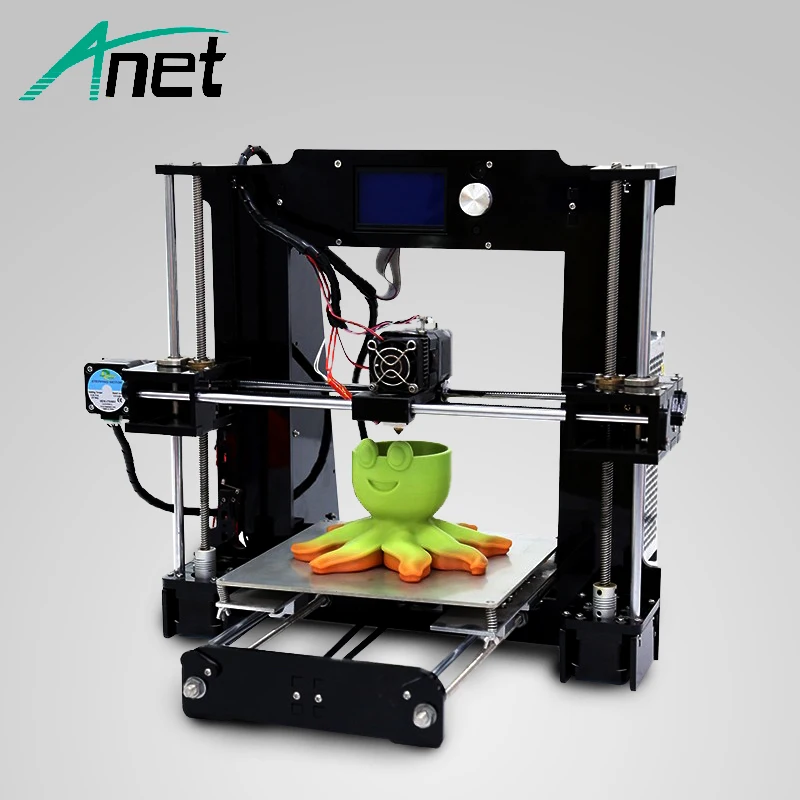

Amazing 3d printer

The Best Cheap 3D Printers for 2022

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

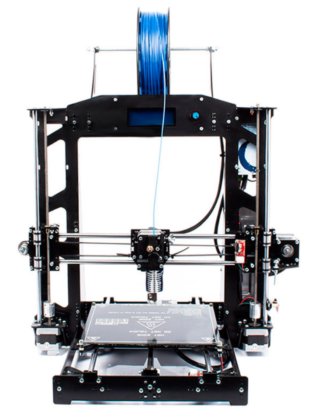

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things. And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

If you're in the market for a beginner or low-cost 3D printer, it's important to know how lower-end models differ. Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

More About Our Picks

Original Prusa Mini

4.5 Outstanding

Best Overall Budget 3D Printer

Bottom Line:

It requires assembly and calibration care (plus shipping from the Czech Republic), but the Original Prusa Mini is a compact, open-frame 3D printer that consistently produces superb-quality output for a great price.

Pros

- Top-notch object quality

- Supports a variety of filament types

- Useful, professionally printed user guide

- Great support resources

- Versatile, user-friendly software

Cons

- First-layer calibration can be tricky

- Only includes starter packets of filament

- Requires monitoring if young children or pets are around

Read Our Original Prusa Mini Review

XYZprinting da Vinci Mini

4.0 Excellent

Best Budget 3D Printer for Schools, Community Centers

Bottom Line:

The XYZprinting da Vinci Mini is a consumer-oriented 3D printer that provides a winning combination of low price, ease of setup and use, solid print quality, and smooth, misprint-free operation.

Pros

- Very low price.

- Reasonably priced filament.

- Good print quality.

- No misprints in testing.

- Easy setup and operation.

- Quiet.

- Prints over a USB or Wi-Fi connection.

Cons

- Occasional problems in trying to launch prints.

- Removing printed objects from the print bed is sometimes tricky.

Read Our XYZprinting da Vinci Mini Review

Toybox 3D Printer

4.0 Excellent

Best Budget 3D Printer for Children

Bottom Line:

The Toybox 3D Printer works well as a model designed for children, offering reliable printing from a browser or mobile device and a few thousand toys to print, plus creative options to output drawings or photos. Just bear in mind the tiny build area.

Pros

- Reliable, misprint-free printing

- Easy setup

- One-touch operation

- Well-composed help resources

- Access to more than 2,000 printable toys and projects

- Lets you create your own printable designs

Cons

- Tiny build area

- Not ideal for importing 3D files created elsewhere

Read Our Toybox 3D Printer Review

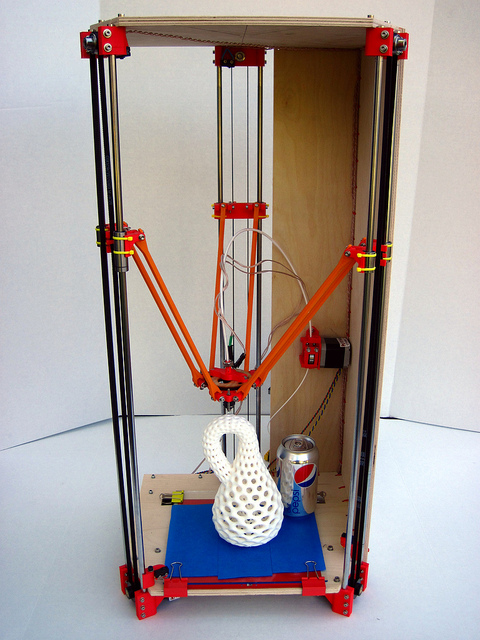

Monoprice Mini Delta V2 3D Printer

4. 0 Excellent

0 Excellent

Best Budget 3D Printer for Beginners, Non-Techies

Bottom Line:

3D printing gurus will be intrigued by the Monoprice Mini Delta V2's use of the delta rather than Cartesian coordinate system, but beginners will just enjoy its low price, ease of use, and speedy printing.

Pros

- Sub-$200 price

- Quick, nearly misprint-free printing

- Easy setup and operation

- Sturdy steel-and-aluminum frame

- Supports multiple filament types

Cons

- Tiny build area

- So-so print quality

- Mere one-year warranty

Read Our Monoprice Mini Delta V2 3D Printer Review

Anycubic i3 Mega S

3.5 Good

Best Budget 3D Printer With an Open Design, Big Build Area

Bottom Line:

The Anycubic i3 Mega S, an inexpensive open-frame 3D printer, produced decent-quality prints in our testing. To get the most out of it, though, may require precise calibration.

Pros

- Modestly priced

- Large build area for an inexpensive printer

- Supports a variety of filament types

- Generally solid print quality

- Uses well-known Cura software

Cons

- Finicky print-platform alignment

- Supported coils of filament are small

- Poorly placed spool holder

Read Our Anycubic i3 Mega S Review

Anycubic Vyper

3.5 Good

Best Budget 3D Printer for the Biggest Build Area Possible

Bottom Line:

Anycubic's modestly priced Vyper whips up large 3D prints on its open-frame design, and provides automatic print-bed leveling. Just know that some minor assembly is required—and printed objects may require a bit of cleanup.

Pros

- Relatively large build area

- Automatic bed leveling

- Simple assembly

Cons

- Short (one-year) warranty

- Includes only a small starter filament coil

- Using Cura software with the Vyper requires tweaking a couple of settings

- Test prints showed some "hairy" filament residue

Read Our Anycubic Vyper Review

Creality Ender-3 V2

3. 5 Good

5 Good

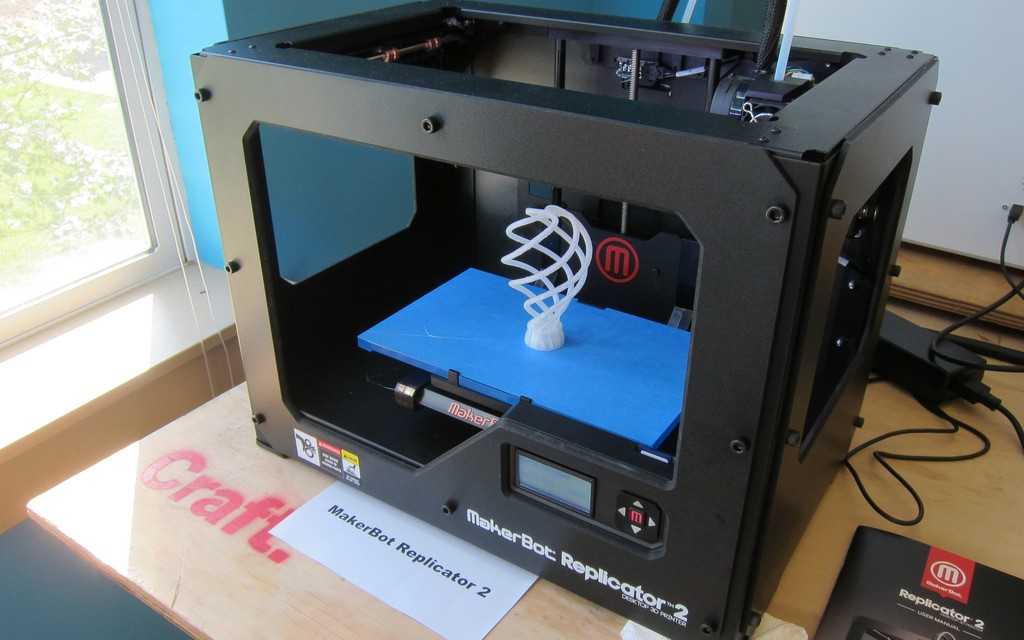

Best Budget 3D Printer for Tinkerers and DIY Types

Bottom Line:

Hands-on tweaking defines Creality's budget-price Ender-3 V2, an open-frame 3D printer that you build from a kit. It produces generally above-par prints, but its print bed can be tricky to keep leveled.

Pros

- Inexpensive

- Slightly above-average print quality

- Good-size build area for its price

- Supports several filament types

Cons

- Manual print-bed leveling can be tricky

- Setup instructions could be deeper, more legible

- Questionable quality control on some parts

Read Our Creality Ender-3 V2 Review

Flashforge Finder 3D Printer

3.5 Good

Best 3D Printer for the Very Tightest Budgets

Bottom Line:

The Flashforge Finder 3D Printer is moderately priced and offers good print quality, but it proved tricky to get up and running in our tests.

Pros

- Quiet.

- Good print quality.

- Connects via USB 2.0 cable, USB thumb drive, or Wi-Fi.

- Reasonably priced.

Cons

- Some objects pulled off the platform during testing.

- Poor documentation.

- Modest build volume.

- Limited to printing with polylactic acid filament (PLA).

Read Our Flashforge Finder 3D Printer Review

Polaroid PlaySmart 3D Printer

3.5 Good

Best Budget 3D Printer for Dabbling in Small Objects

Bottom Line:

The Polaroid PlaySmart 3D Printer is a compact, stylish 3D printer with above-par overall print quality, but, alas, a tiny build area for the money.

Pros

- Small, lightweight for a desktop 3D printer.

- Easy to set up and use.

- Supports PLA, PETG, and wood composite filaments.

- Multiple-color support.

- Wi-Fi camera monitors print jobs.

- Prints from USB drives, SD cards, or mobile devices.

Cons

- High price for its capabilities.

- Small build area.

- Too-brief warranty.

Read Our Polaroid PlaySmart 3D Printer Review

XYZprinting da Vinci Jr. 1.0 A Pro

3.5 Good

Best Budget 3D Printer With Closed Design, Roomy Build Area

Bottom Line:

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

Pros

- Spacious build area

- Works with third-party filaments

- Self-leveling print bed

Cons

- Build plate is not heated

- Limited to PLA- and PETG-based filaments

- Guide tube is prone to detaching

Read Our XYZprinting da Vinci Jr. 1.0 A Pro Review

Monoprice Voxel 3D Printer

3. 0 Average

0 Average

Best Budget 3D Printer for Cheap Filament

Bottom Line:

The Monoprice Voxel is an under-$400 3D printer that's easy to set up and use. It exhibits generally good print quality, but it was unable to print two of our test objects.

Pros

- Easy to set up and use.

- Budget price for printer and filament spools.

- Supports PLA, ABS, and several composite filament types.

- Versatile software.

- Prints over Ethernet or Wi-Fi, or from a USB thumb drive.

Cons

- Frequent misprints on certain test objects.

- Slightly balky touch screen.

Read Our Monoprice Voxel 3D Printer Review

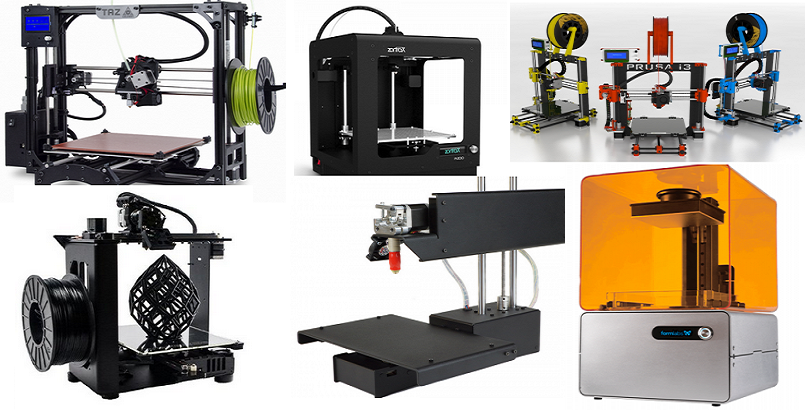

How to Buy a Cheap 3D Printer

The biggest changes to 3D printers over the last few years have come to the cheaper models. Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

(Credit: Zlata Ivleva)

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

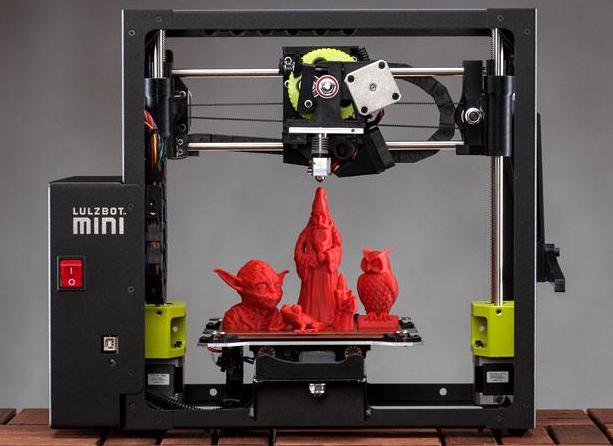

What's the Right Build Volume for a 3D Printer?

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together. ) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(Credit: Molly Flores)

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

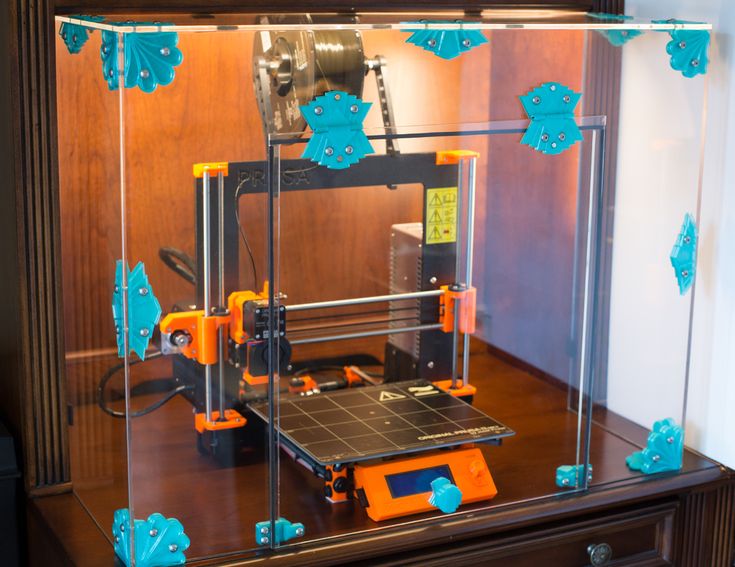

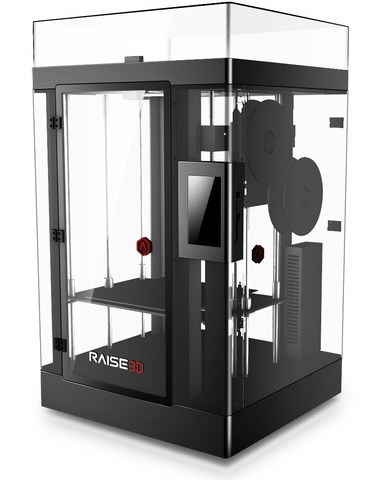

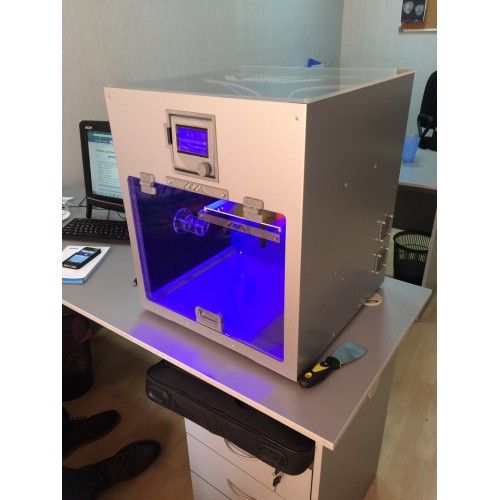

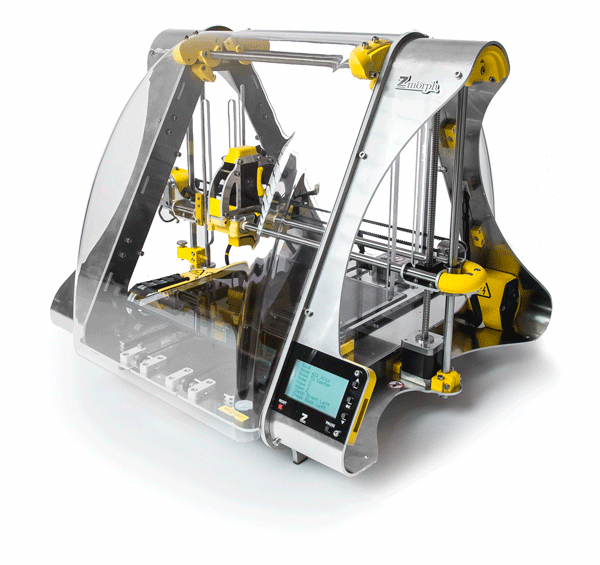

Should I Get an Open-Frame or Closed-Frame 3D Printer?

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

(Credit: Zlata Ivleva)

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

(Credit: Molly Flores)

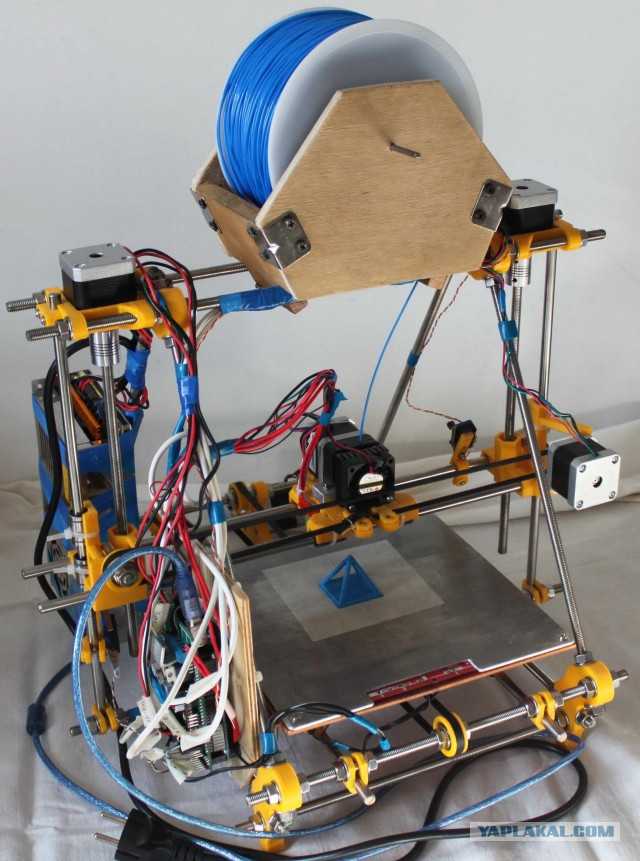

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

(See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

Recommended by Our Editors

3D Printing: What You Need to Know

3D Printer Filaments Explained

(Credit: Molly Flores)

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

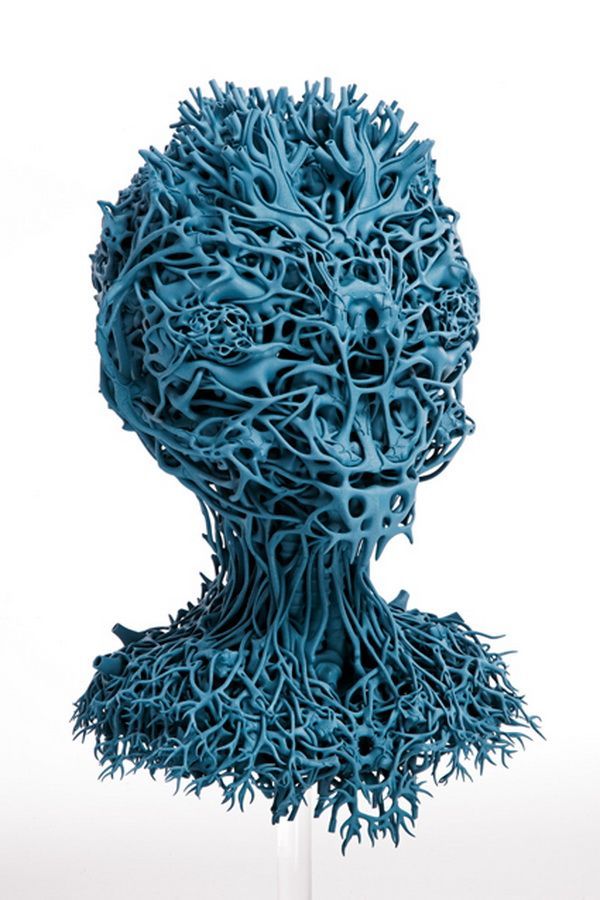

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

(Credit: 3Doodler)

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, What Is the Best Cheap 3D Printer to Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Below, check out a spec breakdown of the best under-$500 3D printers we have reviewed, paralleling our picks above. Also, for a look at the broader market, see our guide to our favorite 3D printers overall.

Prusa MK3S+ 3D Printer Review: The Heavyweight Champ Continues to Dominate

Tom's Hardware Verdict

The Prusa MK3S+ continues to hold its own in a market saturated with low-cost competitors.

Pros

- +

+ PrusaSlicer provides best-in-class model slicing

- +

+ Flexible build platform sets the standard

- +

+ Automatic bed leveling

- +

+ Stealth Mode enables a nearly silent printing experience

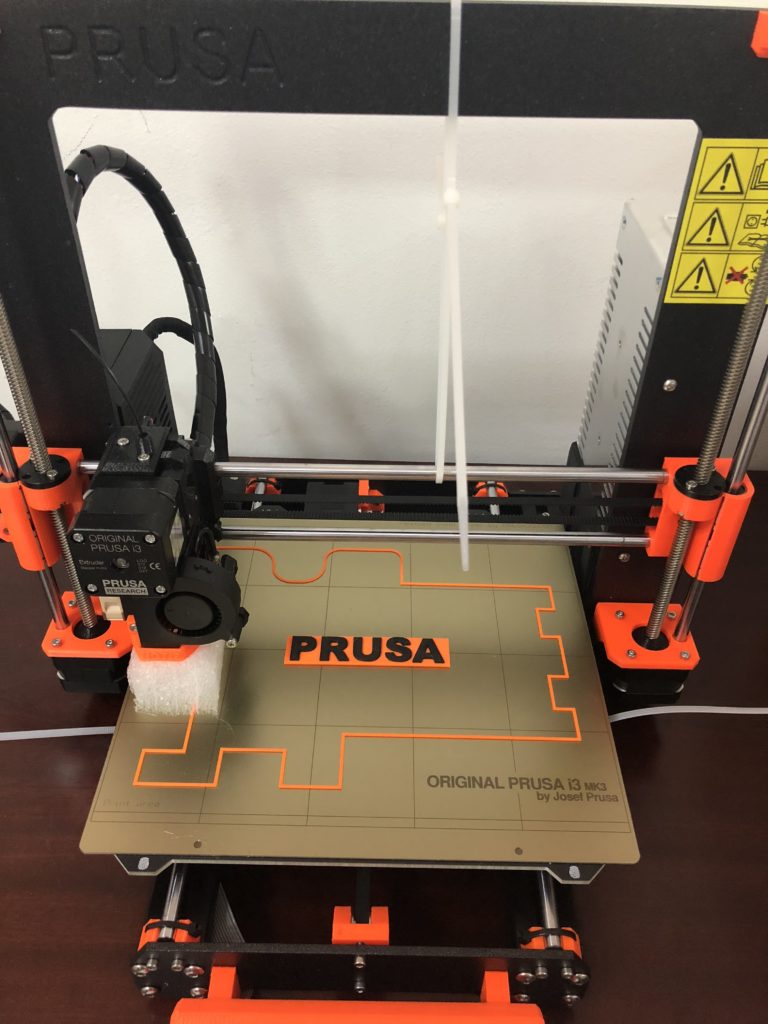

There are few 3D printers with as many industry accolades as the Prusa i3 MK3S+, and after spending some time with this printer, it’s easy to see why it’s one of the best 3D printers currently on the market. With a price tag of $999 for an assembled machine or $750 for a DIY kit, the price point of the MK3S+ is towards the high end for an open format consumer 3D printer, but the features of this machine and the ecosystem created by Prusa (they make their own hardware, software, filament, and more) have made the MK3S+ a formidable machine for anyone interested in taking their 3D printing game to the next level.

The features of the MK3S+ (silent stepper drivers, power-panic, etc.), noteworthy when originally launched, have largely become standard on lower-cost machines and may not seem particularly impressive on a spec sheet. However, clever software implementation and well-written documentation have created a machine that provides a best-in-class printing experience. For instance, the auto-leveling SuperPINDA probe of the MK3S+ maps the build platform for surface distortions, but the printer firmware is capable of storing multiple Z-offsets so you can switch build platforms without having to recalibrate every time.

However, clever software implementation and well-written documentation have created a machine that provides a best-in-class printing experience. For instance, the auto-leveling SuperPINDA probe of the MK3S+ maps the build platform for surface distortions, but the printer firmware is capable of storing multiple Z-offsets so you can switch build platforms without having to recalibrate every time.

The MK3S+ is a visually distinct machine; and the Prusa team has kept their black and orange color scheme for their smaller printer, the Prusa Mini+. The bright orange printed parts on the MK3S+ have created instant brand-recognition for the Prusa line of printers, and Prusa has doubled down on this by reinforcing their branding across their machine. In fact, you can find the word ‘Prusa’ printed, engraved, or etched into the MK3S+ in 25 places, 29 if you’re using a spool of their Prusa Polymers Prusament PLA material.

Specifications

| Machine Footprint | 16. 5 x 16.5 x 15 inches (42.0cm x 42.0cm x 38.0cm) 5 x 16.5 x 15 inches (42.0cm x 42.0cm x 38.0cm) |

| Build Volume | 9.84 x 8.3 x 8.3 inches (250mm x 210mm x 210mm) |

| Material | 1.75mm PLA, ABS, ASA, PETG |

| Extruder Type | Direct Drive |

| Nozzle | .4mm |

| Build Platform | Magnetic Heatbed with removable PEI spring steel sheets |

| Power Supply | 240 Watts |

| Connectivity | USB, SD Card |

| Interface | 3.4-inch Mono LCD and click wheel |

| Filament Run-Out Sensor | Yes |

Included with Prusa MK3S+

The fully assembled Prusa MK3S+ ships with all of the accessories required to make your first print, and also includes enough spare parts to replace almost every fastener on the machine. The fully assembled MK3S+ also includes a bag of Haribo Goldbears, a signature addition from the Prusa team.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The Prusa MK3S+ includes a full spool of silver PLA material, screwdriver, a metal part scraper, a glue stick (for adhesion), an isopropyl alcohol wipe, lubricant for the linear rails, power and USB cables, a sheet of stickers, a printed handbook, and a diagnostic printout that confirms the functionality of the mechanical and electrical systems.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The usefulness of the handbook is hard to overstate. When you’re starting out with your first 3D printer, it can be difficult to pinpoint the cause of problems such as loss-of-extrusion, poor layer adhesion, or a clogged extruder. The included handbook is full of detailed photographs, troubleshooting workflows, and solutions to common problems. This is an invaluable resource for beginners, amateurs, and experts alike, and it’s clear to me that Prusa has set the standard for technical documentation.

Setting up the Prusa MK3S+

(Image credit: Tom's Hardware)The Prusa MK3S+ ships with a completed print attached to the build platform. This print features a serpentine line with 90 degree angles, curves, and a solid block in the center with the Prusa logo facing upwards. This print serves to confirm that the printer is functional and has been properly assembled and calibrated. I was able to easily remove the print from the build platform by bending the steel sheet and carefully removing it.

After powering on, the printer automatically runs through an initial setup process. This process involves calibrating the Z axis by running it all the way to the top of the printer, running the mesh bed leveling process to set the Z offsets, and loading the filament. This entire process only took me a few minutes, and the high level of automation involved means that the only thing I needed to do was insert the filament into the extruder after it had heated up.

(Image credit: Tom's Hardware)You might be surprised to find that the Prusa MK3S+ is based on the RepRap i3 (third iteration) frame, originally released in September of 2012. Despite this nearly decade-old release date, the MK3S+ is full of modern advancements and enough innovative features to still be a top contender in the prosumer 3D printer market.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The bright orange color makes the 3D printed parts on the MK3S+ easy to spot. The brackets mounted to the printer are printed in-house by Prusa using their own Prusament PETG filament. These brackets are robust and sturdy, and the uniform appearance between the printed parts give the printer a professional appearance. This version of the MK3S+ shipped with orange printed brackets, but the printer is also available in an all-black variant. A large selling point of the MK3S+ is the open-source nature of the machine, which means the printed parts are all available to download if you want to download, modify, or print them out yourself.

The brackets mounted to the printer are printed in-house by Prusa using their own Prusament PETG filament. These brackets are robust and sturdy, and the uniform appearance between the printed parts give the printer a professional appearance. This version of the MK3S+ shipped with orange printed brackets, but the printer is also available in an all-black variant. A large selling point of the MK3S+ is the open-source nature of the machine, which means the printed parts are all available to download if you want to download, modify, or print them out yourself.

The monochrome LCD interface and click-wheel on the MK3S+ is one of the few less-than-impressive features on this machine; it feels dated and the UI navigation can be a little clunky. This stands in contrast with printers like the Anycubic Vyper, a sub-$400 machine that features a bright and responsive color touchscreen that shows detailed print statistics during printing. This monochrome display was industry standard when the original 8-bit i3-style of printers was introduced, but it feels outdated when compared to recent printers with color touchscreens.

This monochrome display was industry standard when the original 8-bit i3-style of printers was introduced, but it feels outdated when compared to recent printers with color touchscreens.

The MK3S+ uses a filament spool holder that mounts directly to the frame of the printer. The T-shaped holder is able to hold two spools simultaneously, which is ideal if you plan on swapping between multiple colors to produce a multicolor 3D print. The direct-drive extruder on the MK3S+ feeds filament straight down into the hot end, so mounting the filament directly above the extruder gives the filament a straight path between the spool and the extruder.

(Image credit: Tom's Hardware)At the heart of the MK3S+ is the 8-bit Einsy RAMBo board, housed in a 3D printed enclosure mounted to the frame of the machine. This board is equipped with Trinamic 2130 silent stepper drivers, user-replaceable fuses, and the cable management is clean and professional.

The features made possible by this board (power-panic, live-Z adjust, silent steppers) were all major leaps when originally introduced, but many of these features have made their way down to less expensive FDM 3D printers like the Elegoo Neptune 2. The interface feels sorely in need of an update, and the addition of a color touchscreen and a 32-bit board (such as the one equipped on the Prusa Mini+) would refresh this platform.

(Image credit: Tom's Hardware)The attention to detail on the Prusa MK3S+ is clear, and a perfect example of this is the wire management across the machine. Current-carrying wires are attached to the extruder module with zip ties that act as a strain-relief to prevent the wires from fatiguing and separating. The wires from the power supply are tucked neatly under the frame of the machine, out of sight and reach from users to prevent accidentally unplugging them during printing.

What Makes the Prusa MK3S+ Different?

It can be hard to understand why the Prusa MK3S+ costs so much more than a printer like the Creality Ender 3 Pro, which seems to have similar specs on paper. To understand why this machine is so much more expensive, we need to take a closer look at the individual components of the MK3S+.

To understand why this machine is so much more expensive, we need to take a closer look at the individual components of the MK3S+.

Critical to the success of the MK3S+ is its custom-made Delta 240 Watt power supply, mounted to the frame of the machine. This unit supplies 24V power to the bed with a max current of 10 Amps, which provides fast and reliable heating for printing high temperature materials like PETG and ASA. Less expensive machines typically use lower wattage power supplies, such as the 150W power supply used by the Flashforge Adventurer 3 Lite, which take longer to heat and can have difficulty maintaining a higher temperature.

(Image credit: Tom's Hardware)The 24V heated bed is able to reliably hit 100C, which is more than enough to allow high temperature materials like PETG and ASA to adhere to the build platform without delaminating. The magnetic build platform is firmly held in place without any clips or latches and can easily be removed once it cools to room temperature. PETG in particular is easy to remove from the textured surface of the textured spring steel sheet, and the MK3S+ build platform is best-in-class for high-temperature adhesion.

PETG in particular is easy to remove from the textured surface of the textured spring steel sheet, and the MK3S+ build platform is best-in-class for high-temperature adhesion.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The MK3S+ is equipped with a genuine E3D hot end, and it has the holographic sticker to prove it (seriously). E3D manufactures every component in the hot end from the nozzle to the heatbreak which means you are very unlikely to run into the type of manufacturing defects that occasionally pop up on less expensive printers (incorrectly drilled nozzles, degraded PTFE tube liner, etc.) In addition, this nozzle is rated for a max temperature of 300C (572F), which is easily hot enough to extrude most common thermoplastics and even some higher-temperature engineering-grade materials like Nylon and Polycarbonate.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The printed parts on the MK3S+ are a perfect example of a company applying its in-depth knowledge of a subject to its product. The printed brackets found on the MK3S+ have been printed in PETG, and the outward-facing textured surface shows the level of quality you can expect from using a textured sheet.

The printed brackets found on the MK3S+ have been printed in PETG, and the outward-facing textured surface shows the level of quality you can expect from using a textured sheet.

In addition, I appreciate that Prusa has applied DFAM (Design for Additive Manufacturing) principles to these parts. These DFAM principles include concepts like printing hexagons instead of circles for relief holes, which print without requiring support material, and printing brackets perpendicular to their intended load to create mechanically tough parts.

(Image credit: Tom's Hardware)The Prusa MK3S+ comes equipped with a SuperPINDA probe which is used for hands-free leveling of the build platform. The SuperPINDA (which stands for Super Prusa INDuction Autoleveling sensor) operates by detecting the proximity of the probe to the build platform and storing that information in firmware. The MK3S+ isn’t the first printer to use a probe for bed leveling, but the software implementation in PrusaSlicer means that after the printer has been set up, you can print without spending much time thinking about calibration.

Compared to the manual bed leveling process of a printer like the Creality Ender 3 Pro, the MK3S+ is faster, easier to use, and requires less trial and error. PrusaSlicer includes a “G80” command in the start G-code (the instructions the printer reads when making a part), and this command performs a ‘Mesh Bed Leveling’ which probes the bed in a 3x3 grid to create a mesh surface that is used for calibration. This mesh surface causes the Z-axis motors to undulate over uneven areas while the print head remains perpendicular in the X/Y axis. During my testing, I didn’t need to run a single non-print calibration on the printer after the initial mesh bed leveling.

Build Platforms on Prusa MK3S+

(Image credit: Tom's Hardware)Removing a printed part from the build platform of a 3D printer can be a challenging experience if the printer isn’t calibrated correctly. The Prusa MK3S+ attempts to solve this problem by using a removable build platform that is held in place magnetically and can be flexed to remove parts after the platform has cooled. I’ve tried many different types of build surfaces, and the smooth PEI sheet used by Prusa is by far one of the easiest to print on, remove parts from, and clean.

I’ve tried many different types of build surfaces, and the smooth PEI sheet used by Prusa is by far one of the easiest to print on, remove parts from, and clean.

Prusa also offers a textured steel build platform for the MK3S+ that has a gritty surface which can give printed parts a more uniform appearance. In fact, the signature textured look of the printed parts on the MK3S+ come from this build platform.

Parts printed on a smooth build platform will have a smooth bottom surface, which looks visually distinct from the striations on the sides of the part. By using a textured sheet, I was able to make prints that have a textured appearance on the bottom as well as the sides. This sheet is ideal for printing with PETG; the high print temperature of the material requires a textured surface to stick to, but also needs a surface that it can easily detach from.

Printing on the Prusa MK3S+

(Image credit: Tom's Hardware)The sample prints on the included SD card with the Prusa MK3S+ are a refreshing change from the sample parts that are typically included with low-cost 3D printers. The MK3S+ includes 16 pre-sliced parts that have been prepared for PLA with the total print time included in the file name. The sample prints vary in time from 23 minutes (a simple block with the word PRUSA on it) to almost 14 hours (a castle printed at .1mm layer height), and have all been prepared using sensible settings for the machine and highlight various features (variable layer height, multicolor printing, and fine .1mm layer resolution).

The MK3S+ includes 16 pre-sliced parts that have been prepared for PLA with the total print time included in the file name. The sample prints vary in time from 23 minutes (a simple block with the word PRUSA on it) to almost 14 hours (a castle printed at .1mm layer height), and have all been prepared using sensible settings for the machine and highlight various features (variable layer height, multicolor printing, and fine .1mm layer resolution).

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)One of my favorite sample parts is the planetary gear bearing that prints in a single print. I printed this model using the Prusament Jet Black PLA material, and after removing it from the build platform I was able to easily spin the gear freely. This part really highlights the ability of the MK3S+ to produce parts with functional strength and purpose in addition to parts designed with aesthetics in mind.

(Image credit: Tom's Hardware)Another stand-out sample print included with the MK3S+ is the dragon model titled Adalinda the Singing Serpent by Loubie3D. This model takes a little longer to print (about 8 hours), but the final print is another favorite of mine. Because this model was sliced by Prusa for the MK3S+ printer, the sample print comes out with a high level of detail and no unexpected settings that can cause problems (too many exterior shells, no retraction, etc.) like the sample prints included with other FDM 3D printers.

This model takes a little longer to print (about 8 hours), but the final print is another favorite of mine. Because this model was sliced by Prusa for the MK3S+ printer, the sample print comes out with a high level of detail and no unexpected settings that can cause problems (too many exterior shells, no retraction, etc.) like the sample prints included with other FDM 3D printers.

Printing with PrusaSlicer on the Prusa MK3S+

(Image credit: Prusa)Prusa has developed its own in-house slicer for the Prusa MK3S+, called PrusaSlicer. PrusaSlicer is a fork of the confusing-to-pronounce Slic3r app, which is also a free and open-source app. Prusa has invested a considerable amount of time and effort in PrusaSlicer, and this has translated into one of the most powerful 3D printing slicer apps available for desktop 3D printers on the market.

(Image credit: Prusa)The current version of PrusaSlicer (2.3.3) includes profiles for printers by Prusa, Creality, Lulzbot, and more, and also includes a library of material profiles. In addition to these profiles, PrusaSlicer also includes multiple print setting profiles, which range from ultra-high detail at 0.05mm layer height to a draft mode which offers .3mm layers fast print speed at the expense of reduced quality.

In addition to these profiles, PrusaSlicer also includes multiple print setting profiles, which range from ultra-high detail at 0.05mm layer height to a draft mode which offers .3mm layers fast print speed at the expense of reduced quality.

Slicing Models in PrusaSlicer for the Prusa MK3S+

(Image credit: Prusa)PrusaSlicer is a feature-rich program with a simplified interface that is accessible to beginners, experts, and everyone in between. I’ve spent a lot of time in the PrusaSlicer settings, and I appreciate how much work Prusa has put into making almost every parameter of the printing process addressable without creating an overwhelming interface.

The settings are broken down into three primary categories: Print Settings, Filament Settings, and Printer Settings. Print Settings generally focuses on the speed / quality of the print, Filament Settings is used to determine temperature and extrusion parameters, and Printer Settings is used for global parameters and determining start / stop instructions.

The primary interface offers three settings: Simple, Advanced, and Expert. Simple offers a stripped-down experience with only a few parameters able to be adjusted, while Advanced and Expert allow you to adjust the print on a more granular level.

PrusaSlicer Quality Settings for the Prusa MK3S+ / PLA

(Image credit: Prusa)| Material | Prusa Basic PLA, Silver |

| Layer Height | 0.20 mm |

| Infill Percentage | 15%, Gyroid |

| Print Speed | 45mm/second |

| Extruder Temperature | 215 degrees Celsius (419 degrees Fahrenheit) |

| Heated Bed Temp | 60 degrees Celsius (140 degrees Fahrenheit) |

| Print Time | 1 Hour, 34 Minutes |

There are few prints that are better at testing out a printer than the 3DBenchy, so I used the included spool of silver Prusa PLA to print this model out using the default . 2mm Quality PrusaSlicer settings. I was impressed with the overall quality of the Benchy, and even with a highly-reflective material like a silver PLA which can highlight defects from uneven layers, the layers looked even and consistent throughout.

2mm Quality PrusaSlicer settings. I was impressed with the overall quality of the Benchy, and even with a highly-reflective material like a silver PLA which can highlight defects from uneven layers, the layers looked even and consistent throughout.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The Benchy boat model is designed to highlight various features of a printer (such as the ability to print steep overhangs, small features, etc.), and a quick examination of the model shows that the MK3S+ performed very well and didn’t have any of the common defects typically seen on this model.

PrusaSlicer Spiral Vase Settings for the Prusa MK3S+ / PLA

(Image credit: Prusa)| Material | Prusament PLA, Galaxy Purple |

| Layer Height | 0.20mm |

| Infill Percentage | 0% |

| Print Speed | 60mm/second |

| Extruder Temperature | 215 degrees Celsius (419 degrees Fahrenheit) |

| Heated Bed Temp | 60 degrees Celsius (140 degrees Fahrenheit) |

| Print Time | 3 Hours, 9 Minutes |

Slicing a model using the ‘Spiral Vase’ mode in PrusaSlicer will automatically create a model that is composed of a single continuously rising helical contour, which allows models to be printed a fraction of the time it would normally take to print using multiple layers. This mode is ideal for printing objects like vases or enclosures that only require a single contour as opposed to multiple contours and an infill structure. I printed the Curved Honeycomb Vase by eggnot to highlight this printing mode.

This mode is ideal for printing objects like vases or enclosures that only require a single contour as opposed to multiple contours and an infill structure. I printed the Curved Honeycomb Vase by eggnot to highlight this printing mode.

The Prusament Galaxy Purple is a favorite color of mine due to the glitter additive in the filament. This additive creates layer lines that are evenly blended and have a textured appearance. Combining this material with the Spiral Vase mode produces parts that look almost conventionally manufactured, with layer lines that are difficult to see. This model printed in just over 3 hours in Spiral Vase mode, as opposed to over 13 hours if it had been printed using conventional settings.

PrusaSlicer Speed Settings for the Prusa MK3S+ / PETG

(Image credit: Prusa)| Material | Prusament PETG, Chalky Blue |

| Layer Height | 0.2mm |

| Infill Percentage | 15%, Grid |

| Print Speed | 60mm/second |

| Extruder Temperature | 250 degrees Celsius (482 degrees Fahrenheit) |

| Heated Bed Temp | 90 degrees Celsius (194 degrees Fahrenheit) |

| Print Time | 4 Hours, 5 Minutes |

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)PETG is a material that offers increased mechanical toughness, heat resistance, and flexibility when compared with parts printed with PLA. Prusa has taken advantage of these material properties by printing many of the components on the MK3S+ with PETG, which creates a rigid part that is able to withstand mechanical stress. PETG is also notoriously difficult to print with due to the high level of stringing that can occur when printing multiple parts simultaneously, but I didn’t have any issues when printing with the Prusament PETG material on the MK3S+.

Prusa has taken advantage of these material properties by printing many of the components on the MK3S+ with PETG, which creates a rigid part that is able to withstand mechanical stress. PETG is also notoriously difficult to print with due to the high level of stringing that can occur when printing multiple parts simultaneously, but I didn’t have any issues when printing with the Prusament PETG material on the MK3S+.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)I used the default settings in PrusaSlicer to print the clamp model provided by Prusa that was designed specifically for PETG. This model features a functional thread, a flexible ball-and-socket joint, and can be tensioned without snapping the body of the clamp. The part printed in multiple pieces without stringing, and I was able to easily assemble it and verify functionality without damaging the clamp. If printed in a more brittle material (like PLA), I would expect the clamp to crack at a transition point on the body, but the PETG was able to hold tension without deforming or breaking.

PrusaSlicer 3MF Import for the Prusa MK3S+ / PLA

(Image credit: Prusa)| Material | Prusa Basic PLA, Silver |

| Layer Height | 0.20mm |

| Infill Percentage | 15%, Grid |

| Print Speed | 60mm/second |

| Extruder Temperature | 215 degrees Celsius (419 degrees Fahrenheit) |

| Heated Bed Temp | 60 degrees Celsius (140 degrees Fahrenheit) |

| Print Time | 2 Hours, 17 Minutes |

PrusaPrinters (the online file repository created and maintained by Prusa) offers the unique ability to share 3D printable files that have been pre-sliced and prepared for the MK3S+ with detailed print statistics available from the site. A perfect example of this is the Bag Clip by Andrei; a cam-driven bag clip that highlights the type of design freedom offered by a 3D printer.

This model has been uploaded as a . 3MF file that contains all of the information required to print, such as slicer settings, nozzle and bed temperature, and custom support structures (visibile in the screenshot above.) 3MF is an increasingly popular alternative to the STL file, which doesn’t contain much information aside from the raw geometry of a model.

3MF file that contains all of the information required to print, such as slicer settings, nozzle and bed temperature, and custom support structures (visibile in the screenshot above.) 3MF is an increasingly popular alternative to the STL file, which doesn’t contain much information aside from the raw geometry of a model.

This part printed flawlessly on the first try, and the provided .3MF (or .gcode) allows a user to send this file to anyone else with the same printer and material and feel confident that the part will be indistinguishable in appearance and performance. I’ve always thought of a 3D printer as the replicator from the Michael Crichton novel Timeline, which is able to produce identical objects at various locations by converting them into digital information. However, the success of a part is frequently beholden to the settings selected by a user for fabrication, so the ability to share the fabrication plans is one step closer to being able to send a physical product as a form of digital data.

At a price-point of $999 for an assembled printer (or $749 for a kit), the Prusa MK3S+ is a machine that doesn’t compromise on user experience and is absolutely one of the best 3D printers currently on the market. The MK3S+ has a professional and neat appearance, but the 8-bit monochrome LCD user interface might be a challenge for some users to get past, given the steep price. Interface aside, the prosumer features of the MK3S+ make it a stand-out machine for anyone who is looking for a reliable machine to produce functional parts without worrying about spending a lot of time tinkering.

If you are looking for a less expensive machine outside of the Prusa ecosystem, the Elegoo Neptune 2 (currently on Amazon for $180) offers similar printing size and features (with the notable exception of automatic bed leveling) at a fraction of the price but without the same level of robust support and documentation provided by the MK3S+ or any of the name-brand components like the E3D hotend. If you want the Prusa experience but are looking to spend a little less money, the Prusa Mini+ (available from Prusa for $399 assembled, $349 for a kit) is an excellent place to start.

If you want the Prusa experience but are looking to spend a little less money, the Prusa Mini+ (available from Prusa for $399 assembled, $349 for a kit) is an excellent place to start.

Andrew Sink first used a 3D printer in 2012, and has been enthusiastically involved in the 3D printing industry ever since. Having printed everything from a scan of his own brain to a peanut butter and jelly sandwich, he continues to dive ever more deeply into the endless applications of additive technology. He is always working on new experiments, designs, and reviews and sharing his results on Tom's Hardware, YouTube, and more.

Interesting facts about 3D printing and 3D printers - 3DDevice

Interesting facts about 3D printing and 3D printers

3D printing technology is very versatile and often used for quite unusual purposes. Of course, this leads to interesting results that attract a lot of attention. But all events cannot be covered, and some achievements remain behind the scenes. We believe that this is wrong and in this section we want to list interesting facts about 3D printing that you may not have known. We will tell you about something that goes beyond the usual applications of 3D printing, but, nevertheless, is of great practical value.

We believe that this is wrong and in this section we want to list interesting facts about 3D printing that you may not have known. We will tell you about something that goes beyond the usual applications of 3D printing, but, nevertheless, is of great practical value.

Interesting facts about 3D printing

Let's start with some interesting facts about 3D printing. Of course, many more points can be attributed here. It all depends on the awareness of people. Indeed, today everyone already knows that with the help of a 3D bioprinter it is possible to create artificial organs and living tissues, as well as a lot of other similar information. Therefore, we have chosen revolutionary techniques that are only gaining popularity and are of particular interest and value in certain circles.

1. 3D printing of all-in-one pills

In the US, 3D printed pills for epilepsy can already be found in pharmacies. And scientists do not intend to stop at the production of only one drug. Currently, new methods for 3D printing of medicines are being developed, and researchers pay special attention to SLA technology. The main advantage of using 3D printing for this purpose is the possibility of gradual release of active substances. That is, such a tablet can be programmed for sequential dissolution over a certain time. If you need to take several different medications a day, this can be a real breakthrough in treatment.

Currently, new methods for 3D printing of medicines are being developed, and researchers pay special attention to SLA technology. The main advantage of using 3D printing for this purpose is the possibility of gradual release of active substances. That is, such a tablet can be programmed for sequential dissolution over a certain time. If you need to take several different medications a day, this can be a real breakthrough in treatment.

2. 3D food printing

You probably already know about this, but this fact is worth talking about in more detail. To date, this branch of 3D technology is not too developed, but progress is moving forward rapidly. There are already several 3D printed food restaurants operating around the world, and some culinary specialists are using 3D printing to bring their creative ideas to life. On top of that, 3D printed products represent a real possibility for astronauts. Indeed, with the help of 3D printing, it is possible to endow food with the maximum amount of useful substances and serve it in the most convenient way.

3. 3D printing of living tissues

Interesting facts about 3D printing are simply unthinkable without this item. 3D bioprinting is a real panacea in the world of medicine. With its help, scientists intend to create full-fledged living tissues suitable for implantation into the human body. Experiments are now being actively conducted on the manufacture of artificial organs, bones, blood vessels and even hair using living cells. And such initiatives are extremely successful! Of course, mass 3D printing of full-fledged organs is still a long way off, but we are definitely moving in the right direction.

4. Space

3D printing promises to be a major technology in space. With its help, people will not only conquer the expanses of the universe, but also explore new territories. 3D printing is used to produce parts for rockets, satellites and other spacecraft, and the ISS even has its own 3D printer that works in zero gravity. Moreover, 3D printing is being considered as a potential technology for creating human settlements on the Moon and Mars. Who knows how far 3D technology will take us.

Who knows how far 3D technology will take us.

Don't miss also:

Interesting facts about 3D printers

This is not the end of the facts about 3D printing, but we decided to highlight some of them in a separate paragraph. Here we will write interesting facts about 3D printers that you might not know.

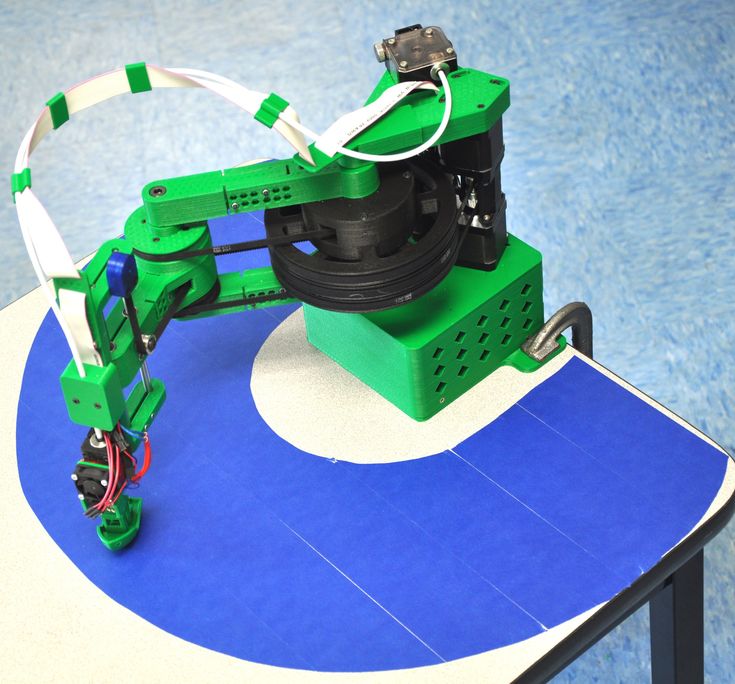

1. Industrial robots-manipulators

This approach is increasingly used in production: industrial robots-manipulators adapted for 3D printing are used as 3D printers. This is interesting primarily because the construction area in such cases is practically not limited by either the dimensions or the X, Y, Z axes. Some companies are even touting the approach as "5D printing" while the work platform is also in motion. And recently, a presentation of the concept of a 3D printer with six axes took place, which allows printing products without supports.

2. 3D printer tattoo machine

Tattoo artists immediately noticed the possibilities of 3D printing and decided to use it for their own purposes. Today, there are several projects for the use of 3D printers as tattoo machines at once, and their results are quite successful. Needless to say, such an application is extremely specific and is unlikely to be widely used. But the idea is interesting.

Today, there are several projects for the use of 3D printers as tattoo machines at once, and their results are quite successful. Needless to say, such an application is extremely specific and is unlikely to be widely used. But the idea is interesting.

3. Huge 3D printers and smartphone printers

3D printing technology is more extreme than ever. This is due to the huge functionality of the technique, which allows it to be applied in a variety of directions. 3D printers print houses, huge metal structures and other large-scale structures. But in parallel with this, the developers also take care of the production of smaller parts. So, the whole world is waiting for a 3D printer for smartphones, the concept of which rocked Kickstarter some time ago. And scientists print microscopic structures and full-fledged electronics, giving odds to professional manufacturers.

4. 3D printer with artificial intelligence

For such an unusual development, the already mentioned robotic arm was used, for which not only the control code was written, but also the artificial intelligence algorithm. As a test, the 3D printer printed an impressive 4-meter structure: a design pavilion. The developers were pleased with the result, but said that this was just an experiment and the technique needed further optimization.

As a test, the 3D printer printed an impressive 4-meter structure: a design pavilion. The developers were pleased with the result, but said that this was just an experiment and the technique needed further optimization.

This concludes our "Interesting Facts About 3D Printing" section. We hope it was informative. And if you think that we have not touched on some interesting facts about 3D printing and 3D printers, write to us by e-mail and we, if necessary, will add your information! Best regards, 3DDevice team.

Also look into our online store and choose 3D pens, 3D printers, 3D scanners and other equipment. In addition, we will readily provide you with 3D printing, 3D modeling, 3D scanning, etc. services. Call or write for any questions. We look forward to collaborating!

Back to Home

3D Production Optimization in the Energy Industry

Case Studies

Experts Recommend

Energy

Author: Nikita Kudryashov

Author: Nikita Kudryashov

Application of 3D printing in the energy industry | Solar cells, batteries and power plants | New generation wind turbines | Graphene and liquid batteries | 3D printing in the gas sector: turbine blades

In a recent article, we talked about how 3D printing is beneficial for the production of solar panels. But this is only a special case of the use of additive technologies in the energy sector. Their potential is much wider - 3D printers can be used for prototyping and manufacturing in other sectors of the industry, for example, in oil and gas companies or to create wind and solar power plants.

But this is only a special case of the use of additive technologies in the energy sector. Their potential is much wider - 3D printers can be used for prototyping and manufacturing in other sectors of the industry, for example, in oil and gas companies or to create wind and solar power plants.

Additive manufacturing is becoming a strong ally of the energy industry, allowing it to explore new areas and applications. In this article, we will discuss all the advantages of 3D printing and talk about projects implemented in the energy industry using additive technologies.

3D printing applications in the energy industry

Prototyping and production

Today, 3D printing is used not only for prototyping, but also for the production of new parts, devices and designs. The examples that we will give perfectly demonstrate the advantages of this technology.

3D technologies allow you to work more efficiently at various levels. You can use 3D printing or 3D modeling to improve the visualization of your projects. 3D models - including printed ones - can be used not only within the company, but also to demonstrate projects to customers.

You can use 3D printing or 3D modeling to improve the visualization of your projects. 3D models - including printed ones - can be used not only within the company, but also to demonstrate projects to customers.

Photo: www.greentechmedia.com

Customization at lower prices

Additive manufacturing attracts many companies with the ability to create parts tailored to individual requirements. If you are making parts to order, then 3D printing is exactly what you need.

No less important is the fact that 3D technologies owe their widespread use in the energy sector to low cost, especially for prototyping - 3D printing allows you to carry out as many iterations as you need.

3D printing in the development of new devices

We already wrote that 3D printing has made a real revolution in renewable energy and that solar panels made on a 3D printer are 20% more efficient than standard ones. New materials and technologies are further increasing the efficiency of devices - for example, recently materials have been developed that have allowed rethinking the production of solar panels.

New materials and technologies are further increasing the efficiency of devices - for example, recently materials have been developed that have allowed rethinking the production of solar panels.

The possibilities of using 3D printing in the energy sector are very wide, but their implementation requires special materials. The properties of the materials depend on the intended use of the final parts - resistance to loads, pressure, chemicals or heat may be required.

Siemens 3D printing technology speeds up turbine blade production by 90%

Energy Innovation: Best Projects Using 3D Printers

We have collected examples of the best energy projects using 3D printers. They will help you better understand the current possibilities and potential of additive manufacturing in this industry.

Solar cells, batteries and power plants

A Dubai-based company has chosen 3D printing for a project called Smart Palm. The idea is to create stations on city streets and beaches where people can charge their phones, connect to Wi-Fi, and so on. "Smart palm trees" have a modern design and collect solar energy.

The idea is to create stations on city streets and beaches where people can charge their phones, connect to Wi-Fi, and so on. "Smart palm trees" have a modern design and collect solar energy.

"Smart palm trees" with solar panels / Photo: inhabitat.com

Stations are printed on reinforced plastic 3D printers. At first it was planned to make them from steel, but the creators sought to reduce the weight of the structure and therefore chose 3D printing from plastic.

Some of Sculpteo's customers work with solar energy and use 3D printing. For example, Simusolar, founded in 2014, is building solar power plants in rural Tanzania, designing and implementing compact, sustainable solutions that help people in their daily lives. The company's customers are farmers, fishermen and villagers who need equipment powered by solar electricity. Simusolar uses 3D printing because there is a need for many custom parts.

The Australian organization CSIRO (Commonwealth Scientific and Industrial Research Organization) uses 3D printers to print rolled solar cells. CSIRO produces A3 size photovoltaic sheets that are suitable for all surfaces (eg windows and buildings). This opens up completely new possibilities: the high efficiency of solar panels and 3D printing technologies allow the company to create accurate and reliable systems. As we have already found out, solar panels printed on a 3D printer are 20% more efficient than traditional ones.

CSIRO produces A3 size photovoltaic sheets that are suitable for all surfaces (eg windows and buildings). This opens up completely new possibilities: the high efficiency of solar panels and 3D printing technologies allow the company to create accurate and reliable systems. As we have already found out, solar panels printed on a 3D printer are 20% more efficient than traditional ones.

Solar cell printed on a 3D printer / Photo: 3DPrint.com

To date, these are the largest photovoltaic cells. They are made of flexible lightweight plastic. Researchers have developed an ink with photoelectric properties that is applied to a strip of flexible plastic. The production process includes coating the strips with an engraved cylinder, applying ink using a slotted die, as well as squeegee printing.

New generation wind turbines

Additive technologies make it possible to create new types of wind turbines. Wind farms are known to be an efficient source of energy, but Orange Silicon Valley decided to go even further and find out if it is possible to manufacture microturbines, and if so, how.

Conventional wind farms are difficult to transport, which is why the company has focused on developing smaller plants. Such installations can be easily transported to areas where it is difficult to use traditional wind turbines. In addition, they are ideal for urban conditions. Prototypes of installations were printed from ABS plastic on a desktop 3D printer.

Startup RCAM Technologies decided to introduce 3D printing for the production of wind farms. The goal of the project is not to create microturbines, but, on the contrary, large ones. Indeed, the higher the setting, the more efficient it works. The idea is simple: print some wind farm parts on the spot. In 2019, StartUs Insights analysts included RCAM Technologies in the list of the best startups using additive technologies in the energy sector.

The rapid development of large-scale 3D printing makes it possible to implement ever larger projects. In other words, 3D printers will make wind energy more efficient. At the moment, the company is creating prototypes of wind turbines using a robotic arm.

At the moment, the company is creating prototypes of wind turbines using a robotic arm.

Graphene and wet batteries

We already know about the benefits of graphene batteries; but if you print them on 3D printers, they become even more productive and greener. Researchers from the City University of Manchester, the University of Chester and Central South University in China have created an entirely new energy storage device.

Inside it are disk electrodes printed with graphene on a 3D printer. This amazing material is the future of electrical engineering and electronics. Many different materials can be used for printing, depending on the purpose of the project. Additive technologies make it possible to create entire systems for the production and storage of renewable energy.

Parts of the Redox Flow battery case printed on a 3D printer / Photo: jss.ecsdl.org

Researchers from IBM and ETH Zurich have created the first liquid battery that simultaneously produces electricity and cold. It is called "Redox Flow" and is produced using 3D printing. The research team uses additive technologies to create a system of microchannels through which the electrolyte moves. This minimizes energy consumption and avoids high internal temperatures.

It is called "Redox Flow" and is produced using 3D printing. The research team uses additive technologies to create a system of microchannels through which the electrolyte moves. This minimizes energy consumption and avoids high internal temperatures.

3D printing in the gas sector: turbine blades

Siemens UK engineers decided to use 3D printing for the production of gas turbine blades. The blades must be resistant to high pressure, speeds up to 1600 km/h and withstand an ambient temperature of 1250°C with rapid cooling down to 400°C.

Siemens UK launches additive manufacturing of turbine blades / Photo: www.siemens.com

What are the advantages of 3D printing for the production of such equipment? The technology speeds up the blade manufacturing process by 90%! This is a typical use case for 3D printing for oil and gas companies.

Steel components are expensive. Additive methods can reduce their cost and allow you to get any parts of any size, fully adapted to specific equipment.