Bugatti 3d printed brake caliper

World premiere: brake caliper from 3-D printer

Molsheim/Wolfsburg

January 22, 2018

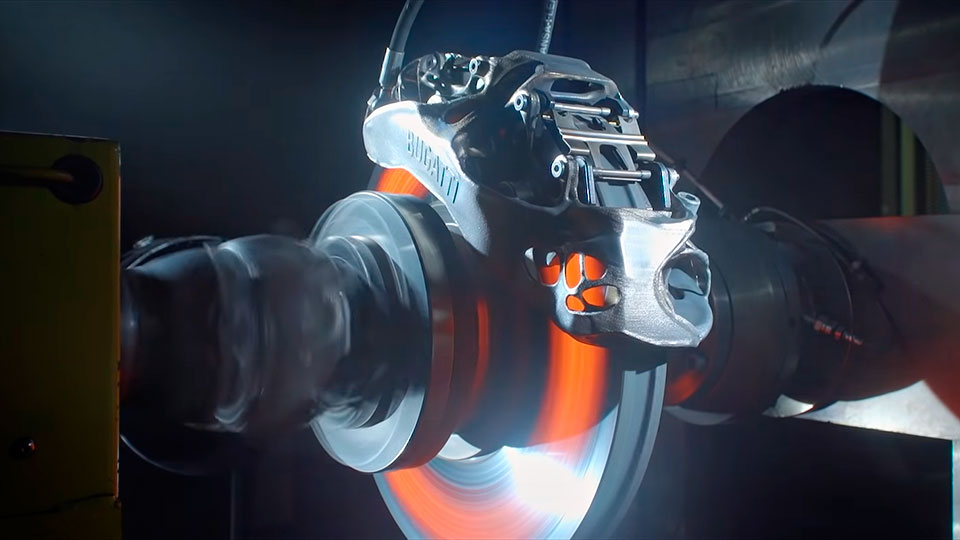

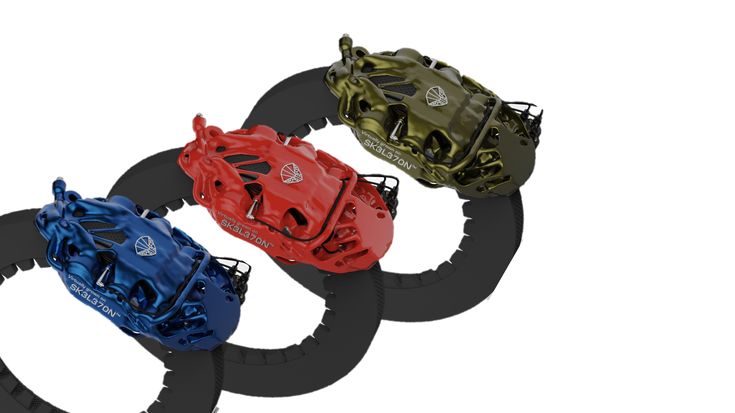

Developed by Bugatti: This eight-piston monobloc brake caliper is the world’s first brake caliper to be produced by 3-D printer and also the largest titanium functional component produced by additive manufacturing. © 2018 Bugatti Automobiles S.A.S.

New eight-piston monobloc brake caliper

- New eight-piston monobloc brake caliper is the world’s first brake caliper to be produced by 3-D printer

- Also largest brake caliper in the automotive industry as a whole

- Bugatti is the first series manufacturer to use titanium, a material calling for extremely complex and challenging processing

- Worldwide innovation is the result of cooperation between the Bugatti Development Department and Laser Zentrum Nord in Hamburg

- French super sports car brand reaches new milestone in development of 3-D printing as a future-oriented technology

- As the technical development laboratory of the Volkswagen Group, Bugatti leads the way in 3-D printing and is a worldwide innovation driver

- 3-D printed components to be trialled for series production this year

- Experience gained to be used in research and development projects of the Volkswagen Group and its brands

This brake caliper is the largest titanium functional component produced by 3-D printing in the world – developed by Bugatti. The photo shows the caliper together with pistons and pads. © 2018 Bugatti Automobiles S.A.S.

Frank Götzke, Head of New Technologies in the Technical Development Department of Bugatti Automobiles S.A.S. © 2018 Bugatti Automobiles S.A.S.

Prof. Dr.-Ing. Claus Emmelmann, formerly Managing Director of Laser Zentrum Nord and now, after its incorporation in the Fraunhofer research organization, Head of the Fraunhofer IAPT. © Deutscher Zukunftspreis 2015

Bugatti develops world’s largest titanium functional component:

produced by additive manufacturing

With its Veyron and Chiron super sports cars, Bugatti has established a position as a pioneer for new technical developments and innovations in the extreme performance sector of the automotive industry over the past few decades and has set breathtaking performance data and records. Now the Development Department of the French luxury brand has achieved a new coup. For the first time, the Bugatti developers have succeeded in designing a brake caliper that can be produced by 3-D printing. But that is by no means all. While the main material used for the additive production of vehicle components to date has been aluminium, the new brake caliper is made from titanium. This is therefore the world’s largest functional component produced from titanium using 3-D printing processes. This new milestone in the development of 3-D printing was reached in cooperation with Laser Zentrum Nord of Hamburg, an institute that has formed part of the Fraunhofer research organization since the beginning of the year. With this world debut, Bugatti has underlined its lighthouse function for 3-D printing within the Volkswagen Group and its role as an innovation driver in the international automotive industry. Vehicle trials for the use of the 3-D titanium brake caliper in series production are to start in the first half of the year.

But that is by no means all. While the main material used for the additive production of vehicle components to date has been aluminium, the new brake caliper is made from titanium. This is therefore the world’s largest functional component produced from titanium using 3-D printing processes. This new milestone in the development of 3-D printing was reached in cooperation with Laser Zentrum Nord of Hamburg, an institute that has formed part of the Fraunhofer research organization since the beginning of the year. With this world debut, Bugatti has underlined its lighthouse function for 3-D printing within the Volkswagen Group and its role as an innovation driver in the international automotive industry. Vehicle trials for the use of the 3-D titanium brake caliper in series production are to start in the first half of the year.

“Vehicle development is a never-ending process. This is particularly true at Bugatti,” says Frank Götzke, Head of New Technologies in the Technical Development Department of Bugatti Automobiles S. A.S. “In our continuing development efforts, we are always considering how new materials and processes can be used to make our current model even better and how future vehicles of our brand could be designed.”

A.S. “In our continuing development efforts, we are always considering how new materials and processes can be used to make our current model even better and how future vehicles of our brand could be designed.”

“As our performance data are often at the physical limits, we are especially demanding,” adds the 48-year-old machine tool and production technician, who holds a degree in engineering. “This is why Bugatti always goes at least one step further than other manufacturers in the development of technical solutions.”

Götzke has worked for the Volkswagen group for more than 22 years. He joined Bugatti in 2001 and played a key role in the development of the Veyron as Head of Chassis Development and in the development of the Chiron in his current position.

Bugatti currently uses the most powerful brakes in the world on the new Chiron. The brake calipers were an entirely new development. They are forged from a block of high-strength aluminium alloy. With eight titanium pistons on each of the front calipers and six on each of the rear units, these are also the largest brake calipers currently installed on a production vehicle. The brake calipers of the Chiron are produced using bionic principles on the basis of a natural model. The new architecture combines minimum weight with maximum stiffness. The inspiration for the design and mode of operation of the brakes was taken from motorsports.

The brake calipers of the Chiron are produced using bionic principles on the basis of a natural model. The new architecture combines minimum weight with maximum stiffness. The inspiration for the design and mode of operation of the brakes was taken from motorsports.

With the newly developed titanium brake caliper from the 3-D printer, Bugatti is now going one step further and breaking new ground. This particular titanium alloy, with the scientific designation of Ti6AI4V, is mainly used in the aerospace industry, for example for highly stressed undercarriage and wing components or in aircraft and rocket engines. The material offers considerably higher performance than aluminium. For example, even as a 3-D printed component, it has a tensile strength of 1,250 N/mm2. This means that a force of slightly more than 125 kg be applied to a square millimetre of this titanium alloy without the material rupturing. The new titanium brake caliper, which is 41 cm long, 21 cm wide and 13. 6 cm high, weighs only 2.9 kg. In comparison with the aluminium component currently used, which weighs 4.9 kg, Bugatti could therefore reduce the weight of the brake caliper by about 40% at the same time as ensuring even higher strength by using the new part.

6 cm high, weighs only 2.9 kg. In comparison with the aluminium component currently used, which weighs 4.9 kg, Bugatti could therefore reduce the weight of the brake caliper by about 40% at the same time as ensuring even higher strength by using the new part.

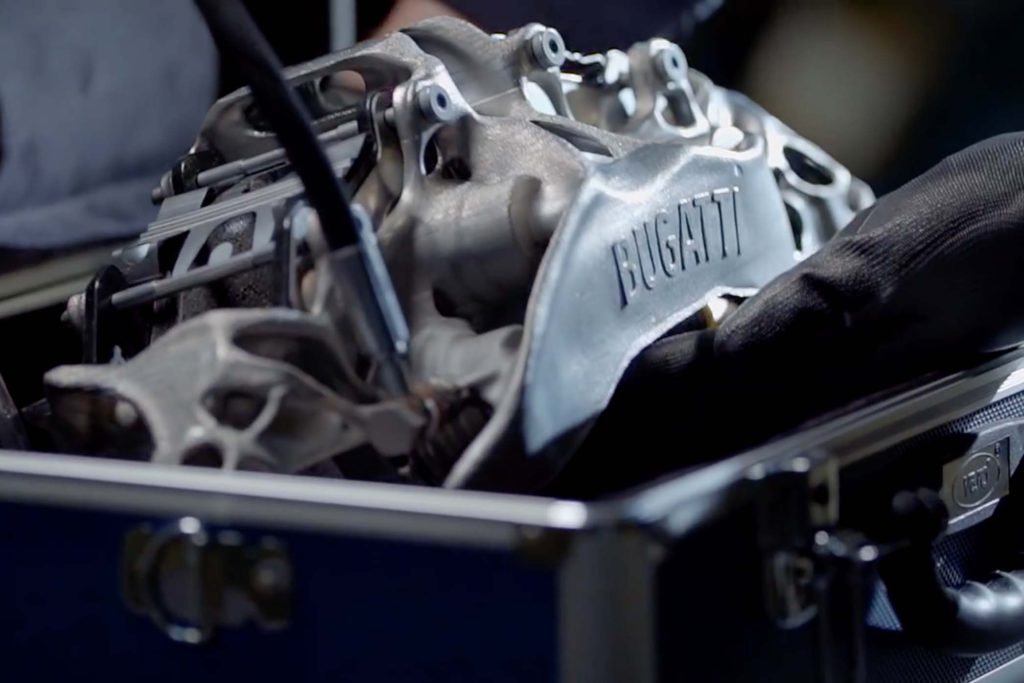

To date, this approach was not feasible because it is extremely difficult or even impossible to mill or forge components from a titanium block as is normal practice with aluminium due to the extremely high strength of the material. This problem has now been solved using an extremely high-performance 3-D printer, which also opens up the possibility of generating even more complex structures which are significantly stiffer and stronger than would be possible with any conventional production process. Frank Götzke found the selective laser melting units required in Hamburg, at Laser Zentrum Nord.

“Laser Zentrum Nord is one of many scientific institutes with which we have developed very good cooperation over the years,” Götzke explains. “Thanks to the large number of projects completed, mainly for the aviation industry, the institute has comprehensive know-how especially in the field of titanium processing and offers mature technology.” Over the past few years, the Hamburg production scientists have received a large number of highly regarded national and international innovation awards for their work in industry.

“Thanks to the large number of projects completed, mainly for the aviation industry, the institute has comprehensive know-how especially in the field of titanium processing and offers mature technology.” Over the past few years, the Hamburg production scientists have received a large number of highly regarded national and international innovation awards for their work in industry.

“Cooperation with Bugatti is a key lighthouse project for us,” says Prof. Dr.-Ing. Claus Emmelmann. Prof. Emmelmann was formerly Managing Director of Laser Zentrum Nord GmbH and has been Head of the Fraunhofer Institute for Additive Production Technologies (Fraunhofer IAPT) since Laser Zentrum Nord was incorporated in the Fraunhofer research organization under this name at the beginning of the year. He also heads the Institute of Laser and System Technologies (iLAS) of Hamburg University of Technology. Emmelmann takes pride in the cooperation between his institute and Bugatti. “We were thrilled to be contacted by Bugatti. I do not know any other carmaker which makes such extreme demands of its products. We were pleased to face up to this challenge.”

I do not know any other carmaker which makes such extreme demands of its products. We were pleased to face up to this challenge.”

The development time for the 3-D-printed titanium brake caliper was very short. From the first idea to the first printed component, it only took about three months. The basic concept, the strength and stiffness simulations and calculations and the design drawings were sent to Laser Zentrum Nord by Bugatti as a complete data package. The institute then carried out process simulation, the design of the supporting structures, actual printing and the treatment of the component. Bugatti was responsible for finishing.

The special 3-D printer at Laser Zentrum Nord, which was the largest printer in the world suitable for titanium at the start of the project, is equipped with four 400-watt lasers.

It takes a total of 45 hours to print a brake caliper. During this time, titanium powder is deposited layer by layer. With each layer, the four lasers melt the titanium powder into the shape defined for the brake caliper. The material cools immediately and the brake caliper take shape. The total number of layers required is 2,213. Following the completion of the final layer, the remaining titanium powder which had not melted is removed from the chamber, cleaned and preserved for reuse in a closed loop. What remains in the chamber is a brake caliper complete with supporting structure which maintains its shape until it has received stabilizing heat treatment and reached its final strength.

The material cools immediately and the brake caliper take shape. The total number of layers required is 2,213. Following the completion of the final layer, the remaining titanium powder which had not melted is removed from the chamber, cleaned and preserved for reuse in a closed loop. What remains in the chamber is a brake caliper complete with supporting structure which maintains its shape until it has received stabilizing heat treatment and reached its final strength.

Heat treatment is carried out in a furnace where the brake caliper is exposed to an initial temperature of 700°C, falling to 100°C in the course of the process, in order to eliminate residual stress and to ensure dimensional stability. Finally, the supporting structures are removed and the component is separated from the tray. In the next production stage, the surface is smoothed in a combined mechanical, physical and chemical process which drastically improves its fatigue strength, i.e. the long-term durability of the component in later vehicle operation. Finally, the contours of functional surfaces, such as the piston contact surfaces or threads, are machined in a five-axis milling machine which takes another 11 hours to complete its work.

Finally, the contours of functional surfaces, such as the piston contact surfaces or threads, are machined in a five-axis milling machine which takes another 11 hours to complete its work.

The result is a delicately shaped component with wall thicknesses between a minimum of only one millimetre and a maximum of four millimetres.

“It was a very moving moment for the team when we held our first titanium brake caliper from the 3-D printer in our hands,” Frank Götzke remembers. “In terms of volume, this is the largest functional component produced from titanium by additive manufacturing methods. Everyone who looks at the part is surprised at how light it is – despite its large size. Technically, this is an extremely impressive brake caliper, and it also looks great.”

The first trials for use in production vehicles are due to be held in the first half of the year; the time schedule is still to be finalized. At that stage, the engineer promises that it will be possible to considerably shorten production times, especially for machining.

Götzke and his team are presenting the results of their work to the Group and its brands. “In 3-D printing development, Bugatti is the leader in the Volkswagen group,” Götzke emphasizes. “Everyone can and should benefit from our projects. This is also part of Bugatti’s role as the Group laboratory for high-tech applications.”

The 3-D-printed titanium brake caliper is only one example of Bugatti’s current research and development work. “We have not only developed the world’s largest titanium component produced by additive manufacturing but also the longest aluminium component to date made by 3-D printing,” Götzke explains, proudly taking a 63-centimetre-long lightweight aluminium windscreen wiper board out of the cabinet. The board only weighs 0.4 kg, half the weight of a conventional die-cast lightweight aluminium board, without any reduction in rigidity. But that is another story.

Read More

Contact

FOR MEDIA ENQUIRIES:

Nicole Auger

Head of Communications

E-Mail: [email protected]

WATCH: Bugatti prepares 3D printed brake caliper for series production

0Shares

In January 2018 performance car brand Bugatti, in partnership with SLM Solutions, unveiled a 3D printed brake caliper. Now, in a new video clip from parent company Volkswagen, the titanium component has been put to the test demonstrating how the company is gearing up towards 3D printing in series production.

Now, in a new video clip from parent company Volkswagen, the titanium component has been put to the test demonstrating how the company is gearing up towards 3D printing in series production.

Large but light

A first for the automotive industry, Bugatti’s brake caliper is tipped to be “the world’s largest 3D printed titanium pressure functional component ever produced.” It is made on an SLM 500 3D printer and takes, on average, 45 hours to complete. This 45 hours equates to 2,213 layers, and 2.9 kg of titanium.

According to Frank Götzke, Head of New Technologies in Technical Development at Bugatti Automobiles S.A.S., “Everyone who looks at the part is surprised at how light it is – despite its large size. Technically, this is an extremely impressive brake caliper, and it also looks great.”

Bugatti’s “world first” SLM 3D printed brake caliper. Photo via Bugatti Automobiles S.A.S.To braking point

In the new clip from Volkswagen the Bugatti caliper is put through its paces “on one of the most powerful brake test benches on the market. ”

”

Placed on a disc repeatedly accelerated to speeds of up to 400 km/h (249 mph) the caliper is proven to withstand temperatures exceeding 1857 °F (1014 °C) – nearing the max speed of the latest Bugatti Chiron (420 km/h, 261 mph).

The company is now seeking to increase the speed of production for these parts while maintaining overall quality.

Next generation automobile production

Volkswagen is investing heavily in the development of 3D printing technologies for its future vehicle production. In 2018, the company won the 3D Printing Industry Award for Automotive/Aerospace Application of the Year through introducing FFF to tooling. Later in the year it became a founding partner of HP Metal Jet 3D printer development. And most recent in Wolfsburg, the automotive manufacturing capital of Germany, the company opened a cutting edge metal additive manufacturing facility.

Eventually, Volkswagen hopes to be able to introduce its 3D printed brake calipers into the series production of next generation Chiron or Divo cars.

Götzke concludes, “In 3D printing development, Bugatti is the leader in the Volkswagen group.”

Nominate the Bugatti 3D printed brake caliper for Automotive Application of the Year in the 2019 3D Printing Industry Awards now..

For all the latest automotive additive manufacturing updates subscribe to our newsletter (it’s free!), follow us on Twitter and like us on Facebook.

Looking for a fresh start in the new year? Visit 3D Printing Jobs to get a head start.

Featured image shows the Bugatti 3D printed brake caliper put to the test. Image via Volkswagen AG

Tags Brake caliper Bugatti Bugatti Chiron Chiron Divo Frank Götzke SLM Solutions Volkswagen VW

Beau Jackson

Bugatti Automobiles successfully tested a brake caliper printed on a 3D printer They print small parts and massive houses, they print tools for craftsmen and automotive spare parts.

The other day, information appeared on the network that Bugatti Automobiles created a brake caliper (caliper) by 3D printing.

The other day, information appeared on the network that Bugatti Automobiles created a brake caliper (caliper) by 3D printing. Of course, this part is made of metal, not plastic, but still, the method of its creation belongs to the "printed". After the element was ready, it was tested, and the caliper passed all the checks, including heating during braking up to a thousand degrees.

The advantage of 3D printing is that it allows you to create complex parts that require little or no post-processing. In addition, it is possible to print composite parts in a single piece, which cannot be done by any other method. The structure of a part can be arbitrarily complex - advanced 3D printers can handle any task.

It should be noted that 3D printing allows you to create analogues of conventional parts, but with less weight. This is achieved, in particular, by changing the overall structure of the element. As for the caliper, it is standard, it was decided not to change its geometric characteristics.

The time to create this part leaves much to be desired, as the process took 45 hours (unfortunately, the company did not say how long it takes to create a standard part). The brake element was created from metal powder and sintered with a 400 watt laser beam. In total, the part consists of 2313 layers of titanium powder.

The tests were carried out not in the field, but on the stand. The brake disc was spun up to a speed corresponding to a speed of 400 km/h under normal conditions. Then the brake was started, the disk stopped. During the second test, the disk warmed up to 1.1 thousand degrees. The temperature was so high that the brake pads caught fire. The company recognized the tests as successful.

If further testing goes well, Bugatti Automobiles will use the new manufacturing process to build all Chiron hypercar calipers.

It should be noted that not only car parts are printed. For example, in the UK they plan to print spare parts for train interiors. In a normal situation, these parts are damaged quite often, and railroad workers are unlikely to carry a large supply with them. In addition, the problem is trains that have been in operation for a long time, and the mass production of spare parts for which has been stopped.

In a normal situation, these parts are damaged quite often, and railroad workers are unlikely to carry a large supply with them. In addition, the problem is trains that have been in operation for a long time, and the mass production of spare parts for which has been stopped.

As a result, railway workers have to ask manufacturers to accept piece orders, which is quite expensive. And if we are not talking about a cosmetic, but a major overhaul, then its cost increases significantly compared to the price of a major overhaul of a conventional train, for which there are spare parts.

Source: railway-technology

Initially, railway workers will create the most breakable elements - plastic handles, various kinds of sheathing elements, plastic covers, armrests. They often break even in new cars, not to mention those that have served several terms.

3D printing is nothing new for vehicle designers. A few years ago, Boeing applied for a patent in the field of 3D printing. The new method involves the creation of spare parts on special printers. If something breaks, then the failed part can be printed in just a few minutes. There are thousands of elements in an airplane, and it is quite difficult to create a stock of parts, and most importantly, it is costly. After all, some spare parts may not be useful, but lie in the warehouse all the time. Boeing is going to get rid of the need to store more than 30,000 parts in stock, using this principle instead.

The new method involves the creation of spare parts on special printers. If something breaks, then the failed part can be printed in just a few minutes. There are thousands of elements in an airplane, and it is quite difficult to create a stock of parts, and most importantly, it is costly. After all, some spare parts may not be useful, but lie in the warehouse all the time. Boeing is going to get rid of the need to store more than 30,000 parts in stock, using this principle instead.

Boeing is already replacing some broken plastic parts in its aircraft with printed ones. But this is just the beginning, we are not talking about 30 thousand yet, the company is testing the replacement technology with only a few hundred spare parts. Most likely in the near future, many industries and transport will use 3D printing of various types.

The first caliper made on a 3D printer

Implementation stories

Automotive industry

Author: Yakov Bondarev

Author: Yakov Bondarev

There is a growing interest in 3D printing in the automotive world, with manufacturers using additive technologies for both prototyping and final product manufacturing. Another company that has made a breakthrough with 3D printing is Bugatti, maker of the Veyron and Chiron supercars. Its new eight-piston monobloc brake caliper is remarkable for many reasons: it is the first to be 3D printed and the largest in automotive history. It is also the largest titanium component to be produced by additive manufacturing.

Another company that has made a breakthrough with 3D printing is Bugatti, maker of the Veyron and Chiron supercars. Its new eight-piston monobloc brake caliper is remarkable for many reasons: it is the first to be 3D printed and the largest in automotive history. It is also the largest titanium component to be produced by additive manufacturing.

The caliper was developed in collaboration with Laser Zentrum Nord, part of the Fraunhofer research organization. It is expected that testing of vehicles with the introduction of the part into mass production will begin in the first half of this year.

Bugatti brake caliper is the first 3D printed and largest in automotive history

“Vehicle development is a never-ending process. And this is especially true in the case of Bugatti,” says Frank Götzke, Head of New Technology at Bugatti Automobiles S.A.S. “During the continuous development process, we are constantly thinking about how new materials and methods can improve the current model and how the next cars of our brand could be designed. Our technical specifications are often close to the limit of physical capabilities, so we are especially demanding. That is why Bugatti is always at least one step ahead of other manufacturers when it comes to technical solutions.”

Our technical specifications are often close to the limit of physical capabilities, so we are especially demanding. That is why Bugatti is always at least one step ahead of other manufacturers when it comes to technical solutions.”

When 3D printed with titanium, the caliper is about 40% lighter and at the same time stronger than the aluminum part.

Bugatti uses the most powerful brakes in the world in the new Chiron hypercar. Its brake calipers are made from high strength aluminum alloy. These are the largest calipers installed on a production car - eight titanium pistons on each of the front calipers and six on the rear. The idea of such a constructive solution is borrowed from motorsport and combines minimum weight with maximum rigidity.

But that's not all the improvements. The new brake caliper was 3D printed from a titanium alloy commonly used in the aerospace industry, aircraft or rocket engines, heavy duty landing gear and wing components. According to its characteristics, the alloy is much better than aluminum - its tensile strength is 1,250 N/mm2. This means that a square millimeter of material can withstand a force of just over 125kg without breaking. It is also very light: the caliper is 41 cm long, 21 cm high and 13.6 cm and weighs only 2.9kg. For comparison, the weight of an aluminum part is 4.9 kg, that is, with titanium 3D printing, the caliper becomes about 40% lighter and at the same time stronger.

According to its characteristics, the alloy is much better than aluminum - its tensile strength is 1,250 N/mm2. This means that a square millimeter of material can withstand a force of just over 125kg without breaking. It is also very light: the caliper is 41 cm long, 21 cm high and 13.6 cm and weighs only 2.9kg. For comparison, the weight of an aluminum part is 4.9 kg, that is, with titanium 3D printing, the caliper becomes about 40% lighter and at the same time stronger.

Previously, titanium could not be used as a material for the manufacture of calipers, because due to its high strength, it is extremely difficult to mill or stamp a titanium blank. However, 3D printing is a completely different story. The technology not only allows the creation of parts from titanium, but also provides higher strength, stiffness and more complex geometries.

Bugatti produced the caliper at the Laser Zentrum Nord on a high-performance SLM machine, which at the time the project was launched was the largest titanium 3D printer in the world.

“Laser Zentrum Nord is one of the many research institutes with which we have been successfully cooperating for many years,” said Götzke. “With a large number of projects carried out mainly for the aviation industry, the institute has comprehensive know-how, especially in the field of titanium processing, and offers reliable technologies.”

Over the past few years, the scientists at Laser Zentrum Nord have won several prestigious national and international innovation awards.

Dr. Eng. Prof. Claus Emmelmann was previously Managing Director of Laser Zentrum Nord GmbH and chaired the Fraunhofer Institute for Additive Manufacturing Technology (Fraunhofer IAPT) after Laser Zentrum Nord became part of the Fraunhofer research organization under that name earlier in the year. He also heads the Institute for Laser and System Technology (iLAS) of the Hamburg University of Technology.

He also heads the Institute for Laser and System Technology (iLAS) of the Hamburg University of Technology.

“The collaboration with Bugatti is a key project and a milestone for us,” says Emmelmann. “We were very excited when Bugatti contacted us. I don't know of any other automaker that makes such high demands on their product. We were glad for the opportunity."

The development of the caliper took a little time - only about three months. Bugatti sent the basic concept, strength and stiffness modeling results, as well as calculations and analysis drawings to Laser Zentrum Nord in a single package. Laser Zentrum Nord then carried out process modeling, supporting structure design and 3D printing. Bugatti finished the part.

Hypercar Bugatti Chiron is equipped with the most powerful brakes in the world

The 3D printer is equipped with four lasers and it took 45 hours to print the brake caliper. The total number of printed layers required to make the part is 2.