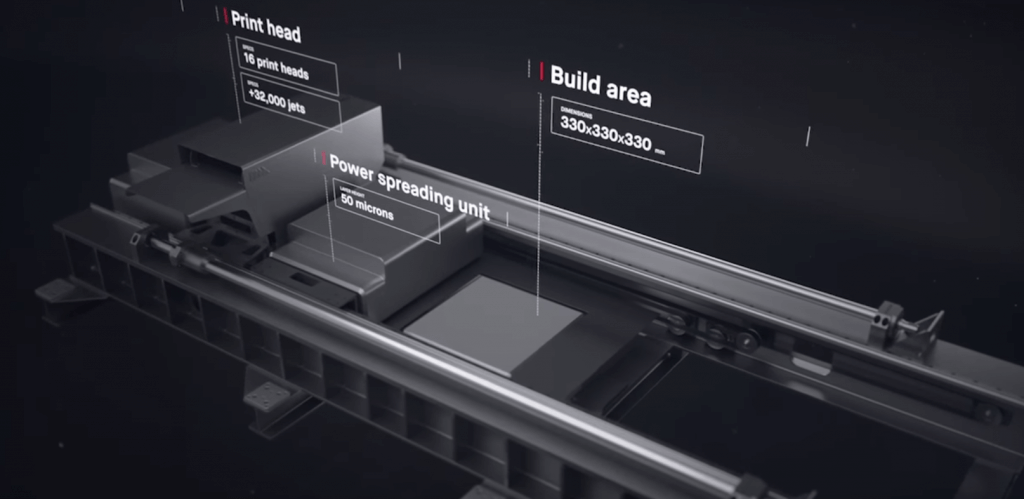

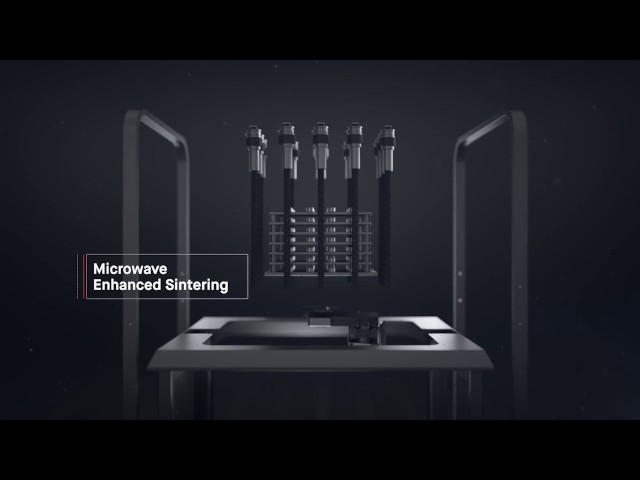

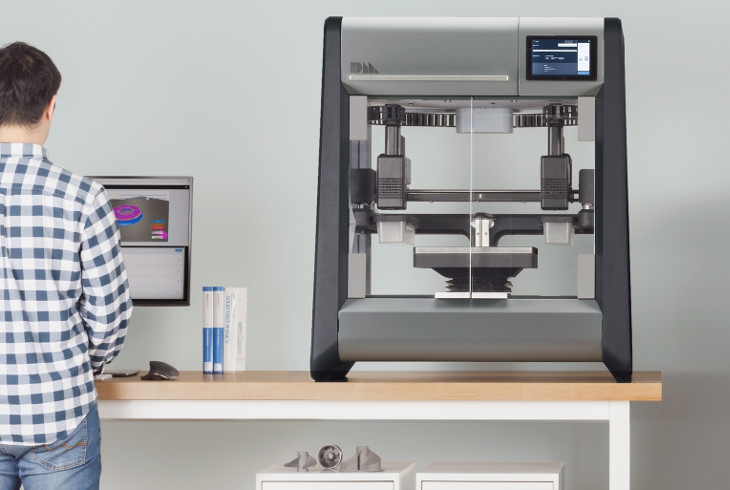

Desktop metal studio 3d printer

Studio System™ | Desktop Metal

_Studio System™ applications

Studio System™ applications span a variety of industries including manufacturing, tooling, automotive, consumer, electronics, and oil & gas.

-

Extrusion Die

h23This die is used in the manufacture of extruded plastic framing.

Extrusion Die

-

Size (mm) 74 x 74 x 56

Cost to print ($) 156.00

Cost to machine ($) 329.67

Cost reduction 52.68%

-

Metal 3D printing reduces lead times and costs - allowing for rapid iteration and refinement of the die design.

Furthermore, lower tooling costs and lead times makes low volume custom extrusion dies economically feasible.

-

Rook Chess Piece

316LOne of six types of movable objects used in the game of chess.

Rook Chess Piece

-

Size (mm) 46 x 46 x 72

Cost to print ($) 46.00

Cost to machine ($) 329.67

Cost reduction 52.68%

-

Unique chess piece designs can easily be 3D printed without the long lead times and costs associated with tooling.

The Studio System’s high resolution print head produces small parts with fine features and surface finish.

The Studio System’s high resolution print head produces small parts with fine features and surface finish.

-

YE6 Burner Tip

316LThis burner tip is used to shape the flame in industrial burners.

YE6 Burner Tip

-

Size (mm) 139 x 139 x 86

Cost to print ($) 193.46

Cost to machine ($) 694.00

Cost reduction 72.00%

-

This burner tip was originally cast in the 1950s, and the tooling has since been lost for it.

When a customer needed a replacement, the quote for new tooling was in the tens of thousands of dollars.

When a customer needed a replacement, the quote for new tooling was in the tens of thousands of dollars.With the Studio System, the company was able to recreate the part with properties similar to the original cast part, with no tooling cost or long lead times for the customer.

-

Putter

17-4 PHCustom designed golf putter is an example of the customization that is possible with 3D printing.

Putter

-

Size (mm) 135 x 92 x 38

Cost to print ($) 128.

00

00Cost to machine ($) 2203.00

Cost reduction 94.00%

-

Golf clubs, especially putters, are typically cast or machined. With the Studio System, manufacturers can achieve excellent material properties without tooling or expensive CNC machining.

The Studio System allows for customization of parts like putters, so each player can have a design that is best suited to them. And when those designs go into mass production, they can be manufactured via binder jetting.

-

Flower Nozzle

316LThis flower nozzle is used to atomize fluid in industrial equipment.

Flower Nozzle

-

Size (mm) 123 x 123 x 45

Cost to print ($) 184.00

-

Due to its complex geometry, these parts would typically be cast followed by extensive secondary machining. With the Studio System, the nozzle can be 3D printed without the lead times and setup costs of casting, enabling one-off and small batch orders.

-

Impeller

316LThis impeller is used to control the pressure and flow of fluids in equipment like pumps and compressors.

Impeller

-

Size (mm) 82 x 82 x 28

Cost to print ($) 63.00

Cost to machine ($) 2138.00

Cost reduction 97.05%

-

Their complex vanes make impellers expensive and difficult to manufacture. When a custom impeller is needed metal 3D printing accelerates design optimization and product development by dramatically reducing lead time and cost.

-

Sheet Metal Embosser

4140This custom embosser is used in sheet metal fabrication.

Sheet Metal Embosser

-

Size (mm) 47 x 28 x 15

Cost to print ($) 14.00

-

Sheet metal tools are used for a broad range of fabrication operations, including stamping, bending, countersinking and embossing.

3D printing with the Studio System reduces tool fabrication costs, shortens production run lead time, and enables rapid iteration and refinement of the sheet metal designs and associated tooling.

-

Zipper Mold

h23This part is an Injection mold insert for manufacturing zinc zippers.

Zipper Mold

-

Size (mm) 46 x 27 x 18

Cost to print ($) 16.00

-

3D printing the mold inserts shortens production run lead time and allows rapid iteration and refinement of zipper designs. Using a high resolution printhead allows for smaller parts with finer features, requiring less post processing.

-

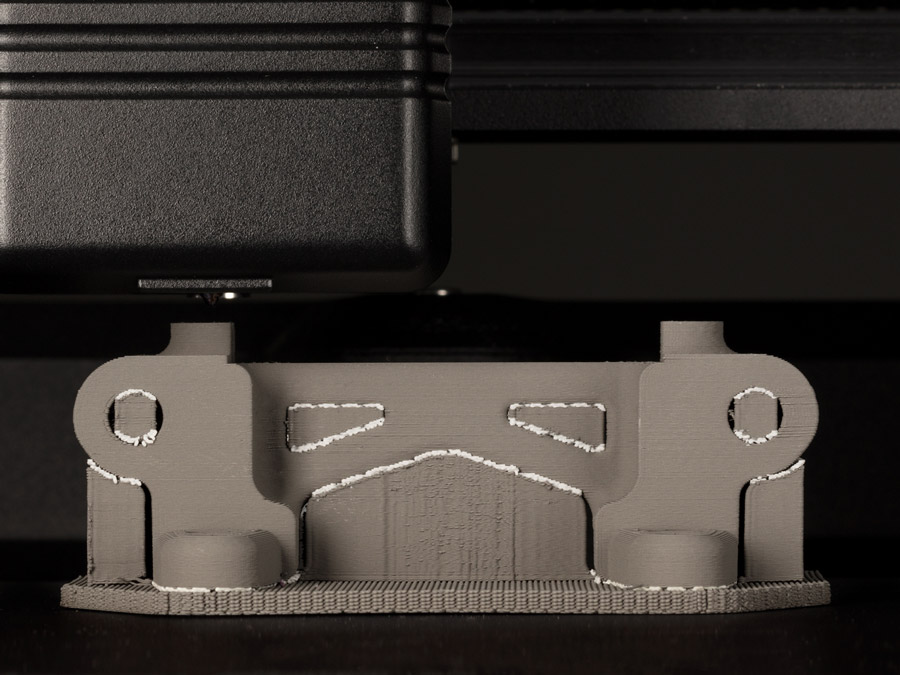

Skateboard Truck

17-4 PHThis part attaches wheels to a skateboard deck, and was optimized using generative design tools

Skateboard Truck

-

Size (mm) 201 x 76 x 52

Cost to print ($) 161.

00

00Cost to DMLS ($) 1163.00

Cost reduction 86.00%

-

Generative design and 3D printing allows for the fabrication of innovative designs impossible with casting (the traditional production method for skateboard trucks).

The Studio System can print that previously impossible geometry, resulting in trucks that are more aesthetically pleasing, stronger, and lighter.

-

Master Drilling Sun Gear

17-4 PHThis part is a sun gear used in a planetary gearbox for an earth-drilling machine.

Master Drilling Sun Gear

-

Size (mm) 118 x 118 x 118

Cost to print ($) 658.

00

00Cost to machine ($) 916.00

Cost reduction 28.17%

-

After exploring a number of alternative manufacturing methods to produce the parts needed to keep crucial machinery up and running, Master Drilling chose 3D printing. The switch to 3D printing cut their lead time for replacement parts from about three months for off-shore castings, to just three weeks printing on-site, thereby reducing downtime for the earth drilling equipment.

-

Mouthpiece Mold

h23Mold insert is used to injection mold medical inhaler mouthpieces.

Mouthpiece Mold

-

Size (mm) 104 x 93 x 48

Cost to print ($) 345.00

Cost to machine ($) 716.77

Cost reduction 51.87%

-

3D printing the hard steel insert to near-net shape eliminates 95% of the required CNC machining and associated tool wear.

Because cooling accounts for 95% of the mold cycle time, the ability to incorporate conformal cooling channels into the mold can reduce mold cycle time and increase throughput.

-

UMC End Effectors

17-4 PHThese grippers are used to fixture and move aerospace forgings on a manufacturing line.

UMC End Effectors

-

Size (mm) 55 x 32 x 16

Cost to print ($) 23.00

Cost to machine ($) 194.00

Cost reduction 88.14%

-

The complex geometry of end effectors requires extensive CNC machining, resulting in long lead times that occupy valuable CNC capacity.

Using metal 3D printing allows for on-demand manufacturing of custom end effectors while lowering part cost and lead time.

Using metal 3D printing allows for on-demand manufacturing of custom end effectors while lowering part cost and lead time.

-

APG Thread Checker Fixture

17-4 PHThis fixture pushes a thread checker into a part on a manufacturing line.

APG Thread Checker Fixture

-

Size (mm) 47 x 28 x 15

Cost to print ($) 14.00

-

This fixture pushes a thread checker into a part on a manufacturing line.

As a wear item, it needs to stand up to repeated use, and must be easily produced to keep the manufacturing line up.

As a wear item, it needs to stand up to repeated use, and must be easily produced to keep the manufacturing line up.The fixture must be regularly replaced as it wears out. Printing the part with the Studio System eliminates CNC lead time and frees up the machine shop for more critical work.

-

BattleBots Bot Support

17-4 PHThis part is a structural member for use in the bot's robotic arm.

BattleBots Bot Support

-

Size (mm) 130 x 117 x 64

Cost to print ($) 106.

00

00Cost to machine ($) 551.90

Cost reduction 81.00%

-

This support is designed to carry a heavy load and withstand punishment. Engineers working on a bot used on a Discovery Channel program BattleBots had less than a month to produce a custom structural element on robotic arm. Using the Studio system, they were able to print a bracket capable of resisting bending and lateral motion while providing the stiffness, strength, weldability and fire resistance required.

-

APG Chuck Jaws

h23This part is used to hold a workpiece in place during machining lathe operations.

APG Chuck Jaws

-

Size (mm) 84 x 78 x 42

Cost to print ($) 117.00

Cost to machine ($) 426.36

Cost reduction 72.56%

-

These chuck jaws closely match the geometry of the part being machined - making them complex to machine. Printing them using the Studio System eliminates CNC lead time and frees up the machine shop for more critical work.

-

O-Ring End Effector

17-4 PHThis end effector is used to stretch and install O-rings on a hydraulic fitting.

O-Ring End Effector

-

Size (mm) 42 x 13 x 17

Cost to print ($) 7.00

Cost to machine ($) 152.17

Cost reduction 95.40%

-

Small, detailed parts like these end effectors typically require expensive CNC machining and have long lead times. Using the Studio System’s high resolution (250μm) printhead allows manufacturers to print small parts with fine features which would be difficult to machine

-

APG Coining Fixture

h23This fixture is used to achieve critical tolerances on metal injection molded (MIM) parts.

APG Coining Fixture

-

Size (mm) 110 x 57 x 31

Cost to print ($) 92.00

Cost to machine ($) 392.00

Cost reduction 75.63%

-

Fixture like this require custom geometry for each application, as well as superior wear resistance. The faster these parts are manufactured, the quicker a company can get get manufacturing lines running.

Printing these parts with the Studio System eliminates CNC lead time and frees up the machine shop for more critical work.

-

Helical Heat Exchanger

CopperUsed in chemical processing to cool a hot gas as it flows through a pipe.

Helical Heat Exchanger

-

Size (mm) 78 x 64 x 58

Cost to print ($) 443.00

Cost to machine ($) 2138.00

Cost reduction 79.28%

-

This heat exchanger enables a much higher heat transfer rate than a traditionally manufactured part.

Featuring thin external fins and a complex, internal helical cooling channel, this exchanger would not be manufacturable as one component via CNC machining.

Featuring thin external fins and a complex, internal helical cooling channel, this exchanger would not be manufacturable as one component via CNC machining. The Studio System allows for the complex geometry of the heat exchanger to easily be printed as a single component.

-

UHT Atomizer

316LThis part is a fuel atomizer for a steam boiler on a liquid natural gas (LNG) tanker.

UHT Atomizer

-

Size (mm) 74 x 74 x 71

Cost to print ($) 129.

00

00Cost to DMLS ($) 1089.00

Cost reduction 88.00%

-

This 3D printed atomizer features complex internal channels and oblong shaped holes, which could not be manufactured with traditional methods. With the Studio System, the engineers were able to radically redesign their conventional atomizers for significantly better performance.

-

Octopus Ring

316LExample of the unique jewelry that can be customized and scaled for a tailored fit.

Octopus Ring

-

Size (mm) 38 x 38 x 30

Cost to print ($) 14.

00

00 -

Unique jewelry pieces can be 3D printed without the design lock-in, long lead times and costs associated with tooling. The Studio System’s high resolution print head produces small parts with fine features and surface finish.

-

Lathe Gear

17-4 PHThis part is a replacement gear for vintage (circa 1940) lathe.

Lathe Gear

-

Size (mm) 82 x 82 x 27

Cost to print ($) 58.

00

00Cost to machine ($) 260.67

Savings vs. machining 77.70%

-

In some cases, replacement parts are no longer available, either off the shelf or from the OEM. Fabricating custom gears via hobbing and broaching is often prohibitively expensive, but metal 3D printing allows for the fabrication of legacy parts at much lower cost.

-

Tri Manifold

Alloy 625This manifold is used to combine three flows into one common flow.

Tri Manifold

-

Size (mm) 108 x 101 x 98

Cost to print ($) 906.

00

00Cost to DMLS ($) 4069.28

Savings vs. machining 77.74%

-

This part converges three flow paths into one via internal channels. These channels would be impossible to machine, and instead would need to be drilled as straight holes and plugged.

Printing on the Studio System allows these channels to be designed for their function rather than their manufacturing method. This part can be produced in just a few days with very little hands on work.

-

Generative Piston Head

4140Prototype piston head for a reciprocating engine, optimized with generative design.

Generative Piston Head

-

Size (mm) 105 x 105 x 54

Cost to print ($) 271.00

Cost to machine ($) 568.13

Savings vs. machining 52.30%

-

Typically CNC machined from aluminum alloy, pistons can be time consuming and difficult to rapidly prototype and test - often taking months or even years to move from design to production.

With the Studio System, various piston designs can be easily prototyped and tested—speeding up product development timelines, reducing time to market, and introducing new opportunities for optimization, including generative design—all while avoiding CNC backlog and lead times.

-

Pump Housing

17-4 PHThis is part of the housing for a hydraulic pump.

Pump Housing

-

Size (mm) 136 x 131 x 47

Cost to print ($) 243.00

Cost to machine ($) 708.68

Savings vs. machining 65.68%

-

This part would typically be cast, followed by secondary machining operations - resulting in long lead times and high costs.

By printing on the Studio System, the long lead time associated with casting can be avoided, and the cost to machine from scratch is greatly reduced - allowing the manufacturer to produce the part in-house and enabling cost-effective rapid design iteration and pilot runs.

-

Guitar tailpiece

17-4 PHThe guitar tailpiece anchors one end of the guitar strings.

Guitar tailpiece

-

Size (mm) 127 x 28 x 20

Cost to print ($) 36.00

Cost to machine ($) 343.

28

28Savings vs. machining 89.51%

-

The guitar tailpiece is typically cast from aluminum, and can be fairly expensive to customize for short manufacturing runs.

Printing in steel allows design freedom and part customization while eliminating tooling costs. Steel tailpieces also exhibit more pleasing resonance and sustain characteristics for some genres and playing styles.

-

Cuff Ring

316LExample of the unique jewelry that can be customized and scaled for a tailored fit.

Cuff Ring

-

Size (mm) 59 x 54 x 80

Cost to print ($) 43.

00

00 -

Unique jewelry pieces can be 3D printed without the design lock-in, long lead times and costs associated with tooling. The Studio System’s high resolution print head produces small parts with fine features and surface finish.

Production System™ | Desktop Metal

-

Seat Belt Pulley

17-4 PHThis output pulley is an essential component of the reclining mechanism in a car seat.

Seat Belt Pulley

-

Size (mm) 48 x 29 x 9

Cost per part ($) 0.

89

89Parts per build 2,740

Annual throughput 995,900

-

This part features an undercut radial groove that, without printing, would require advanced sliders during the press-and-sinter process. Printed on the Production System eliminates the cost and complexities associated with press and sinter.

-

Surgical Tool Nozzle

17-4 PHNozzle used during surgery; customized for each patient.

Surgical Tool Nozzle

-

Size (mm) 27 x 47 x 21

Cost per part ($) 1.

91

91Parts per build 860

Annual throughput 400,140

-

This surgical nozzle features a customized internal channel designed specifically for each patient. The Production System allowed this part to be mass customized and produced without any tooling, allowing it to be fine-tuned for an array of patients.

The internal channel featured in this nozzle would require complex machining operations with multiple fixturing setups; printing on the Production System eliminates those steps, resulting in cost savings.

-

BMW Water Wheel

17-4 PHThe waterwheel is an integral part of the BMW’s engine cooling system.

BMW Water Wheel

-

Size (mm) 63 x 63 x 34

Cost per part ($) 9.74

Parts per build 170

Annual throughput 63,230

-

Initially made of several plastic parts, BMW redesigned this waterwheel for printing on a laser-based system, but found the process to slow and expensive for mass production.

The Production system unlocks higher throughput, allowing the part to be manufactured at a competitive price, bringing the race track to the road.

-

Audi Fixture

17-4 PHThis custom manufacturing fixture was created for use on an Audi production line.

Audi Fixture

-

Size (mm) 127 x 51 x 38

Cost per part ($) 19.18

Parts per build 110

Annual throughput 41,500

-

With complex internal conformal cooling channels that span the base and the wall, this fixture would normally be manufactured in multiple pieces and welded together.

As production increases, this part would be too expensive and time-consuming to scale.

As production increases, this part would be too expensive and time-consuming to scale. Using the Production System, the fixture is printed as a single part with cooling channels intact—reducing part cost, lead time, and manufacturing complexity.

-

Parking Shift Bracket

17-4 PHThis bracket is used in the parking brake assembly of a continuously variable transmission.

Parking Shift Bracket

-

Size (mm) 93 x 44 x 12

Cost per part ($) 2.

84

84Parts per build 680

Annual throughput 248,980

-

This part would require a complex die and multiple secondary operations to be produced via traditional powder metallurgy techniques.

The Production system eliminates the need for tooling, dramatically reducing lead times, reducing part costs and enables the redesign of this part to consolidate an assembly into a single part.

-

Watch Bezel

17-4 PHA watch bezel is the main component that houses the dial and movement.

Watch Bezel

-

Size (mm) 43 x 48 x 9.

5

5Cost per part ($) 1.06

Parts per build 1,200

Annual throughput 497,950

-

Because it prints parts with no tooling, the Production System is capable of printing multiple different watch models in each run, greatly reducing manufacturing part cost and lead time.

-

Ntopology Gear

17-4 PHThis gear features a complex internal lattice structure only achievable via 3D printing.

Ntopology Gear

-

Size (mm) 63 x 63 x 12.

5

5Cost per part ($) 6.09

Parts per build 460

Annual throughput 165,980

-

This part features a complex lattice structure used to lightweight the part while still providing strength.

The Production System allows for the manufacturing of complex geometries that cannot be manufactured any other way.

-

Power Steering Joint

17-4 PHThis joint is designed to power transfer in an electric power steering system.

Power Steering Joint

-

Size (mm) 36 x 36 x 22

Cost per part ($) 1.

89

89Parts per build 1,140

Annual throughput 470,424

-

This joint is used for power transfer between an electric power steering motor and the steering shaft in an automobile. The production system allowed for this part to be produced with no tooling, allowing for accelerated lead time and flexible design.

-

Custom Bolt

17-4 PHThis custom-designed bolt is used in specific applications.

Custom Bolt

-

Size (mm) 70 x 16 x 12

Cost per part ($) 1.

10

10Parts per build 2,280

Annual throughput 829,920

-

Due to the high cost of hard tooling, most bolts are manufactured in quantities of millions. For this bolt, however, only a few tens of thousands were needed. By printing on the Production System this bolt can be produced with no tooling at an dramatically reduced cost per part.

-

Spauger Bit

17-4 PHThis part is a drill bit used to quickly drill holes in clean wood.

Spauger Bit

-

Size (mm) 166 x 12 x 12

Cost per part ($) 1.

95

95Parts per build 800

Annual throughput 280,470

-

Using traditional methods, this spauger bit required more than 20 manufacturing steps. With the Production System, that number is reduced to just four, with post processing only required to reach the desired hardness and surface finish. This greatly reduces the part cost and manufacturing lead time.

-

Stator

17-4 PHThis stator is designed for use in a small electric motor.

Stator

-

Size (mm) 60 x 60 x 16

Cost per part ($) 2.

82

82Parts per build 460

Annual throughput 189,700

-

This stator is part of a small electric motor that was produced in low volume, making it difficult to justify the cost of hard tooling for metal injection molding (MIM). The entire run of parts could be produced in one run of the Production System at the desired part cost and greatly reduced manufacturing lead time.

-

Watch Case

17-4 PHThe case is the main component of a watch, and houses the dial and movement.

Watch Case

-

Size (mm) 47 x 38 x 7.

7

7Cost per part ($) 1.96

Parts per build 1,170

Annual throughput 1,825,824

-

For each different watch model and size, different tooling is required. This makes doing smaller, more custom watch models prohibitively expensive. The Production system eliminates the need for tooling dramatically reducing part cost.

Watch producers can now manufacture on-demand, producing watch designs that never could have been justified before.

Desktop 3D printer Additec μPrinter prints with metal powders and welding wire

News

Additec launches μPrinter, a professional-grade desktop 3D printer.

According to the developers, this is the most compact 3D printer in the world for direct metal laser 3D printing.

According to the developers, this is the most compact 3D printer in the world for direct metal laser 3D printing. No, this time we are not talking about 3D printing with polymer filaments filled with metal powders, but about real printing with metals, using both wire and powder materials. The size of the construction area of the Additec μPrinter 3D printer reaches 160x120x450 mm - not the highest figure, but this is the price of compactness and cost reduction. The developers conceived the device as a laboratory system and a relatively inexpensive entry-level 3D printer for companies interested in full-fledged additive manufacturing of metal products.

The main consumable is ordinary, inexpensive welding wire with a diameter of 0.6 to 1 mm, although metal powders can be sprayed using the same head. Fusion in the standard version is carried out by three diode lasers with a total power of 600 W, but if desired, five lasers can be installed and the power can be increased to 1 kW. Optional upgrades include up to two wire feed systems, each capable of handling four materials simultaneously, or up to four powder feed systems. Each of the emitters will be equipped with a laser designator in the visible range, which makes it easier to focus the beams at one point. To protect against oxidation, a sealed chamber with an inert gas supply is provided.

Optional upgrades include up to two wire feed systems, each capable of handling four materials simultaneously, or up to four powder feed systems. Each of the emitters will be equipped with a laser designator in the visible range, which makes it easier to focus the beams at one point. To protect against oxidation, a sealed chamber with an inert gas supply is provided.

After applying each layer, the system resets the zero on the Z axis, measuring the distance from the top layer, and in case of failure, it cuts the wire itself, returns to the problem area and resumes the process. All this saves argon and reduces operator intervention to a minimum. The designers believe that such functionality will save a lot of time and nerves when working with experimental materials. An on-board camera is provided to monitor the 3D printing process.

“The Additec μPrinter is well suited for R&D. Its ability to handle both bars and powders allows for a wide range of applications. All data from the integrated sensors, including the pressure in the material supply system, the temperature in the working chamber, the oxygen level, and so on, can be displayed for monitoring and analysis through the auxiliary USB connection. Also, any parameter can be changed in G-code on the fly, and we provide a very capable utility that allows you to combine commands and data for testing and automation through a web interface. Finally, a fixed head and an optional transparent panel make it possible to integrate additional equipment for monitoring workflows,” the developers explain.

All data from the integrated sensors, including the pressure in the material supply system, the temperature in the working chamber, the oxygen level, and so on, can be displayed for monitoring and analysis through the auxiliary USB connection. Also, any parameter can be changed in G-code on the fly, and we provide a very capable utility that allows you to combine commands and data for testing and automation through a web interface. Finally, a fixed head and an optional transparent panel make it possible to integrate additional equipment for monitoring workflows,” the developers explain.

Additec μPrinter Desktop System is priced at $90,000 as standard. Additional information is available on the manufacturer's website at this link.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at news@3Dtoday. ru.

ru.

Follow the author

Follow

Don't want

21

More interesting articles

eleven

Subscribe to the author

Subscribe

Don't want

Simon Fraser University scientists have developed a self-learning system that matches in real ...

Read more

ten

Subscribe to the author

Subscribe

Don't want

Scientists of Sechenov University, Baikal Institute of Nature Management, Siberian Branch of the Russian Academy of Sciences...

Read more

59

Subscribe to the author

Subscribe to the author

Subscribe

Don't want to

The 3Dtoday portal, with the support of Creality and Bestfilament, invites everyone to participate in. ..

..

Read more

American and Turkish engineers assembled a "desktop 3D printer for metal »

News

Subscribe to the author

Subscribe

Don't want

13

A team of scientists from California State University and Osman Ghazi University of Eskisehir took on the holy of holies - the creation of a budget 3D printer capable of printing all-metal products. Let's talk about what they did.

Direct 3D printing with metals (without intermediate steps such as growing polymer-metal blanks, and then etching and sintering) can be divided into two areas, referred to in Russian GOST as “synthesis on a substrate” (in the English terminology Powder Bed Fusion or PBF ) and "direct energy and material supply" (Directed Energy Deposition or DED). Synthesis on a substrate involves sintering or fusing metal-powder compositions in containers using laser emitters or electron beam guns. In the direct supply of energy and material, various energy sources can also be used, for example, the same lasers or electron beams, and the materials can be either powders deposited into the sintering or fusion zone or metal wire.

A project by scientists from California State University and Osman Ghazi University of Eskisehir is a variant of the second track called Wire Arc Additive Manufacturing or WAAM. Here, the material is wire, and the products are grown by arc welding, specifically in this case, with a non-consumable electrode in a protective inert atmosphere. WAAM is already being used in industry, for example in the repair and even additive manufacturing of ship parts: in 2017, the Dutch production center RAMLAB produced the first type-certified 3D printed ship propeller ( in the illustrations above and below ).

The resolution of WAAM 3D printers is, to put it mildly, small and requires a lot of post-processing, but they are easily scaled up and do not require fuss with relatively expensive, and often dangerous powders, and at the same time outperform traditional methods in terms of producing geometrically complex products with minimum waste. But you can scale both up and down, and the heroes of our story decided to create such a device not on the basis of an expensive industrial-grade multi-axis robotic arm, but by redesigning a budget desktop FDM 3D printer with the intention of keeping within one thousand dollars.

As a basis, the guys took an open-source "drygost" called Bukobot by the Californian company Deezmaker. The team assembled the device themselves by printing plastic parts on a Stratasys uPrint SE Plus 3D printer, and the power source for the head is an Everlast-branded welding machine. The movable electrode is mounted on one carriage with a mechanism that feeds a metal wire into the melt zone.

Inconel 718 Single Layer Metallography

Experiments were carried out with two types of consumables - AISI 1030 high-carbon steel wire and Inconel 718 heat-resistant nickel-chromium alloy with a diameter of 0.8 mm using tungsten electrodes with a diameter of 2.37 mm and blowing with an inert gas - argon. A series of experiments included experiments on 3D printing at different speeds with the appropriate adjustment of the material feed rate and current strength. For steel, these parameters varied within 2.5-3.5 mm/s with a feed rate of 14-18 mm/s at 45-55A, and with Inconel they tried to print at speeds of 4. 88-5.03 mm/s with a feed rate wire 7.69-10.49 mm/s at 40-50A.

88-5.03 mm/s with a feed rate wire 7.69-10.49 mm/s at 40-50A.

Appearance and section of a 30 layer Inconel 718 specimen

Predictably, the team faced a host of challenges, including mechanical failures, errors in machine code, overheating and even burnout of electrical connections, and electronic and stepper motor failures caused by welder interference.

When working out the parameters, the results varied greatly: when working with the same steel, even at a current of 50A, 3D printing at high speeds produced a series of drops instead of solid lines, so the combination of a paving speed of 3 mm / s with material feed at a speed of 18 mm / s at a current of 55A ( option number 8 in the illustration above ). With these settings, we managed to get a wall of twenty-five layers in the illustration below.

In general, the experiment was recognized as successful, as the very possibility of WAAM 3D printing with metals on budget, self-assembled equipment with a total cost of around one thousand dollars was proved without significant defects, such as interlayer oxidation or cracking. The team's full report can be found at this link.

The team's full report can be found at this link.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

budgetary metal printing WAAM

Follow author

Follow

Don't want

13

More interesting articles

ten

Subscribe to the author

Subscribe

Don't want

Igor Kostusev, an employee of the Arktika shipbuilding enterprise, received the Lomo Regional Prize...

Read more

5

Subscribe to the author

Subscribe

Don't want

Anodizing is a process aimed at creating protective oxide layers on the surfaces of products.