Visions 3d printer

High-Temperature 3D Printers | Vision Miner

Designed for PEEK, ULTEM, and other High-Performance Polymers, these machines are all open-filament, open-source and cutting-edge in their respective categories.

Which Printer Do You Need?

With dual independent extruders capable of 500ºC, an actively-heated chamber reaching 90ºC, and a triple-motor, true-self-leveling 200ºC bed, coupled with the fully open material system, the 22 IDEX is unlocking the potential of in-house additive manufacturing, at a price that disrupts everything the industry has seen before.

LEARN MORE

High-Quality Selective Laser Sintering 3D Printers -- with 9 different polymers to choose from, and a totally open material platform, the Sinterit line of SLS machines are the best we could find on the market, and now, they're available to you and your business.

LEARN MORE

The AON-M2+ is a high temperature, industrial 3D printer that can fabricate the highest performance thermoplastics. Print bigger and better with its actively heated build chamber and large build volume.

Choose from materials that can replace metals, with properties that can withstand the harshest operating conditions.

Avoid getting tied down with costly proprietary polymers, and experience the freedom of choosing between leading chemical companies.

AON M2 ⤑

Essentium is fundamentally changing how things are made. As innovators in both materials and production platforms, Essentium is disrupting traditional manufacturing processes by bringing strength and speed together, at scale, with a no-compromise material set.

At 5-15x faster than the competition, Essentium's High Speed Extrusion (HSE) 3D Printing Platform is built to transform manufacturing floors and solve the issues of strength, speed and cost. You can finally harness the power of 3D printing at scale without sacrificing accuracy or speed.

Did we mention it's all Made in the USA?

ISO 9001:2015 and AS9100D Certified + ITAR Registered

Essentium HSE 180•S Platform

The Intamsys Funmat HT Enhanced is designed specifically to 3D print high-performance functional materials like PEEK, PEI and PPSU, in addition to a broad range of engineering thermoplastics. Users can achieve 50-micron, high-resolution, industrial-quality 3D printing with the Intamsys Funmat HT.

Users can achieve 50-micron, high-resolution, industrial-quality 3D printing with the Intamsys Funmat HT.

The Enhanced version includes a new build platform, ceramic-glass build plates, updated extruder design, auto bed-leveling, independent motor drivers, and more.

FUNMAT HT ⤑

The FUNMAT PRO 410 is an industrial additive manufacturing 3D printer designed for PEEK, PEI & PEI Blends, PPSU and other High-Performance Polymers.

For the very first time, the INTAMSYS FUNMAT PRO 410 features a dual extruder which operate in a large 305 x 305 x 406 mm build chamber (12 x 12 x 16 inch).

FUNMAT PRO 410 ⤑

This printer has been discontinued by Cincinnati, Inc. We have kept this page live for archival purposes.

The SAAM High-Temperature 3D Printer by CINCINNATI can print with virtually any material, from PEEK to Nylon, at a resolution of 11 microns.

Reaching temperatures of 500°C in the printing head, 250°C heated bed, and a heated chamber capable of reaching 160°C, the SAAM HT can print nearly any material on the market. SAAM HT is optimized for fabrication of tooling, fixtures, prototypes, and functional parts.

SAAM HT is optimized for fabrication of tooling, fixtures, prototypes, and functional parts.

Cincinnati SAAM HT ⤑

MAAM (Medium Area Additive Manufacturing) is an industrial sized additive machine built for production manufacturing. A rigid welded frame, CNC controls, and the latest extruder technology are combined in this machine to print parts accurately and consistently at speeds that are unmatched in the filament 3D printer market.

Its dual print head allows for multi-material printing. Its open source material solution, along with its temperature capabilities in the chamber, print bed and nozzle allow for 3D printing the industry’s most highly engineered thermoplastics, even PEEK and ULTEM™.

Cincinnati MAAM ⤑

Cincinnati Incorporated, in partnership with Oak Ridge National Labs, has developed the world's first industrial size 3D printer and taking additive manufacturing to a large scale.

BAAM (Big Area Additive Manufacturing) is an industrial sized, additive machine. The machine uses the proven design and technology from our laser platform, including the machine frame, motion system, and control, and has been adapted with an extruder and feeding system. BAAM was designed to allow 3-D printing to be used for production manufacturing. The size and speed allow large parts to be made quickly. The ability to use commodity thermoplastic materials means that the cost per part will be reasonable. By designing a system with an open architecture for material vendors, material costs will be kept lower and with more options.

The machine uses the proven design and technology from our laser platform, including the machine frame, motion system, and control, and has been adapted with an extruder and feeding system. BAAM was designed to allow 3-D printing to be used for production manufacturing. The size and speed allow large parts to be made quickly. The ability to use commodity thermoplastic materials means that the cost per part will be reasonable. By designing a system with an open architecture for material vendors, material costs will be kept lower and with more options.

REQUEST QUOTE

The Colossus 3D printers are the first FGF printing systems designed with a special accent on materials for furniture, construction applications and large size 3D objects. It also prints with recycled materials, combining cutting-edge technology to give plastics a second life.

Colossus wants to break down the barrier of entry for designers to sell not only their designs but make their vision into objects without current limitations. They also develop 3D technology for the commercial markets, like Furniture, Art, Molds, Automotive, prototyping, small series designs --everything is possible.

They also develop 3D technology for the commercial markets, like Furniture, Art, Molds, Automotive, prototyping, small series designs --everything is possible.

REQUEST QUOTE

Vision best 3D printer models・Cults

NVG 10 - Wilcox L4G24 Mount adapter

€10.08

RNVG Dovetail extension

€1.88

Mercedes-Benz AMG Vision Gran Turismo (2013)

€0.50

Genshin Impact - Amos' Bow [ 3d file .stl ]

€24

Genshin Impact - Wolf's Gravestone [ 3d file .stl ]

€24

Genshin Impact - Mistsplitter Reforged [ 3d file .stl ]

€24

Genshin Impact - Song of Broken Pines [ 3d file .stl ]

€24

Genshin Impact - Cinnabar Spindle [ 3d file .

stl ]

stl ]€24

Genshin Impact - Inazuma Vision [ 3d file .stl ]

€10

Genshin Impact - Liyue Vision [ 3d file .stl ]

€10

Genshin Impact - Mondstadt Vision [ 3d file .stl ]

€12

The OpenScope (Digital night vision monocular)

Free

Flir scout TK, helmet mount all in one

€12.50

mum14 to ris adapter

€2.50

League of Legends Ward

€1.15

Chrysler Vision Rims

€3.18

Genshin Impact Inspired Chongyun Popsicle

€2.30

Starfield Ancient Artifact Spinner - 3D Printed Desk Toy

Free

Mercedes Benz Vision Avtr Concept 2020

€5. 58

58

pvs420 quad monocular(UPDATED)

Free

Nissan 2020 Vision Gran Turismo 2014 PRINTABLE CAR IN SEPARATE PARTS

€5.64

Nissan 2020 Vision Gran Turismo 2014 PRINTABLE CAR IN SEPARATE PARTS

€10.16

Phantom 2 Antenna Holder

Free

Interactive touch terminal 📱

€0.50

Nitesite screen pivot

Free

Mazda 55LM GT GT Vision Printable Body Car

€8.33

Spiderman Mask From Marvel Comics - Fan Art 3D print model

€30

Wonda Vision Crown From Marvel Comics - Fan Art 3D print model

€15

vision inazuma genshin impact

Free

LNVG-M MK2

Free

Faruzan Genshin Impact Accessories

€2

Mercedes Vision

€4 -20% €3. 20

20

4x5 Recessed Lens Board

Free

Ender 3 /Pro/V2 Camera Support

€5.51

VISION MONDSTADT GENSHIN IMPACT

Free

EV100 Case Mod for Eachine Pro58 and Diopters

Free

Vision 6

€5

Scope adapter

Free

Genshin Impact - Baizhu Vision

€1

M2021 LENS ADAPTER UPGRADE

Free

Lock switches for SOG XR locks

€1.71

Helmet adapter and lens protection SIONYX Aurora Sport

€10.18

MINI RAIL FMA PANOBRIDGE RIGHT EYE

€20

MINI RAIL FMA PANOBRIDGE LEFT EYE

€20

GOLF-IN-MINIATURE : The Desktop 18 Hole Miniature Golf Course

Free

6mm Improved X ends for Prusa with clamped rods

Free

Minimal 40mm 60mm 80mm 120mm Fan Shroud

Free

Shortened RepRap Endstop Holder

Free

Alcom | History of 3D printers

May 13, 2018

Since the beginning of the new millennium, the concept of "3D" has firmly entered our daily lives. First of all, we associate it with cinema, photography or animation. But there is hardly a person now who has not heard about such a novelty as 3D printing at least once in his life.

First of all, we associate it with cinema, photography or animation. But there is hardly a person now who has not heard about such a novelty as 3D printing at least once in his life.

What is it and what new opportunities in creativity, science, technology and everyday life bring us 3D printing technologies, we will try to figure it out in the article below. nine0003

But first, a little history. Although there has been a lot of talk about 3D printing in the last few years, in fact, this technology has been around for a long time. In 1984, Charles Hull developed a 3D printing technology for reproducing objects using digital data, and two years later named and patented the stereolithography technique.

At the same time, this company developed and created the first industrial 3D printer. Subsequently, the baton was taken over by 3D Systems, which developed in 1988 printer model for 3D printing at home SLA - 250.

In the same year, fused deposition modeling was invented by Scott Grump. After several years of relative calm, in 1991 Helisys develops and markets a technology for the production of multilayer objects, and a year later, in 1992, the first selective laser soldering system is released at DTM.

After several years of relative calm, in 1991 Helisys develops and markets a technology for the production of multilayer objects, and a year later, in 1992, the first selective laser soldering system is released at DTM.

Then, in 1993, Solidscape was founded, which began mass production of inkjet-based printers that are capable of producing small parts with an ideal surface, and at a relatively low cost. nine0003

At the same time, the University of Massachusetts patents a 3D printing technology similar to conventional 2D inkjet technology. But, perhaps, the peak of development and popularity of 3D printing still fell on the new, 21st century.

In 2005, the first 3D printer capable of printing in color appeared, this is the brainchild of Z Corp called the Spectrum Z510, and literally two years later the first printer appeared that could reproduce 50% of its own components.

Currently, the scope and scope of 3D printing is constantly growing. Everything turned out to be subject to these technologies - from blood vessels to coral reefs and furniture. However, we will talk about the areas of application of these technologies a little later. nine0003

However, we will talk about the areas of application of these technologies a little later. nine0003

So, what is printing on a 3d printer?

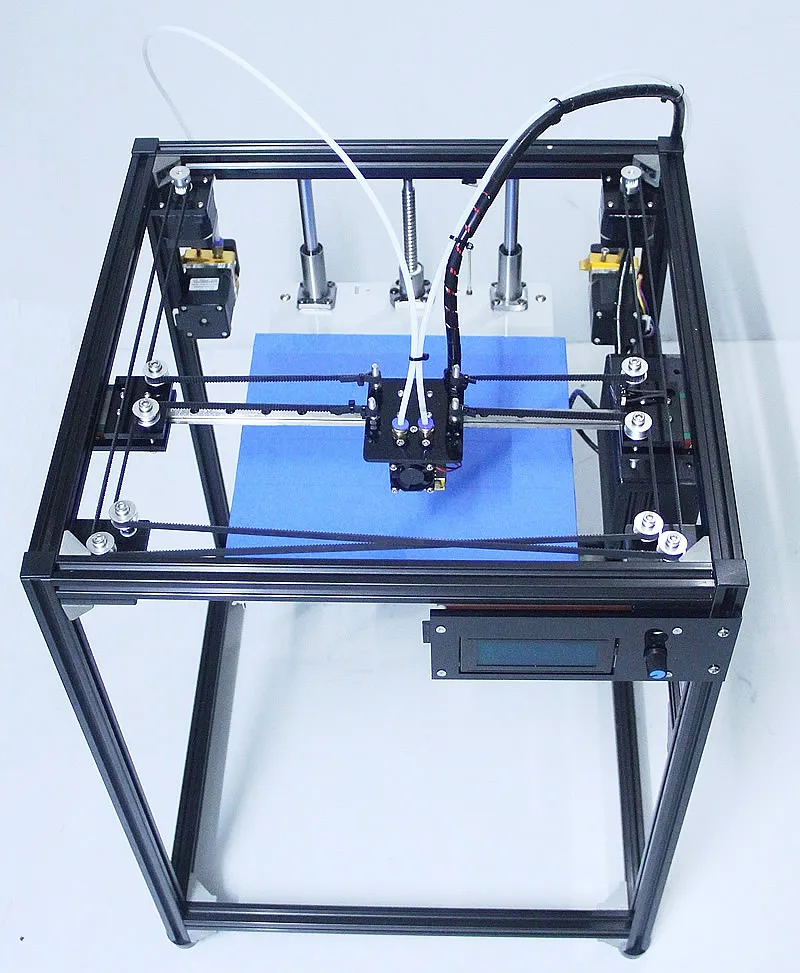

In short, this is the construction of a real object according to a 3D model created on a computer. Then the digital three-dimensional model is saved in the STL file format, after which the 3D printer, to which the file is output for printing, forms a real product.

The printing process itself is a series of repetitive cycles associated with the creation of three-dimensional models, applying a layer of consumables to the desktop (elevator) of the printer, moving the desktop down to the level of the finished layer and removing waste from the surface of the table. nine0003

The cycles follow one after another continuously: the next layer of material is applied on the first layer, the elevator is lowered again and so on until the finished product is on the working table.

How does a 3D printer work?

The application of 3D printing is a serious alternative to traditional methods of prototyping and small-scale production. A three-dimensional or 3D printer, unlike a conventional one that prints two-dimensional drawings, photographs, etc. on paper, makes it possible to output three-dimensional information, that is, to create three-dimensional physical objects. nine0003

A three-dimensional or 3D printer, unlike a conventional one that prints two-dimensional drawings, photographs, etc. on paper, makes it possible to output three-dimensional information, that is, to create three-dimensional physical objects. nine0003

At the moment, this class of equipment can work with photopolymer resins, various types of plastic filament, ceramic powder and metal clay.

What is a 3d printer?

The principle of operation of a 3d printer is based on the principle of gradual (layered) creation of a solid model, which, as it were, is “grown” from a certain material, which will be discussed a little later. The advantages of 3D printing over the usual, manual methods of building models are high speed, simplicity and relatively low cost. nine0003

For example, to create a 3D model or any part manually, it can take quite a long time - from several days to months. After all, this includes not only the manufacturing process itself, but also preliminary work - drawings and diagrams of the future product, which still do not give a complete vision of the final result.

As a result, development costs increase significantly, the period from product development to its mass production increases.

3D technologies, on the other hand, allow you to completely eliminate manual labor and the need to make drawings and calculations on paper - after all, the program allows you to see the model from all angles already on the screen, and eliminate the identified shortcomings not in the process of creation, as is the case with manual production, but directly during development and create a model in a few hours. nine0003

This virtually eliminates the possibility of manual errors.

What is a 3d printer: video

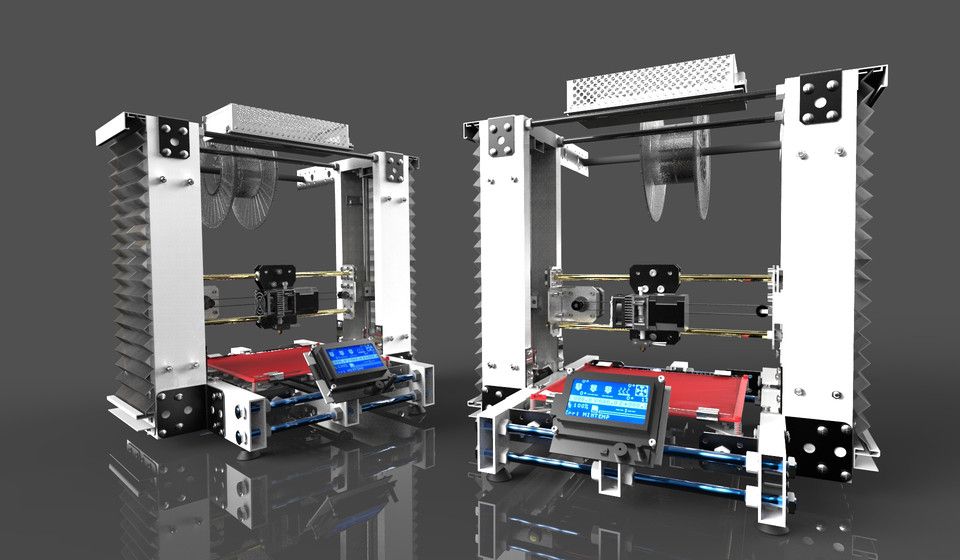

There are various 3D printing technologies. The difference between them lies in the way the product layers are applied. Let's consider the main ones.

The most common are SLS (selective laser plexus), HPM (molten material overlay) and SLA (stereolithiography).

The most widely used technology due to the high speed of building objects is stereolithography or SLA. nine0003

nine0003

SLA Technology

The technology works like this: a laser beam is directed onto a photopolymer, after which the material hardens.

The photopolymer is a translucent material that deforms when exposed to atmospheric moisture.

Once cured, it can be easily glued, machined and painted. The working table (elevator) is in a container with a photopolymer. After the laser beam passes through the polymer and the layer hardens, the working surface of the table moves down. nine0003

SLS Technology

Sintering powder reagents under the action of a laser beam - it is also SLS - the only 3D printing technology that is used in the manufacture of molds for both metal and plastic casting.

Plastic models have excellent mechanical properties, which make them suitable for making full-featured items. SLS technology uses materials that are similar in properties to the brands of the final product: ceramics, powdered plastic, metal. nine0003

nine0003

The 3D printer device looks like this: powder substances are applied to the surface of the elevator and sintered under the action of a laser beam into a solid layer that corresponds to the parameters of the model and determines its shape.

DLP technology

DLP technology is new to the 3D printing market. Stereolithographic printers are positioned today as the main alternative to FDM equipment. This type of printer uses digital light processing technology. Many people wonder what the 3d printer of this sample prints with? nine0003

Instead of a plastic filament and a heating head, photopolymer resins and a DLP projector are used to create three-dimensional figures.

Below you can see how the 3d printer works video:

Having heard about a DLP 3d printer for the first time, what it is is a completely reasonable question. Despite the intricate name, the device is almost no different from other desktop printers. By the way, its developers, represented by

QSQM Technology Corporation, have already launched the first samples of high-tech equipment into a series. It looks like this:

It looks like this:

EBM Technology

It should be noted that SLS/DMLS technologies are far from the only ones in the field of metal printing. Currently, electron beam melting is widely used to create metal three-dimensional objects. Laboratory studies have shown that the use of metal wire for layer-by-layer deposition in the manufacture of high-precision parts is ineffective, so engineers have developed a special material - metal clay.

nine0002 The metal clay used as ink during electron beam melting is made from a mixture of organic glue, metal shavings and a certain amount of water. In order to turn the ink into a solid object, it must be heated to a temperature at which the glue and water will burn out, and the chips will fuse together into a monolith.

EBM 3d printer: how

works It is noteworthy that this principle is also used when working with SLS printers. But unlike them, EBM machines generate directed electron pulses instead of a laser beam to melt metal clay. I must say that this method provides high print quality and excellent drawing of small details. nine0003

I must say that this method provides high print quality and excellent drawing of small details. nine0003

Today, only industrial printers using EBM technology are sold. Here is what one of them looks like:

The video below demonstrates the capabilities of a 3d printer adapted for electron beam melting:

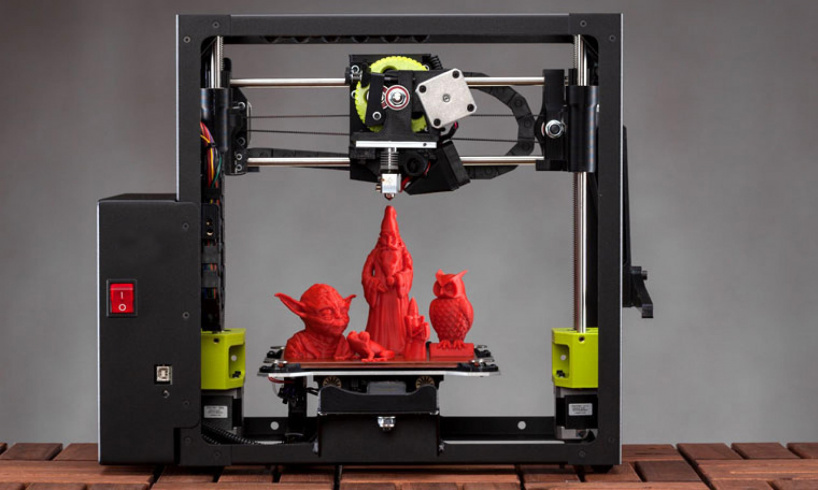

HPM Technology (FDM) HPM

Allows you to create not only models, but also final parts from standard, structural and high-performance thermoplastics. It is the only technology that uses production grade thermoplastics to provide unparalleled mechanical, thermal and chemical strength to parts. nine0003

HPM Printing stands out for its cleanliness, ease of use and suitability for office use. Thermoplastic parts are resistant to high temperatures, mechanical stress, various chemicals, wet or dry environments.

Soluble auxiliary materials allow the creation of complex multi-level shapes, cavities and holes that would be problematic to obtain with conventional methods. HPM 3D printers create parts layer by layer by heating the material to a semi-liquid state and extruding it according to computer-generated paths. nine0003

HPM 3D printers create parts layer by layer by heating the material to a semi-liquid state and extruding it according to computer-generated paths. nine0003

HPM printing uses two different materials - one (main) will consist of the finished part, and an auxiliary, which is used for support. The filaments of both materials are fed from the 3D printer bays into the print head, which moves based on changes in the X and Y coordinates and fuses the material, creating the current layer, until the base moves down and the next layer begins.

When the 3D printer has finished creating the part, it remains to separate the auxiliary material mechanically, or dissolve it with detergent, after which the product is ready for use. nine0003

Interestingly, not only automatic desktop HPM printers are popular these days, but also manual printing devices. Moreover, it would be correct to call them not printing devices, but pens for drawing three-dimensional objects.

Pens are made in the same way as printers using fusing technology. The plastic thread is fed into the pen, where it melts to the desired consistency and is immediately squeezed out through a miniature nozzle! With proper skill, these original decorative figures are obtained:

The plastic thread is fed into the pen, where it melts to the desired consistency and is immediately squeezed out through a miniature nozzle! With proper skill, these original decorative figures are obtained:

And of course, just like technologies, printers themselves differ from each other. If you have a printer that works according to SLA, then it will be impossible to apply SLS technology on it, i.e., each printer was created only for a certain printing technology.

3D printing applications

3D printing has opened up great opportunities for experimentation in areas such as architecture, construction, medicine, education, clothing design, small-scale production, jewelry, and even in the food industry. nine0003

In architecture, for example, 3D printing allows you to create three-dimensional models of buildings, or even entire neighborhoods with all the infrastructure - squares, parks, roads and street lighting.

Thanks to the cheap gypsum composite used, the cost of finished models is low. And more than 390 thousand CMYK shades make it possible to embody any, even the most daring, imagination of an architect in color.

And more than 390 thousand CMYK shades make it possible to embody any, even the most daring, imagination of an architect in color.

3d printer: construction application

In construction, there is every reason to believe that in the near future the process of erecting buildings will be much faster and easier. Californian engineers have created a 3D printing system for large objects. It works on the principle of a construction crane, erecting walls from layers of concrete.

This printer can build a two-story house in just 20 hours.

After that, the workers will only have to carry out finishing work. 3D House 3D printers are gradually gaining a strong position in small-scale production. nine0003

These technologies are mainly used for the production of exclusive products, such as art, role-playing game characters, prototype models of future products or any structural parts.

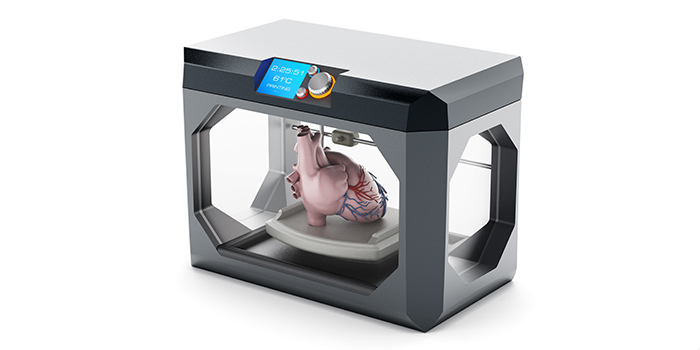

In medicine, thanks to 3D printing technologies, doctors have been able to recreate copies of the human skeleton, which allows them to more accurately practice techniques that increase the guarantee of successful operations.

3D printers are increasingly being used in the field of prosthetics in dentistry, as these technologies allow much faster production of prostheses than with traditional manufacturing. nine0003

Not so long ago, German scientists developed a technology for obtaining human skin. In its manufacture, a gel obtained from donor cells is used. And in 2011, scientists managed to reproduce a living human kidney.

As you can see, the possibilities that 3D printing opens up in almost all areas of human activity are truly endless.

Printers that create culinary masterpieces that reproduce prostheses and human organs, toys and visual aids, clothes and shoes are no longer a figment of the imagination of science fiction writers, but the realities of modern life. nine0003

And what other horizons will open before mankind in the coming years, perhaps, this can only be limited by the imagination of the person himself.

3D Printers

DeltaMaker - another 3D printer / Sudo Null IT News nikitapetrenko

Working with 3D graphics *

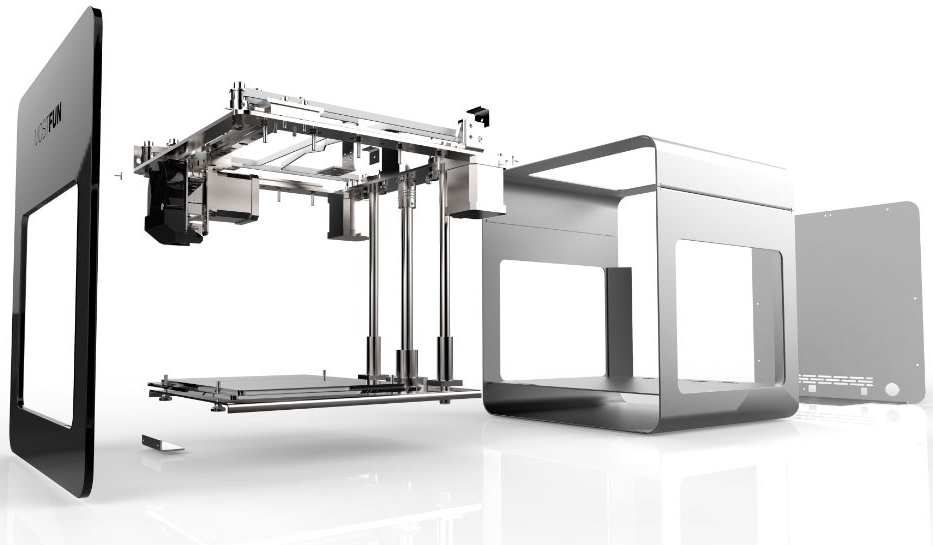

The already relatively large family of 3D printers is replenished again. A few days ago, another rather interesting project was presented on Kickstarter. Not the cheapest, not the most branded, but it allows you to see the whole process of creation “from the inside”. nine0088

And so in order: the printer is really not the cheapest, although it is still more affordable than some competitors ($1599 versus $2199 for the Replicator). DeltaMaker uses a 1.75 mm polymer filament, which is standard for many 3D printers, and creates layers with a thickness of 100 microns. Again, not the best indicator among analogues. All other characteristics practically do not differ from competitors. So why is this project likely to appeal to the public?

To begin with, it's worth noting that half of the amount claimed was raised on Kickstarter in the first 4 days. nine0182

nine0182

“The very vision of 3D printing with DeltaMaker is a little different: the creation process and the finished work can be equally interesting. We want to move 3D printing from production to living rooms, to desktops.

While many artists and designers create works of art with 3D printers, we want to see the creation process itself as art. We want to see an artist who will not only show finished works, but who will also be able to present the process itself.” nine0003

This is how the authors of the idea describe their concept, it sounds inspiring. In addition, the DeltaMaker has a slightly larger print capacity (compared to some competitors).

The printer is really quite stylish. The name itself comes from delta robots. DeltaMaker uses three manipulators that allow you to move the printer head in two planes, while maintaining its spatial orientation (in the horizontal plane). The DeltaMaker raises the print head as it works, with all the action contained between three posts and completely open, so the process itself looks quite interesting, reminiscent of robotic arms used in modern car factories.