3D scanners toronto

White/Structured Light & Laser 3D Scanning Services in Toronto

With a variety of 3D Scanning Services & technologies, we can capture every detail of your part.

We’ll quickly and accurately help you convert a physical object into precise digital 3D models.

From there, you can utilize our design service to make modifications to the file, or we can create 3D digital renderings for your display.

As with many things in the realm of 3D, there is no one-size-fits-all solution when it comes to 3D Scanners. So it’s best to narrow down your particular needs and choose a scanner that suits your specific application.

Contact us today for a consultation to determine what scanning method is right for you.

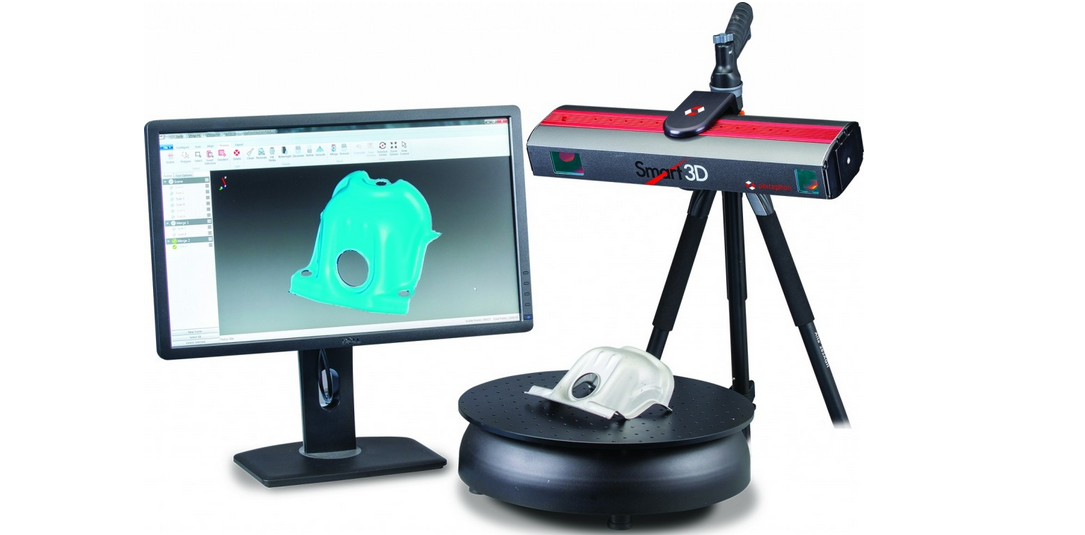

Structured Light ScanningThese 3D scanners project a pattern of lights onto an object. The scanner then reads the reflections in the light to analyze curves and bends in the surface of the object. These scanners are flexible to use, good for many applications and safe on human eyes. These are generally a lower cost, but are not optimal on reflective or refractive surfaces.

Photogrammetry

This method uses multiple cameras to capture the object from different angles along with an algorithm that triangulates common points to analyze depth and create a 3D model. It gives you the best colour detail, however is not the most accurate for making precise measurements.

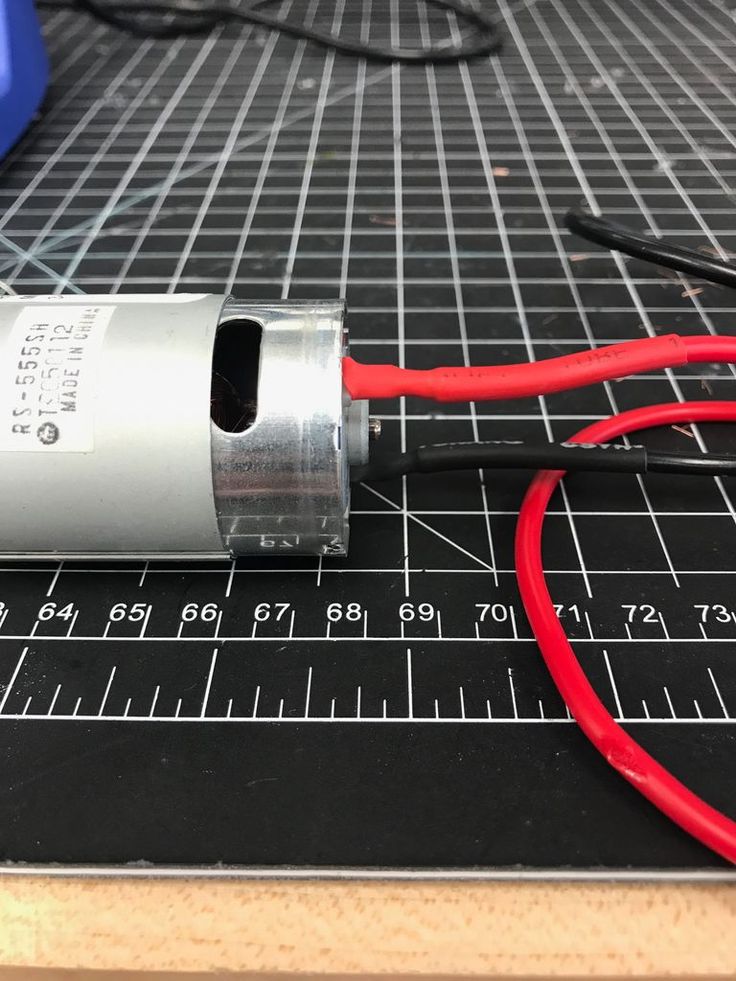

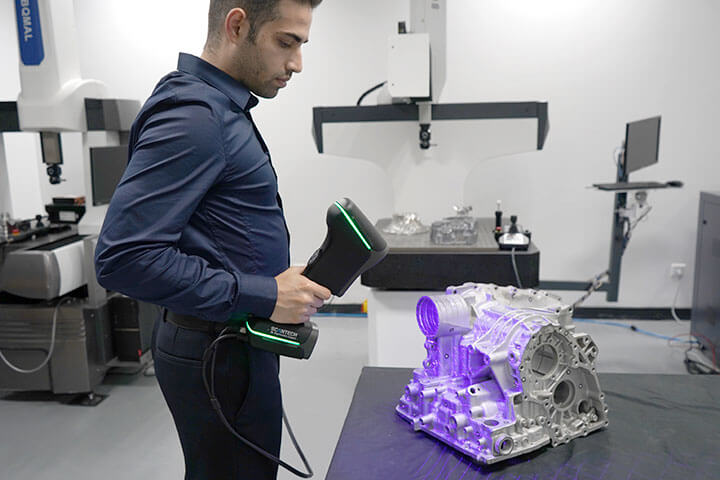

Laser Scanning

These 3D Scanners function similar to Structured Light, except they use lasers instead of a blanket of light. These can be great for precise engineering applications and capturing fine details, but are unsafe for human eyes. They need to be used in a controlled environment.

Reverse Engineering

Creating 3D Models from scratch can be a process that’s both time and cost-intensive. Reverse Engineering using 3D Scanning can complete a job in hours that normally takes days or weeks using traditional methods. Using our 3D scanning techniques and software we can create models

Using our 3D scanning techniques and software we can create models

Files can be delivered in any required CAD or graphic format and be used for inspection, mold and pattern making, tool path creation, tooling verification or additive manufacturing and 3D printing.

Studio Scanning

We have a talented scanning team of experts that would love to help you take your studio and 3D scanning to the next level.

Learn More

Need a thought solution? Get in touch!

Tell us about your next project.

Every member of our team is working hard to build relationships with proactive insight, responsiveness and a genuine desire to help you succeed.

Simply provide the basic idea of your goals and we’ll follow up with you.

Thanks!

Send us mail

Name *

E-Mail *

Subject *

Message *

OBJEX UNLIMITED | ABOUT US

We are at the forefront of the 3D printing revolution and push the boundaries of traditional manufacturing.

Objex Unlimited is your one stop shop for everything 3D. We offer a full in house service bureau and catering our products and services to an array of industries for various application.

Objex Unlimited is a leading service provider as well as authorized equipment reseller for multiple suppliers, and give our customers access to more than just one piece of equipment. Our well rounded facility offers a vast majority of industry leading tools and technology.

Objex Unlimited uses the product and services we sell and are honest about their capabilities. On a daily basis we experience the pros and cons to every element we cater. Come by our studio any time and we will show you in person- our facility and capabilities.

Objex Unlimited has invested in the learning curve so our customers don’t have to. For over a decade Objex Unlimited has grown and employed some of the brightest minds in the 3D realm.

Our team is experienced in the products we offer and the services we provide. We employee a multidisciplinary team of engineers, designers, technicians, artists, sculptors, and mathematicians… and have a trained team that understands a broad range of industries, application, and technologies. Our team has an unmatched range of skills, from concept to design to production to finishing, industrial and organic, engineering and artistic.

Our team is experienced in the products we offer and the services we provide. We employee a multidisciplinary team of engineers, designers, technicians, artists, sculptors, and mathematicians… and have a trained team that understands a broad range of industries, application, and technologies. Our team has an unmatched range of skills, from concept to design to production to finishing, industrial and organic, engineering and artistic.We build lasting relationships with our customers; by going that extra mile and pushing the boundaries of 3D printing and 3D scanning to find the right tech and solutions to our customer’s toughest challenges. We share our experience and expertise to focus on providing solutions that work best for our customers’ needs and requirements to help them get better faster.

Toronto’s 3D Printing Studio and Scanning Service Experts

Objex Unlimited is a 3D solutions provider and Canadian equipment reseller, specializing in 3D Printing, 3D Scanning, and 3D Design Services. Our full in-house service bureau offers customers a one-stop shop for everything 3D; delivering products and services that span an array of industries for various applications.

Our full in-house service bureau offers customers a one-stop shop for everything 3D; delivering products and services that span an array of industries for various applications.

Combining cutting edge technology, art and engineering, Objex Unlimited designs and produces highly detailed physical models, Rapid Prototypes, Concept Models, end us production part and outstanding unique personalized products. We can bring your CAD designs to life by creating real parts you can use and models that can be held in your hand.

Don’t let prototype production hold up your design cycle. When we say rapid, we mean rapid. Our commitment to you is to deliver within days. Whether we 3D print your CAD designs, or work with you through the concept development stage, we offer a high level of quality, service and integrity.

Canada’s 3D Equipment Supplier

As Canada’s Authorized distributor and resellers of 3D Systems, Artec 3D, Mimaki 3D, INTAMSYS, 3DXTech and XYZ 3D Printing products we provide our clients many of the highest quality and most effective 3D solutions on the market; working with industries such as: Jewellery Design and Casting, Geospatial Prototyping, Medical Modelling, Architectural Models, Archaeological Modelling, Full Colour 3D Printing, Geometric Parts, Mechanical Modelling, Organic Art, Toy Development & Unique Art, to name a few.

Every member of our team is working hard to build relationships with proactive insight, responsiveness and a genuine desire to help you succeed.

TELL US ABOUT YOUR NEXT PROJECT.

Join Our Newsletter

Objex Unlimited

36 Fieldway Road,

Toronto, Ontario M8Z 3L2

Email: [email protected]

Phone: 416-233-7165

Mon – Fri

9am – 5pm EST

©2016 Copyright • Objex Unlimited • 36 Fieldway Road, Toronto, ON M8Z 3L2 • 416-233-7165 • Objex Unlimited 3D Printing Studio • Toronto’s 3D Printing and 3D Service Experts • Objex Unlimited is your resource for everything 3D. We take great pride in the services we provide, and will find the best 3D printing solution for you. We will work with you to complete your project and reach your goals ahead of schedule. We offer a variety of 3D printers, 3D scanners, 3D Design, Additive Manufacturing, Rapid Prototyping and 3D software, and will work with you to find the best solution for your needs. We are an authorized reseller of 3D Systems, Artec Group, LMI Technologies, Geomagic and Agisoft 3D products. Our talented and diverse staff deliver high-quality, industry-leading results. Our commitment is to fulfil your project needs within budget and on-time. Servicing: Canada, Ontario, Toronto, Montreal, Quebec, Edmonton, Calgary, Vancouver, Markham, Mississsauga, Oshawa, Richmond Hill, Concord, Durham, Ottawa, Waterloo, Kitchener, Windsor, Guelph, Vaughn.

We are an authorized reseller of 3D Systems, Artec Group, LMI Technologies, Geomagic and Agisoft 3D products. Our talented and diverse staff deliver high-quality, industry-leading results. Our commitment is to fulfil your project needs within budget and on-time. Servicing: Canada, Ontario, Toronto, Montreal, Quebec, Edmonton, Calgary, Vancouver, Markham, Mississsauga, Oshawa, Richmond Hill, Concord, Durham, Ottawa, Waterloo, Kitchener, Windsor, Guelph, Vaughn.

Top 13 3D scanners on the market!・Cults

In the past, 3D scanners were mainly used for industrial and professional applications. For example, scanning architectural objects or creating digital models for films. As technology advances, the price continues to drop. Now, 3D scanning gives the average person the ability to custom-make just about anything they want. With more affordable prices, 3D scanning is becoming more accessible to consumers for personal use.

But first, a basic overview of 3D scanning:

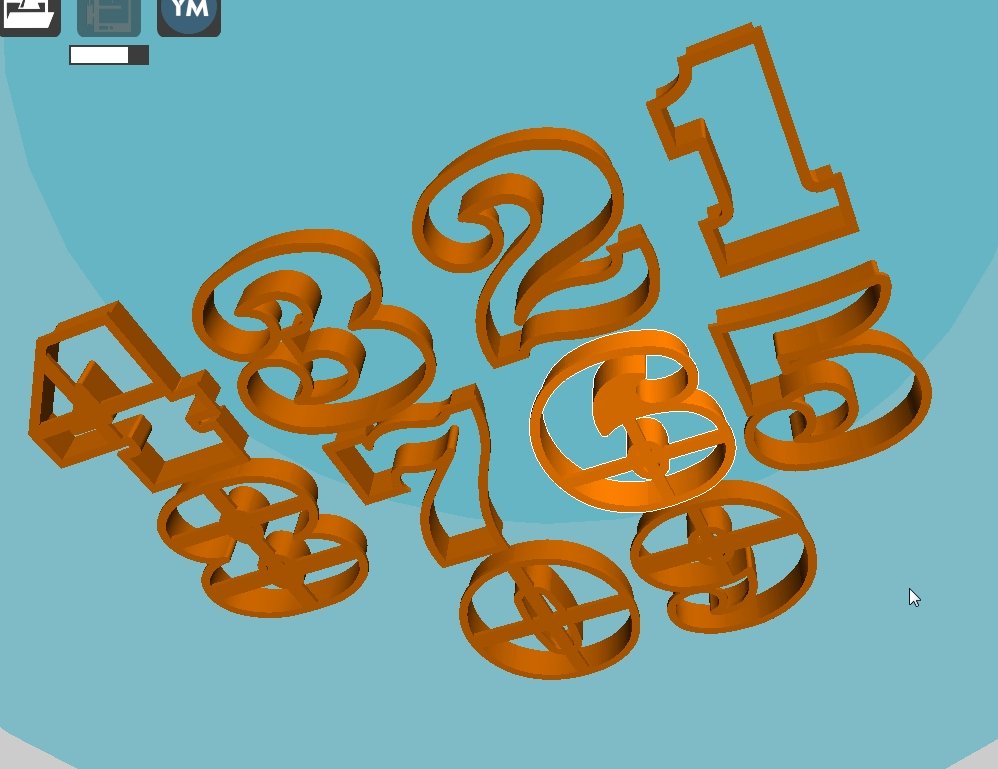

A 3D scanner scans real objects and passes the image data to a 3D modeling program. The object can then be manipulated in the software and - if desired - exported and created on a 3D printer.

The object can then be manipulated in the software and - if desired - exported and created on a 3D printer.

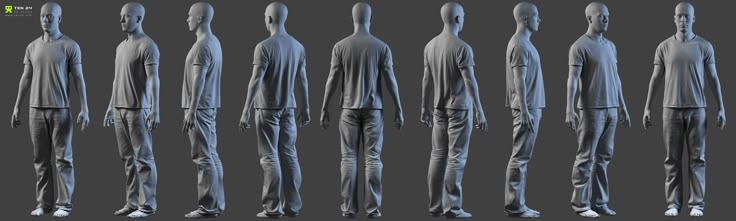

1. Select any object (or person!) you want to scan

Why is 3D scanning useful?

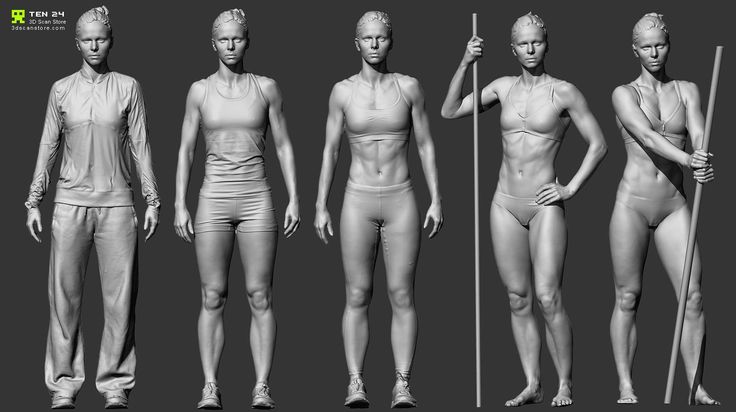

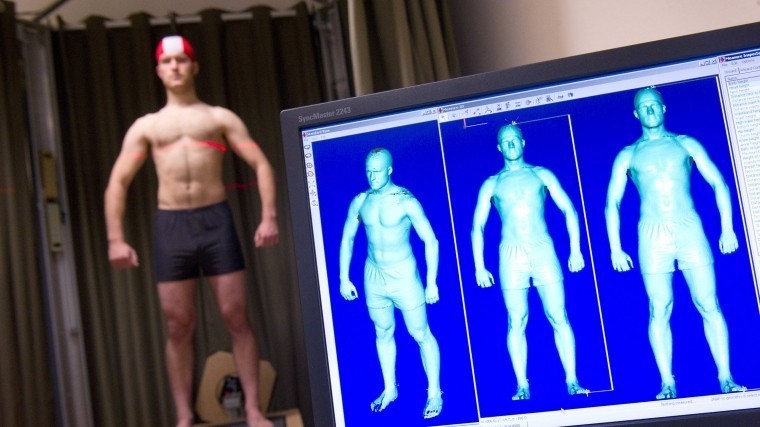

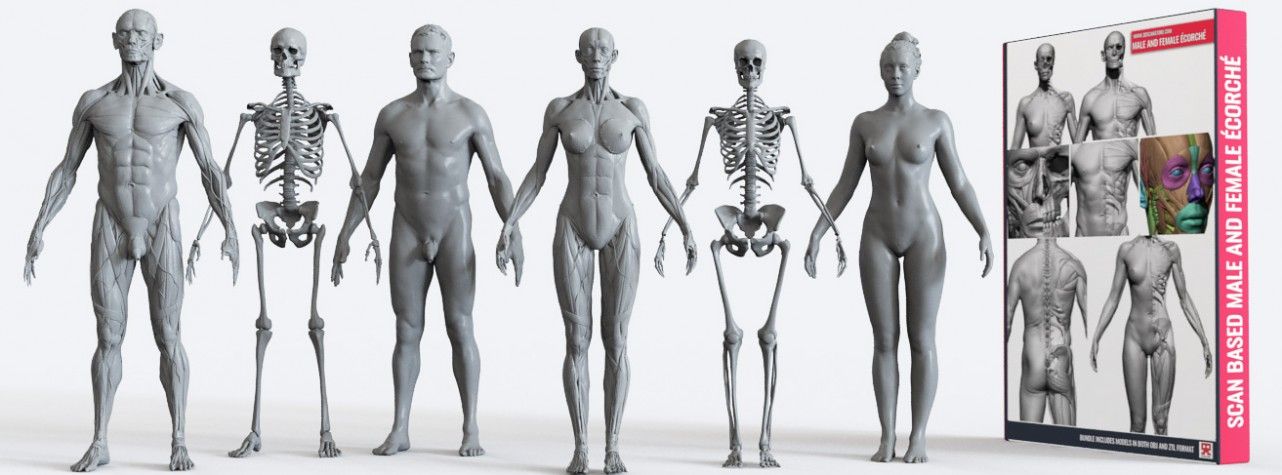

Imagine if you could scan your body and see how clothes fit and look online before you order them? 3D scanning technology can do just that. For example, bodylabs uses 3D scanning to understand how products will work for customers based on their body shape and posture.

2. Scan it and customize it in 3D modeling software

After scanning the object, you can reduce the size or edit it with free 3D design software. You can then choose to 3D print the edited file.

3. Export your model and print it in 3D!

After scanning the model and editing it to your liking, you can export it to .stl format and send it to a printer to bring it to life.

We have listed the 3D scanners below in ascending order of price (from cheapest to most expensive). Their rating does not necessarily reflect our judgment of the quality of the product. We've included some handy YouTube videos that go into more detail about each product.

Their rating does not necessarily reflect our judgment of the quality of the product. We've included some handy YouTube videos that go into more detail about each product.

1. XBox Kinect 3D Scanner - $95 USD

If you want to get by on the cheap, there are ways to use your old Xbox 360 or Xbox One Kinect device to get great results! If you have a Kinect.

2. iSense 3D Scanner for iPhone/iPad - $99

This scanner was developed by 3D Systems as part of the Cubify family. Although they don't sell 3D printers anymore, they keep their 3D scanner in the market. Like a structure sensor, iSense attaches to an iPad or iPhone. Its range of motion is 0.5m more than the Sense.

3. XYZprinting 3D Scanner - $139

XYZprinting 3D Scanner is the cheapest portable 3D scanner on the market. At under $200, it's perfect for anyone looking to get into 3D scanning on a budget.

The size of the scanner is 60 cm x 60 cm x 30 cm, so it is best used for small items. It also uses the new Intel RealSense image capture software, which means it can connect to any Windows device with a 4th generation Intel processor.

It also uses the new Intel RealSense image capture software, which means it can connect to any Windows device with a 4th generation Intel processor.

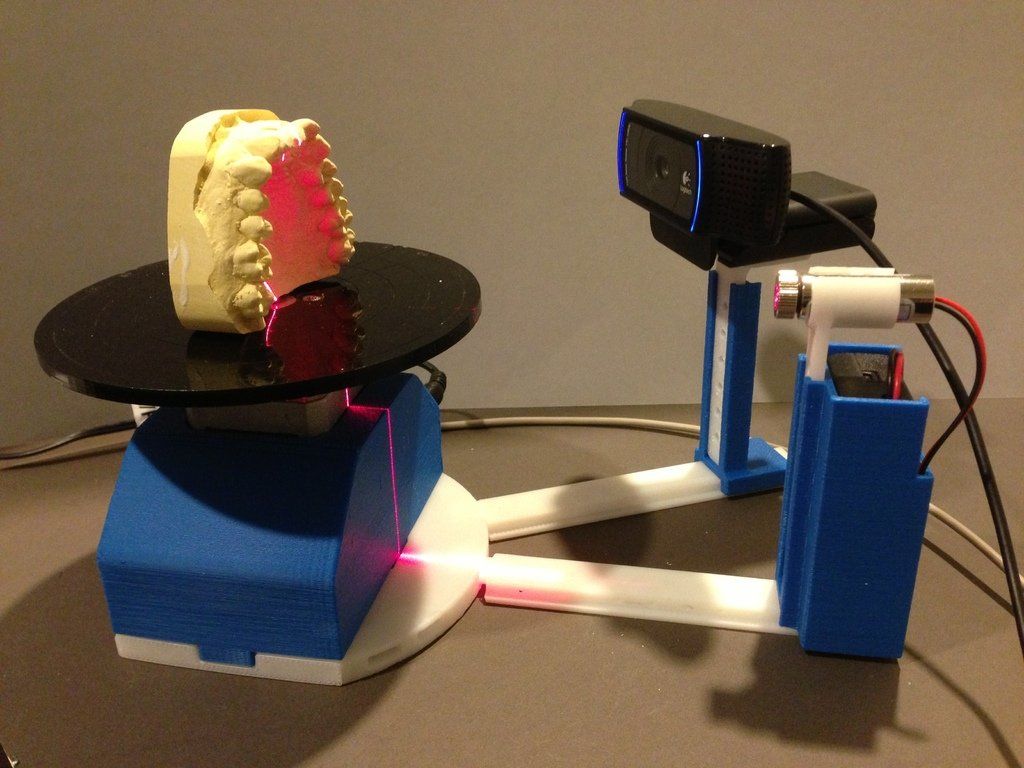

4. BQ Ciclop 3D Scanner Kit - $199

This open source hardware project has been released under an open source license so that all mechanical design, electronics and software information is available to the community for further development . The full package costs about 199 USD. You can even download the design and print it in 3D!

5. Structure Sensor for iPad - $379

Arguably the best scanner on the market, the Structure Sensor was developed through a Kickstarter campaign that attracted over 3,500 people and raised $1.2 million. Structure Sensor turns your regular iPad into a 3D scanner that captures three streams of data at 30 frames per second.

6. Cubify Sense - $399 USD

Cubify Sense is a portable pen scanner that makes it easy to manually scan 3D objects. This makes it possible to use Sense in quite unique areas, with both advantages and disadvantages. Sense is compatible with Windows and Mac OS.

Sense is compatible with Windows and Mac OS.

7. Matter And Form MFS1V1 Desktop 3D Scanner - $467 USD

The first ever crowdfunded 3D scanner, Matter and Form, is a Toronto-based company that has raised nearly half a million dollars to develop this product. It uses a 3D laser scanner with a movable camera head and a 360-degree rotating platform.

MFS1V1 generates a detailed point cloud, which again works very well in some scenarios and less well in others.

8. XYZprinting Da Vinci 1.0 Pro 3-in-1 3D Printer - $810

Da Vinci 1.0 Pro is both a 3D scanner and a 3D printer. It uses a laser diode module with a 2 megapixel camera (higher resolution than 1.2 megapixel iPad scanners). Please note that this machine uses proprietary 3D printing consumables.

9. Einscan-S - $999

Einscan-S has two scanning modes: automatic and free. The first one is the easiest: just place an object on the rotating surface of the Einscan turntable and the machine will scan it in just 3 minutes with an accuracy of . 1 mm. For large models, free scan mode works by rotating the scanner on a tripod around the object. Einscan-S generates one STL file that can be sent directly to your 3D printer. Einscan-S produces 3D printable models with greater accuracy (using "Light Structure Phase Shift Technology" instead of lasers) than competitors, providing industrial quality 3D scanning technology within a consumer's budget.

1 mm. For large models, free scan mode works by rotating the scanner on a tripod around the object. Einscan-S generates one STL file that can be sent directly to your 3D printer. Einscan-S produces 3D printable models with greater accuracy (using "Light Structure Phase Shift Technology" instead of lasers) than competitors, providing industrial quality 3D scanning technology within a consumer's budget.

10. IIIDScan PrimeSense 3D Scanner - $1441 USD

Greater accuracy comes at a price. This tripod-mounted 3D scanner is unique in that it uses a short-range image sensor capable of scanning 3D objects in more detail and at a faster rate than other scanners on the market.

11. Fuel3D Scanify - US$1,500

This is a very high speed handheld 3D scanner capable of capturing an object in less than 1/10th of a second. In this regard, it differs significantly from the other 3D scanners on this list. In practice, it's more like taking a 3D photograph than manually scanning an object. Fuel3D Scanify uses a dual HD stereo laser camera combined with photometric data from three xenon flashes to create reasonably realistic 3D scans in the blink of an eye (so to speak). High tech.

Fuel3D Scanify uses a dual HD stereo laser camera combined with photometric data from three xenon flashes to create reasonably realistic 3D scans in the blink of an eye (so to speak). High tech.

12. NextEngine 3D Scanner HD - $2,995 USD

The NextEngine 3D Scanner HD combines portability with very high accuracy - much better than the scanners at the top of this list. Of course, the higher the accuracy, the higher the price! It uses an electro-optical system with a laser array that scans in tandem. The advantage is that the high-precision scanner has no size limits. The scanner comes with its own mesh creation software package, and you can also check out their NURBS and Solid modeling packages as options.

This is the scanner for those who want to get really serious results from their 3D scanning efforts. If you check out the gallery on their site, you can see how much more detailed NextEngine scans are compared to some of the cheaper scanners on this list. Of course, these are the company's own comparisons for marketing purposes, so feel free to take them with a grain of salt!

13. DAVID SLS-2 Laser Scanner - $3,275

DAVID SLS-2 Laser Scanner - $3,275

The scanner is expensive, but it has a unique use of "light scanning". The company boasts that you can scan everything from insects to elephants. We are told that the SLS-2 can scan 1.2 million peaks in a few seconds. Wow!

What if none of these scanners work for you? What if you want the best of the best? What if you have several thousand dollars set aside for a 3D scanning budget? If you happen to be in this position, take a look at some of these bad guys...

Arctec Eva 3D Scanner - $19,800 (CAD 26,300) dollars)

Creaform HandySCAN 700 - 56 9$00 (CAD 77,700)

This is our list of the best 3D scanners on the market. We hope you find it useful.

via Pinshape

This page has been translated using machine translation. Suggest the best translation

new tool for old problems

The Merriam-Webster Dictionary defines reverse engineering as the process of taking apart and examining a product or device to discover the concepts used in its production, usually with the goal of creating something similar.

This is an old concept dating back to ancient times when reverse engineering was mainly used in wartime to decipher the technological secrets of opponents. A relatively recent and well-known example is the German Enigma cipher machine, which was cracked by the Allies during World War II.

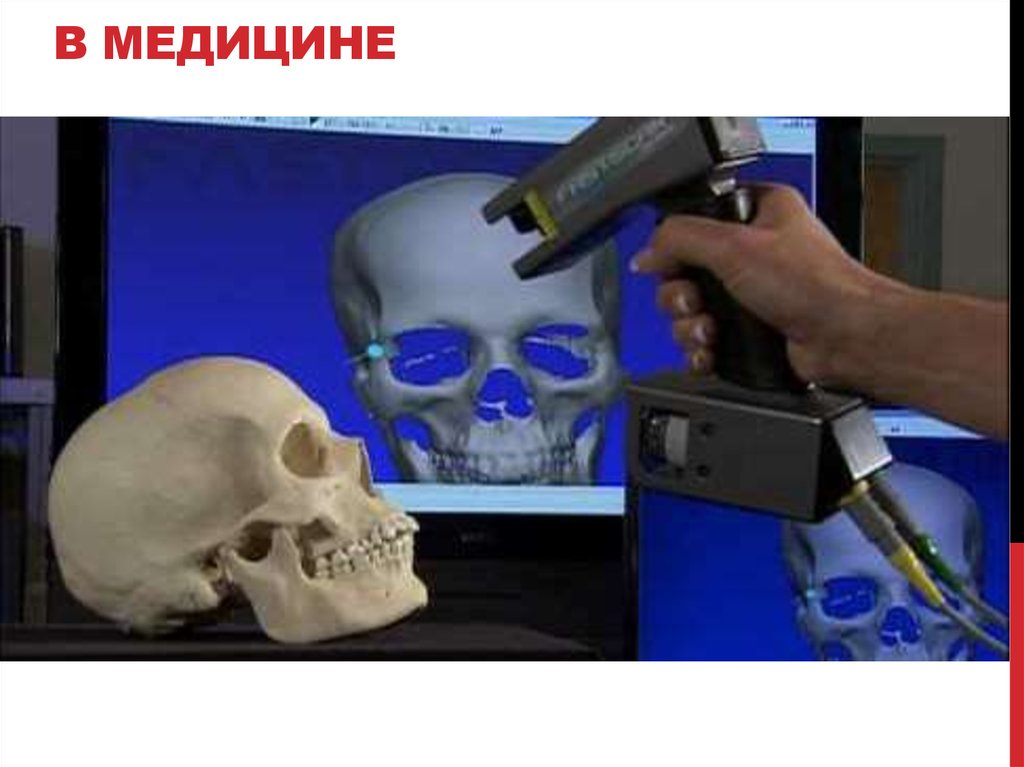

Nowadays, reverse engineering is more often associated with the process of converting the geometry of physical objects into digital 3D models in direct contrast to typical design processes. Such "state of the art" reverse engineering is only possible with relatively new technologies such as 3D scanning.

Before the advent of 3D scanning technology, reverse engineering required extremely labor-intensive manual operations using tools such as calipers. This seriously limited the scope of reverse engineering, given the high quality standards of parts and products in today's market and the associated total cost.

3D scanning can capture the geometry of even the most complex parts extremely quickly and accurately. For example, recently, using a 3D laser scanner, they were able to digitize a huge pump used to pump water from a dry dock in just twenty minutes.

For example, recently, using a 3D laser scanner, they were able to digitize a huge pump used to pump water from a dry dock in just twenty minutes.

This technology allows the use of reverse engineering in situations that go beyond simple comparative analysis and reproduction of details.

Top Applications for 3D Scanning and Reverse Engineering

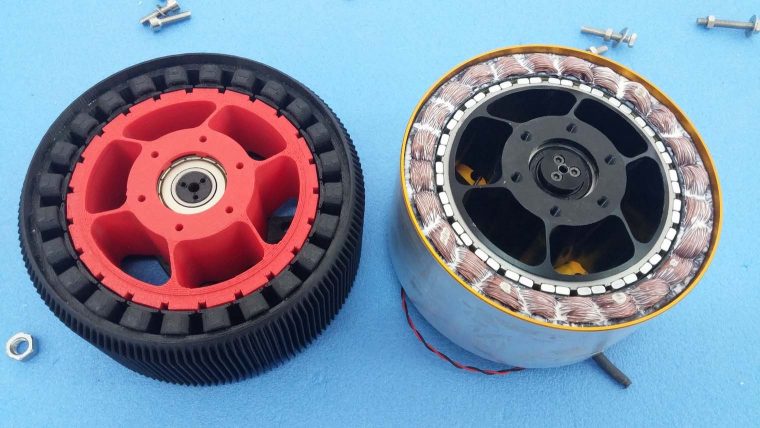

Reverse engineering with 3D scanning offers many possibilities in terms of development and manufacturing. In general, the use cases of reverse engineering can be divided into three main areas: copying parts, modifying parts, and developing completely new components based on an existing environment or objects.

1. Recreating and copying parts

One of the most popular uses for 3D scanners is to recreate damaged or worn parts that are not available from original equipment suppliers or do not have proper documentation. This is a common problem when working with old equipment and antique cars, and in such cases it is difficult to get around with hand measuring tools.

However, with a good 3D scanner and the right software, the task is much easier. Katsuya Tanabiki, for example, shared the reverse engineering process of attaching a face shield to an old motorcycle helmet. One of the two fasteners broke, and it was too difficult to find a new one. This small part was digitized with an EinScan Pro 2X 3D scanner in stationary mode and then 3D printed.

The aerospace and automotive industries are using reverse engineering to digitize components and create a digital inventory of obsolete parts—so-called “digital twins.”

This is where 3D scanning comes into play, given the complexity of the parts, the strict requirements for dimensional accuracy and the standards they must meet. Take, for example, a small turbine redesigned by Print3DD: it would be impossible to accurately reproduce the geometry of the blades without 3D scanning.

2. Parts improvement

Another goal of reverse engineering is to use digitized parts to create new and improved versions, not just reproduce the originals.

This method significantly reduces the time and cost of developing new parts, and ensures that components fit perfectly in assemblies.

Taiwanese company Kiden Design illustrated the process of reverse engineering and optimizing a pipe using 3D scanning, CAD and 3D printing. The EinScan Pro HD 3D scanner manually captured the incorrect geometry of the pipe from opposite sides, and the resulting scans were then stitched into a single, accurate 3D model for optimization in a computer-aided design system.

Another good example of the use of reverse engineering in creating new versions of physical objects is the customization of furniture parts performed by Voxel 3D through 3D scanning and CNC machining. In this project, the carvings of one piece of furniture were digitized using a 3D scanner and integrated into different pieces.

3. Create parts from scratch

The advent of 3D scanning has made possible another solution - the use of digitized parts as references for completely new products.

For example, this procedure is used when a customization with a tight fit of a new part is required. To illustrate this, let's take an example from the Fuller Moto car workshop. Bryan Fuller and his team used the EinScan Pro 2X Plus 3D scanner to digitize the entire legroom in a 1967 Lincoln Continental. The digitized area was used as a reference for designing the new kick panel, and an accurate 3D space model allowed the new part to fit exactly into the allotted space.

This method is also widely practiced by healthcare professionals because body parts are unique and difficult to accurately measure by manual methods. Here, 3D scanning has once again proven itself as an effective digitizing tool.

One example is earmolds that help guide sound from hearing aids to the ear canals. Creating new earmoulds from scratch can take several weeks, during which patients have to suffer from hearing problems.

Thanks to reverse engineering techniques using 3D scanning and 3D printing, Hearing Beyond Audiology in Toronto is able to produce temporary inlays in just one day. These temporary accessories make life easier for patients while waiting for permanent hearing aids to be made or serviced.

These temporary accessories make life easier for patients while waiting for permanent hearing aids to be made or serviced.

Similar 3D scanning reverse engineering techniques are also used in the manufacture of facial prostheses and custom orthotic insoles.

What determines the quality of reverse engineering

The examples above demonstrate the central role of 3D scanning in reverse engineering. Not surprisingly, the efficiency and accuracy of 3D scanning data is critical to successful reverse engineering.

However, the software tools used to process data and work with 3D models are also required to achieve the desired results. To understand the importance of good data and adequate software, let's go through the basic steps of reverse engineering with 3D scanning.

1. Data collection

The very first step in any reverse engineering process is data collection. Regardless of the method, proper planning and preparation can make the difference between good and bad data.

In 3D scanning, this includes selecting the correct device and configuration (handheld or stationary 3D scan), as well as accessories such as turntables, calibration panels, and other fixtures. Proper calibration of the device is essential for obtaining quality data.

Areas of objects or details to be digitized usually require some preparation. In addition to good cleaning, some 3D scanners also require the use of markers and / or special coatings on reflective surfaces - frosting sprays.

Consider the environmental conditions before starting to digitize. A controlled environment (e.g. indoors, no direct sunlight, clean worktop, etc.) is always preferable to reduce data noise, but this is not always possible.

All of the above factors will affect the quality of the data, which in turn will determine how quickly and easily the data will be processed in the next steps.

2. Data processing

The next step is to process the received data or "point clouds". At this stage, the 3D scan data is processed by software tools such as EinScan, resulting in 3D meshes of digitized objects.

At this stage, the 3D scan data is processed by software tools such as EinScan, resulting in 3D meshes of digitized objects.

The 3D model at this stage usually needs some tweaking - removing unnecessary captured data, restoring surfaces and filling in gaps.

This makes it clear why the data collection step is so important: the higher the quality of the data, the less post-processing and corrections will be required.

The processing phase also assigns reference objects to the 3D model, a procedure that helps speed up the next phase of reverse engineering.

3. CAD revision

The last step is to convert the object mesh into a solid 3D model.

No matter how accurate the mesh is, it will not be suitable for most reverse engineering applications used to modify, repair damage, or design new parts.

At this stage, the processed mesh serves as a reference for creating a 3D model in a computer-aided design system using parametric tools.