Diy 3d laser scanner using arduino

6 DIY 3D Scanners You Can Build at Home

Creating a 3D model of a real object can be done extremely fast if you have a 3D scanner at home. The problem is: 3D scanners are expensive to buy new.

If you're looking for a solution, why not try building your own affordable 3D scanner at home? It might not create perfect 3D models, but it's a cost-effective alternative to buying a 3D scanner.

Is It Cheaper to Build a DIY 3D Scanner?

The cost of buying a decent 3D scanner ranges from $700 to $10,000 at the highest end. On the other hand, building a DIY 3D scanner can cost less than $200—some even as little as $35.

Depending on the resolution of your homemade 3D scanner, you will still have to work to tidy up the 3D model so that it can be used for things like 3D printing, game development, or perhaps design prototyping. But overall, it will still speed up the design process when compared to building a model from scratch.

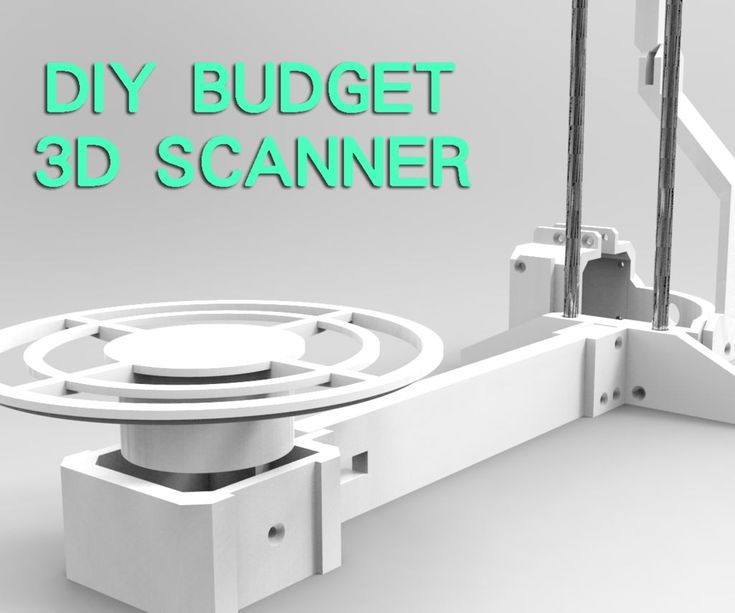

1. Cheap 3D Printed 3D Scanner

This 3D scanner is built using 3D printed parts, featuring both open source software and open source hardware files. If you choose to install the maximum of four lasers, then the cost of the project comes in at $35 to $50. Once it's built, handling the digital scan will require some legwork to smooth out. But considering its price tag, it's well worth giving it a go.

You can find the STL files and a full build guide on Instructables. Besides the 3D printed components, you will need one to four lasers, a stepper motor, a turntable, and an Arduino Nano to bring it all together. One benefit of this project is that it's been built many times by community makers, resulting in plenty of images and feedback surrounding the project to help fill in any gaps.

2. DIY 3D Scanner Using a DSLR Camera

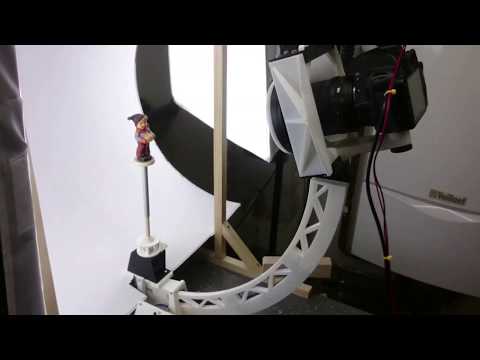

Another option for building a 3D scanner is to use a DSLR camera and a method called photogrammetry. At its most basic, it involves taking a lot of images of an object from different angles and stitching those photos together in a software program to create a 3D model.

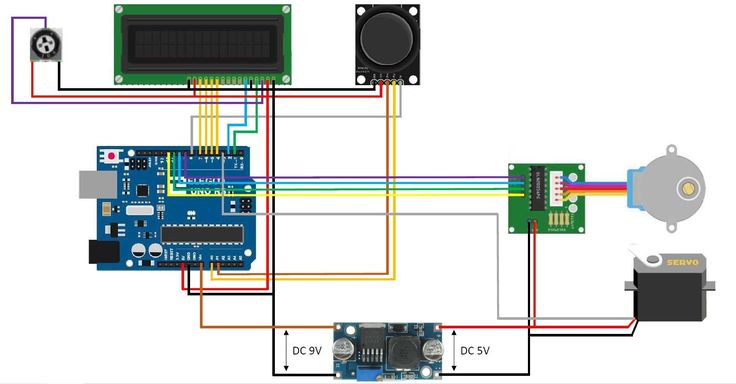

Alongside a DSLR camera, you will need an Arduino, a stepper motor and driver, an LCD screen, and an IR LED. The goal of the hardware is to build a rotating platform that moves by set amounts so that your camera can photograph the object in a very detailed and controlled way. You can find a great explanation of the project on Instructables.

The goal of the hardware is to build a rotating platform that moves by set amounts so that your camera can photograph the object in a very detailed and controlled way. You can find a great explanation of the project on Instructables.

The real difficulty of this project comes in processing the photos. A good photogrammetry program is essential, and that can cost over $150 to license. There is some free software available, but it may come with limitations.

If you're wondering if there is an alternative solution, you can read our guide to how to turn everyday objects into 3D models without a 3D scanner.

3. Optical CT/3D Scanner With Arduino

For something a little different, in this project you will build a 3D scanner that also doubles as an optical CT scanner. This type of scanner will do the trick if you have objects that are semi-transparent, like a gummy bear or a segment of orange. Otherwise, you can use this setup with the photogrammetry method for regular 3D scans.

Everything in this build is enclosed inside a box. This allows greater control over lighting the object to produce sharper images. While it involves some woodworking and construction, the hardware is still powered by a humble Arduino Nano, plus additional parts that you can find at any hardware store.

A great guide is available on Instructables for building the box, alongside details for creating a sleek control panel for changing photo parameters on the go.

4. FabScan: Raspberry Pi + Arduino 3D Scanner

This 3D scanner uses both a Raspberry Pi and an Arduino to build a 3D laser scanner. What sets this build apart is that it can be operated remotely via a web browser on a phone.

Much like other DIY 3D scanners, a stepper motor and driver are used to rotate a turntable holding the object you want to scan. Additionally, you will need a line laser and a Raspberry Pi camera. You can find the guide and a full components list on Instructables.

While the creators have gone with a laser-cut MDF box, you can just as easily use spare parts lying around the home to create the enclosure. Alternatively, cardboard can work too, and painting it black will aid in diffusing the laser light so that it doesn't interfere with the scan.

Alternatively, cardboard can work too, and painting it black will aid in diffusing the laser light so that it doesn't interfere with the scan.

Once you have a good scan of your object, you might be interested in 3D printing it. Haven't got a 3D printer? Here is our pick of the best 3D printers.

5. The Ultimate Human Sized 3D Scanner With Raspberry Pi

While most homemade 3D scanners are built to capture a small object, it's also possible to build a human-sized 3D scanner. The way to do this is with a lot of Raspberry Pis, as you can see over on Instructables.

The maker behind this project scaled up his 3D scanner using a whopping 47 Raspberry Pis plus a Raspberry Pi camera for each module. The goal was to use the photogrammetry method to take a photo of his subject from every possible angle. Because he wanted to capture a 3D model of his two-year-old son, this all had to happen instantly.

Incredibly, it works, and it works very well too. If you have the time and investment to buy a box full of Raspberry Pis, you won't be disappointed because the results are impressive. The maker says you can use fewer Pis and cameras and still get good results, especially if you only need to capture the front of a person’s face.

The maker says you can use fewer Pis and cameras and still get good results, especially if you only need to capture the front of a person’s face.

6. Standalone 3D Scanner

Maybe you're just after a simple and small 3D scanner that you can make over the weekend. If so, then this project will suit you. This 3D scanner on Instructables is designed to be all-in-one, meaning that the photos are compiled onboard and an STL file is saved directly to a memory card. Instead of compiling the photos in a separate photogrammetry program, this 3D scanner handles them for you.

While it doesn't produce incredibly detailed scans, it does make for a rapid way to take a 3D model straight to 3D printing. One thing to bear in mind, however, is that the dimensions of the 3D scanner structure need to be kept exactly as written in order to match the code.

Building a Homemade 3D Scanner

Putting together a 3D scanner at home isn't extremely difficult to achieve. When compared to the expensive price of commercial 3D scanners, it's well worth building a DIY 3D scanner yourself.

With a Raspberry Pi or Arduino and a few extra affordable parts, you'll be well on your way to creating a cheap and awesome 3D scanner.

9 Accurate DIY 3D Scanners You Can 3D Print At Home (2022)

3D scanners can get really expensive. We’d know – we’ve tested and researched them in creating our ranking of the best 3D scanners . However, if you’re willing to be a little more thrifty you can save a lot of money building your own DIY 3D scanner — and have a cheap 3D scanner you can feel proud of building yourself!

DIY projects, especially in an area where precision is key, have an unfairly slap-dash reputation. In fact, there are some very accurate DIY 3D scanners on our list, you just need to assemble them yourself.

The best part: they’re almost free if you 3D print the parts — your only costs are the camera/parts.

However, don’t be fooled – you won’t get $20,000-quality scans from these kits.

And, it takes focus and skill to build such a technical piece of kit – hence we’ve included a couple of easy-assemble kits which cost more, but let you get right down to scanning.

Best DIY 3D Scanner Kit Under $200

HE3D Open Source Ciclop DIY 3D Systems Scanner Kit for 3D Printer

$159.00

Amazon here

Best 3D Scanner Under $1000

$719.00

Amazon here

12/12/2022 05:21 am GMT

Top Picks

Best DIY Scanners – Full Round-Up

- BQ Ciclop: Best 3D scanner kit overall

- Murobo Atlas: Good Ciclop DIY scanner alternative

- Cowtech Ciclop: Upgraded premium Ciclop scanner

- Openscan: Great open source 3D scanner

- AAScan: Great option for Android

- Revopoint POP 2: Best semi-assembled 3D scanner to save you time

For the DIY kits, we’ve included download links and links to documentation to get you started.

But first, let’s cover what to look for in a good homemade 3D scanner:

What Makes a Good DIY 3D Scanner?

- Price-performance ratio: for the price, how good are scans?

- Resolution: how crisp is scan quality

- Accessibility: you may be able to print most of the 3D scanner, but are the rest of the parts easy to buy?

- Ease of assembly and use: quick and easy builds are always better.

The best 3D scanner projects can be built by anyone, newbie or expert.

The best 3D scanner projects can be built by anyone, newbie or expert.

The Best 3D Printable 3D Scanner Kits

Ciclop DIY 3D scanners

Many of the best DIY scanner kits are based on the original Ciclop open-source files. Massive companies like BQ have created their version, as well as tweaked versions such as CowTech Engineering’s take.

We’ve included them all here, as each option are some of the most DIY accurate 3D scanner options for this price range. For a pre-assembled scanner with the same quality, you’d likely need to spend double this.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

BQ Ciclop

- Resolution: 0.3-0.5mm

- DIY 3D scanner technology: laser triangulation

- Price: around $150 — Available on Amazon worldwide here

BQ are a Spanish technology giant who are well-known across Europe for their smartphones, tablets, and 3D printers. They’ve also developed their Ciclop DIY 3D scanner, which scans a volume up to 250 x 205 mm, based on laser triangulation technology.

They’ve also developed their Ciclop DIY 3D scanner, which scans a volume up to 250 x 205 mm, based on laser triangulation technology.

An important feature of the BQ Ciclop is that it’s a completely open source 3D scanner. You’re free to modify it as you wish, following the RepRap philosophy. It’s easily accessible via USB or Bluetooth, and can 3D scan with a resolution of between 0.3-0.5mm.

- We also have a ranking of the best open source 3D printers.

Another great addition to this DIY 3D scanner is that it works with Horus open source 3D scanning suite which BQ also developed. This makes scanning much easier with the compatible program. You can buy just the electronics (includes an Arduino, webcam etc) and print the parts yourself for $115, or buy the whole kit for $240. Not bad.

However, it is worthy of note that the BQ Ciclop is difficult to assemble. Other DIY 3D scanners are quicker and simpler to build, though the Ciclop is still a fantastic DIY 3D digitizer.

Best DIY 3D Scanner Kit Under $200

HE3D Open Source Ciclop DIY 3D Systems Scanner Kit for 3D Printer

$159.00

Yes, you'll get better quality if you spend more on a scanner like the Revopoint POP range, but with this you get to build your own 3D scanner from the parts for several hundred dollars less.

Amazon here

We earn a commission if you make a purchase, at no additional cost to you.

12/12/2022 05:21 am GMT

Murobo Atlas — Great Raspberry Pi 3D Scanner

- Resolution: 0.25mm

- DIY 3D scanner technology: laser triangulation technology

- Price: $200-250 — Available on Amazon worldwide here

Another homemade 3D scanner, the Atlas has the highest quality specs of any DIY 3D scanner we researched. It includes a 3D printed body made from PLA and ABS filaments, which can be purchased online. If you’re a serious DIY fanatic, you can print the parts yourself via the download link here.

It includes a 3D printed body made from PLA and ABS filaments, which can be purchased online. If you’re a serious DIY fanatic, you can print the parts yourself via the download link here.

Depending on if you already own a Raspberry Pi or not, you can save money on the build. This is because the Atlas DIY 3D scanner uses a Raspberry Pi camera to take detailed 3D scans with an accuracy of 0.25mm. Depending on your choice, the Atlas is likely to cost between $200 and $250, which is far less than most professional 3D scanners.

Moreover, Murobo has made considerable efforts to make sure that the Atlas DIY 3D scanner is convenient and simple to use. To achieve this, the Atlas comes with FreeLSS free 3D software which enables you to easily take 3D scans. In addition, you can access your Atlas via your computer’s browser through WiFi, as well as via SD card.

Overall, this DIY 3D scanner Raspberry Pi collaboration is a really interesting and creative way of combining several different innovative technologies to create a scanning device. If you’re an Arduino fan instead, you may be able to make it work for you too.

If you’re an Arduino fan instead, you may be able to make it work for you too.

CowTech Ciclop

- Price: $119 – $159 (depending on whether you’re 3D printing the parts or not) — Available on Amazon here

- Resolution: 0.5 mm

- Maximum scan volume: 200 x 200 x 205 mm

BQ formed the foundations of the DIY 3D scanner kit, and remains one of the best DIY 3D scanner on tight budget options. Then back in 2015, CowTech Engineering used the foundations led by BQ, putting their unique spin on an updated model.

True to the open source movement, Cowtech started a Kickstarter campaign to raise money to put their version of the original, the CowTech Ciclop, into production. The team set the lofty goal to raise $10,000, and were met with surprise when the community rallies to raise $183,000. The CowTech Ciclop DIY 3D scanner kit was born.

So what are the differences between CowTech’s version and BQ’s DIY 3D scanner?

The CowTech Ciclop still uses the Horus 3D software program as it does a fantastic shop for 3D scanning objects. Differences however include a slightly different design, which the team spent days designing so that the parts could be 3D printed on any FDM 3D printer. Some desktop 3D printers only have a small build volume, so CowTech designed parts that can be printed on any printer with a build volume of 115 x 110 x 65 mm, which almost all 3D printers have.

Additionally, CowTech’s Ciclop has adjustable laser holders, and whereas the BQ Ciclop uses threaded rods, CowTech’s DIY 3D scanner uses laser-cut acrylic. This isn’t anything drastic and the scanners still look fairly similar, but CowTech only intended to improve the existing design, not reform it. CowTech sell the Ciclop, ready-to-scan, for $159 on their website. Overall, this is a great cheap DIY 3D scanner, and very effective for laser triangulation 3D scanning.

OpenScan Classic and OpenScan Mini

- Max Scan Volume: 180 x 180 x 180 mm / 80 x 80 x 80 mm

- Accuracy: Up to 50 microns

- DIY 3D scanner technology: Photogrammetry

- Price: Starting at $100.00 up to $200.00 for a complete kit with 3D printed parts and electronic

The Mini and Classic are two low-cost but high-quality 3D printed DIY scanner projects designed by German company OpenScan. In action, the OpenScan uses a stepper motor mounted to a 3D printed frame to rotate an object to capture images from various angles. These are then compiled into a high-quality 3D model using open-source software or OpenScanCloud, ready for 3D printing.

Where the OpenScan Classic and Mini differ from one another is max scan volume and camera/SBC options. The Mini features an 80 x 80 x 80 mm scan volume, while the Classic more than doubles the scan volume to a roomy 180 x 180 x 180 mm, perfect for scanning larger objects. The Openscan Mini – the cheaper and smaller 3D printable 3D scanner.

The Openscan Mini – the cheaper and smaller 3D printable 3D scanner.

The OpenScan Mini is tied to a Raspberry Pi and only works with either a Pi Camera or Arducam IMX 519 and includes one-click easy scanning. This allows the completed scanner to rotate not just the object but also the camera for a more detailed point cloud.

On the other hand, the OpenScan Classic is also compatible with Smartphones and DSLR cameras, which generally means better quality photos and, as a result, higher-quality models. It’s the tinkerer’s option and better suited for those that want to customize the scanner to their needs.

OpenScan offers a solution for all DIY skill levels and budgets, whichever model you decide on. You can customize kits based on your needs or order a complete kit that includes all the electronics and 3D printed parts.

The full assembly guide is here.

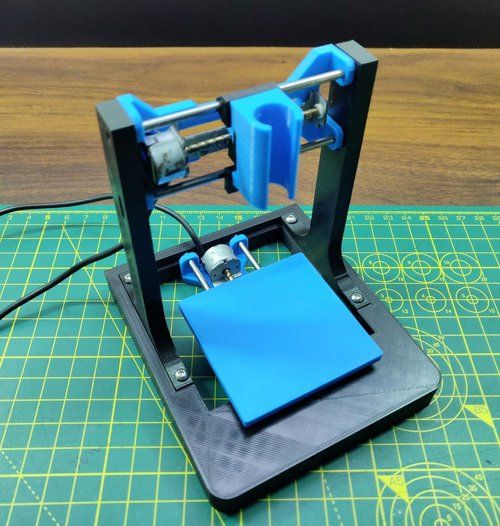

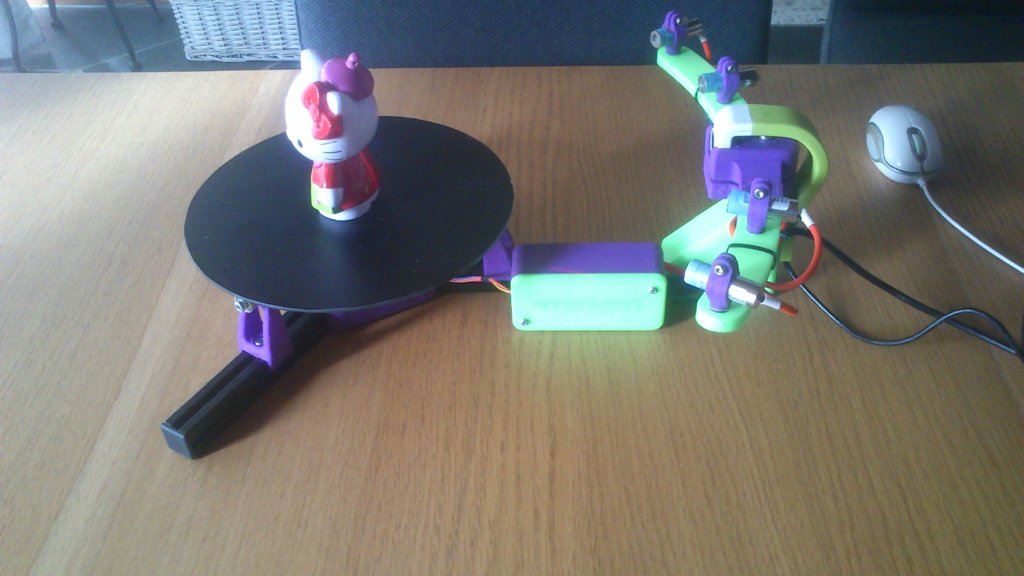

AAScan Open Source 3D Scanner Based on Arduino and Android

AAScan is a very recent (February 2020) DIY open source 3D scanner that’s fully automated in taking photos and moving the object around on the scan plate. All the files are on Thingiverse, which we’ve linked below. Interestingly, the creator stresses that the AAScan is intended to be a purposefully minimalist machine, able to scan but not filled with extra features beyond this primary capacity.

All the files are on Thingiverse, which we’ve linked below. Interestingly, the creator stresses that the AAScan is intended to be a purposefully minimalist machine, able to scan but not filled with extra features beyond this primary capacity.

All the instructions for how to build, print and assemble the AAScan are on the Thingiverse page, requiring an Arduino, some electronics, and either a 3D printer to print the plastic parts or someone else to print them for you — such as from a 3D printing service.

You can view the DIY scanner on Thingiverse here.

FabScan Pi

- DIY 3D scanner technology: laser triangulation

- Price: $100-200 depending on which version

The original FabScan was a DIY 3D scanner built by Francis Engelmann as part of his Bachelor’s thesis back in 2010. Since then, there have been numerous improvements made in new iterations up to the newest model, the FabScan Pi. This new model uses a Raspberry Pi camera along with the new design to offer higher quality 3D scans.

This new model uses a Raspberry Pi camera along with the new design to offer higher quality 3D scans.

Based on laser triangulation technology, the FabScan Pi is one of the best DIY 3D scanner options for those who are into doing it themselves. Depending on if you go for one of the older models or the latest, the price can vary between $100 and around $200 to completely create the 3D scanner. Overall, it’s a really cool kit and thesis which you can make at home.

If you want to create your own FabScan, you can follow the assembly guide here.

DIY Standalone 3D Scanner by Jun Takeda

- DIY 3D scanner technology: Photogrammetry

- Price: $200.00

The DIY Standalone 3D Scanner is an excellent option for those that want a hands-on project that results in a reasonably accurate and easy-to-use stationary 3D scanner.

By combining a Mbed board with a camera and OpenCV libraries, the scanning process is largely automated with just a single button push. The scanner captures multiple images of an object to create a 3D model that’s then output as an STL file written to an SD Card.

The scanner captures multiple images of an object to create a 3D model that’s then output as an STL file written to an SD Card.

To complete the project, you’ll need a GR-LYCHEE as a centerpiece sided by smaller electronic parts, plastic sheets to create the housing, and various nuts and wiring to piece it all together.

As the name implies, it’s very much a DIY project and, as such, would best suit those happy to troubleshoot any potential hurdles with little hand-holding. Though there are instructions, you’re responsible for designing the housing, wiring the board, and calibrating the camera.

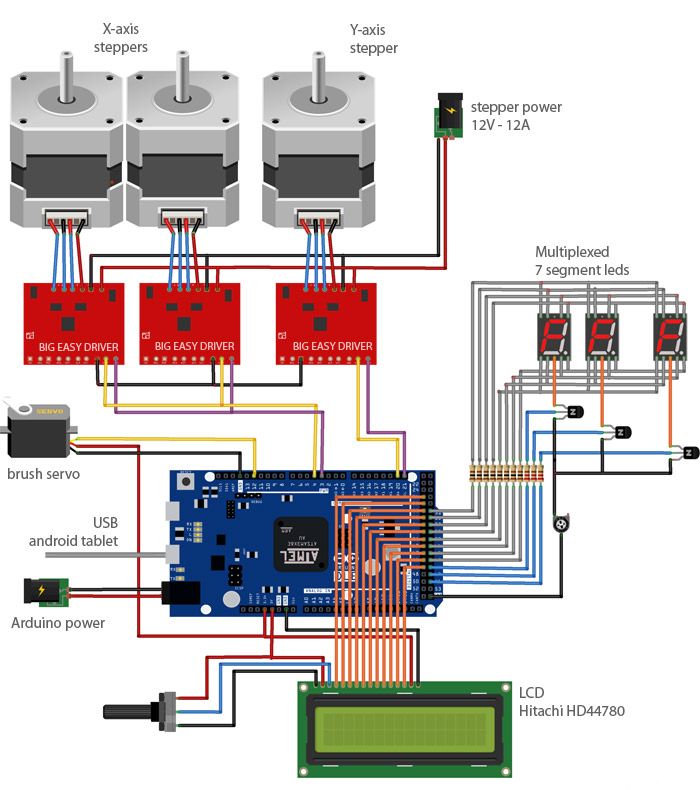

Arduino-Controlled Photogrammetry 3D Scanner by Brian Brocken

- DIY 3D scanner technology: Photogrammetry

- Price: ~$100

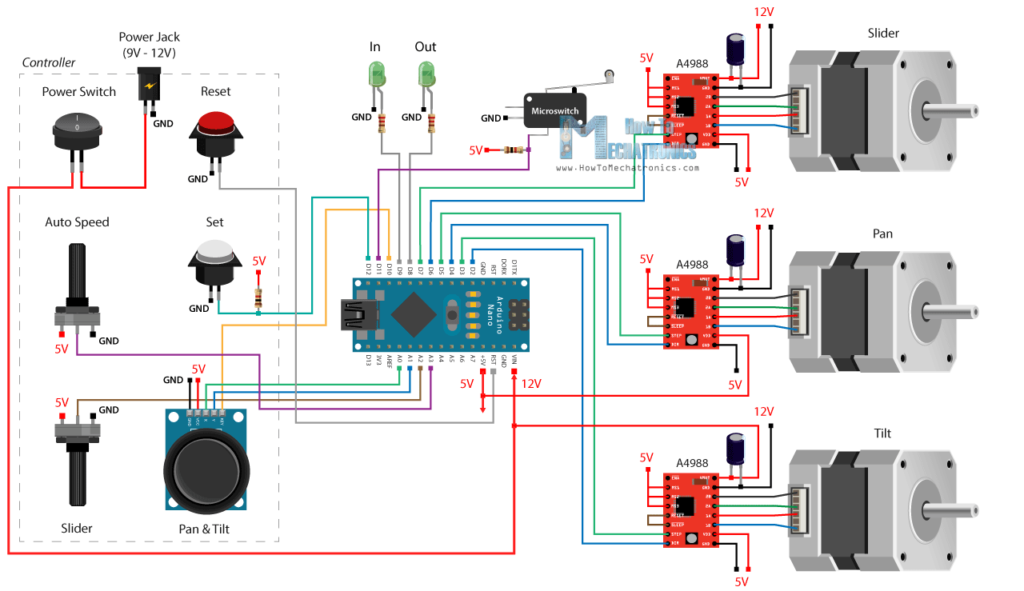

The Arduino-Controlled Photogrammetry 3D Scanner is a 3D printable 3D scanner DIY project that leverages the camera on any run-of-the-mill Smartphone and a cheap Arduino UNO SBC to keep costs low.

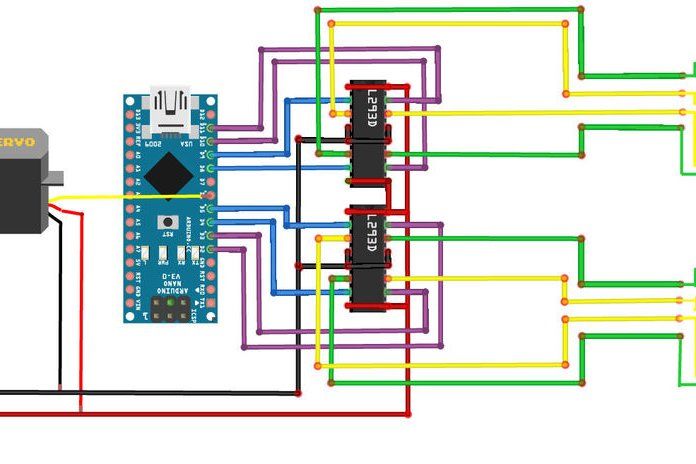

The core idea is to assemble a turntable consisting of 3D printed mechanical parts, including a print-in-place bearing. A Bluetooth-connected Smartphone does the actual scanning via the normal photogrammetry process. As for electronic components, you’ll need a servo motor, LCD screen, Arduino Uno, PCB, stepper motor, Bluetooth remote, regulator, and a small joystick module.

Once assembled, the Arduino-Controlled Photogrammetry 3D Scanner can capture anywhere from 2 to 200 photos in a single 360° rotation for reasonably detailed scans. The images are then sent to photogrammetry software such as AutoDesk Recap Photo to assemble a 3D model.

Aside from the cost of filament, expect to pay no more than $100 for all the parts and the STL files to 3D print the turntable.

Semi-assembled DIY scanners

Revopoint POP / POP 2

- Price: $500-700 — Available at Revopoint store here

- Accuracy: 0.3 mm

- Max Scan Volume: 200 x 300 x 300 mm

- Scan Speed: Up to 8 FPS

- DIY 3D scanner technology: Structured light

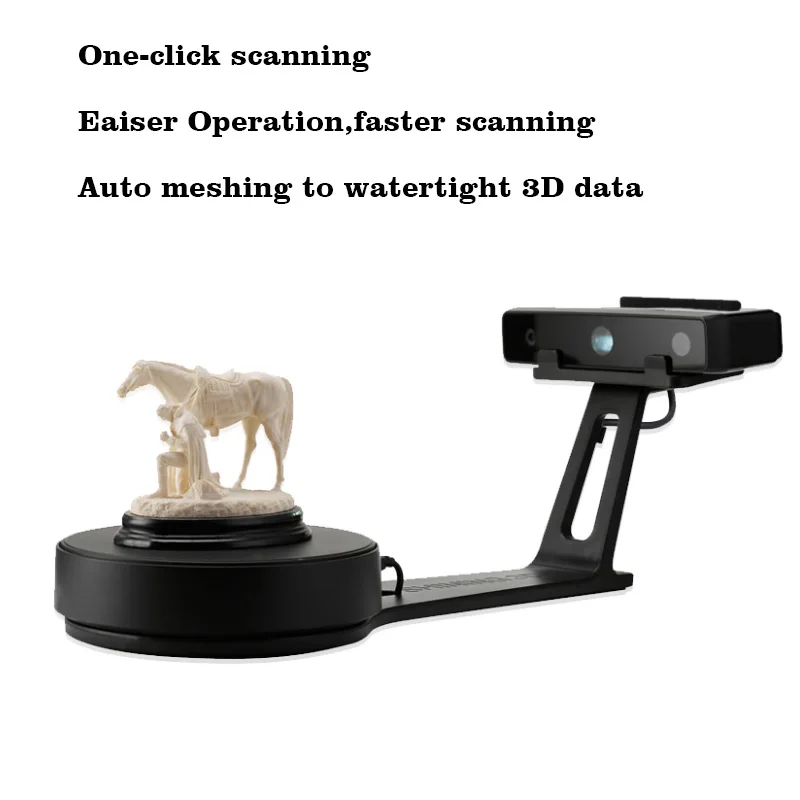

Though not technically a DIY scanner, we thought we’d slide in the Revopoint POP as a cheat option for those that want to save time and want largely better quality scans than you’d get with a homemade alternative.

It comes semi-assembled – you just need to attach the tripod, connect the USB and the turntable, add the sticker markers for better scan tracking, and optionally build and attach the larger turntable – so you can get started in just 5 minutes!

A basic mug scan we did on our Revopoint POP 2.The catch? At around $500, the Revopoint POP is considerably pricier than a DIY scanner. Still, it may be worth paying the premium for the convenience and reliability.

The Revopoint POP offers 0.3 mm accuracy (the POP 2 offers within 0.1 mm!) and automatic alignment technology, making for more detailed and smooth full-color 3D models than DIY scanners. It can capture 360° scans of objects up to 200 x 300 x 300 mm, besting most DIY options.

The main benefit of all this is high accuracy scans that are just about ready for 3D printing with very little post-processing needed to iron out imperfections and poor surface details.

A statue scan we did with our Revopoint POP 2.Ease of use also extends to the intuitive software, which works with Smartphones for on-the-go scanning and features exports to STL and OBJ formats. Alongside, it bundles in best-of both-worlds handheld and stationary modes. Five different scanning profiles allow you to tune the POP to each scan with face, body, feature, mark, and dark mode.

Alongside, it bundles in best-of both-worlds handheld and stationary modes. Five different scanning profiles allow you to tune the POP to each scan with face, body, feature, mark, and dark mode.

Read more: we tested and reviewed the Revopoint POP 2

Best 3D Scanner Under $1000

Revopoint POP 2 3D High-Precision Scanner with 0.05mm Accuracy

$719.00

You'll see just how accurate this scanner is when you try it (I've tested it to confirm a 0.07mm accuracy in my hands-on review) - there's nothing better for under $1000.

Revopoint hereAmazon here

We earn a commission if you make a purchase, at no additional cost to you.

Can You Make a 3D Scanner?

- Choose a DIY 3D scanner design.

- Source the non-3D printable parts such as the camera, stepper motor, single board computer (such as an Arduino), wiring, and other electronic parts.

- 3D print the housing, brackets, turntable, mounts, and other parts required for the 3D scanner project.

- Wire and assemble all the parts.

- Configure and set up the single board computer.

- Test and scan.

FAQs

Which is the Best DIY 3D Scanner?

This depends on how much DIY you want to take on yourself, and how much you are ready to spend.

One of the most cost-effective options is scanners based on the Ciclop open-source 3D scanner design. You can purchase a low-cost Ciclop scanner like the BQ Ciclop or CowTech Ciclop 3D scanner, then 3D print the parts from home and modify and tune the scanner to your liking.

Alternatively, the Revopoint POP is an excellent semi-assembled 3D scanner with great specifications and software at an affordable price for those that want to save time.

What is a DIY 3D Scanner?

A DIY 3D scanner is a cost-effective, home-made device constructed from manufactured or 3D printed parts designed to capture the characteristics of a specific object – such as size, surface details, and shape – by scanning it from multiple angles to create an equivalent point cloud that can be processed into a 3D model via software.

Other articles you may be interested in:

- The best 3D scanners

- The best low-cost 3D scanners

- Top 3D scanner apps for iOS and Android

- The best photogrammetry software

- Structured light 3D scanning vs laser scanning

- 3D body scanners: a guide

- Industrial 3D scanners

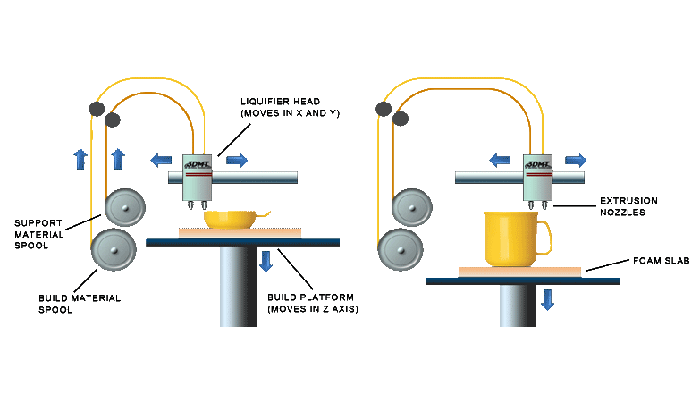

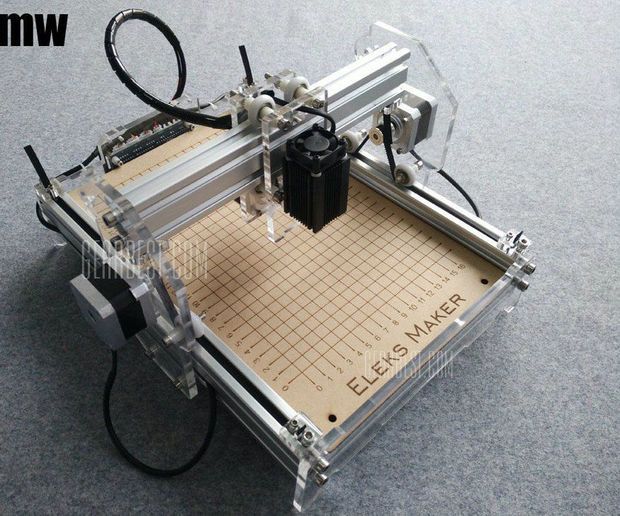

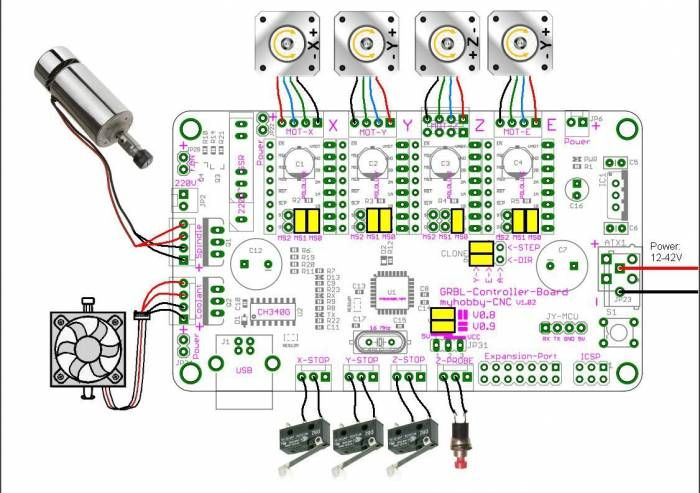

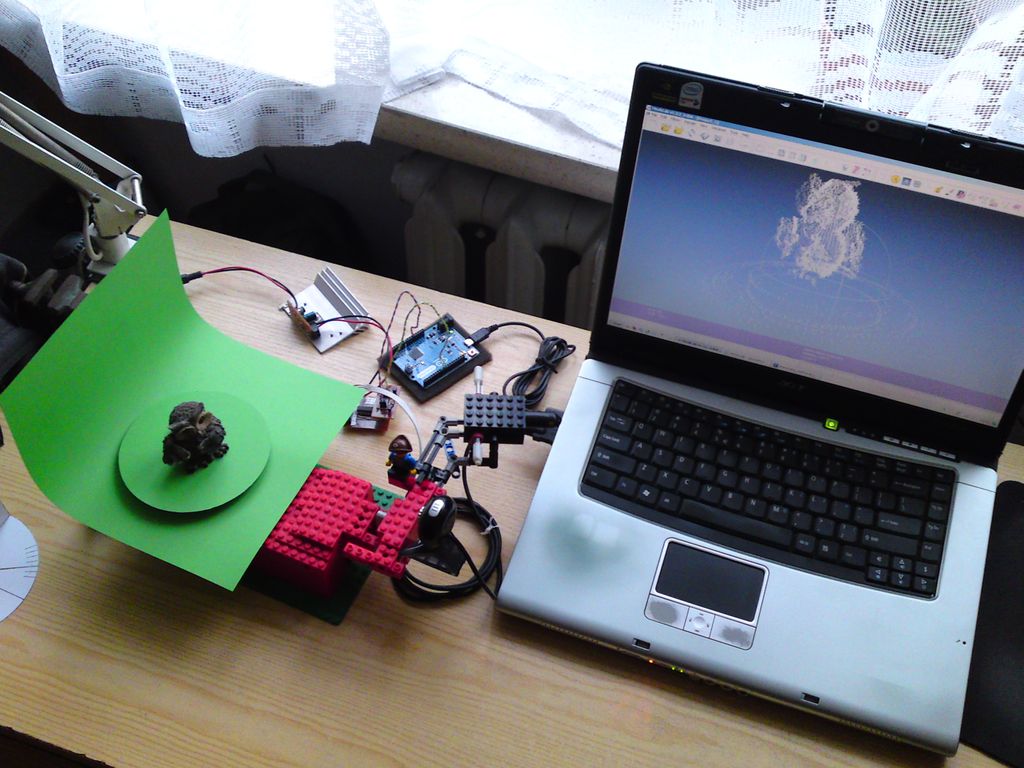

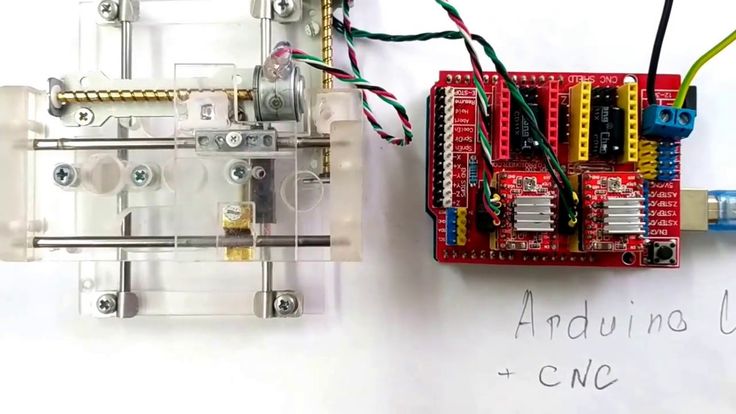

CNC on Arduino | Contact 3D Scanner | Manufacturing

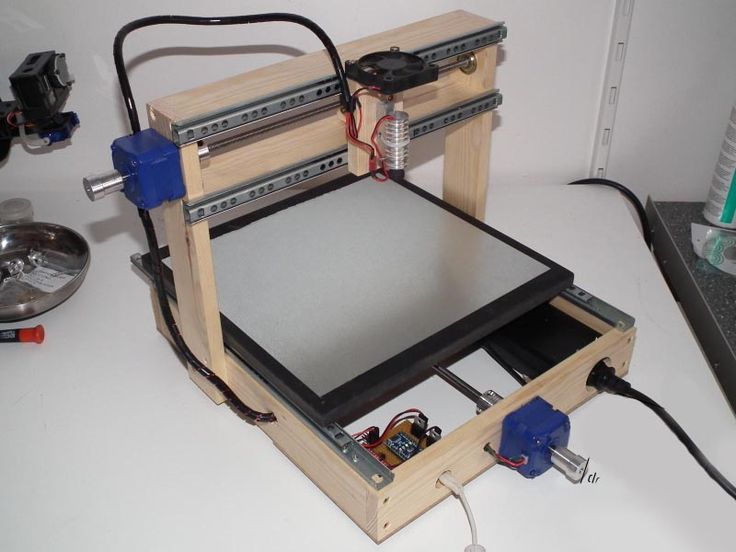

We continue to refine a simple CNC machine on Arduino. Now we make a contact 3D scanner out of it. The mechanical part is extremely simple. Significant improvement will be required for the firmware of the Arduino board, as well as for the machine control program.

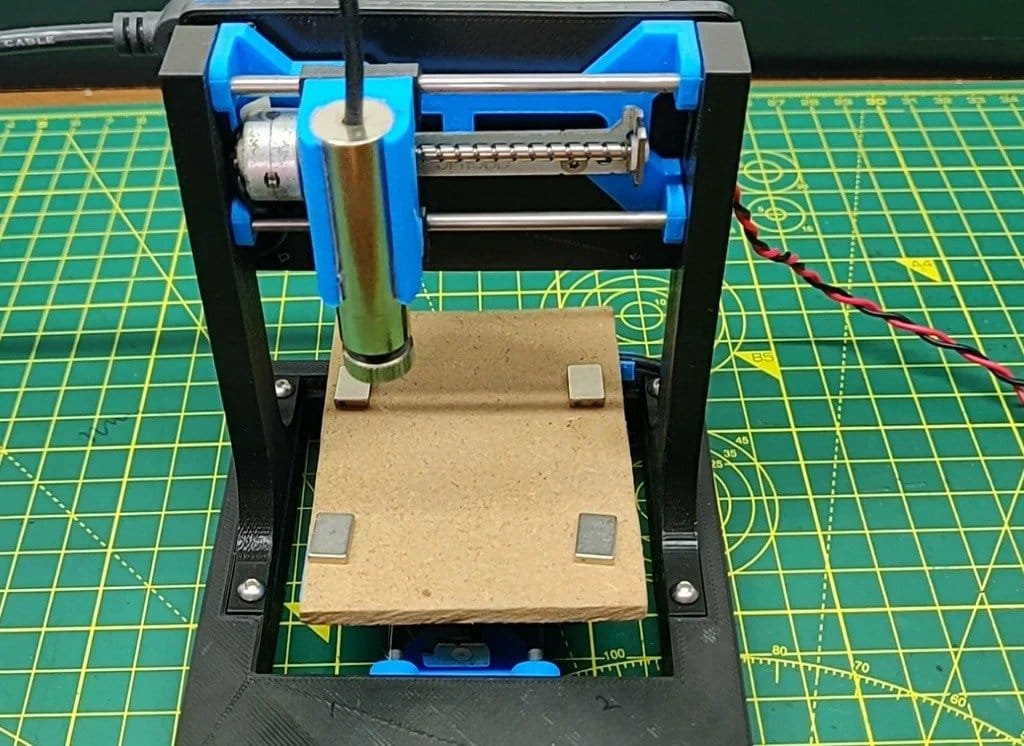

Producing a contact probe for a 3D scanner

To create a 3D scanner from an existing Arduino-based CNC machine, we need a contact sensor. To make it, you will need two metal strips, two nails, a rail, a resistor with a resistance in the range of 1Kom-10Kom and wires. The finished sensor does not look very presentable, but it performs its functions. In the future, you can make a more aesthetic and accurate version of the sensor. The sequence of manufacturing parts of the sensor and its assembly is clear from the photo.

The finished sensor does not look very presentable, but it performs its functions. In the future, you can make a more aesthetic and accurate version of the sensor. The sequence of manufacturing parts of the sensor and its assembly is clear from the photo.

Photo of a contact sensor for a 3D scanner. We attach two brackets of iron strips to the rail. A nail is threaded into each bracket. The nail falls down under the action of gravity (you can put springs from fountain pens). There is a small gap between the sharp end of the top nail and the head of the bottom nail. Now, if the lower nail (probe) rests against the scanned object, it rises along the rail and touches the tip of the upper nail. Thus, the sensor circuit will be closed and a HIGH signal will appear on the digital pin 2 of the Arduino. The Arduino will stop the downward movement of the sensor and raise it to its previous height, and send data to the computer about the obtained distance to the scanned object. Note that in the event of a malfunction, the stylus of the 3D scanner is provided with a significant amount of travel without damaging the sensor or the object being scanned.

Note that in the event of a malfunction, the stylus of the 3D scanner is provided with a significant amount of travel without damaging the sensor or the object being scanned.

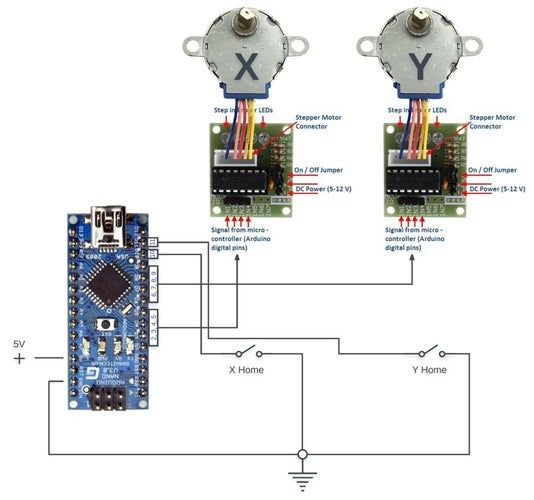

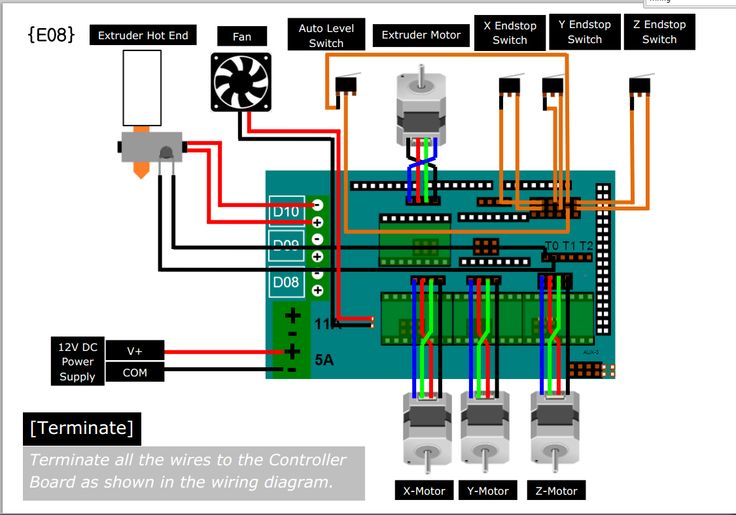

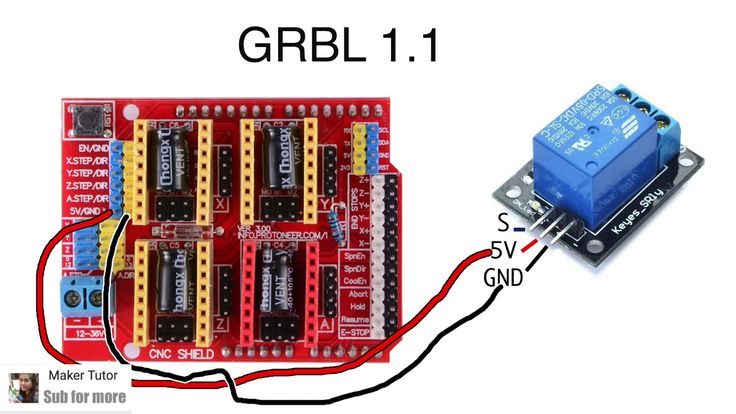

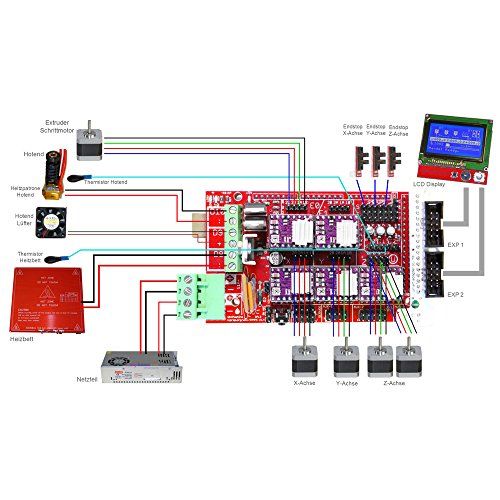

We assemble the scanner on a machine with DM420A stepper motor drivers, because it works much faster, but it can also be assembled on a CNC machine with stepper motor drivers based on the ULN2003 chip. The sensor connection diagram is shown below:

The figure shows the connection diagram of the contact sensor to the Arduino board. The 1KΩ-10KΩ resistor acts as a pull-down resistor, and when the sensor circuit is open, it provides a potential drop at the digital input to 0V. When the sensor circuit is closed on a digital pin operating in INPUT mode, the value HIGH (5V) appears. The sensor circuit closes when the sensor probe touches the scanned object. For the scanner to work, you will need a new firmware, which can be downloaded from the Firmware page. You also need a CNC machine control program of version 1.0.2 or higher, which can be downloaded on the Programs page.

You also need a CNC machine control program of version 1.0.2 or higher, which can be downloaded on the Programs page.

Description of the operation of a 3D scanner based on Arduino

A grid is built over the working area, at the nodes of which the distance to the scanned object is measured using a sensor. Further, using the bicubic interpolation algorithm, the values of the distance to the object in the intervals between the lattice nodes are calculated. Now, having received all the necessary data, the program builds an image or a 3D model of the object. It is possible to upload the obtained values of the distances to the object in the lattice nodes to a separate file, which can later be used at the discretion of the user.

Setting up and running the program for the operation of a 3D scanner based on Arduino

We launch the Arduino CNC program of version 1.0.2 or higher. Select item Scanner in the main menu.

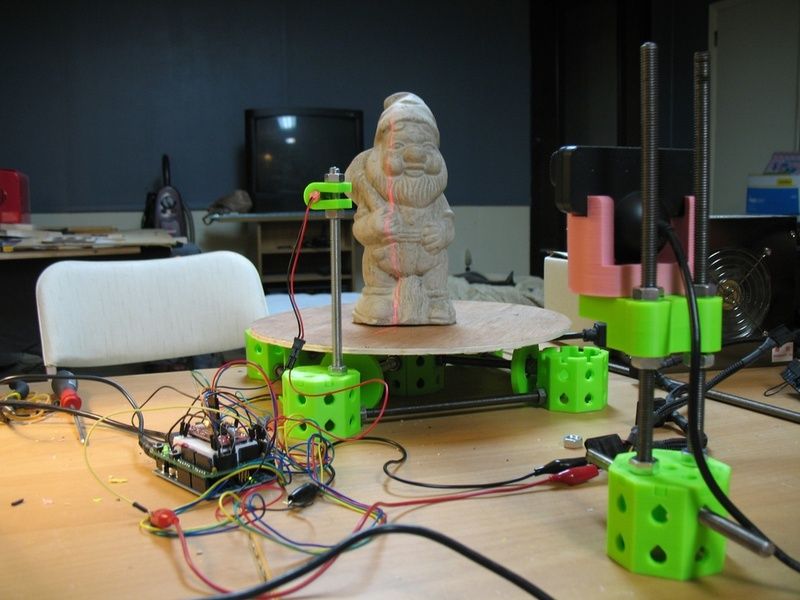

Homemade 3D scanner AASCAN

News

Subscribe to the author

Subscribe

I do not want

14

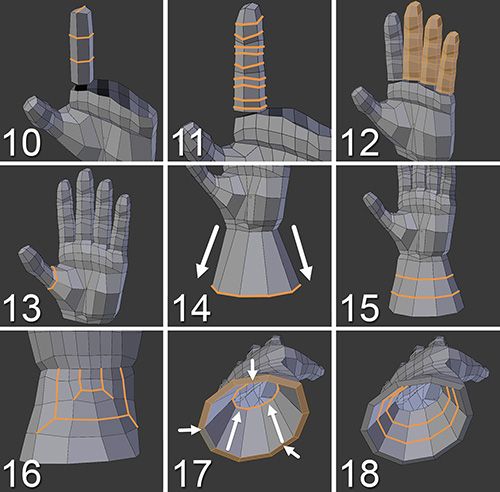

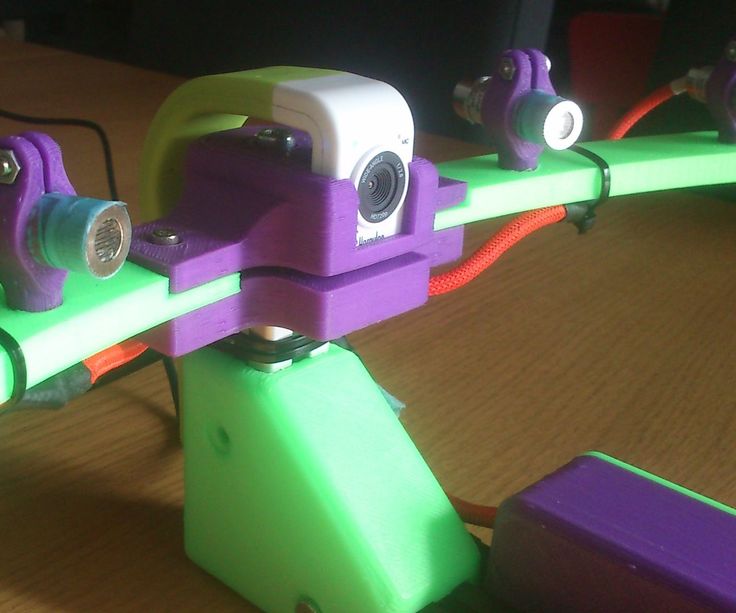

Enthusiast under the nickname QLRO posted the project of a simple desktop photogrammetric 3D scanner collected from the smartphone, micactor-micactor Arduino and 3D printed parts.

To assemble the device, you will need a minimum of components, plus an Android smartphone and a computer. The rotating platform and smartphone stand can be 3D printed. In the original project, the platform is rotated by a 28BYJ-48 stepper motor with an ULN2003 driver and controlled via Arduino. Scanning is carried out by photogrammetry, using the built-in camera of a smartphone.

The system relies on Meshroom photogrammetry software. As the developer explains, the software requires the use of an Nvidia graphics card with CUDA hardware and software architecture. The operation of the device components is coordinated by scripts written in Python: the computer sends commands to the Arduino and the smartphone to rotate the platform and shoot, and after shooting the object from all angles, the images are converted into a digital model. In the current, third version of the software, it is possible to use several cameras at the same time, but so far on an experimental basis.

In the current, third version of the software, it is possible to use several cameras at the same time, but so far on an experimental basis.

The author posted all the necessary files and instructions in the public domain on the Thingiverse website at this link.

3D scanner desktop AAScan QLRO

Follow author

Follow

Don't want

14

Article comments

More interesting articles

eight

Subscribe to the author

Subscribe to the author

Don't want

The project was implemented by employees of the Smart Build construction equipment factory, who provided addi.