Best 1000 3d printer

Best 3D printers under $1,000 in 2023

We may earn revenue from the products available on this page and participate in affiliate programs. Learn more ›

Written By Gabriel Morgan

Updated Jul 13, 2022 12:30 PM

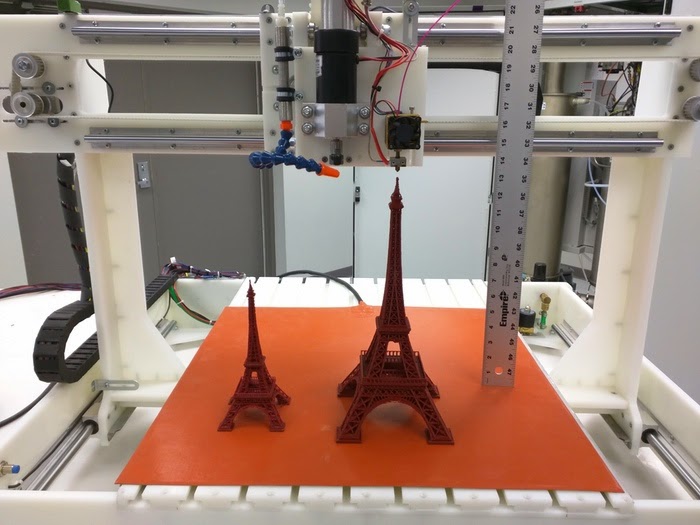

Load up the filament, transfer your slices … the best 3D printers under $1,000 have all the tools that most makers will need to give form to their visions. You might be a hobbyist separately printing and carefully-painting each gargantuan wing of the great gold-dragon for your next D&D campaign. Maybe you’re printing a grip for your old film camera to make it more comfortable to hold. Or perhaps you’re creating a custom prop for a photoshoot for much less than the cost of buying it. Whatever your aims, 3D printers at the sub $1000 price point should give you enough power to achieve them. If you want to go even cheaper, you can check out the best 3D printers for kids.

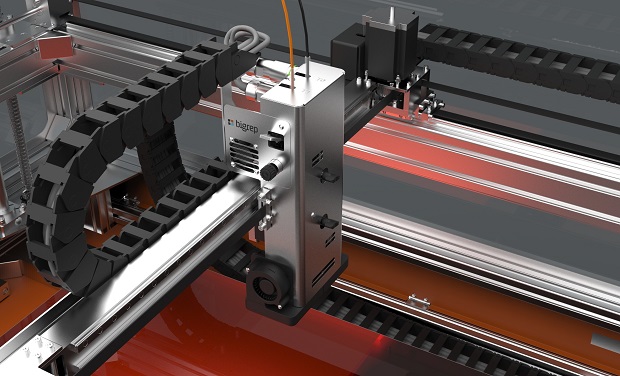

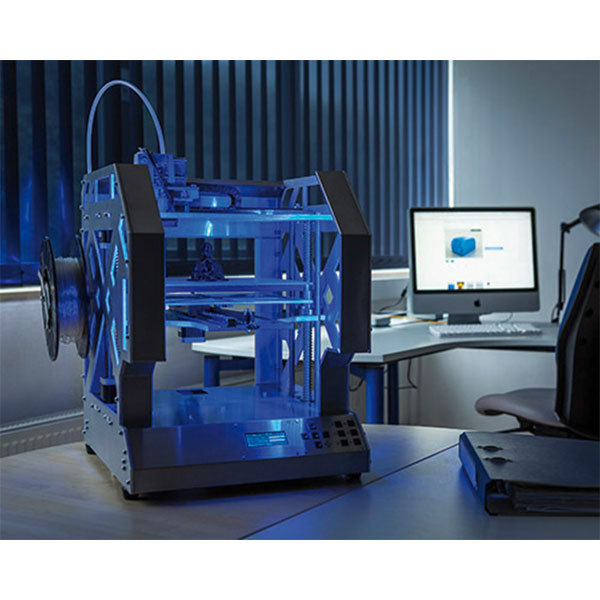

This article focuses on 3D printers at the high-hundreds price-point, that still hover below $1000. At this price point 3D printers get quite capable, delivering some really great features like auto-leveling trays, blistering extruders capable of working with wider sets of materials (such as nylon), extremely high-resolution resin prints, air-filtration, quieter operation, better-connectivity, and dual extruders. Read on for a look at some of the best 3D printers under $1000, and just what it is that makes them so.

- Best overall: R QIDI X-Plus

- Best resin: ANYCUBIC Photon Mono X 6K

- Best dual extruder: BIBO 3D Printer Dual Extruder

- Best kit: Original Prusa i3 MK3S+ kit

- Best budget: Creality Ender-3 S1

3D printers are stuffed full of tech, from their blistering-hot extruders, to their auto leveling trays, to WiFi, and 4k+ LCD arrays for curing liquid resin, Even the Bowden mechanism that’s often used to channel filament comes from an important invention for bicycle construction. With so many mechanical inventions and systems crammed into one device, 3D printers are inherently technical. Because of this, it’s a good idea to familiarize yourself with some parts of how the technology works before you buy.

Because of this, it’s a good idea to familiarize yourself with some parts of how the technology works before you buy.

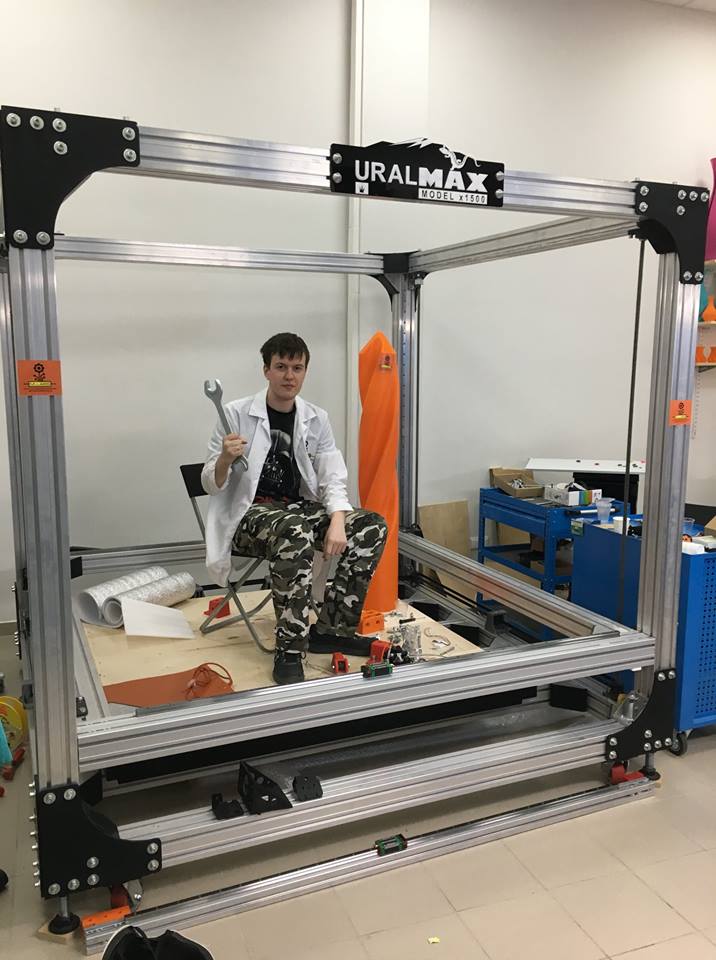

With the first functional 3D printers built in the 1980s, 3D printers didn’t begin to pervade the mass market until the 2000s. While a few inventors and scientists were concurrently working on different elements of technology that would be incorporated into the 3D printer systems of today, Bill Masters was the first inventor who filed a 3D printer patent.

The inventor was camping on the banks of the Chattanooga river one night, staring up at the stars, when the idea came to him. He imagined using one star as a seed point, and then combining the other dots of starlight to create any shape he liked. His analogy for the additive manufacturing process that defines FDM printers of now, is great, likening the tech to “spit wads,” similar to the ones so many children familiarize themselves with at a day in the mall, “When you shoot a lot of wads, they begin to take shape. If you can control the direction of the wads and the motion of the device shooting them, you can produce any desired shape.” We love it.

If you can control the direction of the wads and the motion of the device shooting them, you can produce any desired shape.” We love it.

While there are numerous classes of 3D printers, there are three main families. These are fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). Selective laser sintering uses a laser to fuse powdered material, which is distributed across a bed with a roller. SLS printers are capable of delivering strong functional prints that are sturdy enough for immediate incorporation into manufactured systems. However, the SLS process is very expensive, and is out of reach for most DIY tinkerers. At the sub-$1000 price point, this article focuses on FDM and SLA printers.

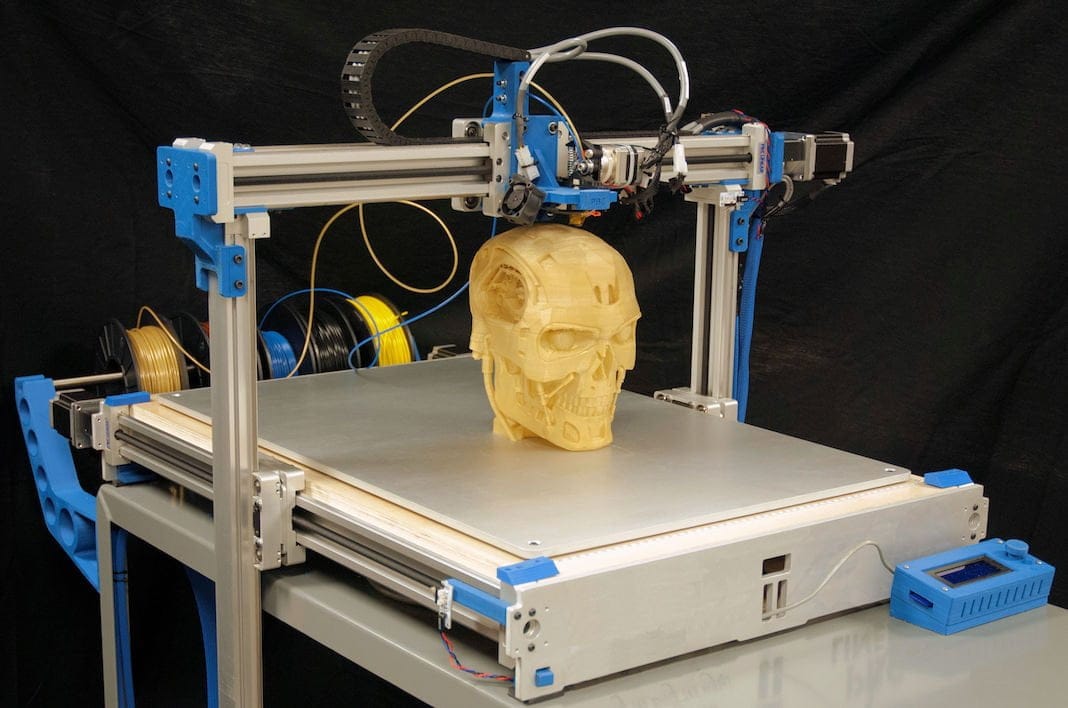

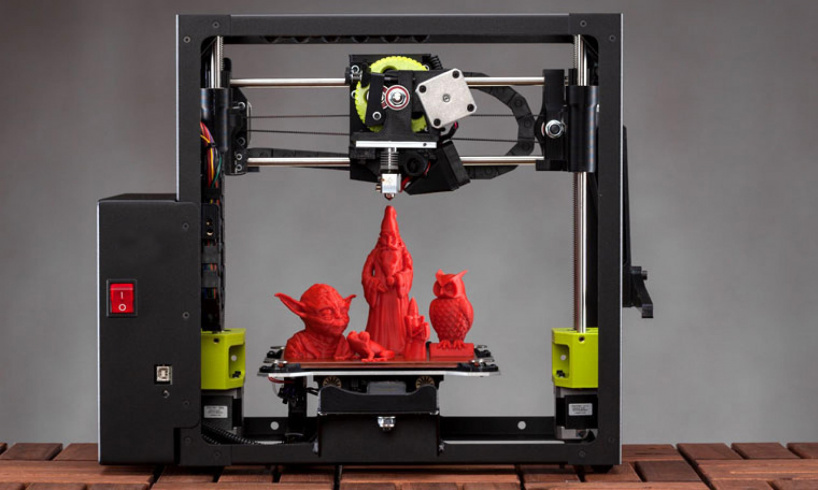

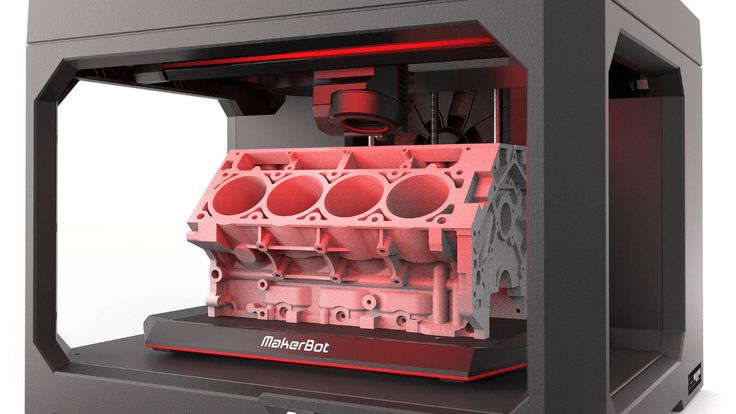

Fused deposition modelingFDM printers are the most common and economical 3D printers on the market. These printers use a superheated nozzle to extrude filament downward onto a heated, leveled tray, building the model up slice-by-slice. FDM printers are suitable for quick prototyping, proof of concepts, and finished projects, and tend to be more economical and user-friendly. FDM printers usually also deliver a greater build area than SLA printers for the price.

FDM printers are suitable for quick prototyping, proof of concepts, and finished projects, and tend to be more economical and user-friendly. FDM printers usually also deliver a greater build area than SLA printers for the price.

FDM printers create objects out of thermoplastics. These common plastics have chemical properties that allow them to melt, form into a shape, and then melt again. These plastics are inherently recyclable, and many are quite cheap. The most common thermoplastics used in FDM printers include ABS, PLA, PETG, and TPU. Some also print nylon, and more.

These thermoplastics have different properties, some are food safe, while others are biodegradable, others are non-toxic for skin contact. However, the manner in which thermoplastic deposits fuse is primarily mechanical, rather than chemical, which runs the risk of leaving voids (or open spaces) in the walls of the print, which leads to inferior structural integrity on the Z axis.

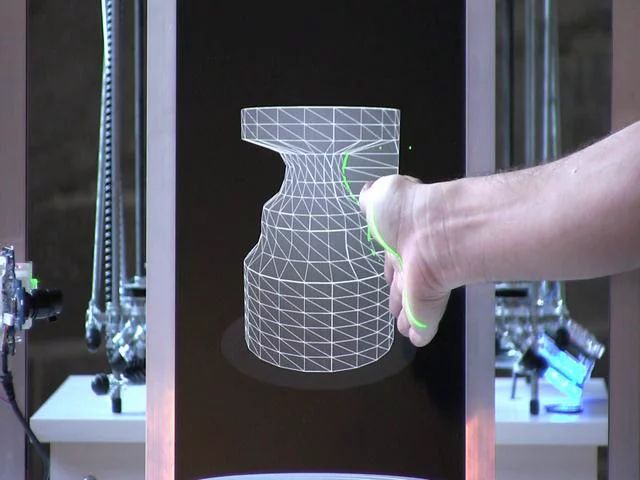

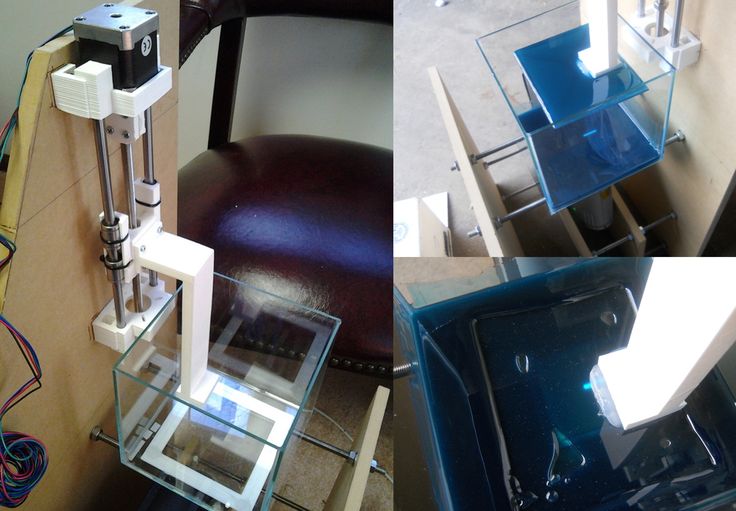

SLA printers use a different process from FDM printers, whereby a laser, or LCD array cures resin in a liquid resin bath, and extrudes it upwards slice by slice. These printers fuse the print onto a heated tray, and lifts it, upside-down, from the liquid resin. They are capable of printing parts and models with greater structural integrity and detail. Because of their high print resolution, SLA printers are the go-to for most hobbyists looking to build intricate models and figurines.

Thermosets in SLA printersSLA printers use thermosetting plastics (thermosets). These resins cure into shape, and cannot be heated to dissolve, rather, heat causes their decomposition. This means that thermosets are not recyclable. However, the curing process of resins give them superior structural integrity to thermoplastics, as the plastic chemically fuses, creating covalent bonds between molecules. These resins achieve prints with better detail, resolution, and strength. Thermoset variety is also wide, including clear resins, wiggly resins, high temp resins, and even dental grade resins.

Thermoset variety is also wide, including clear resins, wiggly resins, high temp resins, and even dental grade resins.

Because there’s so much that goes into great 3D printers there were a lot of features to factor when we were researching the five best. We researched numerous printers from multiple manufacturers, looking for the best feature sets, wherein all parts collaborate for a gestalt of function that’s the most useful for the makers of today. Along the way we looked for a few specific features which we detailed below:

Versatility is always nice. At the mid-level price point below $1000, we start seeing FDM printers that are capable of nylon and some more advanced thermoplastics. We also start seeing SLA printers that are capable of more. We noted this wherever it stood out.

Tray functions are so important to overall printer quality. We looked for printers with trays that get hot enough to keep your models well-secured. We also looked for printers that have auto-leveling functionality, or at least excellent semi-auto leveling.

We looked for printers with trays that get hot enough to keep your models well-secured. We also looked for printers that have auto-leveling functionality, or at least excellent semi-auto leveling.

Extruder & LCD (or laser) quality is extremely important for 3D printing. Extruder quality plays a big role in which thermoplastics the printer can handle. Great extruders get hot, and are light enough to work well with the system. Different extruder dimensions also play into their use for different situations. Some systems even use two extruders. For SLA systems the LCD array (or laser) is extremely important in getting good print resolution and smooth forms.

Overall precision is achieved through lots of factors, but we like to see FDM printers with a multi-column lift system. We looked for FDM printers that don’t leave lines, burrs, or slice edges visible on the sides of the print. We also looked for SLA printers that yield high-res prints with smooth curves.

Connectivity & slicing software can define the quality of your print experience just as much as some of the more mechanical components of your system. Wireless connection is always nice, and printers with a few gigabytes of internal storage also offer a boon. Compatibility with lots of slicing software or one especially good one is also important and we noted this.

User experience and assembly also cannot be overlooked. Some printers get loud — we mean infernal giant-water-bears crawling from the pit sort-of loud (do water-bears roar?). Where we found printers that deal well with sound and fumes, we highlighted them. We also noted the required assembly of each printer. Some want highly customizable printers that might require longer assembly but are capable of modding, but not all do.

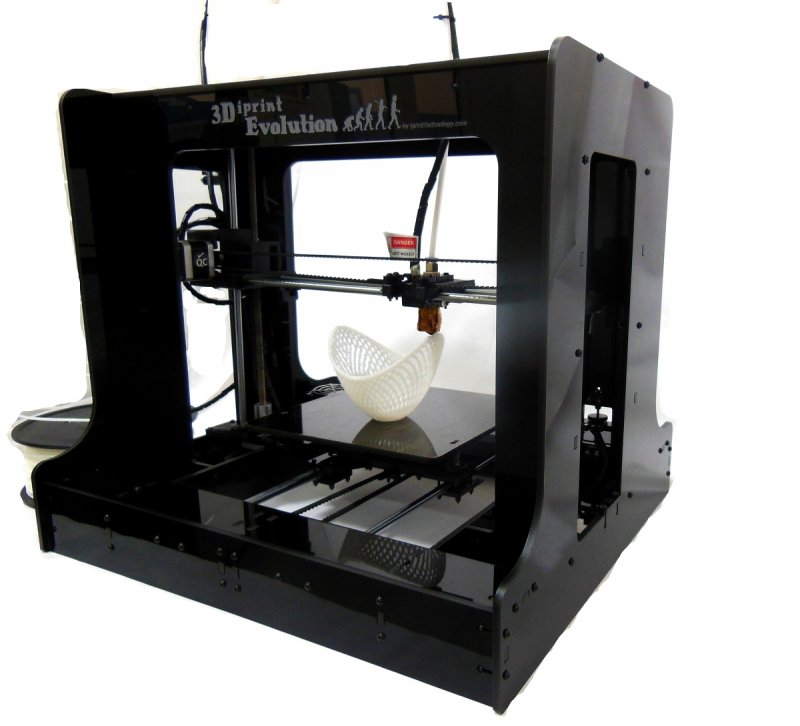

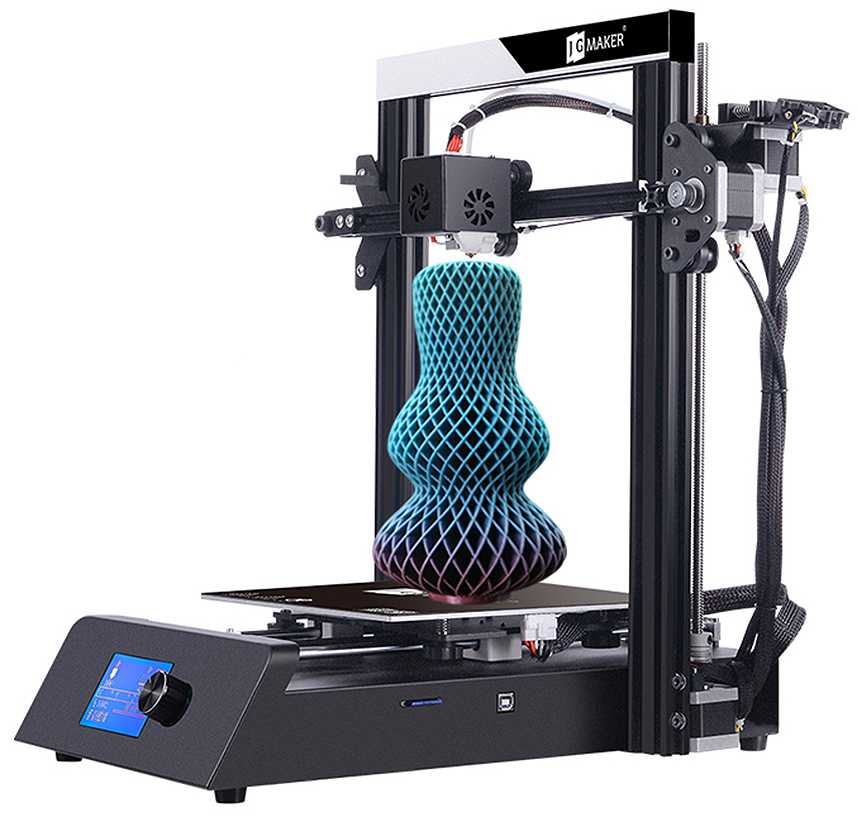

The best 3D printers under $1,000: Reviews & RecommendationsBest overall: R QIDI X-Plus

R QIDI TECHNOLOGY

SEE IT

Why It Made The Cut: An FDM printer with easily-serviceable standard parts, an optional auxiliary-extruder that enables it to print more technical materials, and outstanding customer service.

Specs:

- Print technology: FDM

- Build size: 10.6 x 7.9 x 7.9 inches

- Supported materials: PLA, TPU, PETG, ABS, Nylon, PC, Carbon fiber, and more

- Best slicer software: QIDI Print Slicer (included free)

Pros

- Second extruder for technical-material free upon request

- Excellent customer service and support

- Very easy assembly & simple repair

- High res-smooth prints

Cons

- Manual bed leveling

- Wifi issues with non-QIDI software

Something of a plug-and-play machine, the R QIDI X-Plus is a highly capable FDM printer that has an expanded range of materials, possible via a free supplementary extruder. With easily repaired standard parts, and great customer support, it’s an easy best-overall choice for most.

Shipped from China, the semi-enclosed X-Plus takes hardly any set up. It comes with a standard extruder suitable for PLA, ABS, and TPU. A second technical-material extruder is also available with your purchase free-of-charge by request (which belies the companies communication-forward ethos), and is capable of materials like Nylon, PC, Carbon fiber, and more. To be clear, this second extruder is swappable, rather than supplementary, this isn’t a dual-extruder rig, and the second extruder won’t work in tandem with the standard. However, the technical nozzle is a nice touch, that firmly differentiates this machine from cheaper FDM’s in the sub-$500 price range.

It comes with a standard extruder suitable for PLA, ABS, and TPU. A second technical-material extruder is also available with your purchase free-of-charge by request (which belies the companies communication-forward ethos), and is capable of materials like Nylon, PC, Carbon fiber, and more. To be clear, this second extruder is swappable, rather than supplementary, this isn’t a dual-extruder rig, and the second extruder won’t work in tandem with the standard. However, the technical nozzle is a nice touch, that firmly differentiates this machine from cheaper FDM’s in the sub-$500 price range.

QIDI is all about customer support and easy repairs. Not only are the majority of the parts in this system standard and easily replaceable, but the majority of replacements are also easy to DIY, with included tools for most hardware in the system. QIDI offers exceptional customer service, with knowledgeable agents ready to send you repair parts as needed, and help troubleshoot issues.

While the X-Plus doesn’t have the automatic leveling you might like at this price point, it does have a semi-auto, single-point quick-level system that is reliable and easy. It features QIDI Print Slicer software, that’s free to use with any QIDI system All-in-all, while this system might not be as appealing to hardcore tinkerers as some, those who want consistent quality with easy set-up, good customer support, and a wider than average range of available materials will love it.

It features QIDI Print Slicer software, that’s free to use with any QIDI system All-in-all, while this system might not be as appealing to hardcore tinkerers as some, those who want consistent quality with easy set-up, good customer support, and a wider than average range of available materials will love it.

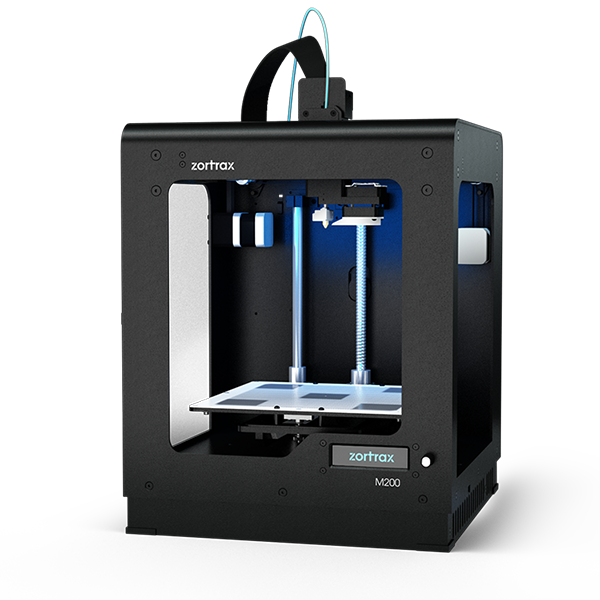

Best Resin: ANYCUBIC Photon Mono X 6K

Why It Made The Cut: 6K LCDs mean better resolution than ever, with more detail and contrast, more build volume, and faster speeds.

Specs:

- Print technology: SLA

- Build size: 9.6 x 7.8 x 4.8 inches

- Supported materials: Resin

- Best slicer software: Anycubic Photon Workshop (free), ChiTuBox, Lychee, more

Pros

- Extreme print detail and resolution

- Great contrast

- Fast, at up to 1s / layer in some instances

- Great out of the box prints

Cons

- Poor connectivity options

- Very smelly

6K — that’s a lot of LCDs, and the ANYCUBIC Photon Mono X 6K leverages them all for extremely high-resolution prints with impeccable contrast. ANYCUBIC is one of the most popular lines of SLA resin printers, and the Photon Mono X is one of the most impressive dogs in the pack.

ANYCUBIC is one of the most popular lines of SLA resin printers, and the Photon Mono X is one of the most impressive dogs in the pack.

With its 6K LCDs the Photon Mono X 6K uses an 9.25 inch monochrome LCD array, with 6% light transmittance, which means quicker printing. The machine is fast, and ANYCUBIC brags up to 1s / layer, in ideal circumstances. Its LCD’s deliver extreme contrast that’s noticeable, and the model sports a much larger build area than its cousins, at 9.6 x 7.8 x 4.8 inches.

ANYCUBIC is compatible with lots of the great slicer software packs, from ChiTuBox, to Lychee, and offers the proprietary Anycubic Photon Workshop free of charge. Sadly, getting your slices to the printer is more difficult than it could be, as the printer’s Wifi is notoriously spotty. It’s built around its LCD screen control and SD card reader, meaning SD is the best way-to-play. Those who like to keep their SLA printer on a well ventilated back porch will appreciate not having to keep their printer connected to a laptop, but those who want to set up a printer farm might groan. Otherwise, it’s a great buy, offering some of the best quality resin prints out there.

Otherwise, it’s a great buy, offering some of the best quality resin prints out there.

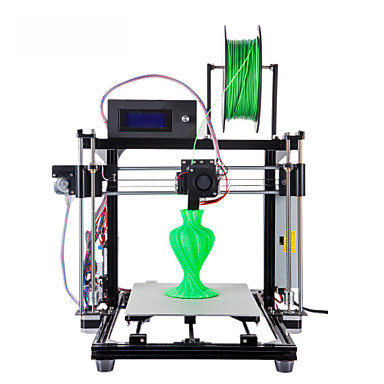

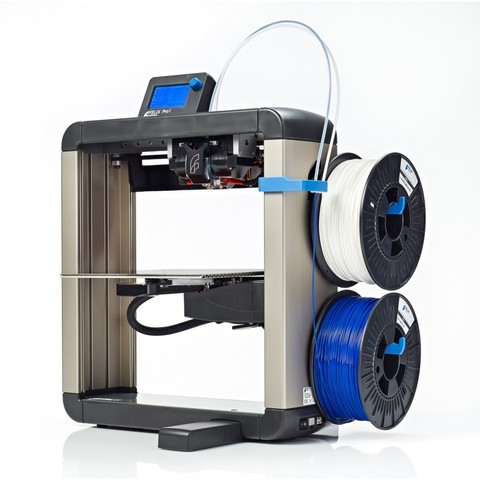

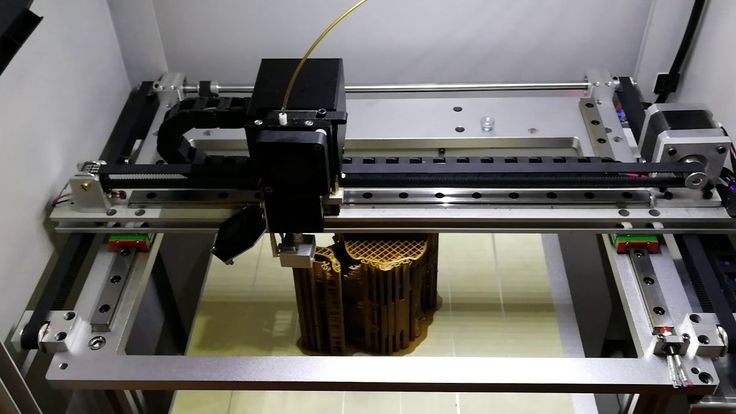

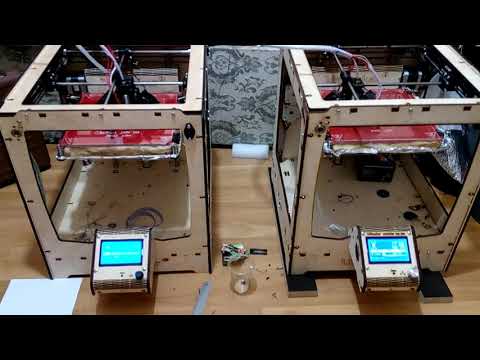

Best dxtruder: BIBO 3D Printer Dual Extruder

Why It Made The Cut: Solid dual extruder support means lots of techniques you can’t get at with other FDM printers, plus WiFi and a touchscreen make it easy to use.

Specs:

- Print technology: FDM

- Build size: 8.4 x 7.3 x 6.3 inches

- Supported materials: ABS, PLA, Dissolvable filament (PVA, HIPS), TPU, PETG, Nylon, PC, Carbon fiber, and more

- Best slicer software: Repetier-Host, Cura, Simplify3D

Pros

- Dual extruders

- Minimal easy assembly

- Wifi control

- Good customer support

Cons

- Difficult maintenance and usability

- Bed isn’t easy to level

If you’re moving up from a basic machine, the BIBO 3D’s dual extruders can open doors you didn’t even know were closed. These include printing dissolvable supports, printing with multiple colors, and 3D printing two duplicate objects simultaneously. But these dual extruders aren’t the BIBO 3D’s only bargaining chip.

These include printing dissolvable supports, printing with multiple colors, and 3D printing two duplicate objects simultaneously. But these dual extruders aren’t the BIBO 3D’s only bargaining chip.

BIBO 3D does a good job with a wider range of materials. Beyond the standards like ABS and PLA, it prints more technical thermoplastics like flexible nylon, and carbon fiber. The system uses an easy touch-screen control panel to set up prints, and can also be controlled via Wifi, meaning you can control it from your phone.

The machine does have a couple of blindspots. Its leveling control isn’t as intuitive as you would expect at the price point. The machine is also packed tight with features, with screws in odd places, and somewhat abstract engineering overall. These issues are offset by great customer service from the company, but they do make the machine’s usability somewhat less optimal than some of the competition. It’s a great option for tinkerers who want extra extruders and wider material possibilities, but in spite of its initial assembly, it may be more hands on than some want.

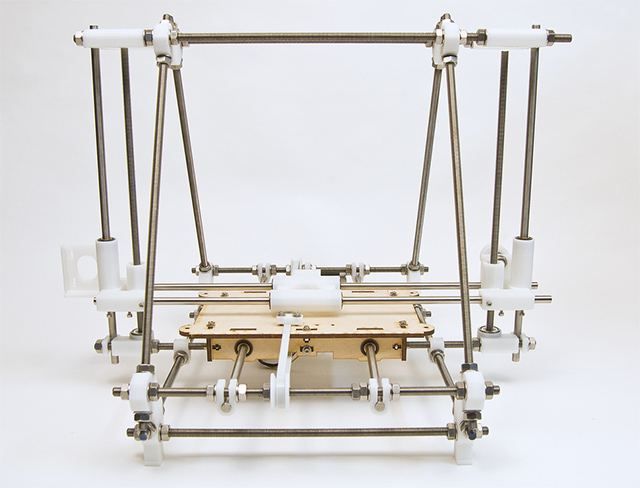

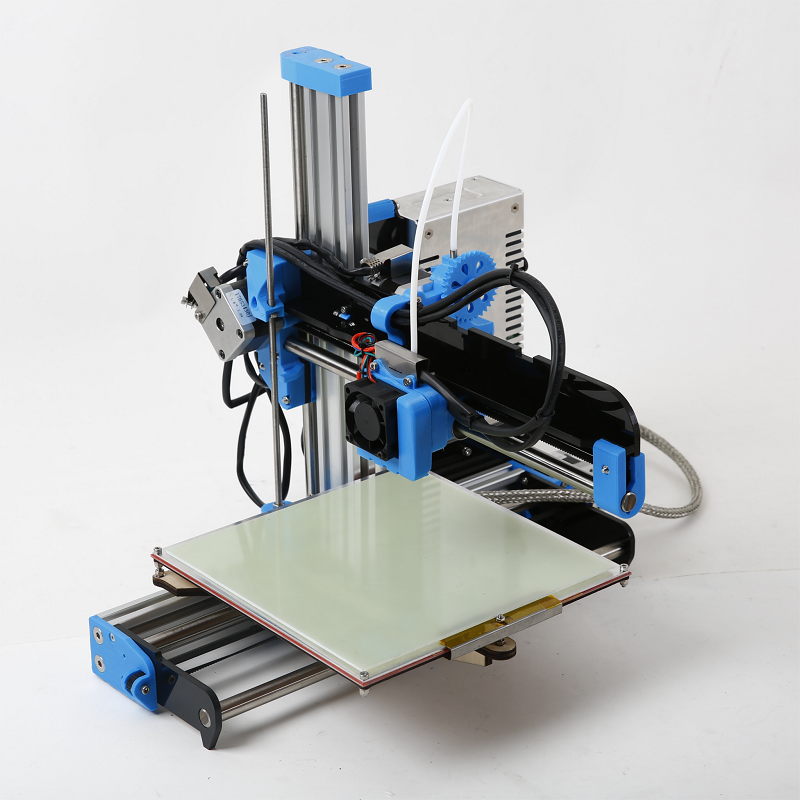

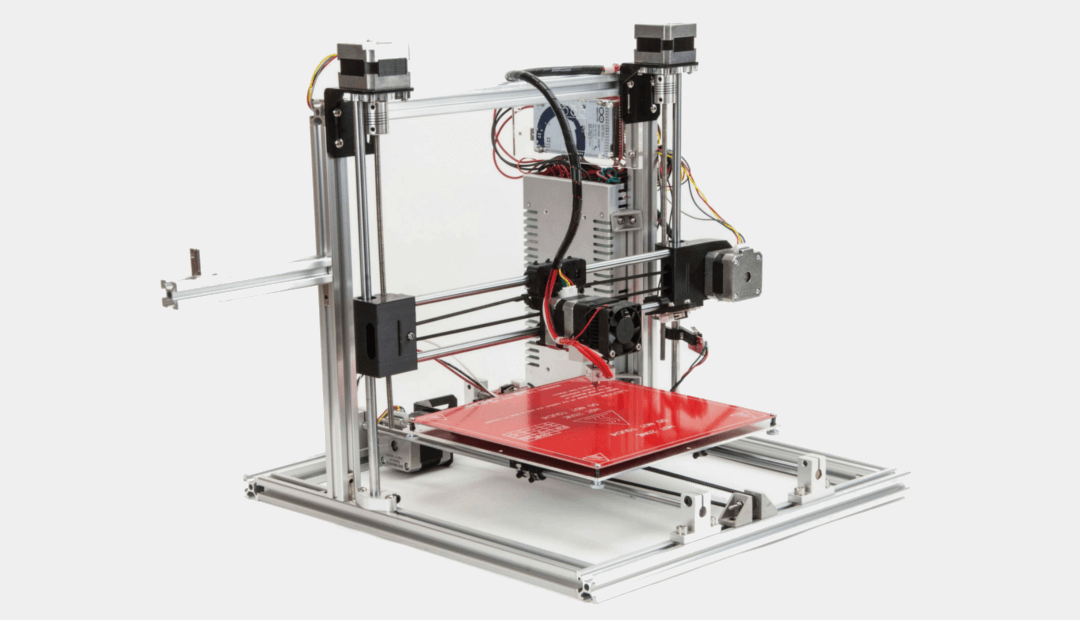

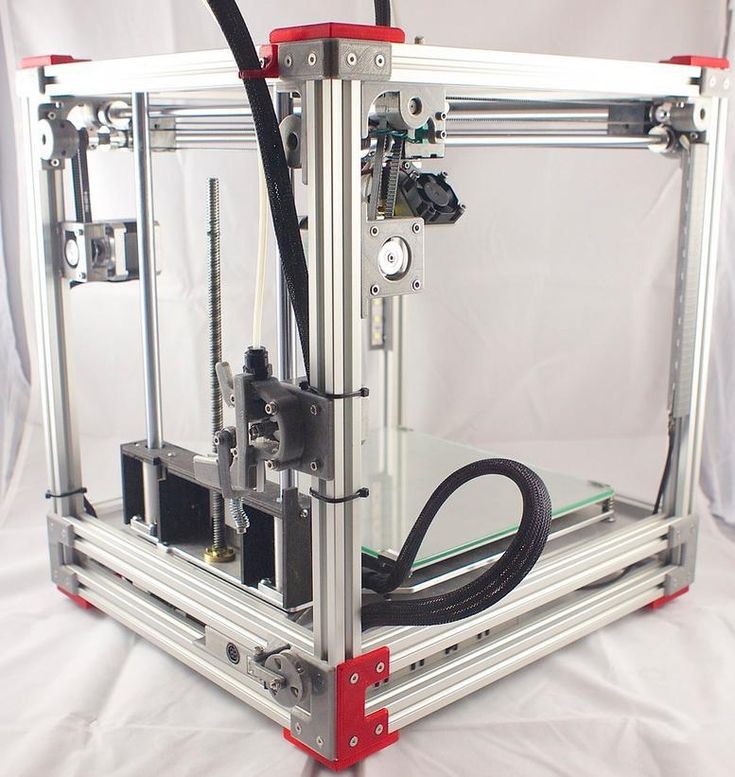

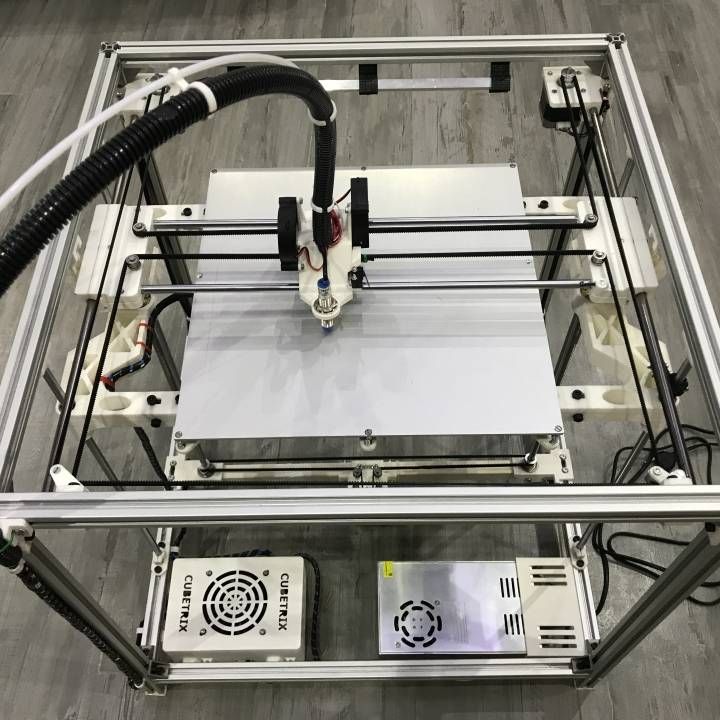

Best kit: Original Prusa i3 MK3S+ kit

prusa3d

SEE IT

Why It Made The Cut: Taking a DIY ethos all the way, the Prusa i3 kit is open-sourced and powerful, with a state-of-the-art-extruder, exceptional leveling, wide filament support and more.

Specs:

- Print technology: FDM

- Build size: 9.84 × 8.3 × 8.3 inches

- Supported materials: PLA, PETG, ASA, ABS, PC (Polycarbonate), CPE, PVA / BVOH, PVB, HIPS, PP (Polypropylene), Flex, nGen, Nylon, Carbon filled, Woodfill

- Best slicer software: PrusaSlicer (proprietary), open source

Pros

- Mesh bed leveling details leveling for every print

- Excellent extruder that can handle an extra wide set of features

- Open source with strong user base for help with all sorts of mods and use cases

- Easy to remove prints

Cons

- Kit requires detailed and rigorous assembly

- Long lead-times for production, allow weeks before it arrives

You can’t get far into 3D printing turf without hearing the name Prusa, and it’s not hard to see why with the Original Prusa i3 MK3S+ kit (an assembled version is also available for a couple hundred more). This kit is a DIY maker’s dream, including some of the best tools in its class for 3D printing.

This kit is a DIY maker’s dream, including some of the best tools in its class for 3D printing.

There’s a few things that make the Prusa i3 special, but we’ll start with its basics. It features a state-of-the-art extruder, as well as an excellent filament monitor. The extruder can handle a much wider than average set of filaments, including the standards, as well as nice additions such as woodfill, and abrasive nylon carbon-fiber. The printer also features an excellent fully automatic bed-leveling system that checks your bed before every print. If that’s not enough, its removable spring steel-sheets make it easy to extract your finished print.

In the end the Prusa i3 is one of the best options out there at the under $1000 price-point, and debatably beats out our top overall pick, the R QIDI X-Plus. However, for the Prusa to reach its full potential this machine requires an operator and builder who rejoices in getting through the weeds that are a major part of its construction, and making it out the other side. This is a printer for tinkerers and DIY makers, and when it’s well understood and loved, it can do wonders.

This is a printer for tinkerers and DIY makers, and when it’s well understood and loved, it can do wonders.

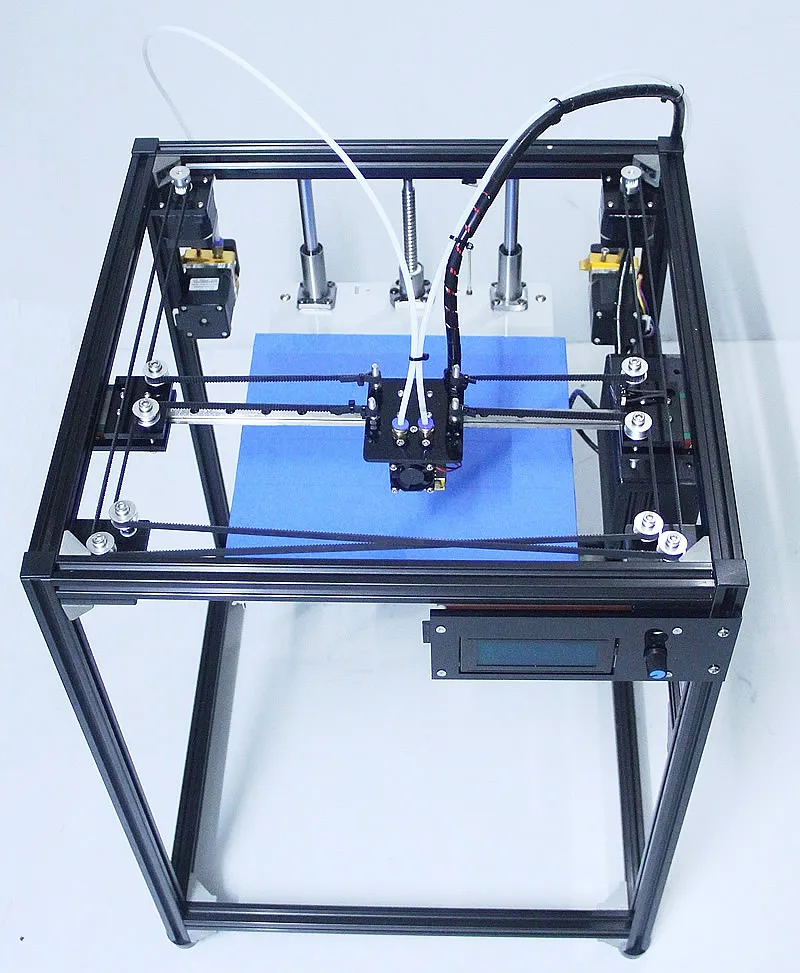

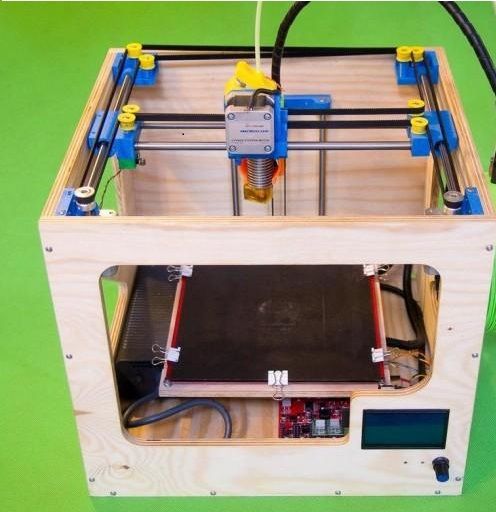

Best budget: Creality Ender-3 S1

Why It Made The Cut: Markedly more affordable than the rest of the printers on this list, the Ender-3 offers some pro level prototyping features, in an upgradeable build that’s priced for beginners.

Specs:

- Print technology: FDM

- Build size: 8.6 x 8.6 x 10.2 inches

- Supported materials: PLA, TPU, PETG, ABS

- Best slicer software: Open source (No preferred), Cura, Simplify3D, PrusaSlicer

Pros

- Open sourced and upgradeable

- Very precise extruder with dual lift

- 16 point auto level

- Easy assembly

Cons

- Loud prints

- Limited feature set compared to more expensive options

Our pick for the best 3d printer under 500, the Creality Ender-3 S1 is still worth a look, even if your possible budget could maybe allow for something pricier. Alongside Prusa, Creality’s Ender series is ever recognizable, and potentially the best known series for beginners. This open-source and expandable system gives you more room to print with than some systems that cost twice as much. With an extruder that hits 500 degrees Fahrenheit it’s also not that restrictive in comparison. Sure it won’t take care of more technical materials, but it does better than most, and if you’re new that might not matter.

Alongside Prusa, Creality’s Ender series is ever recognizable, and potentially the best known series for beginners. This open-source and expandable system gives you more room to print with than some systems that cost twice as much. With an extruder that hits 500 degrees Fahrenheit it’s also not that restrictive in comparison. Sure it won’t take care of more technical materials, but it does better than most, and if you’re new that might not matter.

One of the S1’s standout features is a 16 point auto-leveling system that makes sure your print bed is up to the challenge every time, it also features a removable spring steel-plate, a power-loss recovery feature, and a filament sensor. It delivers solid precision, with a dual-motor design.

While the S1 doesn’t have some of the top features found in models that retail closer to $1000, it’s still an exceptional hobbyist’s 3D printer that’s capable of doing a lot. It’s a great foundation that can be expanded on significantly with mods.

FDM, or fused deposition modeling 3D printers are usually the cheapest, both in terms of up front cost and the cost to replenish their filament over time. They use an additive manufacturing process whereby they apply layers of molten thermoplastics onto a heated tray.

Q: What is the best 3D printer under 1000?The best 3D printer under $1000 for most users is the R QIDI X-Plus. Arriving pre-assembled, this partially enclosed FDM printer is easily serviceable, precise, good for high-quality prints, and is capable of printing a wide array of filaments. QIDI also delivers great customer support.

Q: Which brand 3D printer is best?There are lots of great 3D printer brands. Creality does a great job with powerful hobbyist printers for affordable prices. Prusa makes incredible open sourced printers with some of the best tech around. QIDI is known for precise, easy to use printers with excellent customer support. ANYCUBIC makes exceptional high-res SLA printers. ELEGOO also makes wonderful SLA printers. The best brand is the brand that brings the feature set you need.

QIDI is known for precise, easy to use printers with excellent customer support. ANYCUBIC makes exceptional high-res SLA printers. ELEGOO also makes wonderful SLA printers. The best brand is the brand that brings the feature set you need.

As with any craft business, 3D printer craft can turn a good profit, however, how profitable it will be will depend upon your business practices. Before you invest in a business based on a 3D printer, consider all the factors that will contribute to your business.

Q: Can 3D printers can be acquired for less than 1000?Yes, there are many excellent printers that can be acquired for under 1000. There are even some good ones that cost less than $200.

Q: Do you need a computer for a 3D printer?In some form, you do need a computer for a 3D printer. However, some work-arounds are possible. If you want to buy a 3D printer and can’t afford a computer as well, consider downloading files from your library or school computer and using an SD card to print them on your 3D printer at home.

In some instances enclosed 3D printers are better. Many enclosed 3D printers come preassembled and are easy for beginners to plug in and get started with. Also, 3D printers can emit harmful fumes and light. Most SLA printers, which use bright curing LCDs and / or lasers, feature a UV shield. FDM printers can also benefit from the protection and structural integrity that enclosures provide.

Final thoughts regarding the best 3D printers under $1,000With so many features and advanced processes spun into one functional system, the best 3D printers under $1000 offer astounding feats of engineering, synergized to work together, to bring wildly powerful tools of creation into your workshop. They are used by everyone from design firms who might be prototyping a new invention, to hobbyists building a fleet of figurines. For the best DIY maker’s tool in its class, we recommend the Original Prusa i3 MK3S+ kit. If you’re looking for top notch resolution, you can’t go wrong with the ANYCUBIC Photon Mono X 6K, which is the best SLA 3D printer at its price point. If you want something that’s a little on the cheaper side, the Creality Ender-3 S1 is the best for beginners, and offers a large build space and solid tools. Finally, if ease of use is your prerogative, we recommend the R QIDI X-Plus, as the best overall 3D printer for most users — it might not offer as much tweakage potential as the Prusa i3, but with the X-Plus you’ll be printing great materials within two hours of the package arriving at your door.

6 Best 3D Printers Under $1000 (2023 Update)

- Updated: January 19, 2023

- Pat Nathaniel

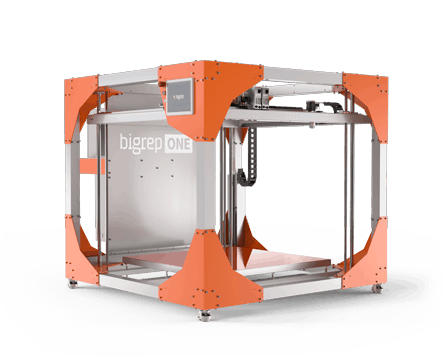

After reviewing the best affordable 3D printers under $500, $300, and $200 it was time to cover the big boys; here’s our look at the best 3D printers under $1000.

We’ve researched and tested 15 different models. The 6 below are the best of the best.

While we don’t all have one grand sitting around to shell out on one of these machines, we’ve set that as our upper limit, and most of the machines cost a good deal less, whilst still maintaining great print quality.

Without further ado…

Artillery Sidewinder X1

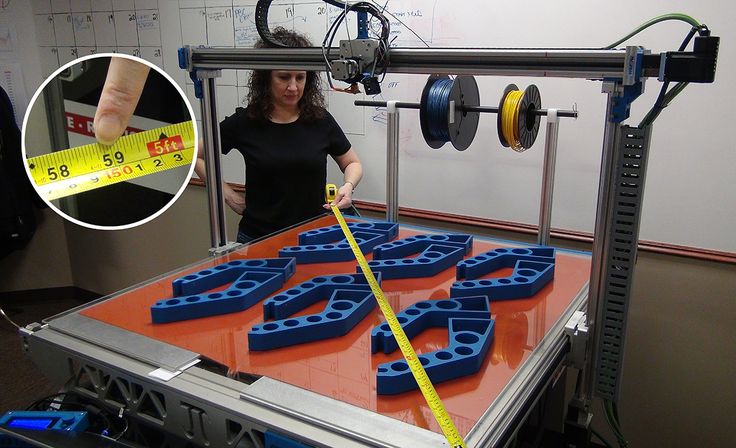

Build volume: 300 x 300 x 400 mm

Check Latest Price

QIDI Tech X-Plus

Build volume: 270 x 200 x 200 mm

Check Latest Price

Prusa i3 MK3S+

Build volume: 250 x 210 x 210 mm

Check Official Website

Check Latest Price

Check Kit Price

Table of Contents

- Top 6 3D Printers Under $1000 At a Glance

- 1. Original Prusa i3 MK3S+

- 2. Creality CR-10 V2

- 3. Artillery Sidewinder X1

- 4. QIDI Tech-X Pro

- 5.

Monoprice Maker Ultimate 2

Monoprice Maker Ultimate 2 - 6. Anycubic Mega X

1. Original Prusa i3 MK3S+ – Best Overall

2. Creality CR-10 V2

3. Artillery Sidewinder X1 – Best Value

4. QIDI Tech-X Pro

5. Monoprice Maker Ultimate 2

6. Anycubic Mega X

1. Original Prusa i3 MK3S+

3D Printer Type: MSLA | Layer Resolution: 0.05 – 0.35 mm | Materials: PLA, ABS, PET, HIPS, Flex PP, Ninjaflex, Laywood, Laybrick, Nylon, Bamboofill, & more | Build Volume: 250 x 210 x 210 mm | Printer Size / Weight: 520 x 480 x 540 mm / 11 kg

Joseph Prusa is an inventor, hobbyist, (you guessed it!) founder of Prusa Research and creator of the Prusa i3 MK3S+.

I’m going to preface this by saying that the MK3S+ is also our most expensive printer on the list, hitting (and exceeding, with tax included) the $1000 mark.

However, for those willing to put in a little extra work, Prusa sells the kit version of this printer for significantly less.

So that’s one to keep in mind!

What I love about this printer is the all-around quality of the machine.

Prusa has built a name for himself as a real pioneer within the industry.

More specifically, each new iteration combines feedback from the previous version – along with new technology and innovation – to create a product that’s objectively better than the last release.

Anyone at all familiar with tech knows how rare this is.

We’ve all been disappointed with new phones, consoles, even electric razors, from companies we thought we trusted.

But the seemingly exponential improvement of Prusa’s designs gives me a level of faith that’s pretty much unmatched across multiple industries.

The MK3S+ itself has some pretty awesome features.

First and foremost, this thing is a beast. Too often stability and durability is overlooked for exciting new features, and you end up with a useless printer in the long run.

The printer is also quiet, and even comes with a patented “stealth mode”, allowing you to hang out in the same room without a good set of headphones.

I can’t fathom how they managed to keep the process so quiet, while maintaining a faster speed than any other printer on the list.

Finally, the printer also introduces a new motherboard which senses shifting layers and missed steps in the 3D printing process. Which, when paired with the great speed and relative quiet of the machine, gives us one more reason to sing this MK3S+’s praises.

As you can no doubt tell, there aren’t too many downsides to this machine. Overall, my biggest problem was the price, which is quite a bit higher than most 3D printing machines on the list.

But, given how much you’re getting for the MK3S+, I’m not complaining.

Also, the initial setup process – both on the physical and virtual side – really tested my patience.

This is a precision machine and should be treated as such. That doesn’t make the tedious setup any less painful, but the payoff is definitely there if you’re willing to put in the sweat equity at the get-go.

That doesn’t make the tedious setup any less painful, but the payoff is definitely there if you’re willing to put in the sweat equity at the get-go.

The Overall Takeaway

So this is our Editor’s Choice, meaning it was my personal favorite printer for under $1000. So as you can perhaps guess, I’d highly recommend this machine to just about anyone.

Anyone who can afford it, that is.

Anyone serious about their 3D printing will be hard-pressed to find a better machine. But if you’re just getting started, or you aren’t too invested in 3D printing, definitely shoot for one of the cheaper options on the list.

What I Liked

- Very quiet

- Excellent speed

- Strong, stable frame

What I Didn't Like

- High price point

- Long setup time

Check Official Website

Check Latest Price

2.

Creality CR-10 V2

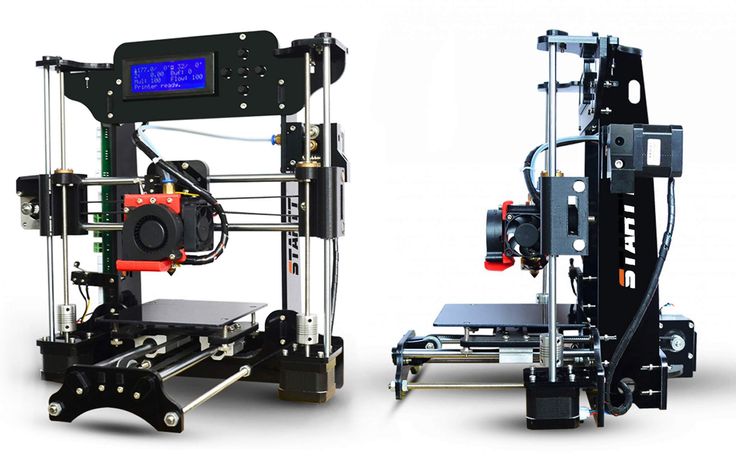

Creality CR-10 V2 3D Printer Type: FDM | Layer Resolution: 0.1 mm | Materials: PLA, ABS, PETG, TPU (flexible), Wood, Nylon, Glow In The Dark | Build Volume: 300 x 300 x 400 mm | Printer Size / Weight: 420 x 550 x 650 mm / 11.5 kg

China-based Creality 3D Technology Co has been around since 2014, and has produced many top-of-the-range printers for home use.

My choice from their (long) catalog is the CR-10 V2, which finds the sweet spot between affordability and quality.

To start, the original CR-10 had some issues with stability, but the redesigned V2 scrapped the original frame, and from my initial experience the new one is a lot better.

Given this was the main issue with the original version – and that version still sold well and was generally well-regarded by other reviewers, the V2 has a lot going for it.

This thing is a workhorse.

It’s advertised at 200 hours non-stop; I’ve come close to that a couple times, and I haven’t had any issues with filament clogging or otherwise. It’s hard to come by any machines that will outwork this one!

Beyond this, the biggest selling-factor for me was definitely its user interface.

You can easily switch between filament colors and types, and the printer even has a feature that will resume your print job if the power goes off.

I was skeptical about this last part, and tested it out for myself. Sure enough, the machine kicked back on and – after a slight delay – began where it had left off, without any errors.

The biggest issue I came across was the out-of-box assembly. While I didn’t have too much trouble with this myself – taking maybe twenty minutes altogether – it could be a potential pain point for less experienced users.

There are also some issues with the pre-loaded settings. They’re going to produce some lower-quality printing than you might want.

They’re going to produce some lower-quality printing than you might want.

Luckily, you can really improve the CR-10’s settings using tuned profiles found on the Reddit page.

The Overall Takeaway

The CR-10 V2 is the best overall printer for beginners, and there are a few reasons why.

First, it has a pretty easy user interface – poor interfaces can be a huge turn-off for people just starting to delve into the field. 3D printing can seem pretty daunting for people who don’t know much about it, and tricky UI isn’t going to do you any favors.

It’s also great because it’ll help introduce new users to the 3D printing community online, and the magic of open-source material.

After all, you’ll need to tinker around with the settings, and using helpful online content will get you printing 3D in no time!

What I Liked

- Solid price point

- Excellent longevity

- Improved stability

What I Didn't Like

- Default settings are janky

- Assembly can be tricky

Click for Best Price

Check Latest Price

3.

Artillery Sidewinder X1

Artillery Sidewinder X1 3D Printer Type: FDM | Layer Resolution: 0.1 mm | Materials: PLA, ABS, TPU, Flexible materials | Build Volume: 300 x 300 x 400 mm | Printer Size / Weight: 550 x 405 x 640 mm / 14 kg

A more recent addition to the field, Artillery hasn’t had the same time to improve their design as Creality or Prusa.

So the fact that the Sidewinder is on this list should say something about the company.

Artillery has only been in the business since 2018…

… but in that time they have established a solid reputation for themselves on the back of their first release; the Sidewinder X1.

And it’s this debut product that makes me so excited to see what they’ll be cooking up for the next few years to come.

What makes the Sidewinder such an excellent option is exactly what I mentioned earlier – a great price tag alongside some superior quality and design.

Rookie companies often try to reinvent the wheel, resulting in some products that are amazing, and some that really fall a little flat.

Which is why I was really surprised when trying out the Sidewinder for the first time.

If nothing else this 3D printer gave the immediate feeling of being designed with confidence and competence.

And you can’t ask for much more than that.

To start, the Sidewinder is super easy to set up.

From opening the box to starting my first job took just a couple minutes, and although you’ll need a bit of fine-tuning following your first projects, after a couple smooth runs you’ll be good to go!

The box also comes with several spare parts, including an extra nozzle.

While it seems like a small advantage, having replacement parts can make your life a lot easier, especially given that they save you having to get in touch with the company, having parts specified, and shipped out, etc.

It also feels very solidly-built, unlike some of the more fragile machines on this list.

As for the printing itself, you’re going to want to do some research on fine-tuning the machine before you plan anything too ambitious.

However, once you’re through with that, the print quality is easily on par with the best machines on this list. Likewise, the print speed and volume are pretty remarkable, for a 3D printer in this price range.

But, like any other piece of tech, this one comes with its issues and quirks.

For one, the Sidewinder uses a ribbon cable, which seems initially helpful, but actually causes more issues than it remedies.

Over the course of 3D printing, this cable can get jostled loose, potentially losing your connection or even shorting out your electronic systems.

Luckily, there are some pretty easy fixes for this – including clips you can print.

And while this didn’t occur with my 3D printer, there are enough reports of bed warping that I should mention it here as well.

In some cases, users have reported that their print bed was so badly warped that it impacted the quality of their prints, which could cause some long-term issues.

The Overall Takeaway

Though this machine isn’t a budget buy, per se, it is a lot less expensive than the first two machines on this list, while offering many of the same features – and some extras!

This machine is great for folks who are really getting into the field – and preferably have some experience with 3D printers already. After all, the machine does require some fine-tuning, which can get a little tiresome or confusing to people who are brand-new to the field.

Those who’ve been around for a while will be able to get the most out of the Sidewinder’s excellent build volume, and won’t have any trouble fronting the cable clips or other replacement parts.

What I Liked

- Solid price point

- Excellent print volume

- Easy UI

What I Didn't Like

- Ribbon cables

- Potential print bed warping

Check Latest Price

Click for Best Price (3DPrintersBay)

and Banggood

4.

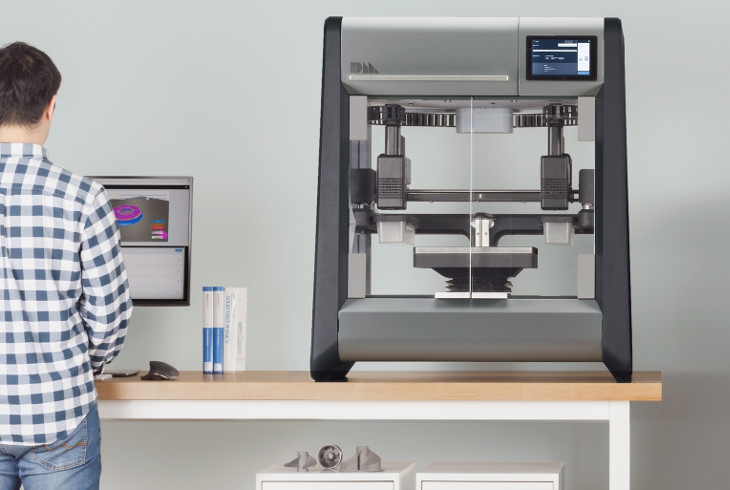

QIDI Tech-X Pro

QIDI Tech-X Pro 3D Printer Type: FDM | Layer Resolution: 0.1 – 0.4mm | Materials: PLA, ABS, TPU, PETG, HIPS | Build Volume: 230 x 150 x 150 mm | Printer Weight: 28.0 kg

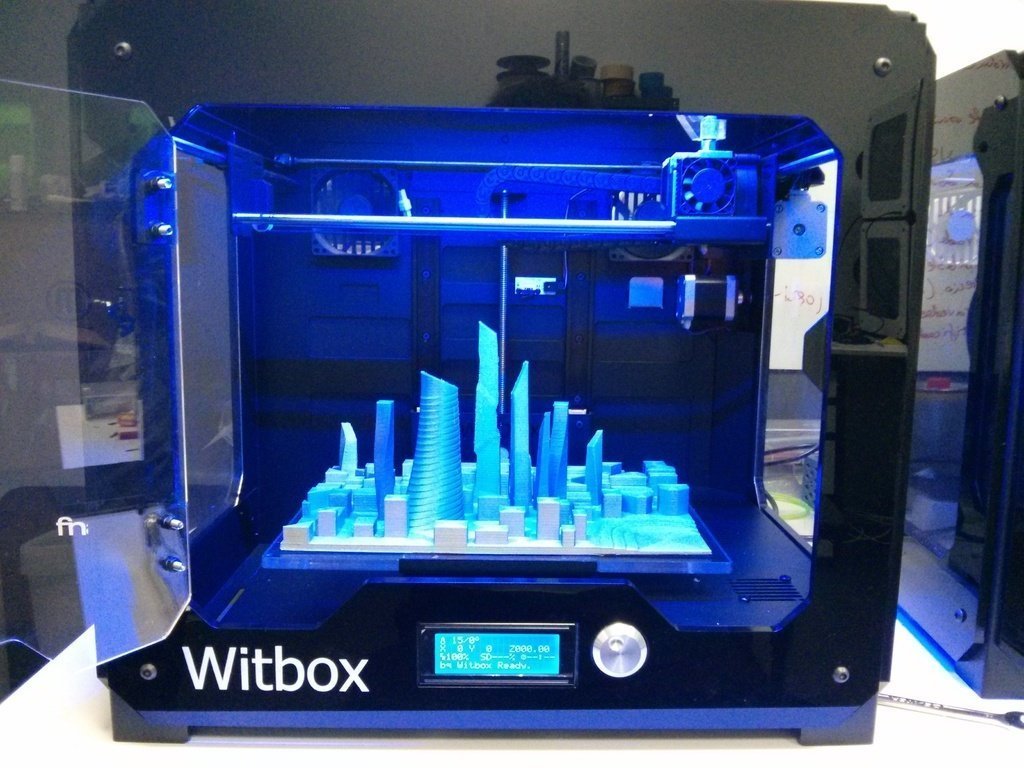

Right out of the box you can tell you’re getting something different with the Qidi.

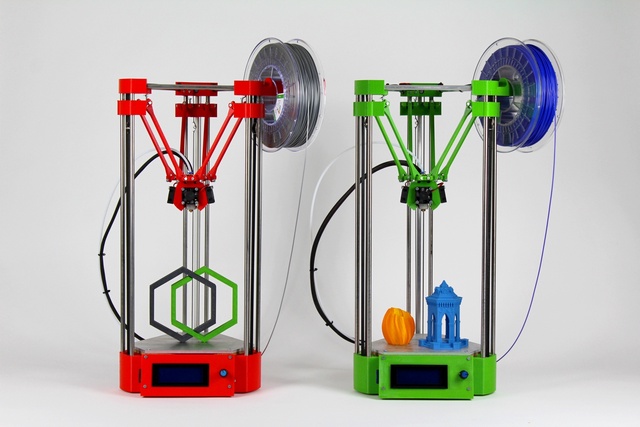

In the most literal sense, this 3D printer looks very different than the previous three on this list. Rather than being in the traditional “tower” form, the printer is cubic, and all of the 3D printing is completed inside the walls of the machine.

But beyond the aesthetic looks of the Qidi, the intentions behind the machine felt a little different as well.

When designing the Tech X Pro, it’s very clear that Qidi prioritized two things; print speed and print volume.

As a result, some of the smaller, quality-of-life improvements in machines like the Prusa aren’t there. But as a result of this focus, the printer can really churn out finished prints.

But as a result of this focus, the printer can really churn out finished prints.

And the overall quality is through the roof.

But let’s not get ahead of ourselves.

The first thing you should always look at is the price, and at around half a grand, the Qidi is right around the middle of the pack for the 3D printers I looked at. You won’t break the bank on this one, but it’s enough bucks to make you do your research before buying.

For that very reasonable price, you’ll get a few standout features.

Chief among these is the dual-extruder, which is a feature that’s normally reserved for very, very expensive machines.

With this, you can print with multiple colors, materials, etc., really opening your world to some awesome possibilities.

And while you might expect a drop-off in quality from Qidi, given how rare it is to see a dual-extruder in cheaper machines, this isn’t really the case.

Overall print quality is still near the top of the list.

The Tech X Pro also comes with four very strong cooling fans.

After a little research of my own, I’m pretty sure these are the biggest factors behind the machine’s insane print volume potential: the fans instantly cool the printing, speeding up the entire process.

Finally, to round it off, the Tech X Pro had some of the easiest out-of-the-box assembly of any 3D printers on the list. The entire process took about 30 minutes, which is actually nothing when compared to some of the more finicky models.

So where did the Tech X Pro fall short?

While the dual-extruder is still far better than it has any right to be – especially at this price – they both get clogged more than you might expect. I’m not certain what design flaw results in this, but it’s been irritating enough to mention.

Likewise, the magnetic base plate is a great idea, but was not implemented very well. It takes a bit more cleaning than usual, and can eat up more of your time with maintenance.

It’s also worth mentioning one of those missing quality-of-life features I mentioned earlier: noise prevention.

This printer is loud.

Really, really loud.

This, combined with the potential for clogged extruders, means you’ll be dealing with a lot of noise, but you may not want to leave the room for too long while you’re 3D printing so you can keep a check on things.

The Overall Takeaway

Ultimately, you should ask yourself whether you want a 3D printer with dual extruders.

And if so, how much you’re willing to spend.

This printer is absolutely the lowest price you can expect with two extruders, and it doesn’t compromise print quality as a result.

But it does require some additional maintenance, which can be pretty irritating

What I Liked

- Dual extruders at a great price

- Excellent cooling speed

- Great print volumeI

What I Didn't Like

- Extruders often clog

- Fans are very loud

Check Latest Price

5.

Monoprice Maker Ultimate 2

Monoprice Maker Ultimate 2 3D Printer Type: FDM | Layer Resolution: 0.1-0.4mm | Materials: PLA, ABS, TPU, TPE, PET, Woodfill, Metal Fill | Build Volume: 200 x 150 x 150 mm | Printer Size / Weight: 380 x 340 x 420mm / 15 kg

Monoprice makes just about everything – from outdoor gear to headphones, to, well, 3D printers.

Which is one of the reasons I was so surprised by their Maker Ultimate 2 3D printer; it’s actually pretty damn good!

The printer is made with a dense metal frame.

While this does make the machine heavier – post-unpacking and setup, the heft and durability is actually a big load off your mind.

After all, you don’t want a machine that’ll shake itself apart or break quickly.

Setup was not the best, as this 3D printer can be tricky at first.

However, if you’re not willing to persevere alone, the Monoprice tech support is top-notch, and they can walk you through any issues you have early on.

At the end of the day, this is the closest thing you’ll get to a real precision 3D printer at this price point, with excellent quality prints right out of the box.

And with a little tweaking, you can improve your print resolution even further.

While the printer’s precision is probably its single best feature, it isn’t the only thing this machine has going for it.

For instance, the Maker continues its all-metal theme by including a full-metal extruder, guaranteeing better performance and a longer lifespan for what is in effect the most important part of any 3D printer.

Monoprice went one step further, too, and added anti-jam features that go a long way towards preventing filament hamming/ clogging.

And unlike the Qidi, the Maker is built with an open-airflow design, meaning the machine’s operations won’t cause uneven heating during the printing process.

So you get all the stability of the four-corner design, with all the benefits of the open-air tower design.

But as usual, this isn’t a perfect machine, and I have quite few initial issues with this particular 3D printer – issues that keep it off the very top of my list.

To start, despite the all-metal extruder, there is a higher failure rate with prints from this machine than any other machine on the list.

This, combined with the fact that the Maker isn’t the cheapest model on the list, is pretty problematic. After all, these machines are made to do one thing: print accurately and efficiently.

I’m not sure if the higher failure rate is linked to the better print details, or if it’s some unrelated design flaw. Either way, it can be extremely frustrating.

But that’s not all.

There are also some persistent issues with the fans, which have a nasty habit of jamming and/ or breaking. It’s possible to replace the fans that are included in the original 3D printer, but that’s not something most people would choose to deal with.

The Overall Takeaway

I said it at the beginning, and I’ll say it again here: how important are the minute details?

With the Maker, you’ll be able to handle the most precise printing available within this price range, and for people who need this, the results may be worth the initial headaches.

For everyone else… well, there are lots of other great machines on the list!f

What I Liked

- Excellent details

- Interesting design

- Full-metal architecture and extruder

What I Didn't Like

- Higher failure rate

- Issues with the fan

- Complex setup

Check Latest Price

6. Anycubic Mega X

3D Printer Type: FDM | Layer Resolution: 0. 05-0.3 mm | Materials: PLA, ABS, TPU, HIPS, Wood, PETG | Build Volume: 300 x 300 x 305 mm | Printer Size / Weight: 500 x 500 x 553 mm / 19 kg

05-0.3 mm | Materials: PLA, ABS, TPU, HIPS, Wood, PETG | Build Volume: 300 x 300 x 305 mm | Printer Size / Weight: 500 x 500 x 553 mm / 19 kg

I had a very good first impression of the Mega X 3D printer, which I bought for a bit less than the average price on this list.

Starting at the very beginning, the unpacking and assembly was easy.

Like, really, really easy.

All that’s required on the physical assembly side is a few screws, three cables, and then leveling your bed.

You can finish this entire process in less than a half-hour, even if you’re pretty new to the field.

The more 3D printers I use, the more importance I place on ease of use; if you’re new, you want to be able to figure out what’s going on, and if you’ve been printing awhile, you want to get right to it and not waste your time fixing tedious problems.

Which is all to say that this 3D printer is very, very simple.

From the first step, you feel like you’re in-control, and that’s important.

Also important: dependability. Whereas many of the other 3D printers on this list require near-constant maintenance and tweaking, this wasn’t at all the case with the Mega X.

For instance, I carried the machine to a different room, and fully expected I would need to relevel the bed.

On the contrary, it was completely level and I could get going on my next project straight away.

And when you do need to tweak something the Mega X is very, very accommodating.

Levelling your bed is a piece of cake, as is cleaning your extruder – though you won’t need to do much of that either.

Finally, it’s worth mentioning again that the price of this 3D printer is super reasonable.

It sits right between “cheap” and “mid-range” for me, and the quality of printing and ease of use makes this one of the best buys on the list.

So where did the printer fall short?

Well, it’s not completely fair, especially at this printer’s excellent price point, but the Mega X doesn’t really excel at any one category.

It isn’t the fastest 3D printer on the list, it doesn’t produce the best details, it isn’t the cheapest, and it isn’t the most durable.

It does have solid ratings in each of these departments, making it a jack-of-all-trades, but if you’re looking for any of these things specifically, there are better options.

There was also the issue of power-loss. The longer your job, the more likely you are to lose power at some point, and many 3D printers have installed some job-continuation features based on that.

The Mega X doesn’t include any of these, so you may lose your project if you lose power.

The Overall Takeaway

This is the quintessential beginner 3D printer.

If you’re just getting into the field, you’re going to have trouble finding a more accessible, better-quality 3D printer at this price.

The Mega X is easy to set up, and is pretty close to being capable of printing right out of the box.

And it generally maintains its current state – meaning you don’t have to continuously tweak and adjust its features once they’re set.

Ultimately…

…if you know what you want from a 3D printer, you can probably find a specialized printer that will outshine the Mega X in any given category.

But if you’re just learning about the field, or want a good, utility 3D printer, you’ve found one right here!

What I Liked

- Very user-friendly

- Quick and easy setup

- Very reliable and sturdy

What I Didn't Like

- Not the best in any category

- Issues with power loss

Click for Best Price

Check Latest Price

Our Pick

So you’ve made it this far (or maybe you just skipped to the end), you’ll know it’s time for me to unveil my #1 pick for 3D printers under 1000.

If not, here it is again!

Winner: The Original Prusa i3 MK3S

To be honest, our last entry on the list gave the Prusa a run for its money. If your budget is any less than $1000, you could do a lot worse than the Mega X or Sidewinder X1.

But at the end of the day, the Prusa is absolutely the gold standard for 3D printers, and its high price point is justified by the superlative quality of this 3D printer.

Unlike the Mega X, the Prusa did excel in multiple categories.

Once everything is set up, configured and otherwise assembled, the Prusa effortlessly, silently, quickly and cleanly prints anything you want it to.

As far as actual printing performance, this 3D printing powerhouse is off the charts!

True, its setup time left something to be desired.

Pair that with its high cost, and you have a pretty demanding machine.

But the effort you put into the Prusa will be paid back tenfold once you get rolling.

So there you have it: my personal list of the best 3D printers under 1 grand on the market today.

We’re just seeing the tip of the iceberg for this field, and I’m plenty excited to see what companies like Prusa can put out in the next few years.

We’re really entering a renaissance for this field, and it’s the perfect time to get started.

So go on, find the best 3D printer on this list, and start creating something innovative today!

Best 3D Printers Under $1,000 Ranked (2022)

Hesitant to shell out $1,000 for a 3D printer? We went through it. Taking this bad experience and turning it into something more positive, we've compiled a list of the best 3D printers under $1,000, all of which are certified winners and are sure to make you happy.

With $1,000 in hand, you are confidently stepping into professional territory. These are feature-packed, versatile machines with more print potential and wider media compatibility than the printers you're about to buy. However, such a large selection can be confusing and lead to indecision. nine0003

However, such a large selection can be confusing and lead to indecision. nine0003

With our guide in hand, you will hopefully be able to make your choice of 3D printer to improve your prototyping, realize your fun home printing goals, improve your workshop or start a business.

Contents

- Best 3D printers under a thousand dollars in 2022

- Flashforge Creator Pro 2

- Prusa i3 MK3S+

- Qidi Tech X-Plus

- D Pulse XE great printer for printing under a thousand dollars abrasive threads

- AnyCubic Photon Mono X 6K

- Creality Ender 6

- Buyer's Guide - What to Expect in a $1,000 3D Printer

- Intended Use

- Print Volume

- Material Compatibility 9 Layers and Print Height

- Dual extruder

- Anti-prefab kit

- Safety features

- FAQ

Best 3D printers under a thousand dollars in 2022

Flashforge Creator Pro 2

- Price: Available in the official Flashforge store

- Assembly volume: 200 x 148 x 150 mm (with dual extruder)

Flashforge Creator Pro 2, an upgrade of the original Creator Pro, offers extensive independent dual extrusion at a price we can afford. Normally, we would expect to pay twice as much for being able to juggle different materials, colors, and support structures, as well as all sorts of fantastic dual printing modes. nine0003

Normally, we would expect to pay twice as much for being able to juggle different materials, colors, and support structures, as well as all sorts of fantastic dual printing modes. nine0003

In testing, Flashforge Creator Pro 2 reliably delivers first-class prints, especially accurate separations when feeding different media and colors through IDEX. Print quality is maintained whether you use PLA, HIPS, PVA or ABS, and the heat-sensitive material does a great job thanks to the fully enclosed chamber and 120°C heated liner.

The build volume seems a bit cramped, especially in light of the IDEX setup, at 200 x 148 x 150mm. Making two prints at the same time actually cuts the printable area in half, which hinders the production of large mirror parts, for example. However, the IDEX system largely compensates for this. nine0003

Another minor note to note is FlashForge's decision to tie Creator Pro 2 to a functional, albeit slightly limited, native FlashPrint slicer. When it comes to slicer manufacturers, FlashPrint is one of the best. However, we always feel left out when we can't run Cura or another third-party slicer full of advanced features.

However, we always feel left out when we can't run Cura or another third-party slicer full of advanced features.

Overall, manufacturers who have outgrown their starter printer, or newcomers looking for some of the cost-effective printing thrills IDEX has to offer, will find the Flashforge Creator Pro 2 a worthwhile purchase. nine0003

Prusa i3 MK3S+

- Price: $749 kit / $999 assembly - Available at Prusa

- Assembly volume: 250 x 210 x 210 mm

The Prusa i3 MK3S+, in its distinctive orange and black colors, is a sophisticated yet easy-to-use printer that regularly makes top lists.

The Prusa i3 MK3S+ is a force in the 3D printing market, combining industry-leading hardware, integrated fault-tolerant tools and sensors that take the guesswork out of complex aspects of 3D printing, and reliable, exquisite print quality regardless of the industry. applications. nine0003

You'll find improved mesh layer alignment thanks to the SuperPinda sensor and elegant power loss recovery in the event of an unexpected power outage. The printer features coveted hardware such as an E3D V6 hot end, MK52″ heating element, and removable PEI magnetic steel sheets textured for various materials.

The printer features coveted hardware such as an E3D V6 hot end, MK52″ heating element, and removable PEI magnetic steel sheets textured for various materials.

These are just a few of the technical and user-friendly features built into the Prusa i3 MK3S+, making it compatible with PLA, ABS, flexible materials, PETG, nylon and more. The 250 x 210 x 210mm building volume of the machine provides ample space for all the most common 3D printing applications such as hobby projects, prototyping, low volume printing and more. nine0003

Newbies might recoil at the steep price tag, but if you're looking to start from scratch with a vibrant user community and exemplary customer support ready to help, the Prusa i3 MK3S+ is in a league of its own.

The Prusa i3 MK3S+'s surface level of ease of use hides enough advanced features and printing power to please more experienced creators and even professionals.

Qidi Tech X-Plus

- Price: Check price on Amazon

- Assembly volume: 270 x 200 x 200 mm

The Qidi Tech X-Plus has earned its place among the best 3D printers under $1,000 for its combination of affordability and the versatility usually associated with more expensive printers. The machine may lack the sophistication found in competing printers, but it works so well with more complex materials that it deserves more than a passing nod as exceptional value for money.

The machine may lack the sophistication found in competing printers, but it works so well with more complex materials that it deserves more than a passing nod as exceptional value for money.

A clever dual interchangeable extruder system is responsible for much of the versatility of the Qidi Tech X-Plus. It allows you to print equally well on PLA, PETG, TPU and similar materials, as well as on heat-sensitive materials such as ABS and nylon, by fine-tuning each extruder to the desired temperature parameters. nine0003

Double sided reversible heated bed meets these specifications, each surface is textured either for low temperature materials or to provide proper adhesion for heat sensitive threads. The processing of various materials also extends to the closed chamber design: when closed, it maintains a stable temperature for ABS; with the covers removed, the PLA has all the airflow needed for reliable prints.

Color touchscreen, Wi-Fi connectivity, dual Z-axis, air filtration system, well controlled bed alignment, decent 270 x 200 x 200mm dimensions for medium to large parts, built-in dual spool holders, print resume and more A: The performance of Qidi Tech X-Plus meets many requirements. nine0003

nine0003

All of this makes the Qidi Tech X-Plus the ideal printer for semi-professional users looking for a good balance between affordability and versatility.

Pulse XE - Great sub thousand dollar 3D printer for printing with abrasive filaments

- Price: $999 - available from Matterhackers

- Assembly volume: 250 x 220 x 215 mm

Pulse XE is the best hard filament 3D printer under $1000

A massive beast, the Pulse XE is a machine ready to handle even the toughest, toughest and most abrasive materials like NylonX, carbon fiber, brass, etc.

In many ways, this is a modified dream machine of a seasoned craftsman that boasts the best equipment and features without any labor-intensive post-purchase modifications at a reasonable price. Among them, the Pulse XE features an E3D V6 hot end, a 300°C heated bed with true LayerLock Garolite, a BLTouch bed level sensor, a Bondtech extruder, and a rugged all-metal frame.

Testing shows how easy it is for the Pulse XE to print quality parts using exotic materials. The machine simply works, delivering consistent prints day in and day out, fully living up to its reputation as a reliable workhorse. nine0003

The machine simply works, delivering consistent prints day in and day out, fully living up to its reputation as a reliable workhorse. nine0003

While the Pulse XE is built to last and handle the most demanding print projects, its physical footprint remains reasonable, balanced with an average working volume of 250 x 220 x 215mm. This printable area, while not extraordinary, should be sufficient for major projects such as models, toys, functional household parts, light prototyping, and printing multiple small parts at the same time.

If you plan to print complex parts and need a 3D printer that can handle the task, we recommend the Pulse XE without any problems. This is the machine most likely to take center stage in your printing system in no time. nine0003

AnyCubic Photon Mono X 6K

- Price: $659

- Assembly volume: 192 x 120 x 245 mm

The AnyCubic Photon Mono X 6K eliminates one of the major drawbacks of resin printing by combining an exceptionally detailed 6K LCD display with one of the largest build volumes of any desktop resin 3D printer without sacrificing print quality. The successful expansion of resin printing capabilities without compromise is the biggest attraction of the AnyCubic Photon Mono X 6K and solidifies its place among the best 3D printers under $1000. nine0003

The successful expansion of resin printing capabilities without compromise is the biggest attraction of the AnyCubic Photon Mono X 6K and solidifies its place among the best 3D printers under $1000. nine0003

The 9.25-inch 6K monochrome LCD offers ultra-fine 34 micron print resolution and 5760 x 3600 pixel resolution. On the AnyCubic Photon Mono X 6K build plate, it delivers a printable area of 192 x 120 x 245mm to create decent-sized parts. Turn up the speed and the printer can confidently print at speeds up to 80mm/h. In other words, the AnyCubic Photon Mono X 6K is no wimp when it comes to part manufacturing.

AnyCubic has earned a well-deserved reputation for delivering best-in-class quality resin printers. The AnyCubic Photon Mono X 6K follows suit, creating truly exceptional detail, beautifully illustrating subtle features with an almost flawless finish. And like its Photon brethren, the Mono X 6K is well made and very easy to use, even though it lacks automatic stock alignment. nine0003

nine0003

For manufacturers looking to print large prints with high fidelity, the AnyCubic Photon Mono X 6K is a smart purchase that's sure to make a difference, whether you're a hobbyist, board gamer, professional prototyper or small business.

Creality Ender 6

- Price: Check the price in the official Creality store here

- Assembly volume: 250 x 250 x 400 mm

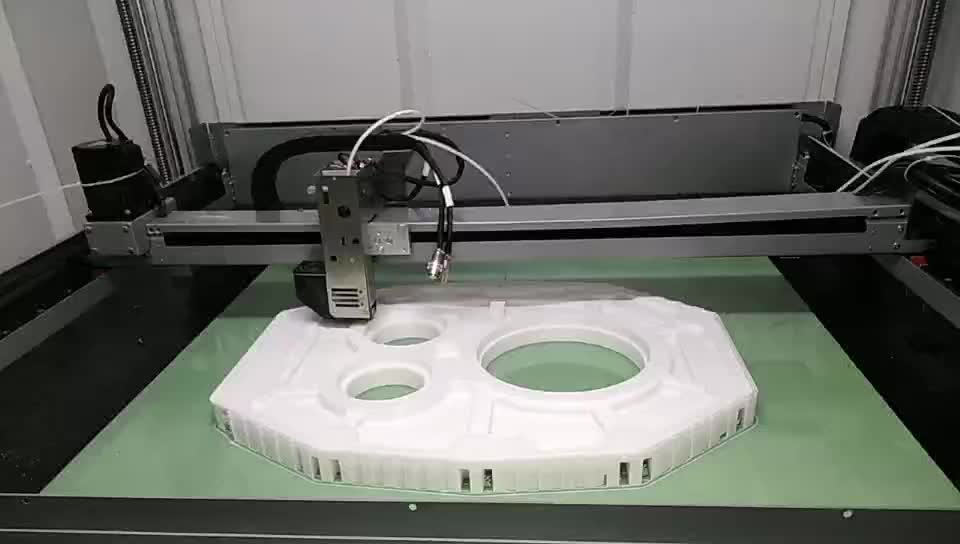

The Creality Ender 6 is the spiritual successor to the popular Creality Ender 5, mixing things up with a Core-XY machine equipped to deliver significantly faster print speeds than most sub-$1,000 FDM printers. Pushed to the limit, the Creality Ender 6 prints at 150 mm/hr at 100 micron layer height, ideal for hobby and semi-professional applications. nine0003

The design is different from what you would expect from an FDM printer, with a boxy all-metal frame surrounded by acrylic covers, except for the top one, for a semi-enclosed chamber. Improvements over the Ender 5 include an increase in build volume to 250 x 250 x 400mm, which means a greater variety of part types and patterns that the Ender 6 can handle. layer. Quality-of-life features such as filament low sensor, print resume, touch screen and silent motherboard chipset also make this printer user-friendly. nine0003

layer. Quality-of-life features such as filament low sensor, print resume, touch screen and silent motherboard chipset also make this printer user-friendly. nine0003

The Creality Ender 6 offers a solid foundation for quality prints and ample room for customization and customization. For this reason, it makes it to our list of the best printers for veterans looking for a solid foundation to build on.

Buyer's Guide - What to Expect in a $1,000 3D Printer

Intended Use

Choose the printer that fits your needs and goals. If you want to create miniatures with great detail and precision, opt for a high resolution resin printer such as the AnyCubic Photon Mono X 6K. nine0003

If you're looking for a reliable professional printer that you can use on a daily basis to experiment and print a wide variety of parts, then a versatile printer like the Prusa i3 MK3S+ or Qidi Tech X-Plus is the right choice for you. A high-speed printer like the Creality Ender 6 is more suitable for small business prototyping or mass printing parts for sale.

Print volume

Generally, there is a correlation between build volume and price; one of them increases, the other also increases. Luckily, the $1,000 price represents a sweet spot of sorts, as the vast majority of printers at this price point have a fairly large build volume. nine0003

If you're planning on printing more impressive parts or models in one go, consider high build volume printers such as the Qidi Tech X-Plus and Prusa i3 MK3S+.

Material Compatibility

At $1,000, you should expect the printer to handle low temperature materials like PLA, PETG and flexibles as standard with ABS printability. Compatibility with both low temperature and high temperature materials gives more application possibilities. If you want to print on a wider range of materials, look for printers with a mandatory closed design and possibly two extruders for convenience. nine0003

As far as resin printers are concerned, they are bound to one type of material, so there is nothing special here, except for decent support for third-party resins.

Print speed, resolution and layer height

Print speed is a combination of many factors, but to get an idea of the printer's capabilities, look at the mm/h in the specification.

At the high end of the scale, you'll find printers like the Creality Ender 6 capable of 150mm/h. nine0003

For resin printers, the 60-80mm/h speed is a solid entry point into the sub-$1,000 3D printer category and reduces print times to hours, not days.

Dual extruder

Although not quite a standard model, there are dual extruder printers or IDEX systems costing around $1,000 such as the Qidi Tech X-Plus and Flashforge Creator Pro 2. These allow you to easily print different types of materials and colors, eliminating from the need to flush the extruder and change the filament. nine0003

If your plans include complex multi-color parts, mirror printing, duplicate printing, etc., we highly recommend dual extruder printers due to the convenience factor.

Automatic Bed Leveling

Automatic Bed Leveling eliminates the need to level the bed, a critical step in the setup process.

The likelihood that a $1000 printer will have an automatic leveling system, or at least a well-managed and well-understood leveling system. If the thought of manually leveling scares you, opt for a printer with automatic bed leveling such as the Prusa i3 MK3S+ or Pulse XE. nine0003

Pre-Assembly Kit

3D printers under $1,000 usually come pre-assembled, sometimes a few simple maneuvers are required to complete assembly. However, you can find similarly priced printers such as the DIY version of the Prusa i3 MK3S+.

If you're up for the challenge and want to take a full 3D printer hardware course, we highly recommend that you choose the kit. The bundled printers are also cheaper, so you can save money here too. If this is your first printer and you don't like manual assembly, you might want to look for a printer that works out of the box and requires little to no assembly. nine0003

Security features

If you are looking to purchase a printer for schools or other educational institutions, you should pay attention to its security features.

Primarily features such as a closed chamber that provides a barrier between hot parts and fingers, an air filtration system to remove toxic fumes, especially when printing ABS, and life-saving features such as print resume function, automatic filament feeding and thread leakage sensor. nine0003

All of these features are standard on the best 3D printers under $1,000, but you may have to shop around to find the printer with the optimal set of security features to suit your needs. A cover-removal shut-off switch should be standard on a resin printer.

FREQUENTLY ASKED QUESTIONS

What is the best 3D printer under $1,000?

Our top pick is the Prusa i3 MK3S+. Prusa has poured years of know-how into iterative updates to its flagship printer. It looks great, prints even better, and has a host of trouble-free features that make the 3D printing process so much easier. nine0003

What is the best resin 3D printer under $1,000?

While there are plenty of great resin 3D printers under $1,000 thanks to the shift towards affordability led by machines like the Elegoo Mars and Phrozen Sonic, it makes sense to make the most of that money by purchasing the AnyCubic Photon Mono X 6K. It manages to balance exceptionally detailed print quality with high build volume, tackling the only issue that plagues resin printers. nine0003

It manages to balance exceptionally detailed print quality with high build volume, tackling the only issue that plagues resin printers. nine0003

What's the best 3D printer kit under $1,000

At the risk of sounding like a broken record, we would once again call the Prusa i3 MK3S+ the best 3D printer kit under $1,000. Not only do you get one of the best 3D printers on the market and pay less per kit than a pre-assembled version, but building the machine piece by piece gives you valuable hands-on experience that makes future upgrades and modifications easier.

Top 20 Inexpensive 3D Printers (from $199 to $1000)

3DPrintStory Reviews Top 20 Inexpensive 3D Printers ($199 to $1000)

Just 10 years ago, a 3D printer cost over $100,000. Today, you can easily find a cheap 3D printer for under $200. It's amazing. nine0003

Today, you can easily find a cheap 3D printer for under $200. It's amazing. nine0003

Naturally, the lower the price, the more restrictions. Some of the printers on our list will not have a heated bed and the workspace will be small. Naturally, the quality of most of the models presented below cannot compete with more expensive counterparts.

But with a little patience and diligence, it is quite possible to achieve high-quality 3D printing on a printer that costs half the price of a flagship smartphone. And it's really cool!

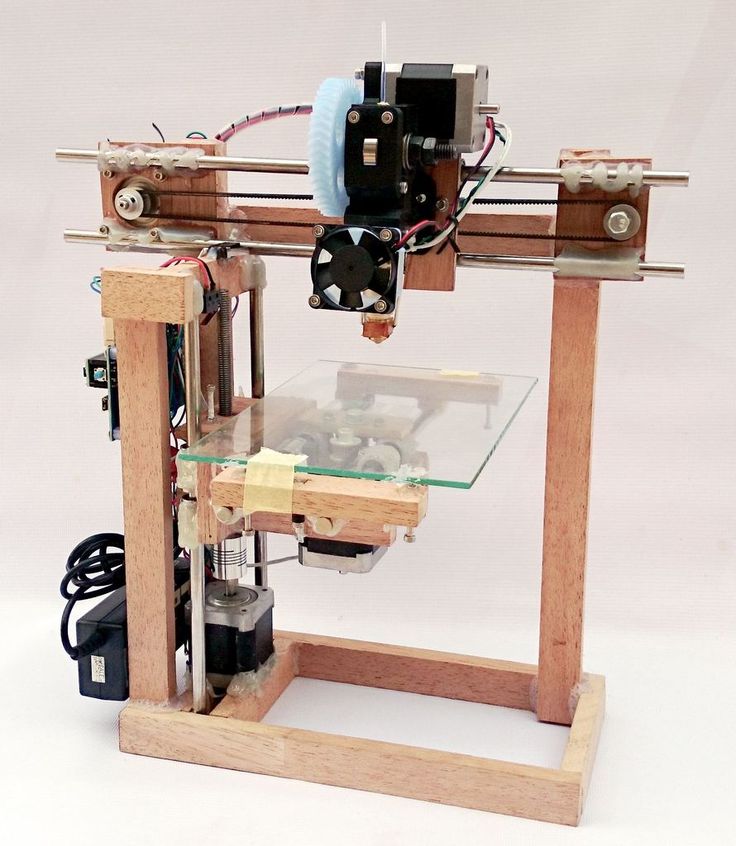

Important note : All 3D printers in this top are supplied assembled by the manufacturer. If you have free time and want to spend less money, you can buy DIY kits and assemble the 3D printer yourself according to the instructions.

List of the best cheap 3D printers in the price range from $ 200 to $ 1000

| 3D Printer | Material Press | Working space | 0273 | 459 | ||

|---|---|---|---|---|---|---|

| Flashforge Finder | PLA | 140 x 140 x 140 | 499 | |||

XYZprinting da Vinci Jr. 1.0 Pro 1.0 Pro | PLA | 150 x 150 x 150 | 499 | |||

| XYZprinting da Vinci Jr. Mix 2.0 | PLA | 150 x 150 x 150 | 599 | |||

| Printrbot Simple If you want to buy them, even if you live in large cities such as Kyiv, Moscow, St. Petersburg, Minsk, it may turn out that these models will not be in the online stores of your city, or they may be with a decent mark-up relative to the cost that indicated in the article. Since most of them are European / American, it is possible that they will not be in stores at all. Therefore, before making a choice, I recommend looking directly at eBay, Amazon, Aliexpress, etc. - many sellers on these planforms deliver to the CIS countries within 1-4 weeks on average. nine0003 It is especially worth monitoring these platforms during the discount period - Black Friday or Chinese New Year (Aliexpress or Gearbest) - prices on such days can be 2 or more times lower than usual and it is worth waiting a few weeks. Monoprice MP Select Mini ($199)

Probably the best 3D printer on our list. Why? Because the Monoprice MP Select Mini is an impressive development with a thoughtful, compact design at a very low price. This model has a quick-change steel material feed wheel, a cooler for cooling the nozzle, a color LCD screen, a heated table, plus the ability to transfer models for 3D printing via microSD or USB. nine0003 The heated bed and the wide temperature range of the extruder are especially pleasing, because for such a small price you get the opportunity to print in different materials: from ABS B to PLA or exotic materials like conductive PLA plastic, wood, metal-based composites and PVA. For those who are worried about the lack of a guarantee - for such a price it is possible without it. This model is upgradeable. For example, you can install a new nozzle, change the table and add WiFi connectivity. nine0003 Small working space - 120 x 120 x 120 mm. Specifications of cheap 3D printer Monoprice MP Select Mini

Back to 3D printer list M3D Micro Retail ($249)

The M3D Micro 3D printer hit the market thanks to Kickstarter. This model was presented with an incredible price of $349. The working space of the M3D Micro is 109 x 113 x 166 mm. There are several body color options. The company has implemented "Micro Motion Technology" - a set of innovative solutions - thanks to which you get excellent quality 3D printing at a small price. Today, this inexpensive 3D printer already costs even less than the price announced on Kickstarter. You can buy it for $249 with a 12 month warranty. By the way, it is already possible to pre-order the next "pro" version. Specifications of cheap 3D printer M3D Micro Retail

Back to 3D printer list XYZprinting da Vinci Mini ($289)

Da Vinci Mini is a successful attempt to make the 3D printer user-friendly. Unfortunately, you can only use the manufacturer's own 3D materials. On average, they cost 20% more than usual. However, the company also argues that the materials used (PLA) will be 100% non-toxic. nine0003 Specifications of cheap 3D printer XYZprinting da Vinci Mini

Back to 3D printer list Monoprice Maker Select V2($299)

The next cheap 3D printer with a good reputation is the Monoprice Maker Select V2. This model is an analogue of the Wanhao Duplicator i3, which, in turn, borrowed the design from the Prusa i3. But this does not affect the quality, as the Monoprice Maker Select V2 is easy to use and gives excellent 3D printing results. Monoprice Maker Select V2 design feature is that the power supply and control panel are placed outside the 3D printer. The working space of this model is 200 x 200 x 180 mm. And this is really a good indicator for the money. nine0003 Specifications of cheap 3D printer Monoprice Maker Select V2

Back to the list of 3D printers New Matter MOD-t ($299)

New Matter is a young startup that offers a 3D printer MOD-t - An interesting design with a minimalistic design. This cheap 3D printer is WiFi enabled so you can manage print settings and print from your computer, tablet or smartphone. The working space is 150 x 150 x 125 mm. Thanks to the case, the noise during its operation is reduced. But the most interesting and attractive thing about MOD-t is the price. Only $299. In general, this is an interesting, high-quality model. Specifications of cheap 3D printer New Matter MOD-t

Back to the list of 3D printers Printrbot Play ($399)

The Printbot Play is a very popular budget 3D printer that is often used in education. This inexpensive, reliable model, which is almost entirely made of metal. The working space is 100 x 100 x 130 mm. Printbot Play has an extruder manufactured by the company itself - Alu Extruder v2. The body is made of powder coated steel and aluminium. SD slot provided. nine0003 You can upgrade the basic design of the Printrbot Play with a heated stand or increase the Y-axis stroke. Back to the list of 3D printers Wanhao Duplicator i3 Plus ($459)

The Wanhao Duplicator i3 Plus is an upgraded version of the popular Wanhao Duplicator i3 (which in turn is based on the Prusa i3). The main features of this cheap 3D printer are a large working space of 200 x 200 x 180 mm, a steel frame, electronics integrated into the design itself (previously it was taken out separately), a slot for a full-size SD card and a touchscreen display for control. nine0003 Wanhao Duplicator i3 Plus Cheap 3D Printer Specifications

Back to the list of 3D printers Flashforge Finder ($499)

FlashForge Finder is one of the newest 3D printers on our list. This affordable 3D printer offers an average working space of 140 x 140 x 140mm. This Finder features a transparent sidewall design so you can view the 3D printing process from any angle. A color display is installed, it is possible to transfer data via WiFi network. The printer comes with some supplies and a USB flash drive, so you can start 3D printing almost immediately. nine0003 Specifications of cheap 3D printer FlashForge Finder

Back to 3D printer list XYZprinting da Vinci Jr. 1.0 Pro ($499)

What's so special about the da Vinci Jr. Also features an auto-calibration mechanism, a closed chamber with a unique cooling system, and a 0.3mm nozzle option for high-quality printing of fine model details. All in all, this is a great 3D printer with a lot of useful features and at a low price. nine0003 Specifications for cheap 3D printer da Vinci Jr. 1.0 Pro

Back to 3D printer list XYZprinting da Vinci Jr. Mix 2.0 ($599) Mix 2.0 ($599)

XYZprinting provides a wide range of low cost 3D printers. And paying attention to each model is quite difficult, although many of them are very interesting. XYZprinting da Vinci Jr. Mix 2.0 stands out because it can print with two different materials and mix them to create multi-colored models. This dual-color 3D printing technology is rare in this price range ($500 to $1,000), so if you're interested in experimenting with multicolor printing, XYZprinting da Vinci Jr. Mix 2.0 is a great choice. nine0003 However, there is a drawback. This 3D printer is not compatible with materials from other manufacturers, so you will have to buy special materials from XYZprinting (as we mentioned above, they cost 20% more, but are not toxic). Specifications of cheap 3D printer XYZprinting da Vinci Jr. Mix 2.0

Printrbot Simple ($599)

Printrbot Simple is the flagship of the Printbot empire. This model has a great open design with a solid aluminum frame and a working space of 150 x 150 x 150mm. This inexpensive 3D printer comes fully assembled at a very good price. As you need and want to experiment, you can add a heated table and expand the workspace in the horizontal plane. nine0003 Specifications of cheap 3D printer Printrbot Simple

Back to the list of 3D printers UP mini 2 ($599)

The UP mini 2 is a low cost 3D printer that packs in impressive design and functionality. For starters, it has a touch screen panel and the ability to connect via WiFi. But the most interesting is further. Implemented power failure protection system. 3D printing will continue after the emergency stop. Built-in HEPA air filtration system. Automatic detection of the height of the extruder nozzle. A separate, closed container for the material, thanks to which it does not deteriorate under the influence of moisture from the environment. nine0003 Great 3D printer for a small price. The only thing that upsets me a little is the small working space - 120 x 120 x 120 mm. Specifications of cheap 3D printer UP mini 2

Back to the list of 3D printers Monoprice Maker Select Ultimate ($699)