Xy resolution 3d printer

What Does Resolution Mean in 3D Printing?

Looking for a high resolution 3D printer? “Resolution” is an often discussed but seldom understood value in the world of 3D printing and additive manufacturing. How does XY and Z resolution influence on the quality of your 3D prints? What's minimum feature size and what layer thickness should you choose?

In this comprehensive guide, you'll learn how 3D printer resolution affects your 3D prints and how it differs between SLA, FDM, and DLP 3D printers.

Technology has been in a resolution war for decades. Televisions recently quadrupled pixel counts from HD to 4K and are poised to do it again soon to 8K. Cell phones, tablets, and anything with a screen will have its resolution as the lead on the spec sheet, provided that it’s something to boast about. But this is nothing new. Resolution wars have been waged since digital technology became popular, and the printing industry was one of the first battlegrounds.

If you were around in the 80’s and 90’s, you remember Canon, Brother, HP, Epson, and Lexmark (among others) battling it out for print speed and resolution. What started at 100x100 dots per inch (DPI) quickly escalated to 300x300, then 600x600, and finally the current industry standard of 1200x1200 DPI. Back then, the meaning of these values was clearly understandable; even the units made perfect sense. Unfortunately, things get more complicated when you add another dimension to printing.

A print’s level of detail is impacted by the 3D printer's resolution in all three dimensions.

In 3D printing and additive manufacturing, there are three dimensions to consider: the two planar 2D dimensions (X and Y) and the Z dimension that makes it 3D printing. Since the planar and Z dimensions are generally controlled via very different mechanisms, their resolutions are going to be different and need to be treated separately. As a result, there is a lot of confusion about what the term “3D printing resolution” means and what level of print quality to expect.

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

We’ll ship a free sample part to your office.

Request a Free Sample Part

Formlabs' high resolution SLA 3D printers have high Z-axis resolution and a low minimum feature size on the XY plane, allowing them to produce fine details

What makes a 3D printer high resolution? There’s not a one-number answer. Since 3D printers produce parts in 3 dimensions, you will have to consider at least two numbers: the minimum feature size of the XY plane and the Z-axis resolution (layer thickness or layer height). The Z-axis resolution is easily determined and therefore widely reported even though it is less related to print quality and surface finish. The more important XY resolution (minimum feature size) is measured via microscopic imaging and is therefore not always found in spec sheets.

Practically, it means that you should pick a 3D printer that performs well in both categories (in all 3 dimensions).

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with increadible details.

Download the White Paper

White Paper

Download this report for an internal test that Formlabs created to determine the dimensional accuracy of the Form 3 and Form 3B.

Download the White Paper

A lot has changed since the first desktop 3D printers became available to the public. Now stereolithography (SLA) 3D printers, like the Form 3+, are competing for the same desktop spots as fused deposition modeling (FDM) 3D printers. One of the main advantages that resin-based SLA 3D printers hold over their plastic-melting cousins is print quality: SLA 3D printers produce significantly smoother and more detailed prints. While SLA printers can usually also achieve significantly smaller layer thicknesses, the reason for the improved print quality lies in their much higher XY-resolution.

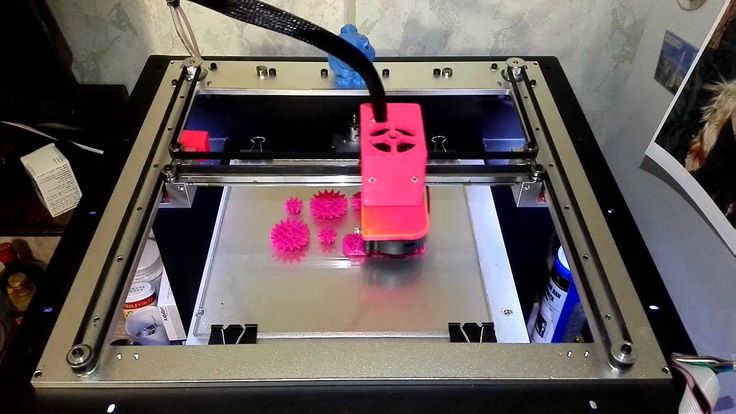

SLA 3D printers (right) offer higher resolution and can produce significantly smoother and more detailed prints than FDM 3D printer (left).

Unlike on FDM 3D printers, minimum feature size in the XY plane on SLA 3D printers is not limited by molten plastic flow dynamics but rather optics and radical polymerization kinetics. While the math is complicated (and outside the scope of this post), it shakes out to this: features on SLA prints can be approximately as small as the diameter of their laser spots. And laser spots can be really small, especially compared to the nozzle size of FDM printers' extruders.

Read our in-depth guide about FDM vs. SLA 3D printers to learn how they compare in terms of print quality, materials, applications, workflow, speed, costs, and more.

Resin 3D printers like SLA, LFS and DLP technologies offer the highest resolutions of all 3D printing processes available on the desktop. The basic units of the these processes are different shapes, making it difficult to compare the different machines by numerical specifications alone.

DLP 3D printers have a fixed matrix of pixels relative to the build area, while laser-based SLA and LFS 3D printers can focus the laser beam on any XY coordinate. This means that laser-based machines, given high-quality optics, can more accurately reproduce the surface of a part even if the laser spot size is larger than the DLP pixel size.

This means that laser-based machines, given high-quality optics, can more accurately reproduce the surface of a part even if the laser spot size is larger than the DLP pixel size.

Whichever resin 3D printing process you choose, however, professional resin 3D printers should be able to capture the finest details of your creations, from photorealistic models to intricate jewelry.

In SLA and LFS 3D printing (left), layer lines are close to invisible. As a result, surface roughness is reduced, which ultimately leads to smooth surfaces, and for clear materials, more translucent parts. DLP 3D printers render images using rectangular voxels, which causes an effect of vertical voxel lines (right).

Learn more about the differences between SLA and DLP 3D printers and see how they compare in terms of resolution, accuracy, precision, build volume, surface finish, speed, and workflow.

In the world of 3D printing, no factor influences print quality more than XY resolution. Often discussed but seldom understood, the definition of XY resolution (also called horizontal resolution) varies by 3D printing technology:

Often discussed but seldom understood, the definition of XY resolution (also called horizontal resolution) varies by 3D printing technology:

- SLA and LFS 3D printers: a combination of the laser’s spot size and the increments by which the laser beam can be controlled

- DLP 3D printers: the pixel size, the smallest feature the projector can reproduce within a single layer

- FDM 3D printers: the smallest movement the extruder can make within a single layer

As a rule of thumb, the lower the number, the better the details. Yet this number is not always included in spec sheets, and when it is, the published value is not always accurate. To truly know a printer’s XY resolution, it’s important to understand the science behind the number.

Practically, how does XY resolution affect your 3D prints? In order to find out, we decided to test the Form 2 SLA 3D printer. The Form 2 has a laser spot size of 140 microns (FWHM), which should allow it to print fine details on the XY plane. We put it to the test to see if this ideal resolution holds true.

We put it to the test to see if this ideal resolution holds true.

To test the Form 2’s minimum feature size on the XY plane, we designed a model (left) with lines ranging from 10 to 200 microns and printed it in Clear Resin (right).

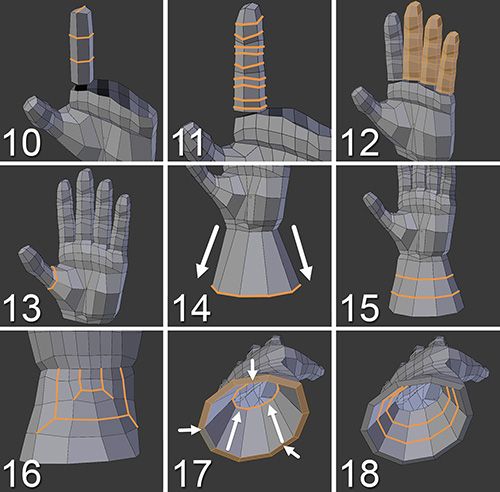

First, we designed and printed a model to test the minimum feature size on the XY plane. The model is a rectangular block with lines of varying widths in horizontal, vertical, and diagonal directions to avoid directional bias. The line widths range from 10 to 200 microns in 10 micron steps and are 200 microns tall, which equates to two layers when printed at 100-micron Z resolution. The model was printed in Clear Resin, washed twice in an IPA bath, and post-cured for 30 minutes.

The model was photographed and tinted green to improve visibility. On the right side of the window, the vertical yellow line with black points measures the width of a photographed line.

After post-curing, we put the model under a microscope and took high-resolution photos for analysis. Using ImageJ, the NIH’s free image analysis software, we first scaled the pixels of the images and then measured the actual widths of the lines printed. We collected over 50 data points per line width to eliminate measuring errors and variability. In total, we printed and analyzed three models on two different printers.

Using ImageJ, the NIH’s free image analysis software, we first scaled the pixels of the images and then measured the actual widths of the lines printed. We collected over 50 data points per line width to eliminate measuring errors and variability. In total, we printed and analyzed three models on two different printers.

The results indicate that the Form 2 has the same ideal and actual XY resolution for features that are 150 microns and larger.

As the print’s line width decreases from 200 to 150 microns, the ideal values are within the 95% confidence interval of the measured value. As the intended line widths get smaller than 150 microns, the measured interval starts to deviate significantly from the ideal. This means that the printer can reliably produce XY features as small as 150 microns, about the size of a human hair.

The Form 2’s minimum feature size on the XY plane is about 150 microns—only 10 microns larger than its 140-micron laser. The minimum feature size can never be smaller than the laser spot size, and there are many factors that affect this value: laser refraction, microscopic contaminants, resin chemistry, and much more. Considering the printer’s entire ecosystem, a 10-micron difference is nominal. Not every 3D printer’s published resolution holds true, so it’s a good idea to do plenty of research before choosing the one that's right for your project.

Considering the printer’s entire ecosystem, a 10-micron difference is nominal. Not every 3D printer’s published resolution holds true, so it’s a good idea to do plenty of research before choosing the one that's right for your project.

If your work calls for prints with intricate details, look for a printer with an XY resolution that’s backed by measurable data, not just a number.

When you read 3D printer spec sheets, you’ll see one value show up more than any else: Z resolution. Also known as layer thickness or layer height, the vertical resolution was the first major numerical differentiation between early 3D printers. Early machines struggled to break the 1 mm barrier, but now layer thicknesses on FDM 3D printers can be sub-0.1 mm thin, while LFS and SLA 3D printers are even more precise.

Formlabs 3D printers support layer thicknesses between 25 to 300 microns, depending on the material. This selection of layer heights gives you the ideal balance of speed and resolution. The main question is: what is the best layer thickness for your print?

The main question is: what is the best layer thickness for your print?

High resolution 3D printing comes with a tradeoff. Thinner layers mean more repetitions, which in turn means longer times: printing at 25 microns vs. 100 usually increases the print time four-fold. More repetitions also mean more opportunities for something to go wrong. For example, even at a 99.99% success rate per layer, quadrupling the resolution lowers the chance of print success from 90% to 67% if one assumes that a failed layer causes total print failure.

Lower layer thickness equals more time, artifacts, and errors.

Does higher resolution (thinner layers) result in better prints? Not always—it depends on the model to be printed and the 3D printer’s XY resolution. In general, thinner layers equals more time, artifacts, and errors. In some cases, printing models at lower resolutions (i.e. thicker layers) can actually result in higher-quality prints.

Thinner layers are typically associated with smoother transitions on diagonals, which leads many users to generalize and push Z resolution to the limits. But what if the model consists mostly of vertical and horizontal edges, with 90-degree angles and few diagonals? In those cases, additional layers don’t improve the quality of the model.

But what if the model consists mostly of vertical and horizontal edges, with 90-degree angles and few diagonals? In those cases, additional layers don’t improve the quality of the model.

The issue is compounded if the XY resolution of the printer in question is not perfect and “colors outside the lines” when drawing the outside edges. More layers means more mismatched ridges on the surface. While the Z resolution is higher, the model will look like it is significantly lower quality in this case.

That being said, there are times when you want higher resolution. Given a printer with good XY resolution and a model with intricate features and many diagonal edges, dialing down the thickness of the layers will yield a much better model. In addition, if that model is short (200 or fewer layers) upping the Z-axis resolution can really improve the quality.

Certain designs benefit from a higher Z resolution: organic forms, rounded arches, small embossings, and intricate engravings.

Intricate models with elaborate details call for a higher Z resolution. SLA 3D printed parts have sharp edges, sleek surfaces, and minimal visible layer lines. This example part was printed on the Formlabs Form 3 desktop SLA 3D printer.

As a general guideline, err on the side of thicker layers and only bump up the Z resolution when completely necessary. With the right printer and a certain type of model, higher Z resolution will capture the intricate details of your design.

Draft Resin, the fastest 3D printing resin available for a Formlabs SLA printers, prints at 200 microns and 100 microns, while retaining the a smooth surface finish.

In PreForm, Formlabs provides users with the choice of different layer thicknesses. Depending on the material and the requirements of the application, parts can be printed in the following layer heights: 200, 160, 100, 50, and 25 microns.

The desktop Form 3+ and the large format Form 3L SLA printers are ideal for high resolution 3D printing.

After learning about 3D printing resolution and sorting out the differences in technology and outcomes, we hope it’s much easier to select 3D printer that best matches your workflow and output needs.

To explore the next generation of SLA 3D printing, learn more about the Form 3 and Form 3L LFS 3D printers.

Curious to see the what high resolution 3D printing looks like firsthand? Order a sample part shipped to your office.

Request a Free Sample Part

How to Understand XY Resolution in SLA/DLP/LCD 3D Printing?

How to Understand XY Resolution in SLA/DLP/LCD 3D Printing?

When it refers to resolution, you may immediately think of televisions, cell phones, tablets and etc. Resolution is closely related to the definition of those electronic products. In 3D printing, resolution is also often mentioned which deeply affects your 3D parts. The two planar 2D dimensions (XY) and the Z dimension make up the so-called resolution in 3D printing. Our next content will focus on XY resolution in SLA/DLP/LCD 3D printing.

Our next content will focus on XY resolution in SLA/DLP/LCD 3D printing.

What’s XY resolution in SLA/DLP/LCD 3D printing?

XY resolution is measured via microscopic imaging and limited by optics and radical polymerization kinetics. Simply speaking, XY resolution is the number of pixels displayed by a laser spot diameter for SLA laser systems, a projector for DLP systems, an array of LEDs shining through an LCD. To figure out those differences, we should learn about their technologies first.

Different technologies about SLA/DLP/LCD 3D printing

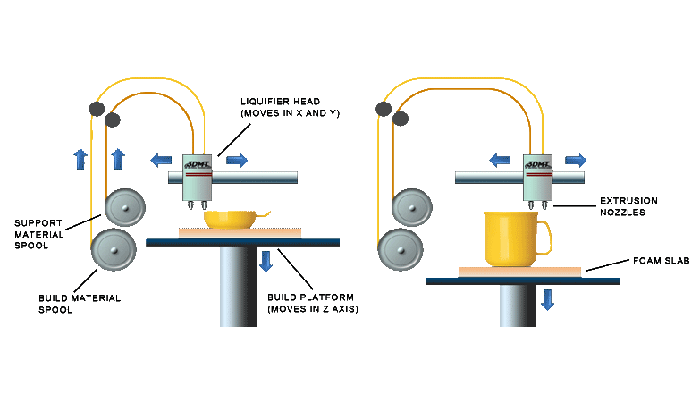

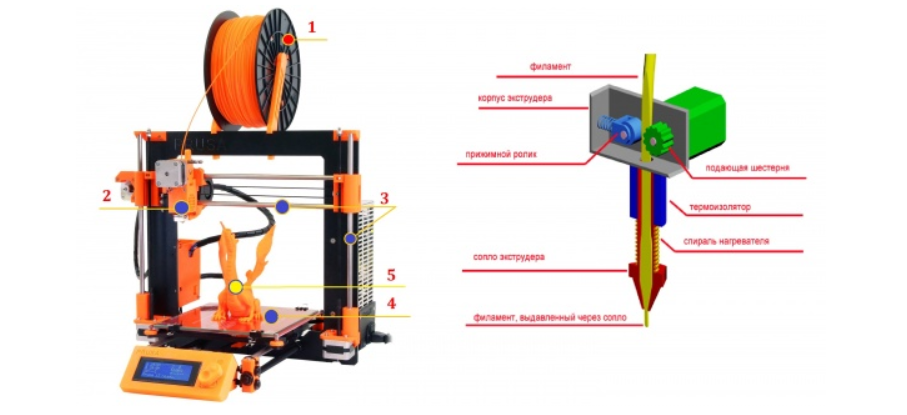

SLA is driven by two mirrors which is known as "galvanometers" or "galvos" (one on the X-axis and one on the Y-axis). The mirrors aim the laser beam quickly across the target print area to cure the resin as it moves along. In order to reproduce a solid object, SLA must slice the entity, layer by layer, into a series of points and lines that are given to the "galvos" as a set of coordinates whose trajectories are tracked by the laser.

DLP uses a digital projector to project individual images of each layer at once across the entire platform. Since the image of each layer is displayed digitally, it is composed of many square pixels.

LCD and DLP are almost the same but with the UV light coming from an array of LEDs shining through an LCD, not a projector. The screen acts as a mask, displaying only the pixels needed for the current layer.

How to calculate the pixel for DLP/LCD?

As XY resolution is fixed for DLP/LCD systems, so there is a equation:

Width / X Axis = Height / Y Axis = Native Pixel Size

If there is a 3D printer with a build area 68mm wide along the X axis. Divide 68mm (the X axis) by 1440 (the LCD width resolution in pixels), this will equal 0.047mm (47µm). And the native pixel size is 47µm.

That means the minimum XY-Axis feature size for this 3D printer is 47 microns. In 3D printing, no factor is more crucial than XY resolution (horizontal resolution or minimum feature size) when considering what matter most to accuracy. XY resolution is the smallest feature the light source can reproduce within a given line or layer. Generally, the lower the value, the better the details.

In 3D printing, no factor is more crucial than XY resolution (horizontal resolution or minimum feature size) when considering what matter most to accuracy. XY resolution is the smallest feature the light source can reproduce within a given line or layer. Generally, the lower the value, the better the details.

XY Resolution: 47µm

XY Resolution: 100µm

XY Resolution: 47µm

XY Resolution: 100µm

So it’s very important to consider the XY resolution on SLA/DLP/LCD 3D printers, as that tells you whether you’re able to print small but finely detailed objects or larger and coarse objects.

Best High-Resolution 3D Printers of 2022: A Complete Buying Guide

Resolution is a little-understood aspect of precision 3D printing, and there are many important factors that affect print quality beyond layer height. This article recommends the best high resolution 3D printers, explains the factors that make up a high resolution 3D printer, and the advantages and disadvantages.

Usually, when choosing a resolution for 3D printing, the Z-axis resolution, or Z-resolution, is the most discussed. This is the vertical resolution, which refers to the minimum height or layer thickness possible for a 3D printer.

Smaller layers mean better resolution and better surface finish on parts with smoother surfaces and sharper edges.

So having a high quality 3D printer that can print at low layer heights can be a big advantage. However, this is not the only factor that affects print quality, there are many others that affect whether a high resolution 3D printer actually prints accurate and smooth details.

Contents

- Resolution in 3D printing: X, Y and Z resolution

- Other factors affecting print quality

- When do high quality 3D printers matter most?

- Best High Resolution 3D Printers

- Ender 3 V2 - Precision 3D Printer Under $0

- Elegoo Mars 2 Pro

- Anycubic Photon Mono 4K

- Elegoo Mars 3 - Best Inexpensive Resin Choice + 3903S

- Formlabs Form 3

- Ultimaker S3

- Advantages of a high resolution 3D printer

- Disadvantages of a precision 3D printer

- High resolution 3D printing technologies

- High resolution 3D printer FAQ

Resolution in 3D printing: X, Y and Z resolution

The Z resolution corresponds to the layer height of the printed part. However, the X and Y planes are also very important in a high resolution 3D printer.

However, the X and Y planes are also very important in a high resolution 3D printer.

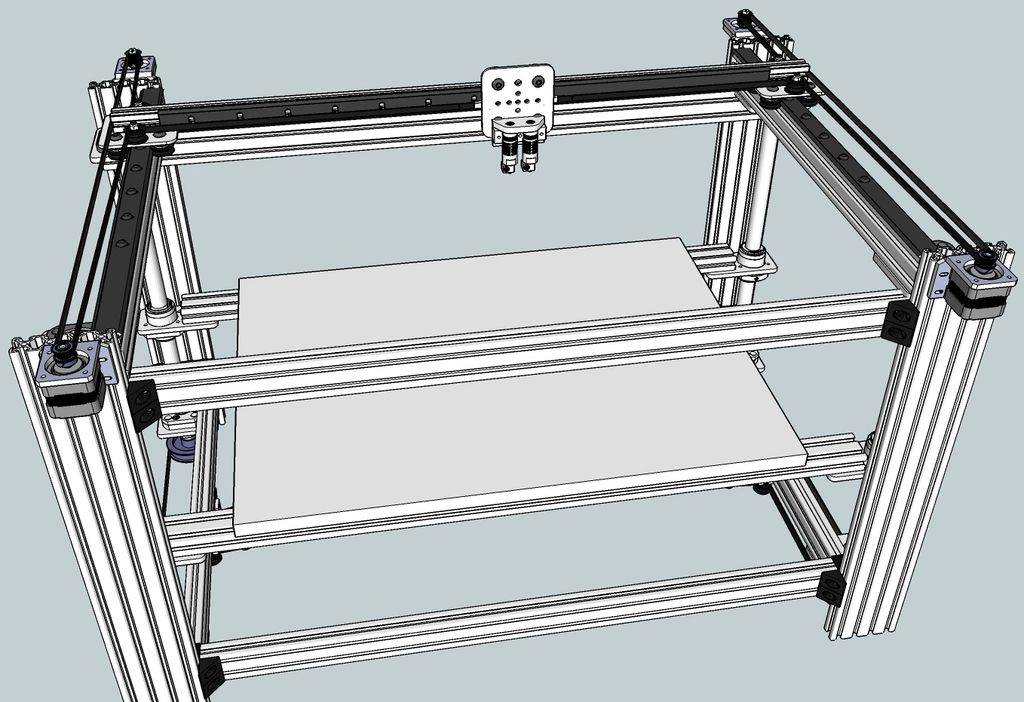

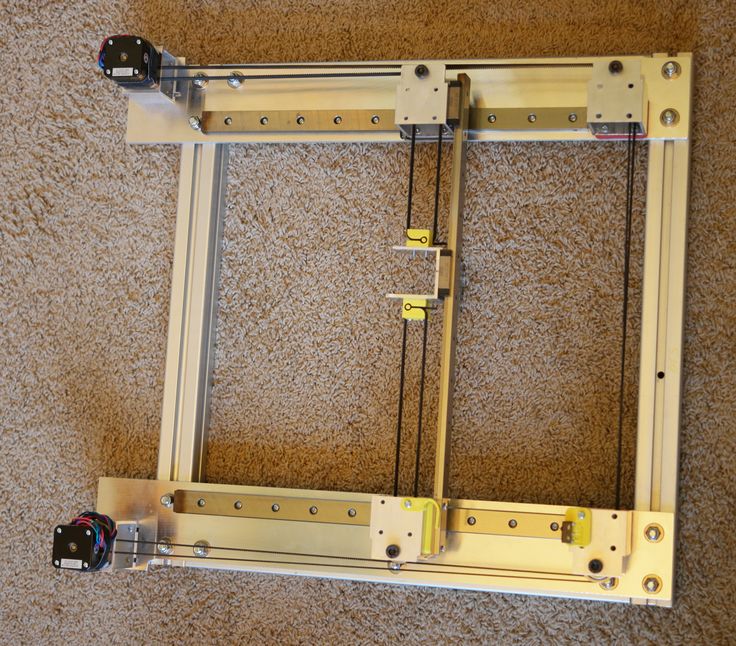

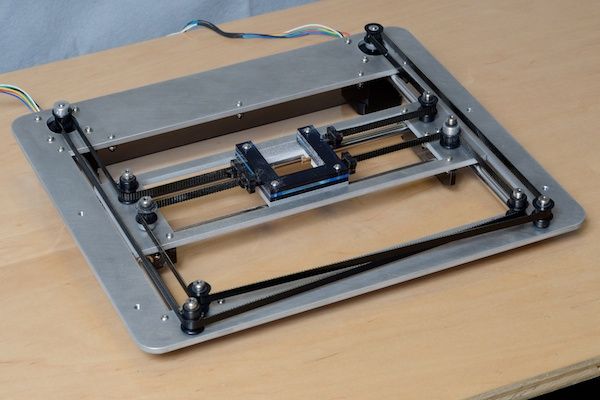

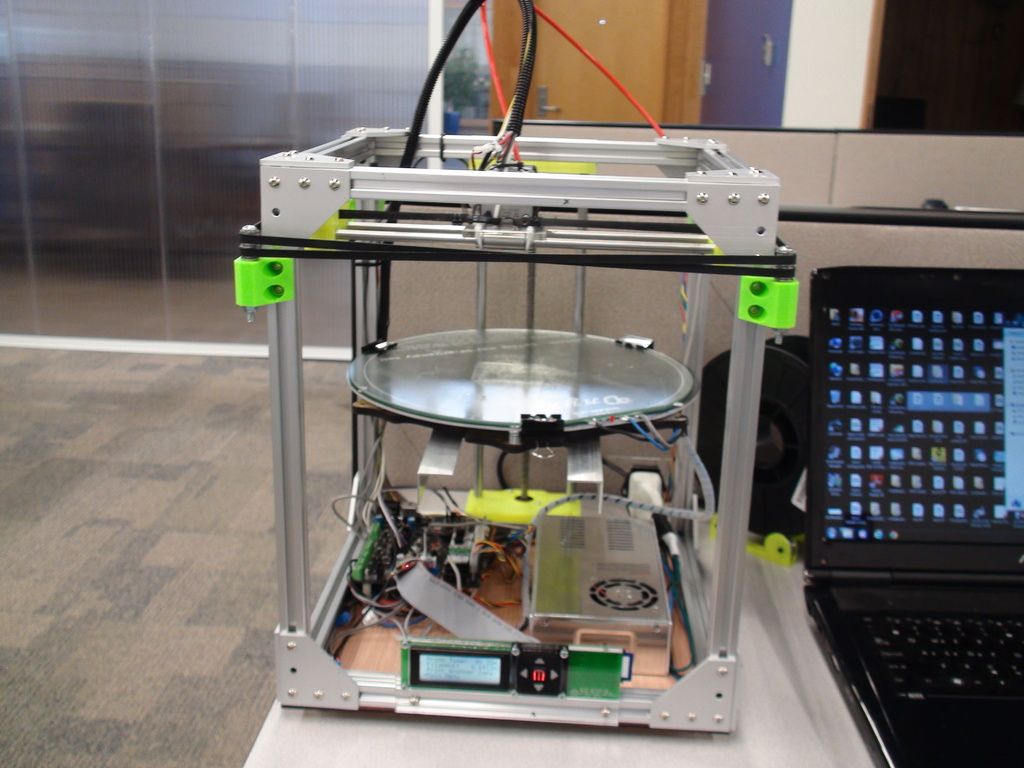

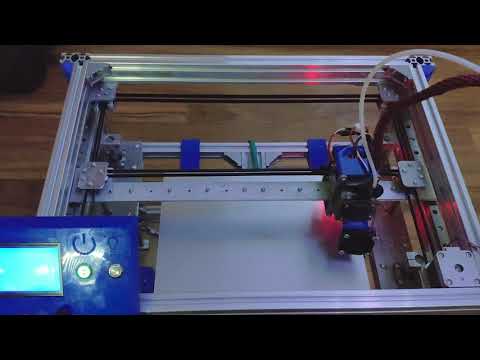

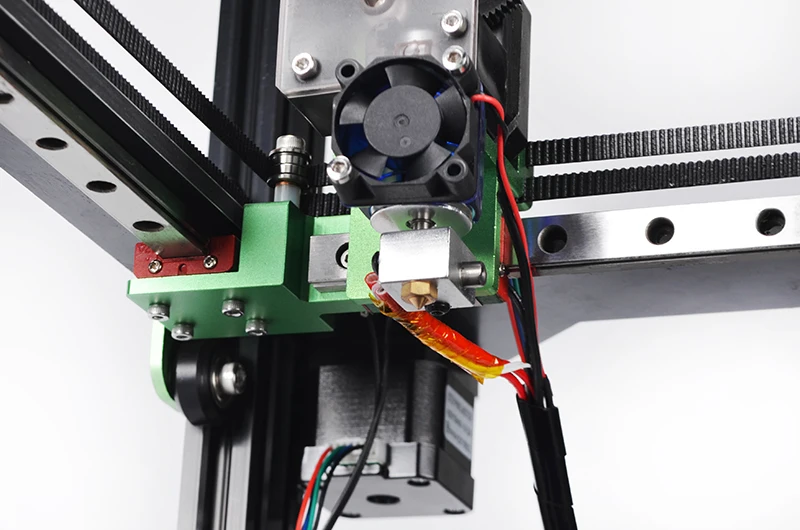

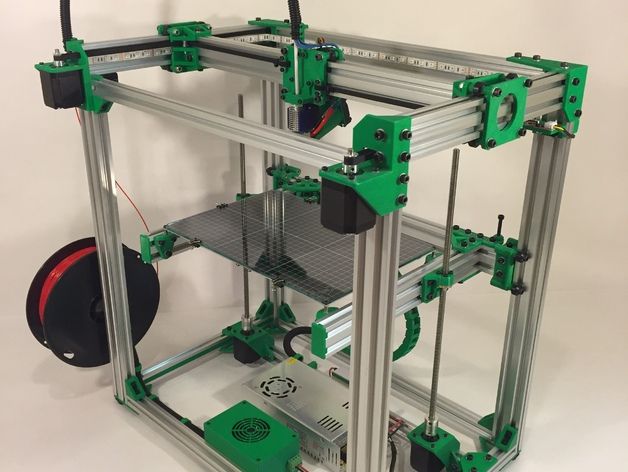

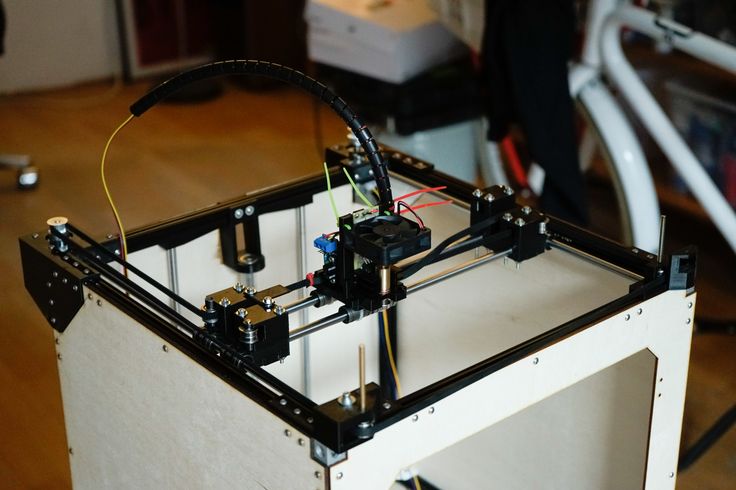

The X and Y axes control the 2D print details: the ones that are inside each 2D layer. Then the Z-axis adds several layers, representing the height - the third dimension. Although these are all axes, the XY and Z axes are controlled by two different systems, with some FDM printers having a much finer resolution in Z than in XY.

low and high resolution in 3d printing layers

X and Y resolution is the smallest movement of the printer's print head (projector, extruder or laser, depending on the technology) within the layer - horizontally.

Various 3D printing technologies are able to provide better resolution than others. For example, SLA 3D printers are more accurate than FDM 3D printers, although their Z-resolutions may look the same on paper. This is mainly due to the better XY resolution resin 3D printers can print at, resulting in smoother surfaces, and better resin printers are able to print parts with barely visible layer lines.

However, other factors can significantly affect print quality.

Other factors affecting print quality

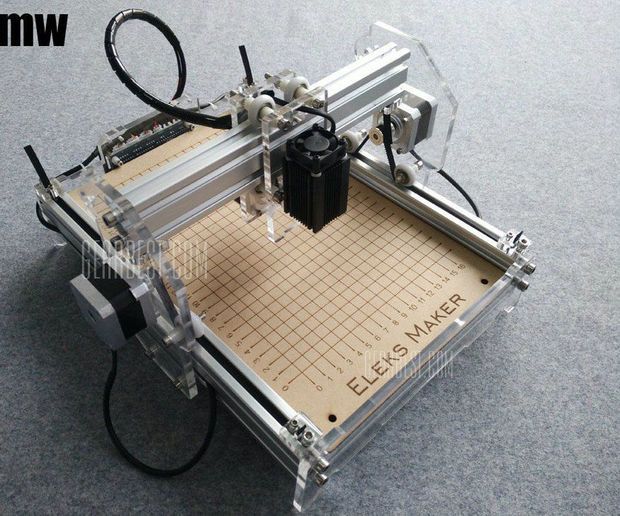

- Nozzle size: Smaller nozzles on FDM 3D printer extruders allow more complex and precise parts to be printed. Standard nozzles are typically 0.4mm, although much smaller 0.1mm or 0.2mm nozzles are available for printing small and precise parts. They are also better suited for printing supports and ledges.

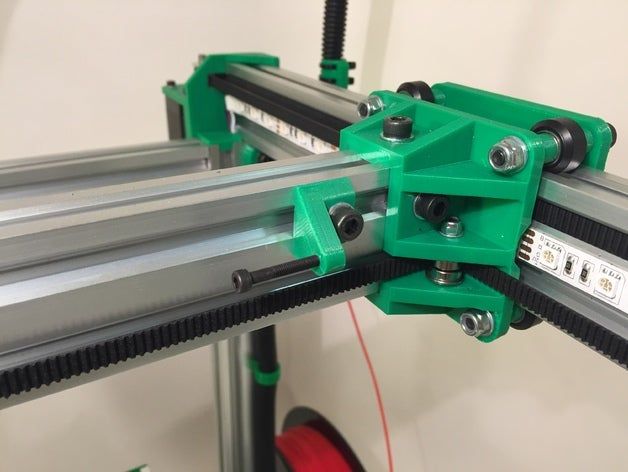

- Frame and Vibration Stability: The strong, heavy metal frame that secures the printer and print bed to the ground is less susceptible to vibrations and other external factors that can affect print quality.

- Material: different materials are more accurate and precise than others, or are easier to print successfully than others.

- Technology: for example, SLA printers are more accurate than FDM and PolyJet offers some of the best accuracy in 3D printing.

- Slicer and Printer Settings: Your 3D slicer settings will be critical to print quality, and even the highest resolution 3D printers will print poor quality models if not optimized.

When do high quality 3D printers matter the most?

If you are planning to 3D print a very simple structure, like a cube, then using a high quality 3D printer, using large or small layers will make no difference. In fact, using low layer heights will cause the exact same print to take much longer.

For these very simple models with few complex parts, a regular cheap 3D printer will work almost as well as a high resolution industrial 3D printer that costs 20 times more.

However, high-quality precision 3D printers greatly improve the quality of more complex parts that have diagonal or arcuate lines or sides, as well as embossing and engraving.

Particularly for curved or diagonal parts, the lower the layer height and the more precise the printer, the less stepped these elements will look and the smoother they will look even up close.

Very high resolution 3D printers such as resin printers are commonly used to 3D print jewelry molds such as this 3D printed ring.

Source: Shapeways.

What's more, if you're printing a small part, such as 3D printing a miniature or desktop model, using an accurate printer with a very low layer height can be worth it, because even if it takes several times longer, it still won't take more than an hour.

Best High Resolution 3D Printers

Now we have illustrated the components that make up a high quality 3D printer, here are some guidelines.

High resolution and quality are relative here, meaning we have chosen printers in each price range that outperform others - a $200 3D printer can't compete with a $20,000 industrial 3D printer, but it can be the best in its class. price range.

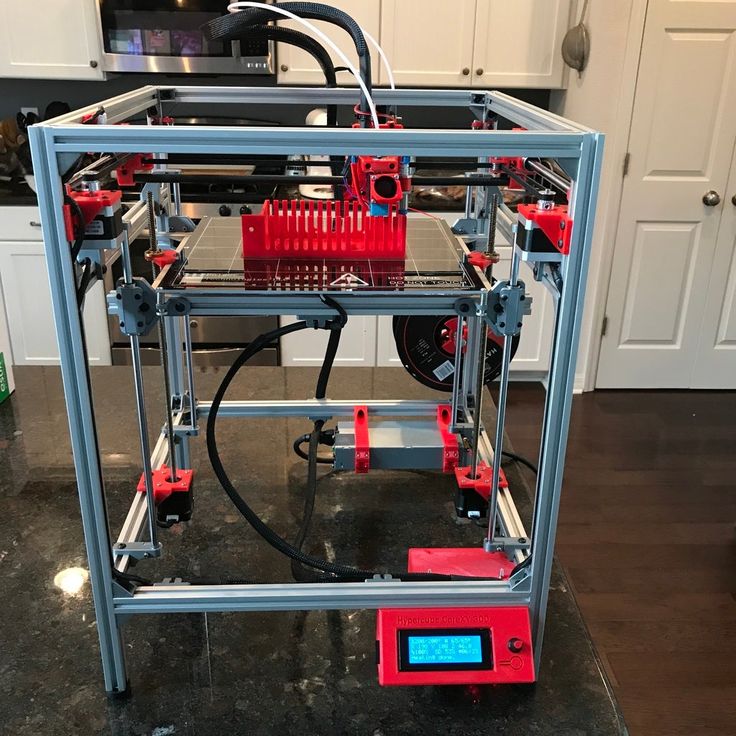

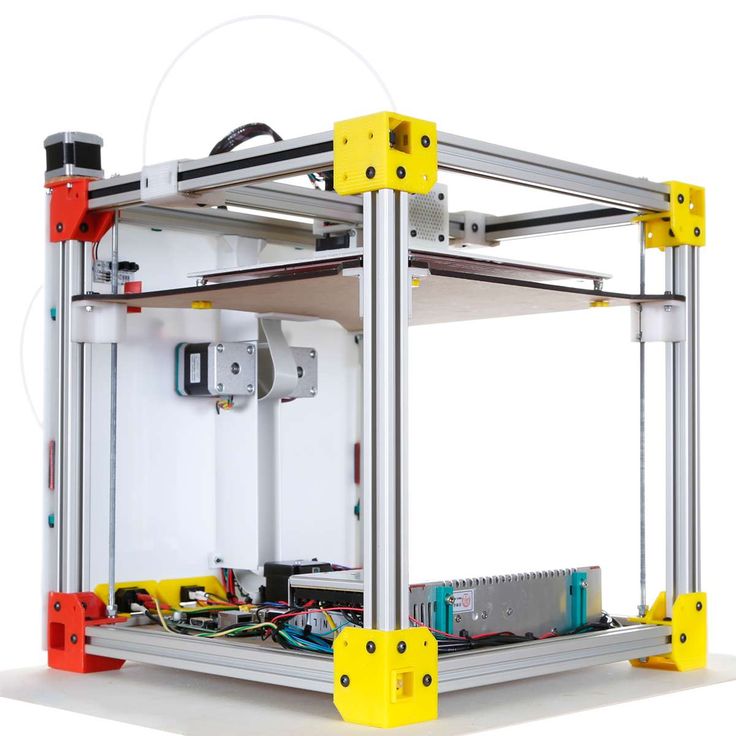

Ender 3 V2 - Under $300 Precision 3D Printer

- Price: $279

- Assembly volume: 220 x 220 x 250 mm

- 3D printer type: FDM 3D printer and DIY 3D printer

- Minimum layer height: 0.

1 mm

The Ender 3 is an inexpensive and relatively high quality 3D printer.

Just as the original Ender 3 began to age, Creality released the Ender 3 V2. A well-designed printer, the Ender 3 V2 eliminates many of the shortcomings of its predecessor while maintaining an affordable price for even the most budget-conscious manufacturers.

Belt tensioners, a 4.2.2 32-bit motherboard, and silent stepper drivers do a lot to present a printer that feels much more modern than the Ender 3. 3 V2 is not amazing: the layer resolution is only 100 microns. But don't be fooled: high resolution printing is only defined by high resolution.

In action, the Ender 3 V2 is built to a level of precision that seems unusually high for an inexpensive FDM printer. With few visible, warping or layering issues, with excellent overall quality for large parts and decent results for small, detailed parts. Added to this is a fairly large build volume - 220 x 220 x 250 mm to be precise - for large projects and even for small-scale printing.

For the price, you also get to work with a decent range of materials - PLA, ABS, PETG, TPU. The only caveat is that you'll have to stick with simpler prints that are relatively free of complex embossing, small details, narrow arches, and the like.

In our experience, the Ender 3 V2 works best when creating household items such as plant pots or, say, vases, figurines, toys, accessories, and the like. We are sure that his printing abilities will be enough for a modest business selling non-geometrically complex products.

Keep in mind that the Ender 3 V2 is largely a hobby printer that needs a fair amount of tweaking to get the best results. Curious beginners and seasoned makers should find this an enjoyable part of the printing process, but "green" beginners may prefer an option with fewer "practical" aspects.

Elegoo Mars 2 Pro

- Price: $299

- Assembly volume: 129 x 80 x 160 mm

- 3D printer type: LCD 3D printer

- Z-axis accuracy: 0.

00125 mm, XY-axis resolution: 0.05 mm

The Elegoo Mars and Anycubic Photon ranges have revolutionized low-cost, high-resolution 3D printing for hobbyists and businesses around the world. The Elegoo Mars 2 is able to create resin models so accurate that it is increasingly being used to 3D print jewelry molds before they are molded into gold or other metal rings, bracelets and chains.

As an MSLA printer, Elegoo Mars prints resin models that outperform FDM counterparts in high resolution 3D prints with almost no visible layers. The 6-inch 2K LCD screen enables fast 3D printing by allowing a layer to be cured every 2 seconds.

In addition, Mars 2 Pro's CNC-machined aluminum construction improves stability by eliminating external vibrations that can affect 3D print detail. In addition, the new and improved build plate is designed for better adhesion and a higher quality result.

The printer is available in 12 languages, so those who do not speak English need not worry, and if you have any problems with the Elegoo Mars 2 Pro, the company will replace it under a 1-year warranty. Overall, this is a great, high quality 3D printer for producing resin parts cheaply and accurately.

3D print of a dinosaur head we made while reviewing the Elegoo Mars 2 Pro.

Anycubic Photon Mono 4K

- Price: $299

- Assembly volume: 132 x 80 x 165 mm

- 3D printer type: LCD 3D printer

- Z-axis accuracy: 0.00125 mm, XY resolution: 0.035 mm

The Anycubic Photon Mono 4K is another iterative upgrade of the venerable family of resin printers, an impressive option for those into high-resolution 3D printers. The Anycubic Photon Mono 4K is without a doubt one of the best cheap high resolution 3D printers out there.

Under the hood of the Anycubic Photon Mono 4K is, you guessed it, a 4K LCD panel capable of delivering 35 micron pixel resolution, 15 microns better than its predecessor. In simple terms, this means a smooth surface and the finest detail in every print, which is immediately visible to the naked eye.

Imperfections are almost indistinguishable and, dare we say, the results are overwhelmingly close to perfection, as we have seen in this price range. Anycubic Photon Mono 4K also penetrates prints with a more than respectable layer cure time of less than 2 seconds.

For us, this printer has great hobby potential. We could hardly find an application where it would not impress. However, the Anycubic Photon Mono 4K comes into its own when working with 3D models and the like, thanks to its penchant for carving out detailed details.

Like other resin printers, the Anycubic Photon Mono 4K has its fair share of clutter and requires a strict regular cleaning routine. The lack of a resume feature and the sometimes unstable native slicer seem like annoying oversights. But these are minor shortcomings for a great inexpensive small form factor resin printer.

Elegoo Mars 3 - Best inexpensive resin choice

- Price: $349 - Available on Amazon here

- Assembly volume: 143 x 90 x 165 mm

- 3D printer type: LCD 3D printer

- Z-axis accuracy: 0.

00125 mm, XY-axis resolution: 0.035 mm

The Elegoo Mars is back and perhaps even better than ever, plus a new number. Fast, superbly detailed, compact and economical, the Elegoo Mars 3 also has the features we prefer to see in high-resolution resin printers, namely a 6.6-inch 4K ultra-monochrome LCD display and razor-slim 35-micron resolution.

Marketing and technical chatter aside, the Elegoo Mars 3 delivers impressively detailed results with clean edges and precise precision suitable for even the most demanding resin projects. The larger case volume of 143 x 90 x 165mm compared to the Mars 2 Pro also allows for larger prints while retaining the finest features and fine details.

We're particularly impressed with how well the printer handles figurines, toys and models, even those we think are big for a resin printer. Most importantly, the Elegoo Mars 3 sticks to the Mars tradition of flawless printers that perform at the same high level day in and day out. In other words, it's a workhorse.

In other words, it's a workhorse.

Despite some concerns about the flimsy lid and the lack of features such as air filtering and Wi-Fi connectivity, we highly recommend the Elegoo Mars 3 to manufacturers, hobbyists and businesses looking for an affordable high resolution 3D printer. Please note that Elegoo Mars 3 is tied to the ChiTuBox slicer and will not work with third party alternatives.

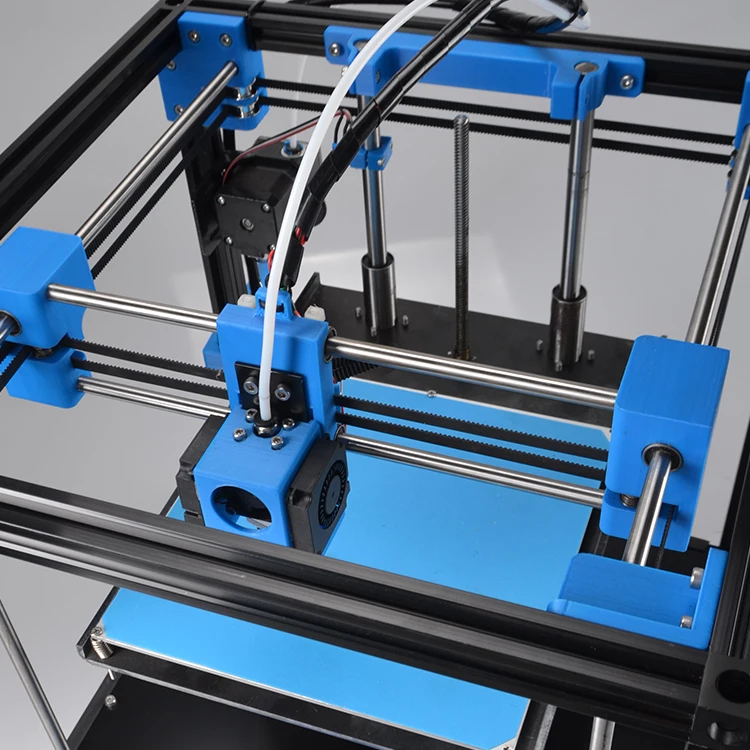

Prusa i3 MK3S+

- Price: $749 set / $999 complete

- Assembly volume: 250 x 210 x 200 mm

- 3D printer type: FDM 3D printer and DIY 3D printer

- Minimum layer height: 50 microns

The Prusa i3 MK3S+ combines high resolution with workhorse reliability and is known as one of the best 3D printers in the world. This FDM printer can print accurate 50 micron layers and do it again and again without fail.

For better XY resolution and detail quality, resin printers like Elegoo Mars are better, but Prusa still has great quality, wider material compatibility - from ABS to PLA, polycarbonate to nylon! - and can even be converted into a color 3D printer that can print 5 colors at once if you purchase the Multi Material Upgrade Kit.

It's fast, constantly improving, and combines superior resolution with tenacity and reliability.

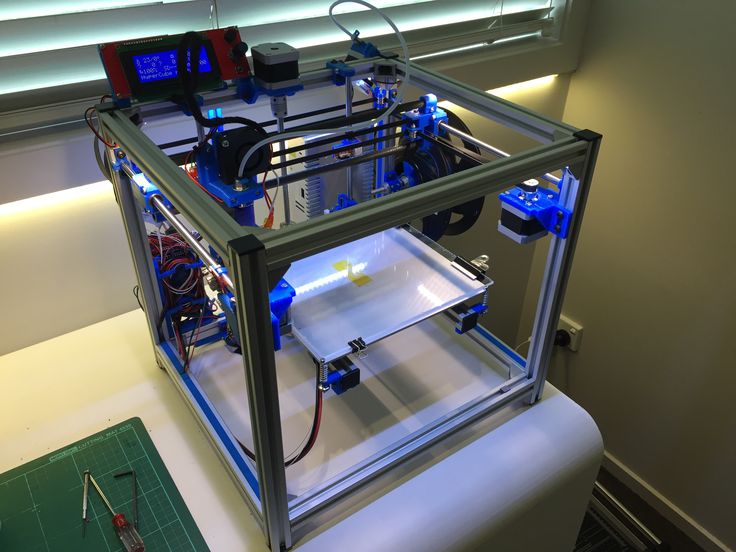

Formlabs Form 3

- Price: $3,499

- Assembly volume: 145 x 145 x 185 mm

- 3D printer type: SLA 3D printer

- XY resolution: 25 microns

Printers from Formlabs, a leading company in consumer 3D resin printing, are currently widely used in the jewelry, dental, medical and hearing aid industries.

If you look at the numbers behind the Formlabs Form 3 - which is, first of all, the build volume of 145 x 145 x 185 mm and a resolution of 25 microns - it does not attract too much attention. However, Formlabs' innovative LFS technology is the type of innovation we love to see. The real sophistication lies in how easy the printer is to use. With Formlabs Form 3, it's all about the machine doing its job, no fiddling or babysitting.

And the results will not keep you waiting. Equipped with high quality resin, the Formlabs Form 3 works exceptionally well, producing gorgeous and detailed prints suitable for commercial purposes. Print failures are virtually non-existent; in order for any errors to occur, it is necessary to physically shake the machine while printing.

Print failures are virtually non-existent; in order for any errors to occur, it is necessary to physically shake the machine while printing.

For the pleasure of owning a Formlabs Form 3, you pay a lot of money. However, these costs are quickly repaid in time savings due to the printer's set-and-forget nature, which can be invaluable in a rapidly changing business environment. For SMBs that require low-volume, trouble-free, accurate models along with prototyping, there is little that can compete with the Formlabs Form 3.

Overall, for precision 3D printing, the Form 3 is one of the best quality high-resolution 3D printers out there.

Ultimaker S3

- Price: $3,850

- Assembly volume: 230 x 190 x 200 mm

- 3D printer type: FDM 3D printer and dual extruder 3D printer

- Minimum layer height: 20 microns

The Ultimaker S3 is smaller but has the same performance as the S5. It is capable of creating incredible 20 micron layers that are so small they are hard to see. While this slows down print times by increasing the number of layers per part, the resulting model will be of unsurpassed quality compared to almost any other FDM printer.

While this slows down print times by increasing the number of layers per part, the resulting model will be of unsurpassed quality compared to almost any other FDM printer.

In addition to being fantastically accurate, the Ultimaker S3 is also a dual-extruder 3D printer that produces accurate, multi-color or multi-material 3D prints and is therefore widely used for prototyping architectural models of buildings prior to construction work.

For those interested in creating architectural models, check out our ranking of the best architectural software.

The printer is easy to use, easy to print with - Ultimaker also owns Cura, the most popular 3D slicer - and delivers fantastic 20 micron precision with a wide range of compatible materials, including carbon fiber. Overall, the printer speaks for itself and proves to be one of the best high resolution 3D printers in FDM.

Benefits of High Resolution 3D Printer

Best Quality: High resolution results in a smoother surface, with excellent detail and detail aesthetics.

The only way to get fine details: models that have arches and sharp diagonal details can look very jagged at high layer heights, and low resolution 3D printers can't adequately print those details.

Ideal settings required: improved accuracy requires perfect calibration, perfect temperature settings to avoid filament or resin defects, and proper bed temperature and adhesion on the platen. Any errors here may result in defects in the print.

Significantly slower: prints with a 25 micron layer height four times longer than with a 100 micron layer because four 25 micron layers equals one 100 micron layer height. Large and complex models may take several days to print.

Higher chance of print failure: The more layers a model has, the more chances for errors to occur that can render a part useless.

High-Resolution 3D Printing Technologies

High-Resolution 3D Printing Technologies include:

FDM - Fused Deposition Modeling

resolution. The process involves layering molten filament onto a fixed build platform using a heated extruder to create patterns. FDM is at the lower end of the high resolution spectrum and is commonly used as a low cost alternative to more expensive technologies. FDM printers typically provide resolutions in the 50 to 200 micron range.

The process involves layering molten filament onto a fixed build platform using a heated extruder to create patterns. FDM is at the lower end of the high resolution spectrum and is commonly used as a low cost alternative to more expensive technologies. FDM printers typically provide resolutions in the 50 to 200 micron range. Resin (SLA, DLP, LCD)

Photopolymerization, commonly known as resin 3D printing, involves projecting a laser or light source to cure a liquid photosensitive resin into layers. Specific technologies include stereolithography (SLA), low power stereolithography (LFS), masked stereolithography (MSLA), and digital light processing (DLP). Resin printers typically achieve a layer resolution of 25-35 microns.

MJF - multi-jet simulation

Multi-jet modeling, or material inkjet, uses inkjet printheads to layer-by-layer melted materials to create a 3D part or model. Expensive and high-precision MJF printers are a reserve of large companies with a large treasury.

PolyJet - Resin Inkjet

PolyJet, or photopolymer inkjet, printers use layers of photosensitive liquid photopolymer resin to create prints, which is fed through the printheads and cured by exposure to ultraviolet light. Like the MJF, the PolyJet is expensive, although the printers are usually smaller.

High Definition 3D Printer FAQ

Are high definition 3D prints more durable?

No, on the contrary. Generally, thicker layers (or lower resolution) produce harsher results. This is because they minimize the number of contact points between layers. Fewer layers in contact with each other means less chance of bond strength problems.

However, print strength depends on many factors, including adhesion and layer height, extruder and bed temperatures, media quality and type, and the printing technology used. The definitive answer depends more on the specific printer than the resolution. A capable device, such as any of the best high resolution 3D printers, produces reliable parts at higher resolution.

What is high resolution 3D printing?

The answer to this question varies greatly depending on who you ask. To keep things simple, high-resolution 3D printing is best described as the process of printing parts with a higher overall quality—whether it be smoothness, quality of finish, detail, or model fidelity—than is typically found in the realm of 3D printing.

What can be done with a high resolution 3D printer?

High resolution 3D printing suitable for a wide range of applications. In the commercial realm, companies prefer high-resolution printing in areas such as dentistry, jewelry, biomedicine, and all kinds of functional prototyping where accuracy is critical. In the hobby realm, creators are turning to high-resolution printing for projects that require fine detail, such as figurines, modeling, and other decorative items.

How does 3D printing resolution affect speed?

Higher resolution reduces speed.

Print speed refers to how quickly the printer applies each layer. Because high resolution printing is synonymous with thinner layers, print speeds are typically slower than low resolution printing. With high-resolution 3D printing, printing speed is sacrificed in favor of accuracy. The exact time depends on the desired resolution, the underlying technologies of the printer being used such as resin or MJF, and the complexity of the model.

Because high resolution printing is synonymous with thinner layers, print speeds are typically slower than low resolution printing. With high-resolution 3D printing, printing speed is sacrificed in favor of accuracy. The exact time depends on the desired resolution, the underlying technologies of the printer being used such as resin or MJF, and the complexity of the model.

What Does Resolution Mean in 3D Printing?

Looking for a high resolution 3D printer? “Resolution” is a term from the field of 3D printing and additive manufacturing that is often talked about, while rarely understanding its meaning. How does XY and Z resolution affect the quality of 3D printed models? What is the minimum element size and what layer thickness should I choose?

This detailed guide explains how 3D printer resolution affects model printing and how it differs between SLA, FDM and DLP printers.

For decades, technology manufacturers have been striving for higher resolution than their competitors. TVs have recently quadrupled their pixel count from HD to 4K, but manufacturers are already thinking about pushing the resolution to 8K. Mobile phones, tablets and other devices with screens show resolution as one of the main characteristics, if, of course, they have something to brag about. But this is nothing new. Resolution wars have been fought since digital became popular and the printing industry became one of the first battlegrounds.

TVs have recently quadrupled their pixel count from HD to 4K, but manufacturers are already thinking about pushing the resolution to 8K. Mobile phones, tablets and other devices with screens show resolution as one of the main characteristics, if, of course, they have something to brag about. But this is nothing new. Resolution wars have been fought since digital became popular and the printing industry became one of the first battlegrounds.

If you lived in the 80s and 90s, you'll remember how Canon, Brother, HP, Epson, and Lexmark (among others) sought to improve print speed and resolution. 100 x 100 dpi quickly grew to 300 x 300, then to 600 x 600. Finally, now the standard resolution is 1200 x 1200 dpi. Then these values were extremely clear, and the use of units of measurement was quite logical. Unfortunately, things get much more complicated when you add another dimension to print.

The level of detail of the model depends on the resolution of the 3D printer in all three dimensions.

In 3D printing and additive manufacturing, there are three dimensions to consider: two planar 2D dimensions (X and Y) and a third dimension, Z, which is used for 3D printing. Since planar measurements and Z measurements are usually controlled by completely different mechanisms, their resolutions will differ. Therefore, they must be considered separately. As a result, there is a lot of confusion about the interpretation of the term "3D printing resolution" and false expectations for print quality.

Experience the quality of stereolithography for yourself. We will send a free sample of the Formlabs stereolithographic 3D printed model directly to your office.

Request a free print sample

Formlabs high-resolution stereolithographic 3D printers feature high Z-axis resolution and a low minimum element size on the XY plane, allowing them to capture fine details.

What affects the high resolution of a 3D printer? It is impossible to name any one isolated factor. Since 3D printers produce models in 3 dimensions, there are at least two factors to consider: the minimum size of the XY plane elements and the resolution of the Z axis (thickness or height of the layer). Z-axis resolution is easy to determine and is therefore more commonly reported, although it is less related to print and surface quality. The more important XY resolution (minimum element size) is measured with a microscope and is therefore not always found in specifications.

Since 3D printers produce models in 3 dimensions, there are at least two factors to consider: the minimum size of the XY plane elements and the resolution of the Z axis (thickness or height of the layer). Z-axis resolution is easy to determine and is therefore more commonly reported, although it is less related to print and surface quality. The more important XY resolution (minimum element size) is measured with a microscope and is therefore not always found in specifications.

In practice, this means that the 3D printer must perform well in both categories (in all 3 dimensions).

White Paper

Download our White Paper to find out how SLA printing works, why thousands of professionals use it today, and how this 3D printing technology can help your work.

Download white paper

A lot has changed since the first desktop 3D printers hit the market. Now stereolithographic (SLA) 3D printers such as the Form 3 directly compete for desktop space with Fused Deposition Modeling (FDM) 3D printers. One of the main advantages of 3D printers that use polymers as consumables over their plastic-melting counterparts is print quality: SLA printers produce models with a smoother surface and a higher degree of detail. While stereolithography printers typically achieve significantly thinner layer thicknesses, the reason for the improved print quality is the much higher XY resolution.

One of the main advantages of 3D printers that use polymers as consumables over their plastic-melting counterparts is print quality: SLA printers produce models with a smoother surface and a higher degree of detail. While stereolithography printers typically achieve significantly thinner layer thicknesses, the reason for the improved print quality is the much higher XY resolution.

SLA printers (right) have higher resolution and produce models with smoother surfaces and more detail than FDM printers (left).

Unlike 3D printers based on FDM technology, the minimum size of elements in the XY plane in stereolithographic 3D printers is not limited by the dynamics of the flow of molten plastic, but is more determined by the optics and kinetics of radical polymerization. Although the calculations are complex (and beyond the scope of this article), it can be said that the details on models produced by stereolithography printers are about the same size as the diameter of the corresponding laser spots. And laser spots can be very small, especially when compared to nozzles on FDM printers.

And laser spots can be very small, especially when compared to nozzles on FDM printers.

Check out our detailed guide comparing FDM vs. SLA 3D printers to see how they differ in terms of print quality, materials, application, workflow, speed, cost, and more.

Technologies Resin-based 3D printing such as SLA, LFS and DLP provide the highest resolution of all 3D printing processes available for desktop printers. The primary units of measure for SLA and DLP processes are different forms, making it difficult to compare printers on a purely numerical basis.

DLP-based 3D printers have a fixed pixel matrix relative to the work area, while SLA- and LFS-printers that use a laser can focus the laser beam on any coordinate of the XY plane. This means that laser 3D printers with high optical quality can accurately reproduce the surface of the model, even if the laser spot size is larger than the pixel size in the DLP printer.

Whichever resin 3D printing technology you choose, professional 3D printers should capture the finest details of your creations, from photorealistic models to fine jewelry.

When printing on 3D printers based on SLA and LFS technologies (left), layer lines are almost invisible. As a result, surface roughness is reduced, resulting in a smooth surface, and when using transparent materials, models with greater transparency. DLP printers use rectangular voxels to render images, which can result in vertical lines (right).

Learn more about the differences between SLA and DLP technologies in terms of resolution, accuracy, clarity, print volume, surface quality, speed, and how they work.

In the world of 3D printing, no other factor affects the quality of models more than XY resolution. She is often mentioned, but rarely understood. The definition of XY resolution (or horizontal resolution) differs depending on the 3D printing technology:

- stereolithographic 3D printers - a combination of laser spot size and the size of the steps with which the beam can be controlled;

- DLP printers - pixel size, the smallest detail that a projector can reproduce in a single layer;

- FDM printers - the smallest distance that the extruder can move within one layer.

Generally, the lower this value, the finer the detail. But this number is not always indicated in the technical specifications, and even if indicated, it is not always correct. To get an idea of true XY resolution, it is important to understand how a printer works.

How does XY resolution affect the quality of your models? To find out, we decided to test a Form 2 stereolithographic 3D printer. The size of the laser spot in the Form 2 printer is 140 µm (FWHM), which should allow it to reproduce fine details on the XY plane. We decided to check if this ideal resolution corresponds to the truth.

To check the minimum feature size on the XY plane for the Form 2 printer, we designed a model (left) with lines ranging from 10 to 200 µm thick and printed it using Clear Resin (right).

We first designed and printed a model to check the minimum element size on the XY plane. The model is a rectangular block with lines of various widths in the horizontal, vertical and diagonal directions, which are applied to prevent displacement. The line thickness is from 10 to 200 µm, the lines are drawn at 10 µm intervals and have a height of 200 µm, which corresponds to two layers when printed at a resolution of 100 µm for the Z axis. Made from Clear Resin, the model was washed twice in isopropyl alcohol and subjected to a within 30 minutes.

The line thickness is from 10 to 200 µm, the lines are drawn at 10 µm intervals and have a height of 200 µm, which corresponds to two layers when printed at a resolution of 100 µm for the Z axis. Made from Clear Resin, the model was washed twice in isopropyl alcohol and subjected to a within 30 minutes.

The model was photographed and painted green for better visibility. The vertical yellow line with black dots on the right side of the window is for measuring the width of the photographed line.

After the final polymerization, we placed the model under the microscope and took a high resolution photograph for further analysis. Using ImageJ, a free image analysis program from the National Institutes of Health (NIH), we scaled the image pixels and measured the actual width of the printed lines. We collected over 50 data points per line width to eliminate measurement errors and variability. We analyzed three models made on two printers.

The results show that the Form 2 has the same ideal and actual XY resolution for model elements as small as 150 µm.

As the line width decreases from 200 to 150 µm, the ideal values are within the 95% confidence interval of the measured value. As the expected linewidth becomes less than 150 µm, the measured interval starts to deviate significantly from the ideal. This means that the printer can reliably reproduce elements up to 150 microns in size, as thick as a human hair, on the XY plane.

The Form 2 has a minimum XY feature size of about 150 µm, only 10 µm larger than the 140 µm spot size of its laser. The minimum element size cannot be less than the laser spot size. There are many factors that affect this value: laser refraction, microscopic contaminants, polymer chemistry, etc. Considering the entire printer ecosystem, a difference of 10 µm is nominal. Not all 3D printers have the reported resolution as the actual resolution, so it's a good idea to do a lot of research before choosing the right resolution for your project.

If you want models with fine detail, look for a printer where XY resolution is not just given as a number, but is supported by measured data.

When looking at the specifications of 3D printers, you will find that one parameter appears more often than any other. This is the Z-axis resolution. Also known as layer thickness or layer height, vertical resolution was the first major numerical parameter by which early 3D printers were distinguished. The first such devices struggled to overcome the barrier of 1 mm, but now the layer thickness in FDM-based 3D printers can be less than 0.1 mm, and even less in LFS and SLA printers.

Formlabs 3D printers support layer thicknesses from 25 to 300 microns, depending on the material. This range of values allows you to find the perfect balance between speed and print quality. But the main question is what layer thickness will be ideal for your model.

The high resolution of 3D printing affects other parameters. The thinner the layer, the more layers need to be printed, resulting in increased model production time: typically, printing at a resolution of 25 µm takes four times longer than printing at a resolution of 100 µm. In addition, the more layers, the higher the probability of errors. For example, even with a layer success rate of 9A 9.99% fourfold increase in resolution reduces the chances of a successful print of the model from 90% to 67%, provided that the layer with the error leads to rejects.

In addition, the more layers, the higher the probability of errors. For example, even with a layer success rate of 9A 9.99% fourfold increase in resolution reduces the chances of a successful print of the model from 90% to 67%, provided that the layer with the error leads to rejects.

The thinner the layer, the longer it takes to print and the more likely it is to cause errors and distortion.

Is it true that the higher the resolution (the thinner the layers), the higher the quality of the finished models? Not always. It depends on the model and resolution of the XY 3D printer. As a general rule, the thinner the layer, the longer it takes to print and the greater the chance of distortion and errors. In some cases, printing models at a lower resolution (i.e., with thicker layers) may even result in better quality.

Thinner layers are usually associated with smoother diagonal transitions, causing many users to push Z resolution to the limit. But what if the model consists mostly of vertical and horizontal faces, with right angles and a small amount of diagonal surfaces? In such cases, increasing the number of layers will not improve print quality.

The problem is exacerbated if the printer's XY resolution is not ideal and it "goes out of bounds" when forming the outer edges. The more layers, the more mismatched protrusions will be on the surface. In this case, the finished model will look much worse, even if the Z resolution is higher.

There are times when you need to increase the resolution. If you have a printer with good XY resolution and a model with complex features and many diagonal faces, reducing the thickness of the layers will allow you to get a physical model of much better quality. Also, if this model is small (no more than 200 layers), then increasing the resolution of the Z-axis will lead to a real improvement in quality.

Some designs benefit from higher Z resolution: organic shapes, rounded arches, fine embossing and intricate engraving.

A tiny model with lots of detail and arches needs a higher Z resolution. This cathedral was printed on a Form 2 printer at 25µm resolution.

Try to stick to this general rule: print thicker layers and increase the Z resolution only when it is really necessary. With the right combination of printer and model type, the higher Z resolution will capture the intricate details of your design.

Gray Resin allows printing at a resolution of 160 microns. Check out the difference in speed for yourself.

Formlabs PreForm software allows you to select the layer thickness. Starting with version PreForm 3.0.3 , Gray Resin can be printed in 160, 100, 50 and 25 µm layer heights. Printing at a resolution of 160 microns will speed up the iteration process and allow engineers to move from design to finished model even faster. And dentists can make more aligners per day without sacrificing quality.

We hope that once you are familiar with the concept of resolution and understand the differences in 3D printing technologies and results, it will be much easier for you to choose a 3D printer that best suits your needs and workflow.