Best resin 3d printer slicer

The Top Slicers for Resin 3D Printers in 2022

Published on August 11, 2022 by Clemens M.

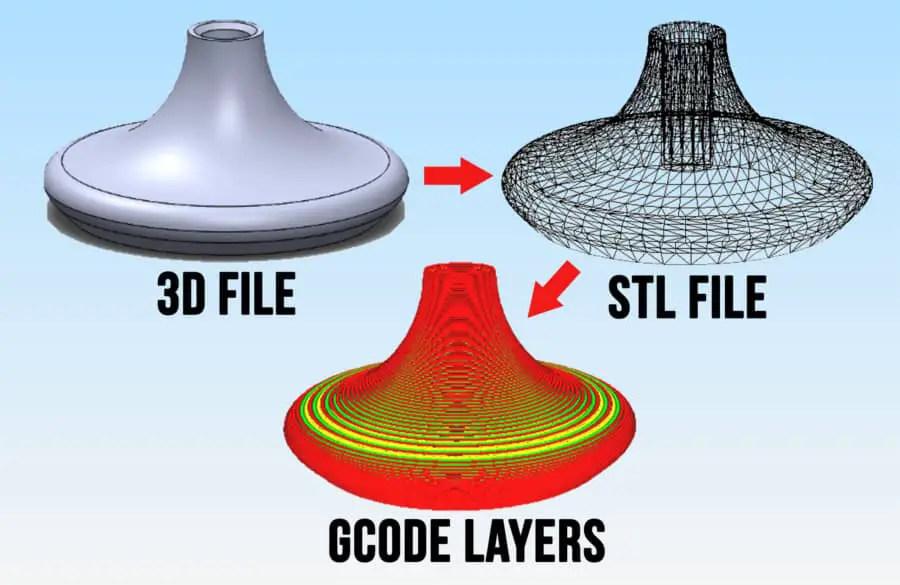

Slicers, or slicing software, are an essential tool in 3D printing. This software is able to slice a 3D model and then transmit to the printer which layer it will need to create and deposit. There are currently multiple solutions on the market that offer a certain number of functionalities and meet different requirements. These include slicers dedicated to 3D resin printing, i.e. photopolymerization (SLA/DLP/LCD), but also the material jetting process. The software allows, for example, to define the required printing supports and the optimal parameters. This makes them more suitable for the constraints of 3D resin printing. But what solutions are currently available on the market? To give you an overview, we have listed the most important slicers on the market for resin 3D printers, both proprietary and open software, in alphabetical order.

BuildBee, an Accessible and Easy-to-Use Slicer for Resin 3D PrintingBuildBee has developed a slicer for cloud-based SLA and DLP processes. It was designed to be as accessible and easy to use as possible and provides a structured workflow to avoid printing errors. It is compatible with a wide range of machines including solutions from Flashforge, Elegoo, Anycubic or Creality. The slicer is based on an artificial intelligence model and also offers a feature to repair 3D models. You can also use it with FDM machines. Be aware that while a free trial is offered, the subscription costs $6 per month.

Launched in 2017 by the Chinese company CBD-Tech, ChiTuBox quickly became a popular choice for many resin 3D printing enthusiasts, due to its easy-to-use interface. efficiency and compatibility with a large range of SLA printers on the market. Considered by many users to be one of the best slicers for resin 3D printers, Chitubox is a software that includes everything you need to make your next resin 3D printing task a success. Although the software was entirely free in the past and its free version includes its most important tools, CBD-Tech also released a pro version, that includes additional extras that allow more detailed adjustments. The premium version is available for $169 per year.

Although the software was entirely free in the past and its free version includes its most important tools, CBD-Tech also released a pro version, that includes additional extras that allow more detailed adjustments. The premium version is available for $169 per year.

Formware is a powerful slicer software that offers an abundance of helpful features for any kind of resin printing task. The premium software includes, besides all the standard SLA slicing tools, a variety of unique extras for more demanding tasks, such as the creation of jewelry or dental implants. While many resin slicer programs are available as a free version, Formware merely offers a 30-day trial, after which users can decide between buying a version for a single user for $154.95 (€ 129.95), or, if necessary, a commercial license of the software for $359.95 (€299.95). Altogether, Formware is a very good choice, especially for professionals who are in need of a premium slicer that provides them with a full package of tools.

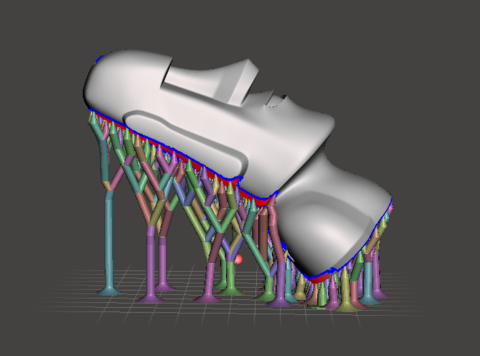

Not a tropical fruit, but a slicer for resin 3D printing, Lychee Slicer – developed by the manufacturer Mango 3D – is already in its 3rd generation. Although this slicer software is only compatible with a list of 3D printers, the list is constantly being expanded by the manufacturer. Lychee Slicer is a slicer software that allows the creation of support structures for even the most demanding 3D models. This is possible thanks to its powerful and intelligent support algorithm. In addition to that, Lychee Slicer also has a special focus on the pixel pipeline, where work is pixel- rather than vector-based, which means that every resin layer is guaranteed to be cured during the printing process.

NanoDLP, a Web Platform and Slicer for Resin 3D PrintersAnother slicing software we would like to introduce to you is NanoDLP. However, this is not just a slicer, but a program that also includes a full web platform enabling users to conveniently monitor and, if needed, control 3D printing remotely. NanoDLP is a slicing software that is compatible with the majority of resin 3D printers available on the market, but if you want to make use of its custom support, you will have to resort to NanoSupport, which is also available for free. The functions of the slicer include, among others, masking, infill patterns and even anti-aliasing support.

NanoDLP is a slicing software that is compatible with the majority of resin 3D printers available on the market, but if you want to make use of its custom support, you will have to resort to NanoSupport, which is also available for free. The functions of the slicer include, among others, masking, infill patterns and even anti-aliasing support.

Photo Credits: NanoDLP

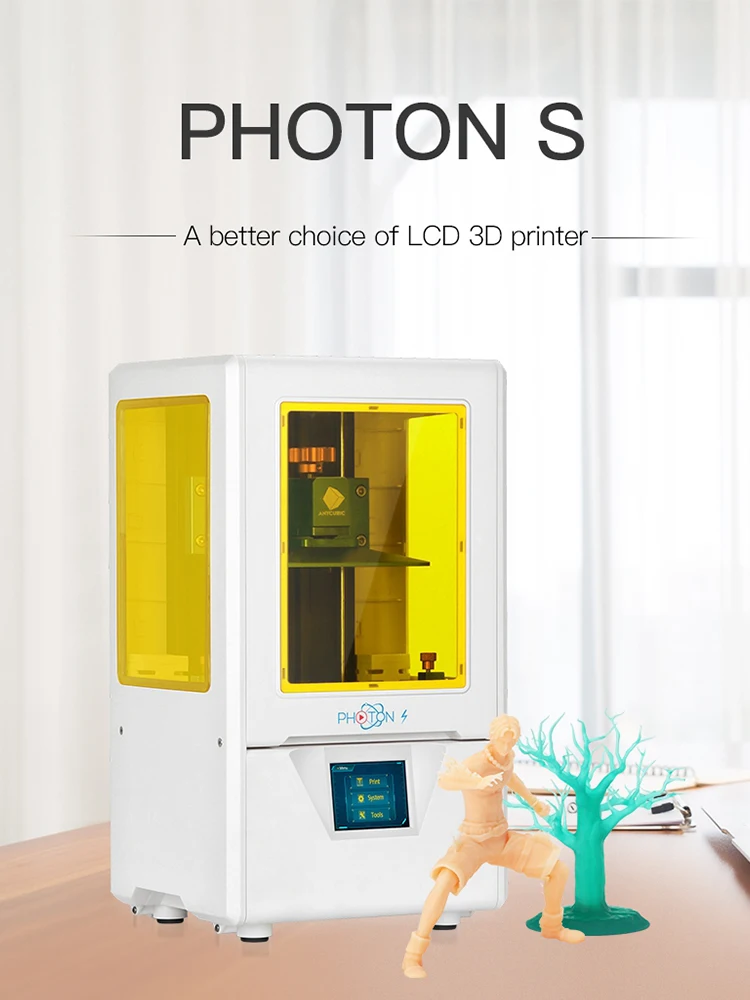

Photon Workshop, Anycubic’s Free Slicer for Resin 3D PrintersThe name of this next slicer on our list should not take you by surprise if you are acquainted already with Anycubic’s popular resin 3D printers. Named after their Photon range, Photon Workshop is their very own slicer which has been designed with the specifications of their resin 3D printers in mind, particularly the Photon Series. The slicer is free to download, though is only compatible with Anycubic 3D printers as of now. Though it has less functionality than many other SLA slicers on the market, it is user-friendly and can be used with both Windows and macOS. Additionally, beyond being the ideal slicer for users of Photon printers, Photon Workshop also has a number of features including automatic and manual support generation and hollowing.

Additionally, beyond being the ideal slicer for users of Photon printers, Photon Workshop also has a number of features including automatic and manual support generation and hollowing.

Yet another addition to our list that was made specifically for use with one brand’s printers, PreForm is a software that is compatible with all of Formlabs’ resin 3D printers. This software is not just a slicer, it is actually a full print preparation and slicer software with a number of features including monitoring capabilities. And it is one of the best slicers to use if you have a Formlabs printer, currently, it is not compatible with machines from other companies. The software is free and can be used with both Windows and macOS. It has been designed to be easy to use, allowing even those who are untrained in 3D printing to set up all necessary parameters quickly with Formlabs’ One-Click Print.

Photo Credits: Formlabs

PrusaSlicer, a Free Open-Source Slicer

PrusaSlicer is a free open-source slicer software for FDM and SLA 3D printers. The software was developed by the eponymous manufacturer Prusa and is based on the open-source slicer Slic3r, which the manufacturer has provided with some improvements to meet the needs of users of its FDM and SLA 3D printers. PrusaSlicer is available in 14 languages and there is a choice of three different versions, all of which are free. Each of them is based on the user’s skills and is divided into beginner, intermediate and advanced. The open-source software is also constantly being developed to meet the latest requirements and support users in their challenges.

Vlare

Vlare Slicer is a free slicer software with its latest version released on May 24, 2022. It features built-in exposure control and reliable automatic support generation with built-in profiles and expert options for successful printing. The easy-to-use interface is particularly suitable for new users, while the expert mode is suitable for professionals who need detailed control. It is also now possible to add text to the 3D models to name just a few of the slicer’s many features.

The easy-to-use interface is particularly suitable for new users, while the expert mode is suitable for professionals who need detailed control. It is also now possible to add text to the 3D models to name just a few of the slicer’s many features.

Z-Suite, an Ambitious Slicer from Zortrax

Z-Suite is a slicer software that is compatible with all third-party LCD 3D printers optimized by Zortrax Inkspire. Some of the features offered by this slicer are, for example, the possibility of filling gaps, automatic generation of supports, smoothing of edges, additional exposure of the supports, and more. One of the best things about the software is that thanks to the WIFI module, it allows you to connect multiple devices together to deal with more ambitious projects. You will be able to manage all the printers from your computer, and apart from that, it also includes intelligent options such as detection of the final material, an updated extruder, and construction platform as well as the use of a camera to avoid any other risks.

Photo Credits: Zortrax

What do you think of our selection of slicers for resin 3D printers? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

4 Best Slicer/Software for Resin 3D Printers – 3D Printerly

If you have been resin 3D printing, you might also wonder which slicer is the best for resin 3D printing since they don’t work the same with filament slicers.

This article will go through some of the best slicers that you can get for your resin 3D printer to give you the best opportunity for success.

The Lychee Slicer is quite new on the scene when compared to other original resin slicers, but because of this, they had a great framework to work from. Mango3D created this advanced slicer software which is compatible with almost all LCD and DLP 3D printers.

It’s free to use, though it has a Pro version which allows you some extra capabilities in terms of functionality, as well as being able to skip the 20-second ad for each export of a sliced file.

For all the features you’re getting, as well as the functionality of the software itself, the ads aren’t very bothersome.

You may be wondering, just how much is this Pro version you speak of? At the time of writing, it will set you back a respectable €2.49 per month with their yearly subscription.

They even give you a chance to use this slicer for 1 month on trial basis, so you can figure out whether its for you. I’d definitely recommend it if you are into resin 3D printing.

The Pro version gives you the following features:

- All the function of the Free edition of Lychee Slicer

- No advertising before slicing

- Advanced support editing mode (IK type)

- Multiple options for supports managements (tips, base, shapes, etc.

)

) - Ball-type for supports tips

- 3D hollowing and hole punching at speed

- More raft types

- Pixel perfect mode

- Variable layers

- Over-exposed supports

- 3D Measurements

- Automatic 3D Model replacement

- And more!

This slicer brings many high-quality functionalities such as creating 3D print models, adding supports by using automatic or manual settings, automatically creating the media, setting print orientation, and many more.

The Lychee Slicer can help you with most of the SLA 3D printers such as those Anycubic Photons, Elegoo Mars/Saturn printers, and plenty more out there so give it a go today.

Lychee Slicer helps you to design and build your 3D models easily, slice them with high precision, and provide you with a lot of amazing features including an island detector and real-time visualization of your print.

Download and try the Lychee Slicer today.

Major Features of the Lychee Slicer

- User-Friendly Interface

- Algorithms for Automatic Supports

- Manual Supports

- Supports Many Languages

- Automatic Print Orientation

- Clipping Mode for Real-Time Visualization of the Print

- Built-in NetFabb model-repairing abilities

Pros of the Lychee Slicer

- It analyzes the model and suggest changes that can improve your 3D printing model.

- Fully-automatic means that it can automatically set the print orientation and create its media as well.

- Supports numerous 3D printers including ELEGOO Mars, Anycubic Photon S, Longer Orange 30, and many more.

- Provide users with maximum control over the operations.

- Fast and high accurate algorithms for better slicing and successful 3D printing.

- For auto supporting, just click on the “Generate Automatic Supports” and the slicer will add supports where they are necessary.

- You can set the density of the supports between low, medium, high, and ultra-high.

- Regular updates quickly such as taking on the Anycubic Photon Mono X file type before any other slicer!

Cons of the Lychee Slicer

- Number of features can get overwhelming at first, but it gets easier with a few tutorials

- You will have to buy its PRO version after one month of trial.

PrusaSlicer is well-reputed and considered one of the best LCD and DLP slicer. The slicer facilitates 3D printer users with various amazing functions and features allowing you to easily scale, rotate, and slice the models with high efficiency.

The slicer facilitates 3D printer users with various amazing functions and features allowing you to easily scale, rotate, and slice the models with high efficiency.

When this slicer first entered the scene, many people looked at it with intrigue and wonder, but it was missing many features.

After much tweaking and upgrades, the PrusaSlicer is a well-respected, top of the range slicer that help you slice your prints like a professional.

Due to its frequent updates, PrusaSlicer is a complete software that includes almost all the features you need for optimal 3D printing.

Users can add supports with one click using the automatic button. The slicer has the “Points” mode that allows the user to manually edit or alter the auto-added supports if needed.

Their supports are especially loved by users, with their unique rafts and large amount of supports to ensure that your models print nicely, from start to finish.

Major Features of the PrusaSlicer

- Open Source and Completely Free

- The Simplest User Interface & Slicing Process

- Smooth Variable Layer Height

- Supports Different Types of Printing Materials (Filament & Resin)

- Supports 14 Languages

- Custom & Auto-Generated Supports

- Auto-Updating Profiles

- Color Print

Pros of the PrusaSlicer

- Years of experience in the printing industry are applied in the slicer’s upgrades.

- The slicer allows the user to control all the printer’s operation through the web browser with its Octoprint application.

- One of the most used slicers by a large group of 3D printer users which show its reliability and efficiency.

- The slicer is capable of using modifier meshes using its powerful tools.

- Available for Windows, Mac, and Linus as well.

- Allows you to save all your necessary parameters, customizations, and settings in a file so that you can use them in the future.

- Support STL file exporting.

Cons of the PrusaSlicer

- The user interface comes with a less modern, older style look which can be boring for some users.

- Navigating through this slicer can be confusing and tricky at times

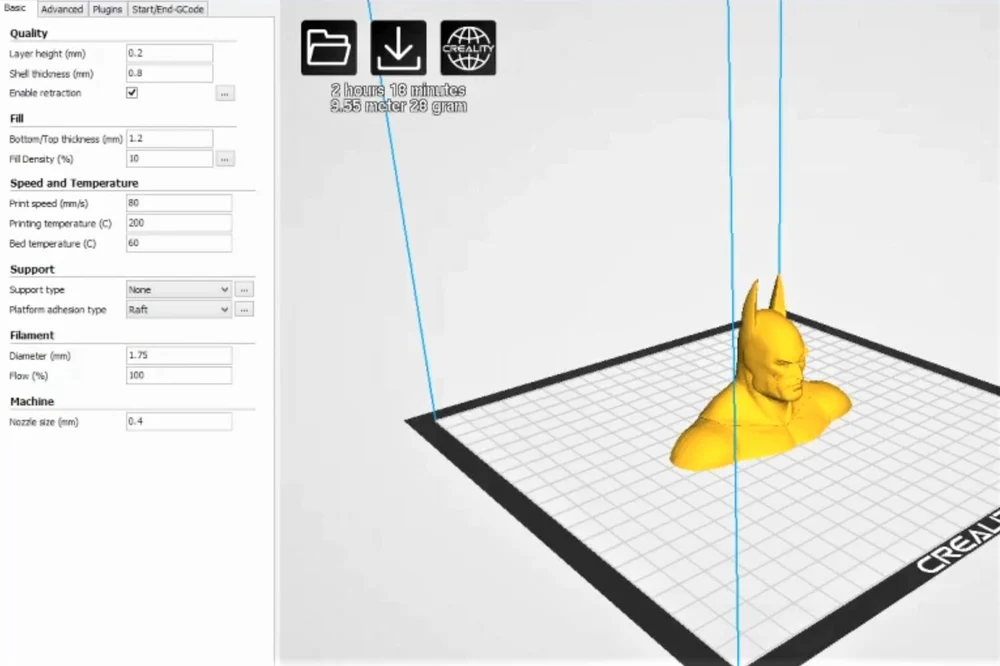

ChiTuBox is a free, powerful, and easy to use 3D printing slicer software. It’s simple and easy to understand user interface makes it convenient for beginners and allows them to use its features without any hassle.

This slicer has jaw-dropping capability when it comes to multiprocessing, and you will realize this at the time of uploading 3D models, slicing models, and adding supports to the models.

When I first got my resin 3D printer, I thought I was stuck with the clunky slicer called the Anycubic Photon Workshop, the proprietary software that is used with Anycubic brands of resin machines.

Luckily, with a bit of research I ran into the ChiTuBox Slicer, which could handle models a lot easier and cleaner. I had many crashes when using the Photon Workshop, but after changing over, those crashes ceased to exist!

I think the best thing about ChiTuBox is the speed and easy navigation you get with it.

Lychee Slicer and PrusaSlicer feel like they have larger learning curves, especially when you are a complete beginner to 3D printing and haven’t touched an FDM filament printer before.

They do have many useful features that you can enjoy in your 3D printing journey.

In addition to its one-click support generating features, it provides many other features such as rotating, scaling, mirroring, hollowing, etc.

The slicer allows you to preview the model in a layer-by-layer view so that it can analyze the printing process and see if there is any improvement needed.

Major Features of the ChiTuBox

- Very Fast Slicing Speed

- Auto Arrange Feature

- Efficient UX (User Experience) and UI (User Interface)

- Supports STL files

- Auto-Generate Supports

- Supports 13 Languages

- Available for Windows, Mac, and Linux

Pros of the ChiTuBox

- It has the capabilities of solid supports generation with perfect density.

- Includes hollowing command for hole creation purposes.

- Includes a “List” feature to provide an easier workflow while working with multiple models

- With the auto-arrange feature, it can arrange the models on the build plate perfectly.

- ChiTuBox slicer is compatible with almost all types of resin 3D printers.

Cons of the ChiTuBox

- You are required to create an account in order to download the slicer.

- Design looks quite boring and monotone, but gets the job done nicely

Meshmixer is a free 3D printing software that allows the users to easily create, correct, and modify your 3D print models.

Depending on its existing volume, features, and easy to use tools, it is an ideal choice for creating 3D models properly with high precision.

Unlike the common CAD models, the 3D polygon mesh models are represented by the infinity of vertices, faces, and edges that can ultimately define the spatial shape or occupying space of the 3D models.

This great Teaching Tech video goes into a tutorial on how to merge some CAD files from Thingiverse to 3D print.

Common CAD software that are widely used by 3D printer users may not be able to represent the models in meshes and this is the point where MeshMixer is utilized.

This is a unique software that not only have several features that you’ll find in common slicer software, but also the other meshing properties for its main use.

Major Features of the MeshMixer

- Hollowing or Holes Creation

- Drag and Drop Mesh Mixer to Join Objects

- Auto Surface Alignment

- 3D Surface Stamping and Sculpting

- 3D Patterns and Lattices

- Branching Support Structure

- Hole Filling and Bridging

- Mirroring and Auto Repair

- Precise 3D Positioning with Axis

- Mesh Smoothing

- Available for Windows and macOS

Pros of the MeshMixer

- Easy to use and operate

- It can easily handle/machine the large model without any hassle

- Comes with an efficient support structure processing

- It is extremely reliable and perfect for hollowing or hole creation tasks

Cons of the MeshMixer

- It is not able to create G-Codes for the common SLA 3D printers

- May require a moderate level graphics card for heavy processing

My Anycubic Photon and the RIGHT polymer slicer.

Photopolymer printing has never been more affordable.

And when I saw the price of Anycubic Photon on Ali on 11.11, I was also tempted (26t.r. - cashback).

You will also need a UV lamp and alcohol.

The most valuable thing in this article is the section about the slicer and photopolymers))

I recommend to look here, there is a lot about this printer.

Looking ahead, it's not too powerful, slow, but a true home printer with amazing prints. nine0003

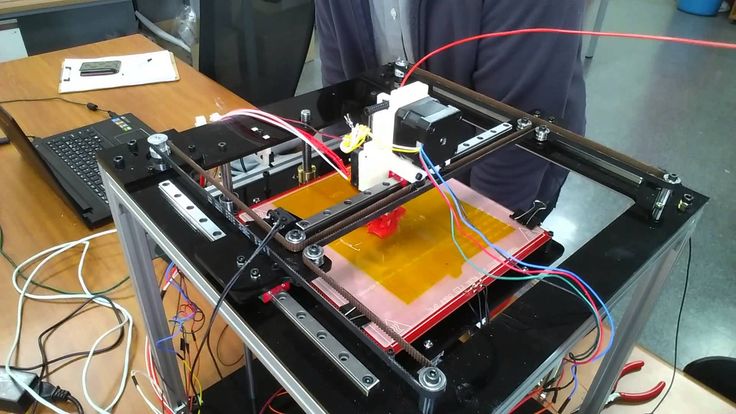

Printer

I ordered from the manufacturer - there are a lot of lots, but they are all the same, some kind of Chinese logic (I took the cheapest one).

When ordering, it is very important to understand that liquids cannot be delivered to Russia - if you want a resin sampler (or a lot of resin), then order from a warehouse in Russia.

The printer is small. Very small. And although everything was in the description of the lot, for me it was a shock:

It comes almost assembled. According to the attached instructions, the zero level is very easily adjusted and you can print. nine0003

According to the attached instructions, the zero level is very easily adjusted and you can print. nine0003

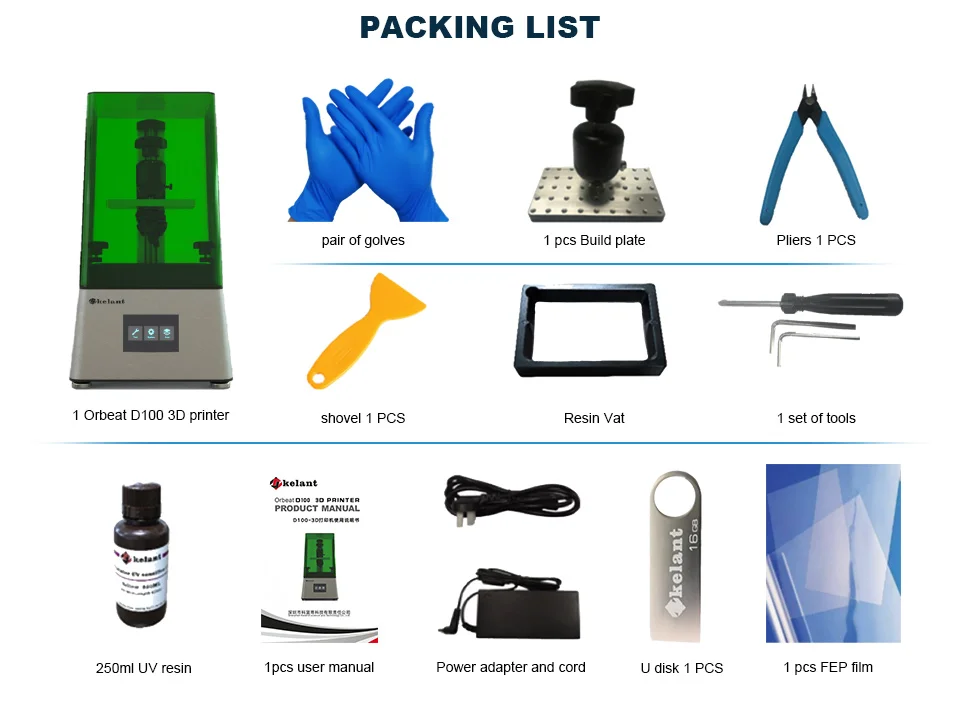

Comes with spare bath film, 300gr of photopolymer, flash drive, resin removal funnels and plastic spatula.

No bug found sticking to the screen. There are no problems with this at all, maybe they fixed it. Very stupid.

Having suffered with it for a month and rummaged around on the Internet, I found the following (there are a lot of interesting things there):

- The Anycubic Photon slicer is a copy of the Chinese Chitu slicer. nine0036

- Chitu has long grown into a new project Chitubox.

It's still a free slicer, but apart from a very buggy registration form, it has the following pluses regarding Anycubic:

- You can make the model hollow!!

- It is in Russian!

- Knows how to calculate the price of a printout (taking into account not only the volume, but also the density of the photopolymer).

- Supports not only Windows, but also Linux and Mac.

- In addition to the hollow model, there are additional buns - you can set the percentage filling and you can make a hole of the desired configuration to drain the resin, which will definitely be inside. Plus, he will save this cut-out part (hole) as a separate model so that it can be printed and pasted back.

- You can open the code created earlier, see the result, change the exposure time (arrow below).

- Automatic placement of models with the selected distance. And away from the edges.

- Improved autosupports, besides a more convenient system for adding/removing supports. nine0036

- More convenient viewing of layers.

- Also suitable for other printers.

- The 'place on selected face' function is something that is sometimes hard to live without;

- Possibility to create a print profile for each polymer and not to remember different parameters for each one.

If you, like me, have problems with registering on their site, then here are the downloaded distributions.

This slicer is already preset for Anycubic Photon (in settings) and will save in the required .photon format. nine0003

Photopolymers

I decided to buy a bunch of flowers at once and turned out to be wrong.

It's better to buy the fastest photopolymer and paint it from an airbrush with Ali, as a result, save time and nerves.

Photopolymer smells. A little, but unpleasant - you can be in the room, but everyone who comes in will ask what it smells like. It can be compared by smell with high-quality ABS. Some manufacturers make odorless photopolymers their chip.

But only open resin smells - when the tray with it is inside the printer, despite the cracks, the smell does not leak out, and the vapors removed by forced ventilation from the print area pass through the carbon filter. nine0003

nine0003

When opening a bottle, be prepared for the contents to get dirty - I use a pack of paper towels a week. It is rubbed off normally, but to remove stains you need alcohol or wet wipes.

There were a lot less spills and smears when I decided to use a syringe.

In addition, when I'm not too lazy, I use thin medical gloves - otherwise it smells from under the nails for a couple of days.

So, we have downloaded the slicer, now the settings for photopolymers. nine0003

There is a big document, with a bunch of manufacturers. I recommend it. For me, they turned out to be the same:

layer 0.02

The number of first layers 3-5

Small resin time

Anycubic Green 6s

Anycubic Grey 7s

FUUNTODO RED 30-40S

WANHAO Green 30- 40s

FunToDo DeepBlack 80s

FunToDo TrueWhite 80s

Gorky Liquid 11s

The time of the first layer is 3 times the time of the other layers. More won't make it worse. This parameter determines how well the part will grip the table.

This parameter determines how well the part will grip the table.

The layer can and should be done more, but I did tests on this one. For a larger layer, simply multiply the exposure time by the magnification factor.

As far as I understand, the stronger the photopolymer pigment, the longer it needs to be exposed. Translucent prints are much faster. nine0003

Also, there is a suspicion that my film is cloudy or the screen is in something. But the new one will not come soon. An error of 20% no more.

To make you understand how big the difference is - a 5 cm high model is printed in translucent Anycubic 8 hours, green Wanhao 25 hours, and black FunToDo 60!!! hours .

By the time the top of the black model is printed, the pigment has already settled on the film and those places where there was no permanent printing (for example, the crossbar of the letter 'P') simply will not be printed. nine0003

Printing process

So, we bought the resin, downloaded the slicer and set it up.

The printing process is simple:

- Throw the 3D model into the slicer and put the resulting '.photon' file on the flash drive.

- We put the bath in the calibrated printer until it stops at the far heads of the bolts. Tightens the bolts on the sides and the platen bolt.

- Pour the shaken up (don't pay attention to the bubbles) photopolymer as much as you feel sorry for - determining the volume of the model by eye. Keep in mind that some resin will displace more of the plate, so don't pour above the middle. In practice, 1 cm is enough for me. In extreme cases, you can pause the print and refill. nine0002 If you use a syringe, you can estimate the required volume using a slicer + stock.

- Close the cover and select the desired file for printing on the screen. What I absolutely love is that it displays a screenshot of the slicer table created when the 'slice' button was clicked.

- Waiting. We are worried!

It is very sad that the first hours of printing are completely invisible, but did the first layer catch on at all?!

There is a pause function when the table rises, but at first, drops on this table still hide the first layers.

nine0003

nine0003 - Open the lid and remove the platen with the top bolt - put it sideways on a paper towel to drain the residue.

- We remove the print from the table not with a plastic spatula, but with a knife or something similar.

The plastic spatula is VERY soft, use it only for bath film.

- Pour the photopolymer back into the bottle - it's best to use a syringe to avoid spilling.

If it is left for a couple of days, the pigment will settle and it is not enough just to mix it with a spatula - it will be necessary to drain the resin, wipe off the film and pour it again. nine0003

If the print fails and the first layer does not stick, there will be a flat plastic 'shit' at the bottom of the tray. Use a plastic spatula to remove it.

When draining resin after a failed print or if you suspect that something has fallen off, unprinted and floats in the tray, use the funnel mesh supplied with the printer. You can not print if there is something conditionally solid in the bath.

Post-processing

In this part, I will be grateful for the comments of the others - how do you do it? nine0045

1-2. The finished imprint must be washed with in alcohol (not vodka!). I don’t remember which manufacturer’s chip is that it can be washed with water, but the rest of the water becomes covered with white streaks, lose strength and even crack.

After getting rid of the resin residue, I sometimes leave it in alcohol for an hour more.

Alcohol is poured into a separate container - it can be reused, if not for wiping the film and printer screen.

2-1. We remove the supports with a model knife, the white traces of the supports can be smeared with alcohol or dichloromethane and they will disappear. nine0003

3. Put the print under the UV lamp for 'a while'. Place not too close to the LEDs - some plastics turn white and even crack from strong heat.

I use a UV nail lamp and put it under it for 3-5 hours. In order not to overheat, he removed the casing, and to turn off the timer, he connected the power directly, not through the control board.

In order not to overheat, he removed the casing, and to turn off the timer, he connected the power directly, not through the control board.

You don't even need to solder anything - all connectors fit.

4. If necessary, paint with an airbrush.

Profit!)

Total

It is not a competitor to FDM printing - expensive, long, small print area.

It won't suit real Rep-Rap'ers - there is little that can be improved, altered, added.

I consider this printer to be a real home printer - it is completely silent, takes up little space, does not require additional devices. I now recommend him to my friends.

Finally, I can do what I bought Anet for many years ago - print miniatures for desktops)

These are not layers - these are scales on the skin!

And here is an example of combining plastic and photopolymer:

Read article - Top best free 3D printing slicer software in 2022

Below is a list of the best free 3D slicers in 2022 - software for converting 3D models into layers for 3D printing.

Cura

Cura is an open source slicing software created by Ultimaker for their 3D printers, but can also be considered a common standard as it is compatible with most other 3D printers. Its functionality can be easily extended with a large number of convenient plugins. Since this is one of the most popular and widely used 3D printer slicers on the market, there's a good chance that a profile for your 3D printer is already available in the software, allowing you to get started right away. If this is not the case, you can download and import a third party profile. nine0003

This 3D printing software is very easy to use and allows you to manage the most important 3D printing settings in a clear interface. Start with "Basic" mode for a quick start, where you can only reconfigure the most basic printer settings. If you need finer control over your print settings, switch to Advanced, Expert, or All for more settings. In these modes, Cura provides users with up to 400 customization options to suit your needs and get the best results. nine0003

nine0003

This slicer is constantly updated and improved, new versions are constantly released, so you can be sure that you get the latest program. Recently, the new version of Cura 5.1 introduced settings for FDM metal printing.

You can also use Cura as a 3D printer remote control software, but the 3D printer must be connected to the PC during printing. Integration with CAD systems such as SolidWorks and Siemens NX makes the software valuable even in professional applications. But for the vast majority of home users, Cura is a simple and affordable 3D printing slicer. nine0003

In addition to ease of use, you can also find many educational resources on how to best use Cura's latest features, as well as a community forum on the Ultimaker website.

Cure download link.

Prusa Slicer

Prusa Research, the company behind the original Prusa 3D printers, has developed its own slicer, PrusaSlicer, based on Slic3r, an open source slicer. PrusaSlicer has gained a lot of popularity very quickly for a number of reasons: not only does it have a large list of Slic3r's adjustable settings, but it also has some handy features that the original software didn't have. nine0003

PrusaSlicer has gained a lot of popularity very quickly for a number of reasons: not only does it have a large list of Slic3r's adjustable settings, but it also has some handy features that the original software didn't have. nine0003

With a redesigned interface, built-in support for Prusa's own range of printers, and user-friendly settings for a range of common media, there are many improvements over the original software. Key features include customizable supports, support printing with different materials, and flexible layer height settings.

PrusaSlicer can be used to cut models for both FDM printers and photopolymer 3D printers. It has various modes allowing you to edit the settings depending on your experience, and the Expert mode opens up a huge list of customization options. However, even simple profiles can work well in PrusaSlicer. There are fewer printer presets than some other popular slicers, but it's just as easy to set up or import custom settings. nine0003

Based on Slic3r, PrusaSlicer supports most of the original features and even accepts Slic3r configuration packages when importing profiles.

Link to download Prusa Slicer.

ideaMaker

Raise3D ideaMaker slicing software is optimized for the company's 3D printers, similar to how PrusaSlicer is optimized for original Prusa printers and Ultimaker Cura for Ultimaker hardware, but like other software, it also works well with third-party 3D printers. nine0003

The workflow and user interface is a bit more complex than Cura and PrusaSlicer, but it's worth a little digging and you'll have quick access to advanced per-layer settings and print modifiers, including the ability to texture models or brand your parts.

By connecting to Raise3D cloud services, you can download hundreds of community and Raise3D-created printer and media profiles for faster and better printing, or create your own library of settings and profiles. nine0003

Customizable supports, model splicing and mesh correction tools are all provided by ideaMaker, which allows you to get consistent print results every time. Print sequencing and built-in compatibility with OctoPrint are also additional features that improve print quality.

Print sequencing and built-in compatibility with OctoPrint are also additional features that improve print quality.

You can also switch between dark and light ideaMaker interface themes for a more comfortable slicer experience.

Download link for ideaMaker. nine0003

CHITUBOX Basic

Chances are if you're using a budget desktop 3D resin printer, it comes with CHITUBOX (now known as CHITUBOX Basic). The software is developed by CTB Systems, which also makes many of the motherboards and firmware for these printers (hence the company's default software is software that goes great with anything). nine0003

The main purpose of CHITUBOX Basic is cutting 3D models for printing on photopolymer 3D printers. With CHITUBOX Basic you get full control over printer settings as well as a large list of common and popular printer profiles and resins.

The most important element of preparation for photopolymer 3D printing is the orientation of the model and the setting of supports. Orientation is not the easiest - it does not have an automatic mode, but the generation of automatic support is quite reliable and in many cases gives good results. More fine-tuning may be required to properly support parts, but the support customization options are simple and intuitive. nine0003

Orientation is not the easiest - it does not have an automatic mode, but the generation of automatic support is quite reliable and in many cases gives good results. More fine-tuning may be required to properly support parts, but the support customization options are simple and intuitive. nine0003

Link to download CHITUBOX Basic.

Lychee Slicer

With a wide variety of 3D printer profiles and resins, the Lychee Slicer is an attractive third-party option for your model slicing needs. This, and being one of the most user-friendly and easy-to-use slicers, makes the Lychee Slicer an excellent multifunctional solution for desktop resin printers. nine0003

Automatic model orientation will help you get started preparing for 3D printing, but you can skip it and just hit the Magic button and let Lychee Slicer take care of everything. The results can sometimes be unpredictable, but when working with simple models, you will save time this way.

Some options are not available in the free version of Lychee Slicer, but this is not a problem. The free version is fully functional and has rich functionality.

Link to download Lychee Slicer.

Kiri:Moto

Written entirely to run in the browser, Kiri:Moto is a powerful tool that can be used to prepare models for 3D printing, laser engraving or CNC milling (the common factor here is that they are all exported via G-code) . The settings are simpler than locally installed slicers, but they provide most of what you would normally need, including z-axis retract settings. nine0003

There is complete freedom to add printers using a few simple parameters such as build area, G-code type, and number of extruders. In addition, there are necessary options for customizing and exporting G-code files.

Link to Kiri:Moto.

IceSL

IceSL is an amazing 3D printing software. This is not just a slicer, but also a 3D modeling tool.