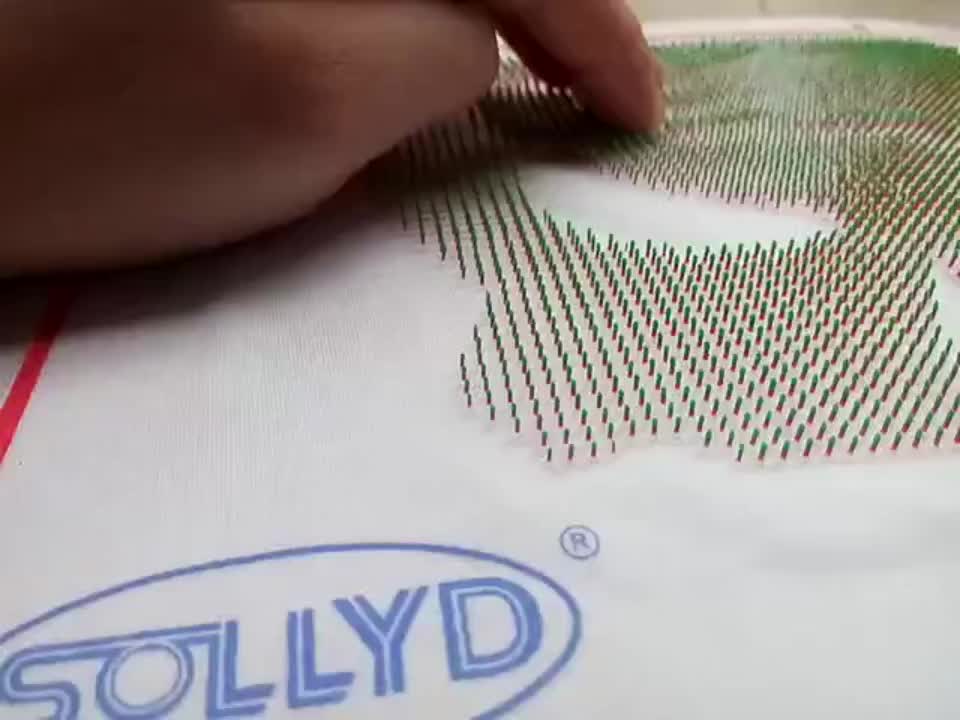

Screen printing 3d effect

8 SPECIAL EFFECTS SCREEN PRINTING INKS YOU NEED TO KNOW ABOUT – FN-INK

You've come up with a killer t-shirt design. It's edgy, creative, and eye-catching. You can't wait to print it, but when you look at your ink shelf, your heart drops a little. You don't have a screen printing ink that's going to bring that art to life. You need something special. That's where special effects inks come in. They're designed to make prints sparkle, shimmer, shine, stretch, puff, and so much more. Check out these eight special effects inks and see where your imagination takes you.

SPARKLE WITH FN-INK METALLIC GOLD

Who doesn’t love gold? Make a print look like a million bucks with FN-INK Metallic Gold. The ink is stock full of golden flakes, sparkling and glittering when a flash of light hits it. Gold makes a statement. It’s not for the light-hearted. Spread your message with FN-INK Metallic Gold.

MAKE PRINTS GLISTEN WITH FN-INK METALLIC SILVER

Gray has its uses, but it doesn’t have a pop, a wow factor. You can make jaws drop when you print with metallic silver ink. This liquid metal-like ink is sure to stop viewers in their tracks. It glistens and twinkles, bringing life to the print. Plus, FN-INK Metallic Silver is so FN easy to print (seriously, it flows like butter). Once you start printing with it, you’ll be finding excuses to incorporate it into every design.

RELATED: SCREEN PRINT ANY COLOR WITH AN INK MIXING SYSTEM

SHIMMER & SHINE WITH FN-INK PEARL

Sometimes, a print may require a subtle special effect. Something that catches the eye, but isn’t obnoxious. Create a soft shimmer with FN-INK Pearl. FN-INK Pearl is a metallic ink that produces a pearlescent effect (who would have guessed). When printed, it glints in the light, drawing more attention than it would without the shine. It’s a subdued special effect ink that’s for the quiet, yet intriguing prints.

GET 3D WITH FN-INK PUFF

Make a print literally stand out from a shirt by using a puff additive. To get a little scientific, a puff ink is chemically made up of spherules that expand when exposed to heat, causing the puff effect. Make a design have a little bit of loft, or make it puff up like a balloon, the choice is up to you. FN-INK Puff is a unique way to make screen prints 3D.

To get a little scientific, a puff ink is chemically made up of spherules that expand when exposed to heat, causing the puff effect. Make a design have a little bit of loft, or make it puff up like a balloon, the choice is up to you. FN-INK Puff is a unique way to make screen prints 3D.

LOOSEN UP WITH FN-INK CURABLE REDUCER

Alright, this isn’t a special effect that a person could see, but it’s a special effect screen printers love for their production. A curable reducer lessens an ink’s thickness. Seems simple, maybe too simple… Have you ever dealt with a thick ink where no matter how much you stirred it, warmed it up, or played around with it, it was nearly impossible to print? (Looking at you, white, long-bodied plastisol inks.) Trying to print with super thick inks slows down production and tires you out much faster. It’s not ideal. But with a curable reducer, that all goes away. Mix it in and that ink becomes buttery smooth, flowing through screens with ease. It’s a special effect ink for screen printers’ production.

UNLEASH YOUR POTENTIAL FN-INK EXTENDER BASE

The real question is what can you NOT do with FN-INK Extender Base? It’s an ink that has multiple party tricks. Extender Base is essentially clear plastisol ink (it has no pigment). A screen printer can have a field day with clear ink. First, you can print the clear ink directly to a shirt and let the shirt’s color shine through. Secondly, you can mix it with colors to either create a vintage look or watermark effect. Lastly, you can use it to “extend” an ink: if you’re running low on an ink color but need to make it last through a job, you can add a bit of Extender Base to the ink to get more out of it. FN-INK Extender Base is a plastisol ink with many special effects.

RELATED: 3 REASONS WHY PLASTISOL INK IS THE BEST SCREEN PRINTING INK

GO TO NEW LENGTHS WITH FN-INK STRETCH

Plastisol ink naturally has some flexibility, but what happens when you need real flexibility? You know, garments made with spandex, nylon, or a poly-blend are usually meant to be more form-fitting. A print on a form-fitting garment may be stretched past what it can normally handle. To avoid the possibility of the print cracking and breaking, use an ink like FN-INK Stretch. Inks like FN-INK Stretch are formulated to provide extra pliability and durability when needed. It lets screen prints go to new lengths, literally.

A print on a form-fitting garment may be stretched past what it can normally handle. To avoid the possibility of the print cracking and breaking, use an ink like FN-INK Stretch. Inks like FN-INK Stretch are formulated to provide extra pliability and durability when needed. It lets screen prints go to new lengths, literally.

FIGHT DYE MIGRATION WITH FN-INK BARRIER BLACK

Speaking of poly-blend garments… Polyester shirts, leggings, yoga pants, etc. are prone to dye migration (when the dyes from the fabric seep into the ink of the print). What can you do to prevent that from happening? Use a blocker base like FN-INK Barrier Black. Blocker bases are chock-full of carbon, an ingredient that fights dye migration. So, print it as a base and it’ll stop those t-shirt dyes from messing with your print. It’s a special effect that gets rid of a potential headache for you. 😉

Be bold, unique, and original. Make t-shirt designs sparkle, glisten, and shimmer. Bring art to new levels, stretch to new lengths, and unleash your potential. With FN-INK’s eight specialty inks and additives, your screen prints are bound to make an impression. Add some to your arsenal today.

Bring art to new levels, stretch to new lengths, and unleash your potential. With FN-INK’s eight specialty inks and additives, your screen prints are bound to make an impression. Add some to your arsenal today.

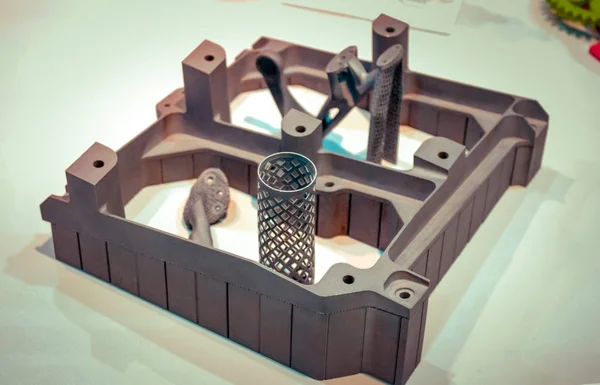

3D High Density Plastisol Ink – For a raised print effect achieved under a lower cure temperature. — Total Ink Solutions

by Total Ink Solutions®

Save Liquid error (product-badge line 32): Computation results in '-Infinity'%

$95.00

SKU PF3D-015-1G

White - $95.00 Lemon Yellow - $95.00 Chrome Yellow - $95.00 Golden Yellow - $95.00 Athletic Gold - $95.00 Burnt Orange - $95.00 Orange/Red - $95.00 Holiday Green - $95.00 Bright Green - $95.00 Kelly Green - $95.00 Dallas Green - $95. 00 Turquoise - $95.00 Ultramarine Blue - $95.00 Light Royal Blue - $95.00 Royal Blue - $95.00 Sky Blue - $95.00 Bright Blue - $95.00 Light Blue - $95.00 Dark Navy Blue - $95.00 Light Navy Blue - $95.00 Purple - $95.00 Light Purple - $95.00 Scarlet Red - $95.00 Flag Red - $95.00 Maroon - $95.00 Light Maroon - $95.00 Tan - $95.00 Light Brown - $95.00 Dark Brown - $95.00 Black - $95.00 Primrose Yellow - $95.00 Bright Gold - $95.00 Light Green - $95.00 Hunter Green - $95.00 Forest Green - $95.00 Columbia Blue - $95.00 Bear Navy Blue - $95.00 Mono Blue - $95.00 Cardinal Red - $95.

00 Turquoise - $95.00 Ultramarine Blue - $95.00 Light Royal Blue - $95.00 Royal Blue - $95.00 Sky Blue - $95.00 Bright Blue - $95.00 Light Blue - $95.00 Dark Navy Blue - $95.00 Light Navy Blue - $95.00 Purple - $95.00 Light Purple - $95.00 Scarlet Red - $95.00 Flag Red - $95.00 Maroon - $95.00 Light Maroon - $95.00 Tan - $95.00 Light Brown - $95.00 Dark Brown - $95.00 Black - $95.00 Primrose Yellow - $95.00 Bright Gold - $95.00 Light Green - $95.00 Hunter Green - $95.00 Forest Green - $95.00 Columbia Blue - $95.00 Bear Navy Blue - $95.00 Mono Blue - $95.00 Cardinal Red - $95. 00 Warm Red - $95.00 Bright Red - $95.00 Deep Red - $95.00 Dove Gray - $95.00 Heather Gray - $95.00 Russell Gray - $95.00 Dark Gray - $95.00 Beige - $95.00 Khaki - $95.00 Flesh - $95.00 Light Pink - $95.00 Fuchsia - $95.00 Aqua Blue - $95.00 Teal - $95.00 Vegas Gold - $95.00 Sienna Brown - $95.00 Pale Blue - $95.00 True Orange - $95.00 True Kelly Green - $95.00 Lime Green - $95.00 Reflex Blue - $95.00 Pink - $95.00

00 Warm Red - $95.00 Bright Red - $95.00 Deep Red - $95.00 Dove Gray - $95.00 Heather Gray - $95.00 Russell Gray - $95.00 Dark Gray - $95.00 Beige - $95.00 Khaki - $95.00 Flesh - $95.00 Light Pink - $95.00 Fuchsia - $95.00 Aqua Blue - $95.00 Teal - $95.00 Vegas Gold - $95.00 Sienna Brown - $95.00 Pale Blue - $95.00 True Orange - $95.00 True Kelly Green - $95.00 Lime Green - $95.00 Reflex Blue - $95.00 Pink - $95.00

White Lemon Yellow Chrome Yellow Golden Yellow Athletic Gold Burnt Orange Orange/Red Holiday Green Bright Green Kelly Green Dallas Green Turquoise Ultramarine Blue Light Royal Blue Royal Blue Sky Blue Bright Blue Light Blue Dark Navy Blue Light Navy Blue Purple Light Purple Scarlet Red Flag Red Maroon Light Maroon Tan Light Brown Dark Brown Black Primrose Yellow Bright Gold Light Green Hunter Green Forest Green Columbia Blue Bear Navy Blue Mono Blue Cardinal Red Warm Red Bright Red Deep Red Dove Gray Heather Gray Russell Gray Dark Gray Beige Khaki Flesh Light Pink Fuchsia Aqua Blue Teal Vegas Gold Sienna Brown Pale Blue True Orange True Kelly Green Lime Green Reflex Blue Pink Color

1 2 3 4 5 6 7 8 9 10+ Quantity

Quantity

Share this:Download PMS Color Guide

3D High Density Plastisol Ink Series

Total Ink Solutions® 3D Series is a phthalate free plastisol ink that has extremely vibrant colors, and a high-density formulation to create amazing 3D printing effects. This is the solution needed for all of your 3D effect printing.

This is the solution needed for all of your 3D effect printing.

Features:

- Vibrant colors.

- Creamy Inks.

- High-Density 3D Effect

Stock Use:

100% Cotton

50% Cotton / 50% Polyester

Details:

Please Allow 48 hours for this product to ship, since it is custom made at the time of order.

When direct printing over dark garments no under base is required. The thickness and density of the ink will prevent the dye migration from occurring. Make sure to use a capillary film as suggested below. This is crucial for the printing of the High Density Ink.

Stencil Instructions:

It should be made with thick capillary film between 200 and 1000 microns.

Screen Mesh:

Mesh between 15 to 86T monofilament polyester is recommended.

Curing Instructions:

Flash at 250°F (121°C) for 3 - 5 seconds and cure at 320°F (160°C) – 330°F (165°C). ** NOTE: Excessive Heat applied to 3D print will result in cracking of prints

Clean Up:

OPTIWASH 125 – Ink Remover

Storage Information:

Store at 65-90°F (18-32°C), avoiding direct sunlight. Best Use within one year of manufacturing date.

Best Use within one year of manufacturing date.

Compliance:

In Compliance with CPSIA (Consumer Product Safety Improvement Act) 2008 Section 101 Lead Content in substrates (<300 ppm lead) as Section 108 Phthalates (<.1 dbp dehp>

Features of silk screen printing

Modern silk screen printing only remotely resembles an ancient technique that was used to decorate walls and fabrics even before our era. Initially, all operations were carried out in a handicraft way, and natural silk nets were used to transfer images. Today, this function is performed by stencils, which are made of synthetic materials or metal. High-tech equipment is used to print bright, durable images on the surface of textile products. nine0003

Fig.1. Stages of printing on fabric by screen printing.

This technology makes it possible to decorate any fabric product with logos, inscriptions, graphic and artistic drawings.

In its purest form, screen printing is a direct printing of images, without the use of intermediate media.The basis for drawing a pattern can be a fabric that has not yet been cut or already prepared for sewing, as well as the product itself - a T-shirt, sweatshirt, sweatshirt, baseball cap. nine0010

The main tool of modern screen printing is a special printing plate, or stencil. This is a frame with metal, polyester or nylon fine mesh. Through it, the paint is transferred under pressure to the textile base. To obtain high quality printing, the mesh material is pulled onto the frame with maximum force. Thus, the coincidence of the contours of the colored elements of the image is achieved, and distortions of its linear dimensions are excluded.

During the manufacture of the stencil form, the mesh is impregnated with a photosensitive compound. Under the action of ultraviolet irradiation, it polymerizes, and from places that have not been exposed to exposure, it is subsequently easily washed out. When transferring the image to the base material, the ink is forced through these open areas of the stencil.

You can get a multi-color drawing with the help of several runs. During each of them, one color is applied. After completion of all operations, the product is placed in a tunnel oven for drying or polymerized in natural conditions. nine0003

Advantages of the method

The popularity of silk screen printing is due to a wide list of its advantages:

- The method is applicable to all kinds of fabrics, natural and synthetic.

- Drawing can be applied both on a flat and on a three-dimensional cylindrical base.

- Thick layers of ink are allowed, unlike other printing methods.

- To decorate the print, you can use decoration with rhinestones, foiling. nine0021

- Printing speed of screen printing images is generally fast.

- Colors of drawings remain saturated for a long time.

- Silk screen print stays crisp and bright even after multiple washes.

This method can be used for printing on any type of fabric, including those with a pronounced texture.

Types of silk screen printing

The following methods are available:

Fig.2. In addition to direct silk screen printing, there are methods such as 3D printing and foiling.

- Full color direct silkscreen.

The image is divided into CMYK (basic) and pantone colors. The textile base for printing can be dyed in any of the colors. This technology is used to obtain drawings of rich colors, with smooth tint transitions.- 3D printed.

Allows you to create embossed images with crisp edges. Such prints look more impressive than usual ones. Sometimes they are ordered for responsible promotions to attract additional attention of potential customers.- Foiling.

The method is used to create bright metallic coatings using foils of gold, silver or other colors.- Thermal rise.

Obtaining company logos and inscriptions with the effect of foaming (bloating).For this, not only paints are used, but also a special thermographic powder, as well as heating. nine0021

- Creating lighting effects.

Fluorescent inks and other components with similar properties are used for printing. In twilight and darkness, such images glow in different colors.- Thermal transfer.

This method is used to print images in hard to reach places and on textiles that cannot be positioned on the equipment. Silk screen printing in this case is used to transfer the pattern to an intermediate medium. nine0021

Fig.3. Silk screen printing helps to make on the fabric not only patterns with the effect of foaming and glow, but also images in places that are hard to reach for the equipment.Types and characteristics of fabric inks

According to the type of binder, inks for silk screen printing are divided into several types. Each of them has its own distinctive features.

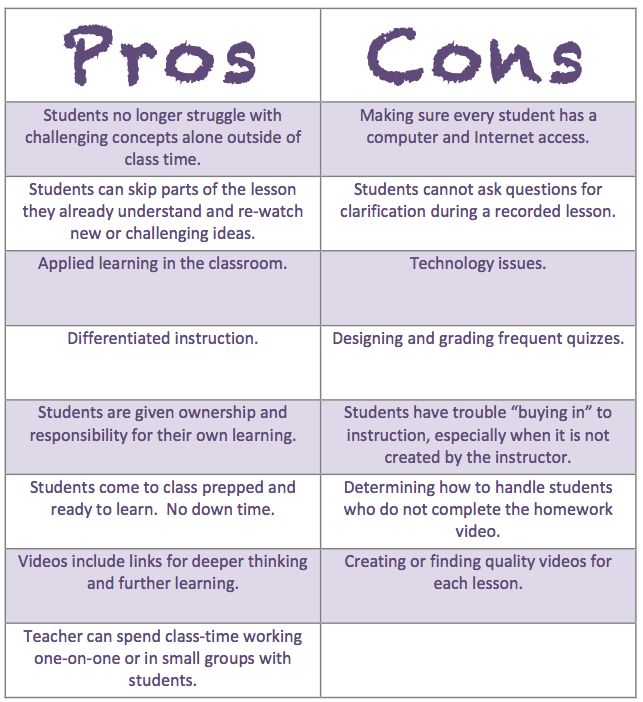

Basic properties, pros and cons of inks for printing on fabric by silkscreen:

Paint type Ultraviolet Solvent Aquatic Plastisol Toxicity Medium High Low Low Flexibility Low Low/medium nine0103 MediumHigh Solvent evaporation conditions UV treatment Natural or hot air drying Solvent evaporation at 150°C and above Polymerization at 130-170°C Pros Creating glossy surfaces. nine0103 Large selection of materials that can serve as the basis for printingFast drying

Print softness. Dry cleaning and ironing allowed. Etching series availableFast tissue penetration. Good color reproduction. High quality raster printing Cons Translucent structure. High price Long drying prints, bad smell Raster print quality is not good enough Ironing according to pattern is not recommended

Fig.4. Various screen printing inks can glow in the dark, have toxic emissions when applied, and are water-based.Fluorescent, phosphorescent, reflective, metallized paints are used to obtain special effects. Additives are also used for thermal lifting (Puff), elasticity (Stretch), gloss (Glitter), obtaining a 3D effect (Hi-Square). nine0003

Silk-screen printing has a soft texture. It stretches easily with the fabric while maintaining integrity.

It does not wash off, does not peel off and does not fade over time.

Prices for silk screen printing depend on the characteristics of the material, the type of image, the number of colors, the availability of special effects. When ordering a large batch of T-shirts in bulk, including those with prints, there is an opportunity to save on the cost of one item.

MDMprint: the art of surprise, or 3D effects in printing

Natalia Shlykova • Visiting the Printing House • 2019.05.20

MGI JETvarnish 3DS & iFoil S by Konica Minolta at MDMprintMDMprint has mastered almost every conceivable way of applying images to printed materials over the nine years of its work in the Moscow printing market, becoming a universal business partner for its numerous clients, not only among professional customers, but also private consumers of printing services. In addition to the technically advanced production, which can hardly be called only digital, MDMprint has a network of copy centers in Moscow, where anyone can order printed products of various levels of complexity, using an almost unlimited list of services of this production company - from the production of business printing and multi-page corporate publications to interior design.

printing and branded souvenirs, including those made on textiles. A few months ago, the plant's capabilities were further enhanced with the installation of a new machine, the MGI JETvarnish 3DS & iFoil S from Konica Minolta. The uniqueness of this digital equipment lies in the ability to perform selective foiling and varnishing, creating unique digital and offset prints with tactile 3D effects. The appearance of this device in many ways changed the approach of the printing house to doing business, views on printing in general and created the prerequisites for the formation of a completely new market for printing services. nine0003

Augmented Reality

MDMprint General Director Ruslan Galifanov notes: “Due to the development and increasing spread of digital equipment, the threshold for entering the digital printing market today is not too high, which leads to the emergence of a large number of players who are not always competent in matters of economics and production technology.

In turn, the actions of such market participants have a negative impact on the formation of pricing and attitudes towards the printing product. Therefore, our task is to provide the market with a unique selling proposition that goes far beyond the usual color printing. Introduce a new component to the list of our capabilities that would distinguish us and provide a competitive advantage. Konica Minolta MGI JETvarnish 3DS & iFoil S finishing equipment turned out to be such a solution for us, which made it possible to produce truly attractive, bright, textured products.” nine0003

The MGI JETvarnish 3DS & iFoil S digital machine is equipped with variable height single pass spot varnish and foil over varnish units. Such features of the equipment allow you to create three-dimensional areas of the image (letters, logos, background texture, etc.) both with the help of convex varnish and in combination with foil, additionally highlighting the desired elements of decor or text. At the same time, finishing operations are performed digitally, excluding the stage of making clichés, as in traditional embossing, or screen forms.

nine0003

“Today we are seeing a clear trend that many catalogs and magazines are moving to digital printing. Some publications have electronic versions. However, despite this, there remains a need for tactile perception of the product, for the ability to feel it physically, to flip through the pages, to run a finger over the decor elements. It is obvious that it will not be possible to do this virtually. Even the results we get with MGI JETvarnish 3DS & iFoil S cannot be fully conveyed through photographs to demonstrate our capabilities through electronic means. To offer such services, you need to see them with your own eyes. Understanding this, we had to significantly revise our own approaches to business organization,” notes Ruslan. nine0003

Positive changes

Even before the advent of digital finishing equipment, MDMprint has long mastered the traditional ways of decorating printed products - foil stamping on a crucible press, screen varnishing and others. However, according to Ruslan, the product that is obtained on the MGI Jetvarnish 3DS & iFoil S is a completely different product, expensive and presentable looking.

“There is interest in this type of product on the market, and it “catches” even those customers who, it would seem, have been in the printing industry for a long time and know almost everything about its capabilities,” Ruslan notes. “Many people are surprised that such spectacular effects can be done digitally, quickly and with impressive results. But this result is better to see once than to try to describe it for a long time. Therefore, we have developed a series of product samples that fully reflect the capabilities of our new digital equipment, collected them in a demo folder, which we now proudly demonstrate to our customers. To be honest, we have not practiced this way of interacting with customers before. Until recently, we worked in the incoming call mode. In other words, they processed those orders that were received by managers. Today, a lot has changed in our daily work. We are building an active sales department, when managers themselves initiate a dialogue with customers and offer to get acquainted with our capabilities.

One of the tools in communication with customers is just a demo folder with product samples made on MGI. However, we also understand that, in addition to technical tools in the form of MGI Jetvarnish 3DS & iFoil S, we will have to seriously deal with the design of the printing that we are going to produce on this equipment. Therefore, another step in promoting our new services was the strengthening of the design department. Today we employ 8 professional designers who understand not only graphic design, but also can technically competently prepare layouts taking into account the requirements of our equipment.” nine0003

Printing as an art

Ruslan notes that, having such equipment as MGI Jetvarnish 3DS & iFoil S, we have to form a market for these services ourselves: “Today we have the opportunity to produce unique product samples and position printing as an art. We believe that only by creating the value of printing for customers can we effectively develop in this market. We do not have the task of selling just a printed sheet.

We want to produce a printing product that will help our clients solve their business problems, and therefore be an effective tool for attracting attention, and most importantly, keeping interest. There is no doubt that sales competition is growing, so all available tools should be used as much as possible. And the more interesting this tool, the more likely it is to attract customers. This applies both to our new equipment, which acts as a tool to attract customers to our printing house, and printed products with visual and tactile 3D effects that create a different dimension of printing, which, in turn, is a tool to attract customers already for our customers. Today we aim to create a high-quality printing product and teach the market that this is how it should be. The main thing is that we love what we do, and this moves us forward.” nine0003

Companies

MDMprintKonica Minolta

People

Ruslan Galifanov

Products

JETvarnish 3DS

Share

Related topics

01/06/2023 / Traditional offset

The largest printing holding is being created in Russia

29.

Learn more