation if your needs involve creating larger multi-color or multi-material objects.

The dual extruders on the Ultimaker S3 have swappable print cores that let you print with advanced materials if you need to. Over 200 materials are tried and tested on the S3, making it one of the most compatible dual extruder printers in terms of filaments.

Additional features include a 4.3-inch touchscreen with an easy-to-use UI, an onboard camera for remote monitoring, and an automatic bed leveling system to give you perfect bed adhesion and first layers every time.

The Ultimaker S3 is a premium 3D printer, and at a price point of over $4000, it is undoubtedly not for primary hobby purposes. The features it provides and the materials it supports are more geared towards industrial prototyping and end-component solutions for industries. If you’re someone who fits in that bracket, the S3 is a good choice for your 3D printing needs.

If you’re someone who fits in that bracket, the S3 is a good choice for your 3D printing needs.

Standout Features

- Swappable print cores

- Onboard camera

- Automatic bed leveling

Technical Details | |

|---|---|

| Build volume | 230 x 190 x 200 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 280 °C |

| Bed leveling | Automatic |

| Connectivity | Wi-Fi, Ethernet, USB |

| Compatible materials | PLA, ABS, PETG, NylonX, TPU, PVA, PP, PC |

What We Like

- Excellent print quality

- Professional software support

- Wide material compatibility

Could Be Better

- Limited build volume

- Expensive replacement parts

Find Ultimaker S3 at

MatterHackers

BCN3D Sigma D25

Best professional

Check Price

MatterHackers

Improving on the R17 and R19 Sigma’s series of independent dual extruder (IDEX) 3D printers, BCN3D’s new Sigma D25 is a professional-grade 3D printer that comes in a new light gray color and with a desktop-sized footprint. It features an independent extruder system, letting you print with multiple print modes and enhance your productivity.

It features an independent extruder system, letting you print with multiple print modes and enhance your productivity.

The Sigma D25 includes stainless steel, precision linear rails on the X-axis, and a robust Z-axis designed for durability and maximum print accuracy. For better bed adhesion, its new aluminum heated build plate comes with a silicon thermal pad to evenly heat its area.

It also includes a new set of custom-made E3D hot ends coupled with Bondtech extruders that support a wide variety of materials and deliver a consistent 3D printing performance. The filament spools are neatly tucked within the printer frame itself, protecting them from any external debris and giving the printer a clean look.

BCN3D Sigma D25 aims to deliver the highest dual extrusion 3D printing in a clean-looking, easy-to-use package. The large build volume, IDEX system, and interface make it suitable for batch printing, print farms, and educational purposes.

Standout Features

- IDEX setup

- Built-in filament holders

- Large build volume

Technical Details | |

|---|---|

| Build volume | 420 x 300 x 200 mm |

| Dual extrusion setup | IDEX |

| Max hot end temperature | 300°C |

| Bed leveling | Manual |

| Connectivity | SD card, Wifi, Ethernet |

| Compatible materials | PLA, PVA, PET-G, TPU, PP, PA |

What We Like

- Easy to use interface

- Great build quality

Could Be Better

- Manual bed leveling

- Limited Z-height

Find BCN3D Sigma D25 at

MatterHackers

Raise3D Pro 3

Best professional

Check Price

MatterHackers

The Raise3D Pro 3 is one of the flagship 3D printers by the Raise3D team. It builds upon the previous generation of the Pro 2 series of industrial 3D printers. Its improvements lie with its new dual extruder setup, interchangeable hot end, and airflow system to give you great 3D printing results every time.

It builds upon the previous generation of the Pro 2 series of industrial 3D printers. Its improvements lie with its new dual extruder setup, interchangeable hot end, and airflow system to give you great 3D printing results every time.

The Pro 3 comes with a large build volume of 300 x 300 x 300mm. That volume is fully enclosed to isolate the print area from the external environment. Additionally, it includes a HEPA filtration system to keep away potantially unhealthy 3D printer fumes.

Its automatic bed leveling minimizes the calibration time required, resulting in improved productivity. The built-in ‘EVE intelligent assistant’, too, is a unique feature with the Pro 3 designed to locate and resolve any issues and give helpful feedback to the user.

The Raise 3D Pro 3 is for professional users who need a robust, large-sized 3D printer that lets you execute multi-material 3D printing on an industrial scale. You can use it to carry out batch 3D printing with advanced materials and end-use components without hassles.

Standout Features

- Airflow manager

- Interchangeable hot ends

- EVE Smart assistant

Technical Details | |

|---|---|

| Build volume | 300 x 300 x 300 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 300°C |

| Bed leveling | Automatic |

| Connectivity | Wi-Fi, LAN, USB port |

| Compatible materials | PLA, ABS, HIPS, PC, TPU, TPE, PETG, ASA, PP, PVA, Nylon |

What We Like

- Professional build quality

- High repeatability

- Auto bed leveling

- Large filament compatibility

Could Be Better

- Large investment

Find Raise3D Pro 3 at

MatterHackers

Ultimaker S5

Best professional

Check Price

AmazonMatterHackers

The Ultimaker S5 is the bigger brother of the Ultimaker S3, but with a larger build volume to utilize the benefits of dual extrusion 3D printing fully. It is similar to the S3 in many aspects, but the additional upgrades and add-ons make it an automated industrial-level 3D printer.

It is similar to the S3 in many aspects, but the additional upgrades and add-ons make it an automated industrial-level 3D printer.

The S5’s large build volume of 330 x 240 x 300 mm is suitable for big-sized objects, and it can be fully enclosed with an optional air management system to maintain a stable temperature in the printing area. This makes it more suitable as a Nylon 3D printer or to work with other high-temperature filaments.

To expand this 3D printer further, you can add a material station that takes up to six materials and automatically choose the required material for the current print without any user intervention.

The swappable print cores, retracting nozzles, and automatic bed leveling are the same as the S3, delivering a predictable and high-quality 3D printing experience each time.

The Ultimaker S5 is an excellent printer for industrial environments and can be upgraded to fulfill even more complex needs. It is our top pick for the best dual extruder 3D printer for professionals.

Standout Features

- Large build volume

- Additional upgrades

- Swappable print cores

Technical Details | |

|---|---|

| Build volume | 330 x 240 x 300 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 280°C |

| Bed leveling | Automatic |

| Connectivity | Wi-Fi, Ethernet, USB |

| Compatible materials | PLA, ABS, PETG, NylonX, TPU, PVA, PP, PC |

What We Like

- Wide material compatibility

- Premium components

- Reliable

Could Be Better

- Pricy upgrades

Find Ultimaker S5 at

AmazonMatterHackers

What to Look For When Buying a Dual Extruder 3D Printer

Dual extruder type

When you consider buying a dual extruder 3D printer, you’ll come across technologies such as the IDEX system, double hot ends, and a single Y-shaped hot end.

The IDEX system lets you simultaneously 3D print with two independently driven extruders and a hot end setup.The advantages of an IDEX system are the multiple printing modes that you get with it. You get to duplicate and mirror your models, effectively resulting in increased productivity.

If you look at the single hot end setup, you’ll notice that the hot end is much lighter, and you do not lose any printing area to a second print head. The downside, though, is that this setup is more likely to run into issues, as a single print head is used for multiple materials at a single time.

The most common and relatively more accessible dual extrusion system is double hot ends. You get two individual hot-ends and extruders, and each hot end can be configured to print a single material with maximum efficiency. However, two hot ends next to each other occupy extra space, cost more, and do not increase productivity like the IDEX system.

If you want a printer for maximum productivity and are looking to run it into print farms or to run multiple batches of prints, the best dual extruder 3D printer for you is an IDEX one. In contrast, the dual hot end setup is more suitable for conventional dual extrusion 3D printing, where you do not need to print many parts.

In contrast, the dual hot end setup is more suitable for conventional dual extrusion 3D printing, where you do not need to print many parts.

Printing modes

While the single nozzle and the dual hot ends styles let you print with multiple materials and soluble supports, printing modes are truly available only on the IDEX style of dual extruder 3D printers.

There are four printing modes that come with dual extruder 3D printers – Mirror, duplication, soluble supports, and multi-material mode. The mirror mode lets you print symmetrical mirrored objects, and you can print the part and its inverse simultaneously. For example, shoes, gloves, and other things come in a couple but are symmetrically opposite.

Another helpful model is the duplication mode, which helps carry out batch prints. In duplication mode, both the hot ends repeat the same movements and produce identical copies of the original design. It drastically improves your productivity rates and is suitable for print farms.

The soluble supports and the multi-material modes are similar and not just available in the best dual extruder 3D printers; any dual extruder printer can do them. While the primary nozzle is used for the main filament, you can use the secondary nozzle with either soluble supports or a differently colored material.

Print Volume

The dual extruder design reduces the printing volume of any 3D printer due to the extra space the secondary extruder takes up. This results in a smaller printing volume on the Y-axis in dual extruder printers compared to a single extruder setup.

When you use print modes, too, you’ll realize that the print area is reduced considerably due to the second extruder’s size in mirror mode. Hence, in the case of dual extruder printing, it becomes more crucial to look at the actual printing volume that you’ll get.

If you need a bigger print size, you should look at the Raise3D Pro 3, Ultimaker S5, and the BCN3D Sigma D25. These printers come with a large print volume that gives you more freedom to take full advantage of their dual extrusion capabilities.

Print Speed

Even with the addition of a second hot end on the motion system, the printing speeds of dual extruder 3D printers are relatively unaffected. Powerful stepper motors and a rigid frame can compensate for the added weight of the hot end.

Almost all of the 3D printers in this list can comfortably print at around 60-100 mm/s of printing speeds, while travel speeds go up to 200 mm/s. These speeds give you a good balance between print quality and lead times.

If you consider the other benefits of dual extruder 3D printers, you’ll realize that the printing modes lead to a considerable increase in overall productivity. The ability to print with two print heads simultaneously easily triumphs the faster printing speeds of any other 3D printer.

Filament Compatibility

Ensuring that your 3D printer is compatible with many filaments is one of the primary things you need to consider while buying any 3D printer. More so with dual extruder 3D printers due to their second print head.

The second print head is helpful for printing soluble supports. If you’re getting a dual extruder printer specifically for printing with soluble filaments such as PVA and HIPS, you should check whether or not it is compatible with these materials.

Every printer in this list is equipped to print with these materials. And some of the dual extruder 3D printers like the Ultimaker S3, S5, Raise3D Pro 3 go beyond and let you swap your print heads for printing with specific materials, thus increasing their material compatibility.

Enclosure

A 3D printer enclosure plays a crucial role with dual extruder 3D printers. The isolated printing area on enclosed 3D printers lets you print with tricky materials such as ABS filament and keeps 3D printing fumes within the printer body itself.

Aside from the Sovol SV02 and the Tenlog TL-D3, all other dual extruder 3D printers come with at least a partially enclosed design. And with the Creator Pro 2, you get the benefits of both; you can choose to keep the printer open on the top while printing with PLA and fully enclose it when you want to print with ABS.

The Ultimaker S5 goes a step beyond its airflow management system, however, the QIDI Tech i-Fast is the only dual extruder 3D printer on the list with an actively heated build chamber. This ensures that you get the best print quality and that the printer is compatible with a wide variety of materials.

Warranty

Warranty is often an overlooked factor when buying dual extruder 3D printers. You need to carefully evaluate the warranty conditions and everything that is covered within it. Some manufacturers offer a warranty on specific components for a short while, while the best dual extruder 3D printers tend to get comprehensive coverage of any manufacturing defect in the printer.

In this list, all the dual extruder 3D printers have at least a 12 months warranty period that covers any manufacturing defect from the company’s end.

FAQ

Are dual extruder printers faster?

Even the best dual extruder 3D printers are not necessarily faster than any other 3D printer. However, the dual extrusion process leads to an overall increase in productivity due to the ability to print multiple copies at the same time.

However, the dual extrusion process leads to an overall increase in productivity due to the ability to print multiple copies at the same time.

Can dual extruder printers print with soluble filaments?

Yes, all of the dual extruder 3D printers in this list are capable of printing with soluble filaments.

How many extruders can a 3D printer have?

Most 3D printers have a limit of two extruders. However, depending on the electronics capabilities and general hardware setup, some 3D printers can have up to four or five extruders.

What is the advantage of a dual extruder printer?

The dual extruder setup allows for printing with multiple materials, which leads to an increase in productivity. Additionally, dual extruder printers are compatible with a wider range of filaments.

Do dual extruder printers have an enclosed build area?

No, dual extruder printers do not necessarily have an enclosed build area as it is not necessary for their operation. However, some dual extruder printers do come with a partially or fully enclosed design.

However, some dual extruder printers do come with a partially or fully enclosed design.

Can you 3D print multiple objects at once?

Yes, dual extruder 3D printers can print multiple objects at once provided that they have the necessary build volume. However, the print quality may not be as good as if you were to print them one at a time.

What is the average price of a dual extruder 3D printer?

Dual extruder 3D printers generally cost more than single extruder 3D printers. However, the price difference is not as significant as it used to be and there are a number of excellent dual extruder 3D printers in the market at a wide range of prices.

You can find a good one, like the Flashforge Creator Pro 2, for around $650. The best dual extruder 3D printers, however, cost multiple thousands of dollars.

How do you print multiple filaments?

To print multiple filaments, you need to have a dual extruder 3D printer with two extruders. The filaments are then loaded into the extruders and the printer will print with both filaments simultaneously.

Conclusion

Dual extruder 3D printers let you print with multiple materials simultaneously, and that too with ease. Especially with the IDEX style of printers and the multi-material capabilities, you get the added benefits of various printing modes that increase your overall productivity and are great for the batch style of prints.

From the list, the best dual extruder 3D printer that stands out on the top is the Flashforge Creator Pro 2. It gives you the benefits of the IDEX system, is fully enclosed, and has broad material compatibility while still being affordable and accessible for professionals and hobbyists alike. Its only downside is a relatively small print volume.

If print area is your main criteria, you should consider the QIDI Tech i-Fast and the BCN3D Sigma D25 for their large print chambers in decent footprint size. These are professional dual extruder 3D printers with advanced features, excellent print quality, and great for industrial prototyping needs.

Let us know your thoughts on the list, and if you have anything else to add, feel free to comment below.

up to 10 materials per model / Habr

MIT has developed a 3D printer that can print ten materials at once. The company wants the device to be able to print fully functional objects such as printed circuit boards soon.

Article Mary-Ann Russon from Ibtimes.co.uk translated for you by Top 3D Shop .

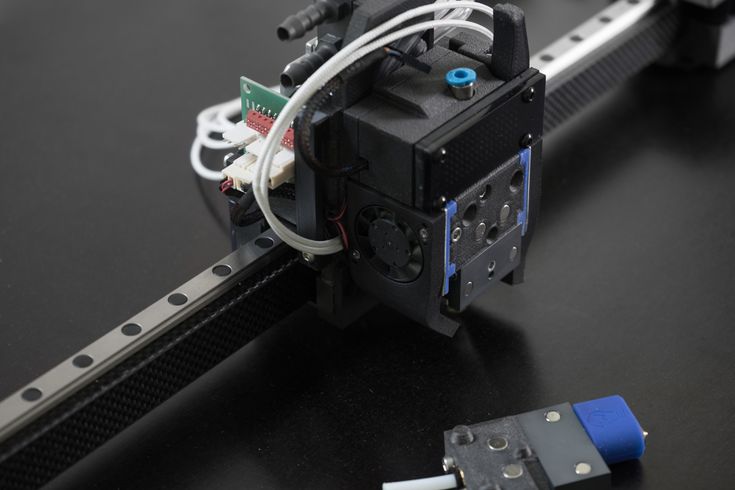

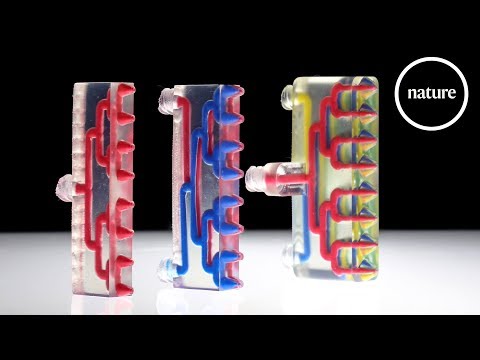

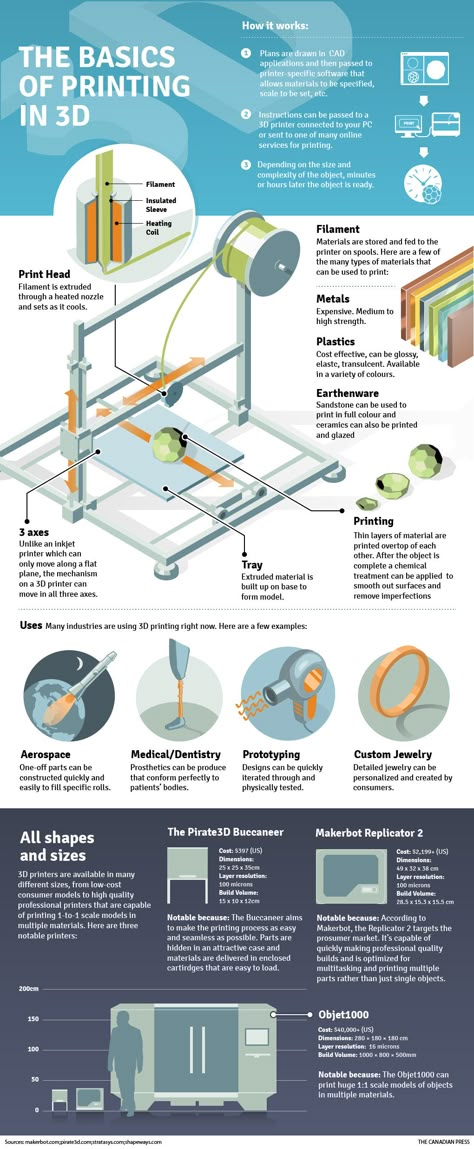

Researchers at the MIT Computer Science and Artificial Intelligence Laboratory (CSAIL) have made a breakthrough in 3D printing by developing a prototype 3D printer that can use up to 10 different materials simultaneously on a single object.

At the moment, most 3D printers can print only one material during one process, many can already print two, and very rare models can print three or five. Multi-material 3D printers have existed before - Stratasys launched the world's first full-color multi-material 3D printer in January 2014. He was able to print rubber and plastic objects, but his problem was the extremely high cost ($250,000). Another disadvantage of this solution is that it still required human intervention in the printing process.

He was able to print rubber and plastic objects, but his problem was the extremely high cost ($250,000). Another disadvantage of this solution is that it still required human intervention in the printing process.

MIT's new 3D printer, the MultiFab, doesn't have these drawbacks. It's a $7,000 all-in-one system that can quickly print multi-material objects with no operator intervention required.

How MultiFab works

During printing, the printer monitors the progress of work, for this it uses three-dimensional machine vision.

The data received from optical sensors allows the 3D printer computer to independently calibrate the device and correct errors that occur.

Specialized components such as electronic components can be added to the model during printing. The device will continue to print around these components, including them in the final product.

“With MultiFab, we have combined two worlds – traditional manufacturing and 3D printing. We will be able to make a number of new objects that were impossible to create until recently.

We will be able to make a number of new objects that were impossible to create until recently.

Right now, 3D printers are mainly used for prototyping, creating injection molds and other types of blanks, but MultiFab will create full-fledged functional objects by combining several materials with different properties,

said Javier Ramos, research engineer with CSAIL and co-author of the research paper.

Modern electronics in the future

LED lenses that were 3D printed using MIT MultiFab.

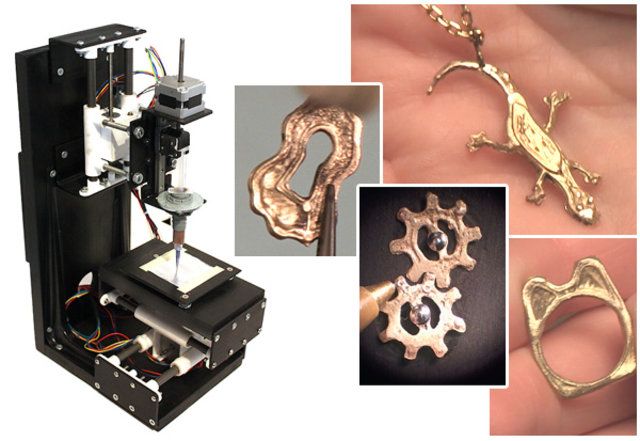

So far, CSAIL researchers have already succeeded in printing LED lenses, a plastic metal blade holder, and smartphone cases that are printed immediately around the gadget. The developers believe that MultiFab will find its application in the production of consumer electronics, medical imaging and telecommunications.

The next step for researchers is to 3D print objects with built-in motors and actuators. If the finished products can function, it will open up opportunities for 3D printing in advanced electronics such as building robots.

“Designers and engineers are used to designing with only one material. With the advent of such equipment, the design paradigm itself will change. This will require new hardware and software, and we will have to change the way we, as engineers and designers, approach the development process.

Imagine someone who sells electric wine openers but doesn't have the $7,000 to buy such a printer—he can walk into a copy shop with a digital model and print a batch of the finished product for a reasonable price. I dream of my equipment being used for such purposes”,

Ramos said.

Share your opinion in the comments.

Material Combination 3D Printer

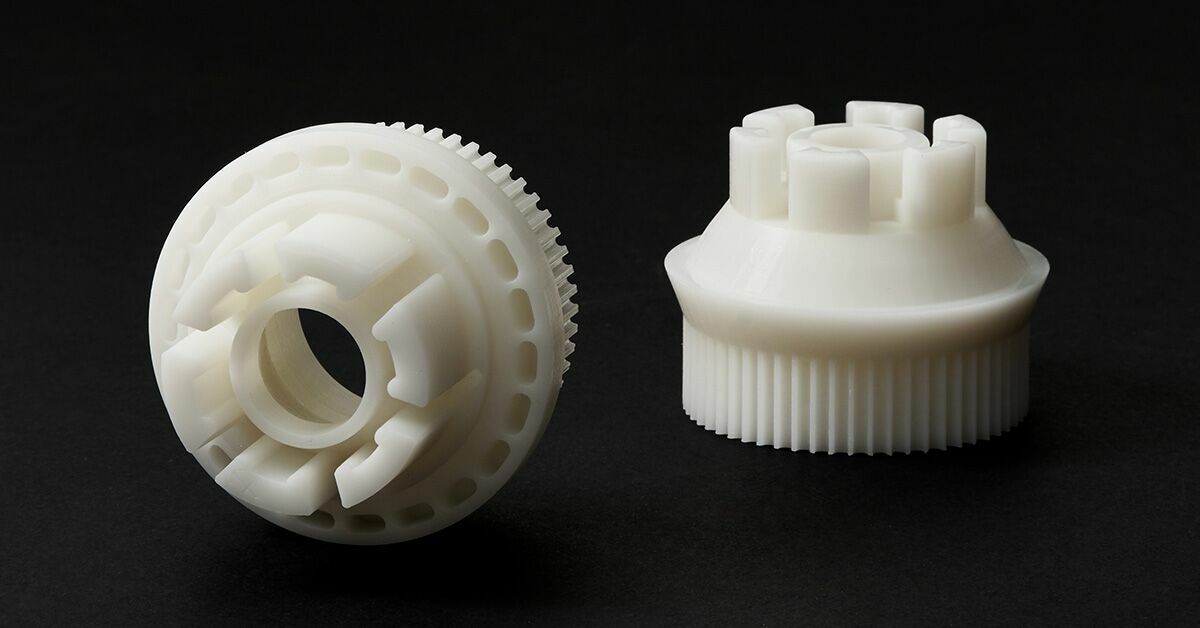

The ProJet 5500x 3D printer is capable of creating versatile products with any physical properties you need: flexible, strong, heat-resistant, transparent. This is possible thanks to the MJP technology, which allows mixing materials with different properties. It provides fast and high-quality printing using composite materials.

The ProJet 5500x prints twice as fast as any other printer in its class. Given the impressive size of the camera, finished models can be over half a meter long.

The ability to use multiple materials with different colors and properties at the same time allows you to create incredibly realistic and functional prototypes, both large and small. Due to its unique capabilities, the ProJet 5500x will be of interest to a wide range of manufacturers, scientists, designers, developers, and researchers.

Benefits of the ProJet 5500x

- Fast print speeds, a wide range of options and a large build chamber make it easy to create models of the desired size with desired plastic and elastic properties.

- More materials, from engineering plastics to rubbers. The result is highly detailed, ultra-precise parts with exceptional strength and high temperature resistance. The resulting models do not require post-processing.

- The ProJet 5500x uses many different materials in a single print session, producing results that are strictly within specifications.

It is the ideal solution for a wide range of applications, including multi-layer casting, multi-material assemblies, elastic elements, durable flexible joints, and high temperature testing.

It is the ideal solution for a wide range of applications, including multi-layer casting, multi-material assemblies, elastic elements, durable flexible joints, and high temperature testing. - With an industrial-grade print head, the ProJet 5500x is approximately 60% faster than comparable systems, allowing you to create larger parts or many small parts in a single workflow.

Applications

Exceptional power and a huge working chamber make the ProJet 5500x a key working tool in various areas of industrial production, medical research, military technology, and the space industry. The 3D printer is ideal for the production of complex structures from multiple materials with different properties, such as flexible products, hinges, high temperature test parts, snap-on flexible elements, functional units of complex assemblies, etc.

Materials

In printing, the ProJet 5500x uses a range of specially developed VisiJet materials that are mixed during the model building process. Thanks to this unique technology, the printed part will have precisely programmed properties. And an impressive working chamber measuring 533x381x300 mm will provide space for the implementation of the most complex and large-scale projects.

Thanks to this unique technology, the printed part will have precisely programmed properties. And an impressive working chamber measuring 533x381x300 mm will provide space for the implementation of the most complex and large-scale projects.

Custom-designed for the ProJet 5500x, VisiJet materials are perfect for the 3D printer's printhead, which comes with a 5-year manufacturer's warranty.

- Elasticity. The ProJet 5500x uses a stretchy black material. It is rubbery and has incredible tear resistance with up to 700% elongation. The model can be twisted when stretched, subjected to shocks and other mechanical actions.

- Strength. The white material is similar in properties to ABS plastic, and has an excellent tensile strength and rigidity - at the level of 56 MPa. Bending strength - 74 MPa.

- Heat resistant. ABS-like material has a high temperature resistance. So, at a pressure of 0.45 MPa, the heat resistance is 54 ⁰С.

- Transparency. The material imitates the properties of polycarbonate and has functional strength while resisting scratches.

Learn more