Can we 3d print food

The Top Applications in Food 3D Printing

Published on June 24, 2022 by Alexandrea P.

What might have once seemed a fantasy, is quickly becoming a reality. Food 3D printing has been growing rapidly in the past few years and already we are seeing 3D printed food being sold and even offered in universities and there are more and more 3D printers designed specifically for food 3D printing. From meat to desserts and everything in between, initiatives mixing 3D technologies and food are increasingly common as they allow for not just more complex and original shapes and innovative recipes, but also adapt to specific diets. For your convenience, we have gathered some of the applications we have seen in food 3D printing including food and gadgets. Check out the list which is in no particular order, if it is used in the realm of cooking, you will find it below!

3D Print Liquids and Fruits with Dovetailed Design Studio

We previously told you have Dovetailed Design Studio’s efforts to make a 3D printer that could make fruit using spherication. Well, since then, the technology has advanced. Dovetailed’s nufood 3D printer is what they consider to be the world’s first liquid-based 3D printer and it allows for the creation of small flavor bursts, including of course for fruit. Indeed, one of the first applications was with the combination of fruit juice and sodium alginate powder for the creation of different fruits. Now, fruit flavored droplets are still being made by the company for luxury food and cocktails. The company hopes the printer will add playfulness and joy to cooking.

Photo Credits: Dovetailed Design Studio

Barilla Makes 3D Printed Pasta

The renowned Italian company Barilla, which specializes in pasta, developed the first 3D printer for fresh pasta in collaboration with the Dutch company TNO in 2016. With it, they have managed not only to offer good quality to the dishes around pasta, but it can also be used to create unique shapes. Now the company has announced that on its website it is already selling at least 15 different 3D printed pasta models. Some famous chefs are said to be already using some of these pastas in their kitchens.

Some famous chefs are said to be already using some of these pastas in their kitchens.

3D Printed Meat is Now Available

Additive manufacturing has now made it possible not only to produce meat substitutes such as those from Nova Meat or Redefine Meat, but even “real” meat products can be 3D printed. This is achieved by means of a process in which viable animal cells are used in the 3D printing process. In the future, this could put an end to factory farming with the help of additive manufacturing, which makes it possible to produce muscle as well as fat cells with pinpoint precision and industrial production speed. Hybrid products that combine the advantages of animal and vegetable protein are also well received by consumers, as the cooperation between the two companies Meatech and Enough shows.

The 3D Printed Seafood Making Waves

In the food 3D printing sector, the Austrian start-up Revo Foods has recently been making the news. Using various plants, the startup aims to 3D print several seafood products, such as salmon slices. While Revo Foods currently offers products in the form of spreads that have not been 3D printed, in the near future the company hopes to take advantage of 3D technologies to develop an automated production line and 3D print more salmon, in all its forms!

Using various plants, the startup aims to 3D print several seafood products, such as salmon slices. While Revo Foods currently offers products in the form of spreads that have not been 3D printed, in the near future the company hopes to take advantage of 3D technologies to develop an automated production line and 3D print more salmon, in all its forms!

Photo Credits: Revo Foods

3D Printed Food Based on Seaweed

In Chile, nutrition experts have developed foods designed from algae through additive manufacturing. Filled with important nutrients and attractive shapes, these foods were developed from Cochayuyo algae, a plant found in Chile that is an important source of plant protein. Because of the advantages of 3D printing, the teams in charge of this project have developed edible figurines designed to attract children. In this way, they hope to make children want to eat plant proteins. Regarding the printing process, if the technology used is not specified, the experts confide however to be able to 3D print an edible figurine in only 7 minutes.

Restaurants Serving 3D Printed Food

It is clear that 3D printing plays and will increasingly play a very important role in our lives. A clear example of this is the number of new developments in the food sector related to this technology. 3D printed food has all the advantages brought by using 3D manufacturing but applied to the culinary world. Therefore, there are many chefs around the world who are already turning to the technology in their kitchens. That being said, having a 3D printer in a restaurant is an expensive option and therefore many restaurants cannot afford it. Others use 3D printers as way to attract consumers, as is the case of the restaurant Cocina Hermanos Torres, a Michelin-starred restaurant.

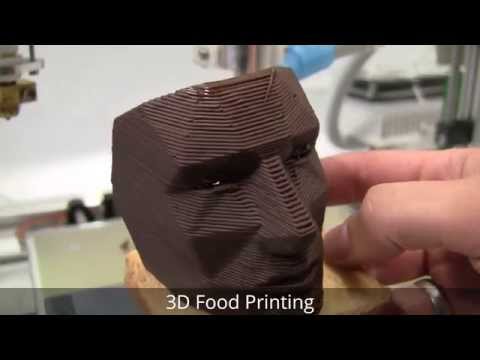

3D Printed Chocolate is Gaining in Popularity

Currently, there are a lot of companies that are dedicated to 3D printing chocolate, in fact, there are universities that are studying how to find the perfect crunchy chocolate through topological optimization. Multiple companies are looking to reinvent chocolate and adapt it to the digital age. To do this, master chocolatiers are combining additive manufacturing technologies with their traditional techniques. In this way, they successfully develop different ranges of chocolates with unique shapes and exclusive flavors. One example is Mona Lisa 3D Studio, a company that 3D prints your creations or designs in chocolate scale.

Multiple companies are looking to reinvent chocolate and adapt it to the digital age. To do this, master chocolatiers are combining additive manufacturing technologies with their traditional techniques. In this way, they successfully develop different ranges of chocolates with unique shapes and exclusive flavors. One example is Mona Lisa 3D Studio, a company that 3D prints your creations or designs in chocolate scale.

3D printing skips processing steps, such as mold design, mold making and mold testing (photo credits: Mona Lisa 3D Studio)

3D Printed Beverages and Cocktails

As unlikely as it may sound, 3D printing has now even found its way into the beverage market. The abundance of possibilities, that are enabled by using 3D printing, gave new beverage printing companies innovative ideas to print drinks in many ways, making them a new trend. Amazing ideas such as 3D polycapsules at the bottom of biodegradable cups, that are activated with the addition of water to make smart energy drinks, or 3D artwork, created inside a glass filled with a cocktail, the options are endless! With additive manufacturing making its debut and just barely scratching the surface of what is possible in the beverage industry, it is highly likely that we will see many new and exciting projects emerge in the near future.

Cake Made Using 3D Printing

As you might have guessed from the 3D printed chocolate, desserts can also be created with the use of additive manufacturing! For those with a sweet tooth, there are a number of 3D printed cakes that look as good as they taste. For example, Nina Métayer decorated this cake with the rose window of the Notre Dame de Paris, which was reproduced perfectly using 3D printing. But making Mont Blanc in cake form is no problem either, as Chef Francisco Migoya has shown. Using milk chocolate, marron glacé pieces, crispy meringues, heavy freeze-dried cream, and a crumbled vanilla cookie as a substitute for the pie crust, he conjured up this pie, printing out a 3D model of the famous mountain for the purpose.

Kitchenware from the UAUProject

UAUProject, which originates from a studio in Warsaw, Poland, has set itself the goal of generating no waste and no emissions and placing a particularly strong focus on the aspect of sustainability. The products, which are based on personalizable and individual kitchen utensils, are produced by 3D printing from plant-based bioplastics such as PLA and are fully recyclable and compostable in industrial plants. In order to counteract overproduction, the UAUProject has focused on production to order in order to be able to act sustainably in a more targeted manner.

The products, which are based on personalizable and individual kitchen utensils, are produced by 3D printing from plant-based bioplastics such as PLA and are fully recyclable and compostable in industrial plants. In order to counteract overproduction, the UAUProject has focused on production to order in order to be able to act sustainably in a more targeted manner.

Photo Credits: UAUProject

Turning Food Waste into 3D Printed Cutlery

In addition to the interesting projects previously mentioned, the use of 3D printing in the circular economy within the gastronomic field is also worth mentioning. And yes, although it may seem strange, there are also many projects dedicated to the reuse of food waste for use with 3D printing. Companies like Upprinting Food, based in the Netherlands, seek to take advantage of food waste to give it a second life by creating sustainable and uniquely designed food. But not only can food be created anew, there are also other initiatives that use these leftovers to create everyday objects. For example, the Barbara Gollackner studio launched last year an original 3D printed tableware made from industrial food waste. Called Wasteware, the tableware includes plates, cutlery and even bowls – interesting initiatives to promote recycling and the circular economy!

For example, the Barbara Gollackner studio launched last year an original 3D printed tableware made from industrial food waste. Called Wasteware, the tableware includes plates, cutlery and even bowls – interesting initiatives to promote recycling and the circular economy!

On the right, a plate made by the startup Upprinting Food. On the left, part of the Wasteware tableware,

Objects to Preserve Your Food

When buying fruits and vegetables, it’s not always easy to ensure proper preservation – you’ve probably thrown away overripe or even rotten produce. To prevent this food waste, designer Lea Randebrock came up with the “Clay Pantry” collection: these are 3D printed objects made from clay that help preserve food. And to make it work, the objects have been designed to be watered, like plants -; clay is a porous material that will allow water to evaporate and thus cool the food inside. The collection includes several pieces that can all be integrated into smaller or larger living spaces.

What do you think of food 3D printing? Will you adopt it in your kitchen? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

Food 3D printing Guide - how does it work and what can be done today

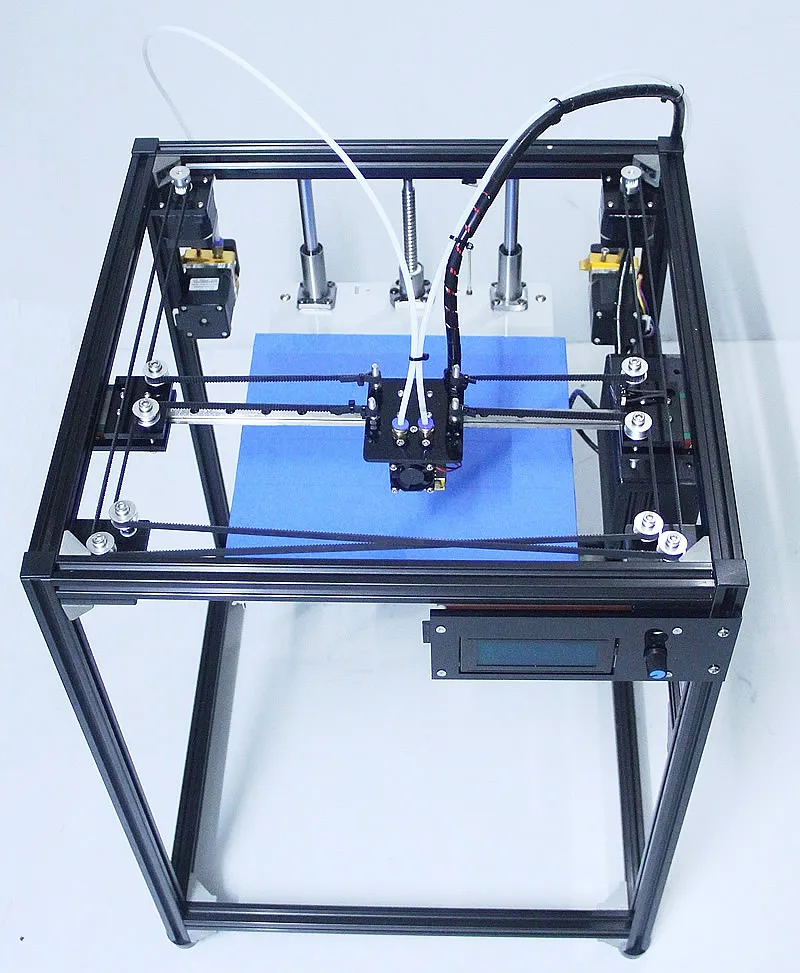

How does a food 3D printer work?The concept is the same as traditional 3D printing: a food 3D printer heats up edible ingredients before 3D printing them on the build plate, layer by layer. Another option, similar to SLS 3D printing, is to use ingredients in the form of a dry powder that is then solidified by the food 3D printer.

Discover our selection of the best food 3D printers to 3D print food or chocolate at home.

3D printing of sweet desserts

3D printing chocolateBecause of its natural physical properties, chocolate suits 3D printing perfectly. It melts at the temperature of the human body and solidifies as soon as it cools down. It is therefore easy to create customized chocolate desserts without changing the chocolate’s original taste.

It melts at the temperature of the human body and solidifies as soon as it cools down. It is therefore easy to create customized chocolate desserts without changing the chocolate’s original taste.

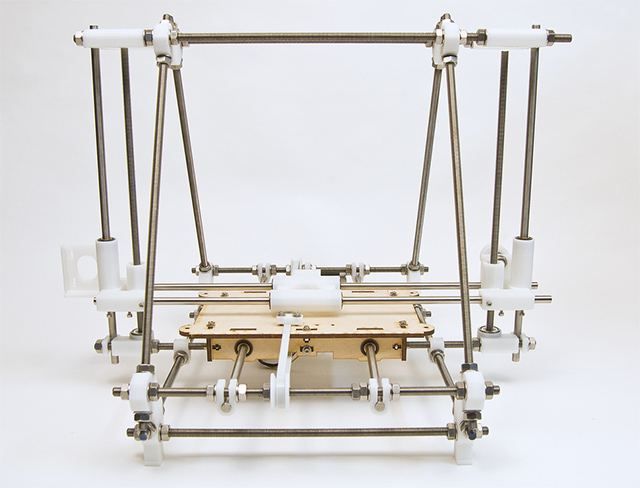

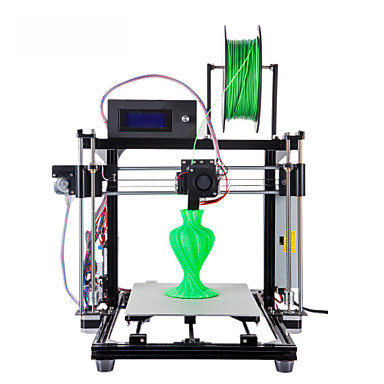

Choc Edge has already released two versions of its 3D printer to make all types of chocolate designs. The 3Drag printer uses FDM technology. It is possible to 3D print almost any chocolate design that the user creates.

3D printing with sugarSugar is a malleable material that can take many forms and colors, and it is also compatible with 3D printing. Some research groups such as The CandyFab Project or the Sugar Lab from 3D Systems have developed 3D printers specialized in the printing of sugar and candies with creative 3D shapes, as shown in photos on their websites.

Sugar candy 3D printed with a Chefjet 3D printer from 3D Systems.Food 3D printing: a marketing tool

Custom 3D printed biscuitsFood 3D printing provides the opportunity to satisfy customers to see their own customized cookies created before their eyes.

This is how Oreo chose to exhibit 3D printers during the SXSW 2014 festival, allowing customers to choose the color of their Oreos’ cream.

Oreo at the SXSW festival with 3D printed cream.3D print edibles that look like you

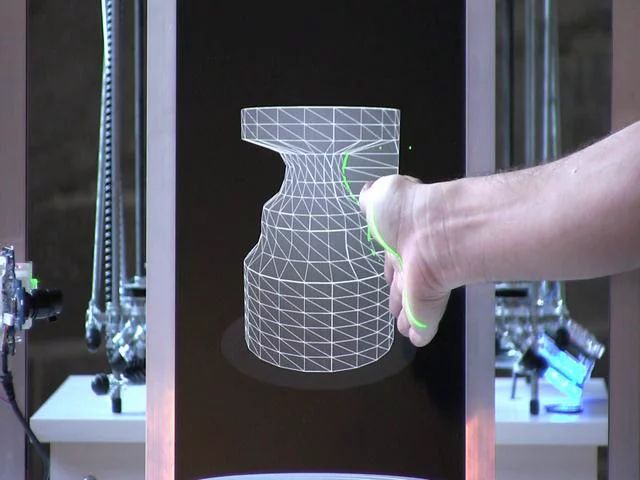

With the best 3D scanners it is possible to create a 3D model of your own head, and to 3D print it with edible food. Some manufacturers provide the opportunity to eat pancakes or waffles with the shape of your face.

A 3D printed “face pancake” by the design company Kinneir Dufort.For one of their marketing campaigns, mayonnaise manufacturer Hellmann’s even offered customers the possibility to 3D print their face on burger buns.

Create your own product line3D printing enables the consumer to participate in the creation of a new range of products. Barilla, for example, organized a contest in 2014 to reward the best 3D model design for a new Barilla pasta.

In two months, designers sent out 216 pasta proposals from 20 different countries, and the winning design was sold by Barilla as a new product!

Barilla new pasta design by Loris Tupin, French designer at the Barilla contest.

3D printing for the food industry

100% 3D printed mealsFoodini 3D printers sold by Natural Machines and Bocusini, which successfully ran a Kickstarter crowdfunding campaign, are among the most successful 3D food printers.

These two 3D printers allowed for the very first fully 3D printed meals. These are made of successive layers, in the same way that pizzas are prepared.

The dough is cooked during 3D printing, while the tomato sauce (made of powder), water, and oil are added, followed by a layer of protein.

3D printing meatFurther pushing the boundaries of 3D printing, some scientists want to use biomaterials and animal stem cells to create 3D printed meat.

Scientists behind this approach point out the huge amount of resources needed for meat production through livestock and highlight food 3D printing as a solution to the growing needs of the world’s growing population.

Steak chips by Modern Meadow.

Brooklyn-based Modern Meadow has already successfully 3D printed steak chips made from synthetic animal protein. The company has attracted the attention of New York’s wealthiest investors, including the Rockefellers. They are now even 3D printing vegan leather.

3

D printing organic foodChloé Rutzerveld, a Dutch culinary designer, managed to 3D print a structure made of a succession of layers of dough, made of edible soil.

Organic 3D printed food by Dutch designer Chloé Rutzerveld.Mushrooms seeds, spores, and yeast are then added after a few days to offer an innovative and eco-friendly snack.

Food 3D printing in space

The strength of 3D printing is that they enable the production of a wide variety of products with reduced amounts of raw material.

Based on this simple principle, engineers see 3D printing as the ideal technology to feed astronauts on long space missions. Edibles can even last for 30 years in special plastic bags.

3D printed food for seniors:

The ‘Performance’ projectThis initiative plans to make food for the elderly with a 3D printer. Some companies such as Gel Manche already offer products with a different texture, called “smooth food”. This technology restores the product to its original form, but its texture is soft and can be swallowed very easily by people with chewing or swallowing difficulties.

Gel Manche’s 3D printed food menu.90,000 in 100 years, food will be “downloaded” through the network and print on a 3D printerFresh number

RG-Nedel

Rodina

thematic applications

Union

Fresh number

04/11/2016 00:58

Category:

Digital

Julia Voronina

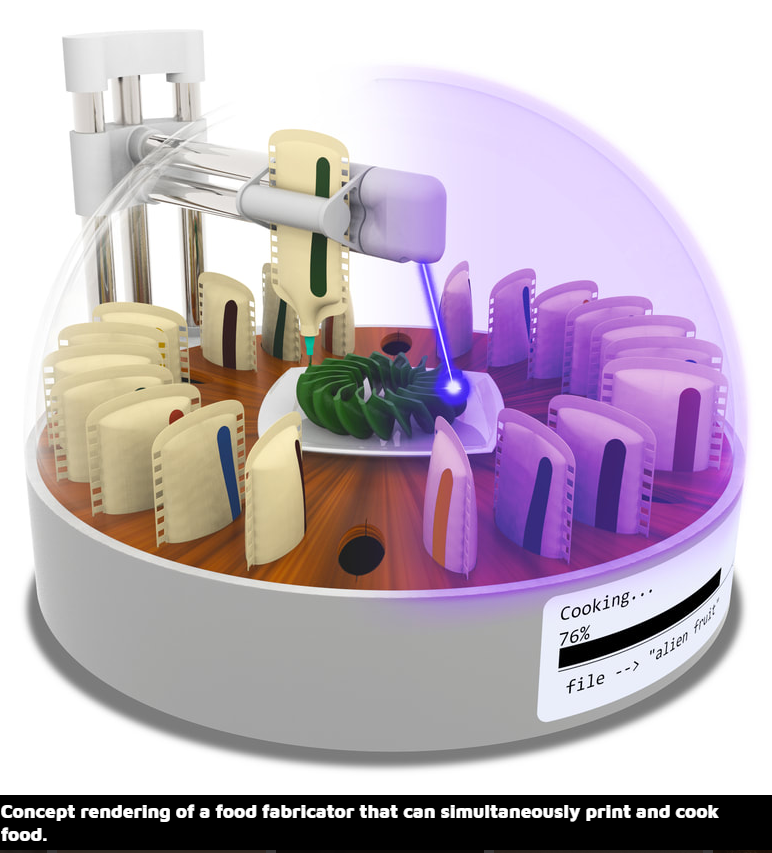

In the future, people will be able to eat 3D-printed meals. This opinion was expressed by futurologists and urbanists from the University of Westminster (UK) in a study of the development of technology and society by 2116. The authors of the report painted a picture of a high-tech utopia. In their opinion, in 2116 every ordinary inhabitant of the planet will be able to "download" food from the Internet via a direct link and print it on a home printer. So far it seems like a fantasy, but the prerequisites for such a future already exist. nine0003

The authors of the report painted a picture of a high-tech utopia. In their opinion, in 2116 every ordinary inhabitant of the planet will be able to "download" food from the Internet via a direct link and print it on a home printer. So far it seems like a fantasy, but the prerequisites for such a future already exist. nine0003

3D printers that can print food already exist and can be used to make candies and chocolates. Barilla recently developed the world's first 3D paste printer. With the help of water and semolina flour ground from durum wheat, the machine can print pasta of any shape.

Large international companies are also actively investing in the development of 3D printing technologies. For example, the American manufacturer of aviation, space and military equipment Boeing has proposed printing technology in the air. nine0003

New technology uses multiple printers to feed diamagnetic material. As follows from the project description, the printers should be located around the main point where the first portion of material is fed to create the base. The material is a superconductor, which is held in a magnetic field during strong cooling. Printers, in turn, apply layers to the substrate.

The material is a superconductor, which is held in a magnetic field during strong cooling. Printers, in turn, apply layers to the substrate.

Experts believe that this method outperforms the standard printing method. Firstly, he builds the object not from the bottom up, but from any side, thanks to the retention of the base in the magnetic field. Secondly, the base can be rotated in any direction. Thus, we are not limited to traditional 3D printing, but can try different manifestations of it. nine0003

"Printing a product in the air is a fantastic future that is manifesting right before our eyes," said Vyacheslav Maksimov, CROC's Industrial Solutions Director. for the manufacture of unique small-scale parts".

But the cost of 3D printing is decreasing every year, 3D printers for consumers appear regularly. For example, there is a project for a compact 3D printer OLO, designed for use with any smartphone with a display up to 5.8 inches. Unique smartphone 3D printer can be ordered by early adopters for just 9$9, and in October, when it's released, the price will jump to $450. The printer works on the principle of stereolithography - it prints objects from a liquid photopolymer resin that hardens under the action of light from a smartphone screen. The assembled system looks like a cube of three parts: at the bottom of the smartphone, on top of the printer itself from two components.

The printer works on the principle of stereolithography - it prints objects from a liquid photopolymer resin that hardens under the action of light from a smartphone screen. The assembled system looks like a cube of three parts: at the bottom of the smartphone, on top of the printer itself from two components.

It takes quite a long time to print, for example, a 5 cm ball is formed in three hours. After printing, it is enough to rinse the object with water. Like other stereolithographic 3D printers, OLO has a very high resolution - it forms layers with a thickness of 0.036 millimeters. OLO resin is available in eight colors and four types to create objects of varying hardness. The printer operates silently, powered by four conventional batteries. nine0003

The fabrication area is 7.5 x 10 x 5 cm. The item to print can be selected from a library of ready-made models or created independently using special 3D scanning software.

Experts attribute the reduction in the cost of 3D printing, among other things, to the reduction of non-productive costs: materials, energy and time.

Printed tablet

In March of this year, the US Food and Drug Administration approved the first 3D printed medicine, an antiepileptic drug in tablet form. nine0003

The company that produced the drug is going to start producing three more drugs in this way, according to the computerworld.ru portal. 3D printing of tablets does not provide advantages in terms of production efficiency, but provides more control over the structure and composition of the drug compared to traditional molding technology. In particular, a 3D printed tablet dissolves better and is easier to swallow.

Experts believe that perhaps someday 3D printers will be used to produce individual medicines directly in pharmacies on prescription. nine0003

By the way, 3D printer technology was invented over 10 years ago and licensed by Therics. It experimented with printing various pills, but then did not achieve commercial success.

Rossiyskaya gazeta - Federal issue: No. 76(6944)

Technologies

3952 views Posted on: 06/24/2019

Author: 3D4U. COM.UA nine0003

COM.UA nine0003

Three-dimensional printing is in demand today in many areas of human activity, including the creation of ready-made food with its help. If a printer with a plastic extruder can only create replicas of food, despite the fact that the price of 3D prototyping is quite low, some modern models can also print full-fledged meals. So, the ZMorph company has developed a device that allows you to change the print head with a plastic string to a cartridge for dough, pasta or chocolate. nine0003

The Choc Edge 3D printer is for chocolate printing only. As a rule, the extruder draws a contour with a thick mass, which is heated so that it does not freeze in the nozzle. However, by setting a low speed to allow the already formed pattern to harden, you can apply new layers and print the product up to a certain height. Another printer, Chocola3D, can create not only chocolate products, but also beautiful cream desserts or pasta dishes.

Cakes can only be called food conditionally, a diet made entirely of them will not be good for health, since a person also needs hot food. The Pancakebot 3D printer only prepares pancakes and pancakes, depending on the dough in the cartridge, and immediately fries them on a metal baking sheet. At the same time, he can draw any contours, thanks to which snacks are very interesting in shape. Soon it will be possible to supply an ordinary household device with the Discov3ry extruder developed by Structur3d for chocolate and icing, especially since the price of a 3D printer in Ukraine is quite affordable. nine0003

The Pancakebot 3D printer only prepares pancakes and pancakes, depending on the dough in the cartridge, and immediately fries them on a metal baking sheet. At the same time, he can draw any contours, thanks to which snacks are very interesting in shape. Soon it will be possible to supply an ordinary household device with the Discov3ry extruder developed by Structur3d for chocolate and icing, especially since the price of a 3D printer in Ukraine is quite affordable. nine0003

However, 3D printing technology researchers have gone further, and today good results have already been achieved in obtaining special nanocellulose, which is well absorbed by the body. Any plant organic matter can be processed into it. This product, as a binder and filler, is mixed with precisely measured portions of proteins, fats and carbohydrates to create a particular dish. Today, such a printer is capable of printing only dough-like mass, but in the future it is planned to use laser processing to shape the appearance of any dish right in the process of creation. nine0003

nine0003

Related articles

- Top 20 interesting toys for children on a 3D printer.

Category: 3D printing

02/15/2022

14119 views

What kind of toys can be created on a 3d printer? What are the advantages of 3d printing toys at home? In this article you will find...

Read more - 12 common 3D printing mistakes to avoid.

5987 views

As an industry, 3D printing is evolving every day, so it's important to know all aspects of this technology today. In this...

Read more - 9 romantic 3D printed gifts for Valentine's Day.

Category: 3D printing

02/09/2022

2111 views

3D printing can help you create unique and personalized gifts for your significant other. Compilation 9...

Read more - What can be printed on a 3D printer?

Category: 3D printing

03.

Learn more